Ecu MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1330 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-10

Inspection procedure 4

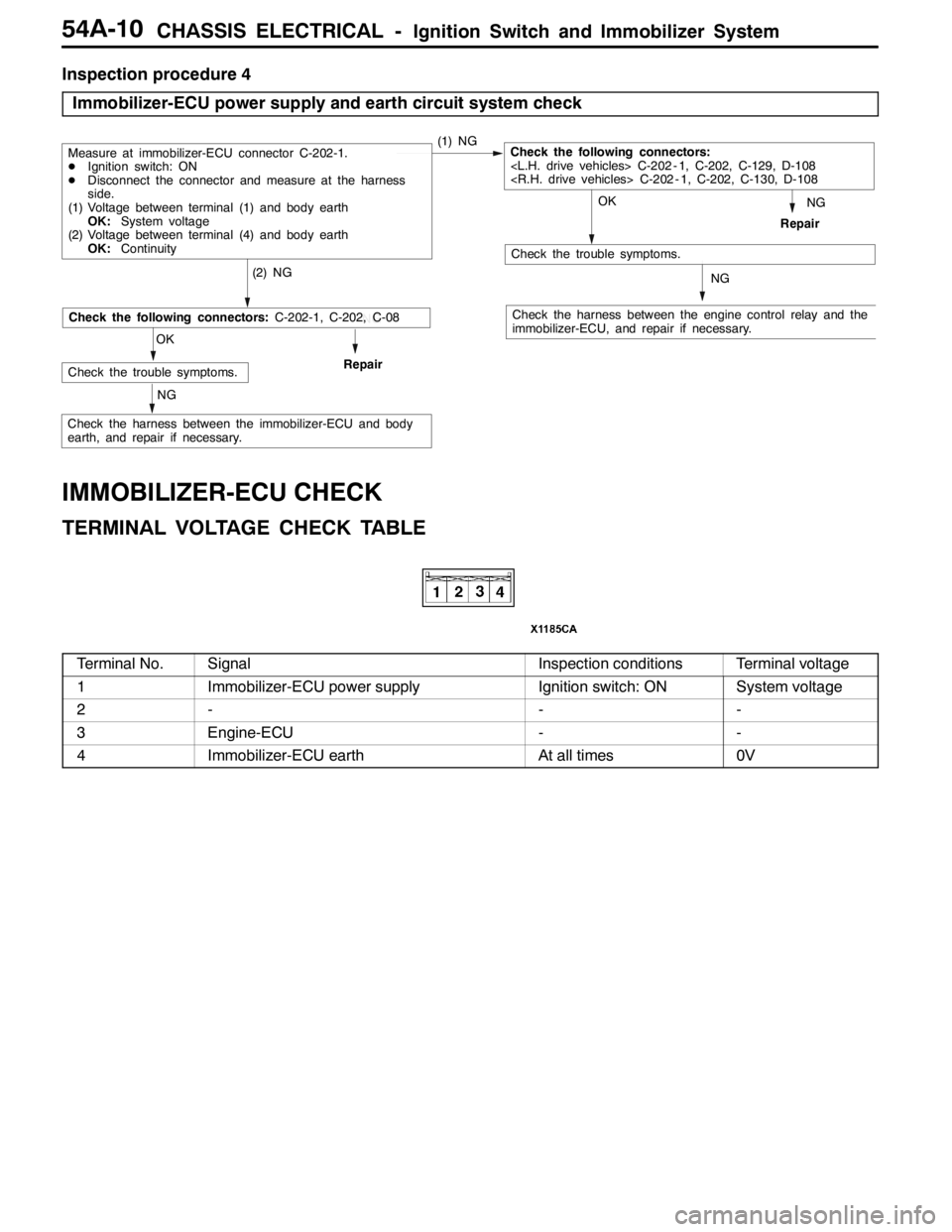

Immobilizer-ECU power supply and earth circuit system check

NG

Check the harness between the engine control relay and the

immobilizer-ECU, and repair if necessary.

OK

Check the trouble symptoms.

(2) NG

Repair

Measure at immobilizer-ECU connector C-202-1.

DIgnition switch: ON

DDisconnect the connector and measure at the harness

side.

(1) Voltage between terminal (1) and body earth

OK:System voltage

(2) Voltage between terminal (4) and body earth

OK:Continuity(1) NGCheck the following connectors:

NG

NG

OK

Check the trouble symptoms.Repair

NG

Check the following connectors:C-202-1, C-202, C-08

Check the harness between the immobilizer-ECU and body

earth, and repair if necessary.

IMMOBILIZER-ECU CHECK

TERMINAL VOLTAGE CHECK TABLE

Terminal No.SignalInspection conditionsTerminal voltage

1Immobilizer-ECU power supplyIgnition switch: ONSystem voltage

2---

3Engine-ECU--

4Immobilizer-ECU earthAt all times0V

Page 1331 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-11

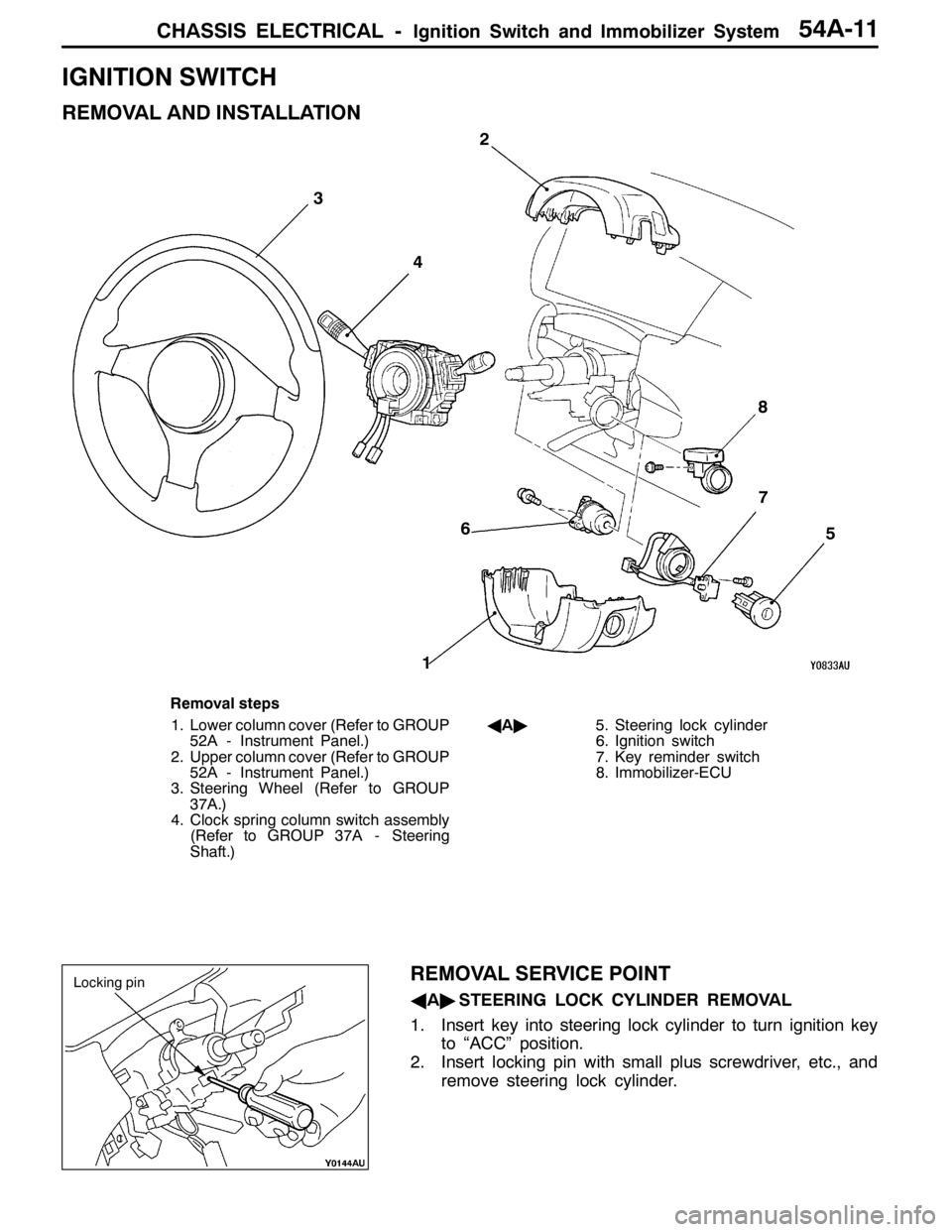

IGNITION SWITCH

REMOVAL AND INSTALLATION

7

6

15 32

4

8

Removal steps

1. Lower column cover (Refer to GROUP

52A - Instrument Panel.)

2. Upper column cover (Refer to GROUP

52A - Instrument Panel.)

3. Steering Wheel (Refer to GROUP

37A.)

4. Clock spring column switch assembly

(Refer to GROUP 37A - Steering

Shaft.)AA"5. Steering lock cylinder

6. Ignition switch

7. Key reminder switch

8. Immobilizer-ECU

REMOVAL SERVICE POINT

AA"STEERING LOCK CYLINDER REMOVAL

1. Insert key into steering lock cylinder to turn ignition key

to “ACC” position.

2. Insert locking pin with small plus screwdriver, etc., and

remove steering lock cylinder.

Locking pin

Page 1332 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-12

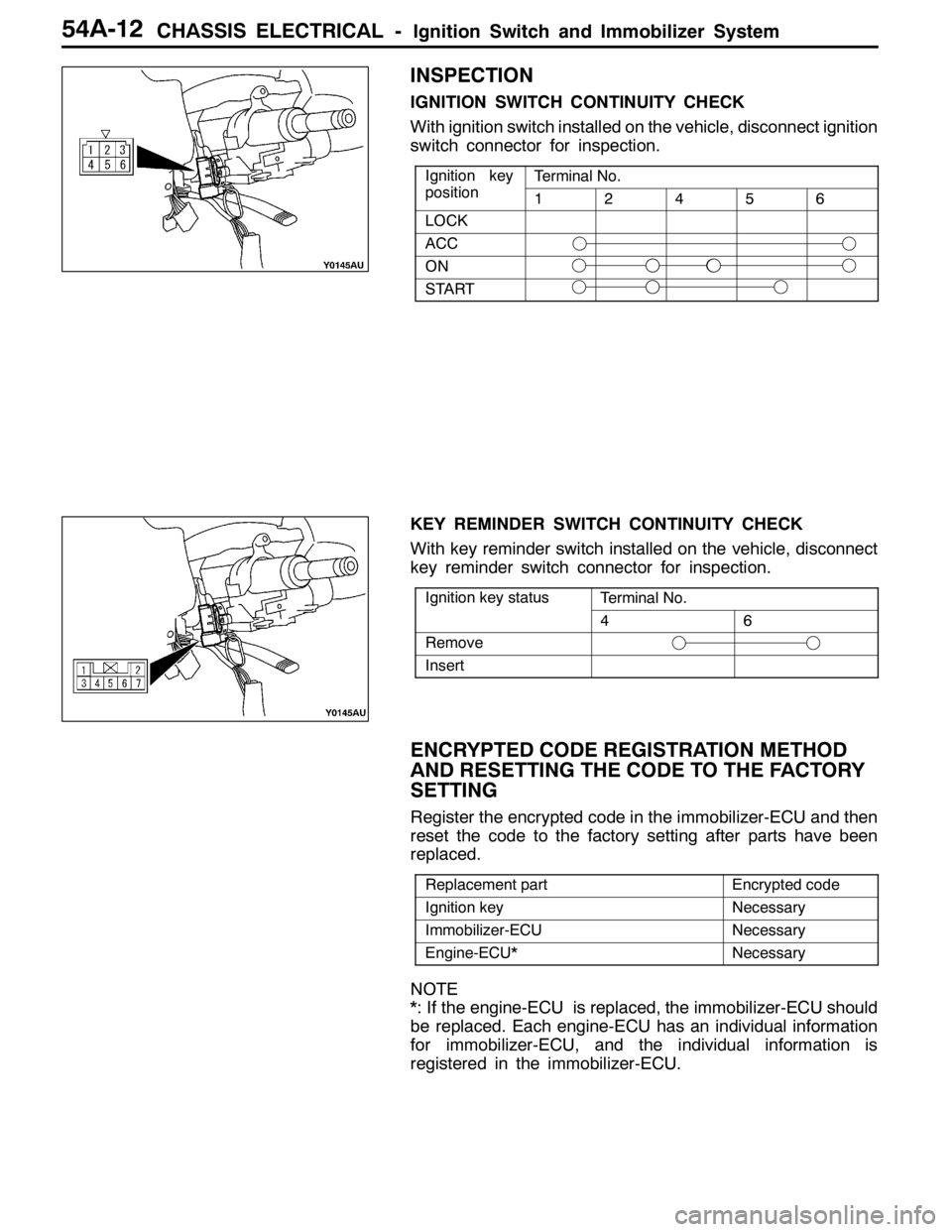

INSPECTION

IGNITION SWITCH CONTINUITY CHECK

With ignition switch installed on the vehicle, disconnect ignition

switch connector for inspection.

Ignition key

iti

Terminal No.gy

position12456

LOCK

ACC

ON

START

KEY REMINDER SWITCH CONTINUITY CHECK

With key reminder switch installed on the vehicle, disconnect

key reminder switch connector for inspection.

Ignition key statusTerminal No.gy

46

Remove

Insert

ENCRYPTED CODE REGISTRATION METHOD

AND RESETTING THE CODE TO THE FACTORY

SETTING

Register the encrypted code in the immobilizer-ECU and then

reset the code to the factory setting after parts have been

replaced.

Replacement partEncrypted code

Ignition keyNecessary

Immobilizer-ECUNecessary

Engine-ECU*Necessary

NOTE

*: If the engine-ECU is replaced, the immobilizer-ECU should

be replaced. Each engine-ECU has an individual information

for immobilizer-ECU, and the individual information is

registered in the immobilizer-ECU.

Page 1333 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-13

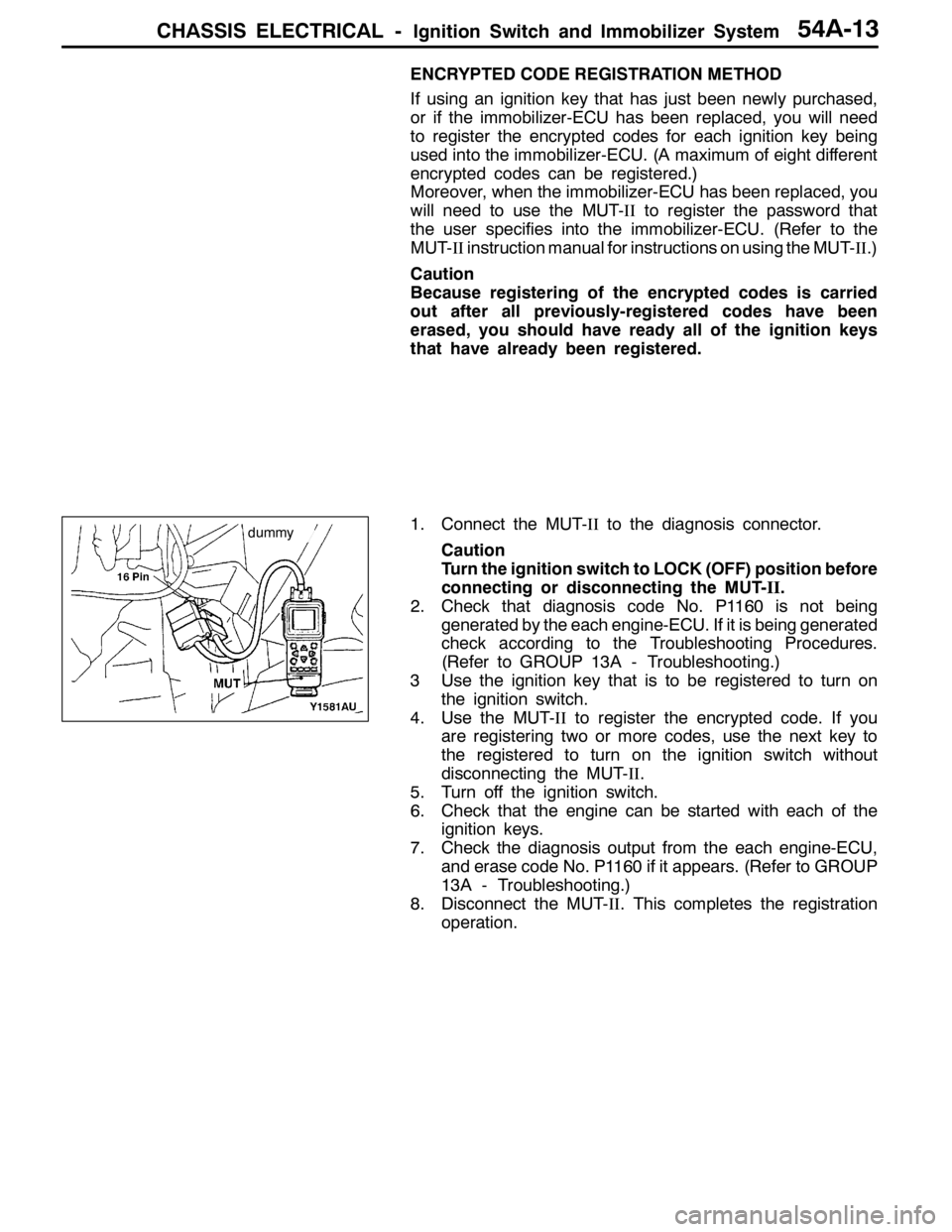

ENCRYPTED CODE REGISTRATION METHOD

If using an ignition key that has just been newly purchased,

or if the immobilizer-ECU has been replaced, you will need

to register the encrypted codes for each ignition key being

used into the immobilizer-ECU. (A maximum of eight different

encrypted codes can be registered.)

Moreover, when the immobilizer-ECU has been replaced, you

will need to use the MUT-IIto register the password that

the user specifies into the immobilizer-ECU. (Refer to the

MUT-IIinstruction manual for instructions on using the MUT-II.)

Caution

Because registering of the encrypted codes is carried

out after all previously-registered codes have been

erased, you should have ready all of the ignition keys

that have already been registered.

1. Connect the MUT-IIto the diagnosis connector.

Caution

Turn the ignition switch to LOCK (OFF) position before

connecting or disconnecting the MUT-II.

2. Check that diagnosis code No. P1160 is not being

generated by the each engine-ECU. If it is being generated

check according to the Troubleshooting Procedures.

(Refer to GROUP 13A - Troubleshooting.)

3 Use the ignition key that is to be registered to turn on

the ignition switch.

4. Use the MUT-IIto register the encrypted code. If you

are registering two or more codes, use the next key to

the registered to turn on the ignition switch without

disconnecting the MUT-II.

5. Turn off the ignition switch.

6. Check that the engine can be started with each of the

ignition keys.

7. Check the diagnosis output from the each engine-ECU,

and erase code No. P1160 if it appears. (Refer to GROUP

13A - Troubleshooting.)

8. Disconnect the MUT-II. This completes the registration

operation.

dummy

Page 1336 of 1449

CHASSIS ELECTRICAL -Combination Meter54A-16

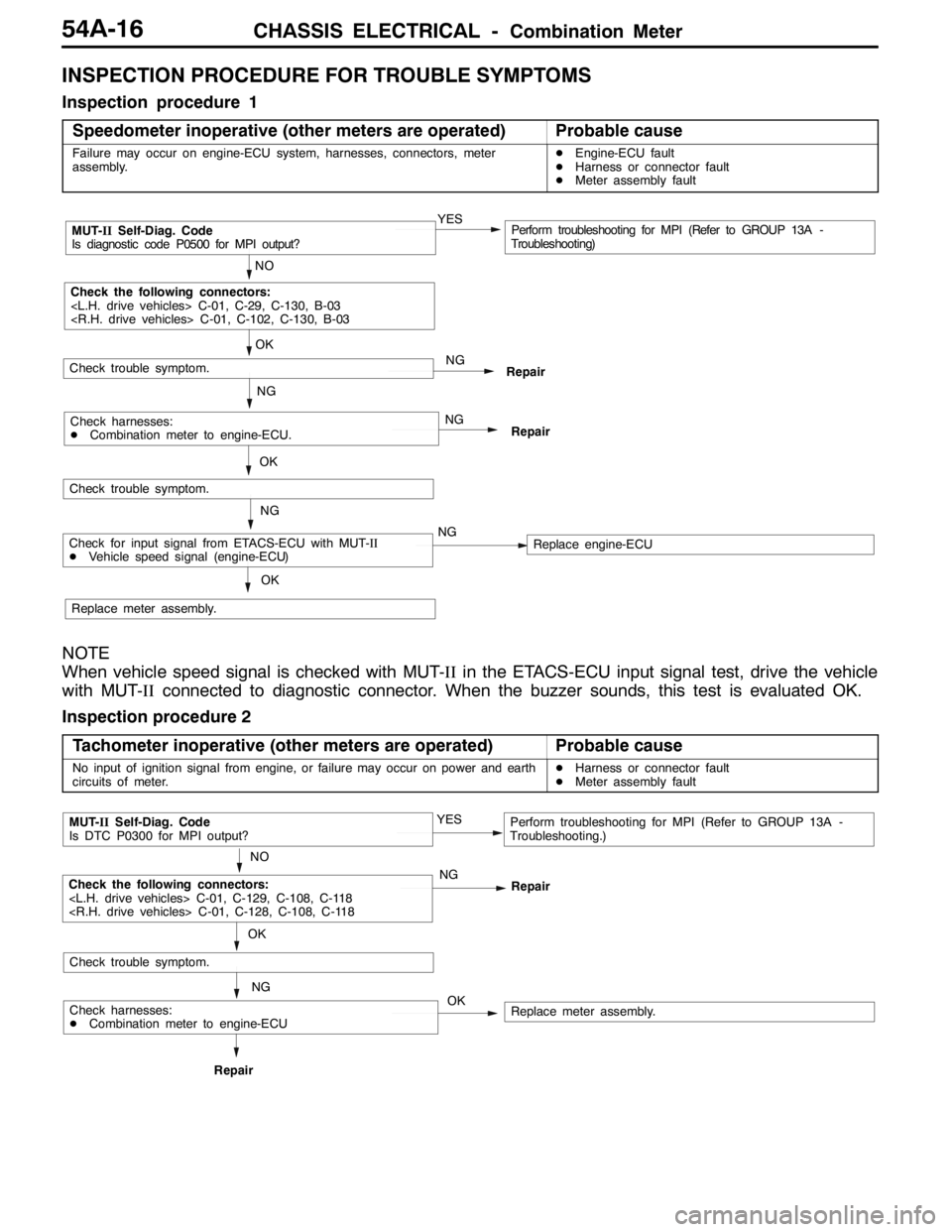

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection procedure 1

Speedometer inoperative (other meters are operated)

Probable cause

Failure may occur on engine-ECU system, harnesses, connectors, meter

assembly.DEngine-ECU fault

DHarness or connector fault

DMeter assembly fault

NO

MUT-IISelf-Diag. Code

Is diagnostic code P0500 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting)

OK

NG

Check the following connectors:

Repair

OK

Check trouble symptom.

NG

NG

RepairCheck harnesses:

DCombination meter to engine-ECU.

Check trouble symptom.

NG

Replace meter assembly.

OK

Check for input signal from ETACS-ECU with MUT-II

DVehicle speed signal (engine-ECU)NGReplace engine-ECU

NOTE

When vehicle speed signal is checked with MUT-IIin the ETACS-ECU input signal test, drive the vehicle

with MUT-IIconnected to diagnostic connector. When the buzzer sounds, this test is evaluated OK.

Inspection procedure 2

Tachometer inoperative (other meters are operated)

Probable cause

No input of ignition signal from engine, or failure may occur on power and earth

circuits of meter.DHarness or connector fault

DMeter assembly fault

OK

NO

MUT-IISelf-Diag. Code

Is DTC P0300 for MPI output?YESPerform troubleshooting for MPI (Refer to GROUP 13A -

Troubleshooting.)

NG

NG

RepairRepair

Check trouble symptom.

OK

Check the following connectors:

Replace meter assembly.Check harnesses:

DCombination meter to engine-ECU

Page 1339 of 1449

CHASSIS ELECTRICAL -Combination MeterCHASSIS ELECTRICAL -Combination Meter54A-19

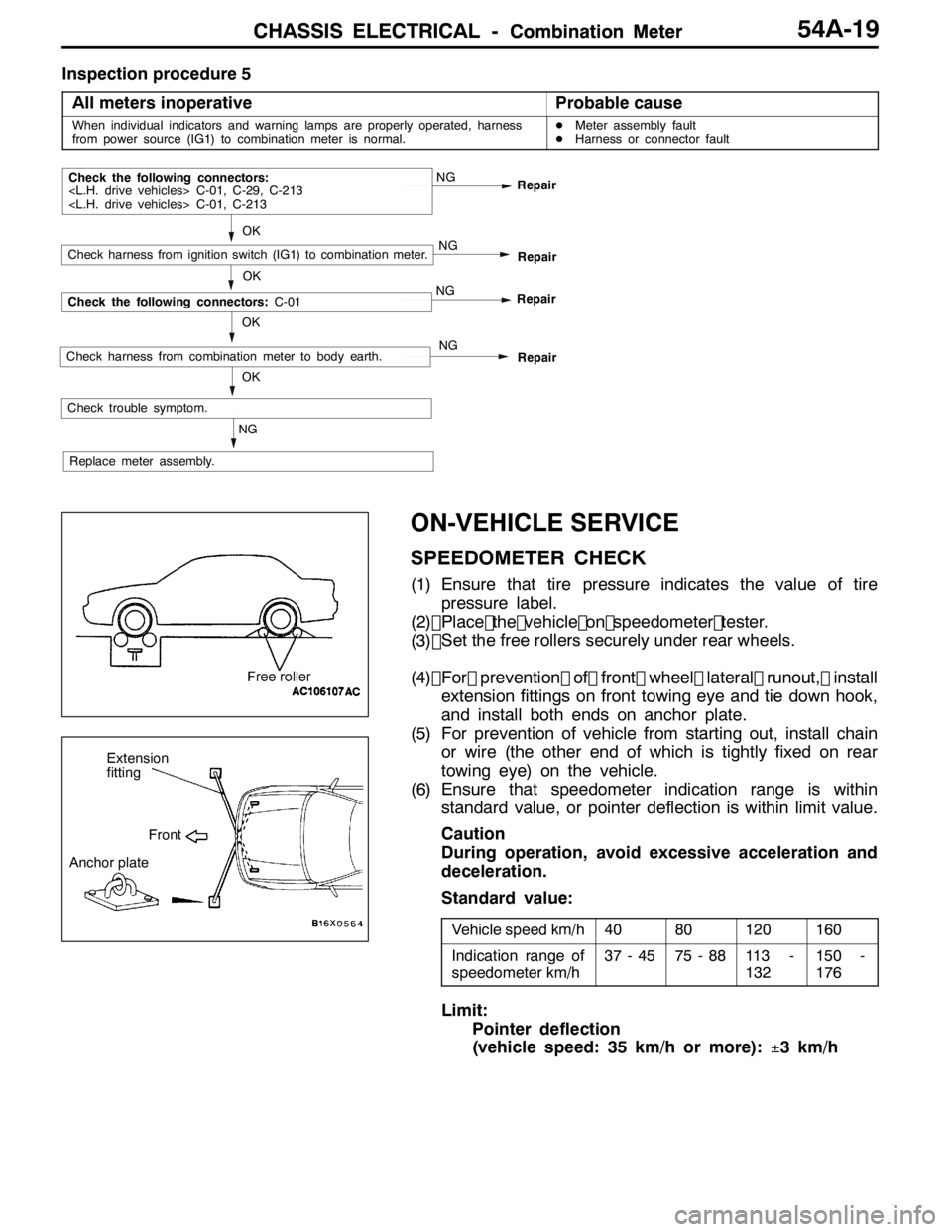

Inspection procedure 5All meters inoperative

Probable cause

When individual indicators and warning lamps are properly operated, harness

from power source (IG1) to combination meter is normal.D Meter assembly fault

D Harness or connector fault

NG Repair

NG

OK

Check trouble symptom. Repair

OK

Check the following connectors:

NG

Check harness from ignition switch (IG1) to combination meter.

Replace meter assembly. Repair

NG

OK

Check the following connectors:

C-01

NG

RepairCheck harness from combination meter to body earth.

ON-VEHICLE SERVICE

SPEEDOMETER CHECK

(1) Ensure that tire pressure indicates the value of tirepressure label.

(2) Place the vehicle on speedometer teste r.

(3)

(4) For prevention of front wheel lateral runout, install

extension fittings on front towing eye and tie down hook,

and install both ends on anchor plate.

(5) For prevention of vehicle from starting out, install chain or wire (the other end of which is tightly fixed on rear

towing eye) on the vehicle.

(6) Ensure that speedometer indication range is within standard value, or pointer deflection is within limit value.

Caution

During operation, avoid excessive acceleration and

deceleration.

Standard value:

Vehicle speed km/h4080120160

Indication range of

speedometer km/h37 - 4575 - 8811 3 -

132150 -

176

Limit:

Pointer deflection

(vehicle speed: 35 km/h or more): ±3 km/h

Extension

fitting

Front

Anchor plate

OK

Set the free rollers securely under rear wheels.

Page 1344 of 1449

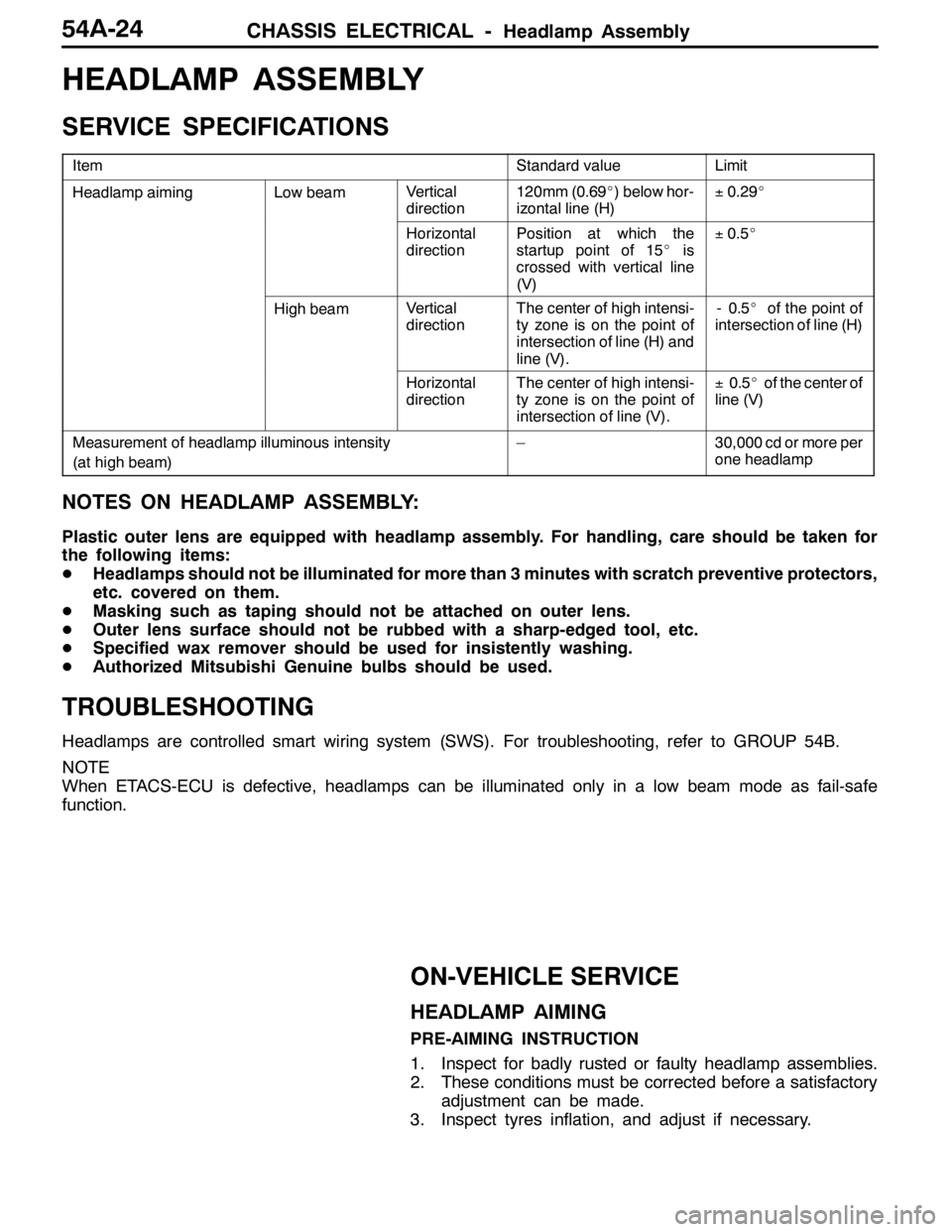

CHASSIS ELECTRICAL -Headlamp Assembly54A-24

HEADLAMP ASSEMBLY

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Headlamp aimingLow beamVertical

direction120mm (0.69_) below hor-

izontal line (H)±0.29_

Horizontal

directionPosition at which the

startup point of 15_is

crossed with vertical line

(V)±0.5_

High beamVertical

directionThe center of high intensi-

ty zone is on the point of

intersection of line (H) and

line (V).- 0.5_of the point of

intersection of line (H)

Horizontal

directionThe center of high intensi-

ty zone is on the point of

intersection of line (V).±0.5_of the center of

line (V)

Measurement of headlamp illuminous intensity

(at high beam)–30,000 cd or more per

one headlamp

NOTES ON HEADLAMP ASSEMBLY:

Plastic outer lens are equipped with headlamp assembly. For handling, care should be taken for

the following items:

DHeadlamps should not be illuminated for more than 3 minutes with scratch preventive protectors,

etc. covered on them.

DMasking such as taping should not be attached on outer lens.

DOuter lens surface should not be rubbed with a sharp-edged tool, etc.

DSpecified wax remover should be used for insistently washing.

DAuthorized Mitsubishi Genuine bulbs should be used.

TROUBLESHOOTING

Headlamps are controlled smart wiring system (SWS). For troubleshooting, refer to GROUP 54B.

NOTE

When ETACS-ECU is defective, headlamps can be illuminated only in a low beam mode as fail-safe

function.

ON-VEHICLE SERVICE

HEADLAMP AIMING

PRE-AIMING INSTRUCTION

1. Inspect for badly rusted or faulty headlamp assemblies.

2. These conditions must be corrected before a satisfactory

adjustment can be made.

3. Inspect tyres inflation, and adjust if necessary.

Page 1359 of 1449

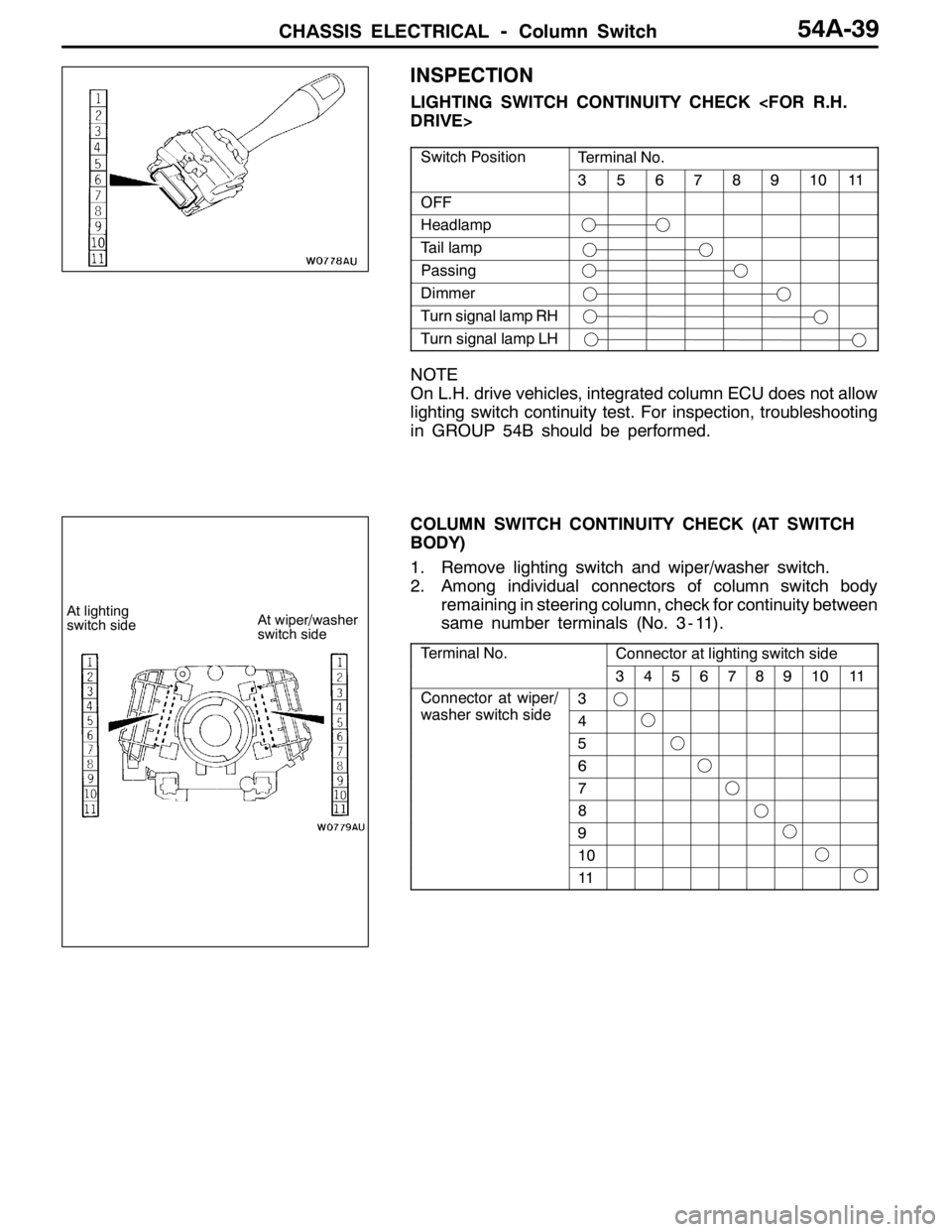

CHASSIS ELECTRICAL-Column Switch54A-39

INSPECTION

LIGHTING SWITCH CONTINUITY CHECK

Switch PositionTerminal No.

3567891011

OFF

Headlamp

Tail lamp

Passing

Dimmer

Turn signal lamp RH

Turn signal lamp LH

NOTE

On L.H. drive vehicles, integrated column ECU does not allow

lighting switch continuity test. For inspection, troubleshooting

in GROUP 54B should be performed.

COLUMN SWITCH CONTINUITY CHECK (AT SWITCH

BODY)

1. Remove lighting switch and wiper/washer switch.

2. Among individual connectors of column switch body

remaining in steering column, check for continuity between

same number terminals (No. 3 - 11).

Terminal No.Connector at lighting switch side

34567891011

Connector at wiper/

hit hid

3p

washer switch side4

5

6

7

8

9

10

11

At lighting

switch sideAt wiper/washer

switch side

Page 1365 of 1449

54B-1

SMART WIRING

SYSTEM (SWS)

CONTENTS

SPECIAL TOOLS 2...........................

TROUBLESHOOTING 2.......................

Before Commencing Troubleshooting 2...........

Standard Flow of Diagnostic Troubleshooting 2...

Diagnostic Functions 2.........................Diagnosis Code Chart 3........................

Diagnosis Code Inspection Procedures 4.........

Trouble Symptom Chart 7.......................

Inspection Procedures for Trouble Symptoms 10..

Check at ECU Terminals 34.....................

Page 1366 of 1449

SWS -Special Tools/Troubleshooting54B-2

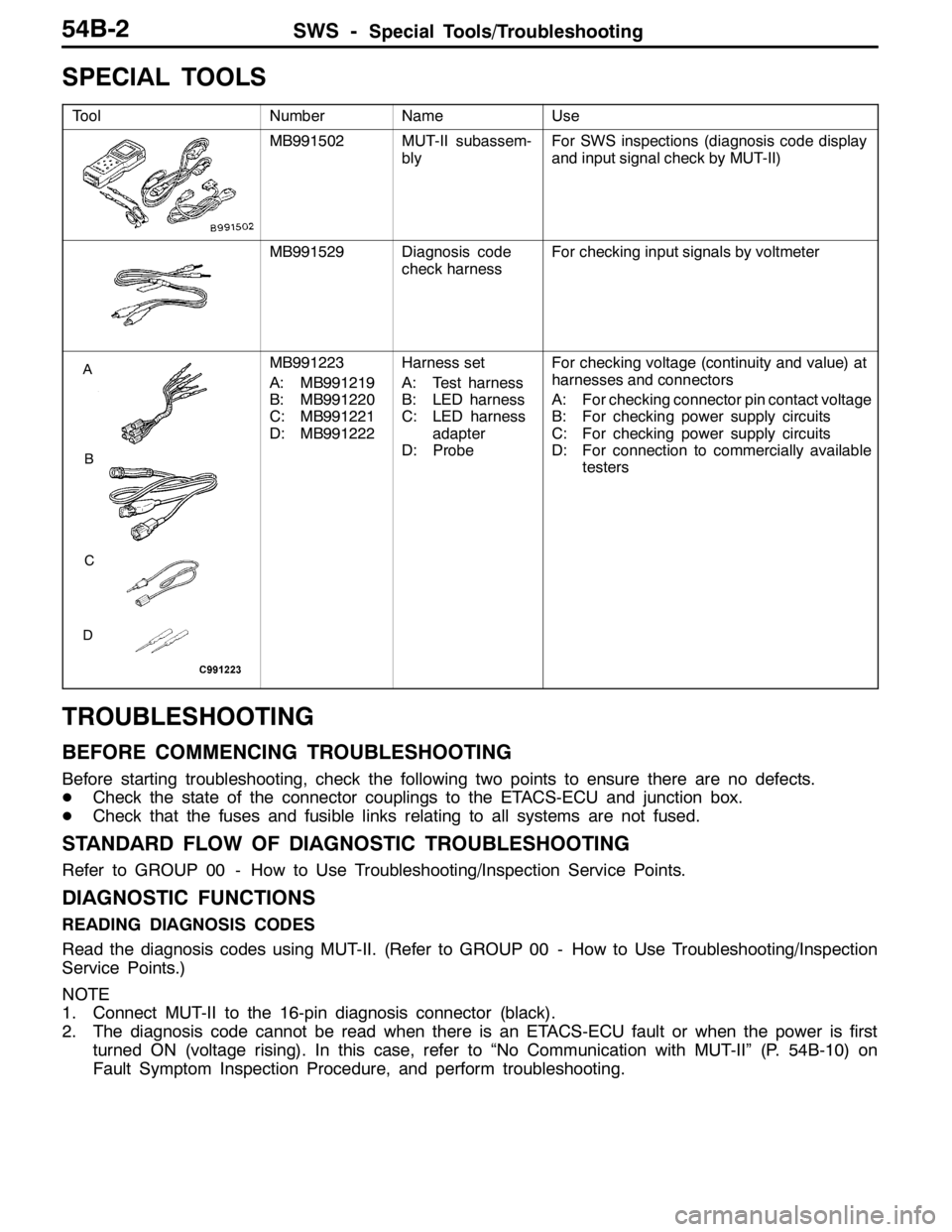

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-II subassem-

blyFor SWS inspections (diagnosis code display

and input signal check by MUT-II)

MB991529Diagnosis code

check harnessFor checking input signals by voltmeter

A

B

C

D

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeFor checking voltage (continuity and value) at

harnesses and connectors

A: For checking connector pin contact voltage

B: For checking power supply circuits

C: For checking power supply circuits

D: For connection to commercially available

testers

TROUBLESHOOTING

BEFORE COMMENCING TROUBLESHOOTING

Before starting troubleshooting, check the following two points to ensure there are no defects.

DCheck the state of the connector couplings to the ETACS-ECU and junction box.

DCheck that the fuses and fusible links relating to all systems are not fused.

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

DIAGNOSTIC FUNCTIONS

READING DIAGNOSIS CODES

Read the diagnosis codes using MUT-II. (Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.)

NOTE

1. Connect MUT-II to the 16-pin diagnosis connector (black).

2. The diagnosis code cannot be read when there is an ETACS-ECU fault or when the power is first

turned ON (voltage rising). In this case, refer to “No Communication with MUT-II” (P. 54B-10) on

Fault Symptom Inspection Procedure, and perform troubleshooting.