service MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1129 of 1449

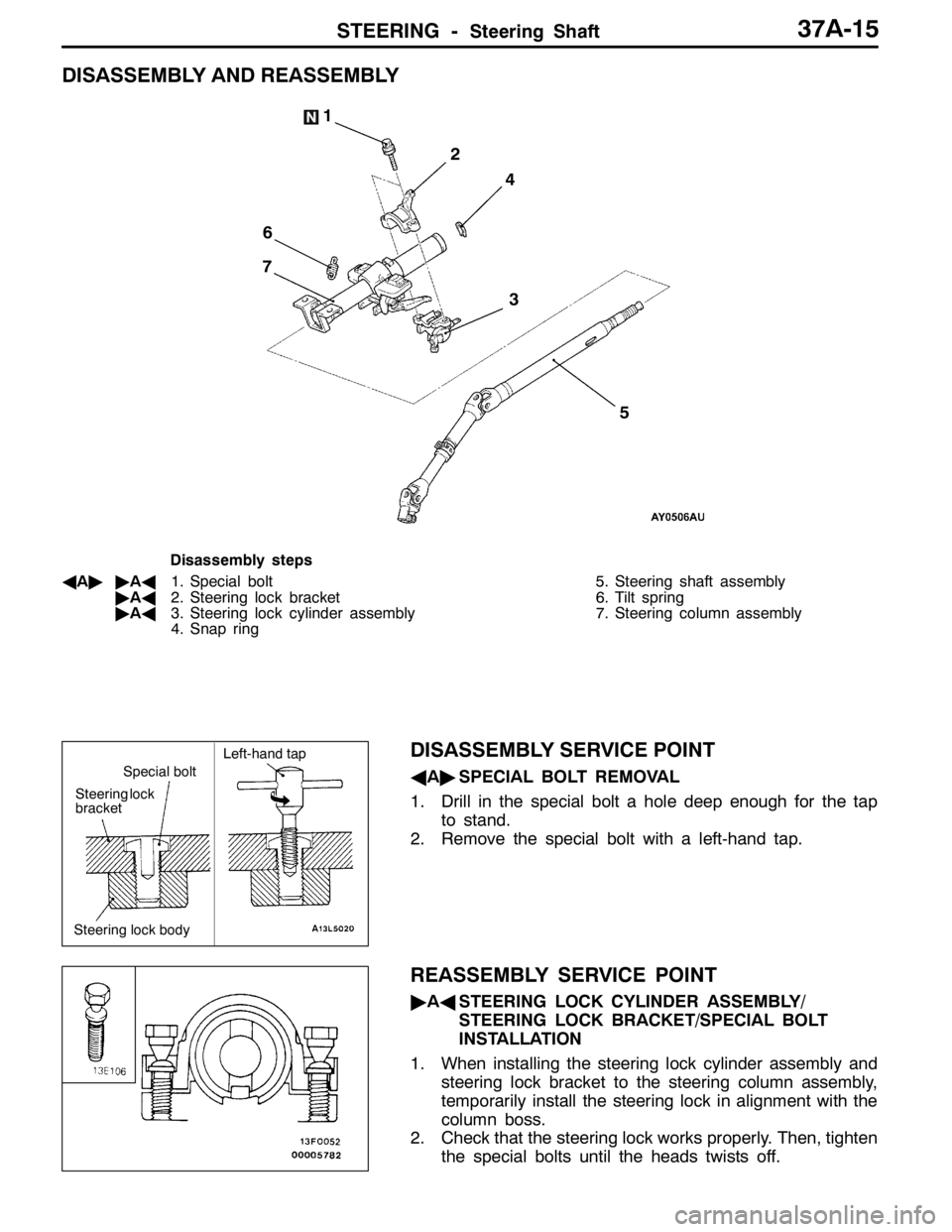

STEERING -Steering Shaft37A-15

DISASSEMBLY AND REASSEMBLY

1

2

3 4

5 6

7

Disassembly steps

AA""AA1. Special bolt

"AA2. Steering lock bracket

"AA3. Steering lock cylinder assembly

4. Snap ring5. Steering shaft assembly

6. Tilt spring

7. Steering column assembly

DISASSEMBLY SERVICE POINT

AA"SPECIAL BOLT REMOVAL

1. Drill in the special bolt a hole deep enough for the tap

to stand.

2. Remove the special bolt with a left-hand tap.

REASSEMBLY SERVICE POINT

"AASTEERING LOCK CYLINDER ASSEMBLY/

STEERING LOCK BRACKET/SPECIAL BOLT

INSTALLATION

1. When installing the steering lock cylinder assembly and

steering lock bracket to the steering column assembly,

temporarily install the steering lock in alignment with the

column boss.

2. Check that the steering lock works properly. Then, tighten

the special bolts until the heads twists off.

Steering lock

bracket

Steering lock body

Special boltLeft-hand tap

Page 1132 of 1449

STEERING - Power Steering Gear Box and Linkage37A-18

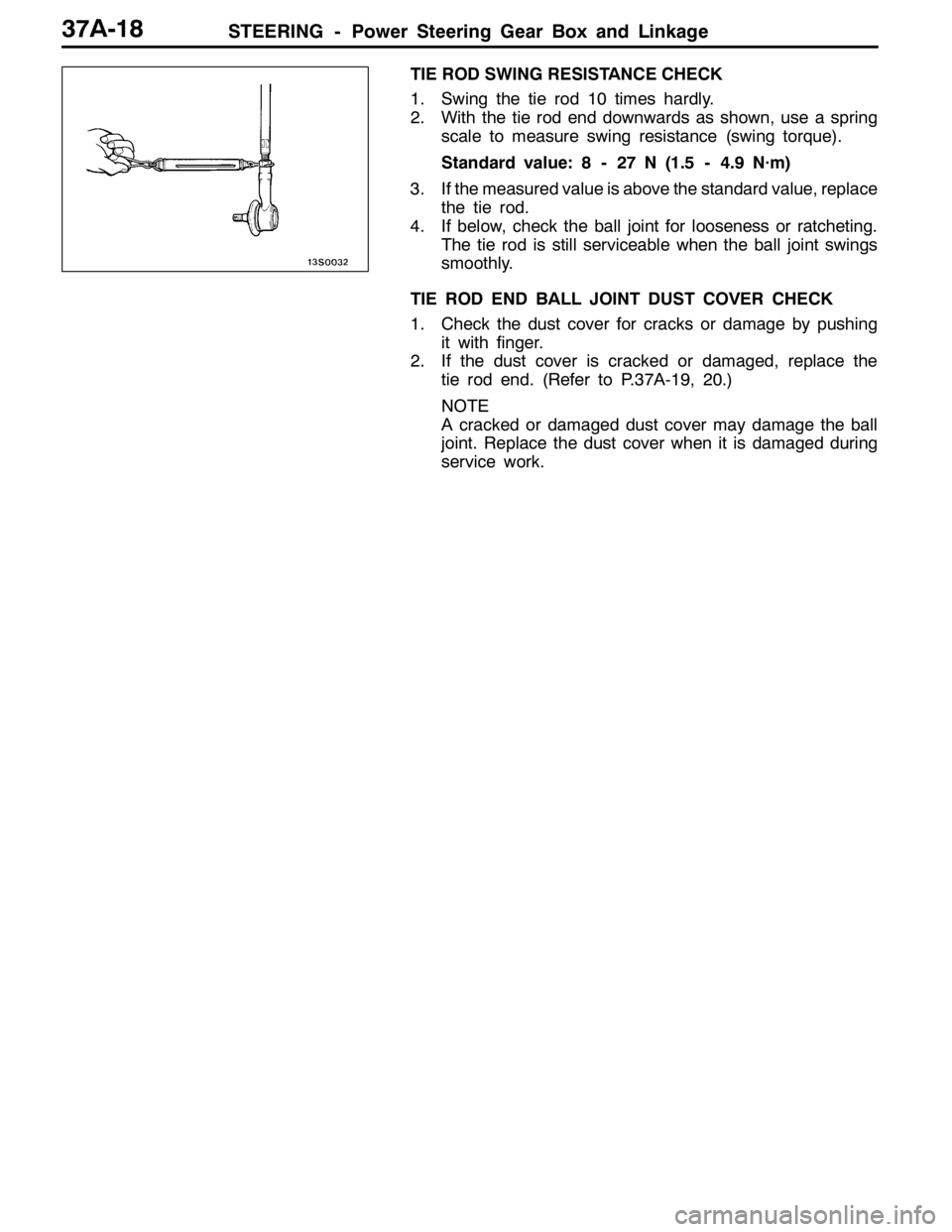

TIE ROD SWING RESISTANCE CHECK

1. Swing the tie rod 10 times hardly.

2. With the tie rod end downwards as shown, use a spring

scale to measure swing resistance (swing torque).

Standard value: 8 - 27 N (1.5 - 4.9 N·m)

3. If the measured value is above the standard value, replace

the tie rod.

4. If below, check the ball joint for looseness or ratcheting.

The tie rod is still serviceable when the ball joint swings

smoothly.

TIE ROD END BALL JOINT DUST COVER CHECK

1. Check the dust cover for cracks or damage by pushing

it with finger.

2. If the dust cover is cracked or damaged, replace the

tie rod end. (Refer to P.37A-19, 20.)

NOTE

A cracked or damaged dust cover may damage the ball

joint. Replace the dust cover when it is damaged during

service work.

Page 1136 of 1449

STEERING - Power Steering Gear Box and Linkage37A-22

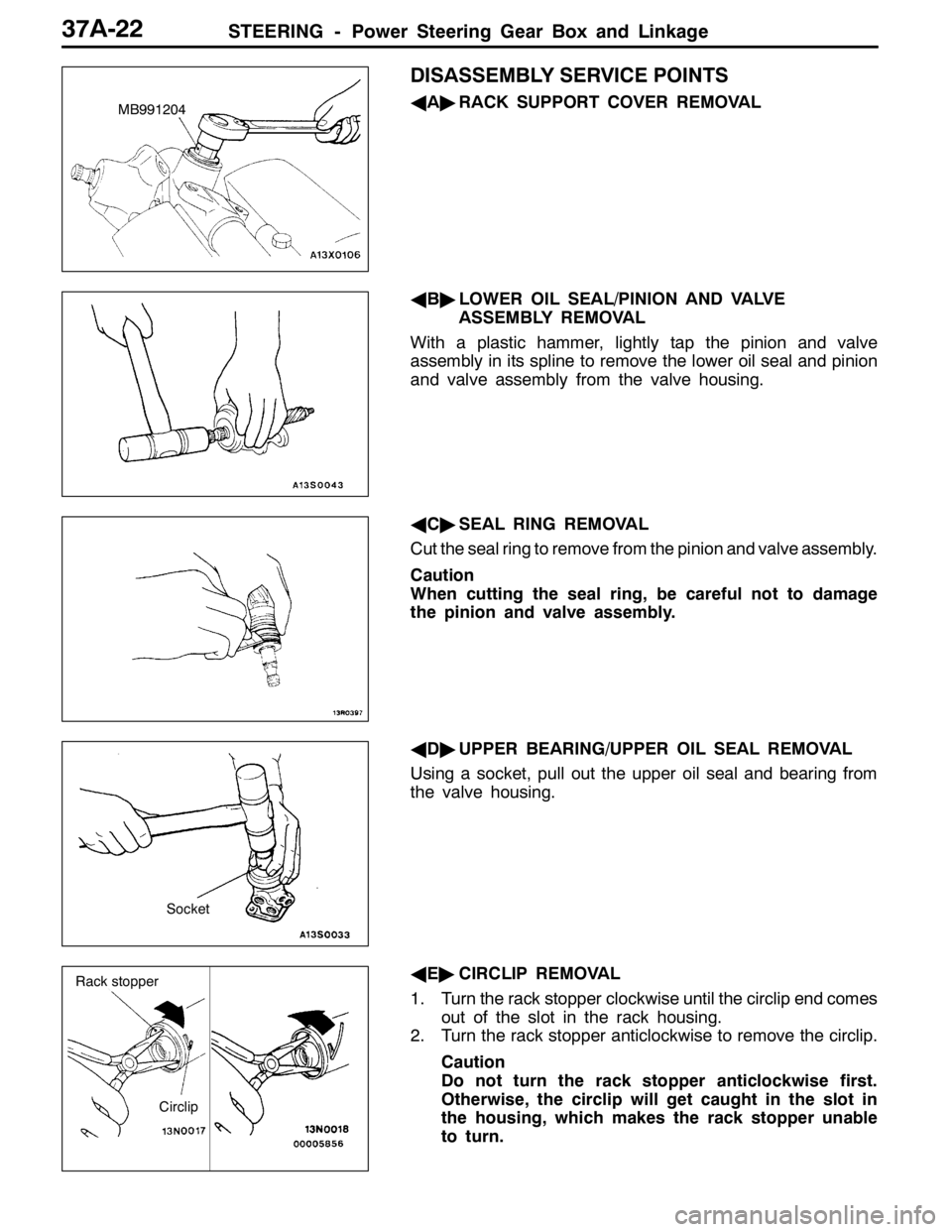

DISASSEMBLY SERVICE POINTS

AA"RACK SUPPORT COVER REMOVAL

AB"LOWER OIL SEAL/PINION AND VALVE

ASSEMBLY REMOVAL

With a plastic hammer, lightly tap the pinion and valve

assembly in its spline to remove the lower oil seal and pinion

and valve assembly from the valve housing.

AC"SEAL RING REMOVAL

Cut the seal ring to remove from the pinion and valve assembly.

Caution

When cutting the seal ring, be careful not to damage

the pinion and valve assembly.

AD"UPPER BEARING/UPPER OIL SEAL REMOVAL

Using a socket, pull out the upper oil seal and bearing from

the valve housing.

AE"CIRCLIP REMOVAL

1. Turn the rack stopper clockwise until the circlip end comes

out of the slot in the rack housing.

2. Turn the rack stopper anticlockwise to remove the circlip.

Caution

Do not turn the rack stopper anticlockwise first.

Otherwise, the circlip will get caught in the slot in

the housing, which makes the rack stopper unable

to turn.MB991204

Socket

Circlip

Rack stopper

Page 1138 of 1449

STEERING - Power Steering Gear Box and Linkage37A-24

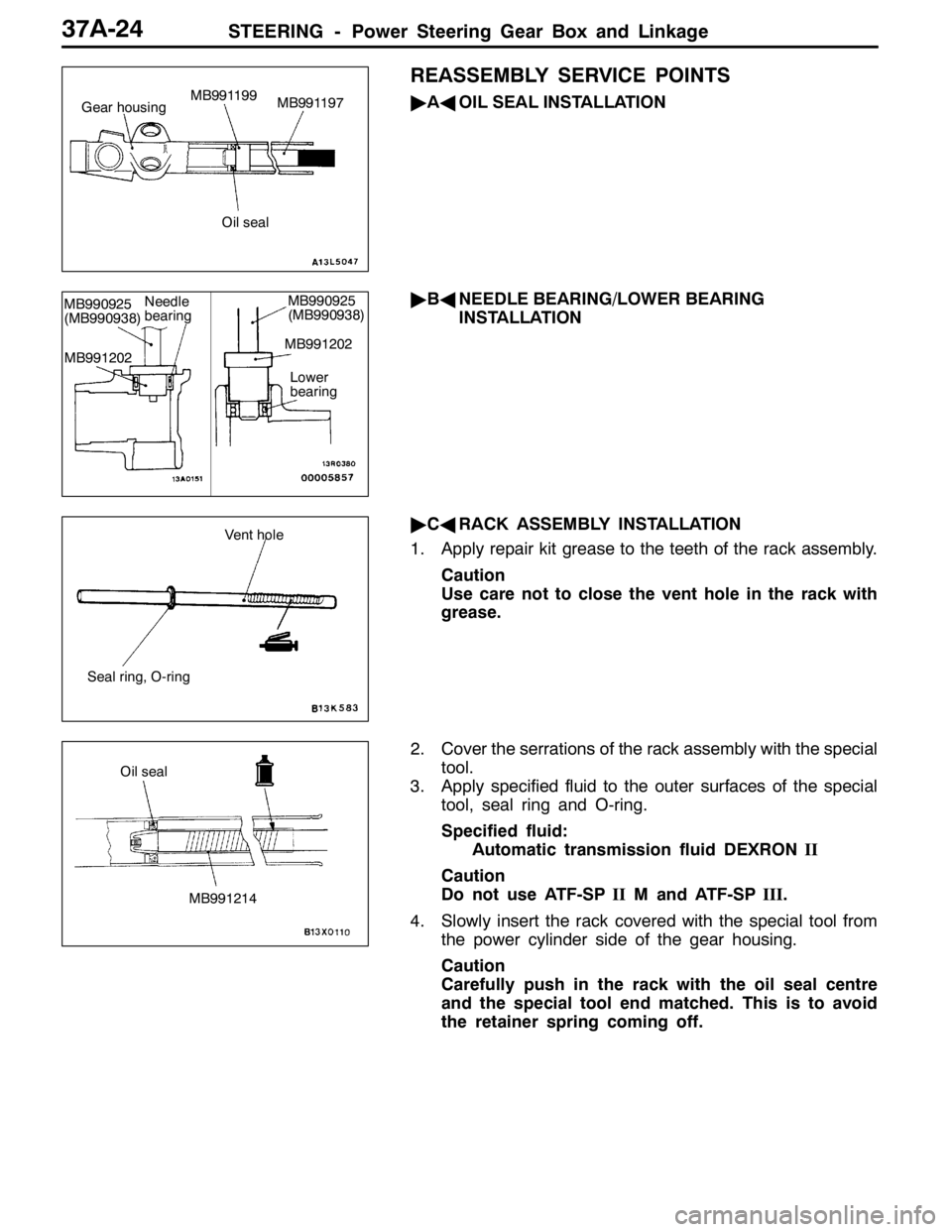

REASSEMBLY SERVICE POINTS

"AAOIL SEAL INSTALLATION

"BANEEDLE BEARING/LOWER BEARING

INSTALLATION

"CARACK ASSEMBLY INSTALLATION

1. Apply repair kit grease to the teeth of the rack assembly.

Caution

Use care not to close the vent hole in the rack with

grease.

2. Cover the serrations of the rack assembly with the special

tool.

3. Apply specified fluid to the outer surfaces of the special

tool, seal ring and O-ring.

Specified fluid:

Automatic transmission fluid DEXRONII

Caution

Do not use ATF-SPIIM and ATF-SPIII.

4. Slowly insert the rack covered with the special tool from

the power cylinder side of the gear housing.

Caution

Carefully push in the rack with the oil seal centre

and the special tool end matched. This is to avoid

the retainer spring coming off.MB991197

Gear housing

Oil seal MB991199

Needle

bearingMB990925

(MB990938)

MB991202

Lower

bearing MB990925

(MB990938)

MB991202

Vent hole

Seal ring, O-ring

MB991214 Oil seal

Page 1142 of 1449

STEERING - Power Steering Gear Box and Linkage37A-28

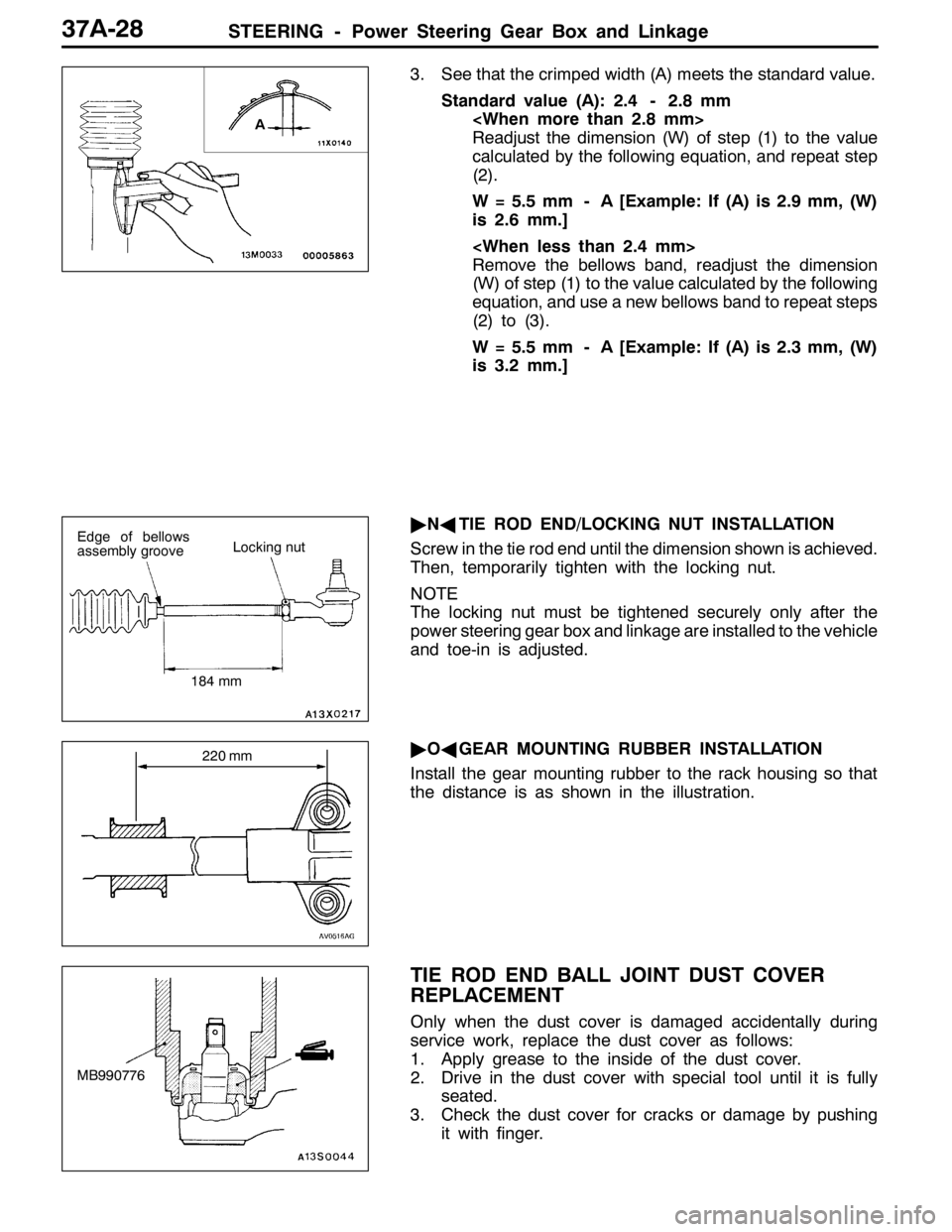

3. See that the crimped width (A) meets the standard value.

Standard value (A): 2.4-2.8 mm

Readjust the dimension (W) of step (1) to the value

calculated by the following equation, and repeat step

(2).

W = 5.5 mm-A [Example: If (A) is 2.9 mm, (W)

is 2.6 mm.]

Remove the bellows band, readjust the dimension

(W) of step (1) to the value calculated by the following

equation, and use a new bellows band to repeat steps

(2) to (3).

W = 5.5 mm-A [Example: If (A) is 2.3 mm, (W)

is 3.2 mm.]

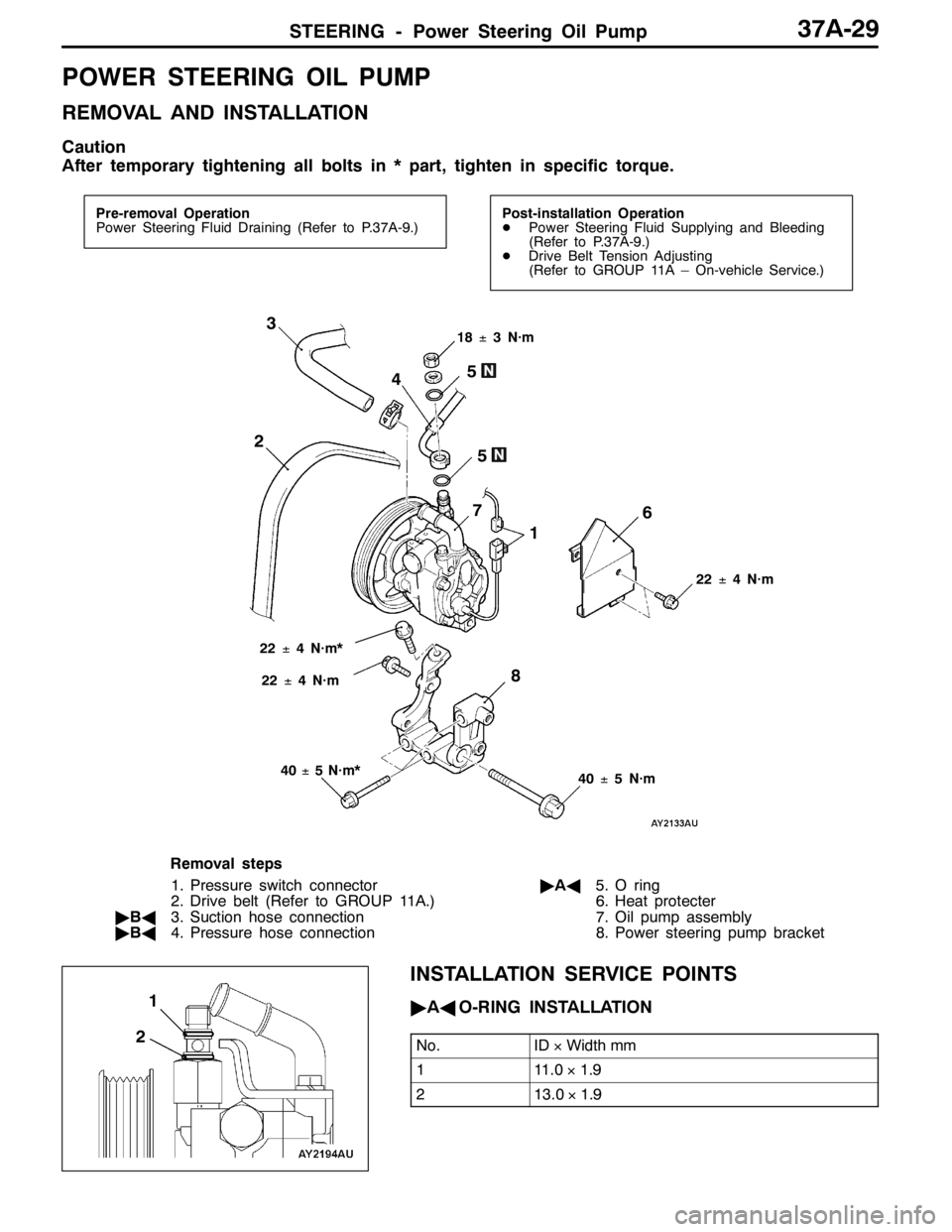

"NATIE ROD END/LOCKING NUT INSTALLATION

Screw in the tie rod end until the dimension shown is achieved.

Then, temporarily tighten with the locking nut.

NOTE

The locking nut must be tightened securely only after the

power steering gear box and linkage are installed to the vehicle

and toe-in is adjusted.

"OAGEAR MOUNTING RUBBER INSTALLATION

Install the gear mounting rubber to the rack housing so that

the distance is as shown in the illustration.

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

Only when the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Apply grease to the inside of the dust cover.

2. Drive in the dust cover with special tool until it is fully

seated.

3. Check the dust cover for cracks or damage by pushing

it with finger.

A

Edge of bellows

assembly grooveLocking nut

184 mm

220 mm

MB990776

Page 1143 of 1449

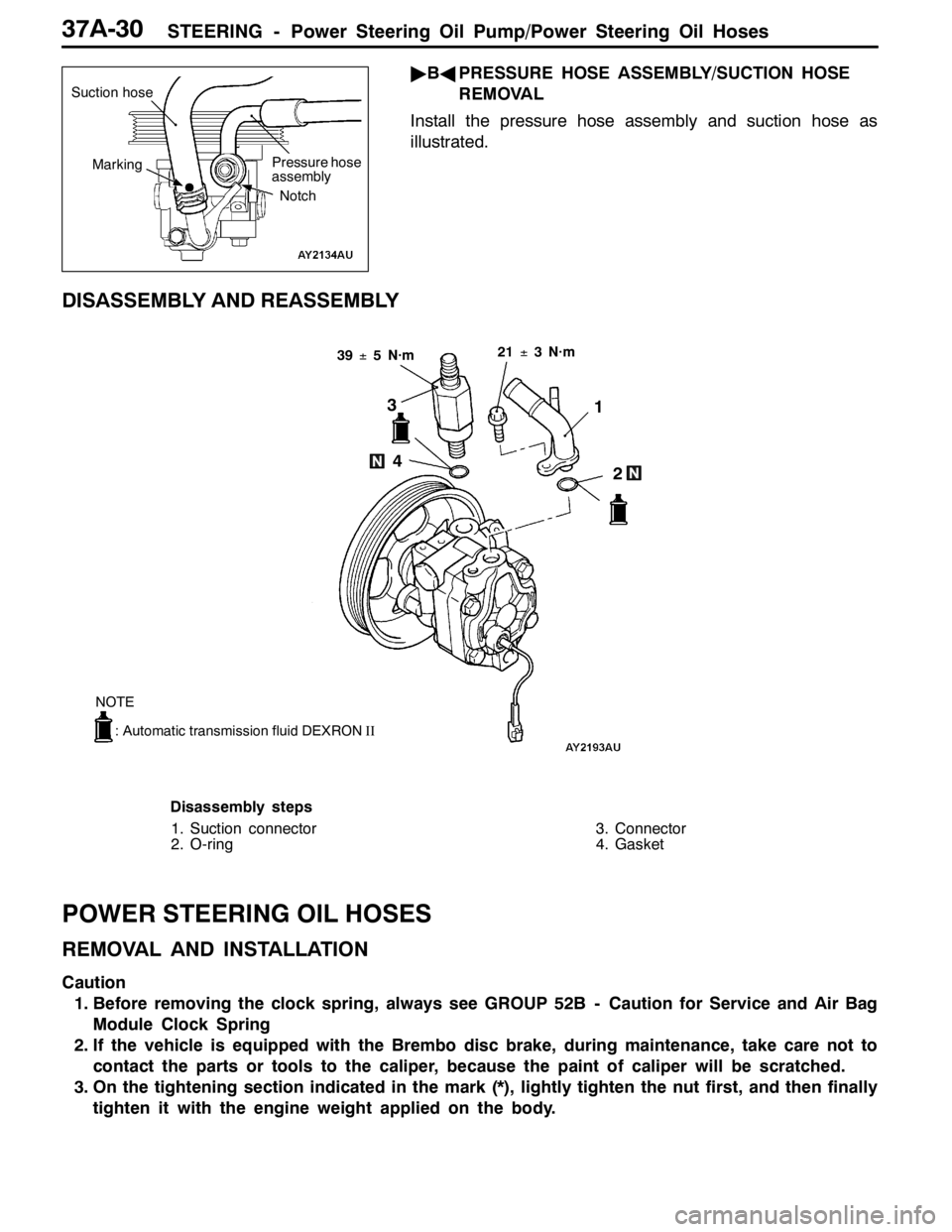

STEERING - Power Steering Oil Pump37A-29

POWER STEERING OIL PUMP

REMOVAL AND INSTALLATION

Caution

After temporary tightening all bolts in * part, tighten in specific torque.

Pre-removal Operation

Power Steering Fluid Draining (Refer to P.37A-9.)Post-installation Operation

DPower Steering Fluid Supplying and Bleeding

(Refer to P.37A-9.)

DDrive Belt Tension Adjusting

(Refer to GROUP 11A – On-vehicle Service.)

22±4 N·m

8

40±5 N·m 18±3 N·m

3

45

2

5

22±4 N·m*

1 7

6

40±5 N·m* 22±4 N·m

Removal steps

1. Pressure switch connector

2. Drive belt (Refer to GROUP 11A.)

"BA3. Suction hose connection

"BA4. Pressure hose connection"AA5. O ring

6. Heat protecter

7. Oil pump assembly

8. Power steering pump bracket

INSTALLATION SERVICE POINTS

"AAO-RING INSTALLATION

No.ID×Width mm

111.0×1.9

213.0×1.9

21

Page 1144 of 1449

STEERING - Power Steering Oil Pump/Power Steering Oil Hoses37A-30

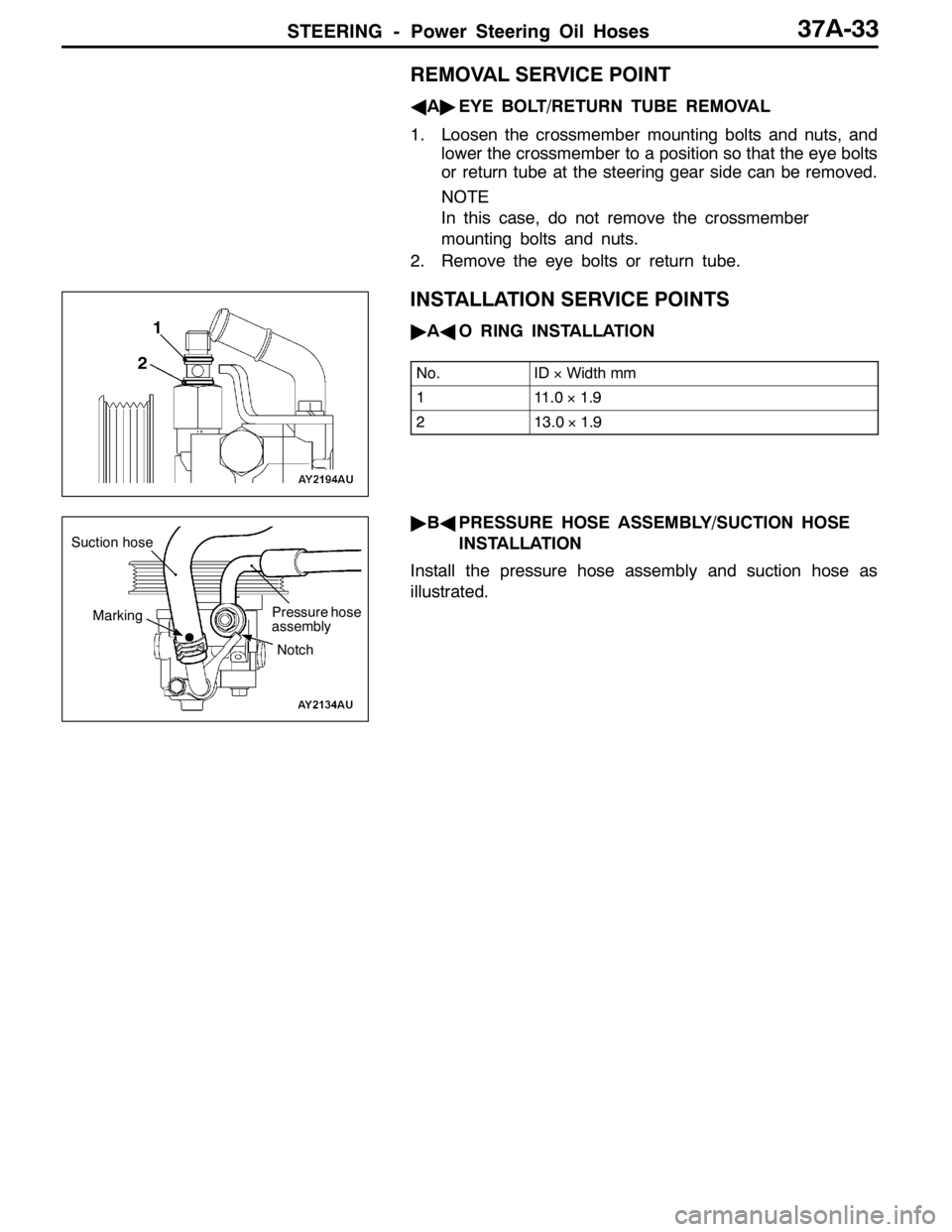

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

REMOVAL

Install the pressure hose assembly and suction hose as

illustrated.

DISASSEMBLY AND REASSEMBLY

21±3 N·m

3

4

2 1

39±5 N·m

: Automatic transmission fluid DEXRONII

NOTE

Disassembly steps

1. Suction connector

2. O-ring3. Connector

4. Gasket

POWER STEERING OIL HOSES

REMOVAL AND INSTALLATION

Caution

1. Before removing the clock spring, always see GROUP 52B - Caution for Service and Air Bag

Module Clock Spring

2. If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to

contact the parts or tools to the caliper, because the paint of caliper will be scratched.

3. On the tightening section indicated in the mark (*), lightly tighten the nut first, and then finally

tighten it with the engine weight applied on the body.

Suction hose

Pressure hose

assembly

Marking

Notch

Page 1147 of 1449

STEERING - Power Steering Oil Hoses37A-33

REMOVAL SERVICE POINT

AA"EYE BOLT/RETURN TUBE REMOVAL

1. Loosen the crossmember mounting bolts and nuts, and

lower the crossmember to a position so that the eye bolts

or return tube at the steering gear side can be removed.

NOTE

In this case, do not remove the crossmember

mounting bolts and nuts.

2. Remove the eye bolts or return tube.

INSTALLATION SERVICE POINTS

"AAO RING INSTALLATION

No.ID×Width mm

111.0×1.9

213.0×1.9

"BAPRESSURE HOSE ASSEMBLY/SUCTION HOSE

INSTALLATION

Install the pressure hose assembly and suction hose as

illustrated.

1

2

Suction hose

Pressure hose

assembly

Marking

Notch

Page 1149 of 1449

42-1

BODY

CONTENTS

HOOD2 .................................

ON-VEHICLE SERVICE 2..................

Adjustment of Clearance around Hood 2......

Adjustment of Alignment of Hood Stepped

Portion and Hood Striker 2..................

Adjustment of Hood Height 2.................

HOOD 3..................................

FENDER4 ..............................

SPECIAL TOOL 4.........................

FENDER 5................................

FUEL FILLER DOOR7 .................

STRUT TOWER BAR AND REAR END

CROSS BAR8 ...........................

WINDOW GLASS9 .....................

ADHESIVE 9..............................

SPECIAL TOOLS 9........................

WINDOW REPAIR 9.......................

WINDSHIELD 11...........................

REAR WINDOW GLASS 16................

DOORS19 ..............................

SERVICE SPECIFICATIONS 19.............ADHESIVES 19............................

SPECIAL TOOLS 19.......................

TROUBLESHOOTING 20...................

ON-VEHICLE SERVICE 20.................

Door Adjustment 20.........................

Door Window Glass Adjustment 21...........

Adjustment and Replacement during Power

Window Malfunction 22......................

Power Window Safety Mechanism Check 22..

Power Window Timer Function Check 22......

Door Outside Handle Looseness Check 23....

Power Window Operation Current Check 23...

Circuit Breaker Check 23....................

Power Window Check 23....................

Door Inside Handle Looseness Check and

Adjustment 24...............................

DOOR ASSEMBLY 25......................

DOOR TRIM AND

WATERPROOF FILM 27....................

DOOR GLASS AND REGULATOR 32.......

DOOR HANDLE AND LATCH 35...........

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP 38.......

TRUNK LID41 ..........................

Page 1150 of 1449

BODY -Hood42-2

HOOD

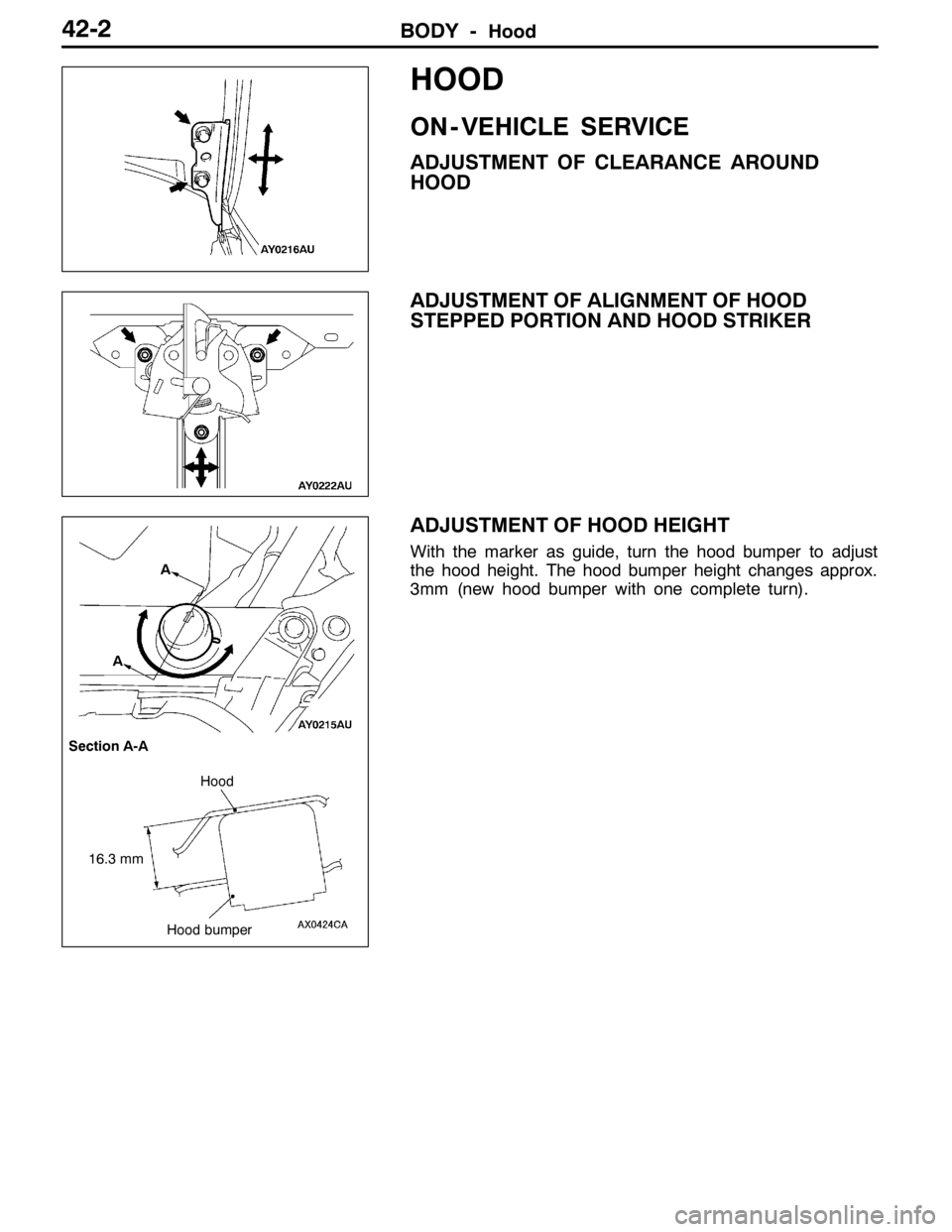

ON - VEHICLE SERVICE

ADJUSTMENT OF CLEARANCE AROUND

HOOD

ADJUSTMENT OF ALIGNMENT OF HOOD

STEPPED PORTION AND HOOD STRIKER

ADJUSTMENT OF HOOD HEIGHT

With the marker as guide, turn the hood bumper to adjust

the hood height. The hood bumper height changes approx.

3mm (new hood bumper with one complete turn).

A

A

Section A-A

16.3 mmHood

Hood bumper