Leak MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 602 of 1449

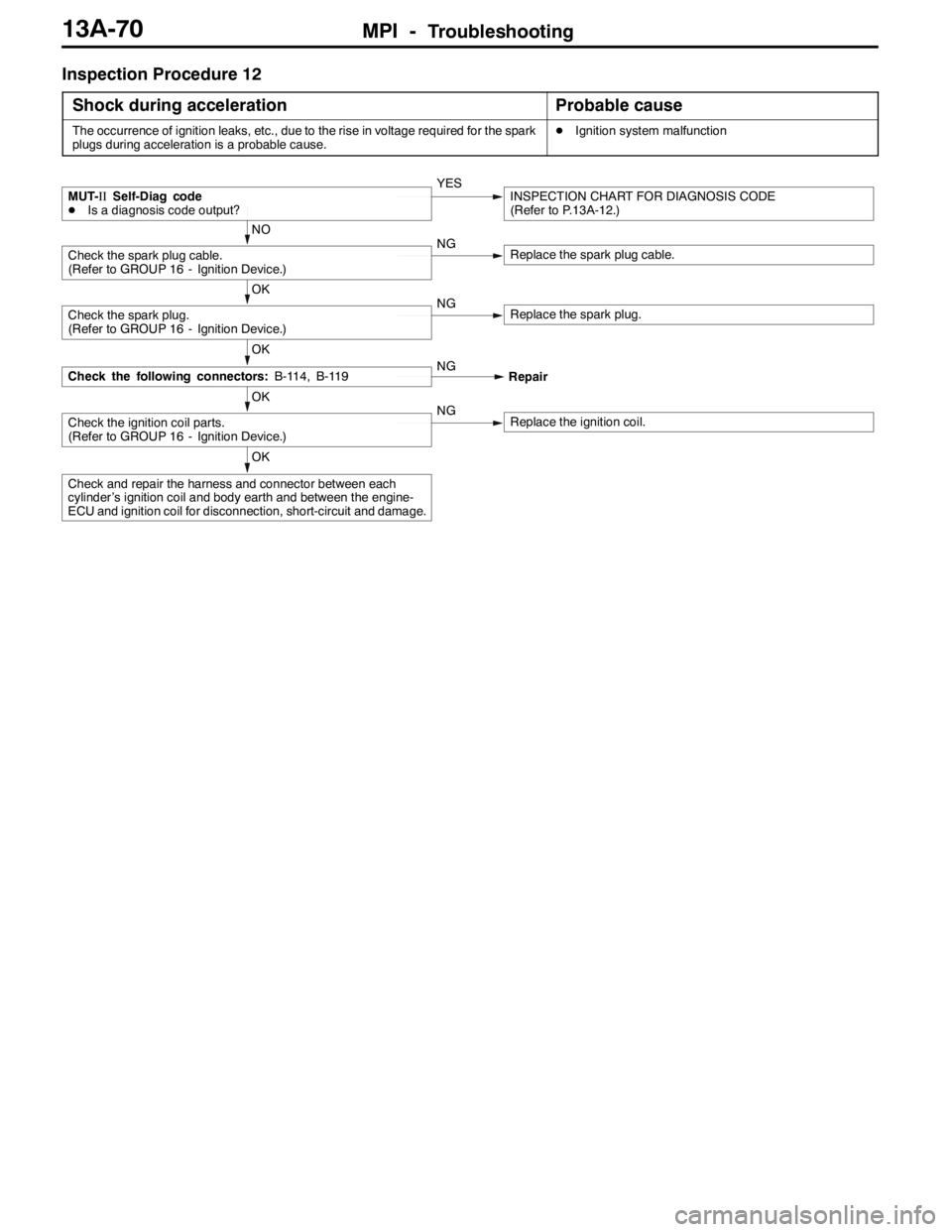

MPI -Troubleshooting13A-70

Inspection Procedure 12

Shock during acceleration

Probable cause

The occurrence of ignition leaks, etc., due to the rise in voltage required for the spark

plugs during acceleration is a probable cause.DIgnition system malfunction

OK

Check and repair the harness and connector between each

cylinder’s ignition coil and body earth and between the engine-

ECU and ignition coil for disconnection, short-circuit and damage.

OK

Check the ignition coil parts.

(Refer to GROUP 16 - Ignition Device.)NGReplace the ignition coil.

OK

Check the following connectors:B-114, B-119NG

Repair

OK

Check the spark plug.

(Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug.

NO

Check the spark plug cable.

(Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug cable.

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 607 of 1449

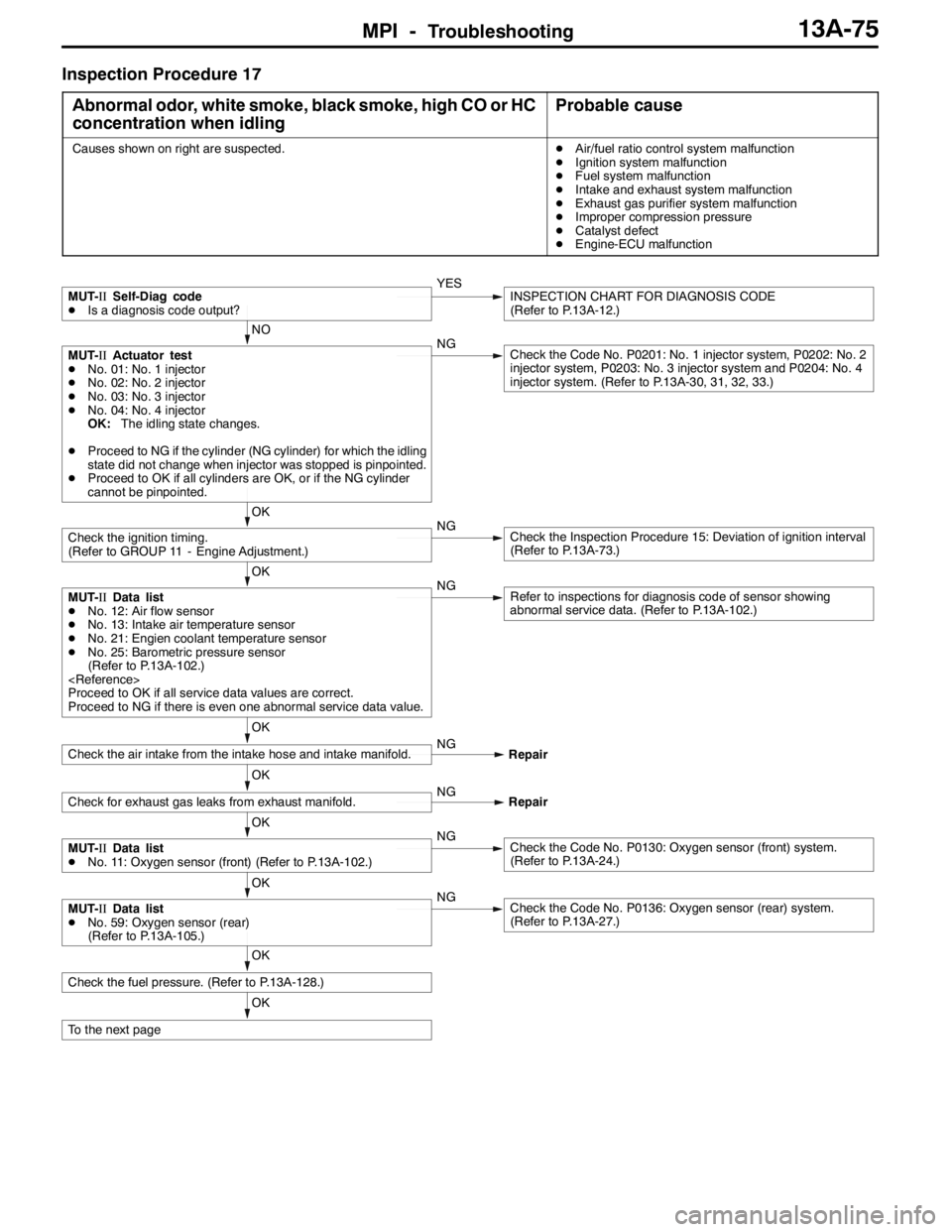

MPI -Troubleshooting13A-75

Inspection Procedure 17

Abnormal odor, white smoke, black smoke, high CO or HC

concentration when idling

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DCatalyst defect

DEngine-ECU malfunction

OK

To the next page

OK

Check the fuel pressure. (Refer to P.13A-128.)

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check for exhaust gas leaks from exhaust manifold.NG

Repair

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 21: Engien coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-102.)

OK

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck the Inspection Procedure 15: Deviation of ignition interval

(Refer to P.13A-73.)

NO

MUT-IIActuator test

DNo. 01: No. 1 injector

DNo. 02: No. 2 injector

DNo. 03: No. 3 injector

DNo. 04: No. 4 injector

OK:The idling state changes.

DProceed to NG if the cylinder (NG cylinder) for which the idling

state did not change when injector was stopped is pinpointed.

DProceed to OK if all cylinders are OK, or if the NG cylinder

cannot be pinpointed.NGCheck the Code No. P0201: No. 1 injector system, P0202: No. 2

injector system, P0203: No. 3 injector system and P0204: No. 4

injector system. (Refer to P.13A-30, 31, 32, 33.)

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 611 of 1449

MPI -Troubleshooting13A-79

Inspection Procedure 19

Overheating

Probable cause

Causes shown on right are suspected.DEngine coolant insufficient or deteriorated

DFan controller malfunction

DEngine coolant temperature sensor malfunction

DThermostat malfunction

DWater pump malfunction

DCondenser fan relay malfunction

DRadiator core malfunction

DEngine-ECU malfunction

NO

NG

Replace or replenish the engine coolant.

OK

Replace the radiator core.

OK

Check the water pump. (Refer to GROUP 14 - Water pump.)NGReplace the water pump.

OK

Check the thermostat. (Refer to GROUP 14 - Thermostat.)NGReplace the thermostat.

OK

MUT-IIData list

DNo. 21: Engine coolant temperaure sensor

OK:Approximately the same as the ambient temperature

when cooled.

Between 80 - 120_C when hot.NGCheck the Code No. P0115: Engine coolant temperature

sensor system. (Refer to P.13A-19.)

MUT-IIData list

21 Engine coolant temperature sensor (Refer to P.13A-102.)

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan rotates (low speed).

OK:Condenser fan rotates (high speed).NGCheck the Inspection Procedure 25: Condenser fan control

relay system. (Refer to P.13A-89.)

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan rotates.NGCheck the Inspection Procedure 24: Radiator fan control relay

system. (Refer to P.13A-87.)

OK

Check the engine coolant.

(Refer to GROUP 14 - On-vehicle Service.)

If the engine coolant level is low, check whether the engine

coolant has leaked, and repair if required.

MUT-IISelf-Diag Code

Is a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE (Refer to

P.13A-12.)

Page 649 of 1449

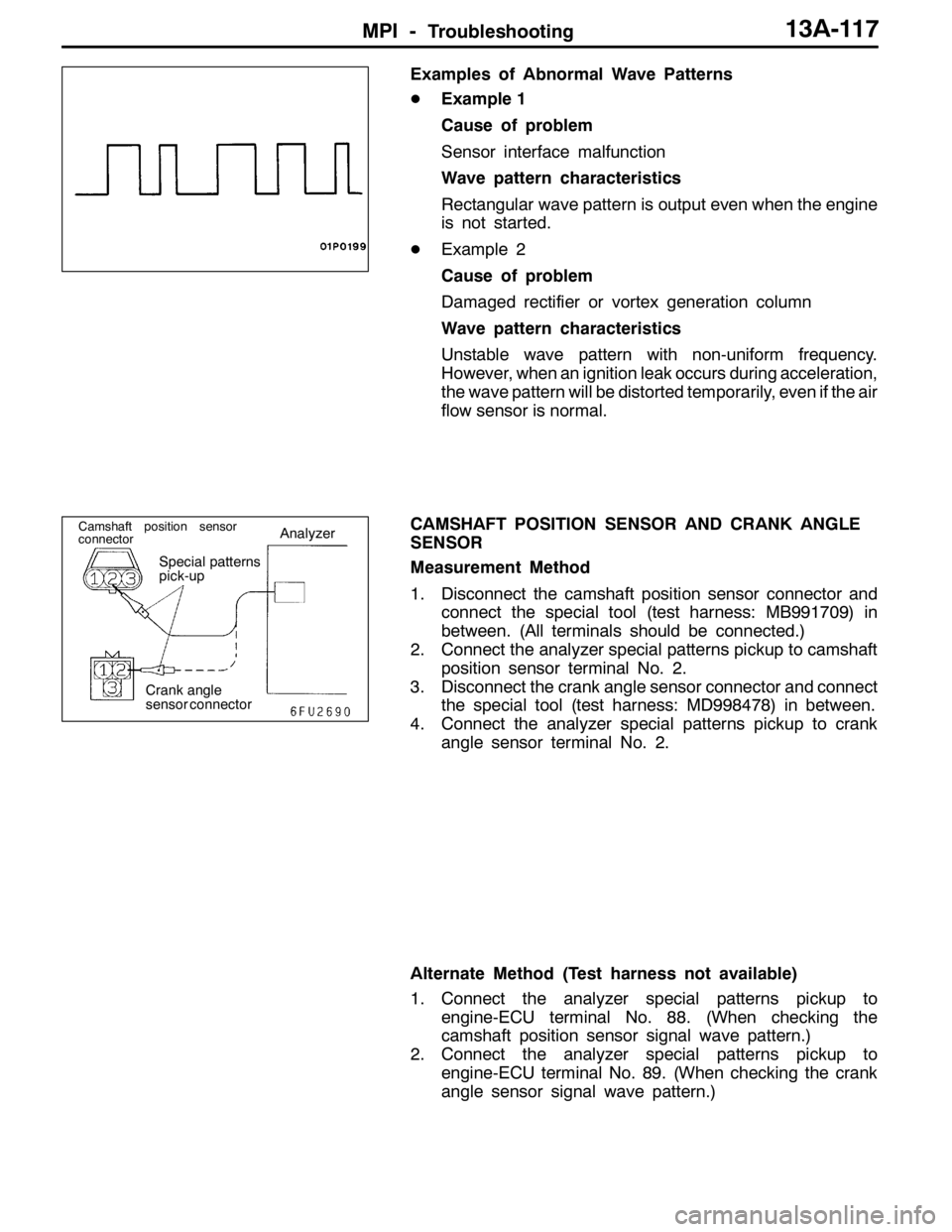

MPI -Troubleshooting13A-117

Examples of Abnormal Wave Patterns

DExample 1

Cause of problem

Sensor interface malfunction

Wave pattern characteristics

Rectangular wave pattern is output even when the engine

is not started.

DExample 2

Cause of problem

Damaged rectifier or vortex generation column

Wave pattern characteristics

Unstable wave pattern with non-uniform frequency.

However, when an ignition leak occurs during acceleration,

the wave pattern will be distorted temporarily, even if the air

flow sensor is normal.

CAMSHAFT POSITION SENSOR AND CRANK ANGLE

SENSOR

Measurement Method

1. Disconnect the camshaft position sensor connector and

connect the special tool (test harness: MB991709) in

between. (All terminals should be connected.)

2. Connect the analyzer special patterns pickup to camshaft

position sensor terminal No. 2.

3. Disconnect the crank angle sensor connector and connect

the special tool (test harness: MD998478) in between.

4. Connect the analyzer special patterns pickup to crank

angle sensor terminal No. 2.

Alternate Method (Test harness not available)

1. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 88. (When checking the

camshaft position sensor signal wave pattern.)

2. Connect the analyzer special patterns pickup to

engine-ECU terminal No. 89. (When checking the crank

angle sensor signal wave pattern.)

Crank angle

sensor connector

Camshaft position sensor

connectorAnalyzer

Special patterns

pick-up

Page 661 of 1449

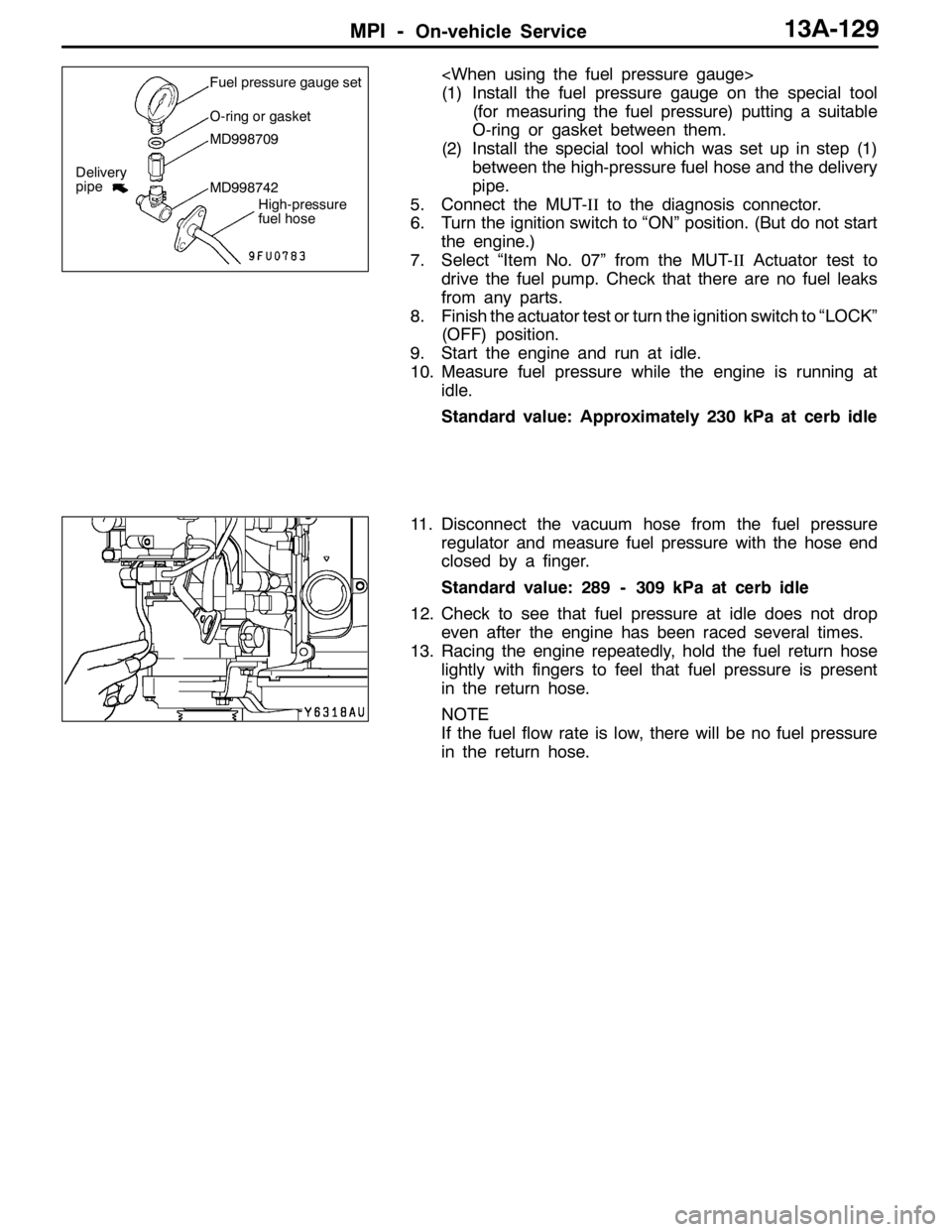

MPI -On-vehicle Service13A-129

(1) Install the fuel pressure gauge on the special tool

(for measuring the fuel pressure) putting a suitable

O-ring or gasket between them.

(2) Install the special tool which was set up in step (1)

between the high-pressure fuel hose and the delivery

pipe.

5. Connect the MUT-IIto the diagnosis connector.

6. Turn the ignition switch to “ON” position. (But do not start

the engine.)

7. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump. Check that there are no fuel leaks

from any parts.

8. Finish the actuator test or turn the ignition switch to “LOCK”

(OFF) position.

9. Start the engine and run at idle.

10. Measure fuel pressure while the engine is running at

idle.

Standard value: Approximately 230 kPa at cerb idle

11. Disconnect the vacuum hose from the fuel pressure

regulator and measure fuel pressure with the hose end

closed by a finger.

Standard value: 289 - 309 kPa at cerb idle

12. Check to see that fuel pressure at idle does not drop

even after the engine has been raced several times.

13. Racing the engine repeatedly, hold the fuel return hose

lightly with fingers to feel that fuel pressure is present

in the return hose.

NOTE

If the fuel flow rate is low, there will be no fuel pressure

in the return hose.Fuel pressure gauge set

O-ring or gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

Page 662 of 1449

MPI -On-vehicle Service13A-130

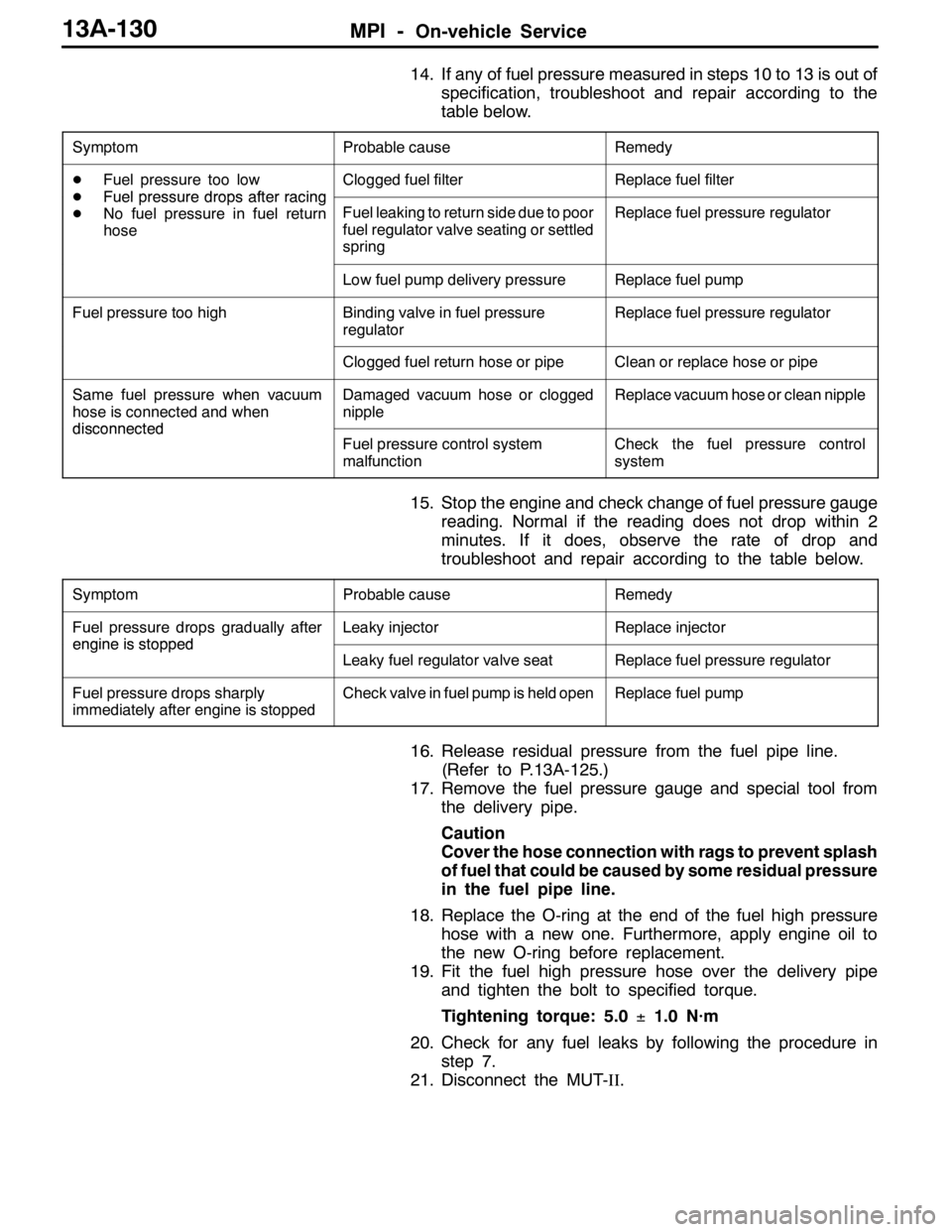

14. If any of fuel pressure measured in steps 10 to 13 is out of

specification, troubleshoot and repair according to the

table below.

SymptomProbable causeRemedy

DFuel pressure too low

DFuelpressuredropsafterracing

Clogged fuel filterReplace fuel filter

DFuelpressuredrops after racing

DNo fuel pressure in fuel return

hose

Fuel leaking to return side due to poor

fuel regulator valve seating or settled

springReplace fuel pressure regulator

Low fuel pump delivery pressureReplace fuel pump

Fuel pressure too highBinding valve in fuel pressure

regulatorReplace fuel pressure regulator

Clogged fuel return hose or pipeClean or replace hose or pipe

Same fuel pressure when vacuum

hose is connected and when

disconnected

Damaged vacuum hose or clogged

nippleReplace vacuum hose or clean nipple

disconnectedFuel pressure control system

malfunctionCheck the fuel pressure control

system

15. Stop the engine and check change of fuel pressure gauge

reading. Normal if the reading does not drop within 2

minutes. If it does, observe the rate of drop and

troubleshoot and repair according to the table below.

SymptomProbable causeRemedy

Fuel pressure drops gradually after

engineisstopped

Leaky injectorReplace injector

engineisstopped

Leaky fuel regulator valve seatReplace fuel pressure regulator

Fuel pressure drops sharply

immediately after engine is stoppedCheck valve in fuel pump is held openReplace fuel pump

16. Release residual pressure from the fuel pipe line.

(Refer to P.13A-125.)

17. Remove the fuel pressure gauge and special tool from

the delivery pipe.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

18. Replace the O-ring at the end of the fuel high pressure

hose with a new one. Furthermore, apply engine oil to

the new O-ring before replacement.

19. Fit the fuel high pressure hose over the delivery pipe

and tighten the bolt to specified torque.

Tightening torque: 5.0±1.0 N·m

20. Check for any fuel leaks by following the procedure in

step 7.

21. Disconnect the MUT-II.

Page 669 of 1449

MPI -On-vehicle Service13A-137

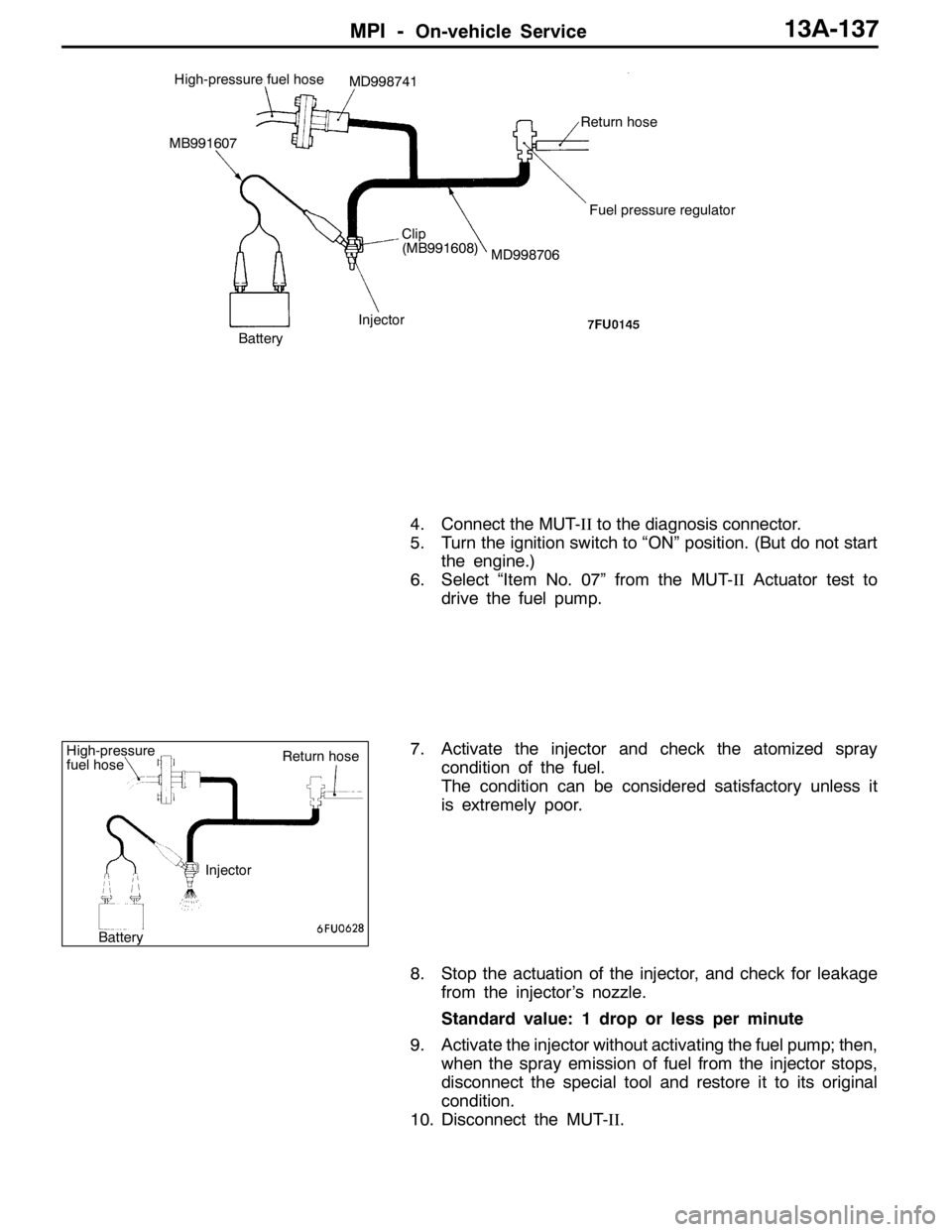

MB991607

High-pressure fuel hoseMD998741

MD998706Return hose

BatteryInjectorFuel pressure regulator

Clip

(MB991608)

4. Connect the MUT-IIto the diagnosis connector.

5. Turn the ignition switch to “ON” position. (But do not start

the engine.)

6. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump.

7. Activate the injector and check the atomized spray

condition of the fuel.

The condition can be considered satisfactory unless it

is extremely poor.

8. Stop the actuation of the injector, and check for leakage

from the injector’s nozzle.

Standard value: 1 drop or less per minute

9. Activate the injector without activating the fuel pump; then,

when the spray emission of fuel from the injector stops,

disconnect the special tool and restore it to its original

condition.

10. Disconnect the MUT-II.

High-pressure

fuel hose

BatteryInjectorReturn hose

Page 672 of 1449

MPI -On-vehicle Service13A-140

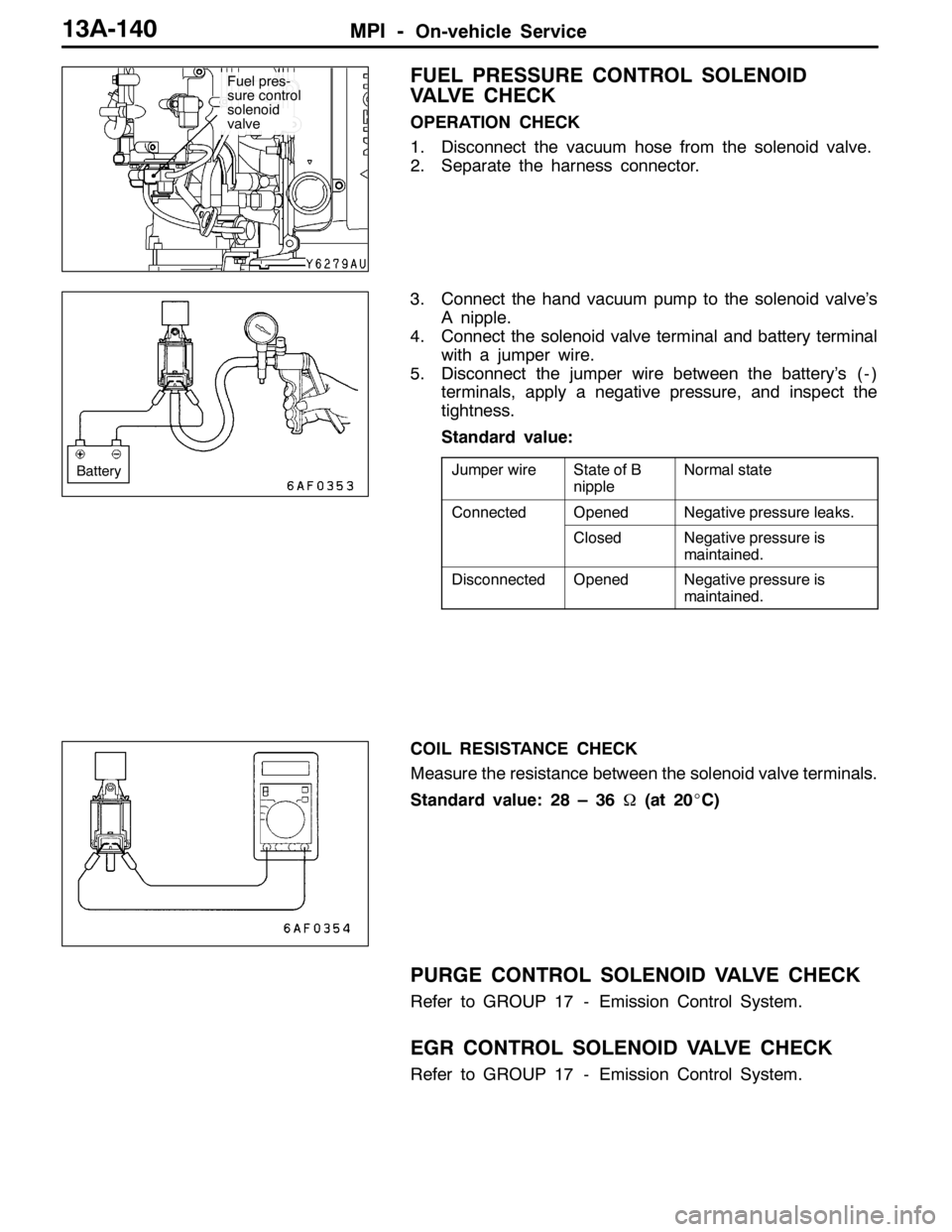

FUEL PRESSURE CONTROL SOLENOID

VALVE CHECK

OPERATION CHECK

1. Disconnect the vacuum hose from the solenoid valve.

2. Separate the harness connector.

3. Connect the hand vacuum pump to the solenoid valve’s

A nipple.

4. Connect the solenoid valve terminal and battery terminal

with a jumper wire.

5. Disconnect the jumper wire between the battery’s ( - )

terminals, apply a negative pressure, and inspect the

tightness.

Standard value:

Jumper wireState of B

nippleNormal state

ConnectedOpenedNegative pressure leaks.

ClosedNegative pressure is

maintained.

DisconnectedOpenedNegative pressure is

maintained.

COIL RESISTANCE CHECK

Measure the resistance between the solenoid valve terminals.

Standard value: 28 – 36Ω(at 20_C)

PURGE CONTROL SOLENOID VALVE CHECK

Refer to GROUP 17 - Emission Control System.

EGR CONTROL SOLENOID VALVE CHECK

Refer to GROUP 17 - Emission Control System.

Fuel pres-

sure control

solenoid

valve

Battery

Page 673 of 1449

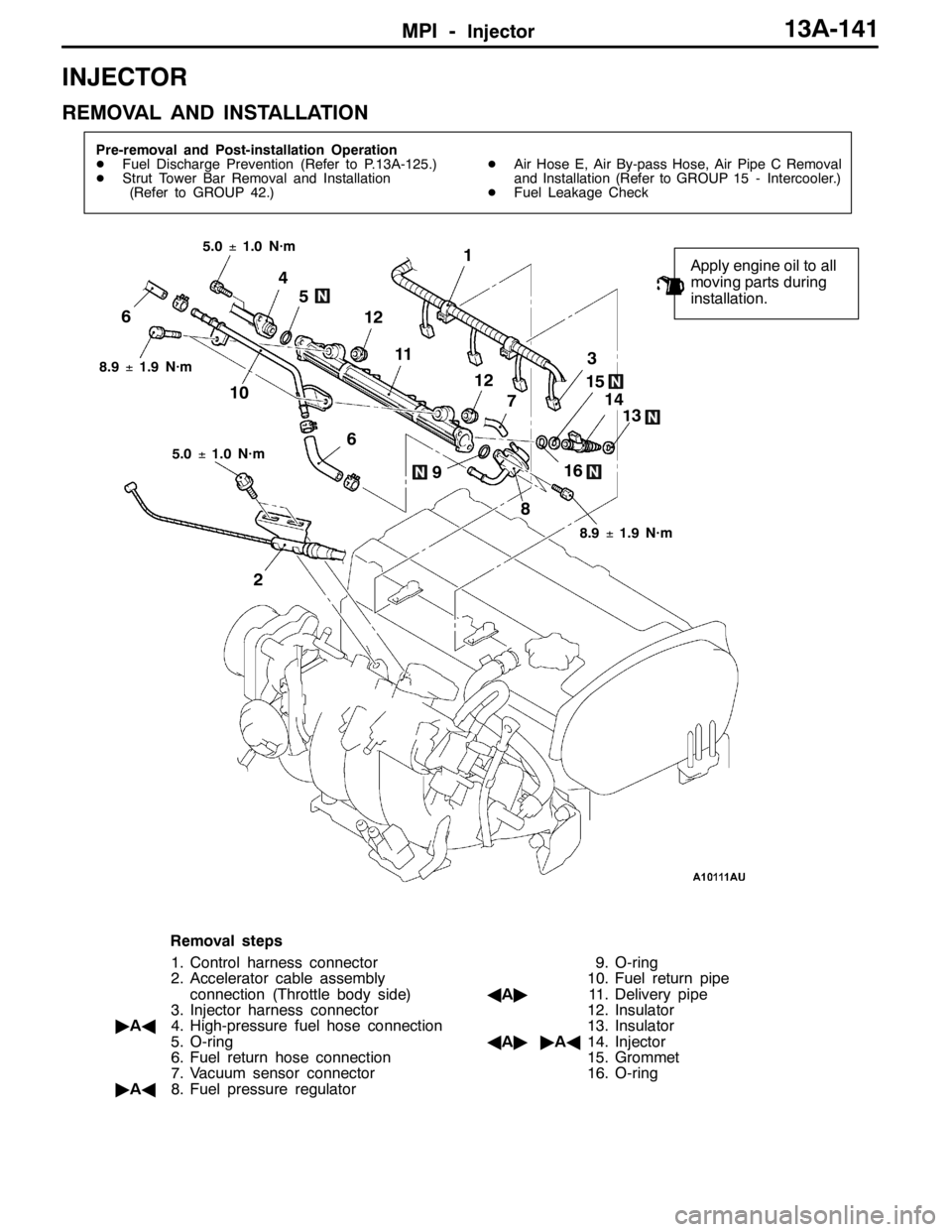

MPI -Injector13A-141

INJECTOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DFuel Discharge Prevention (Refer to P.13A-125.)

DStrut Tower Bar Removal and Installation

(Refer to GROUP 42.)DAir Hose E, Air By-pass Hose, Air Pipe C Removal

and Installation (Refer to GROUP 15 - Intercooler.)

DFuel Leakage Check

21

3

13 5

6

7

8 9 1011 12

4

8.9±1.9N·m

8.9±1.9N·m 5.0±1.0N·m

Apply engine oil to all

moving parts during

installation.

14 15

16 12

6

5.0±1.0N·m

Removal steps

1. Control harness connector

2. Accelerator cable assembly

connection (Throttle body side)

3. Injector harness connector

"AA4. High-pressure fuel hose connection

5. O-ring

6. Fuel return hose connection

7. Vacuum sensor connector

"AA8. Fuel pressure regulator9. O-ring

10. Fuel return pipe

AA"11. Delivery pipe

12. Insulator

13. Insulator

AA""AA14. Injector

15. Grommet

16. O-ring

Page 682 of 1449

FUEL SUPPLY - General Information/On-vehicle Service13B-2

GENERAL INFORMATION

DThe steel fuel tank is located under the floor of the rear seats to provide increased safety and increase

the amount of luggage compartment space.

DThe fuel tank has been equipped with a valve assembly which incorporates a fuel cut-off valve to

prevent fuel from leaking out in the event of a collision for adjusting the pressure inside the fuel

tank.

DThe fuel pump module contains a fuel pump, fuel filter, and fuel pressure regulator.

ON-VEHICLE SERVICE

FUEL PUMP AND GAUGE ASSEMBLY (FUEL

PUMP)

1. FUEL PUMP OPERATION CHECK

Refer to GROUP 13A - On-vehicle service

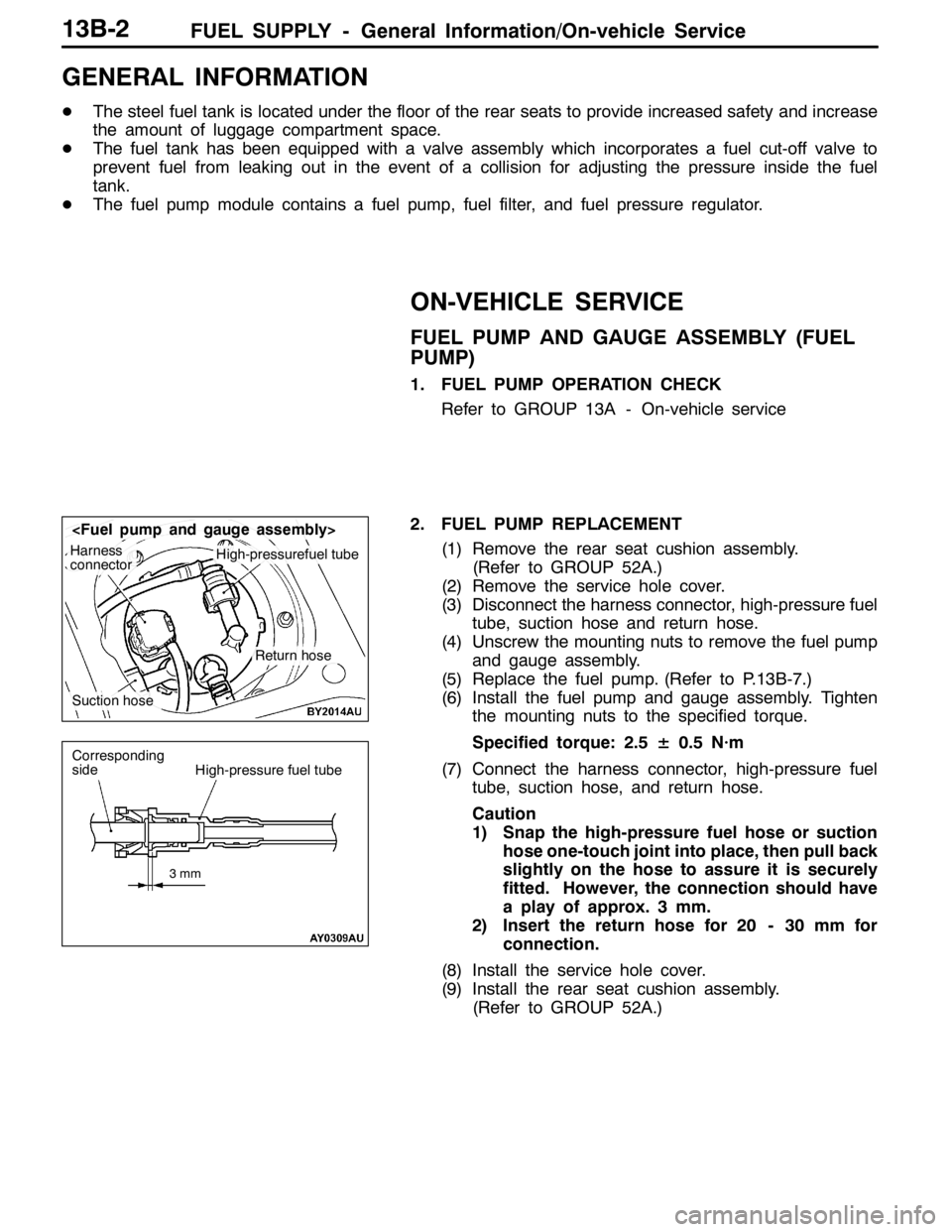

2. FUEL PUMP REPLACEMENT

(1) Remove the rear seat cushion assembly.

(Refer to GROUP 52A.)

(2) Remove the service hole cover.

(3) Disconnect the harness connector, high-pressure fuel

tube, suction hose and return hose.

(4) Unscrew the mounting nuts to remove the fuel pump

and gauge assembly.

(5) Replace the fuel pump. (Refer to P.13B-7.)

(6) Install the fuel pump and gauge assembly. Tighten

the mounting nuts to the specified torque.

Specified torque: 2.5± 0.5 N·m

(7) Connect the harness connector, high-pressure fuel

tube, suction hose, and return hose.

Caution

1) Snap the high-pressure fuel hose or suction

hose one-touch joint into place, then pull back

slightly on the hose to assure it is securely

fitted. However, the connection should have

a play of approx. 3 mm.

2) Insert the return hose for 20 - 30 mm for

connection.

(8) Install the service hole cover.

(9) Install the rear seat cushion assembly.

(Refer to GROUP 52A.)

Harness

connectorHigh-pressurefuel tube

Suction hose

Return hose

3mm

Corresponding

sideHigh-pressure fuel tube