ABS MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1436 of 1449

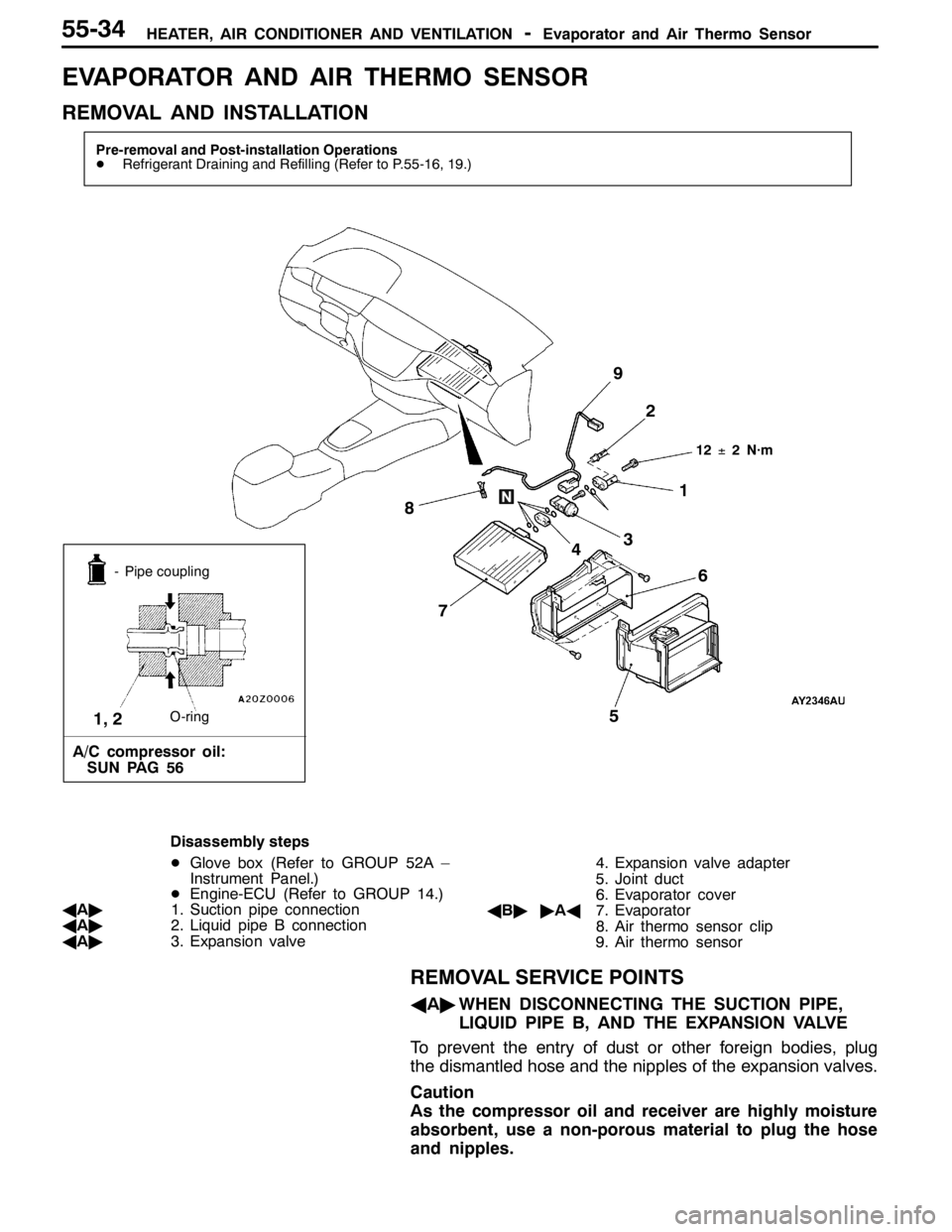

HEATER, AIR CONDITIONER AND VENTILATION-Evaporator and Air Thermo Sensor55-34

EVAPORATOR AND AIR THERMO SENSOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.)

1 2

3

4

56

7 8

12±2 N·m

- Pipe coupling

O-ring

A/C compressor oil:

SUN PAG 56

1, 2

9

Disassembly steps

DGlove box (Refer to GROUP 52A –

Instrument Panel.)

DEngine-ECU (Refer to GROUP 14.)

AA"1. Suction pipe connection

AA"2. Liquid pipe B connection

AA"3. Expansion valve4. Expansion valve adapter

5. Joint duct

6. Evaporator cover

AB""AA7. Evaporator

8. Air thermo sensor clip

9. Air thermo sensor

REMOVAL SERVICE POINTS

AA"WHEN DISCONNECTING THE SUCTION PIPE,

LIQUID PIPE B, AND THE EXPANSION VALVE

To prevent the entry of dust or other foreign bodies, plug

the dismantled hose and the nipples of the expansion valves.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.

Page 1438 of 1449

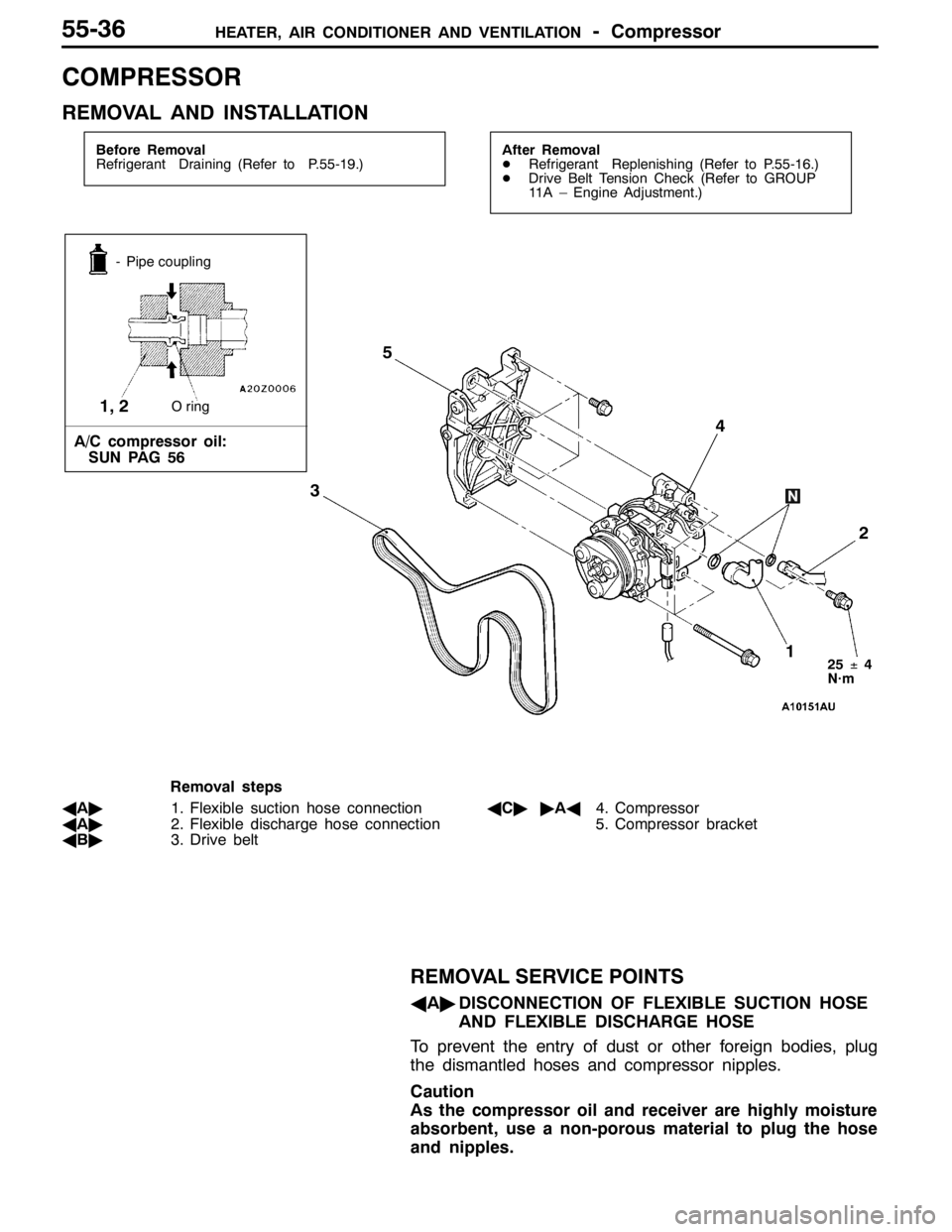

HEATER, AIR CONDITIONER AND VENTILATION-Compressor55-36

COMPRESSOR

REMOVAL AND INSTALLATION

Before Removal

Refrigerant Draining (Refer to P.55-19.)After Removal

DRefrigerant Replenishing (Refer to P.55-16.)

DDrive Belt Tension Check (Refer to GROUP

11A – Engine Adjustment.)

25±4

N·m

2 4

1

- Pipe coupling

O ring

A/C compressor oil:

SUN PAG 56

1, 2

5

3

Removal steps

AA"1. Flexible suction hose connection

AA"2. Flexible discharge hose connection

AB"3. Drive beltAC""AA4. Compressor

5. Compressor bracket

REMOVAL SERVICE POINTS

AA"DISCONNECTION OF FLEXIBLE SUCTION HOSE

AND FLEXIBLE DISCHARGE HOSE

To prevent the entry of dust or other foreign bodies, plug

the dismantled hoses and compressor nipples.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.

Page 1443 of 1449

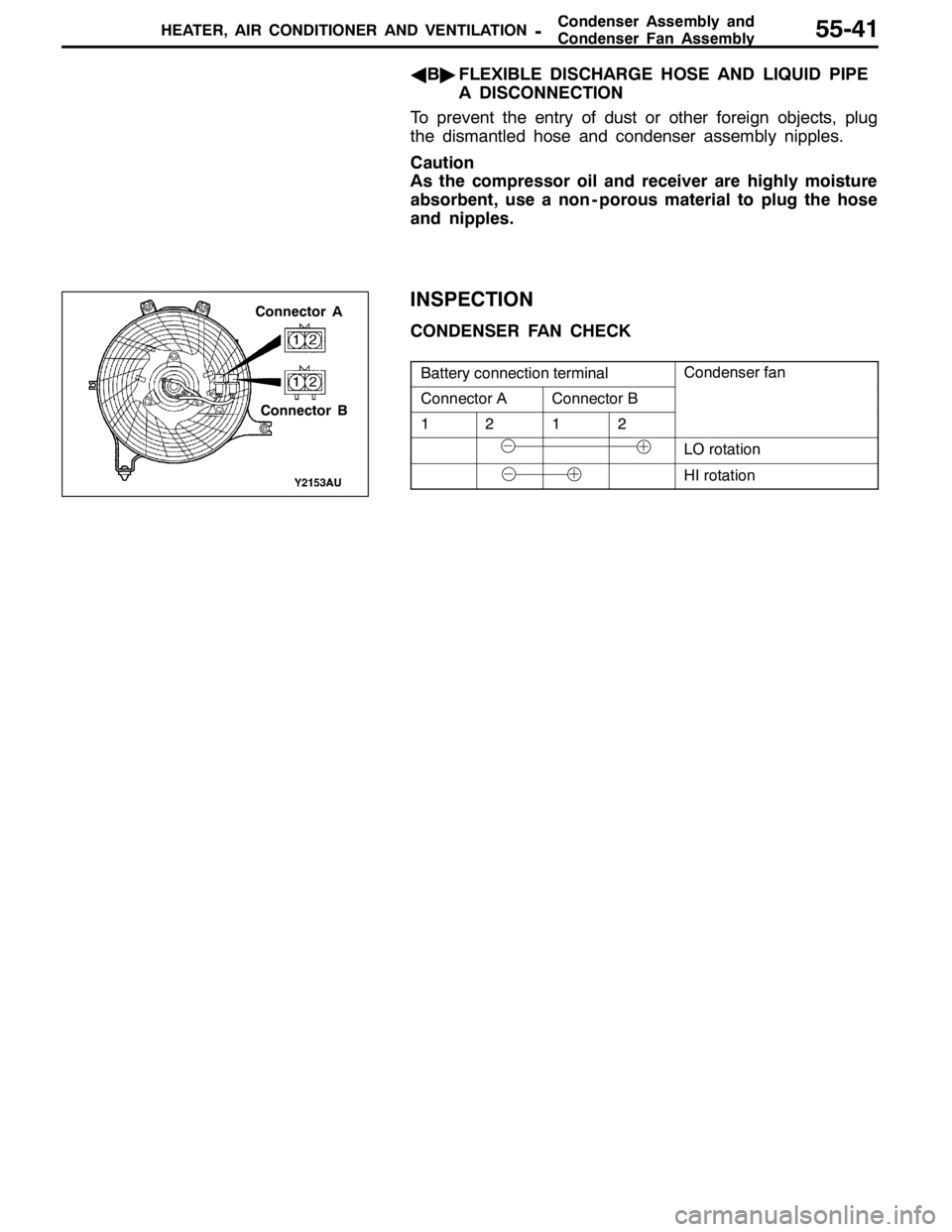

CondenserAssemblyand

Condenser Fan Assembly HEATER, AIR CONDITIONER AND VENTILATION-55-41

AB"FLEXIBLE DISCHARGE HOSE AND LIQUID PIPE

A DISCONNECTION

To prevent the entry of dust or other foreign objects, plug

the dismantled hose and condenser assembly nipples.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non - porous material to plug the hose

and nipples.

INSPECTION

CONDENSER FAN CHECK

Battery connection terminalCondenser fan

Connector AConnector B

1212

LO rotation

HI rotation

Connector A

Connector B

Page 1444 of 1449

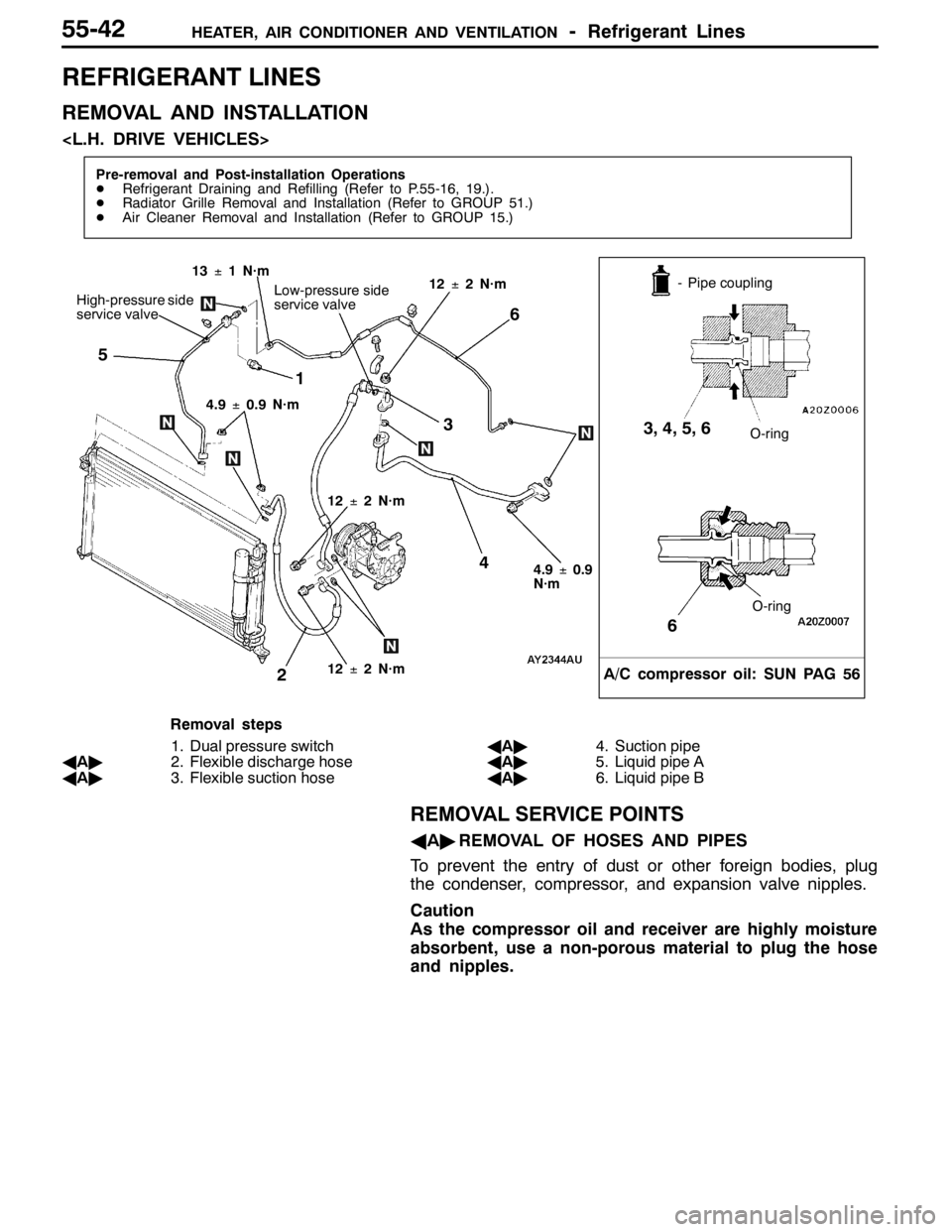

HEATER, AIR CONDITIONER AND VENTILATION-Refrigerant Lines55-42

REFRIGERANT LINES

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.).

DRadiator Grille Removal and Installation (Refer to GROUP 51.)

DAir Cleaner Removal and Installation (Refer to GROUP 15.)

1

2

- Pipe coupling

O-ring

A/C compressor oil: SUN PAG 56

3, 4, 5, 6

5

4

13±1 N·m

O-ring

6

12±2 N·m4.9±0.9

N·m

High-pressure side

service valve

4.9±0.9 N·m6

3

12±2 N·m

Low-pressure side

service valve12±2 N·m

Removal steps

1. Dual pressure switch

AA"2. Flexible discharge hose

AA"3. Flexible suction hoseAA"4. Suction pipe

AA"5. Liquid pipe A

AA"6. Liquid pipe B

REMOVAL SERVICE POINTS

AA"REMOVAL OF HOSES AND PIPES

To prevent the entry of dust or other foreign bodies, plug

the condenser, compressor, and expansion valve nipples.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.

Page 1445 of 1449

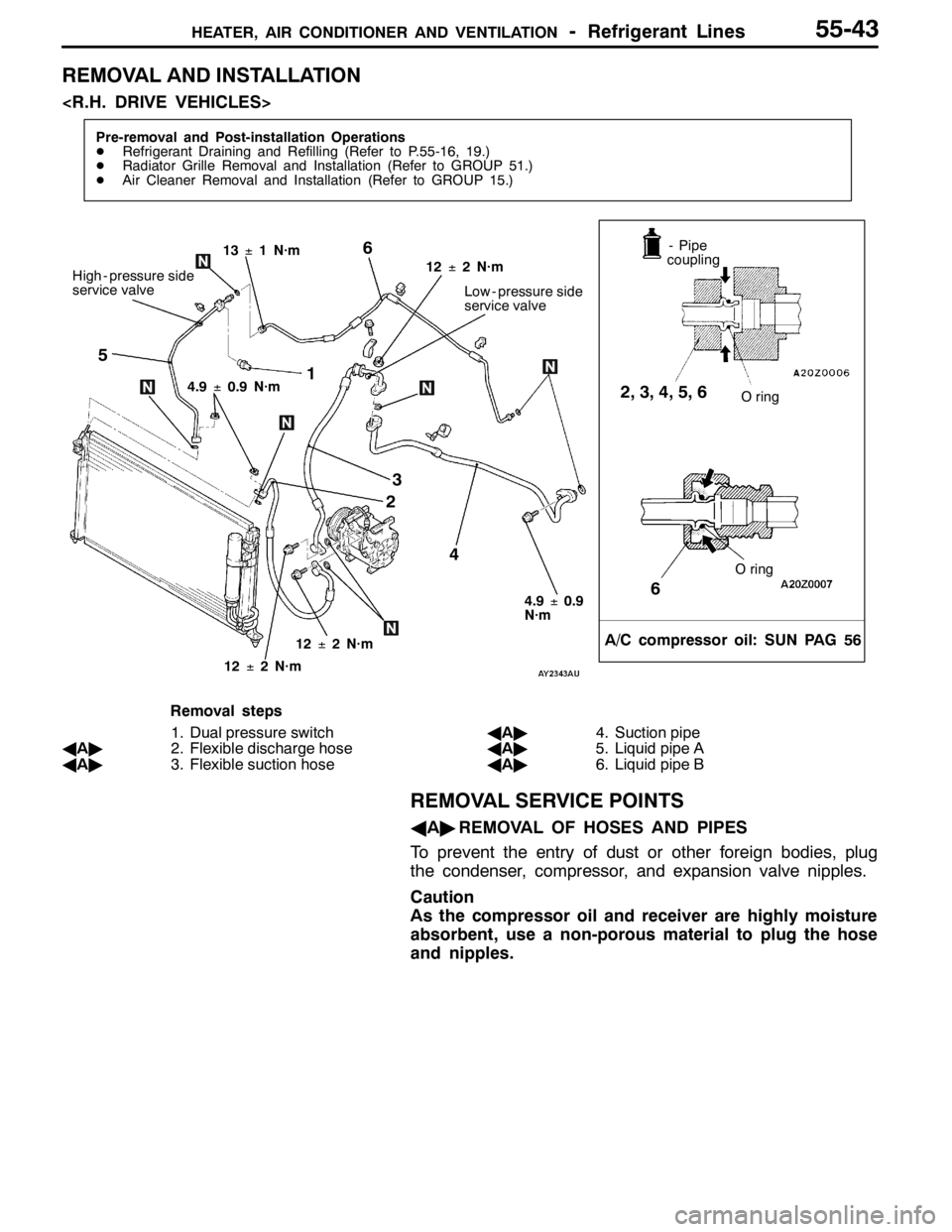

HEATER, AIR CONDITIONER AND VENTILATION-Refrigerant Lines55-43

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.)

DRadiator Grille Removal and Installation (Refer to GROUP 51.)

DAir Cleaner Removal and Installation (Refer to GROUP 15.)

1

23

- Pipe

coupling

O ring

A/C compressor oil: SUN PAG 56

2, 3, 4, 5, 6

6

513±1 N·m

Low - pressure side

service valve

O ring

6

12±2 N·m 4.9±0.9 N·m

High - pressure side

service valve

4.9±0.9

N·m

4

12±2 N·m

12±2 N·m

Removal steps

1. Dual pressure switch

AA"2. Flexible discharge hose

AA"3. Flexible suction hoseAA"4. Suction pipe

AA"5. Liquid pipe A

AA"6. Liquid pipe B

REMOVAL SERVICE POINTS

AA"REMOVAL OF HOSES AND PIPES

To prevent the entry of dust or other foreign bodies, plug

the condenser, compressor, and expansion valve nipples.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.