ABS MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1099 of 1449

ABS <4WD> -On-vehicle Service35B-29

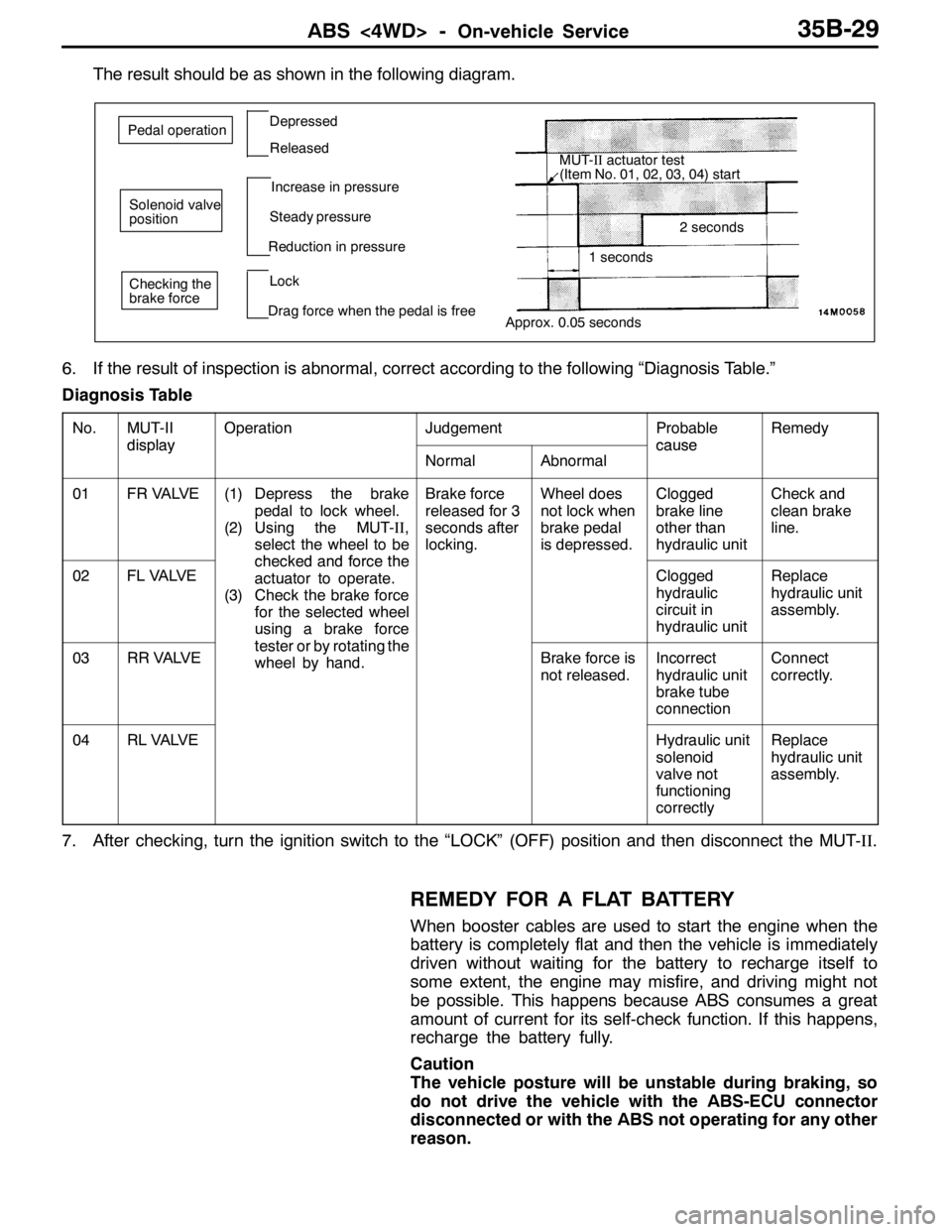

The result should be as shown in the following diagram.

Approx. 0.05 seconds

Pedal operationDepressed

Released

Solenoid valve

positionIncrease in pressure

Steady pressure

Reduction in pressure

Checking the

brake forceLock

Drag force when the pedal is freeMUT-IIactuator test

(Item No. 01, 02, 03, 04) start

2 seconds

1 seconds

6. If the result of inspection is abnormal, correct according to the following “Diagnosis Table.”

Diagnosis Table

No.MUT-II

display

OperationJudgementProbable

cause

Remedy

display

NormalAbnormal

cause

01FR VALVE(1) Depress the brake

pedal to lock wheel.

(2) Using the MUT-II,

select the wheel to be

checkedandforcethe

Brake force

released for 3

seconds after

locking.Wheel does

not lock when

brake pedal

is depressed.Clogged

brake line

other than

hydraulic unitCheck and

clean brake

line.

02FL VALVEchecked and force the

actuator to operate.

(3) Check the brake force

for the selected wheel

using a brake force

ttbttith

Clogged

hydraulic

circuit in

hydraulic unitReplace

hydraulic unit

assembly.

03RR VALVE

g

tester or by rotating the

wheel by hand.Brake force is

not released.Incorrect

hydraulic unit

brake tube

connectionConnect

correctly.

04RL VALVEHydraulic unit

solenoid

valve not

functioning

correctlyReplace

hydraulic unit

assembly.

7. After checking, turn the ignition switch to the “LOCK” (OFF) position and then disconnect the MUT-II.

REMEDY FOR A FLAT BATTERY

When booster cables are used to start the engine when the

battery is completely flat and then the vehicle is immediately

driven without waiting for the battery to recharge itself to

some extent, the engine may misfire, and driving might not

be possible. This happens because ABS consumes a great

amount of current for its self-check function. If this happens,

recharge the battery fully.

Caution

The vehicle posture will be unstable during braking, so

do not drive the vehicle with the ABS-ECU connector

disconnected or with the ABS not operating for any other

reason.

Page 1100 of 1449

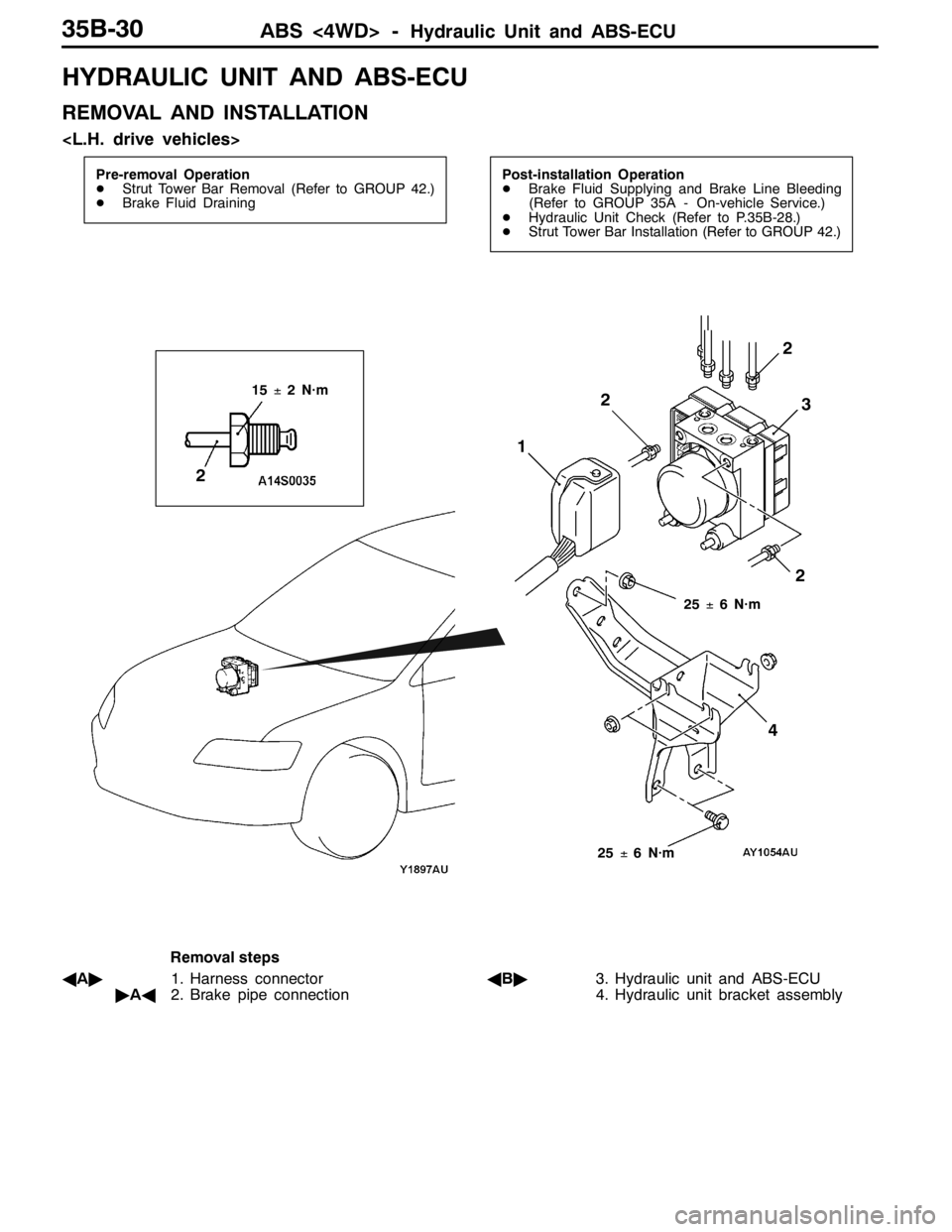

ABS <4WD> -Hydraulic Unit and ABS-ECU35B-30

HYDRAULIC UNIT AND ABS-ECU

REMOVAL AND INSTALLATION

Pre-removal Operation

DStrut Tower Bar Removal (Refer to GROUP 42.)

DBrake Fluid DrainingPost-installation Operation

DBrake Fluid Supplying and Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

DHydraulic Unit Check (Refer to P.35B-28.)

DStrut Tower Bar Installation (Refer to GROUP 42.)

23

42

2

2

15±2 N·m

25±6 N·m

1

25±6 N·m

Removal steps

AA"1. Harness connector

"AA2. Brake pipe connectionAB"3. Hydraulic unit and ABS-ECU

4. Hydraulic unit bracket assembly

Page 1101 of 1449

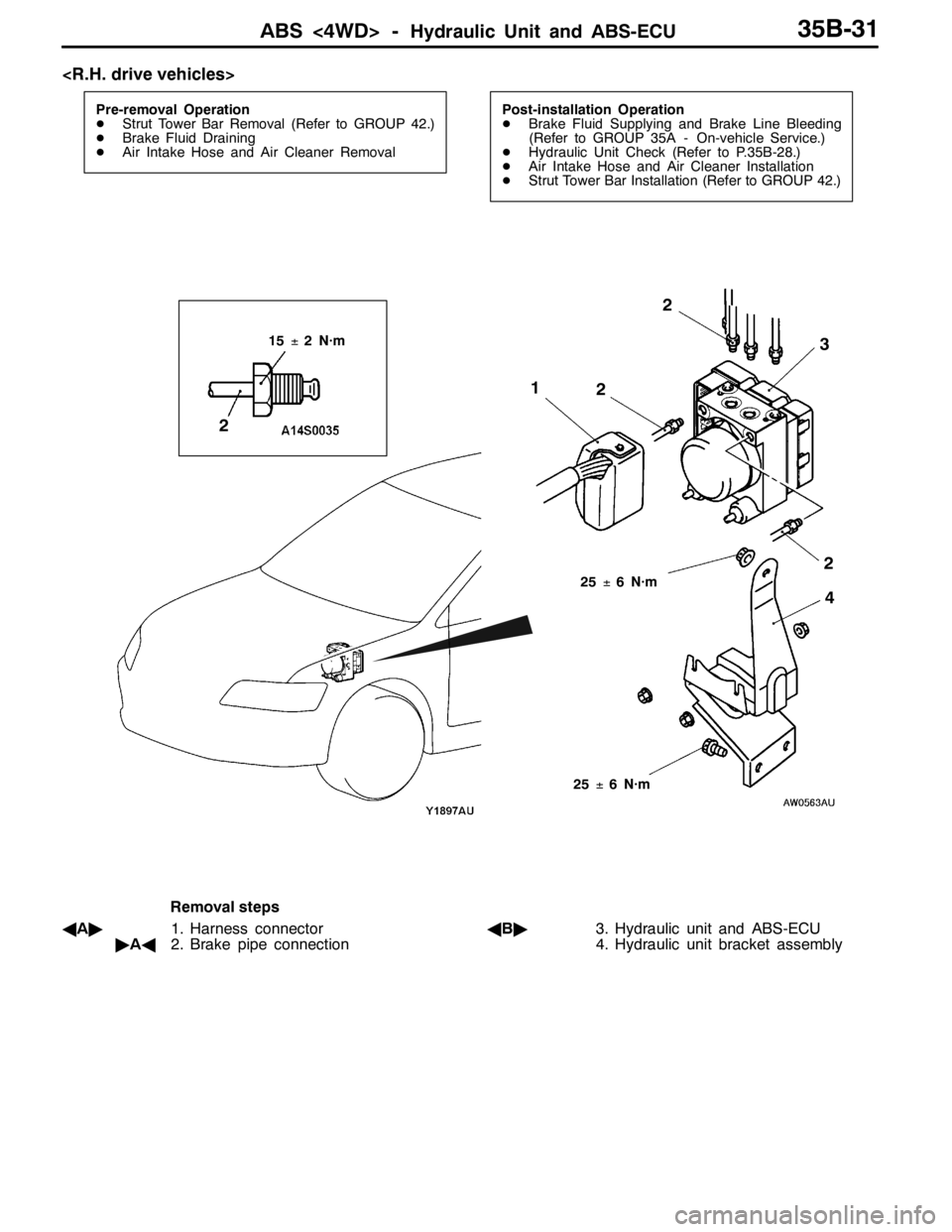

ABS <4WD> -Hydraulic Unit and ABS-ECU35B-31

Pre-removal Operation

DStrut Tower Bar Removal (Refer to GROUP 42.)

DBrake Fluid Draining

DAir Intake Hose and Air Cleaner RemovalPost-installation Operation

DBrake Fluid Supplying and Brake Line Bleeding

(Refer to GROUP 35A - On-vehicle Service.)

DHydraulic Unit Check (Refer to P.35B-28.)

DAir Intake Hose and Air Cleaner Installation

DStrut Tower Bar Installation (Refer to GROUP 42.)

213

4 2

2

2

15±2 N·m

25±6 N·m

25±6 N·m

Removal steps

AA"1. Harness connector

"AA2. Brake pipe connectionAB"3. Hydraulic unit and ABS-ECU

4. Hydraulic unit bracket assembly

Page 1102 of 1449

ABS <4WD> -Hydraulic Unit and ABS-ECU35B-32

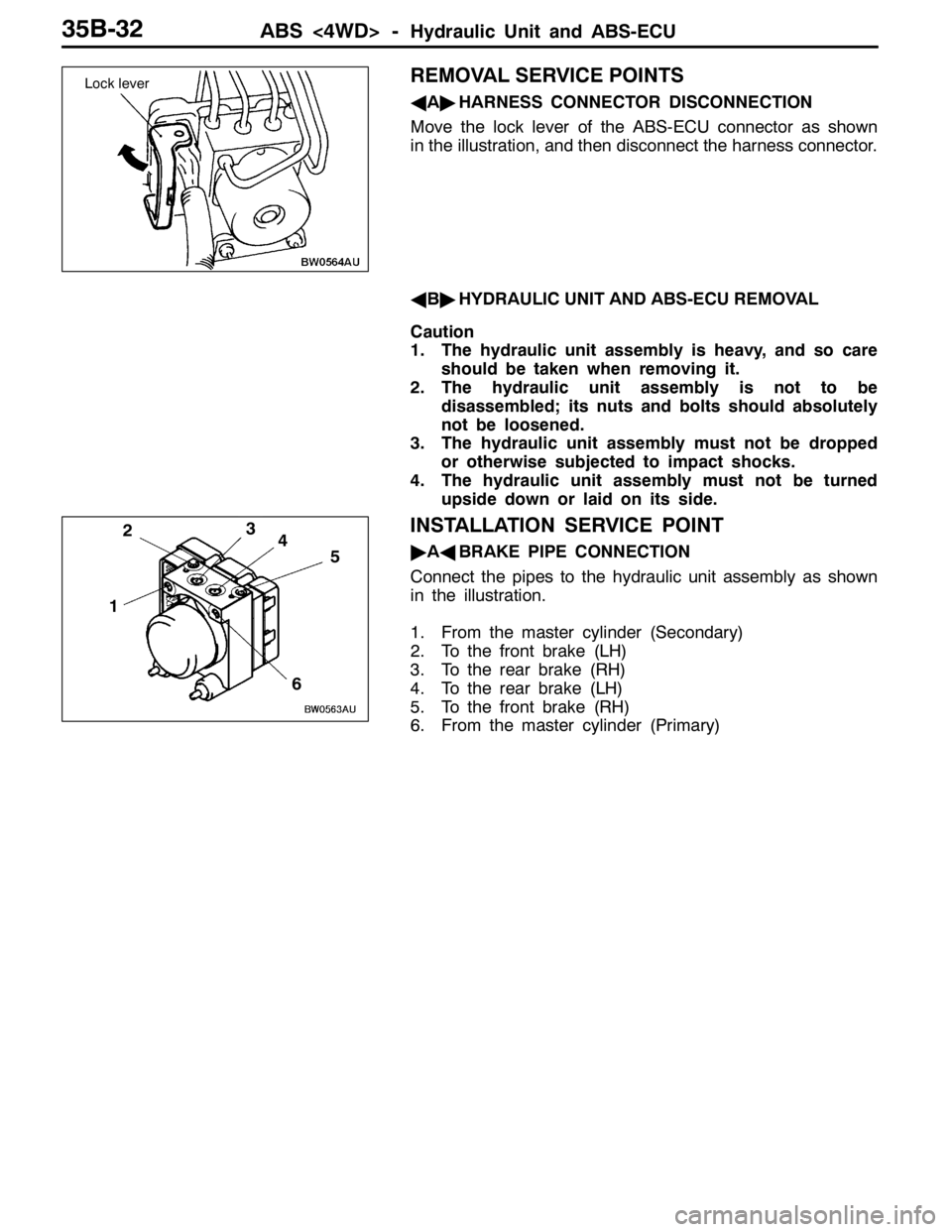

REMOVAL SERVICE POINTS

AA"HARNESS CONNECTOR DISCONNECTION

Move the lock lever of the ABS-ECU connector as shown

in the illustration, and then disconnect the harness connector.

AB"HYDRAULIC UNIT AND ABS-ECU REMOVAL

Caution

1. The hydraulic unit assembly is heavy, and so care

should be taken when removing it.

2. The hydraulic unit assembly is not to be

disassembled; its nuts and bolts should absolutely

not be loosened.

3. The hydraulic unit assembly must not be dropped

or otherwise subjected to impact shocks.

4. The hydraulic unit assembly must not be turned

upside down or laid on its side.

INSTALLATION SERVICE POINT

"AABRAKE PIPE CONNECTION

Connect the pipes to the hydraulic unit assembly as shown

in the illustration.

1. From the master cylinder (Secondary)

2. To the front brake (LH)

3. To the rear brake (RH)

4. To the rear brake (LH)

5. To the front brake (RH)

6. From the master cylinder (Primary)

Lock lever

1

234

5

6

Page 1103 of 1449

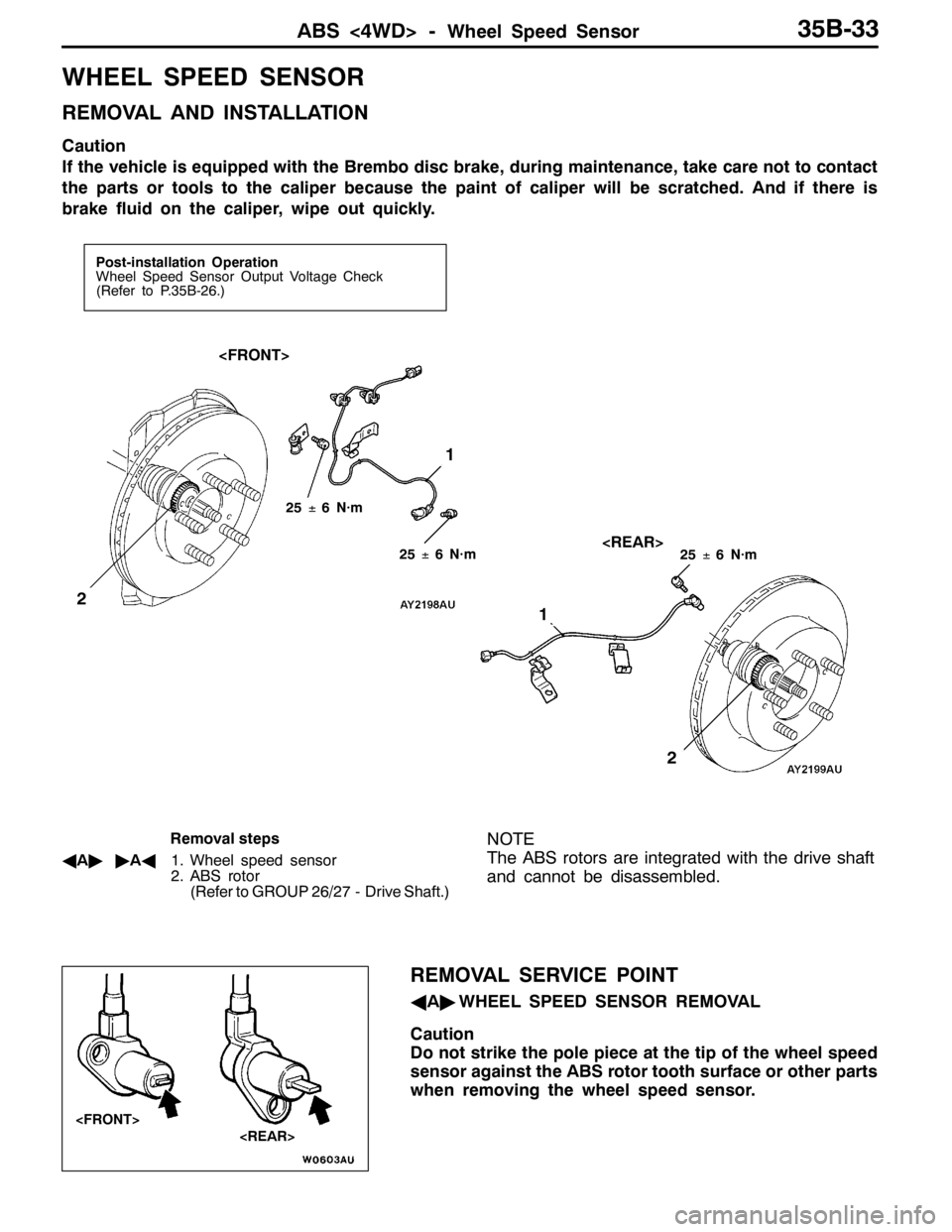

ABS <4WD> -Wheel Speed Sensor35B-33

WHEEL SPEED SENSOR

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched. And if there is

brake fluid on the caliper, wipe out quickly.

Post-installation Operation

Wheel Speed Sensor Output Voltage Check

(Refer to P.35B-26.)

1

2

1

2

25±6 N·m

25±6 N·m25±6 N·m

Removal steps

AA""AA1. Wheel speed sensor

2. ABS rotor

(Refer to GROUP 26/27 - Drive Shaft.)NOTE

The ABS rotors are integrated with the drive shaft

and cannot be disassembled.

REMOVAL SERVICE POINT

AA"WHEEL SPEED SENSOR REMOVAL

Caution

Do not strike the pole piece at the tip of the wheel speed

sensor against the ABS rotor tooth surface or other parts

when removing the wheel speed sensor.

Page 1104 of 1449

ABS <4WD> -Wheel Speed Sensor35B-34

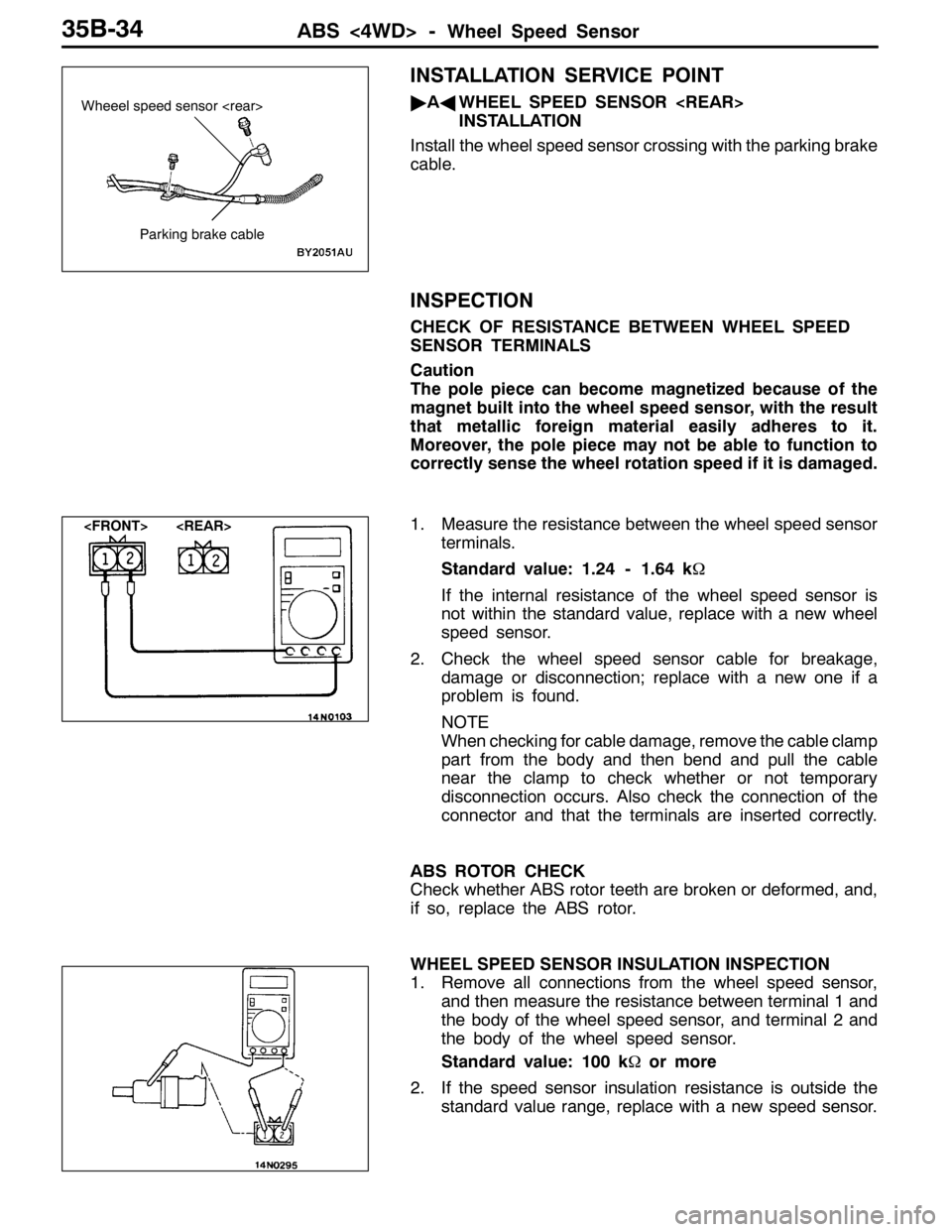

INSTALLATION SERVICE POINT

"AAWHEEL SPEED SENSOR

INSTALLATION

Install the wheel speed sensor crossing with the parking brake

cable.

INSPECTION

CHECK OF RESISTANCE BETWEEN WHEEL SPEED

SENSOR TERMINALS

Caution

The pole piece can become magnetized because of the

magnet built into the wheel speed sensor, with the result

that metallic foreign material easily adheres to it.

Moreover, the pole piece may not be able to function to

correctly sense the wheel rotation speed if it is damaged.

1. Measure the resistance between the wheel speed sensor

terminals.

Standard value: 1.24 - 1.64 kΩ

If the internal resistance of the wheel speed sensor is

not within the standard value, replace with a new wheel

speed sensor.

2. Check the wheel speed sensor cable for breakage,

damage or disconnection; replace with a new one if a

problem is found.

NOTE

When checking for cable damage, remove the cable clamp

part from the body and then bend and pull the cable

near the clamp to check whether or not temporary

disconnection occurs. Also check the connection of the

connector and that the terminals are inserted correctly.

ABS ROTOR CHECK

Check whether ABS rotor teeth are broken or deformed, and,

if so, replace the ABS rotor.

WHEEL SPEED SENSOR INSULATION INSPECTION

1. Remove all connections from the wheel speed sensor,

and then measure the resistance between terminal 1 and

the body of the wheel speed sensor, and terminal 2 and

the body of the wheel speed sensor.

Standard value: 100 kΩor more

2. If the speed sensor insulation resistance is outside the

standard value range, replace with a new speed sensor.

Wheeel speed sensor

Parking brake cable

Page 1105 of 1449

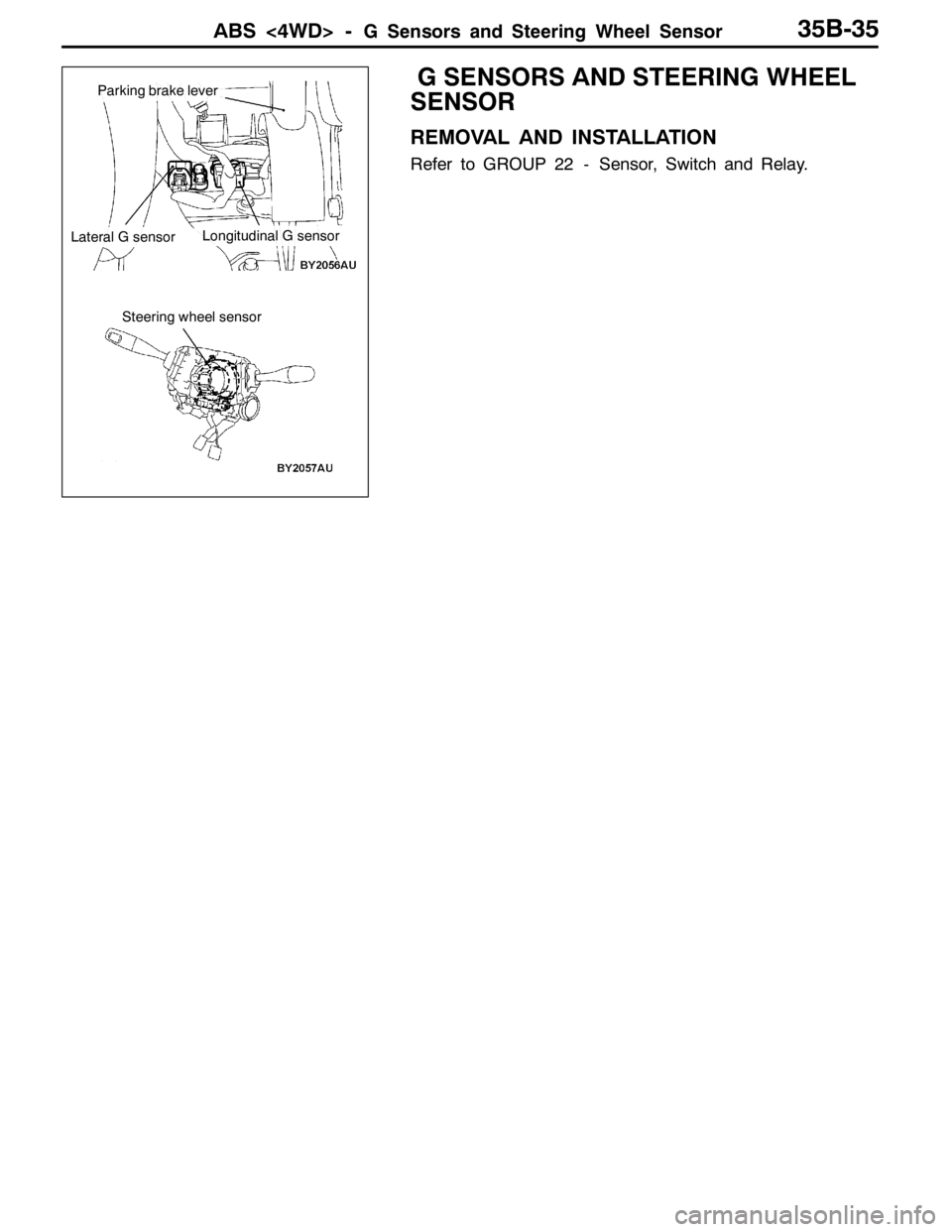

ABS <4WD> -G Sensors and Steering Wheel Sensor35B-35

G SENSORS AND STEERING WHEEL

SENSOR

REMOVAL AND INSTALLATION

Refer to GROUP 22 - Sensor, Switch and Relay.

Parking brake lever

Lateral G sensorLongitudinal G sensor

Steering wheel sensor

Page 1123 of 1449

STEERING -On-vehicle Service37A-9

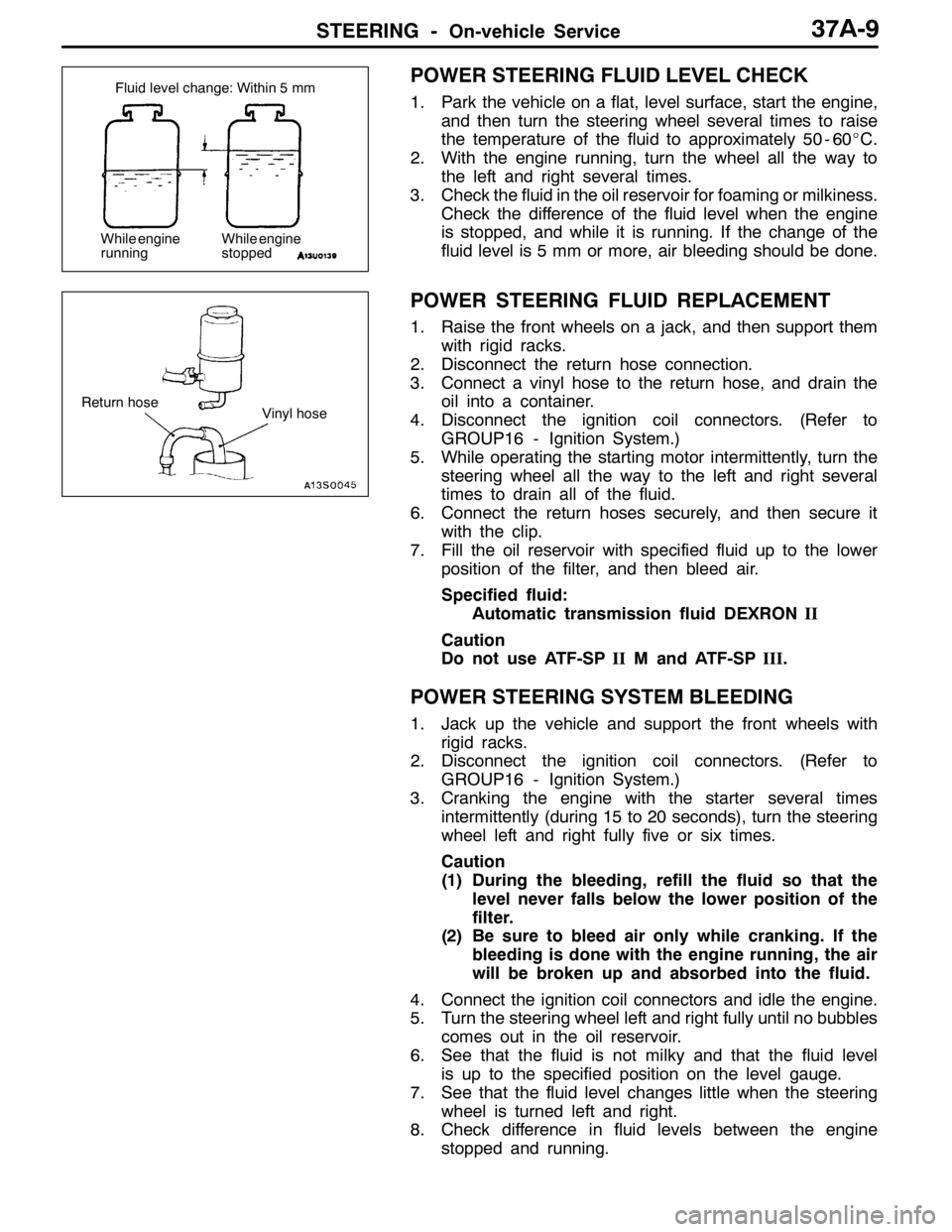

POWER STEERING FLUID LEVEL CHECK

1. Park the vehicle on a flat, level surface, start the engine,

and then turn the steering wheel several times to raise

the temperature of the fluid to approximately 50 - 60_C.

2. With the engine running, turn the wheel all the way to

the left and right several times.

3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine

is stopped, and while it is running. If the change of the

fluid level is 5 mm or more, air bleeding should be done.

POWER STEERING FLUID REPLACEMENT

1. Raise the front wheels on a jack, and then support them

with rigid racks.

2. Disconnect the return hose connection.

3. Connect a vinyl hose to the return hose, and drain the

oil into a container.

4. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

5. While operating the starting motor intermittently, turn the

steering wheel all the way to the left and right several

times to drain all of the fluid.

6. Connect the return hoses securely, and then secure it

with the clip.

7. Fill the oil reservoir with specified fluid up to the lower

position of the filter, and then bleed air.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

POWER STEERING SYSTEM BLEEDING

1. Jack up the vehicle and support the front wheels with

rigid racks.

2. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

3. Cranking the engine with the starter several times

intermittently (during 15 to 20 seconds), turn the steering

wheel left and right fully five or six times.

Caution

(1) During the bleeding, refill the fluid so that the

level never falls below the lower position of the

filter.

(2) Be sure to bleed air only while cranking. If the

bleeding is done with the engine running, the air

will be broken up and absorbed into the fluid.

4. Connect the ignition coil connectors and idle the engine.

5. Turn the steering wheel left and right fully until no bubbles

comes out in the oil reservoir.

6. See that the fluid is not milky and that the fluid level

is up to the specified position on the level gauge.

7. See that the fluid level changes little when the steering

wheel is turned left and right.

8. Check difference in fluid levels between the engine

stopped and running.

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Return hose

Vinyl hose

Page 1140 of 1449

STEERING - Power Steering Gear Box and Linkage37A-26

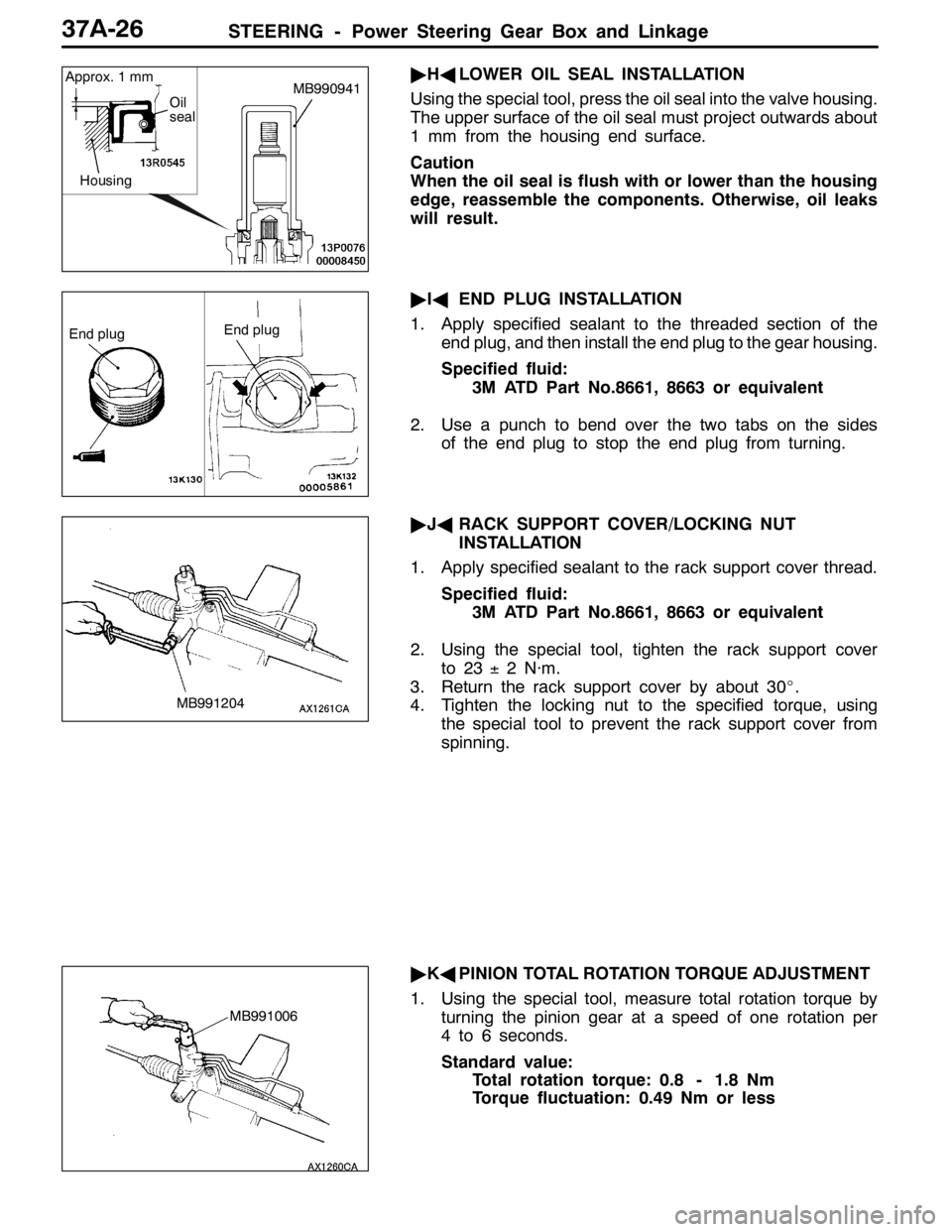

"HALOWER OIL SEAL INSTALLATION

Using the special tool, press the oil seal into the valve housing.

The upper surface of the oil seal must project outwards about

1 mm from the housing end surface.

Caution

When the oil seal is flush with or lower than the housing

edge, reassemble the components. Otherwise, oil leaks

will result.

"IAEND PLUG INSTALLATION

1. Apply specified sealant to the threaded section of the

end plug, and then install the end plug to the gear housing.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Use a punch to bend over the two tabs on the sides

of the end plug to stop the end plug from turning.

"JARACK SUPPORT COVER/LOCKING NUT

INSTALLATION

1. Apply specified sealant to the rack support cover thread.

Specified fluid:

3M ATD Part No.8661, 8663 or equivalent

2. Using the special tool, tighten the rack support cover

to 23±2 N·m.

3. Return the rack support cover by about 30_.

4. Tighten the locking nut to the specified torque, using

the special tool to prevent the rack support cover from

spinning.

"KAPINION TOTAL ROTATION TORQUE ADJUSTMENT

1. Using the special tool, measure total rotation torque by

turning the pinion gear at a speed of one rotation per

4 to 6 seconds.

Standard value:

Total rotation torque: 0.8-1.8 Nm

Torque fluctuation: 0.49 Nm or lessMB990941 Approx. 1 mmOil

seal

Housing

End plugEnd plug

MB991204

MB991006

Page 1430 of 1449

HEATER, AIR CONDITIONER AND VENTILATION-Heater Unit and Blower Assembly55-28

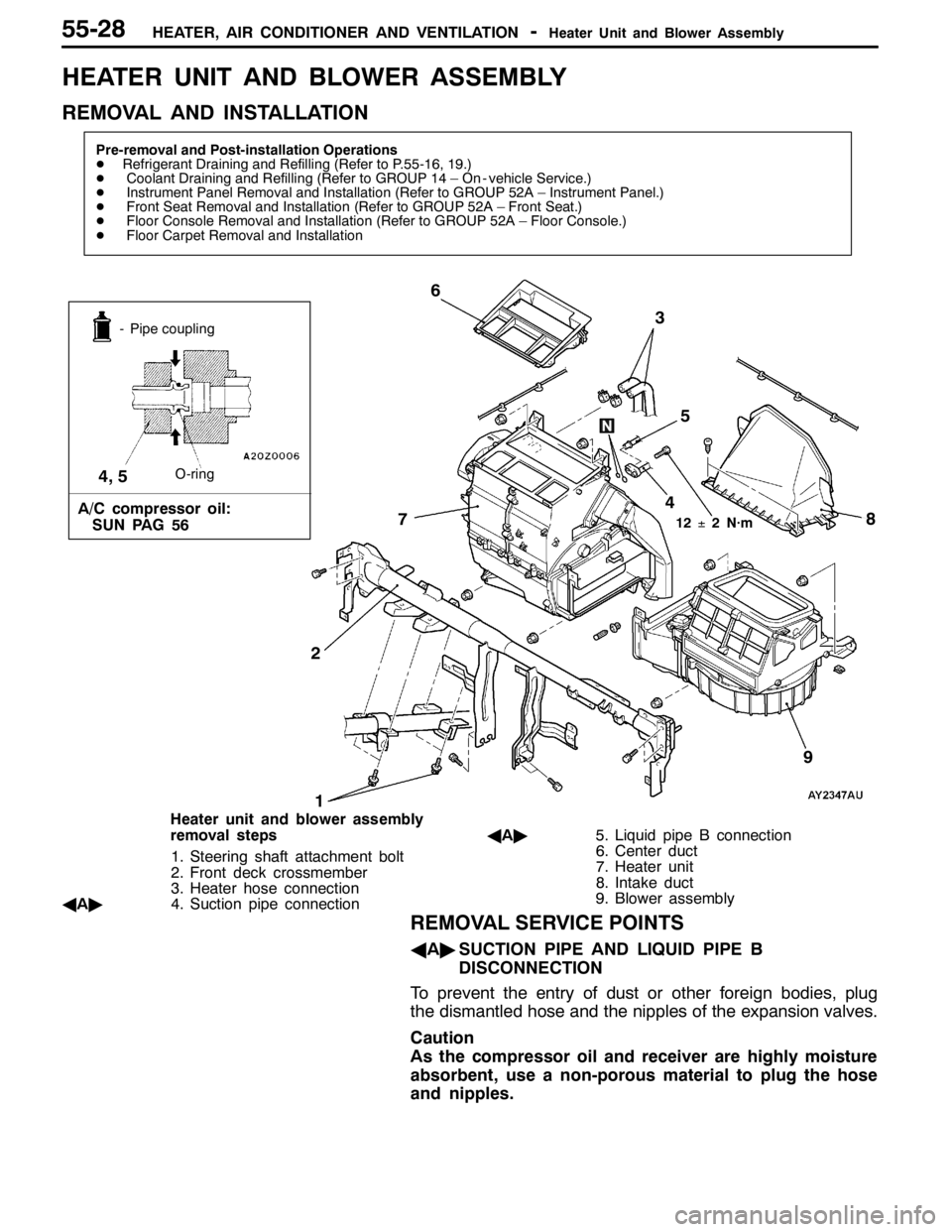

HEATER UNIT AND BLOWER ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

DRefrigerant Draining and Refilling (Refer to P.55-16, 19.)

DCoolant Draining and Refilling (Refer to GROUP 14 – On - vehicle Service.)

DInstrument Panel Removal and Installation (Refer to GROUP 52A – Instrument Panel.)

DFront Seat Removal and Installation (Refer to GROUP 52A – Front Seat.)

DFloor Console Removal and Installation (Refer to GROUP 52A – Floor Console.)

DFloor Carpet Removal and Installation

13

5 6

2

12±2 N·m

- Pipe coupling

O-ring

A/C compressor oil:

SUN PAG 56

4, 5

9

7

4

8

Heater unit and blower assembly

removal steps

1. Steering shaft attachment bolt

2. Front deck crossmember

3. Heater hose connection

AA"4. Suction pipe connectionAA"5. Liquid pipe B connection

6. Center duct

7. Heater unit

8. Intake duct

9. Blower assembly

REMOVAL SERVICE POINTS

AA"SUCTION PIPE AND LIQUID PIPE B

DISCONNECTION

To prevent the entry of dust or other foreign bodies, plug

the dismantled hose and the nipples of the expansion valves.

Caution

As the compressor oil and receiver are highly moisture

absorbent, use a non-porous material to plug the hose

and nipples.