torque MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 848 of 1449

MANUAL TRANSMISSION - On-vehicle Service MANUAL TRANSMISSION - On-vehicle Service22A-40

ON-VEHICLE SERVICE

TRANSMISSION OIL CHECK

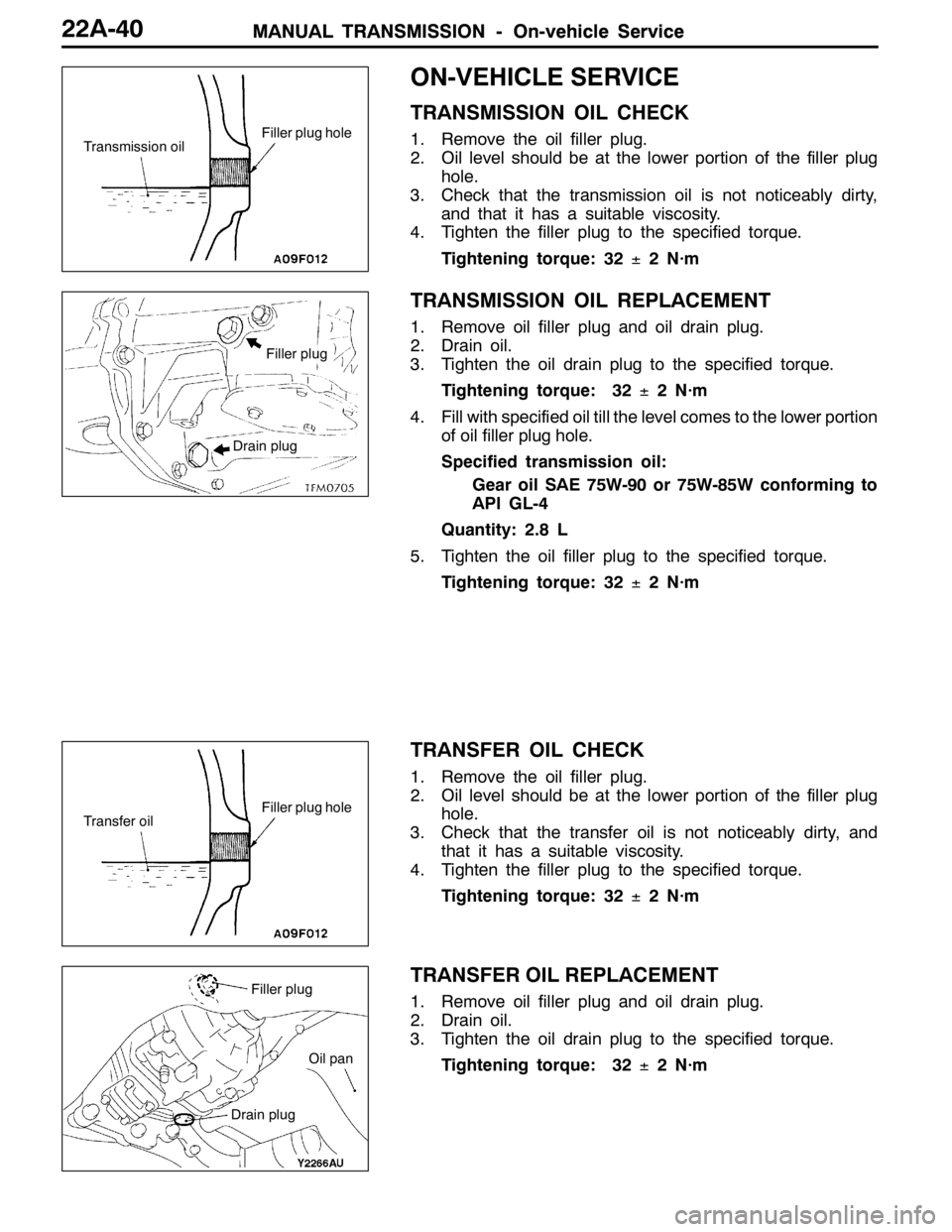

1. Remove the oil filler plug.

2. Oil level should be at the lower portion of the filler plug

hole.

3. Check that the transmission oil is not noticeably dirty,

and that it has a suitable viscosity.

4. Tighten the filler plug to the specified torque.

Tightening torque: 32±2 N·m

TRANSMISSION OIL REPLACEMENT

1. Remove oil filler plug and oil drain plug.

2. Drain oil.

3. Tighten the oil drain plug to the specified torque.

Tightening torque: 32±2 N·m

4. Fill with specified oil till the level comes to the lower portion

of oil filler plug hole.

Specified transmission oil:

Gear oil SAE 75W-90 or 75W-85W conforming to

API GL-4

Quantity: 2.8 L

5. Tighten the oil filler plug to the specified torque.

Tightening torque: 32±2 N·m

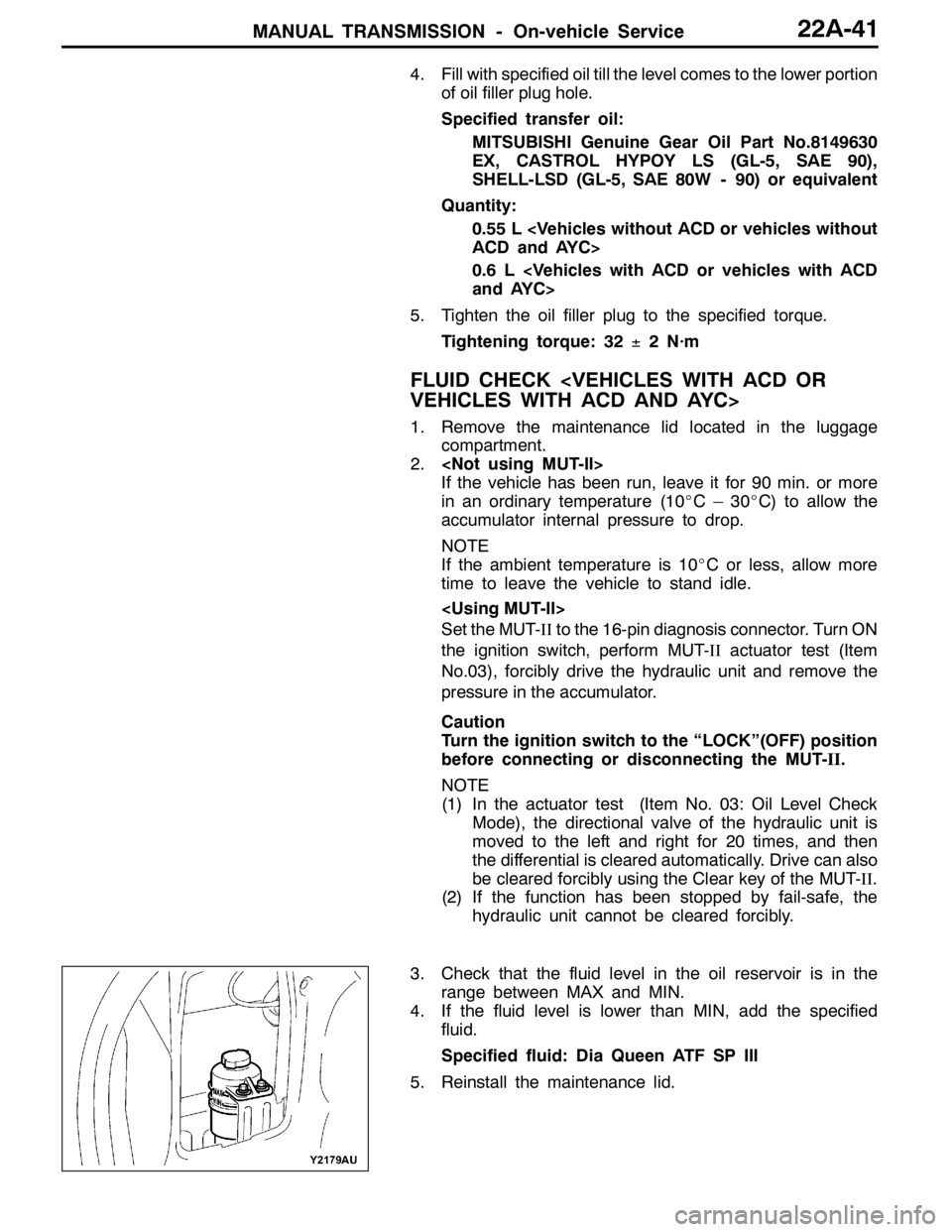

TRANSFER OIL CHECK

1. Remove the oil filler plug.

2. Oil level should be at the lower portion of the filler plug

hole.

3. Check that the transfer oil is not noticeably dirty, and

that it has a suitable viscosity.

4. Tighten the filler plug to the specified torque.

Tightening torque: 32±2 N·m

TRANSFER OIL REPLACEMENT

1. Remove oil filler plug and oil drain plug.

2. Drain oil.

3. Tighten the oil drain plug to the specified torque.

Tightening torque: 32±2 N·m

Transmission oilFiller plug hole

Filler plug

Drain plug

Transfer oilFiller plug hole

Filler plug

Drain plug

Oil pan

Page 849 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-41

4. Fill with specified oil till the level comes to the lower portion

of oil filler plug hole.

Specified transfer oil:

MITSUBISHI Genuine Gear Oil Part No.8149630

EX, CASTROL HYPOY LS (GL-5, SAE 90),

SHELL-LSD (GL-5, SAE 80W - 90) or equivalent

Quantity:

0.55 L

0.6 L

5. Tighten the oil filler plug to the specified torque.

Tightening torque: 32±2 N·m

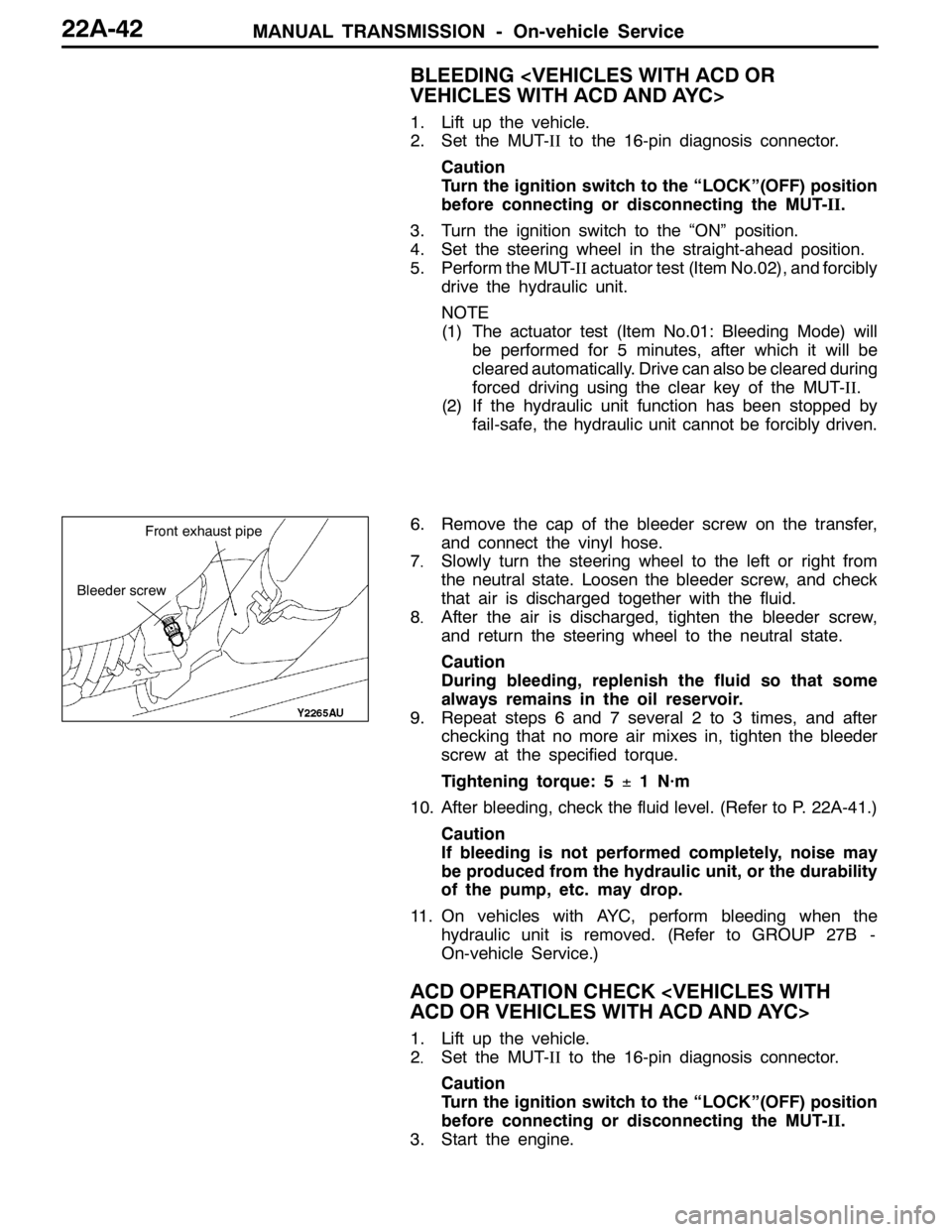

FLUID CHECK

1. Remove the maintenance lid located in the luggage

compartment.

2.

If the vehicle has been run, leave it for 90 min. or more

in an ordinary temperature (10_C–30_C) to allow the

accumulator internal pressure to drop.

NOTE

If the ambient temperature is 10_C or less, allow more

time to leave the vehicle to stand idle.

Set the MUT-IIto the 16-pin diagnosis connector. Turn ON

the ignition switch, perform MUT-IIactuator test (Item

No.03), forcibly drive the hydraulic unit and remove the

pressure in the accumulator.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

NOTE

(1) In the actuator test (Item No. 03: Oil Level Check

Mode), the directional valve of the hydraulic unit is

moved to the left and right for 20 times, and then

the differential is cleared automatically. Drive can also

be cleared forcibly using the Clear key of the MUT-II.

(2) If the function has been stopped by fail-safe, the

hydraulic unit cannot be cleared forcibly.

3. Check that the fluid level in the oil reservoir is in the

range between MAX and MIN.

4. If the fluid level is lower than MIN, add the specified

fluid.

Specified fluid: Dia Queen ATF SP III

5. Reinstall the maintenance lid.

Page 850 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-42

BLEEDING

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Turn the ignition switch to the “ON” position.

4. Set the steering wheel in the straight-ahead position.

5. Perform the MUT-IIactuator test (Item No.02), and forcibly

drive the hydraulic unit.

NOTE

(1) The actuator test (Item No.01: Bleeding Mode) will

be performed for 5 minutes, after which it will be

cleared automatically. Drive can also be cleared during

forced driving using the clear key of the MUT-II.

(2) If the hydraulic unit function has been stopped by

fail-safe, the hydraulic unit cannot be forcibly driven.

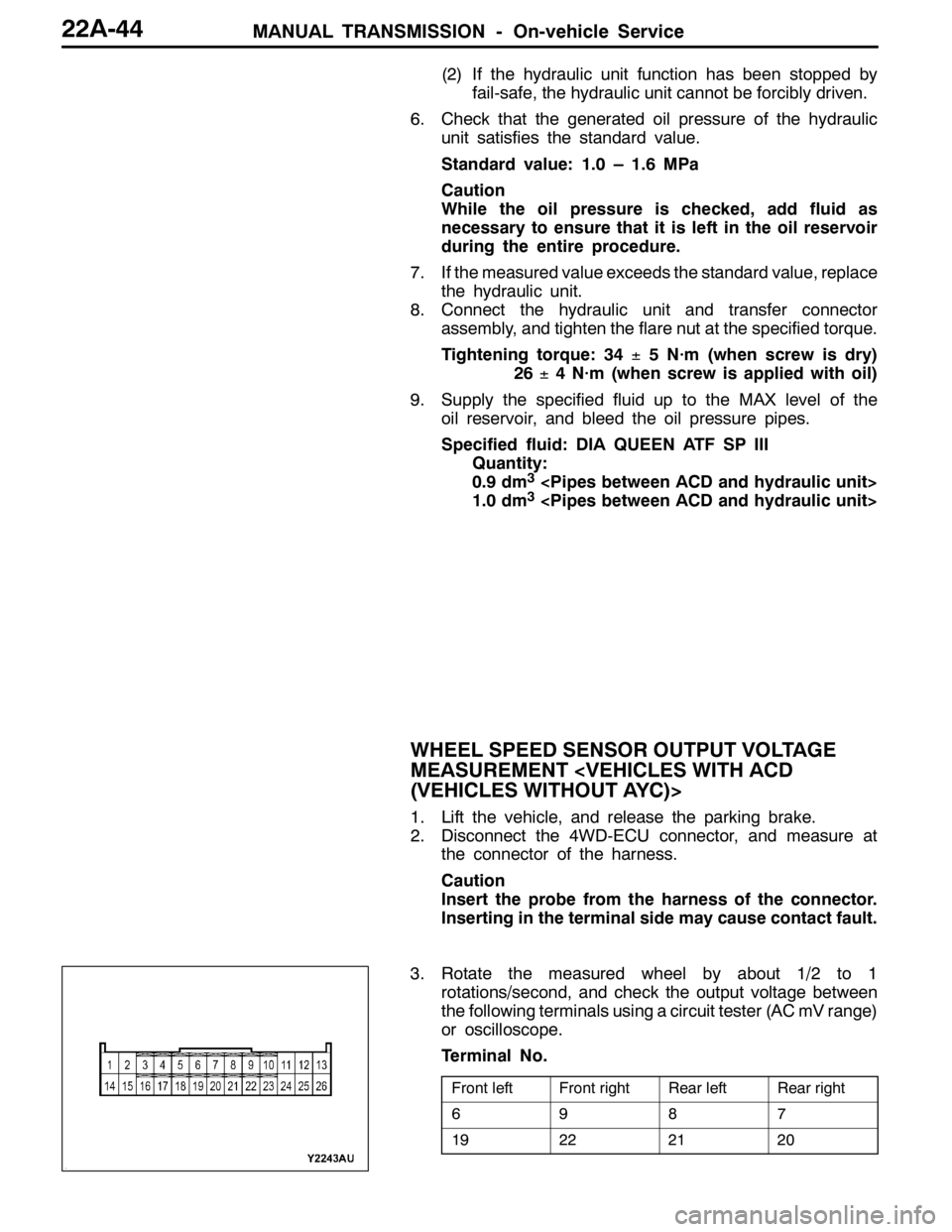

6. Remove the cap of the bleeder screw on the transfer,

and connect the vinyl hose.

7

.Slowly turn the steering wheel to the left or right from

the neutral state. Loosen the bleeder screw, and check

that air is discharged together with the fluid.

8

.After the air is discharged, tighten the bleeder screw,

and return the steering wheel to the neutral state.

Caution

During bleeding, replenish the fluid so that some

always remains in the oil reservoir.

9. Repeat steps 6 and 7 several 2 to 3 times, and after

checking that no more air mixes in, tighten the bleeder

screw at the specified torque.

Tightening torque: 5±1 N·m

10. After bleeding, check the fluid level. (Refer to P. 22A-41.)

Caution

If bleeding is not performed completely, noise may

be produced from the hydraulic unit, or the durability

of the pump, etc. may drop.

11. On vehicles with AYC, perform bleeding when the

hydraulic unit is removed. (Refer to GROUP 27B -

On-vehicle Service.)

ACD OPERATION CHECK

1. Lift up the vehicle.

2

.Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Start the engine.

Bleeder screw

Front exhaust pipe

Page 852 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-44

(2) If the hydraulic unit function has been stopped by

fail-safe, the hydraulic unit cannot be forcibly driven.

6. Check that the generated oil pressure of the hydraulic

unit satisfies the standard value.

Standard value: 1.0 – 1.6 MPa

Caution

While the oil pressure is checked, add fluid as

necessary to ensure that it is left in the oil reservoir

during the entire procedure.

7. If the measured value exceeds the standard value, replace

the hydraulic unit.

8. Connect the hydraulic unit and transfer connector

assembly, and tighten the flare nut at the specified torque.

Tightening torque: 34±5 N·m (when screw is dry)

26±4 N·m (when screw is applied with oil)

9. Supply the specified fluid up to the MAX level of the

oil reservoir, and bleed the oil pressure pipes.

Specified fluid: DIA QUEEN ATF SP III

Quantity:

0.9 dm

3

1.0 dm3

WHEEL SPEED SENSOR OUTPUT VOLTAGE

MEASUREMENT

1. Lift the vehicle, and release the parking brake.

2. Disconnect the 4WD-ECU connector, and measure at

the connector of the harness.

Caution

Insert the probe from the harness of the connector.

Inserting in the terminal side may cause contact fault.

3. Rotate the measured wheel by about 1/2 to 1

rotations/second, and check the output voltage between

the following terminals using a circuit tester (AC mV range)

or oscilloscope.

Terminal No.

Front leftFront rightRear leftRear right

6987

19222120

Page 867 of 1449

22B-1

MANUAL

TRANSMISSION

OVERHAUL

CONTENTS

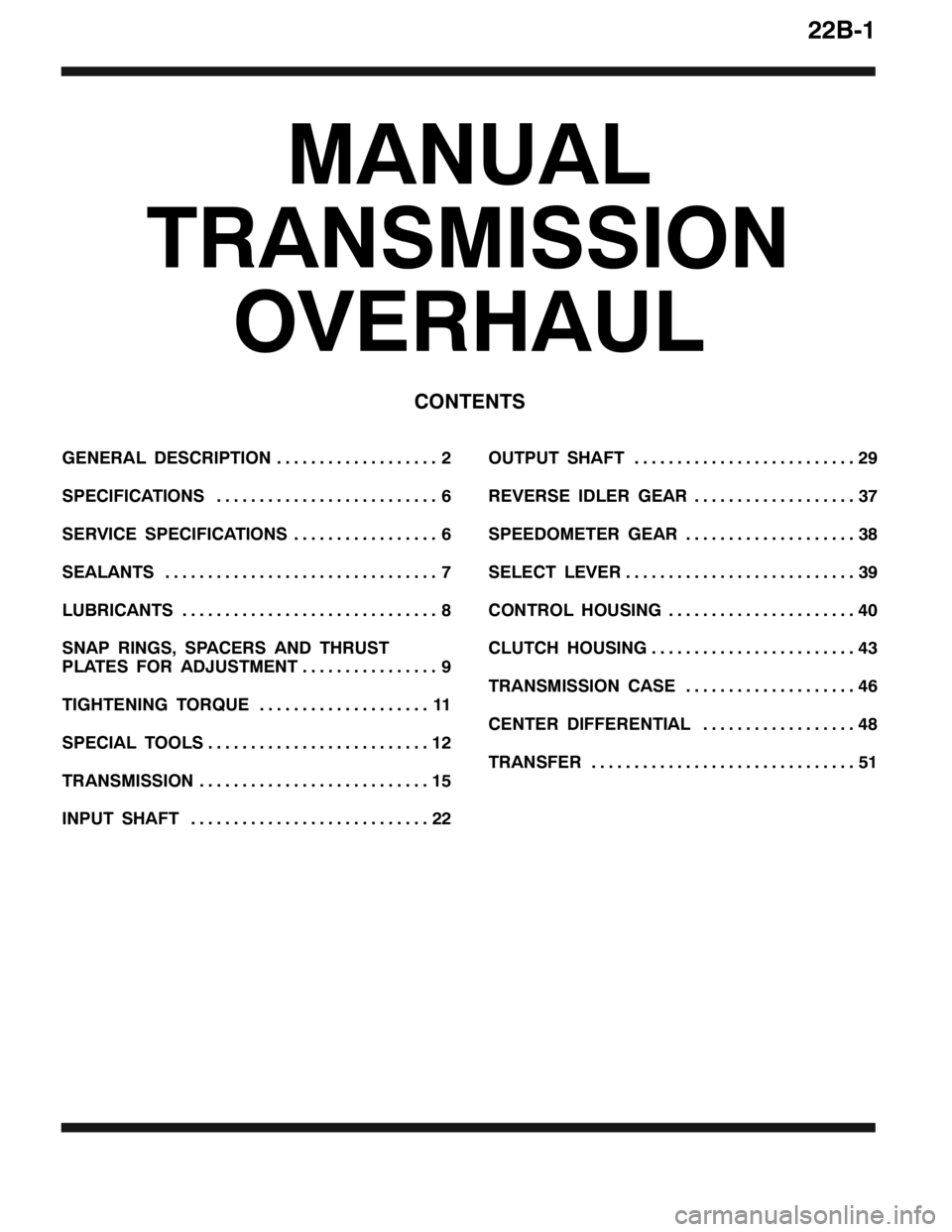

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 6..........................

SERVICE SPECIFICATIONS 6.................

SEALANTS 7................................

LUBRICANTS 8..............................

SNAP RINGS, SPACERS AND THRUST

PLATES FOR ADJUSTMENT 9................

TIGHTENING TORQUE 11....................

SPECIAL TOOLS 12..........................

TRANSMISSION 15...........................

INPUT SHAFT 22............................OUTPUT SHAFT 29..........................

REVERSE IDLER GEAR 37...................

SPEEDOMETER GEAR 38....................

SELECT LEVER 39...........................

CONTROL HOUSING 40......................

CLUTCH HOUSING 43........................

TRANSMISSION CASE 46....................

CENTER DIFFERENTIAL 48..................

TRANSFER 51...............................

Page 877 of 1449

MANUAL TRANSMISSION OVERHAUL -Tightening Torque22B-11

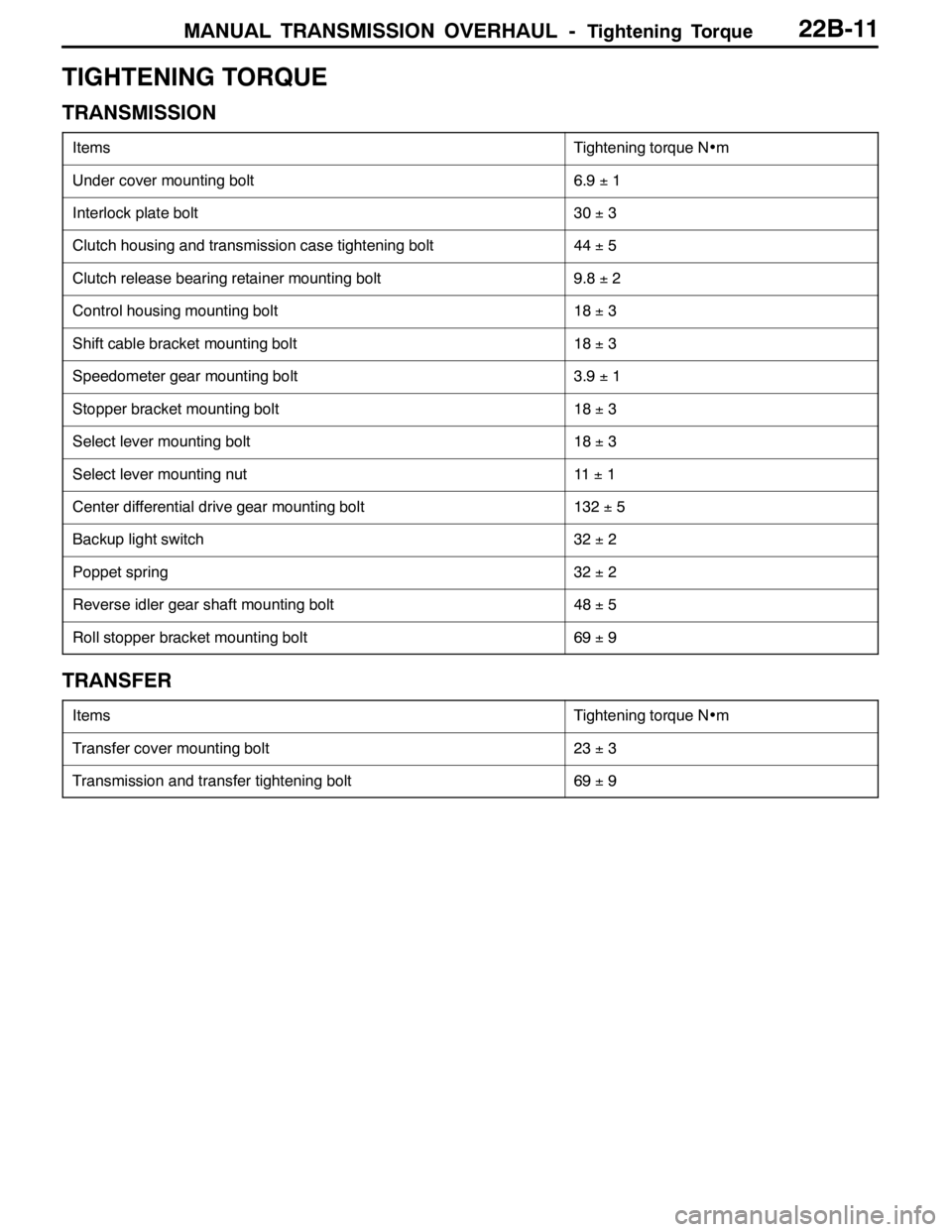

TIGHTENING TORQUE

TRANSMISSION

ItemsTightening torque N•m

Under cover mounting bolt6.9±1

Interlock plate bolt30±3

Clutch housing and transmission case tightening bolt44±5

Clutch release bearing retainer mounting bolt9.8±2

Control housing mounting bolt18±3

Shift cable bracket mounting bolt18±3

Speedometer gear mounting bolt3.9±1

Stopper bracket mounting bolt18±3

Select lever mounting bolt18±3

Select lever mounting nut11±1

Center differential drive gear mounting bolt132±5

Backup light switch32±2

Poppet spring32±2

Reverse idler gear shaft mounting bolt48±5

Roll stopper bracket mounting bolt69±9

TRANSFER

ItemsTightening torque N•m

Transfer cover mounting bolt23±3

Transmission and transfer tightening bolt69±9

Page 885 of 1449

MANUAL TRANSMISSION OVERHAUL -Transmission22B-19

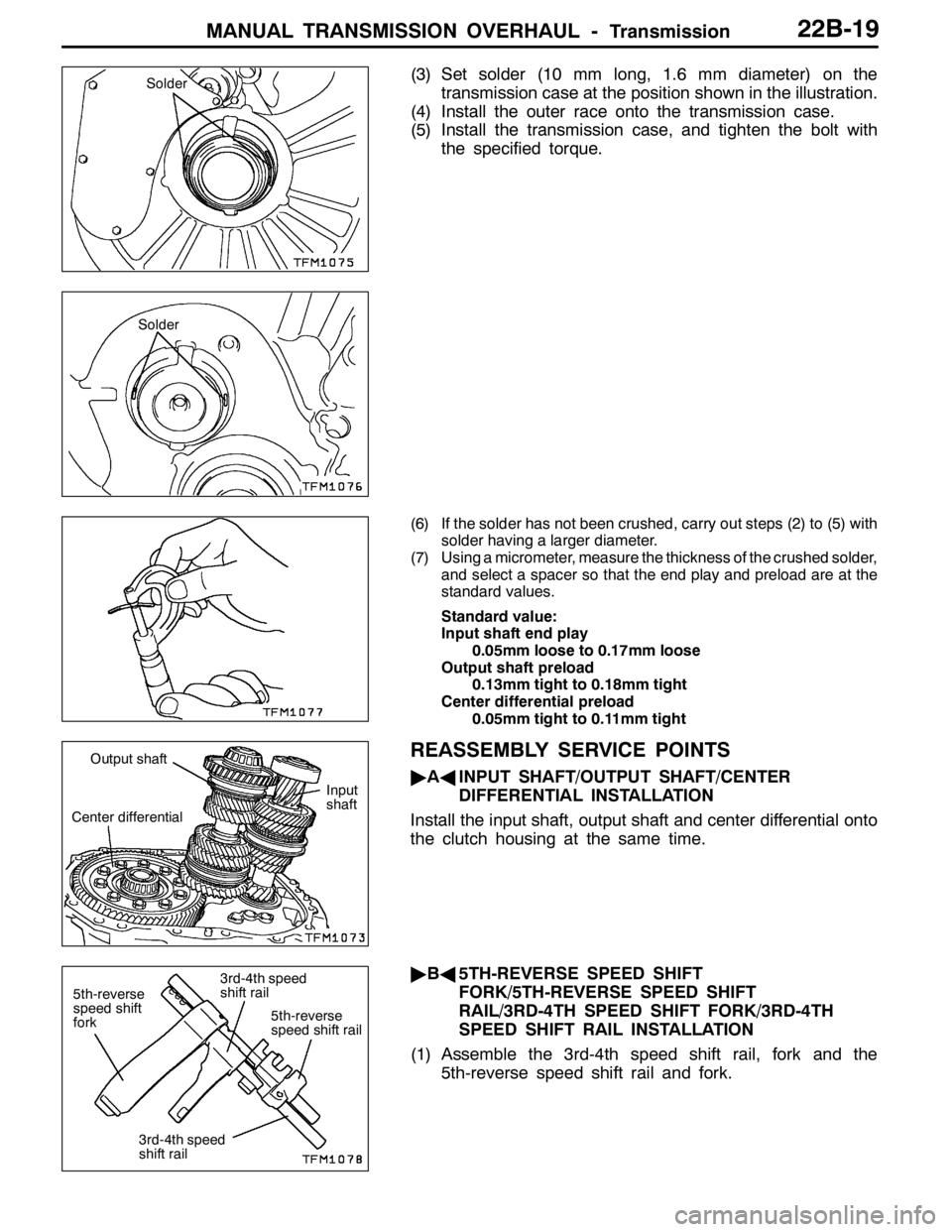

(3) Set solder (10 mm long, 1.6 mm diameter) on the

transmission case at the position shown in the illustration.

(4) Install the outer race onto the transmission case.

(5) Install the transmission case, and tighten the bolt with

the specified torque.

(6) If the solder has not been crushed, carry out steps (2) to (5) with

solder having a larger diameter.

(7) Using a micrometer, measure the thickness of the crushed solder,

and select a spacer so that the end play and preload are at the

standard values.

Standard value:

Input shaft end play

0.05mm loose to 0.17mm loose

Output shaft preload

0.13mm tight to 0.18mm tight

Center differential preload

0.05mm tight to 0.11mm tight

REASSEMBLY SERVICE POINTS

"AAINPUT SHAFT/OUTPUT SHAFT/CENTER

DIFFERENTIAL INSTALLATION

Install the input shaft, output shaft and center differential onto

the clutch housing at the same time.

"BA5TH-REVERSE SPEED SHIFT

FORK/5TH-REVERSE SPEED SHIFT

RAIL/3RD-4TH SPEED SHIFT FORK/3RD-4TH

SPEED SHIFT RAIL INSTALLATION

(1) Assemble the 3rd-4th speed shift rail, fork and the

5th-reverse speed shift rail and fork.

Solder

Solder

Output shaft

Center differentialInput

shaft

3rd-4th speed

shift rail

5th-reverse

speed shift rail 5th-reverse

speed shift

fork

3rd-4th speed

shift rail

Page 916 of 1449

MANUAL TRANSMISSION OVERHAUL -Center Differential22B-50

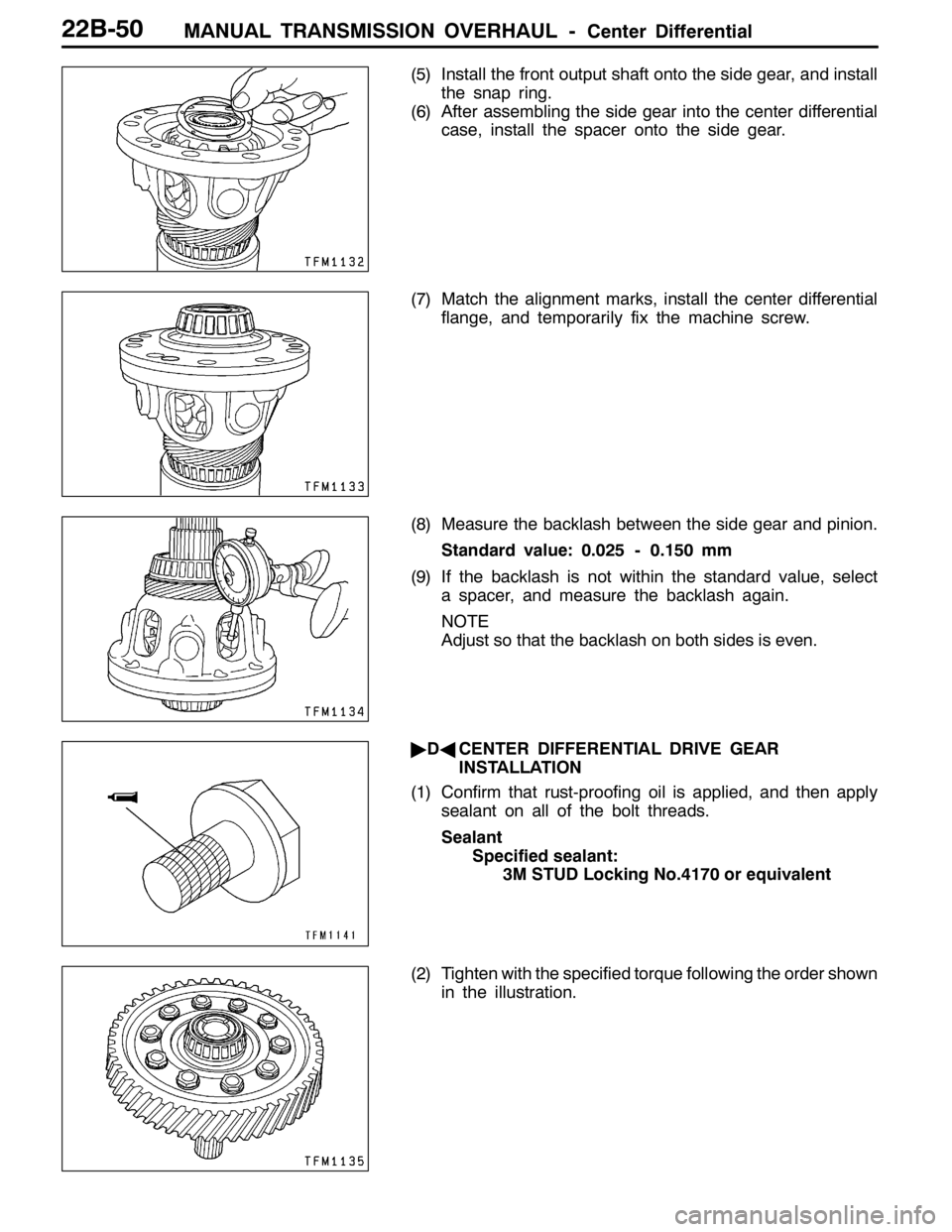

(5) Install the front output shaft onto the side gear, and install

the snap ring.

(6) After assembling the side gear into the center differential

case, install the spacer onto the side gear.

(7) Match the alignment marks, install the center differential

flange, and temporarily fix the machine screw.

(8) Measure the backlash between the side gear and pinion.

Standard value: 0.025 - 0.150 mm

(9) If the backlash is not within the standard value, select

a spacer, and measure the backlash again.

NOTE

Adjust so that the backlash on both sides is even.

"DACENTER DIFFERENTIAL DRIVE GEAR

INSTALLATION

(1) Confirm that rust-proofing oil is applied, and then apply

sealant on all of the bolt threads.

Sealant

Specified sealant:

3M STUD Locking No.4170 or equivalent

(2) Tighten with the specified torque following the order shown

in the illustration.

Page 931 of 1449

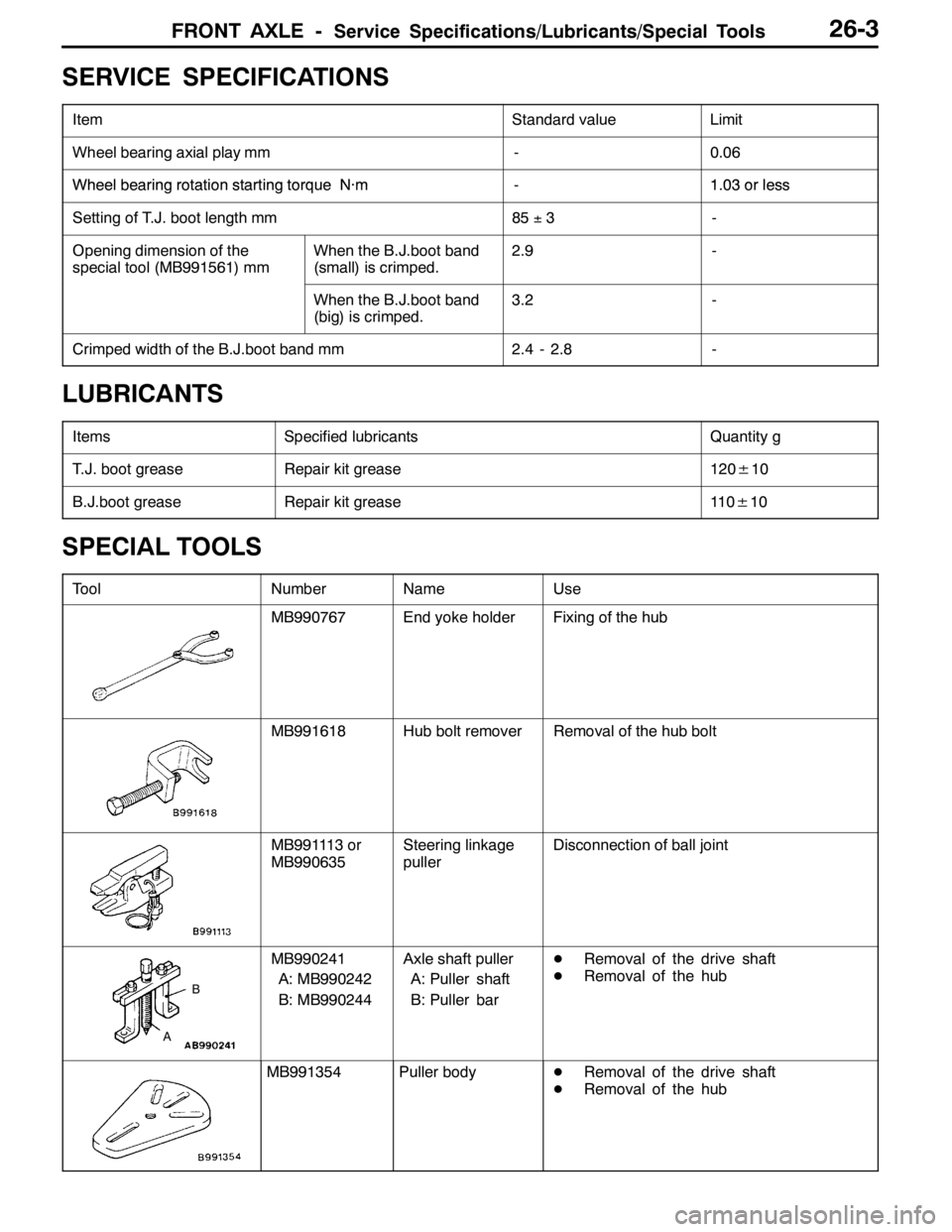

FRONT AXLE -Service Specifications/Lubricants/Special Tools26-3

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Wheel bearing axial play mm-0.06

WheelbearingrotationstartingtorqueN·m-103orlessWheelbearing rotation startingtorqueN·m-1.03orless

Setting of T.J. boot length mm85±3-

Opening dimension of the

special tool (MB991561) mmWhen the B.J.boot band

(small) is crimped.2.9-

When the B.J.boot band

(big) is crimped.3.2-

Crimped width of the B.J.boot band mm2.4 - 2.8-

LUBRICANTS

ItemsSpecified lubricantsQuantity g

T.J. boot greaseRepair kit grease120±10

B.J.boot greaseRepair kit grease11 0±10

SPECIAL TOOLS

ToolNumberNameUse

MB990767End yoke holderFixing of the hub

MB991618Hub bolt removerRemoval of the hub bolt

MB991113 or

MB990635Steering linkage

pullerDisconnection of ball joint

A

B

MB990241

A: MB990242

B: MB990244Axle shaft puller

A: Puller shaft

B: Puller barDRemoval of the drive shaft

DRemoval of the hub

MB991354Puller bodyDRemoval of the drive shaft

DRemoval of the hub

Page 932 of 1449

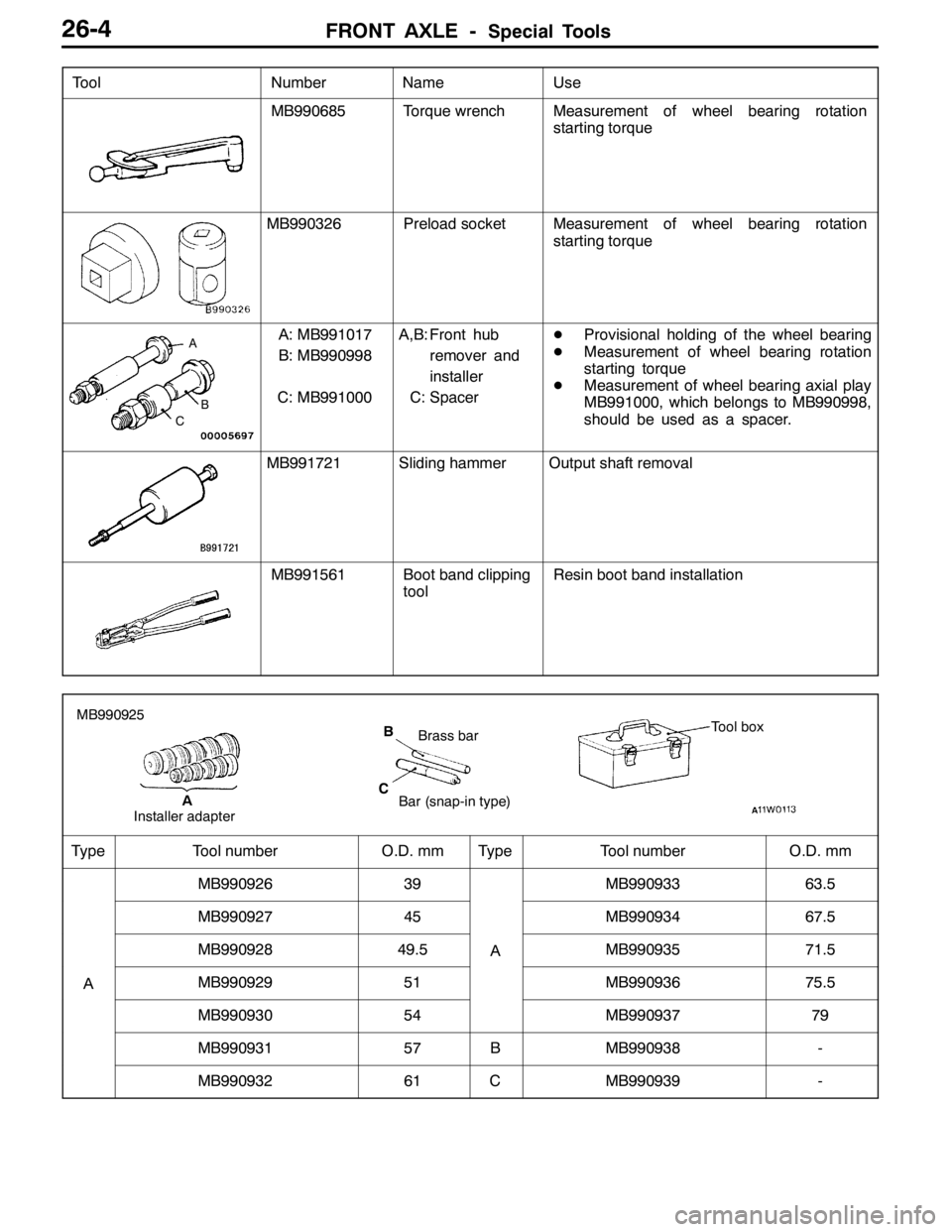

FRONT AXLE -Special Tools26-4

Tool UseName Number

MB990685Torque wrenchMeasurement of wheel bearing rotation

starting torque

MB990326Preload socketMeasurement of wheel bearing rotation

starting torque

A

B

C

A: MB991017

B: MB990998

C: MB991000A,B: Front hub

remover and

installer

C: SpacerDProvisional holding of the wheel bearing

DMeasurement of wheel bearing rotation

starting torque

DMeasurement of wheel bearing axial play

MB991000, which belongs to MB990998,

should be used as a spacer.

MB991721Sliding hammerOutput shaft removal

MB991561Boot band clipping

toolResin boot band installation

MB990925

Brass bar

Installer adapterTool box

Bar (snap-in type) ACB

TypeTool numberO.D. mmTypeTool numberO.D. mm

MB99092639MB99093363.5

MB99092745MB99093467.5

MB99092849.5AMB99093571.5

AMB99092951MB99093675.5

MB99093054MB99093779

MB99093157BMB990938-

MB99093261CMB990939-