torque MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 442 of 1449

ENGINE -Timing Belt and Timing Belt B11A-36

AC"TIMING BELT B REMOVAL

Caution

When the timing belt B is reused, use a chalk to indicate

an arrow of rotation direction on the back of the belt

so that it can be re-assembled in the same direction as

before.

INSTALLATION SERVICE POINTS

"AATIMING BELT B/TIMING BELT B TENSIONER

INSTALLATION

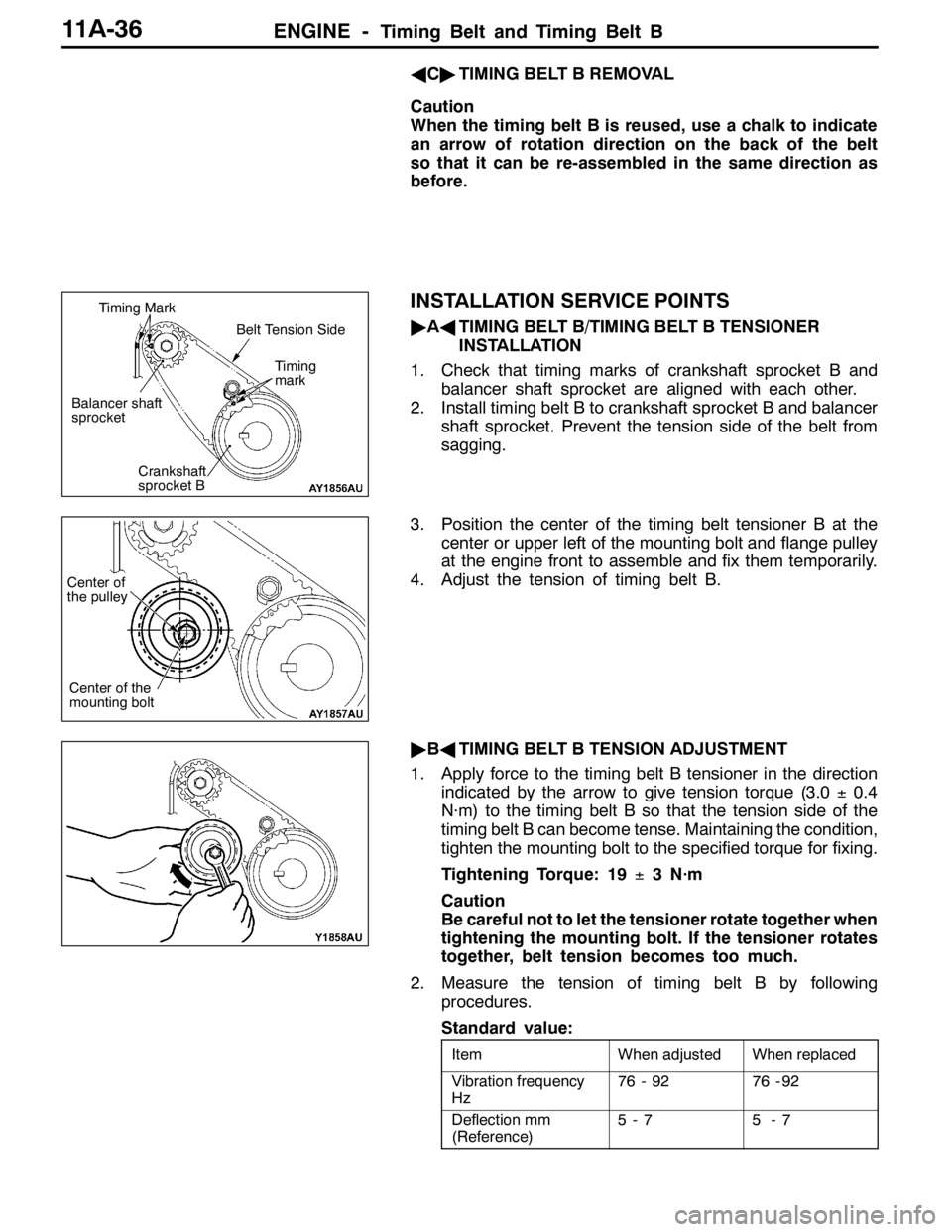

1. Check that timing marks of crankshaft sprocket B and

balancer shaft sprocket are aligned with each other.

2. Install timing belt B to crankshaft sprocket B and balancer

shaft sprocket. Prevent the tension side of the belt from

sagging.

3. Position the center of the timing belt tensioner B at the

center or upper left of the mounting bolt and flange pulley

at the engine front to assemble and fix them temporarily.

4. Adjust the tension of timing belt B.

"BATIMING BELT B TENSION ADJUSTMENT

1. Apply force to the timing belt B tensioner in the direction

indicated by the arrow to give tension torque (3.0±0.4

N·m) to the timing belt B so that the tension side of the

timing belt B can become tense. Maintaining the condition,

tighten the mounting bolt to the specified torque for fixing.

Tightening Torque: 19±3 N·m

Caution

Be careful not to let the tensioner rotate together when

tightening the mounting bolt. If the tensioner rotates

together, belt tension becomes too much.

2. Measure the tension of timing belt B by following

procedures.

Standard value:

ItemWhen adjustedWhen replaced

Vibration frequency

Hz76 - 9276 - 92

Deflection mm

(Reference)5-75-7

Crankshaft

sprocket B

Timing

mark

Timing Mark

Belt Tension Side

Balancer shaft

sprocket

Center of

the pulley

Center of the

mounting bolt

Page 444 of 1449

ENGINE -Timing Belt and Timing Belt B11A-38

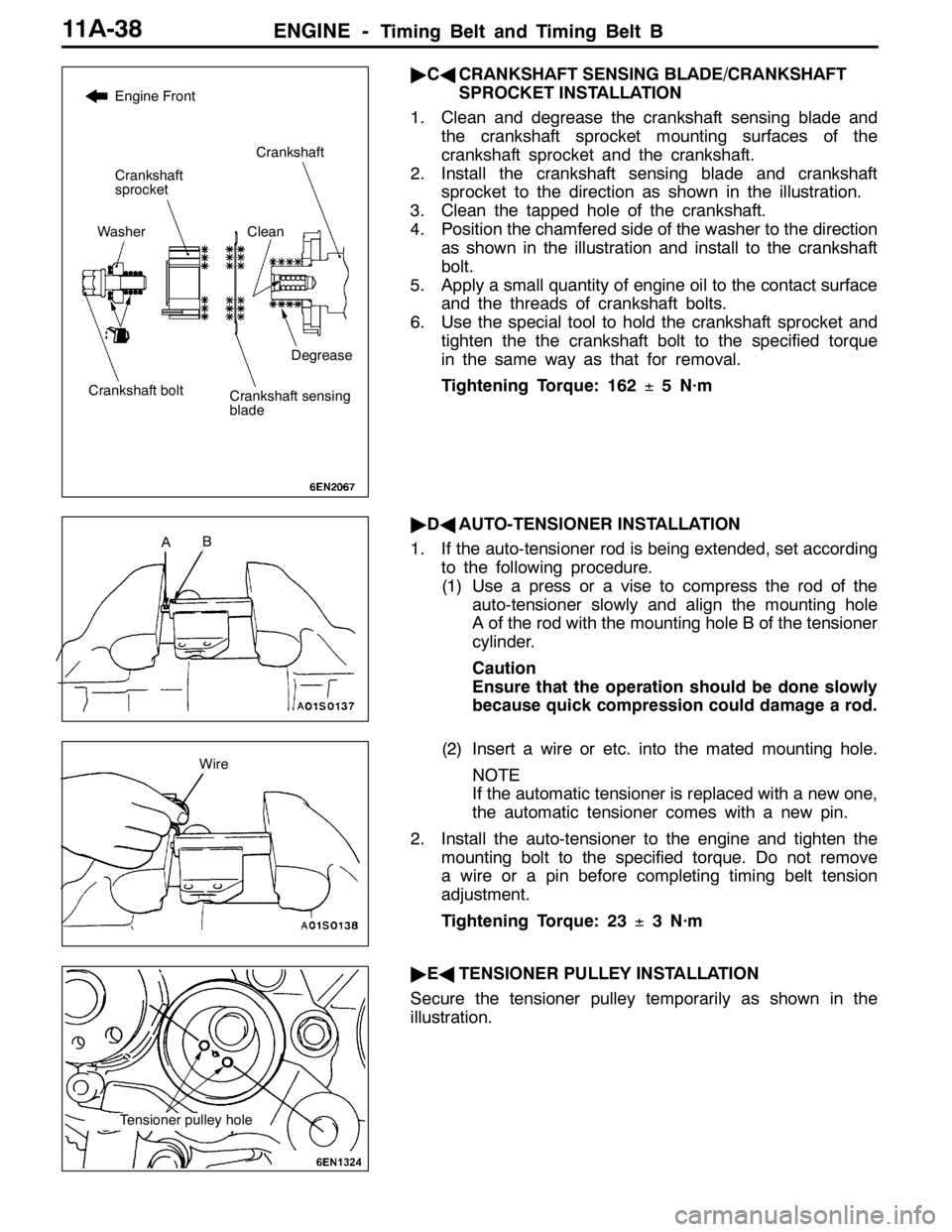

"CACRANKSHAFT SENSING BLADE/CRANKSHAFT

SPROCKET INSTALLATION

1. Clean and degrease the crankshaft sensing blade and

the crankshaft sprocket mounting surfaces of the

crankshaft sprocket and the crankshaft.

2. Install the crankshaft sensing blade and crankshaft

sprocket to the direction as shown in the illustration.

3. Clean the tapped hole of the crankshaft.

4. Position the chamfered side of the washer to the direction

as shown in the illustration and install to the crankshaft

bolt.

5. Apply a small quantity of engine oil to the contact surface

and the threads of crankshaft bolts.

6. Use the special tool to hold the crankshaft sprocket and

tighten the the crankshaft bolt to the specified torque

in the same way as that for removal.

Tightening Torque: 162±5 N·m

"DAAUTO-TENSIONER INSTALLATION

1. If the auto-tensioner rod is being extended, set according

to the following procedure.

(1) Use a press or a vise to compress the rod of the

auto-tensioner slowly and align the mounting hole

A of the rod with the mounting hole B of the tensioner

cylinder.

Caution

Ensure that the operation should be done slowly

because quick compression could damage a rod.

(2) Insert a wire or etc. into the mated mounting hole.

NOTE

If the automatic tensioner is replaced with a new one,

the automatic tensioner comes with a new pin.

2. Install the auto-tensioner to the engine and tighten the

mounting bolt to the specified torque. Do not remove

a wire or a pin before completing timing belt tension

adjustment.

Tightening Torque: 23±3 N·m

"EATENSIONER PULLEY INSTALLATION

Secure the tensioner pulley temporarily as shown in the

illustration.

Clean

Engine Front

Degrease

Crankshaft

Crankshaft

sprocket

Washer

Crankshaft boltCrankshaft sensing

blade

AB

Wire

Tensioner pulley hole

Page 447 of 1449

ENGINE -Timing Belt and Timing Belt B11A-41

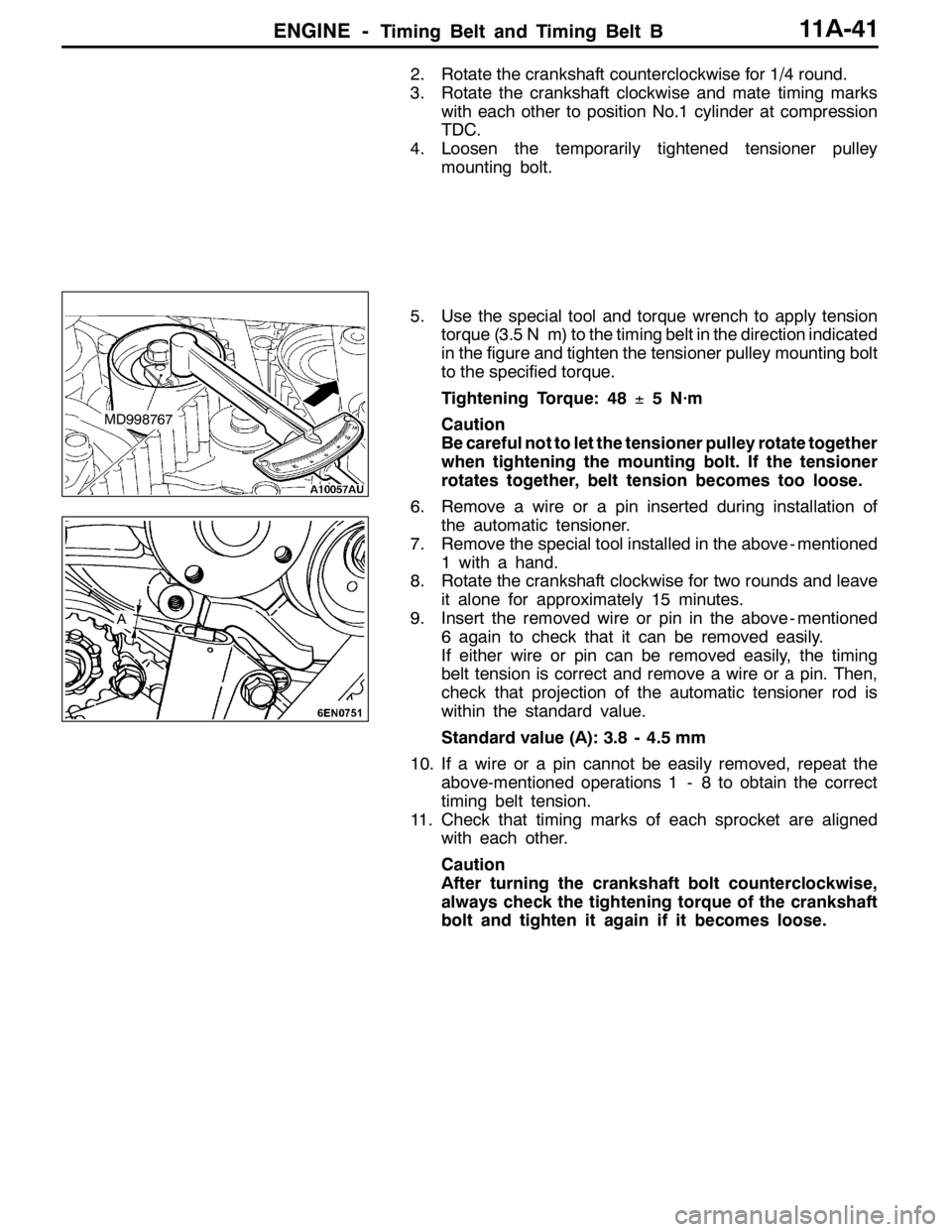

2. Rotate the crankshaft counterclockwise for 1/4 round.

3. Rotate the crankshaft clockwise and mate timing marks

with each other to position No.1 cylinder at compression

TDC.

4. Loosen the temporarily tightened tensioner pulley

mounting bolt.

5. Use the special tool and torque wrench to apply tension

torque (3.5 N��m) to the timing belt in the direction indicated

in the figure and tighten the tensioner pulley mounting bolt

to the specified torque.

Tightening Torque: 48±5 N·m

Caution

Be careful not to let the tensioner pulley rotate together

when tightening the mounting bolt. If the tensioner

rotates together, belt tension becomes too loose.

6. Remove a wire or a pin inserted during installation of

the automatic tensioner.

7. Remove the special tool installed in the above - mentioned

1 with a hand.

8. Rotate the crankshaft clockwise for two rounds and leave

it alone for approximately 15 minutes.

9. Insert the removed wire or pin in the above - mentioned

6 again to check that it can be removed easily.

If either wire or pin can be removed easily, the timing

belt tension is correct and remove a wire or a pin. Then,

check that projection of the automatic tensioner rod is

within the standard value.

Standard value (A): 3.8 - 4.5 mm

10. If a wire or a pin cannot be easily removed, repeat the

above-mentioned operations 1 - 8 to obtain the correct

timing belt tension.

11. Check that timing marks of each sprocket are aligned

with each other.

Caution

After turning the crankshaft bolt counterclockwise,

always check the tightening torque of the crankshaft

bolt and tighten it again if it becomes loose.

MD998767

A

Page 453 of 1449

ENGINE -Engine Assembly11A-47

AD"ENGINE ASSEMBLY REMOVAL

After checking that all the cables, hoses, and harness

connectors have been disconnected, lift the engine with a

chain block slowly and remove the engine assembly located

at the upper engine room.

INSTALLATION SERVICE POINTS

"AAENGINE ASSEMBLY INSTALLATION

Install the engine assembly while checking that none of cables,

hoses, or harness connectors, etc. has been engaged.

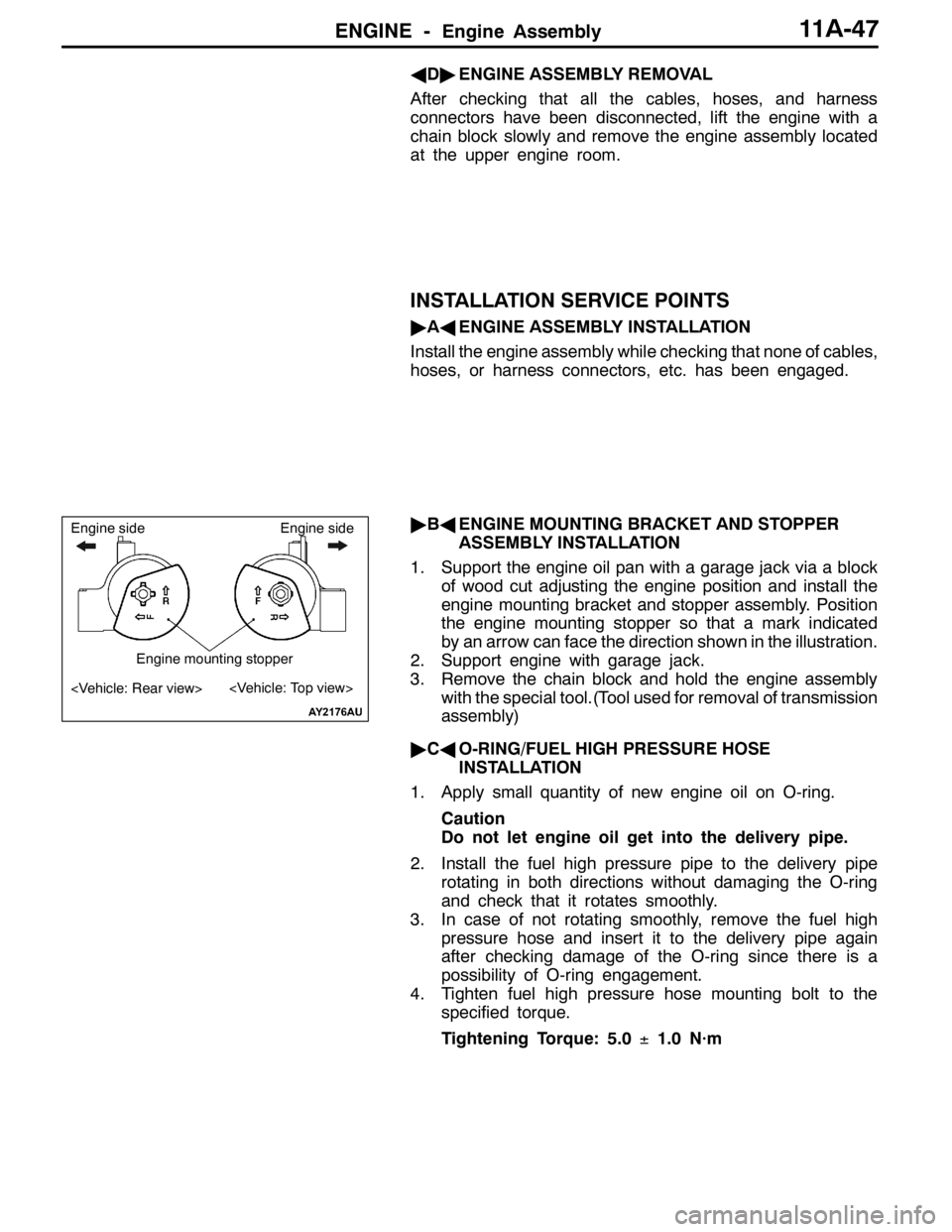

"BAENGINE MOUNTING BRACKET AND STOPPER

ASSEMBLY INSTALLATION

1. Support the engine oil pan with a garage jack via a block

of wood cut adjusting the engine position and install the

engine mounting bracket and stopper assembly. Position

the engine mounting stopper so that a mark indicated

by an arrow can face the direction shown in the illustration.

2. Support engine with garage jack.

3. Remove the chain block and hold the engine assembly

with the special tool.(Tool used for removal of transmission

assembly)

"CAO-RING/FUEL HIGH PRESSURE HOSE

INSTALLATION

1. Apply small quantity of new engine oil on O-ring.

Caution

Do not let engine oil get into the delivery pipe.

2. Install the fuel high pressure pipe to the delivery pipe

rotating in both directions without damaging the O-ring

and check that it rotates smoothly.

3. In case of not rotating smoothly, remove the fuel high

pressure hose and insert it to the delivery pipe again

after checking damage of the O-ring since there is a

possibility of O-ring engagement.

4. Tighten fuel high pressure hose mounting bolt to the

specified torque.

Tightening Torque: 5.0±1.0 N·m

Engine mounting stopper

Engine side

Page 455 of 1449

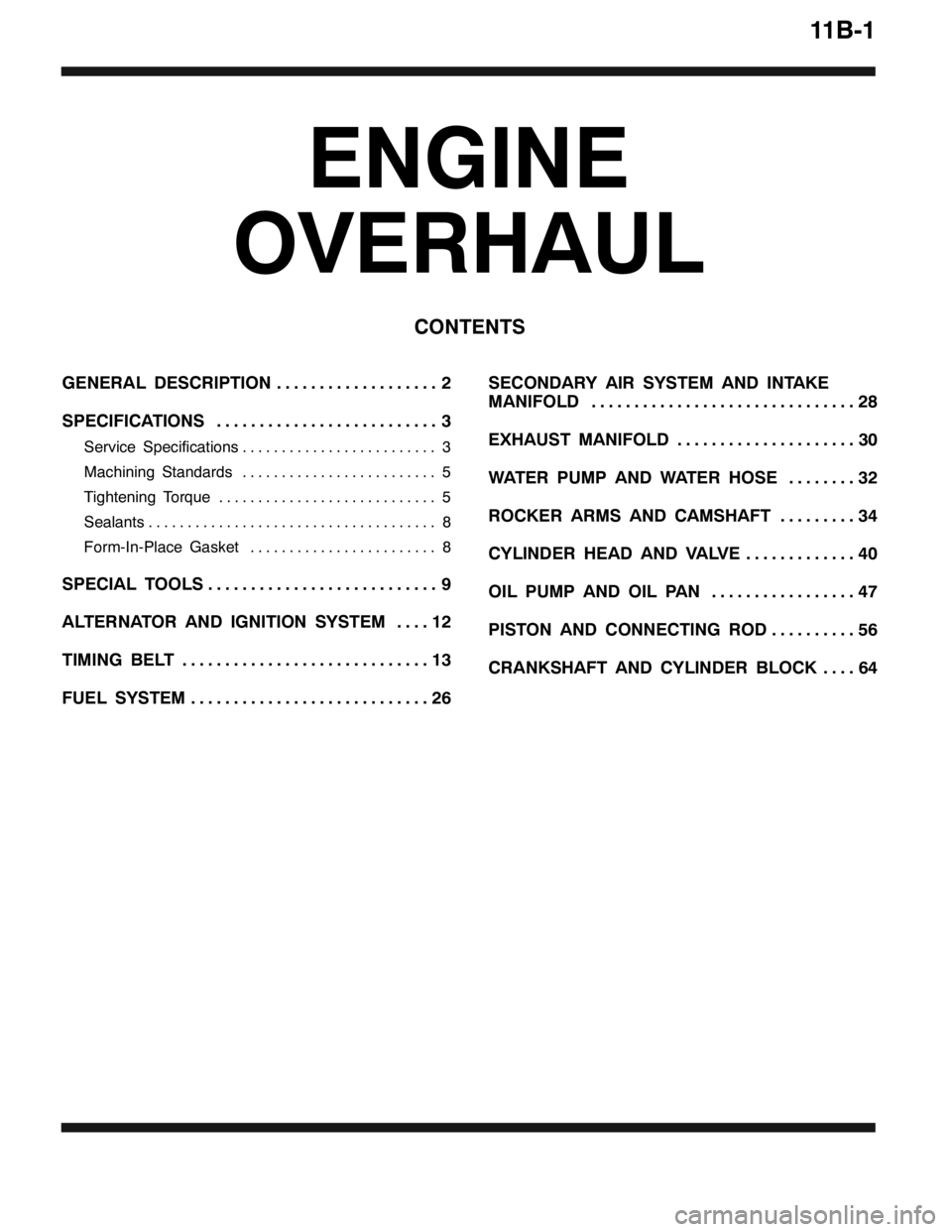

11B-1

ENGINE

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 3..........................

Service Specifications 3.........................

Machining Standards 5.........................

Tightening Torque 5............................

Sealants 8.....................................

Form-In-Place Gasket 8........................

SPECIAL TOOLS 9...........................

ALTERNATOR AND IGNITION SYSTEM 12....

TIMING BELT 13.............................

FUEL SYSTEM 26............................SECONDARY AIR SYSTEM AND INTAKE

MANIFOLD 28...............................

EXHAUST MANIFOLD 30.....................

WATER PUMP AND WATER HOSE 32........

ROCKER ARMS AND CAMSHAFT 34.........

CYLINDER HEAD AND VALVE 40.............

OIL PUMP AND OIL PAN 47.................

PISTON AND CONNECTING ROD 56..........

CRANKSHAFT AND CYLINDER BLOCK 64....

Page 459 of 1449

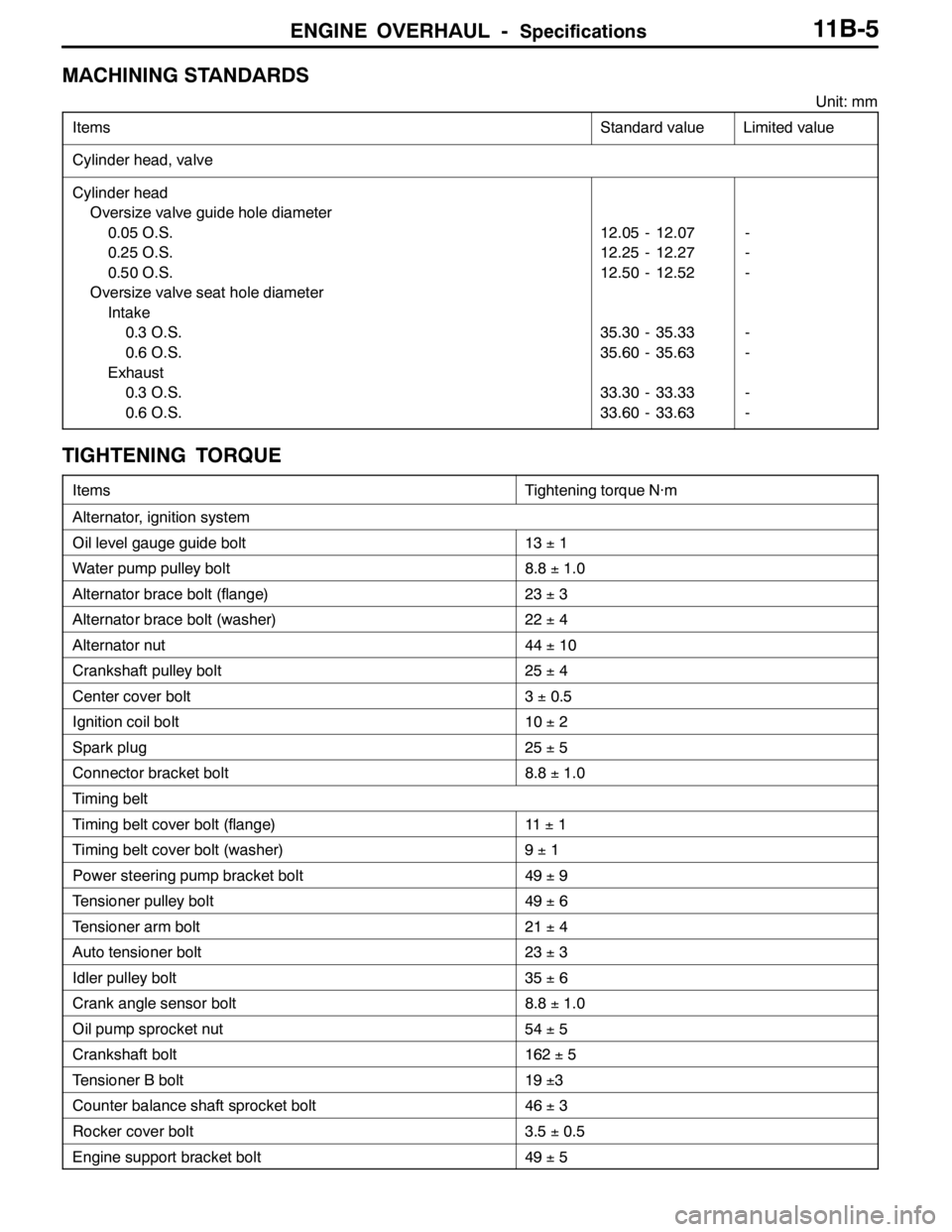

ENGINE OVERHAUL -Specifications11B-5

MACHINING STANDARDS

Unit: mm

Items

Standard valueLimited value

Cylinder head, valve

Cylinder head

Oversize valve guide hole diameter

0.05 O.S.

0.25 O.S.

0.50 O.S.

Oversize valve seat hole diameter

Intake

0.3 O.S.

0.6 O.S.

Exhaust

0.3 O.S.

0.6 O.S.

12.05 - 12.07

12.25 - 12.27

12.50 - 12.52

35.30 - 35.33

35.60 - 35.63

33.30 - 33.33

33.60 - 33.63-

-

-

-

-

-

-

TIGHTENING TORQUE

ItemsTightening torque N·m

Alternator, ignition system

Oil level gauge guide bolt13±1

Water pump pulley bolt8.8±1.0

Alternator brace bolt (flange)23±3

Alternator brace bolt (washer)22±4

Alternator nut44±10

Crankshaft pulley bolt25±4

Center cover bolt3±0.5

Ignition coil bolt10±2

Spark plug25±5

Connector bracket bolt8.8±1.0

Timing belt

Timing belt cover bolt (flange)11±1

Timing belt cover bolt (washer)9±1

Power steering pump bracket bolt49±9

Tensioner pulley bolt49±6

Tensioner arm bolt21±4

Auto tensioner bolt23±3

Idler pulley bolt35±6

Crank angle sensor bolt8.8±1.0

Oil pump sprocket nut54±5

Crankshaft bolt162±5

Tensioner B bolt19±3

Counter balance shaft sprocket bolt46±3

Rocker cover bolt3.5±0.5

Engine support bracket bolt49±5

Page 460 of 1449

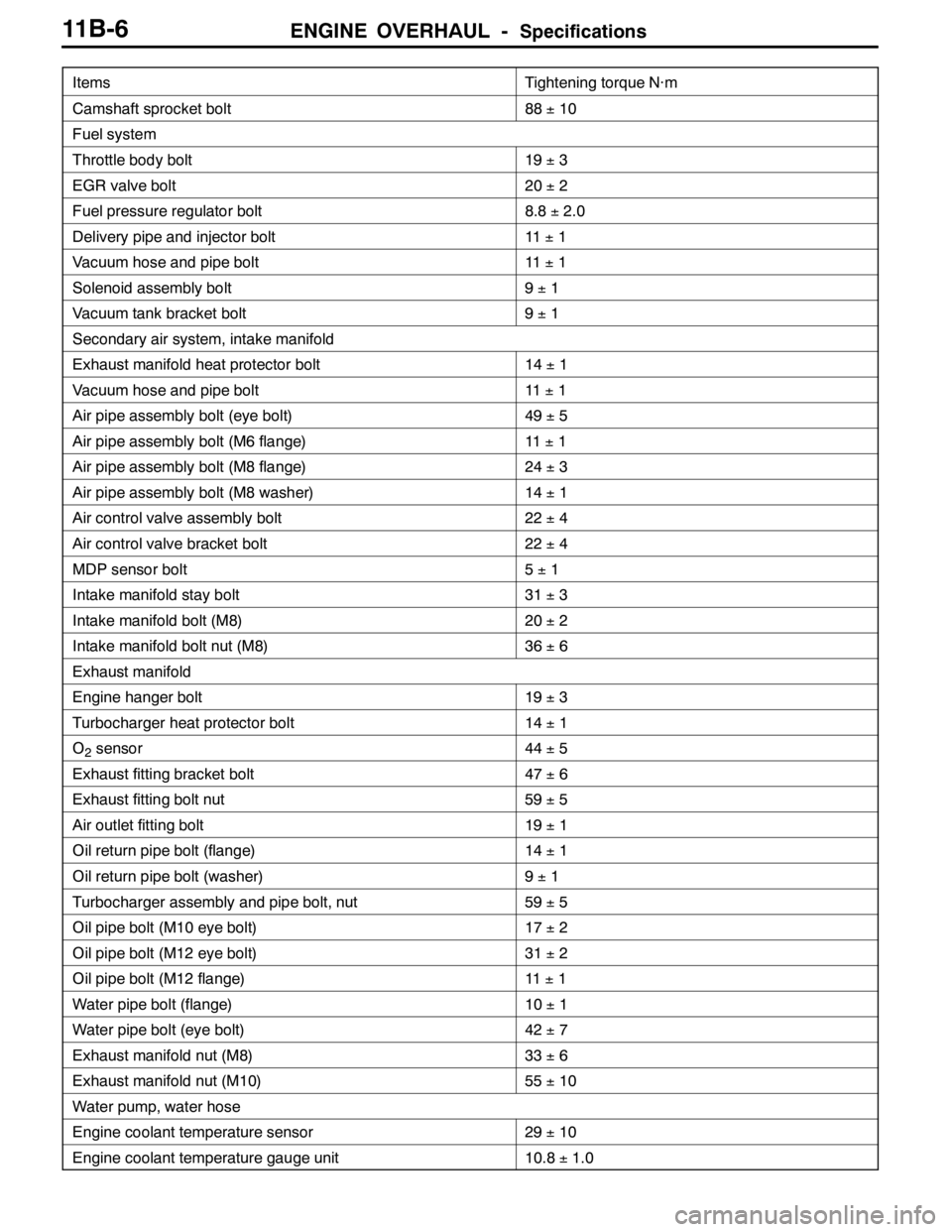

ENGINE OVERHAUL -Specifications11B-6

Items Tightening torque N·m

Camshaft sprocket bolt88±10

Fuel system

Throttle body bolt19±3

EGR valve bolt20±2

Fuel pressure regulator bolt8.8±2.0

Delivery pipe and injector bolt11±1

Vacuum hose and pipe bolt11±1

Solenoid assembly bolt9±1

Vacuum tank bracket bolt9±1

Secondary air system, intake manifold

Exhaust manifold heat protector bolt14±1

Vacuum hose and pipe bolt11±1

Air pipe assembly bolt (eye bolt)49±5

Air pipe assembly bolt (M6 flange)11±1

Air pipe assembly bolt (M8 flange)24±3

Air pipe assembly bolt (M8 washer)14±1

Air control valve assembly bolt22±4

Air control valve bracket bolt22±4

MDP sensor bolt5±1

Intake manifold stay bolt31±3

Intake manifold bolt (M8)20±2

Intake manifold bolt nut (M8)36±6

Exhaust manifold

Engine hanger bolt19±3

Turbocharger heat protector bolt14±1

O2sensor44±5

Exhaust fitting bracket bolt47±6

Exhaust fitting bolt nut59±5

Air outlet fitting bolt19±1

Oil return pipe bolt (flange)14±1

Oil return pipe bolt (washer)9±1

Turbocharger assembly and pipe bolt, nut59±5

Oil pipe bolt (M10 eye bolt)17±2

Oil pipe bolt (M12 eye bolt)31±2

Oil pipe bolt (M12 flange)11±1

Water pipe bolt (flange)10±1

Water pipe bolt (eye bolt)42±7

Exhaust manifold nut (M8)33±6

Exhaust manifold nut (M10)55±10

Water pump, water hose

Engine coolant temperature sensor29±10

Engine coolant temperature gauge unit10.8±1.0

Page 461 of 1449

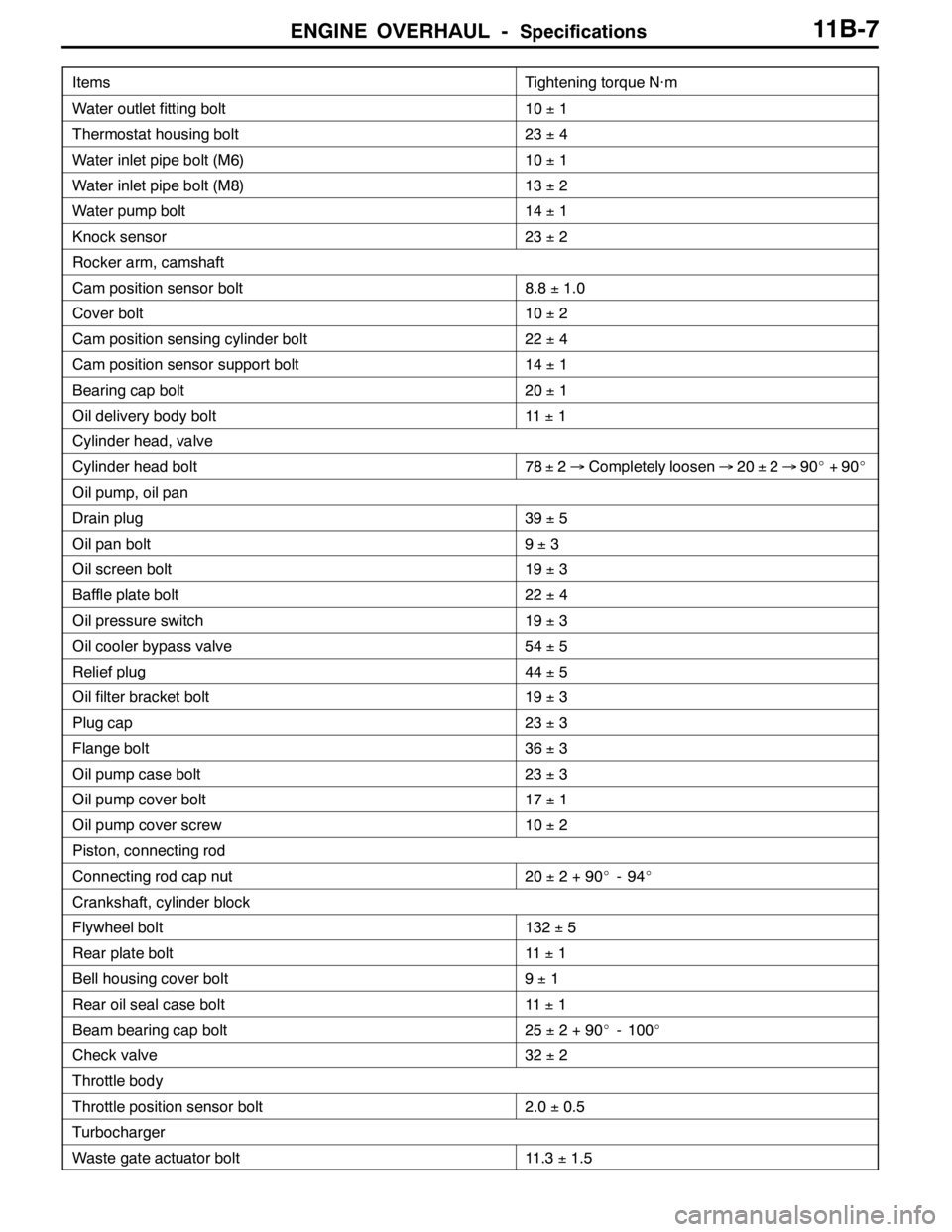

ENGINE OVERHAUL -Specifications11B-7

Items Tightening torque N·m

Water outlet fitting bolt10±1

Thermostat housing bolt23±4

Water inlet pipe bolt (M6)10±1

Water inlet pipe bolt (M8)13±2

Water pump bolt14±1

Knock sensor23±2

Rocker arm, camshaft

Cam position sensor bolt8.8±1.0

Cover bolt10±2

Cam position sensing cylinder bolt22±4

Cam position sensor support bolt14±1

Bearing cap bolt20±1

Oil delivery body bolt11±1

Cylinder head, valve

Cylinder head bolt78±2→Completely loosen→20±2→90_+90_

Oil pump, oil pan

Drain plug39±5

Oil pan bolt9±3

Oil screen bolt19±3

Baffle plate bolt22±4

Oil pressure switch19±3

Oil cooler bypass valve54±5

Relief plug44±5

Oil filter bracket bolt19±3

Plug cap23±3

Flange bolt36±3

Oil pump case bolt23±3

Oil pump cover bolt17±1

Oil pump cover screw10±2

Piston, connecting rod

Connecting rod cap nut20±2+90_-94_

Crankshaft, cylinder block

Flywheel bolt132±5

Rear plate bolt11±1

Bell housing cover bolt9±1

Rear oil seal case bolt11±1

Beam bearing cap bolt25±2+90_- 100_

Check valve32±2

Throttle body

Throttle position sensor bolt2.0±0.5

Turbocharger

Waste gate actuator bolt11.3±1.5

Page 469 of 1449

ENGINE OVERHAUL -Timing Belt11B-15

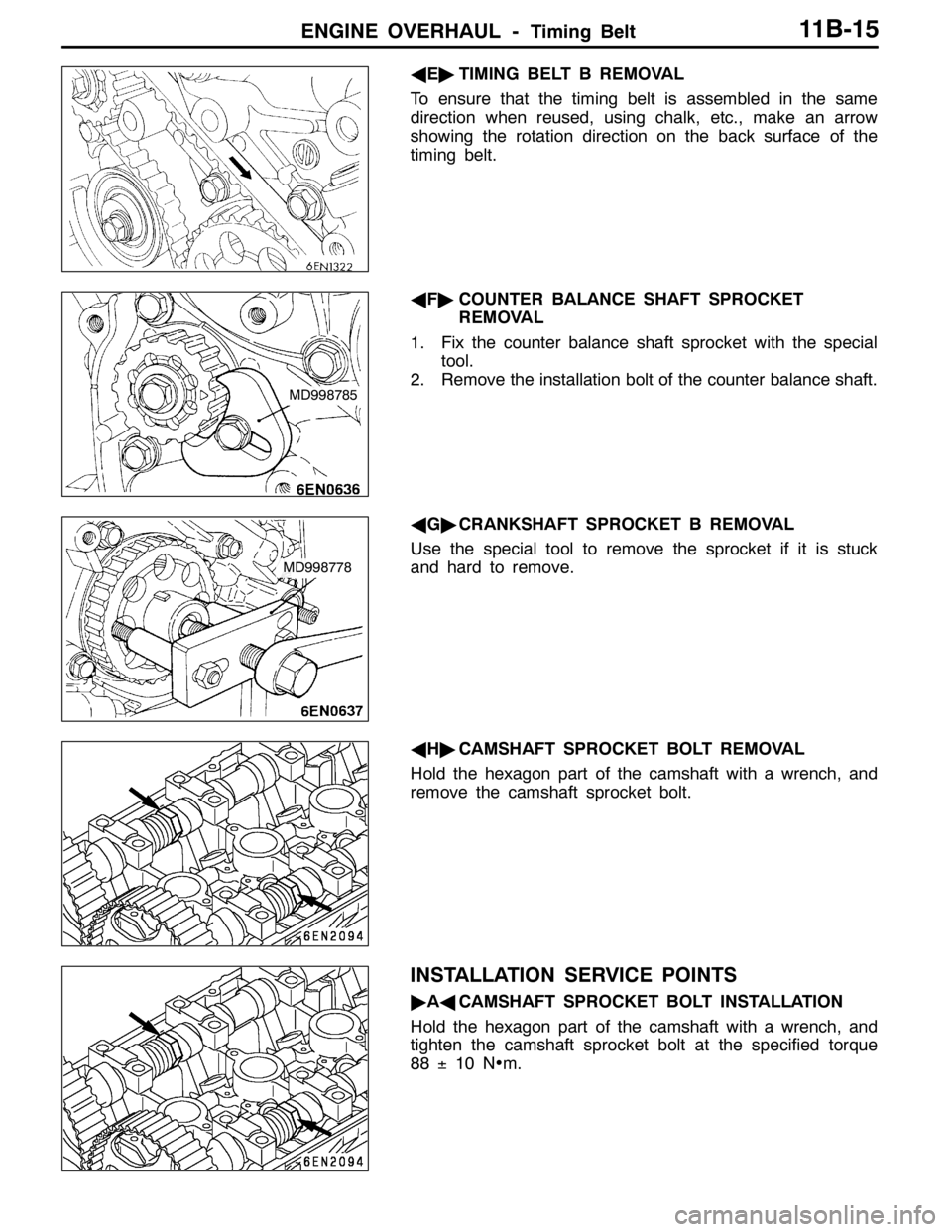

AE"TIMING BELT B REMOVAL

To ensure that the timing belt is assembled in the same

direction when reused, using chalk, etc., make an arrow

showing the rotation direction on the back surface of the

timing belt.

AF"COUNTER BALANCE SHAFT SPROCKET

REMOVAL

1. Fix the counter balance shaft sprocket with the special

tool.

2. Remove the installation bolt of the counter balance shaft.

AG"CRANKSHAFT SPROCKET B REMOVAL

Use the special tool to remove the sprocket if it is stuck

and hard to remove.

AH"CAMSHAFT SPROCKET BOLT REMOVAL

Hold the hexagon part of the camshaft with a wrench, and

remove the camshaft sprocket bolt.

INSTALLATION SERVICE POINTS

"AACAMSHAFT SPROCKET BOLT INSTALLATION

Hold the hexagon part of the camshaft with a wrench, and

tighten the camshaft sprocket bolt at the specified torque

88±10 N•m.

MD998785

MD998778

Page 471 of 1449

ENGINE OVERHAUL -Timing Belt11B-17

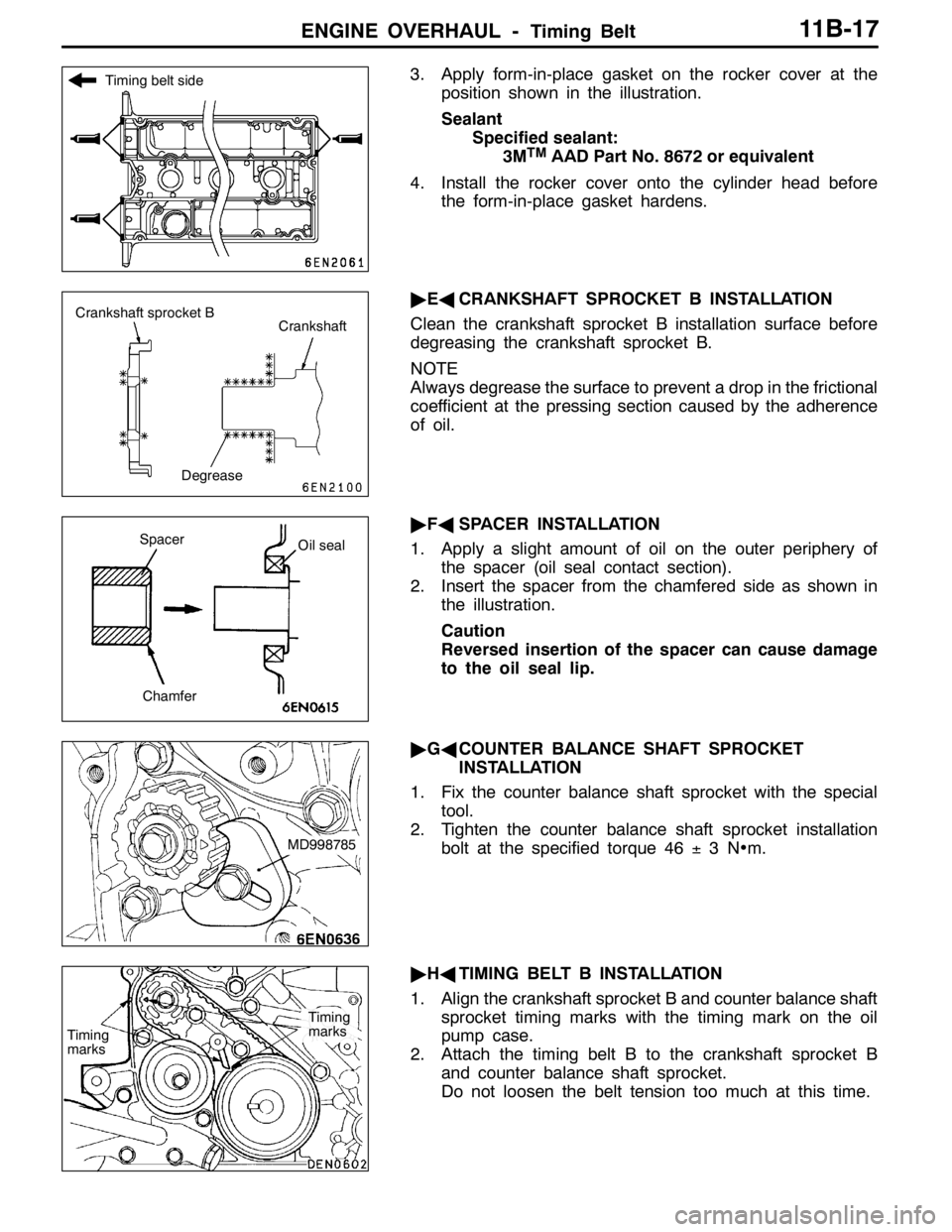

3. Apply form-in-place gasket on the rocker cover at the

position shown in the illustration.

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

4. Install the rocker cover onto the cylinder head before

the form-in-place gasket hardens.

"EACRANKSHAFT SPROCKET B INSTALLATION

Clean the crankshaft sprocket B installation surface before

degreasing the crankshaft sprocket B.

NOTE

Always degrease the surface to prevent a drop in the frictional

coefficient at the pressing section caused by the adherence

of oil.

"FASPACER INSTALLATION

1. Apply a slight amount of oil on the outer periphery of

the spacer (oil seal contact section).

2. Insert the spacer from the chamfered side as shown in

the illustration.

Caution

Reversed insertion of the spacer can cause damage

to the oil seal lip.

"GACOUNTER BALANCE SHAFT SPROCKET

INSTALLATION

1. Fix the counter balance shaft sprocket with the special

tool.

2. Tighten the counter balance shaft sprocket installation

bolt at the specified torque 46±3N•m.

"HATIMING BELT B INSTALLATION

1. Align the crankshaft sprocket B and counter balance shaft

sprocket timing marks with the timing mark on the oil

pump case.

2. Attach the timing belt B to the crankshaft sprocket B

and counter balance shaft sprocket.

Do not loosen the belt tension too much at this time.

Timing belt side

Crankshaft sprocket B

Crankshaft

Degrease

Spacer

Oil seal

Chamfer

MD998785

Timing

marks

Timing

marks