service MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1227 of 1449

INTERIOR -Instrument Panel52A-9

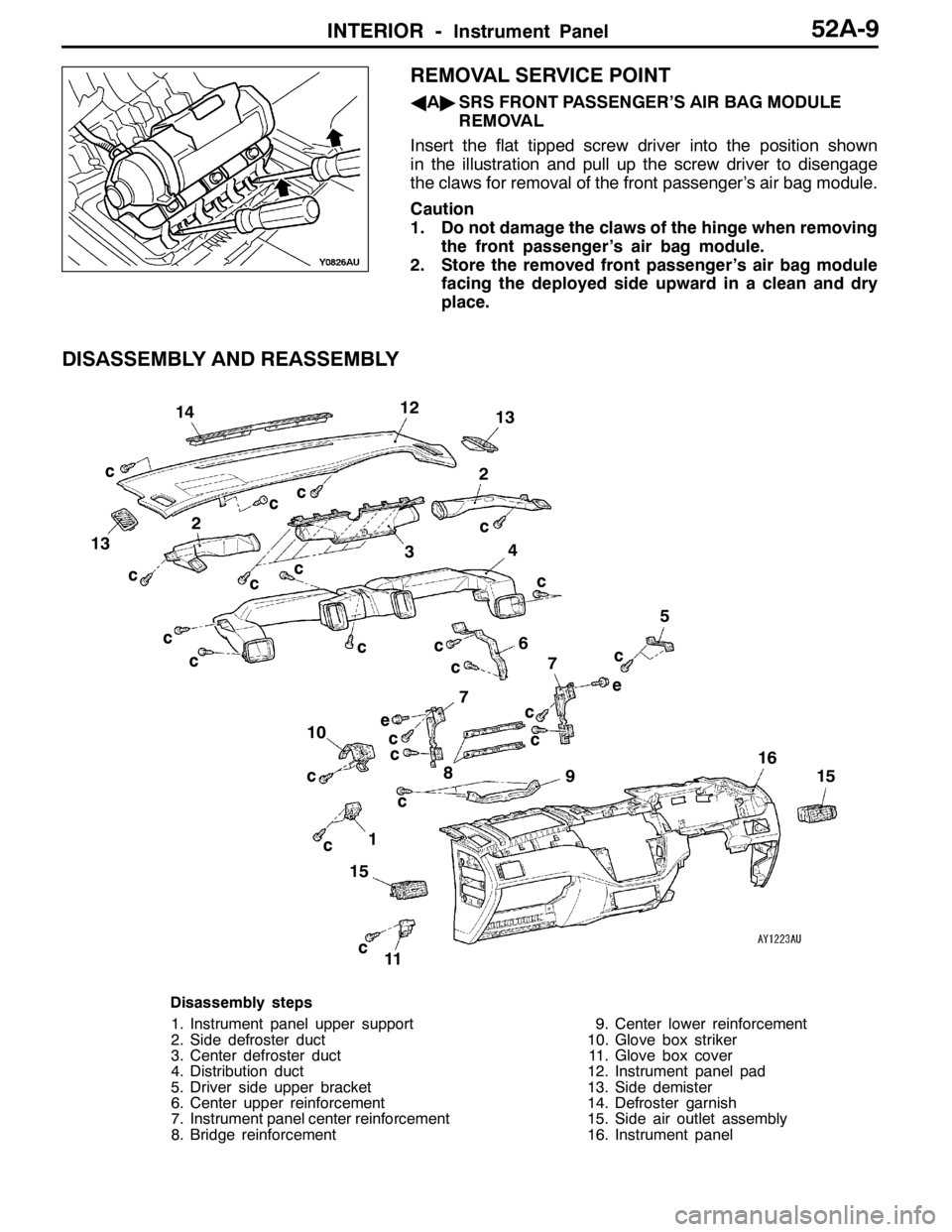

REMOVAL SERVICE POINT

AA"SRS FRONT PASSENGER’S AIR BAG MODULE

REMOVAL

Insert the flat tipped screw driver into the position shown

in the illustration and pull up the screw driver to disengage

the claws for removal of the front passenger’s air bag module.

Caution

1. Do not damage the claws of the hinge when removing

the front passenger’s air bag module.

2. Store the removed front passenger’s air bag module

facing the deployed side upward in a clean and dry

place.

DISASSEMBLY AND REASSEMBLY

1314

15 c12

13

2

32

4

6

75

7

10

18

916

15

11 cc

c

c

cccc

cc

c

cc

e

c

c e

c

c

c c

c

c

Disassembly steps

1. Instrument panel upper support

2. Side defroster duct

3. Center defroster duct

4. Distribution duct

5. Driver side upper bracket

6. Center upper reinforcement

7. Instrument panel center reinforcement

8. Bridge reinforcement9. Center lower reinforcement

10. Glove box striker

11. Glove box cover

12. Instrument panel pad

13. Side demister

14. Defroster garnish

15. Side air outlet assembly

16. Instrument panel

Page 1232 of 1449

INTERIOR -Rear Floor Console52A-14

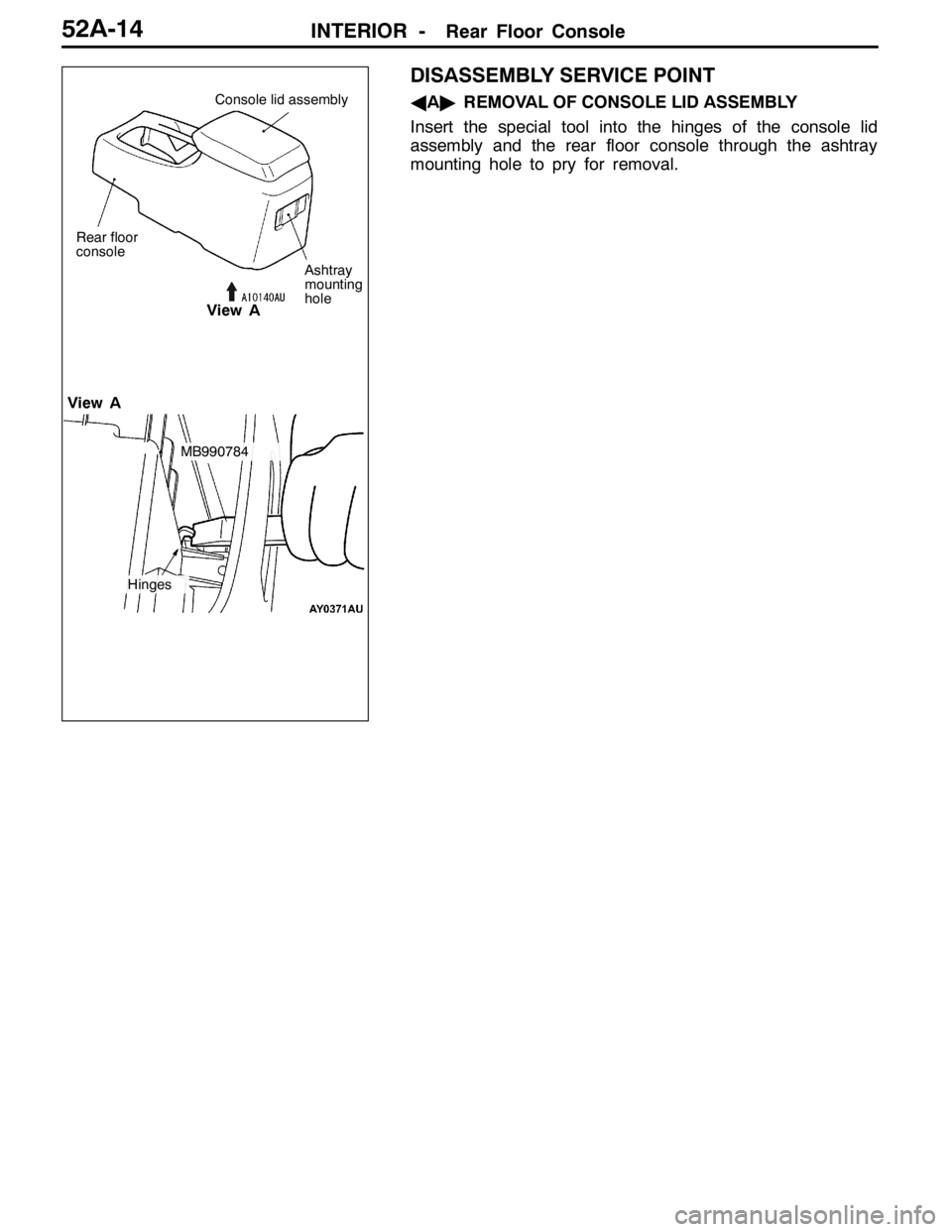

DISASSEMBLY SERVICE POINT

AA"REMOVAL OF CONSOLE LID ASSEMBLY

Insert the special tool into the hinges of the console lid

assembly and the rear floor console through the ashtray

mounting hole to pry for removal.Console lid assembly

Ashtray

mounting

hole Rear floor

console

MB990784

Hinges

View A

View A

Page 1235 of 1449

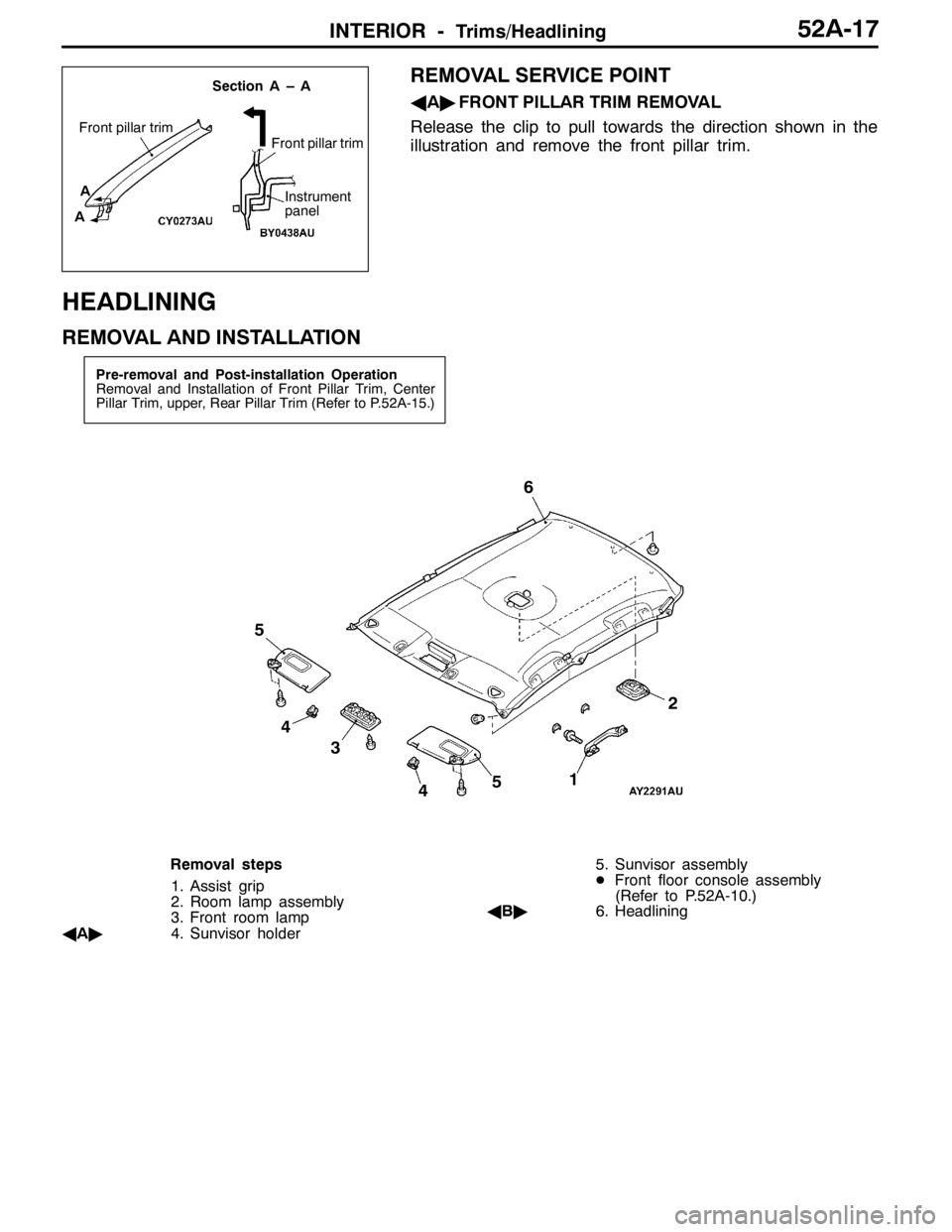

INTERIOR -Trims/Headlining52A-17

REMOVAL SERVICE POINT

AA"FRONT PILLAR TRIM REMOVAL

Release the clip to pull towards the direction shown in the

illustration and remove the front pillar trim.

HEADLINING

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Removal and Installation of Front Pillar Trim, Center

Pillar Trim, upper, Rear Pillar Trim (Refer to P.52A-15.)

12

3 4 56

45

Removal steps

1. Assist grip

2. Room lamp assembly

3. Front room lamp

AA"4. Sunvisor holder5. Sunvisor assembly

DFront floor console assembly

(Refer to P.52A-10.)

AB"6. Headlining

Section A – A

Front pillar trim

A

AFront pillar trim

Instrument

panel

Page 1236 of 1449

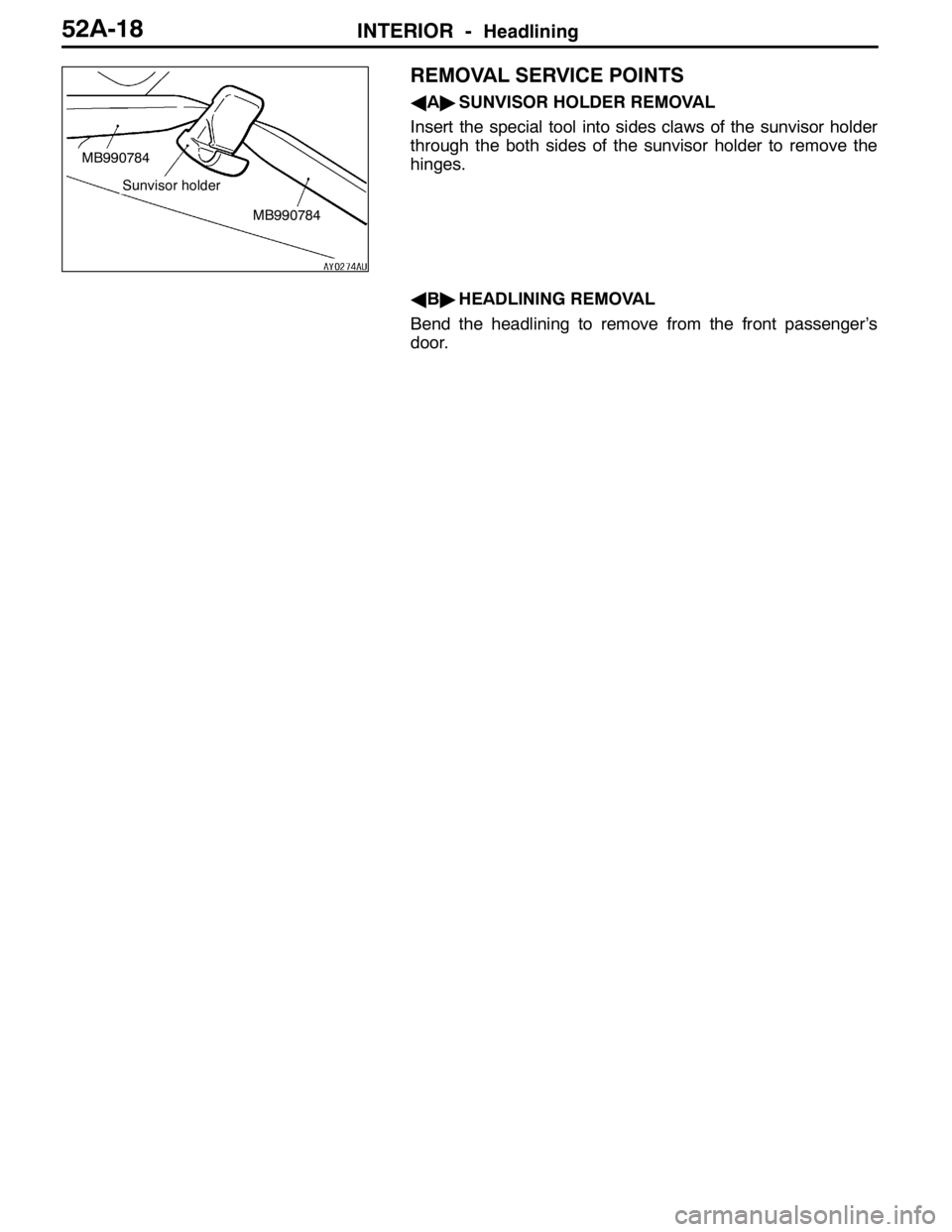

INTERIOR -Headlining52A-18

REMOVAL SERVICE POINTS

AA"SUNVISOR HOLDER REMOVAL

Insert the special tool into sides claws of the sunvisor holder

through the both sides of the sunvisor holder to remove the

hinges.

AB"HEADLINING REMOVAL

Bend the headlining to remove from the front passenger’s

door.

Sunvisor holder

MB990784

MB990784

Page 1237 of 1449

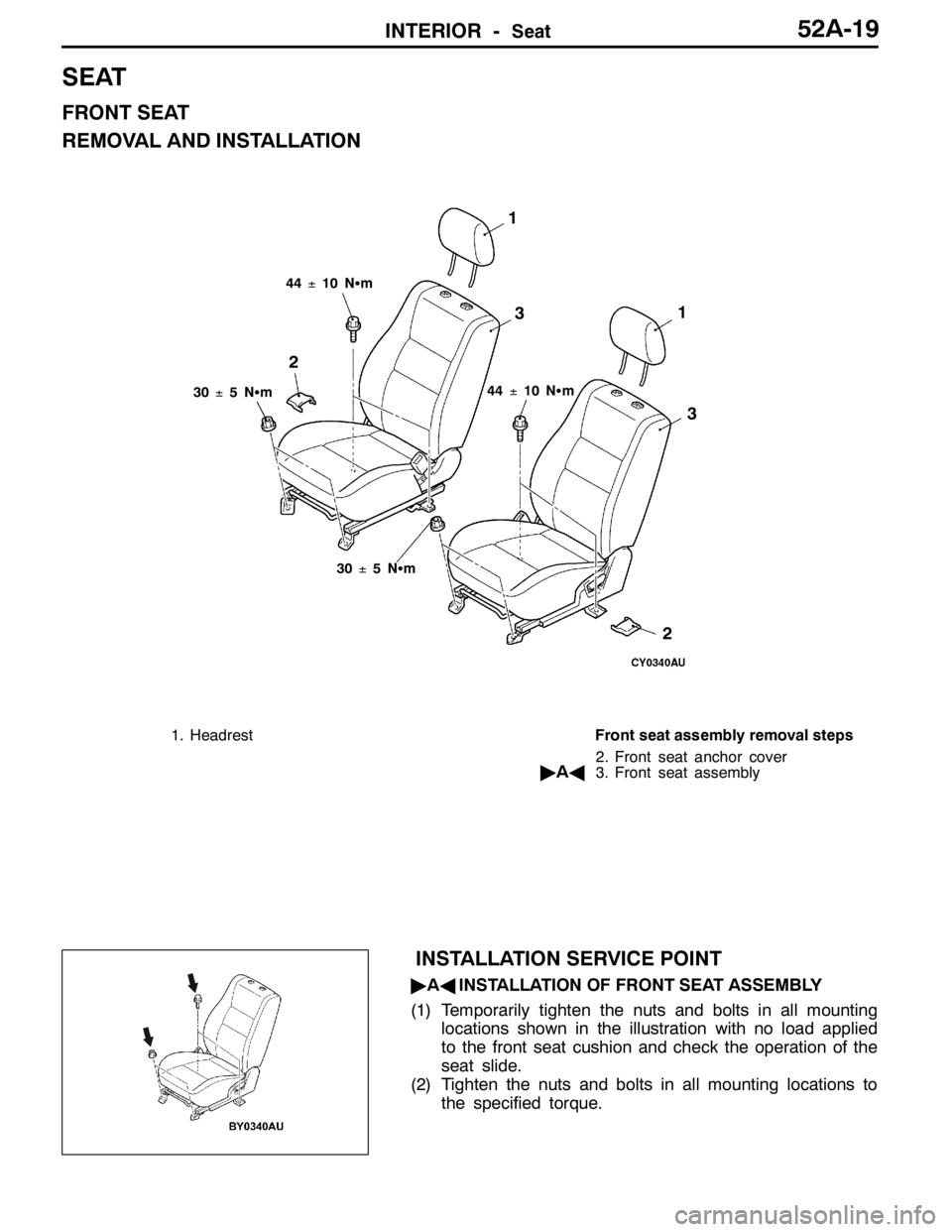

INTERIOR -Seat52A-19

SEAT

FRONT SEAT

REMOVAL AND INSTALLATION

1

1

2

2 3

3

44±10 NSm

44±10 NSm

30±5NSm

30±5NSm

1. HeadrestFront seat assembly removal steps

2. Front seat anchor cover

"AA3. Front seat assembly

INSTALLATION SERVICE POINT

"AAINSTALLATION OF FRONT SEAT ASSEMBLY

(1) Temporarily tighten the nuts and bolts in all mounting

locations shown in the illustration with no load applied

to the front seat cushion and check the operation of the

seat slide.

(2) Tighten the nuts and bolts in all mounting locations to

the specified torque.

Page 1240 of 1449

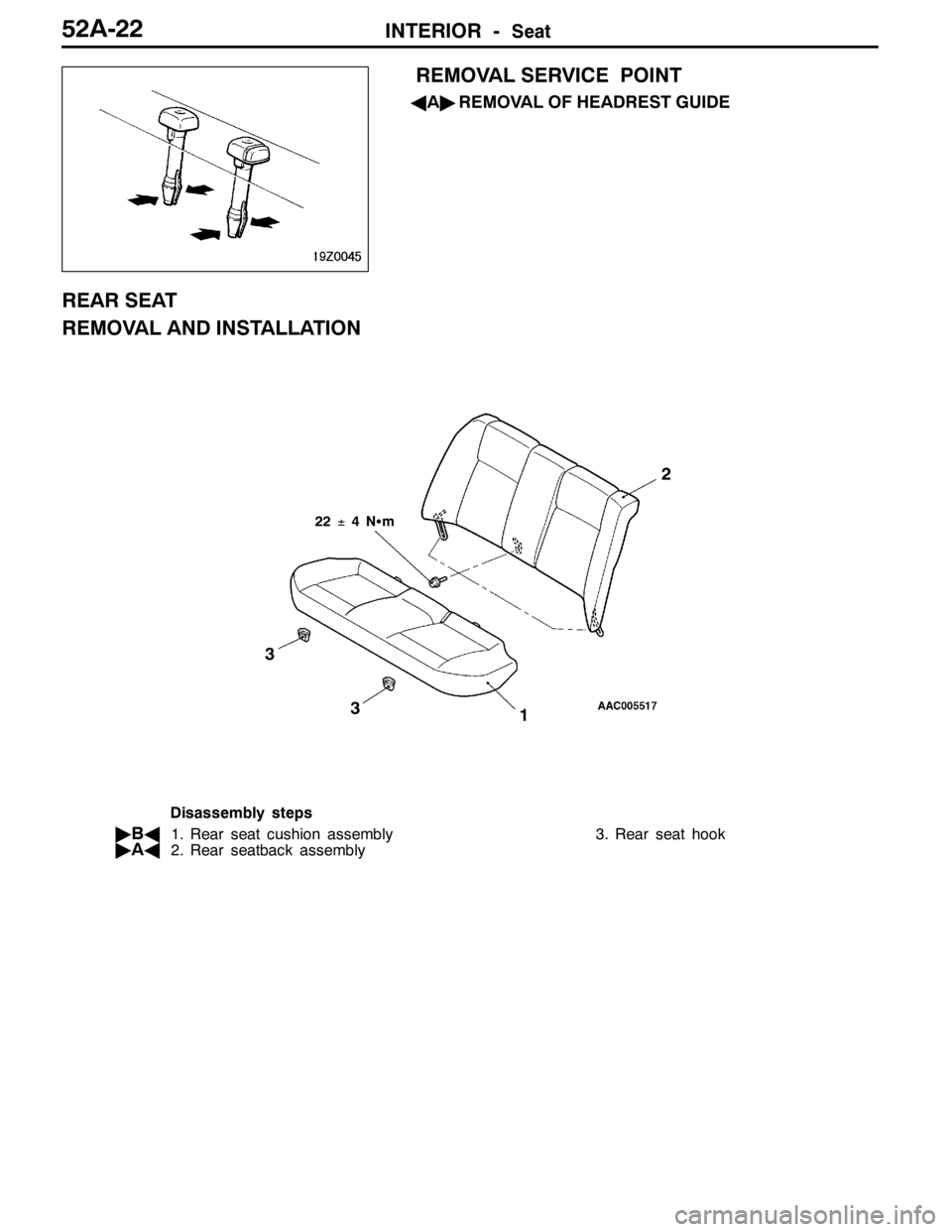

INTERIOR -Seat52A-22

REMOVAL SERVICE POINT

AA"REMOVAL OF HEADREST GUIDE

REAR SEAT

REMOVAL AND INSTALLATION

12

3

22±4NSm

3

Disassembly steps

"BA1. Rear seat cushion assembly

"AA2. Rear seatback assembly3. Rear seat hook

Page 1241 of 1449

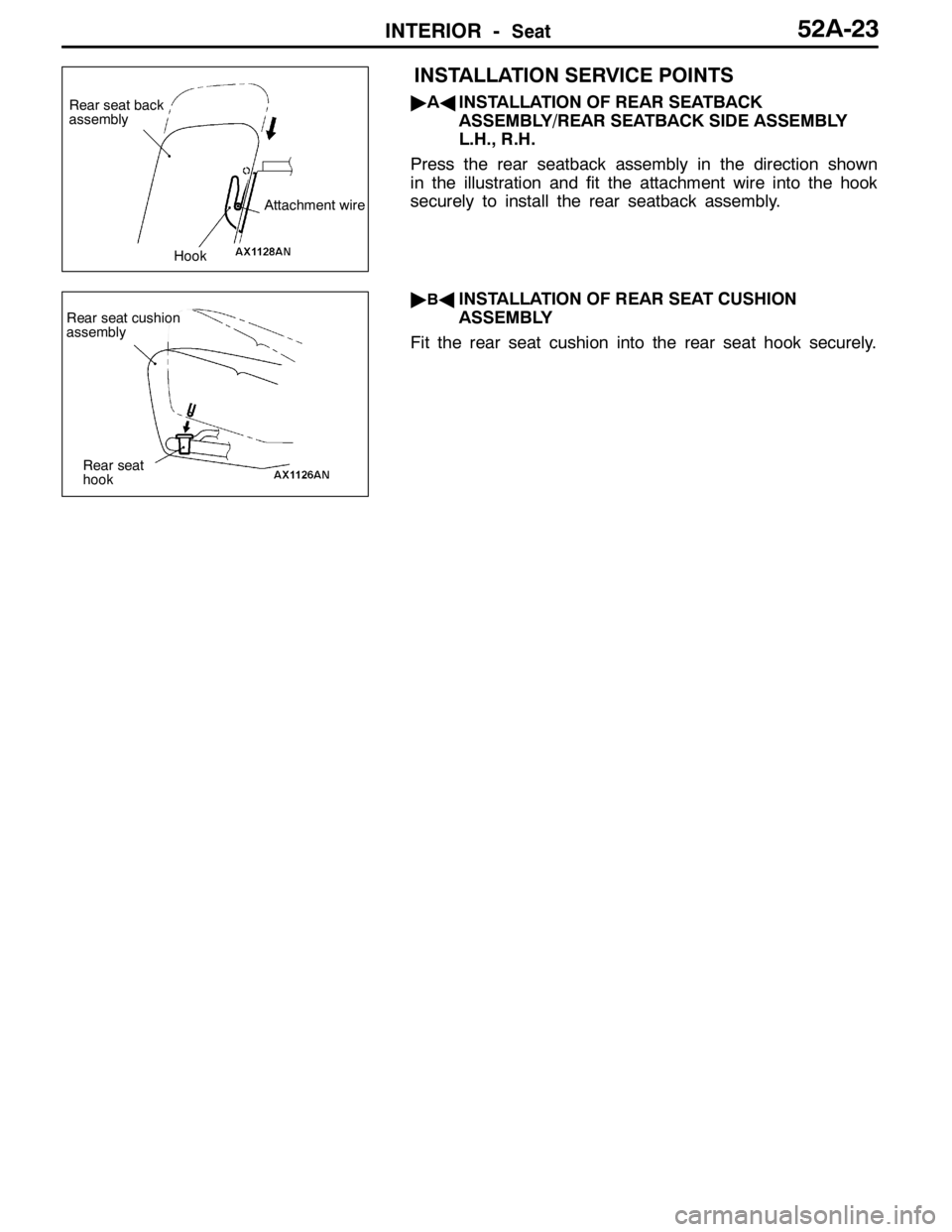

INTERIOR -Seat52A-23

INSTALLATION SERVICE POINTS

"AAINSTALLATION OF REAR SEATBACK

ASSEMBLY/REAR SEATBACK SIDE ASSEMBLY

L.H., R.H.

Press the rear seatback assembly in the direction shown

in the illustration and fit the attachment wire into the hook

securely to install the rear seatback assembly.

"

BAINSTALLATION OF REAR SEAT CUSHION

ASSEMBLY

Fit the rear seat cushion into the rear seat hook securely.

Rear seat back

assembly

Attachment wire

Hook

Rear seat cushion

assembly

Rear seat

hook

Page 1245 of 1449

52B-1

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

CONTENTS

GENERAL INFORMATION 2..................

SRS SERVICE PRECAUTIONS 3..............

SPECIAL TOOLS 5...........................

TEST EQUIPMENT 6.........................

TROUBLESHOOTING 6.......................

SRS MEINTENANCE 42......................

POST-COLLISION DIAGNOSIS 45.............

INDIVIDUAL COMPONENT SERVICE 49.......

WARNING/CAUTION LABELS 49..............SRS AIR BAG CONTROL UNIT

(SRS-ECU) 50................................

AIR BAG MODULES AND CLOCK

SPRING 52..................................

SEAT BELT PRE-TENSIONER 61..............

AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER DISPOSAL

PROCEDURES 64............................

Undeployed Air Bag Module and Seat Belt

Pre-tensioner Disposal 64.......................

Deployed Air Bag Module and Seat Belt

Pre-tensioner Disposal Procedures 75............

CAUTION

DCarefully read and observe the information in the SERVICE PRECAUTIONS (P.52B-3.) prior to any service.

DFor information concerning troubleshooting or maintenance, always observe the procedures in the Troubleshooting

(P.52B-6.) section.

DIf any SRS components are removed or replaced in connection with any service procedures, be sure to follow the

procedures in the INDIVIDUAL COMPONENT SERVICE section (P.52B-49.) for the components involved.

DIf you have any questions about the SRS, please contact your local distributor.

Page 1246 of 1449

SRS -General InformationSRS -General Information52B-2

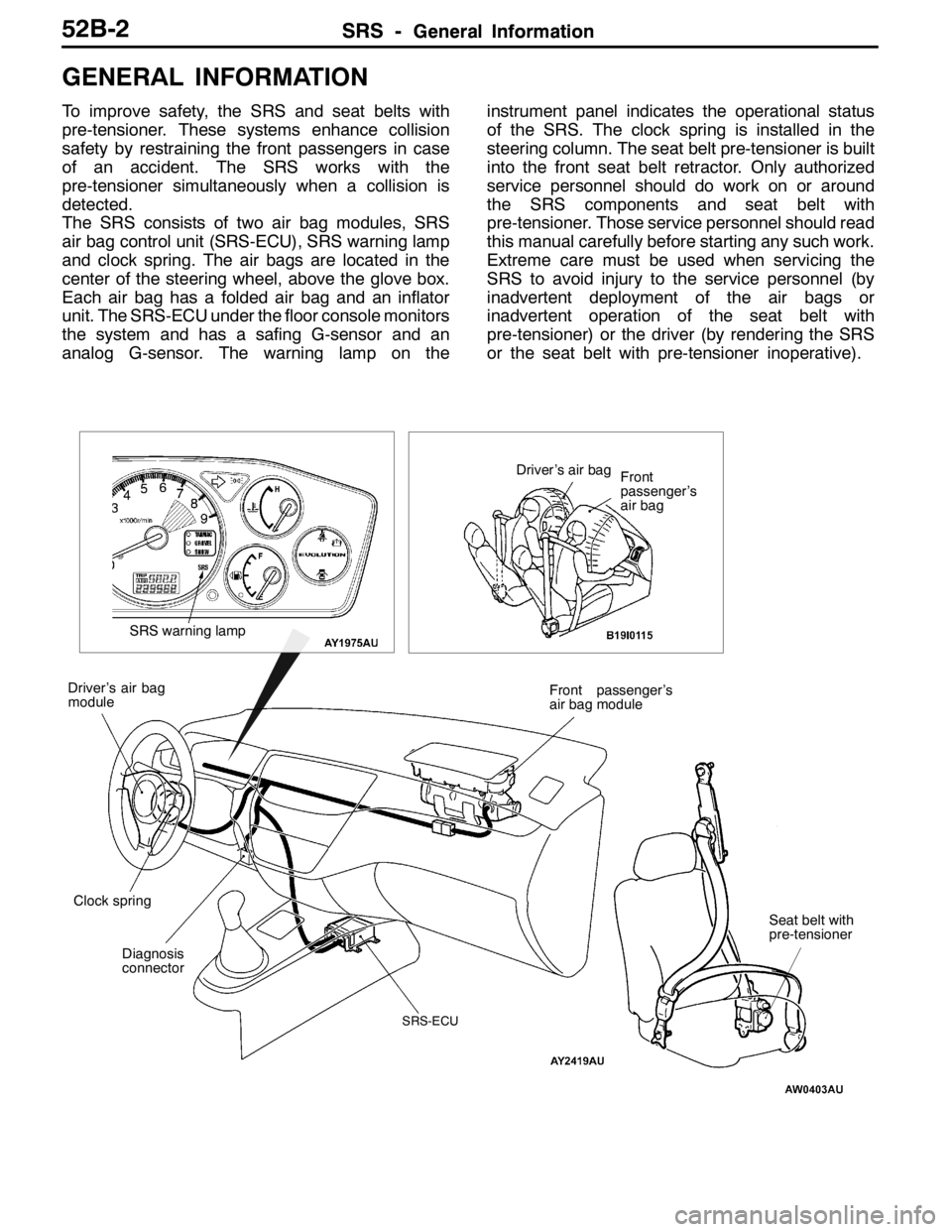

GENERAL INFORMATION

To improve safety, the SRS and seat belts with

pre-tensioner. These systems enhance collision

safety by restraining the front passengers in case

of an accident. The SRS works with the

pre-tensioner simultaneously when a collision is

detected.

The SRS consists of two air bag modules, SRS

air bag control unit (SRS-ECU), SRS warning lamp

and clock spring. The air bags are located in the

center of the steering wheel, above the glove box.

Each air bag has a folded air bag and an inflator

unit. The SRS-ECU under the floor console monitors

the system and has a safing G-sensor and an

analog G-sensor. The warning lamp on theinstrument panel indicates the operational status

of the SRS. The clock spring is installed in the

steering column. The seat belt pre-tensioner is built

into the front seat belt retractor. Only authorized

service personnel should do work on or around

the SRS components and seat belt with

pre-tensioner. Those service personnel should read

this manual carefully before starting any such work.

Extreme care must be used when servicing the

SRS to avoid injury to the service personnel (by

inadvertent deployment of the air bags or

inadvertent operation of the seat belt with

pre-tensioner) or the driver (by rendering the SRS

or the seat belt with pre-tensioner inoperative).

Diagnosis

connectorFront passenger’s

air bag module

Clock spring Driver’s air bag

module

SRS-ECU

SRS warning lamp

Driver’s air bag

Front

passenger’s

air bag

Seat belt with

pre-tensioner

Page 1247 of 1449

SRS -SRS Service Precautions52B-3

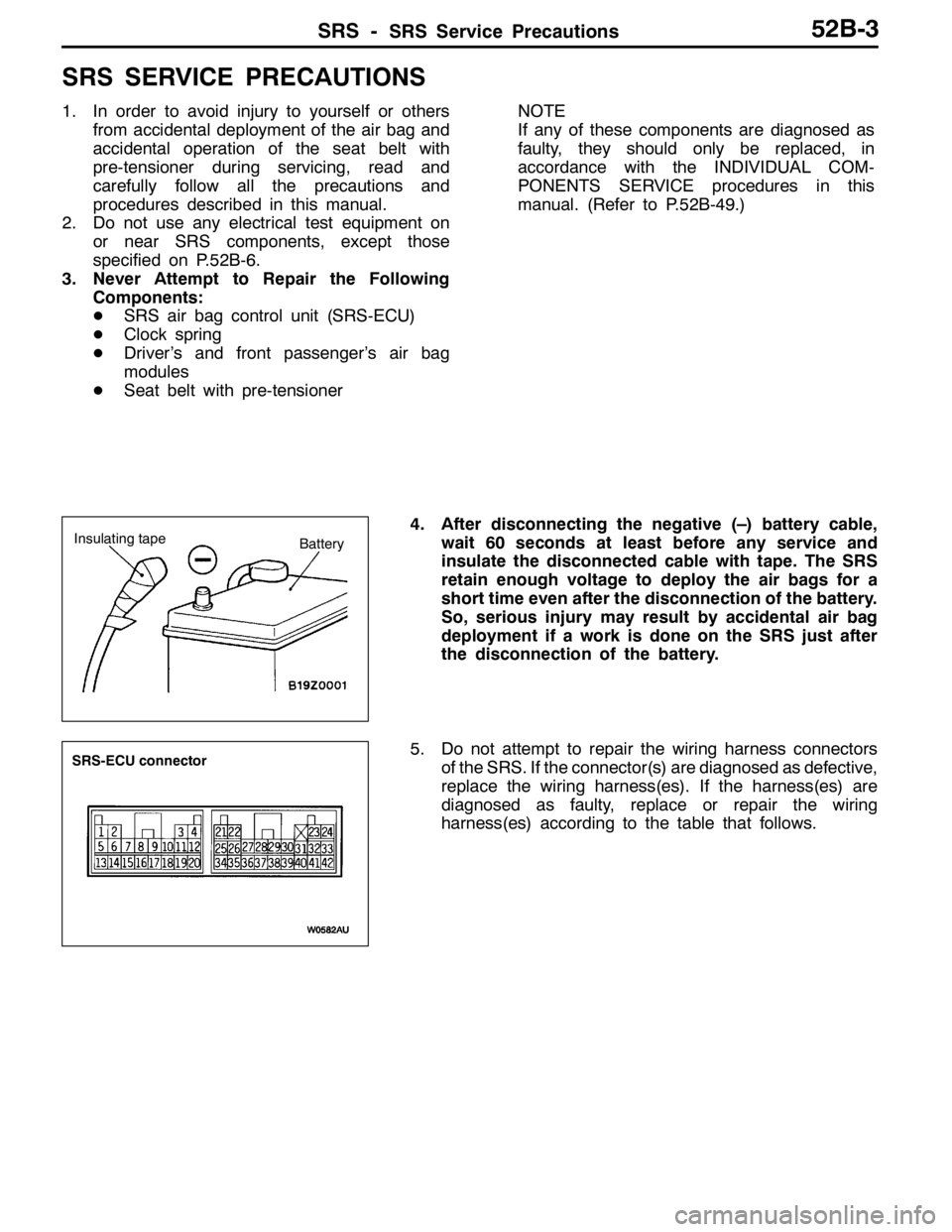

SRS SERVICE PRECAUTIONS

1. In order to avoid injury to yourself or others

from accidental deployment of the air bag and

accidental operation of the seat belt with

pre-tensioner during servicing, read and

carefully follow all the precautions and

procedures described in this manual.

2. Do not use any electrical test equipment on

or near SRS components, except those

specified on P.52B-6.

3. Never Attempt to Repair the Following

Components:

DSRS air bag control unit (SRS-ECU)

DClock spring

DDriver’s and front passenger’s air bag

modules

DSeat belt with pre-tensionerNOTE

If any of these components are diagnosed as

faulty, they should only be replaced, in

accordance with the INDIVIDUAL COM-

PONENTS SERVICE procedures in this

manual. (Refer to P.52B-49.)

4. After disconnecting the negative (–) battery cable,

wait 60 seconds at least before any service and

insulate the disconnected cable with tape. The SRS

retain enough voltage to deploy the air bags for a

short time even after the disconnection of the battery.

So, serious injury may result by accidental air bag

deployment if a work is done on the SRS just after

the disconnection of the battery.

5. Do not attempt to repair the wiring harness connectors

of the SRS. If the connector(s) are diagnosed as defective,

replace the wiring harness(es). If the harness(es) are

diagnosed as faulty, replace or repair the wiring

harness(es) according to the table that follows.

Insulating tape

Battery

SRS-ECU connector