change time MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1072 of 1449

ABS <4WD> -General Information35B-2

GENERAL INFORMATION

ABS has been adopted as optional equipment in

RS-IIto maintain directional stability and steering

performance during sudden braking or braking on

slippery road surfaces.

The ABS control method is a 4-sensor, 4-channel

method which provides independent control for all

wheels.

Following system for Lancer EVOLUTION-VII has

been modified from Lancer EVOLUTION-VI Tommi

Makinen Edition.DBy adding lateral G sensor, longitudinal G

sensor and steering wheel sensor, optimized

ABS control at the time of cornering.

DBy inputting parking brake switch signal to

ABS-ECU with pulling parking brake lever, ABS

control has been optimized.

DABS-ECU outputs ABS signal to 4WD-ECU.

DG sensor (lateral), steering wheel sensor and

parking brake switch have been added to the

diagnosis and service data.

DABS-ECU connector has been changed.

EBD CONTROL

In ABS, electronic control method is used by which

the rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control solenoid

valves in accordance with the vehicle’s rate of

deceleration and the front and rear wheel slippage

which are calculated from the each wheel speed

sensor’s signal. EBD control is a control system

which provides a high level of control for both vehicle

braking force and vehicle stability. The system has

the following features:

DBecause the system provides the optimum rear

wheel braking force regardless of the vehicleladen condition and the condition of the road

surface, the system reduces the required pedal

depression force, particularly when the vehicle

is heavily laden or driving on road surfaces

with high frictional coefficients.

DBecause the duty placed on the front brakes

has been reduced, the increases in pad

temperature can be controlled to improve the

wear resistance characteristics of the pad,

during front brakes applying.

DControl valves such as the proportioning valve

are no longer required.

SPECIFICATIONS

ItemSpecifications

ABS control method4-sensor, 4-channel

No. of ABS rotor teethFront43

Rear43

ABS speed sensorTypeMagnet coil typep

Gap between sensor and rotor mm0.85

Page 1123 of 1449

STEERING -On-vehicle Service37A-9

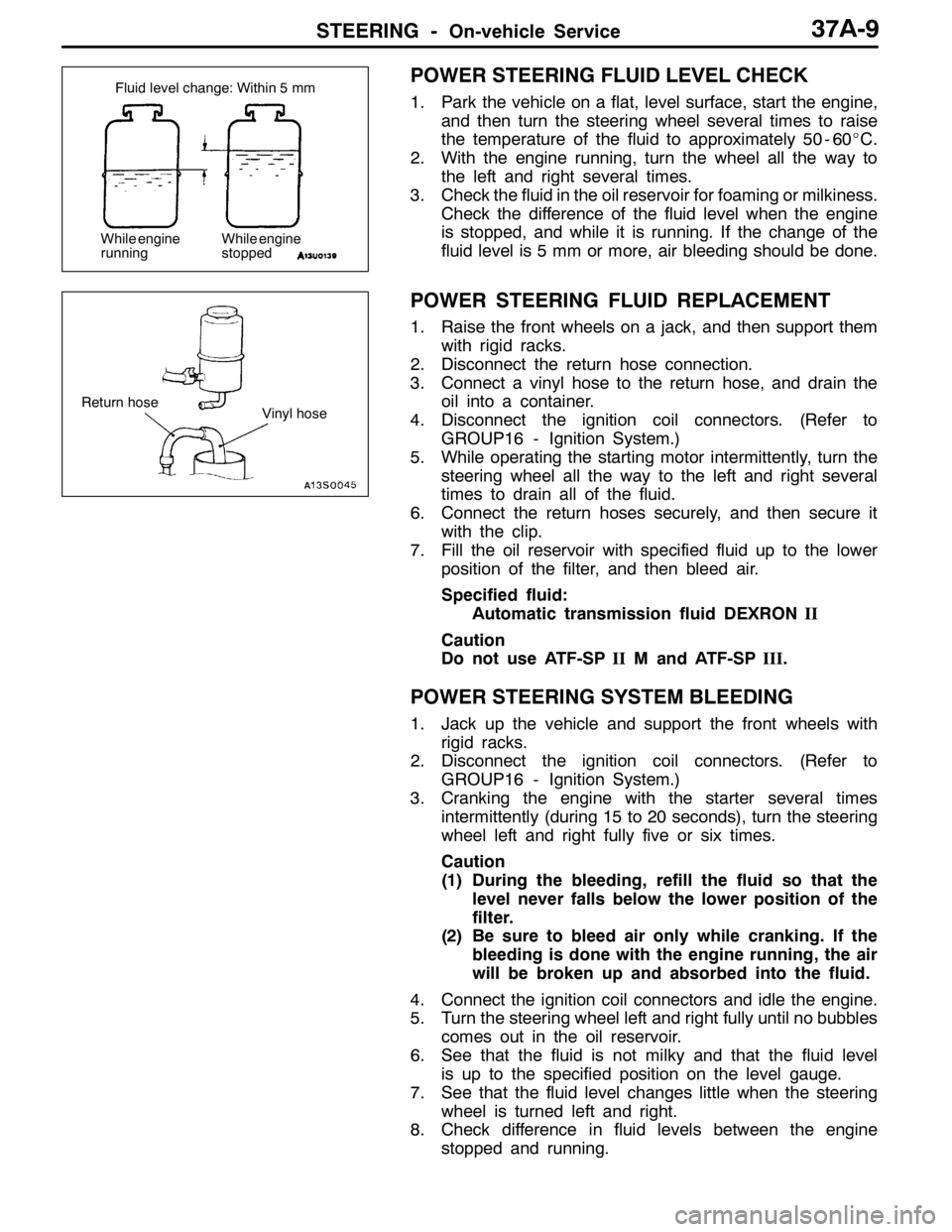

POWER STEERING FLUID LEVEL CHECK

1. Park the vehicle on a flat, level surface, start the engine,

and then turn the steering wheel several times to raise

the temperature of the fluid to approximately 50 - 60_C.

2. With the engine running, turn the wheel all the way to

the left and right several times.

3. Check the fluid in the oil reservoir for foaming or milkiness.

Check the difference of the fluid level when the engine

is stopped, and while it is running. If the change of the

fluid level is 5 mm or more, air bleeding should be done.

POWER STEERING FLUID REPLACEMENT

1. Raise the front wheels on a jack, and then support them

with rigid racks.

2. Disconnect the return hose connection.

3. Connect a vinyl hose to the return hose, and drain the

oil into a container.

4. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

5. While operating the starting motor intermittently, turn the

steering wheel all the way to the left and right several

times to drain all of the fluid.

6. Connect the return hoses securely, and then secure it

with the clip.

7. Fill the oil reservoir with specified fluid up to the lower

position of the filter, and then bleed air.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

POWER STEERING SYSTEM BLEEDING

1. Jack up the vehicle and support the front wheels with

rigid racks.

2. Disconnect the ignition coil connectors. (Refer to

GROUP16 - Ignition System.)

3. Cranking the engine with the starter several times

intermittently (during 15 to 20 seconds), turn the steering

wheel left and right fully five or six times.

Caution

(1) During the bleeding, refill the fluid so that the

level never falls below the lower position of the

filter.

(2) Be sure to bleed air only while cranking. If the

bleeding is done with the engine running, the air

will be broken up and absorbed into the fluid.

4. Connect the ignition coil connectors and idle the engine.

5. Turn the steering wheel left and right fully until no bubbles

comes out in the oil reservoir.

6. See that the fluid is not milky and that the fluid level

is up to the specified position on the level gauge.

7. See that the fluid level changes little when the steering

wheel is turned left and right.

8. Check difference in fluid levels between the engine

stopped and running.

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Return hose

Vinyl hose

Page 1124 of 1449

STEERING -On-vehicle Service37A-10

9. If the level changes more than 5 mm, the air is badly

bled. So, bleed air again.

Caution

(1) If the fluid level rises suddenly after the engine

is stopped, the bleeding is incomplete.

(2) Incomplete bleeding causes abnormal noises

from the pump and the flow-control valve. This

could lessen the life of the pump and the other

parts.

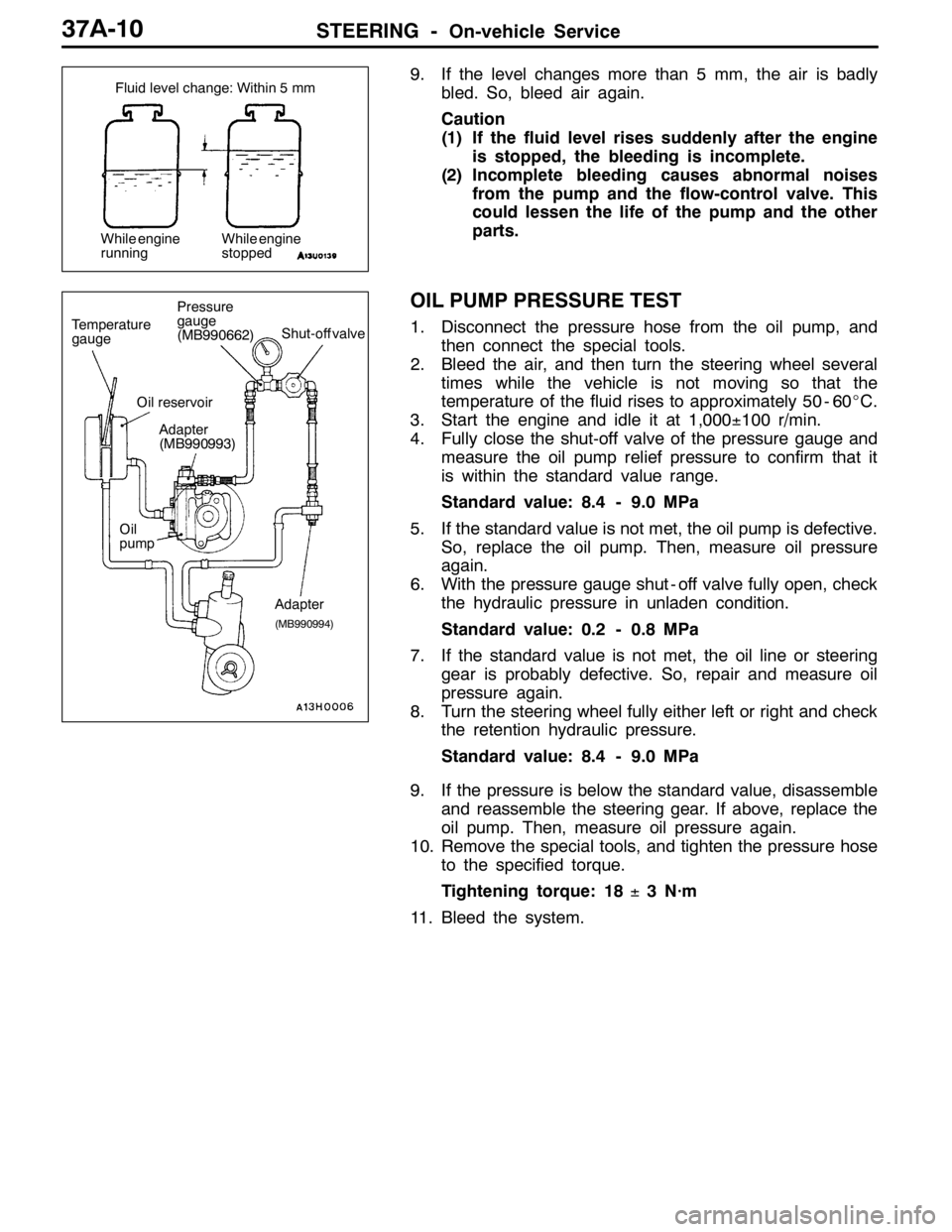

OIL PUMP PRESSURE TEST

1. Disconnect the pressure hose from the oil pump, and

then connect the special tools.

2. Bleed the air, and then turn the steering wheel several

times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50 - 60_C.

3. Start the engine and idle it at 1,000±100 r/min.

4. Fully close the shut-off valve of the pressure gauge and

measure the oil pump relief pressure to confirm that it

is within the standard value range.

Standard value: 8.4 - 9.0 MPa

5. If the standard value is not met, the oil pump is defective.

So, replace the oil pump. Then, measure oil pressure

again.

6. With the pressure gauge shut - off valve fully open, check

the hydraulic pressure in unladen condition.

Standard value: 0.2 - 0.8 MPa

7. If the standard value is not met, the oil line or steering

gear is probably defective. So, repair and measure oil

pressure again.

8. Turn the steering wheel fully either left or right and check

the retention hydraulic pressure.

Standard value: 8.4 - 9.0 MPa

9. If the pressure is below the standard value, disassemble

and reassemble the steering gear. If above, replace the

oil pump. Then, measure oil pressure again.

10. Remove the special tools, and tighten the pressure hose

to the specified torque.

Tightening torque: 18±3 N·m

11. Bleed the system.

Fluid level change: Within 5 mm

While engine

runningWhile engine

stopped

Temperature

gaugePressure

gauge

(MB990662)Shut-off valve

Oil

pumpOil reservoir

Adapter

(MB990994)

Adapter

(MB990993)

Page 1205 of 1449

EXTERIOR -Windshield Wiper and Washer51-13

WINDSHIELD WIPER AND WASHER

SERVICE SPECIFICATIONS

ItemStandard value

Stopposition of the windshield wiper arm/blade assembly(distance between the edgeof34±5Stoppositionofthewindshieldwiperarm/bladeassembly(distancebetweentheedgeof

the wiper blade and the end of the deck garnish) mm

34±5

TROUBLESHOOTING

The windshield wiper-washer is controlled by the smart wiring system (SWS). Refer to Group 54B for

troubleshooting.

NOTE

If ETACS-ECU is faulty, the windshield wiper can be operable in LO mode only as the fail - safe function.

(Normally the windshield wiper is operable when the ignition switch is turned to the ACC position. When

the fail - safe function is enabled, it is operable only when the ignition switch is turned to the ON position.)

ON-VEHICLE SERVICE

WINDSHIELD INTERMITTENT WIPER

INSPECTIONS

(1) Check the change in the intermittent time of the wiper

operation by using the windshield intermittent wiper

volume.

(2) Carry out troubleshooting if any of them is faulty.

(Refer to Group 54B.)

Page 1348 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-28

HEADLAMP INTENSITY MEASUREMENT

1. Using a photometer, and following its manufacture’s

instruction manual.

2. Maintain an engine speed of 2,000 r/min., with the battery

in the charging condition

3. Set the headlamps to high beam

4. Measure the headlamp centre intensity (a point of H line

and V line) and check to be sure that the limit value

is satisfied.

Limit:

High beam 30,000 cd or more per one headlamp

NOTE

1. There may be special local regulations pertaining to

headlamp intensity, be sure to make any adjustments

necessary to satisfy such regulations.

2. If an illuminometer is used to make the measurements,

convert its values to photometer values by using the

following formula.

I=Er

2Where:

I=intensity (cd)

E=illumination (lux)

r=distance (m) from headlamps to illuminometer

Caution

1. On the headlamp not yet adjusted, perform aiming

with connector removed and the lamps switched off,

if applicable. In addition, care should be taken to

prevent a change of optical axis when connector is

reconnected.

2. Plastic outer lens are equipped with headlamps. When

lens surface is covered with materials for not

penetrating light, headlamp operation time should be

within 3 minutes. In addition, masking such as taping

should not be performed.

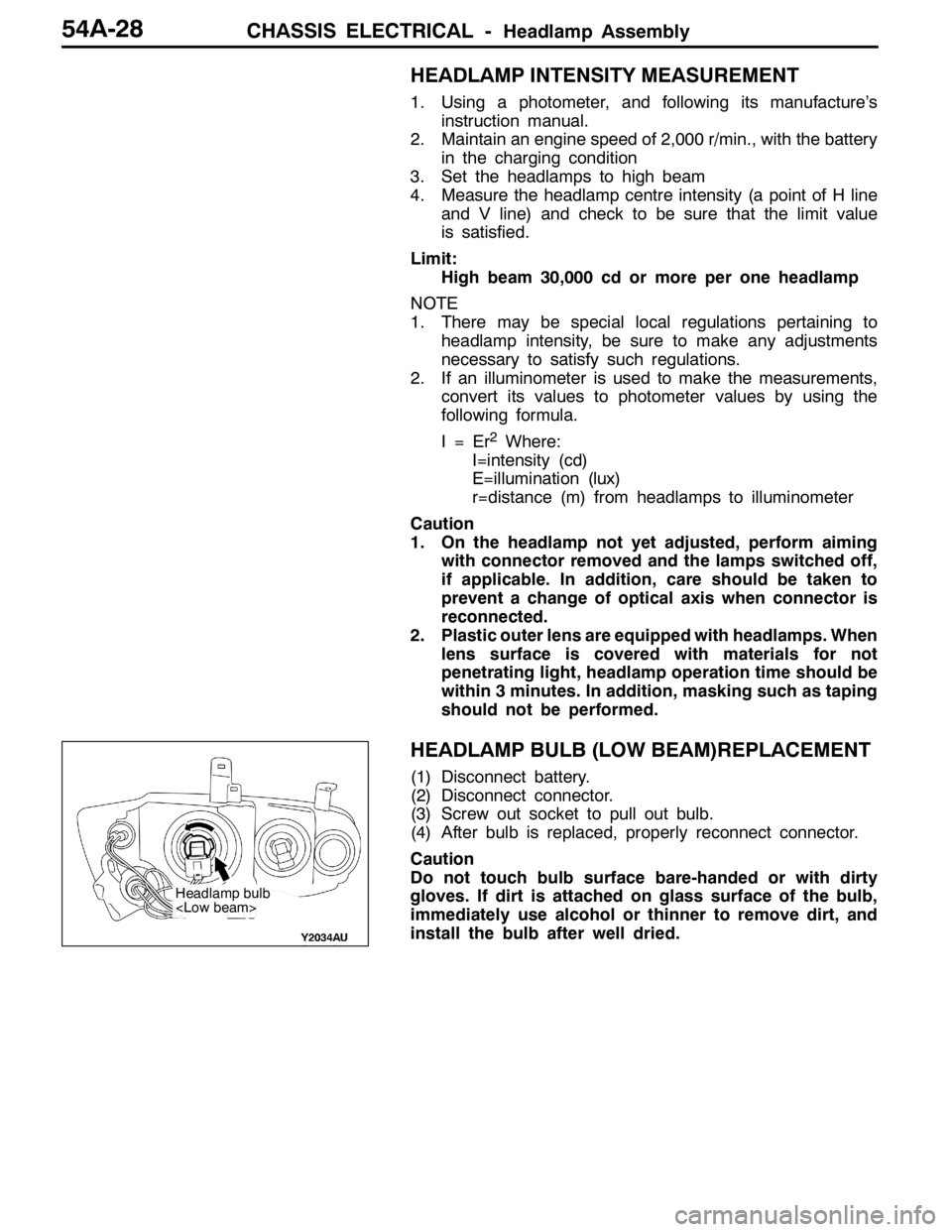

HEADLAMP BULB (LOW BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

Headlamp bulb

Page 1399 of 1449

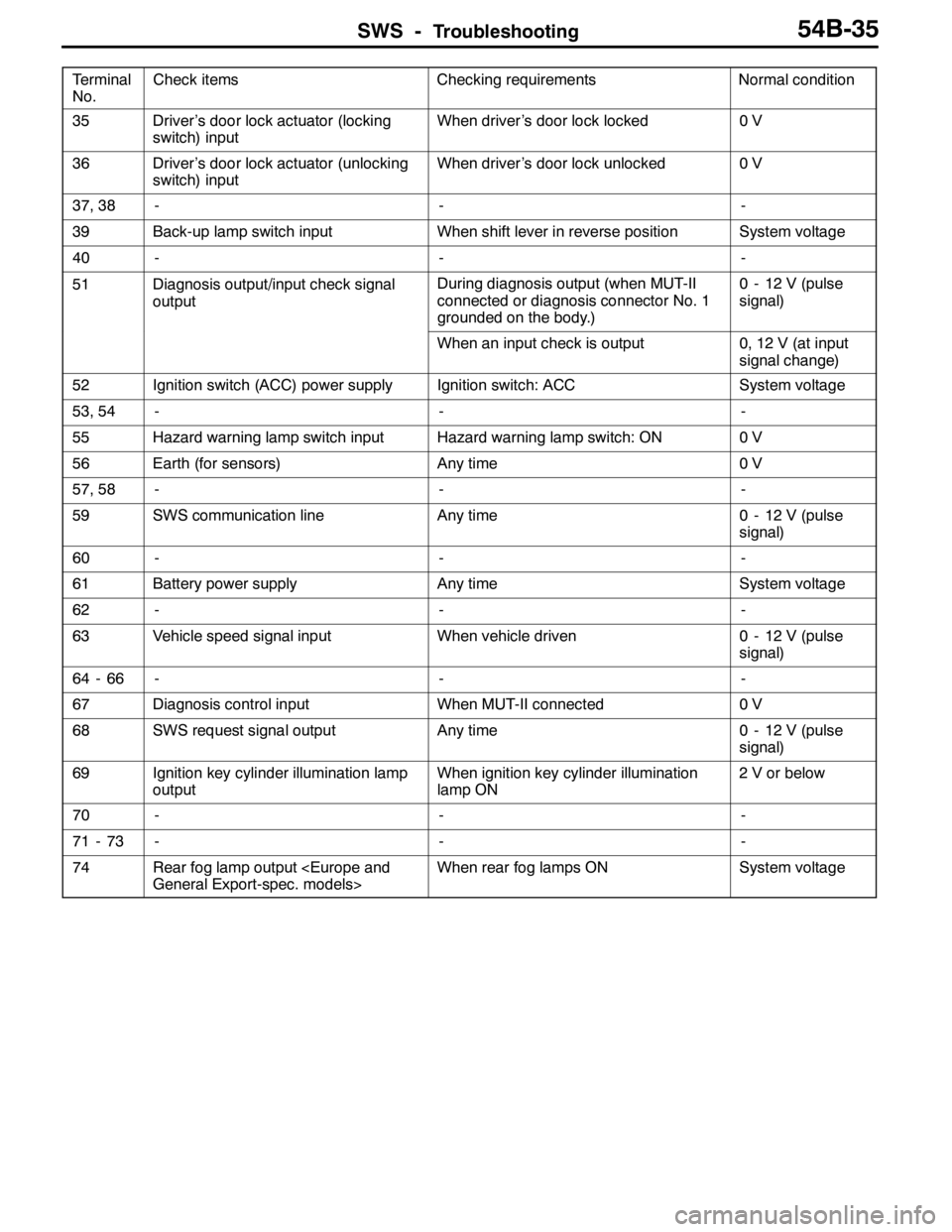

SWS -Troubleshooting54B-35

Terminal

No.Normal condition Checking requirements Check items

35Driver’s door lock actuator (locking

switch) inputWhen driver’s door lock locked0V

36Driver’s door lock actuator (unlocking

switch) inputWhen driver’s door lock unlocked0V

37, 38---

39Back-up lamp switch inputWhen shift lever in reverse positionSystem voltage

40---

51Diagnosis output/input check signal

outputDuring diagnosis output (when MUT-II

connected or diagnosis connector No. 1

grounded on the body.)0 - 12 V (pulse

signal)

When an input check is output0, 12 V (at input

signal change)

52Ignition switch (ACC) power supplyIgnition switch: ACCSystem voltage

53, 54---

55Hazard warning lamp switch inputHazard warning lamp switch: ON0V

56Earth (for sensors)Any time0V

57, 58---

59SWS communication lineAny time0 - 12 V (pulse

signal)

60---

61Battery power supplyAny timeSystem voltage

62---

63Vehicle speed signal inputWhen vehicle driven0 - 12 V (pulse

signal)

64 - 66---

67Diagnosis control inputWhen MUT-II connected0V

68SWS request signal outputAny time0 - 12 V (pulse

signal)

69Ignition key cylinder illumination lamp

outputWhen ignition key cylinder illumination

lamp ON2 V or below

70---

71 - 73---

74Rear fog lamp output

Page 1415 of 1449

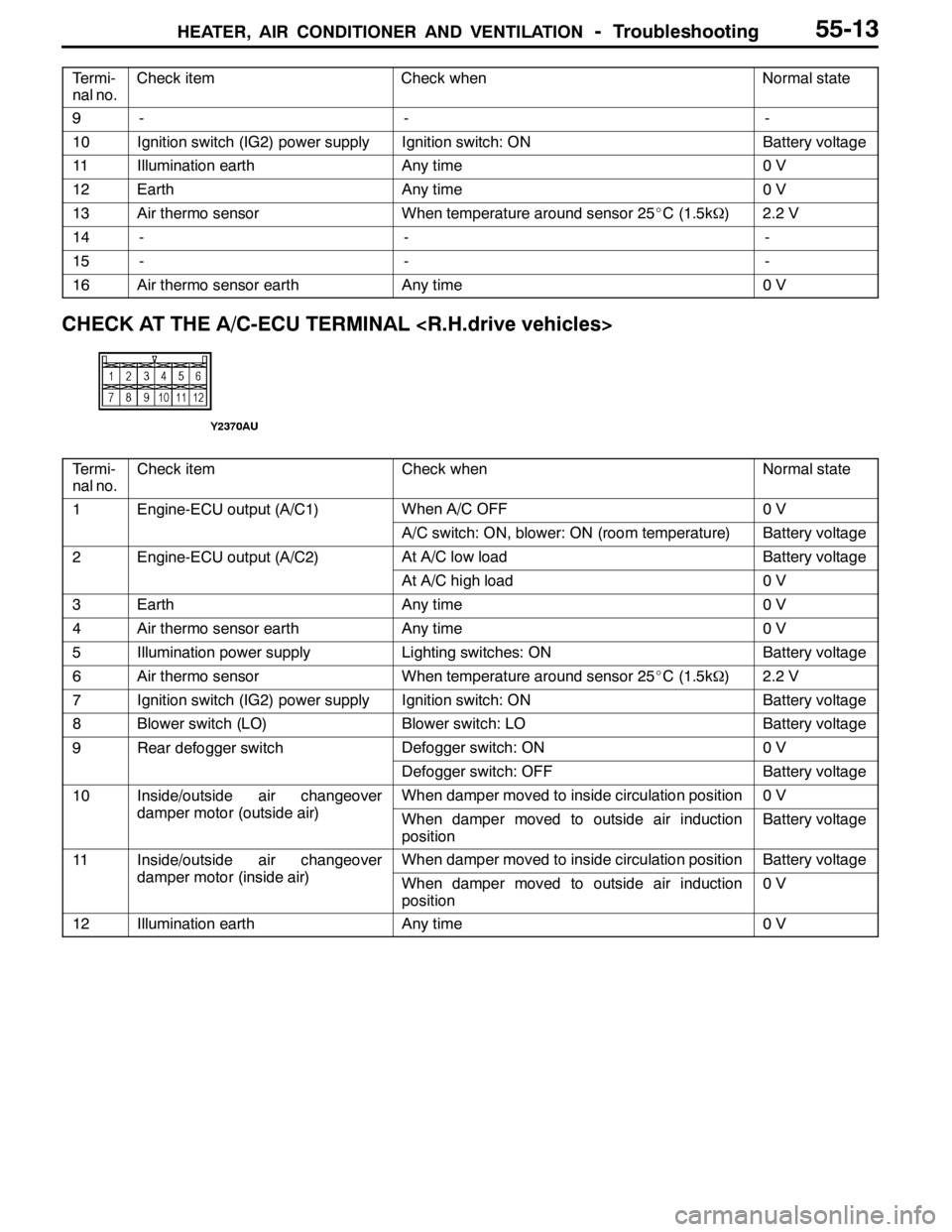

HEATER, AIR CONDITIONER AND VENTILATION-Troubleshooting55-13

Termi-

nal no.Normal state Check when Check item

9---

10Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

11Illumination earthAny time0V

12EarthAny time0V

13Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

14---

15---

16Air thermo sensor earthAny time0V

CHECK AT THE A/C-ECU TERMINAL

Termi-

nal no.Check itemCheck whenNormal state

1Engine-ECU output (A/C1)When A/C OFF0Vgp()

A/C switch: ON, blower: ON (room temperature)Battery voltage

2Engine-ECU output (A/C2)At A/C low loadBattery voltagegp()

At A/C high load0V

3EarthAny time0V

4Air thermo sensor earthAny time0V

5Illumination power supplyLighting switches: ONBattery voltage

6Air thermo sensorWhen temperature around sensor 25_C (1.5kΩ)2.2 V

7Ignition switch (IG2) power supplyIgnition switch: ONBattery voltage

8Blower switch (LO)Blower switch: LOBattery voltage

9Rear defogger switchDefogger switch: ON0Vgg

Defogger switch: OFFBattery voltage

10Inside/outside air changeover

dt(tidi)

When damper moved to inside circulation position0Vg

damper motor (outside air)When damper moved to outside air induction

positionBattery voltage

11Inside/outside air changeover

dt(i idi)

When damper moved to inside circulation positionBattery voltageg

damper motor (inside air)When damper moved to outside air induction

position0V

12Illumination earthAny time0V

Page 1435 of 1449

Resister, Blower Motor, Inside/outside

Air Changeover Damper MotorHEATER, AIR CONDITIONER AND VENTILATION-55-33

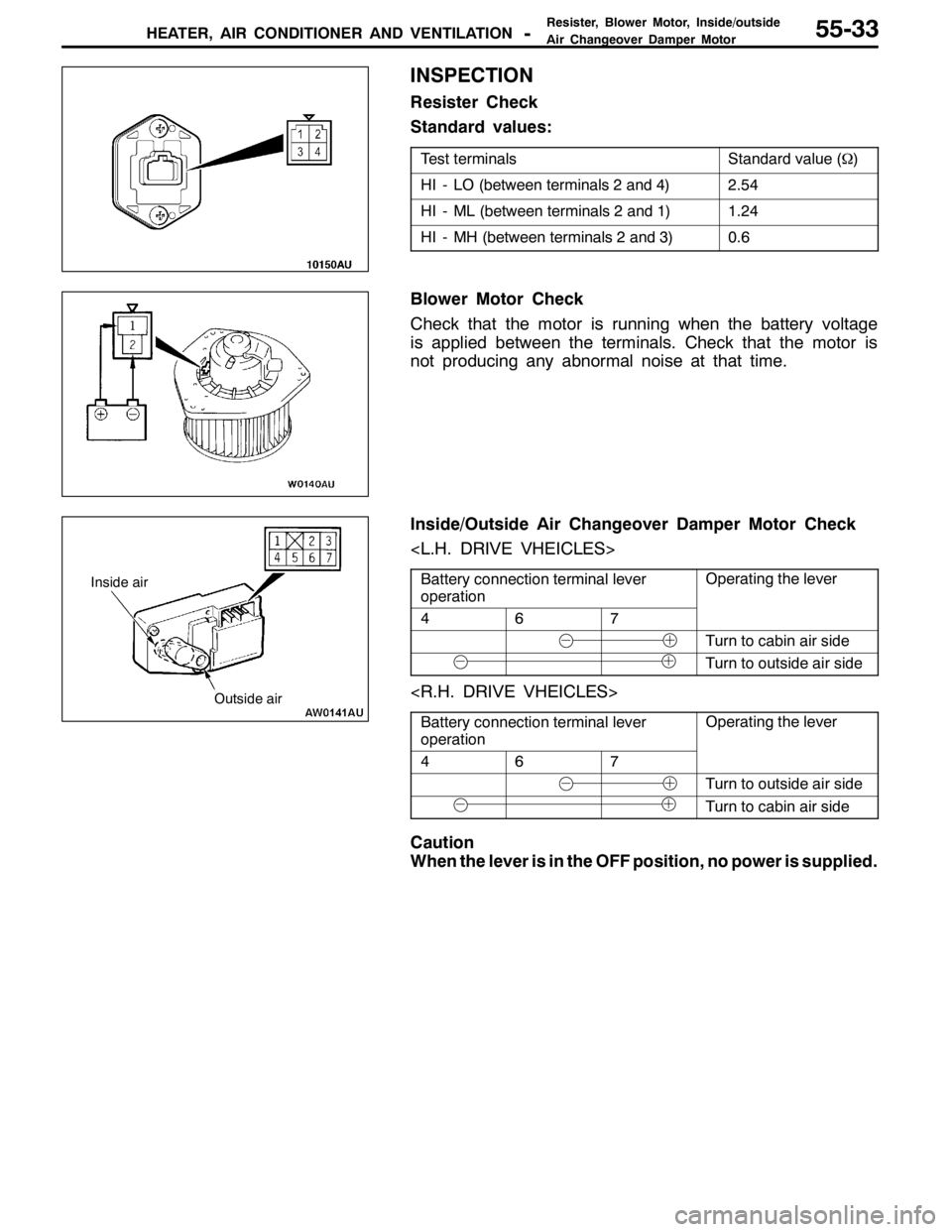

INSPECTION

Resister Check

Standard values:

Test terminalsStandard value (Ω)

HI - LO (between terminals 2 and 4)2.54

HI - ML (between terminals 2 and 1)1.24

HI - MH (between terminals 2 and 3)0.6

Blower Motor Check

Check that the motor is running when the battery voltage

is applied between the terminals. Check that the motor is

not producing any abnormal noise at that time.

Inside/Outside Air Changeover Damper Motor Check

Battery connection terminal lever

operationOperating the lever

467

Turn to cabin air side

Turn to outside air side

Battery connection terminal lever

operationOperating the lever

467

Turn to outside air side

Turn to cabin air side

Caution

When the lever is in the OFF position, no power is supplied.

Inside air

Outside air