weight MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1116 of 1449

STEERING -General Information37A-2

GENERAL INFORMATION

The system has been equipped with the MOMO

leather 3-spoke-type steering wheel with built-in

SRS airbag.

The steering column is equipped with tilt steering

mechanism.

The power steering is an integral rack and piniontype that combines the steering gear and linkage

into one light-weight and compact assembly.

The steering system uses a vane oil pump with

a fluid flow control system, so that steering effort

varies with engine speed.

ItemLancer EVOLUTION-

Steering wheelTypeMOMO 3-spoke typeg

Outside diameter mm380

365

Maximum number of turns2.1

Steering columnColumn mechanismTilt steering

Power steering typeIntegral type

Oil pumpTypeVariable capacity type (vane pump)pp

Basic discharge amount cm3/rev.9.6

Relief pressure MPa8.3 - 9.0

Reservoir typeSeparate type

Pressure switchEquipped

Steering gear and linkageTypeRack and pinionggg

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius)68.61

Rack stroke mm146

Steering angleInner wheel32°gg

Outer wheel (for reference)27°

Power steering fluidSpecified lubricantsAutomatic transmission fluid DEXRON IIg

Quantity LApproximately 1.0

Page 1144 of 1449

STEERING - Power Steering Oil Pump/Power Steering Oil Hoses37A-30

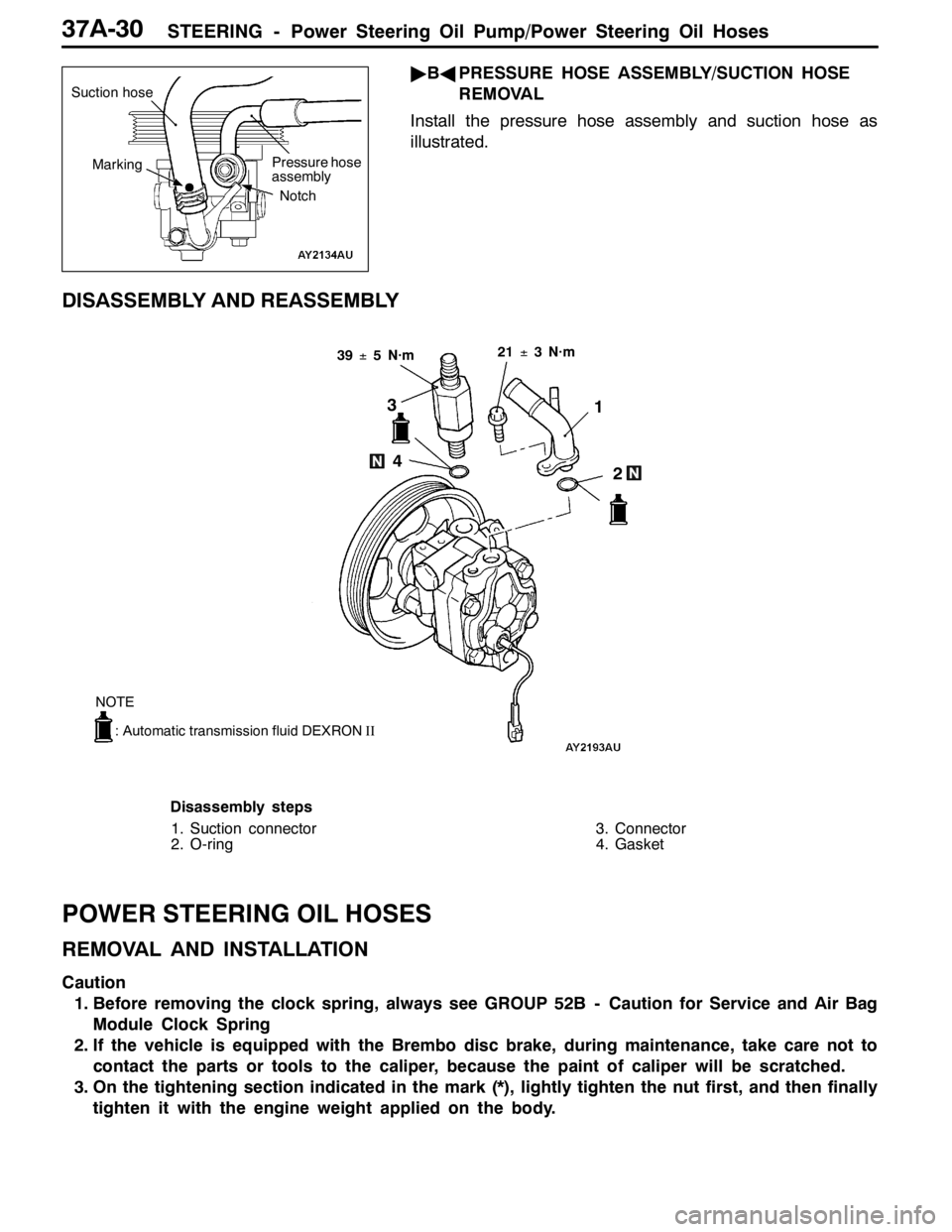

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

REMOVAL

Install the pressure hose assembly and suction hose as

illustrated.

DISASSEMBLY AND REASSEMBLY

21±3 N·m

3

4

2 1

39±5 N·m

: Automatic transmission fluid DEXRONII

NOTE

Disassembly steps

1. Suction connector

2. O-ring3. Connector

4. Gasket

POWER STEERING OIL HOSES

REMOVAL AND INSTALLATION

Caution

1. Before removing the clock spring, always see GROUP 52B - Caution for Service and Air Bag

Module Clock Spring

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper, because the paint of caliper will be scratched.

3. On the tightening section indicated in the mark (*), lightly tighten the nut first, and then finally

tighten it with the engine weight applied on the body.

Suction hose

Pressure hose

assembly

Marking

Notch

Page 1345 of 1449

CHASSIS ELECTRICAL -Headlamp Assembly54A-25

4. If the fuel tank is not full, place a weight in luggage room

of vehicle to simulate weight of a full tank 0.8 kg per litre.

5. There should be no other load in the vehicle other than

driver or substituted weight of approximately 75 kg placed

in driver’s position.

6. Thoroughly clean headlamp lenses.

7. Place the vehicle on a level floor, perpendicular to a flat

screen 10m away from the bulb center - marks on the

headlamp lens.

8. Rock vehicle sideways to allow vehicle to assume its

normal position.

9. Bounce the front suspension through three (3) oscillations

by applying the body weight to hood or bumper.

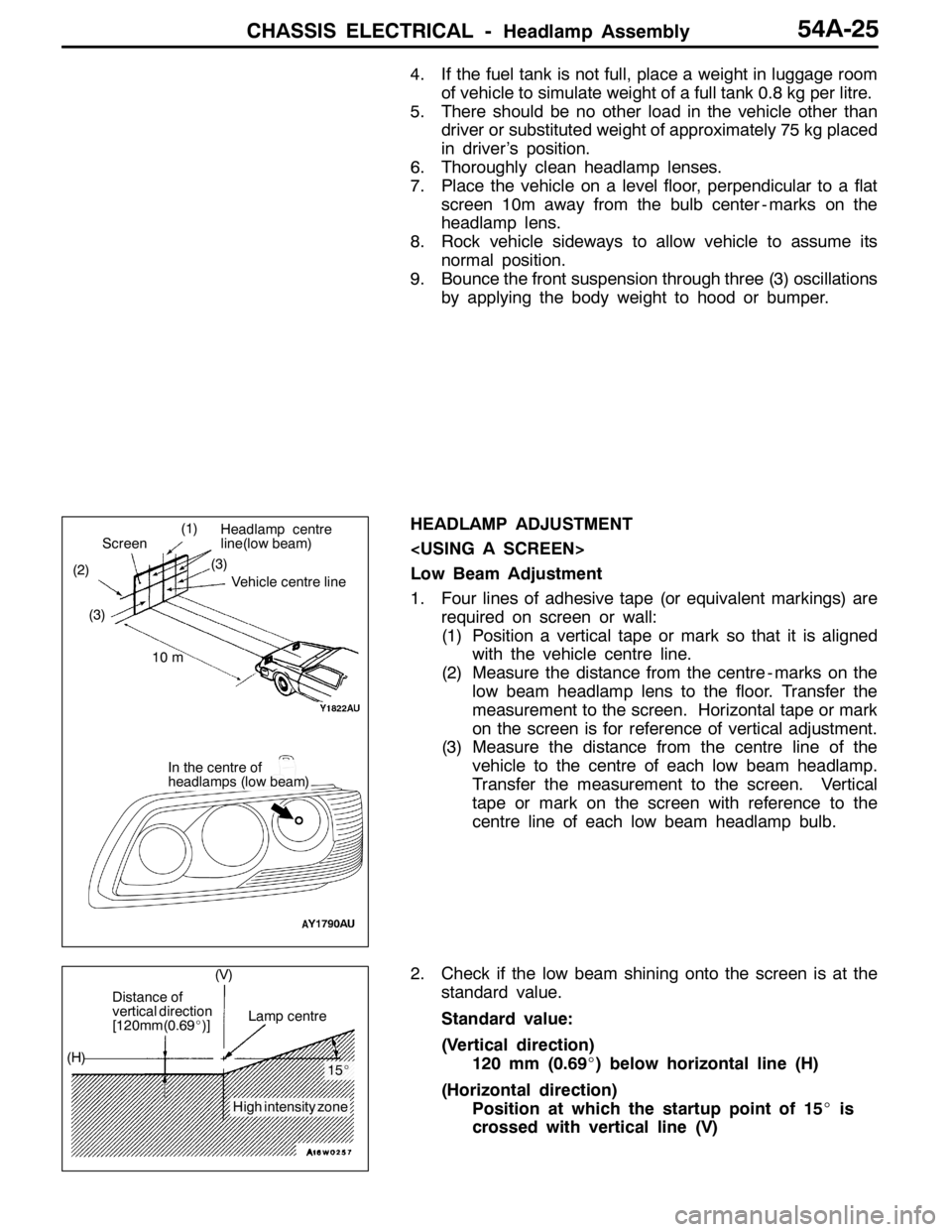

HEADLAMP ADJUSTMENT

Low Beam Adjustment

1. Four lines of adhesive tape (or equivalent markings) are

required on screen or wall:

(1) Position a vertical tape or mark so that it is aligned

with the vehicle centre line.

(2) Measure the distance from the centre - marks on the

low beam headlamp lens to the floor. Transfer the

measurement to the screen. Horizontal tape or mark

on the screen is for reference of vertical adjustment.

(3) Measure the distance from the centre line of the

vehicle to the centre of each low beam headlamp.

Transfer the measurement to the screen. Vertical

tape or mark on the screen with reference to the

centre line of each low beam headlamp bulb.

2. Check if the low beam shining onto the screen is at the

standard value.

Standard value:

(Vertical direction)

120 mm (0.69_) below horizontal line (H)

(Horizontal direction)

Position at which the startup point of 15_is

crossed with vertical line (V)

(1)

(2)(3)

Headlamp centre

line(low beam)

Vehicle centre line

Screen

10 m

In the centre of

headlamps (low beam) (3)

Distance of

vertical direction

[120mm(0.69_)]Lamp centre

15_

High intensity zone (H)(V)