steering MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 358 of 1449

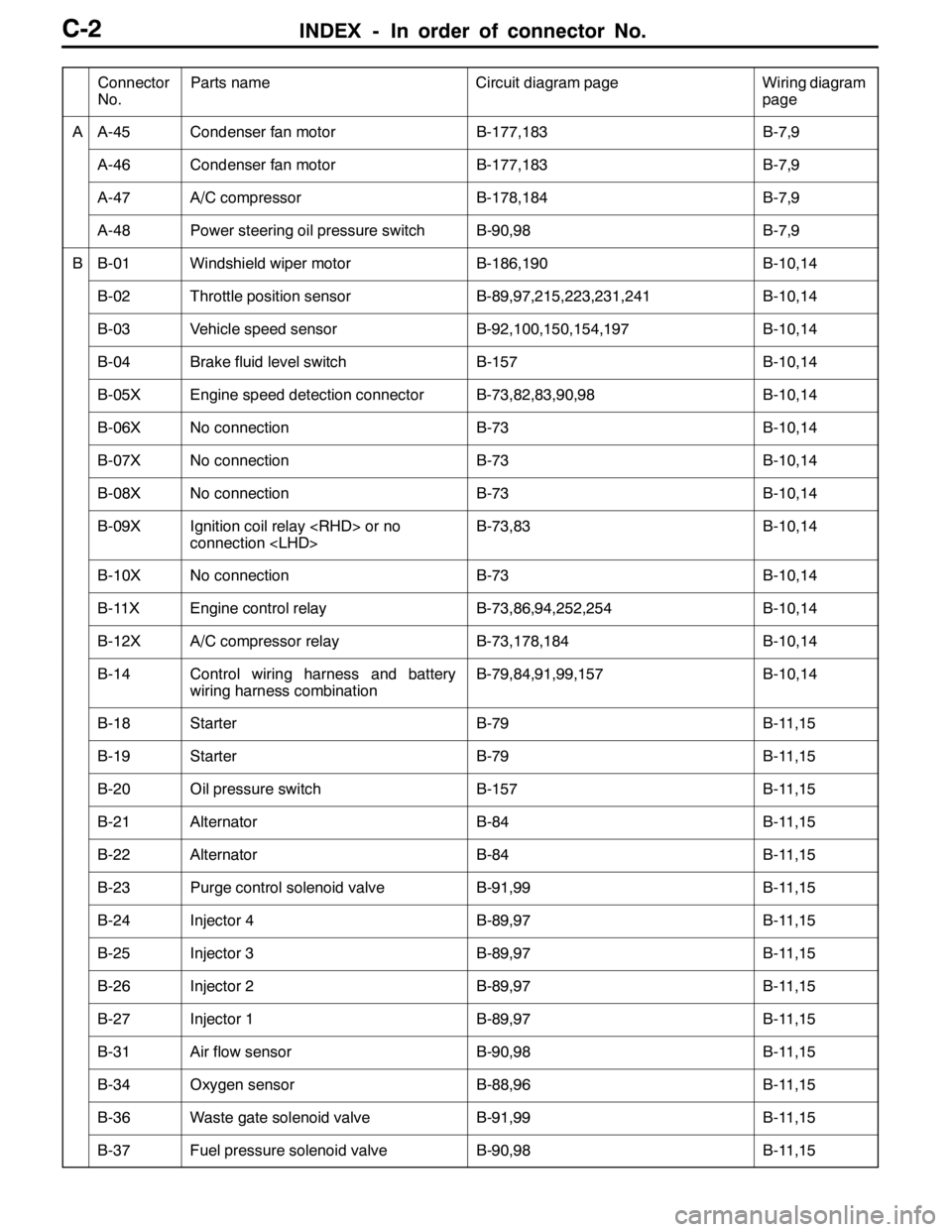

INDEX - In order of connector No.C-2

Wiring diagram

page Circuit diagram page Parts name Connector

No.

AA-45Condenser fan motorB-177,183B-7,9

A-46Condenser fan motorB-177,183B-7,9

A-47A/C compressorB-178,184B-7,9

A-48Power steering oil pressure switchB-90,98B-7,9

BB-01Windshield wiper motorB-186,190B-10,14

B-02Throttle position sensorB-89,97,215,223,231,241B-10,14

B-03Vehicle speed sensorB-92,100,150,154,197B-10,14

B-04Brake fluid level switchB-157B-10,14

B-05XEngine speed detection connectorB-73,82,83,90,98B-10,14

B-06XNo connectionB-73B-10,14

B-07XNo connectionB-73B-10,14

B-08XNo connectionB-73B-10,14

B-09XIgnition coil relay

connection

B-10XNo connectionB-73B-10,14

B-11XEngine control relayB-73,86,94,252,254B-10,14

B-12XA/C compressor relayB-73,178,184B-10,14

B-14Control wiring harness and battery

wiring harness combinationB-79,84,91,99,157B-10,14

B-18StarterB-79B-11,15

B-19StarterB-79B-11,15

B-20Oil pressure switchB-157B-11,15

B-21AlternatorB-84B-11,15

B-22AlternatorB-84B-11,15

B-23Purge control solenoid valveB-91,99B-11,15

B-24Injector 4B-89,97B-11,15

B-25Injector 3B-89,97B-11,15

B-26Injector 2B-89,97B-11,15

B-27Injector 1B-89,97B-11,15

B-31Air flow sensorB-90,98B-11,15

B-34Oxygen sensorB-88,96B-11,15

B-36Waste gate solenoid valveB-91,99B-11,15

B-37Fuel pressure solenoid valveB-90,98B-11,15

Page 364 of 1449

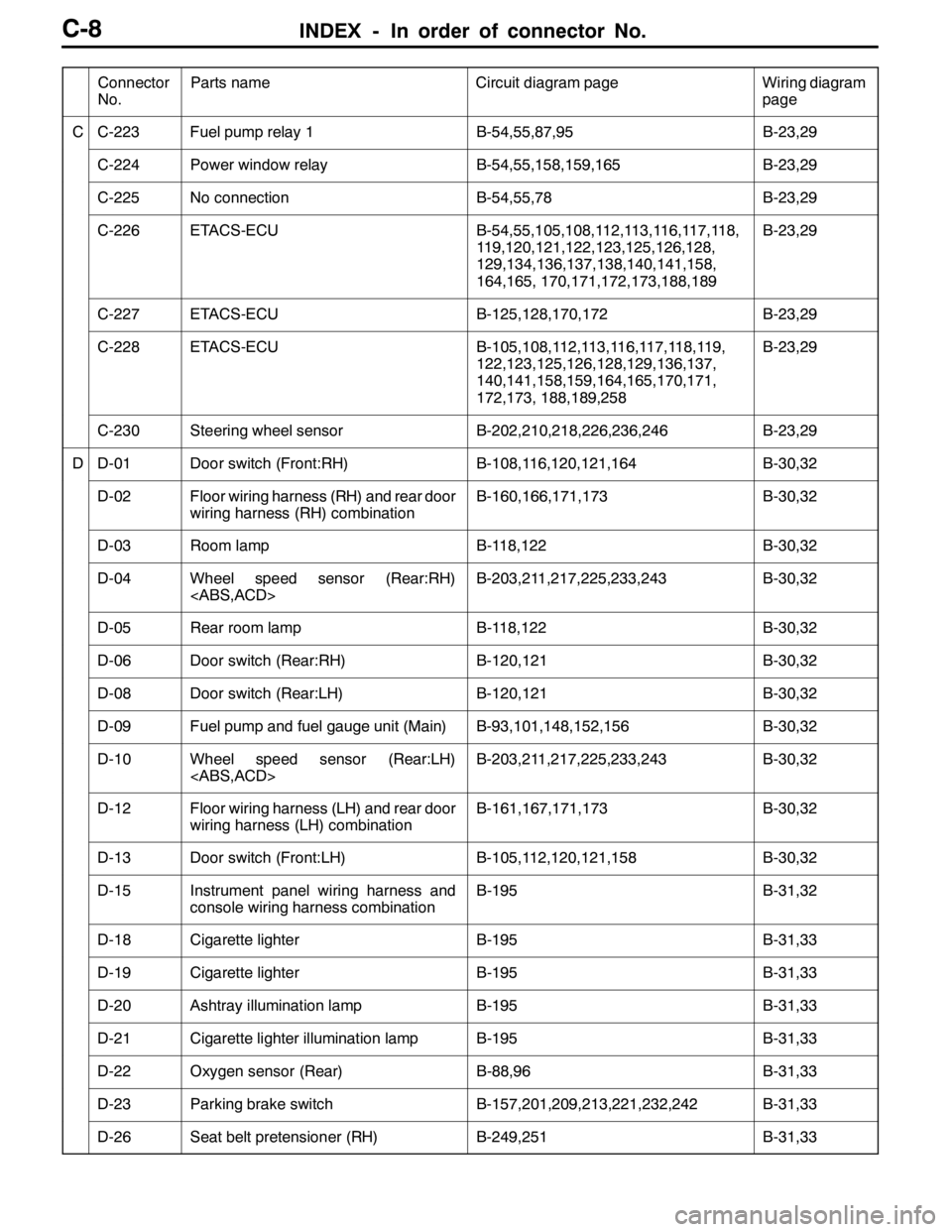

INDEX - In order of connector No.C-8

Wiring diagram

page Circuit diagram page Parts name Connector

No.

CC-223Fuel pump relay 1B-54,55,87,95B-23,29

C-224Power window relayB-54,55,158,159,165B-23,29

C-225No connectionB-54,55,78B-23,29

C-226ETACS-ECUB-54,55,105,108,112,113,116,117,118,

119,120,121,122,123,125,126,128,

129,134,136,137,138,140,141,158,

164,165, 170,171,172,173,188,189B-23,29

C-227ETACS-ECUB-125,128,170,172B-23,29

C-228ETACS-ECUB-105,108,112,113,116,117,118,119,

122,123,125,126,128,129,136,137,

140,141,158,159,164,165,170,171,

172,173, 188,189,258B-23,29

C-230Steering wheel sensorB-202,210,218,226,236,246B-23,29

DD-01Door switch (Front:RH)B-108,116,120,121,164B-30,32

D-02Floor wiring harness (RH) and rear door

wiring harness (RH) combinationB-160,166,171,173B-30,32

D-03Room lampB-118,122B-30,32

D-04Wheel speed sensor (Rear:RH)

D-05Rear room lampB-118,122B-30,32

D-06Door switch (Rear:RH)B-120,121B-30,32

D-08Door switch (Rear:LH)B-120,121B-30,32

D-09Fuel pump and fuel gauge unit (Main)B-93,101,148,152,156B-30,32

D-10Wheel speed sensor (Rear:LH)

D-12Floor wiring harness (LH) and rear door

wiring harness (LH) combinationB-161,167,171,173B-30,32

D-13Door switch (Front:LH)B-105,112,120,121,158B-30,32

D-15Instrument panel wiring harness and

console wiring harness combinationB-195B-31,32

D-18Cigarette lighterB-195B-31,33

D-19Cigarette lighterB-195B-31,33

D-20Ashtray illumination lampB-195B-31,33

D-21Cigarette lighter illumination lampB-195B-31,33

D-22Oxygen sensor (Rear)B-88,96B-31,33

D-23Parking brake switchB-157,201,209,213,221,232,242B-31,33

D-26Seat belt pretensioner (RH)B-249,251B-31,33

Page 374 of 1449

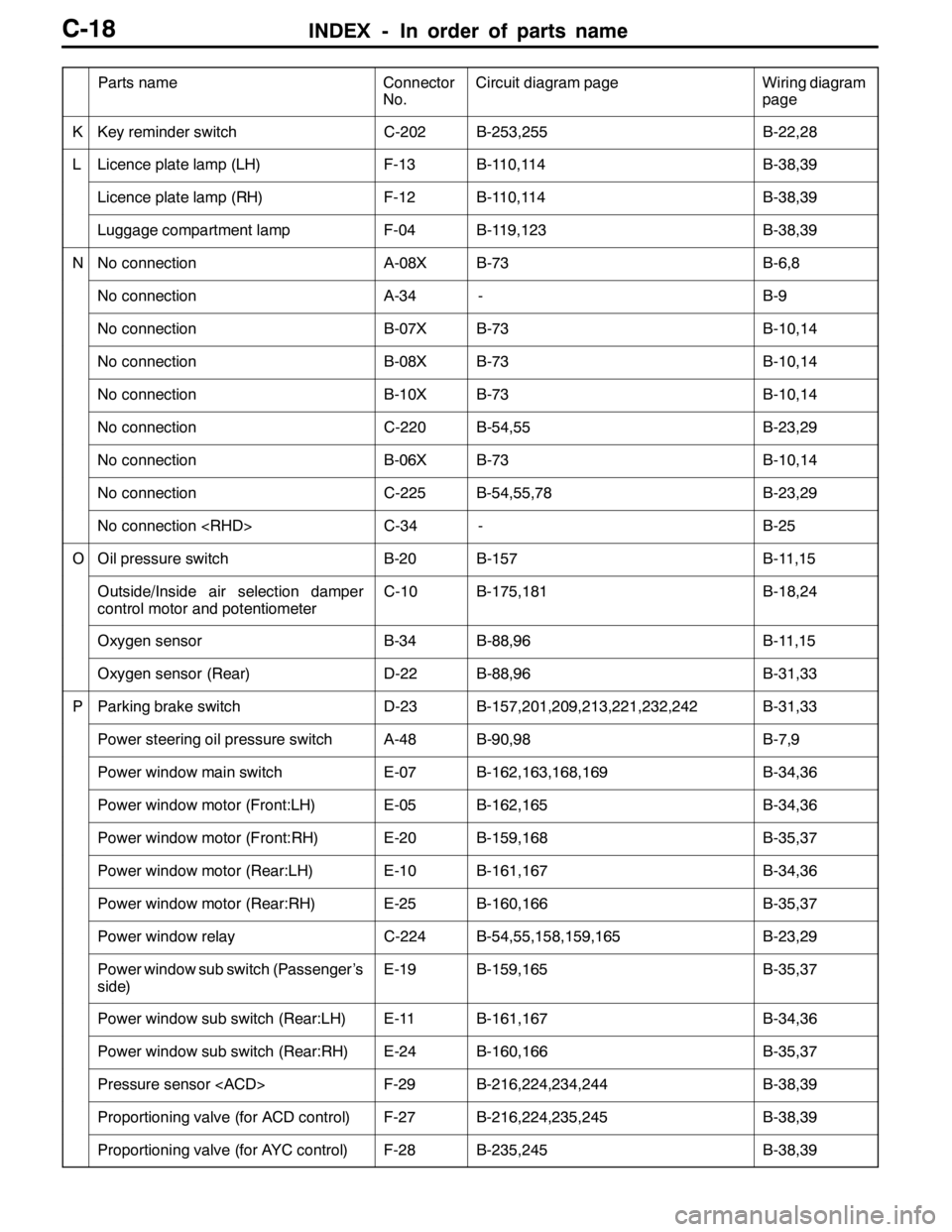

INDEX - In order of parts nameC-18

Wiring diagram

page Circuit diagram page Connector

No. Parts name

KKey reminder switchC-202B-253,255B-22,28

LLicence plate lamp (LH)F-13B-110,114B-38,39

Licence plate lamp (RH)F-12B-110,114B-38,39

Luggage compartment lampF-04B-119,123B-38,39

NNo connectionA-08XB-73B-6,8

No connectionA-34-B-9

No connectionB-07XB-73B-10,14

No connectionB-08XB-73B-10,14

No connectionB-10XB-73B-10,14

No connectionC-220B-54,55B-23,29

No connectionB-06XB-73B-10,14

No connectionC-225B-54,55,78B-23,29

No connection

OOil pressure switchB-20B-157B-11,15

Outside/Inside air selection damper

control motor and potentiometerC-10B-175,181B-18,24

Oxygen sensorB-34B-88,96B-11,15

Oxygen sensor (Rear)D-22B-88,96B-31,33

PParking brake switchD-23B-157,201,209,213,221,232,242B-31,33

Power steering oil pressure switchA-48B-90,98B-7,9

Power window main switchE-07B-162,163,168,169B-34,36

Power window motor (Front:LH)E-05B-162,165B-34,36

Power window motor (Front:RH)E-20B-159,168B-35,37

Power window motor (Rear:LH)E-10B-161,167B-34,36

Power window motor (Rear:RH)E-25B-160,166B-35,37

Power window relayC-224B-54,55,158,159,165B-23,29

Power window sub switch (Passenger’s

side)E-19B-159,165B-35,37

Power window sub switch (Rear:LH)E-11B-161,167B-34,36

Power window sub switch (Rear:RH)E-24B-160,166B-35,37

Pressure sensor

Proportioning valve (for ACD control)F-27B-216,224,235,245B-38,39

Proportioning valve (for AYC control)F-28B-235,245B-38,39

Page 376 of 1449

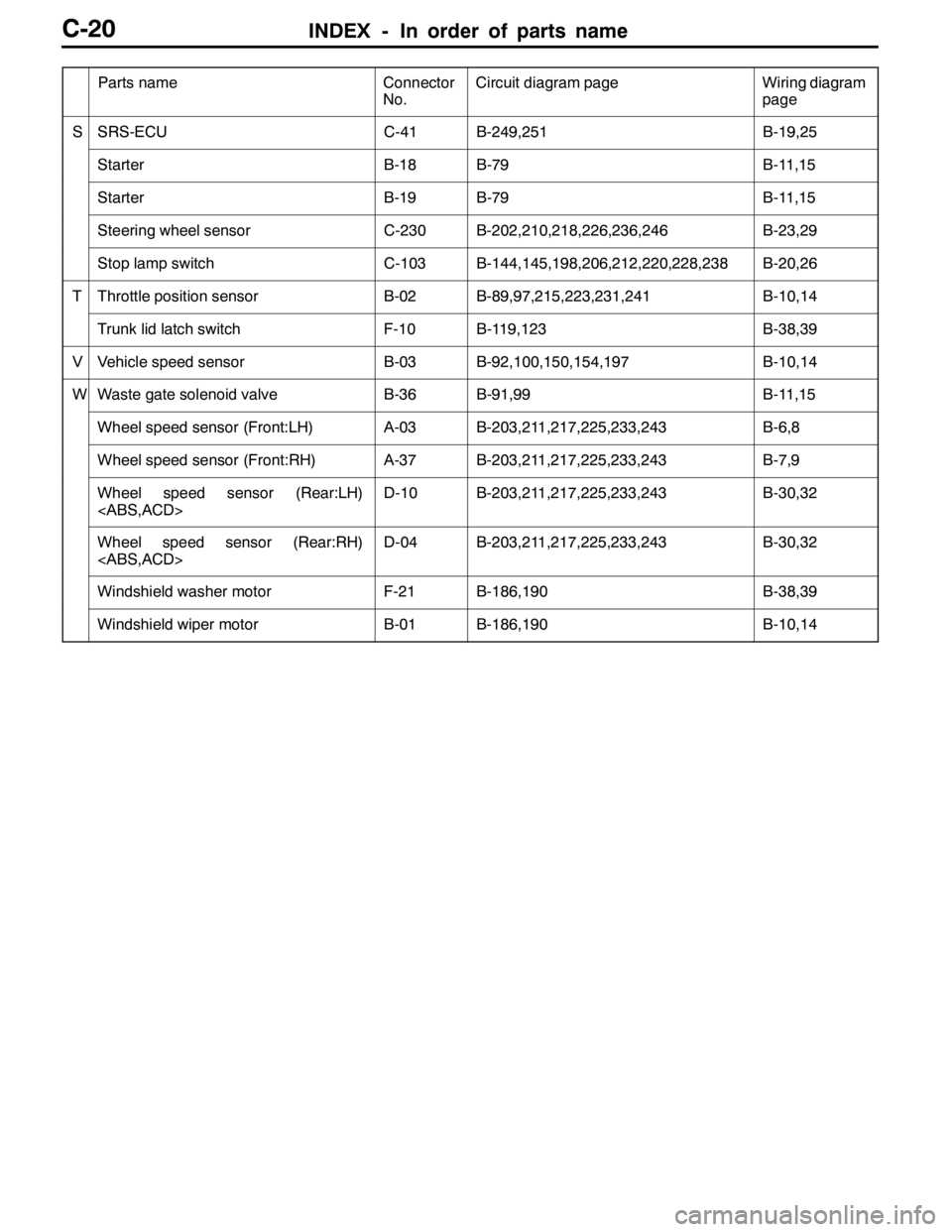

INDEX - In order of parts nameC-20

Wiring diagram

page Circuit diagram page Connector

No. Parts name

SSRS-ECUC-41B-249,251B-19,25

StarterB-18B-79B-11,15

StarterB-19B-79B-11,15

Steering wheel sensorC-230B-202,210,218,226,236,246B-23,29

Stop lamp switchC-103B-144,145,198,206,212,220,228,238B-20,26

TThrottle position sensorB-02B-89,97,215,223,231,241B-10,14

Trunk lid latch switchF-10B-119,123B-38,39

VVehicle speed sensorB-03B-92,100,150,154,197B-10,14

WWaste gate solenoid valveB-36B-91,99B-11,15

Wheel speed sensor (Front:LH)A-03B-203,211,217,225,233,243B-6,8

Wheel speed sensor (Front:RH)A-37B-203,211,217,225,233,243B-7,9

Wheel speed sensor (Rear:LH)

Wheel speed sensor (Rear:RH)

Windshield washer motorF-21B-186,190B-38,39

Windshield wiper motorB-01B-186,190B-10,14

Page 393 of 1449

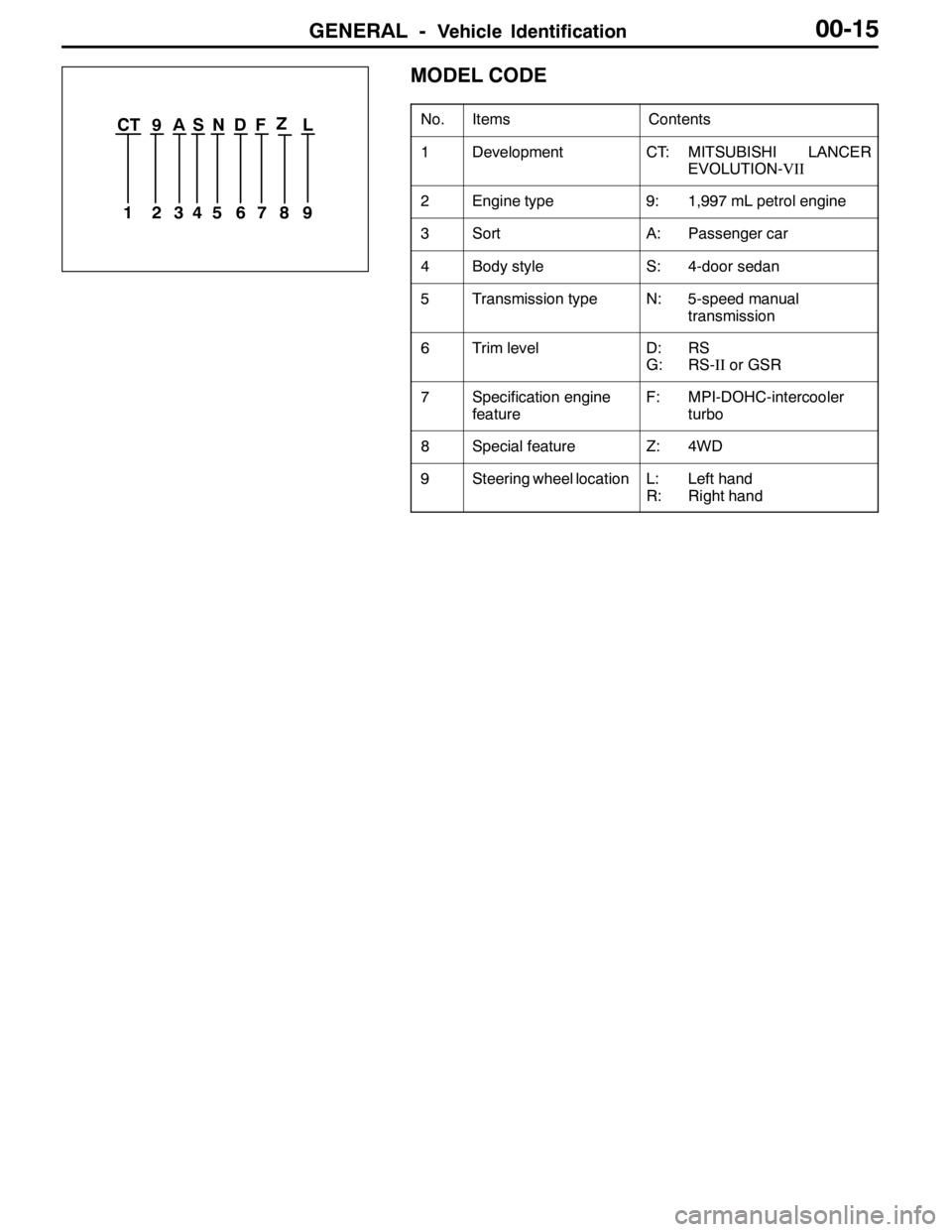

GENERAL -Vehicle Identification00-15

MODEL CODE

No.ItemsContents

1DevelopmentCT: MITSUBISHI LANCER

EVOLUTION-VII

2Engine type9: 1,997 mL petrol engine

3SortA: Passenger car

4Body styleS: 4-door sedan

5Transmission typeN: 5-speed manual

transmission

6Trim levelD: RS

G: RS-IIor GSR

7Specification engine

featureF: MPI-DOHC-intercooler

turbo

8Special featureZ: 4WD

9Steering wheel locationL: Left hand

R: Right hand

123456789 CT 9 A S N D F L

Z

Page 396 of 1449

GENERAL -Precautions Before Service00-18

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

1. Items to follow when servicing SRS

(1) Be sure to read GROUP 52B - Supplemental Restraint System (SRS).

For safe operations, please follow the directions and heed all warnings.

(2) Wait at least 60 seconds after disconnecting the battery cable before doing any further work.

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the battery cable is disconnected.

(3) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

DSun visor

DGlove box

DSRS-ECU

DSteering wheel

DSteering Joint Cover

DAir bag module (driver’s side and front passenger’s side)

DClock spring

DSeat belt with pre-tensioner

(4) Always use the designated special tools and test equipment.

(5) Store components removed from the SRS in a clean and dry place.

The air bag module should be stored on a flat surface and placed so that the pad surface is

facing upward.

Do not place anything on top of it.

(6) Never attempt to disassemble or repair the SRS components (SRS-ECU, air bag module, clock

spring and seat belt with pre-tensioner).

(7) Whenever you finish servicing the SRS, check the SRS warning lamp operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing of the air bag module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP 52B - Air Bag Module Disposal Procedures.)

2. Observe the following when carrying out operations on places where SRS components are installed,

including operations not directly related to the SRS air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat, so remove the SRS components before drying

or baking the vehicle after painting.

DSRS-ECU, air bag module, clock spring: 93_C or more

DSeat belt with pre-tensioner: 90_C or more

After re-installing them, check the SRS warning lamp operation to make sure that the system

functions properly.

Page 399 of 1449

GENERAL -Supplemental Restraint System (SRS)00-21

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

To improve safety, the SRS and seat belts with

pre-tensioner. These systems enhance collision

safety by restraining the front passengers in case

of an accident. The SRS works with the

pre-tensioner simultaneously when a collision is

detected.

The SRS consists of two air bag modules, SRS

air bag control unit (SRS-ECU), SRS warning lamp

and clock spring. The air bags are located in the

center of the steering wheel, above the glove box.

Each air bag has a folded air bag and an inflator

unit. The SRS-ECU under the floor console monitors

the system and has a safing G-sensor and an

analog G-sensor. The warning lamp on theinstrument panel indicates the operational status

of the SRS. The clock spring is installed in the

steering column. The seat belt pre-tensioner is built

into the front seat belt retractor. Only authorized

service personnel should do work on or around

the SRS components and seat belt with

pre-tensioner. Those service personnel should read

this manual carefully before starting any such work.

Extreme care must be used when servicing the

SRS to avoid injury to the service personnel (by

inadvertent deployment of the air bags or

inadvertent operation of the seat belt with

pre-tensioner) or the driver (by rendering the SRS

or the seat belt with pre-tensioner inoperative).

Diagnosis

connectorFront passenger’s

air bag module

Clock spring Driver’s air bag

module

SRS-ECU

SRS warning lamp

Driver’s air bag

Front

passenger’s

air bag

Seat belt with

pre-tensioner

Page 414 of 1449

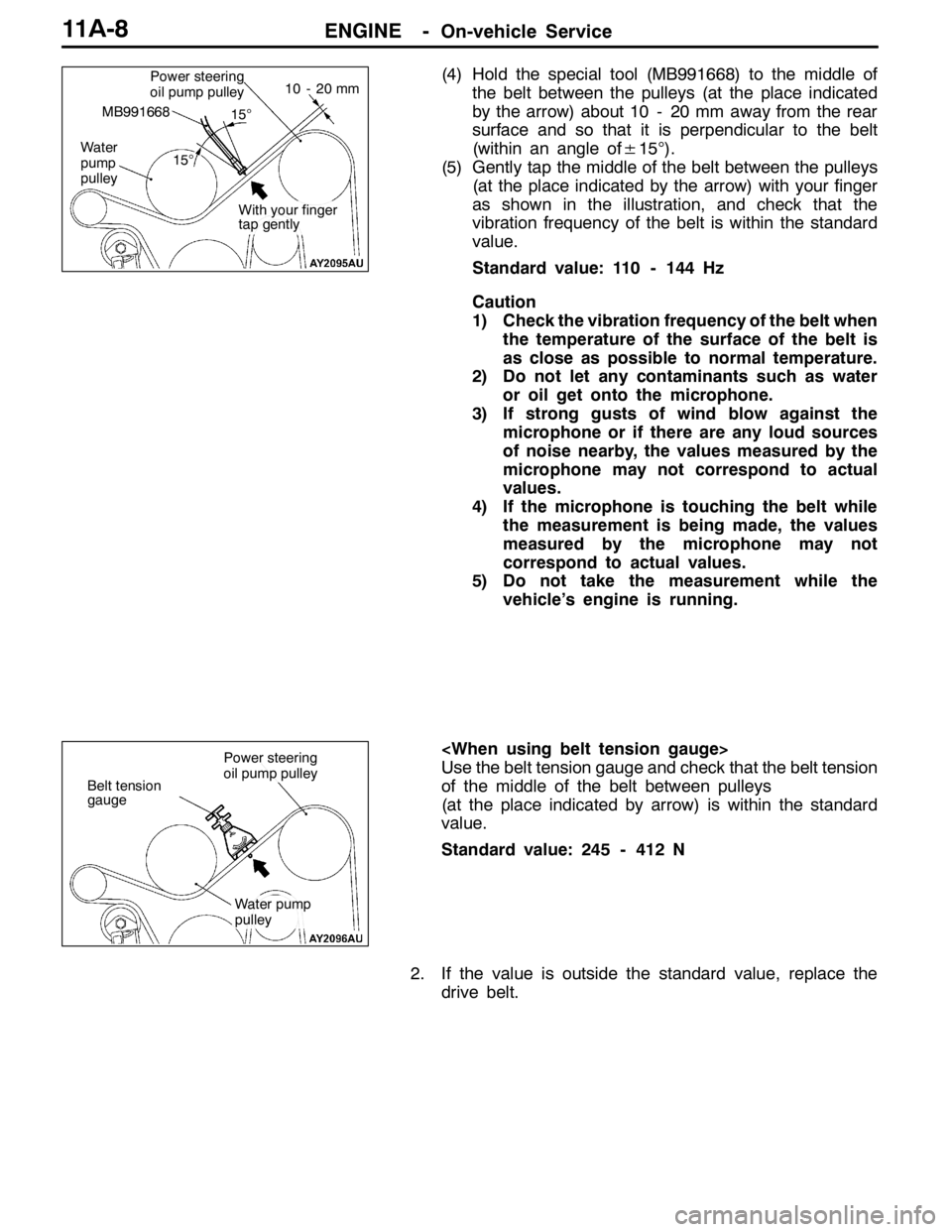

ENGINE -On-vehicle Service11A-8

(4) Hold the special tool (MB991668) to the middle of

the belt between the pulleys (at the place indicated

by the arrow) about 10 - 20 mm away from the rear

surface and so that it is perpendicular to the belt

(within an angle of±15°).

(5) Gently tap the middle of the belt between the pulleys

(at the place indicated by the arrow) with your finger

as shown in the illustration, and check that the

vibration frequency of the belt is within the standard

value.

Standard value: 110 - 144 Hz

Caution

1) Check the vibration frequency of the belt when

the temperature of the surface of the belt is

as close as possible to normal temperature.

2) Do not let any contaminants such as water

or oil get onto the microphone.

3) If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values.

4) If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not

correspond to actual values.

5) Do not take the measurement while the

vehicle’s engine is running.

Use the belt tension gauge and check that the belt tension

of the middle of the belt between pulleys

(at the place indicated by arrow) is within the standard

value.

Standard value: 245 - 412 N

2. If the value is outside the standard value, replace the

drive belt.Power steering

oil pump pulley

Water

pump

pulley

MB991668

10 - 20 mm

15°

15°

With your finger

tap gently

Belt tension

gauge

Power steering

oil pump pulley

Water pump

pulley

Page 451 of 1449

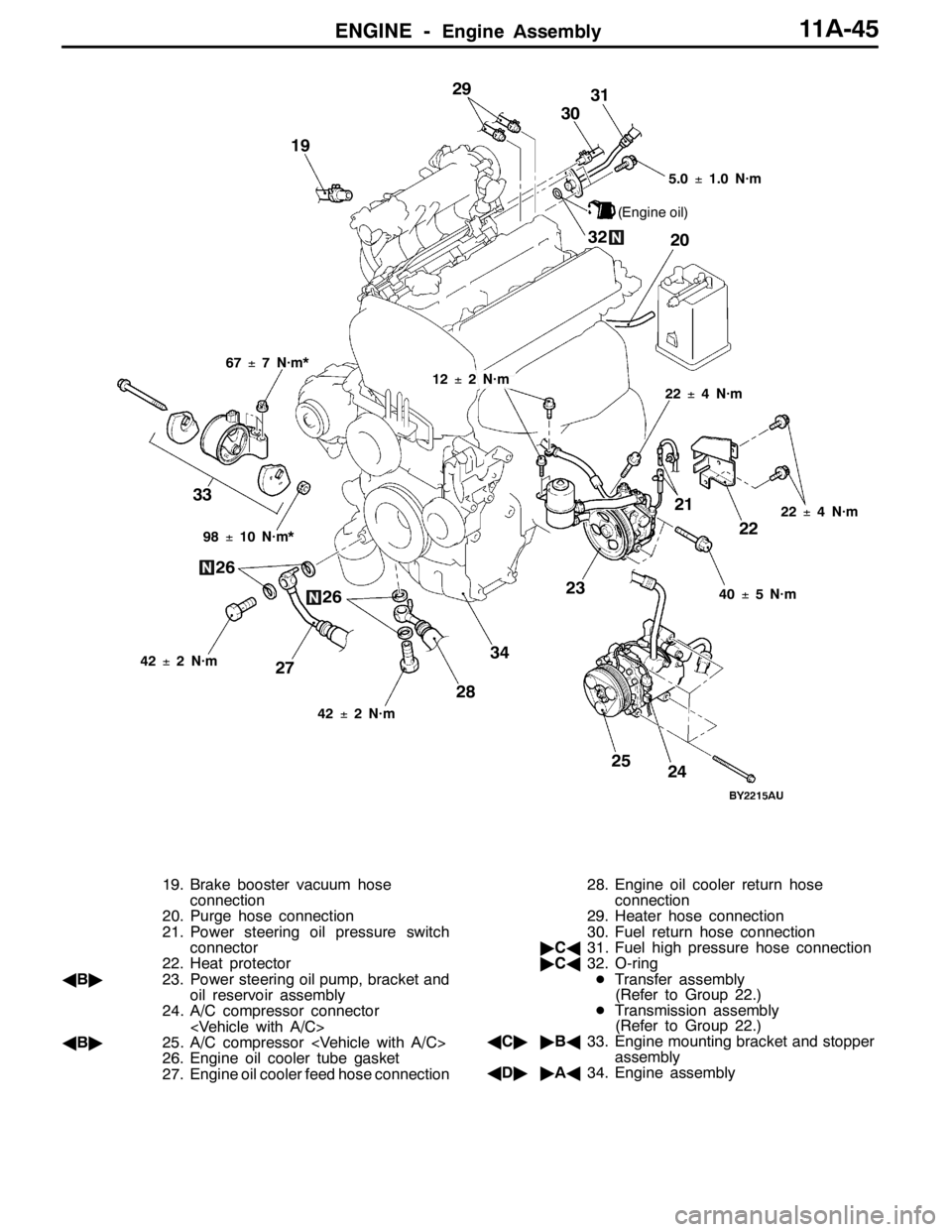

ENGINE -Engine Assembly11A-45

67±7 N·m*

23 33

24 29

3031

32

2722

98±10 N·m*5.0±1.0 N·m

(Engine oil)

20

21 19

25

42±2 N·m22±4 N·m

40±5 N·m

42±2 N·m

26

26

2834

22±4 N·m12±2 N·m

19. Brake booster vacuum hose

connection

20. Purge hose connection

21. Power steering oil pressure switch

connector

22. Heat protector

AB"23. Power steering oil pump, bracket and

oil reservoir assembly

24. A/C compressor connector

AB"25. A/C compressor

26. Engine oil cooler tube gasket

27. Engine oil cooler feed hose connection28. Engine oil cooler return hose

connection

29. Heater hose connection

30. Fuel return hose connection

"CA31. Fuel high pressure hose connection

"CA32. O-ring

DTransfer assembly

(Refer to Group 22.)

DTransmission assembly

(Refer to Group 22.)

AC""BA33. Engine mounting bracket and stopper

assembly

AD""AA34. Engine assembly

Page 452 of 1449

ENGINE -Engine Assembly11A-46

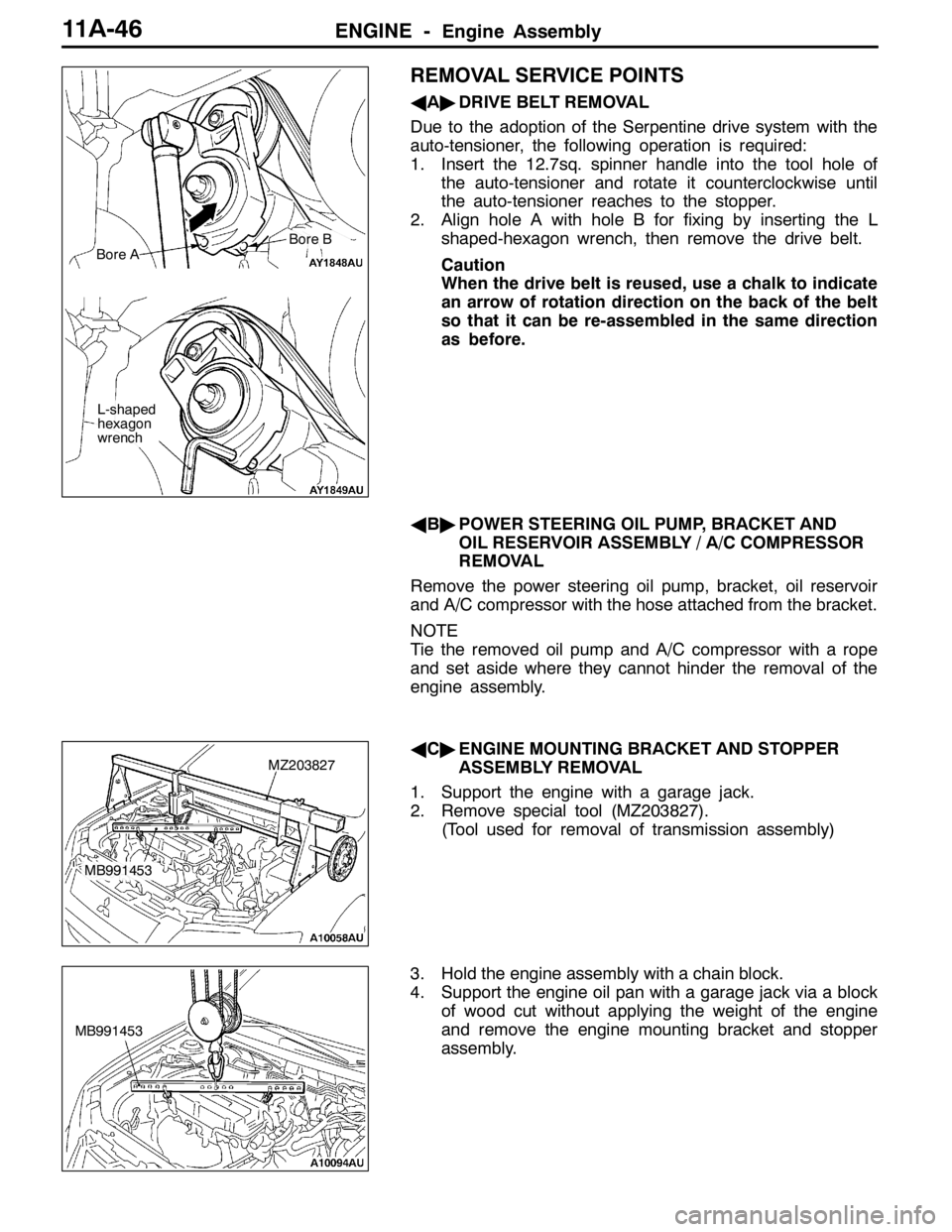

REMOVAL SERVICE POINTS

AA"DRIVE BELT REMOVAL

Due to the adoption of the Serpentine drive system with the

auto-tensioner, the following operation is required:

1. Insert the 12.7sq. spinner handle into the tool hole of

the auto-tensioner and rotate it counterclockwise until

the auto-tensioner reaches to the stopper.

2. Align hole A with hole B for fixing by inserting the L

shaped-hexagon wrench, then remove the drive belt.

Caution

When the drive belt is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction

as before.

AB"POWER STEERING OIL PUMP, BRACKET AND

OIL RESERVOIR ASSEMBLY / A/C COMPRESSOR

REMOVAL

Remove the power steering oil pump, bracket, oil reservoir

and A/C compressor with the hose attached from the bracket.

NOTE

Tie the removed oil pump and A/C compressor with a rope

and set aside where they cannot hinder the removal of the

engine assembly.

AC"ENGINE MOUNTING BRACKET AND STOPPER

ASSEMBLY REMOVAL

1. Support the engine with a garage jack.

2. Remove special tool (MZ203827).

(Tool used for removal of transmission assembly)

3. Hold the engine assembly with a chain block.

4. Support the engine oil pan with a garage jack via a block

of wood cut without applying the weight of the engine

and remove the engine mounting bracket and stopper

assembly.

Bore A

L-shaped

hexagon

wrench

Bore B

MZ203827

MB991453

MB991453