key MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1286 of 1449

SRS - SRS Maintenance52B-42

SRS MAINTENANCE

The SRS must be inspected by an authorized dealer 10 years

after the date of vehicle registration.

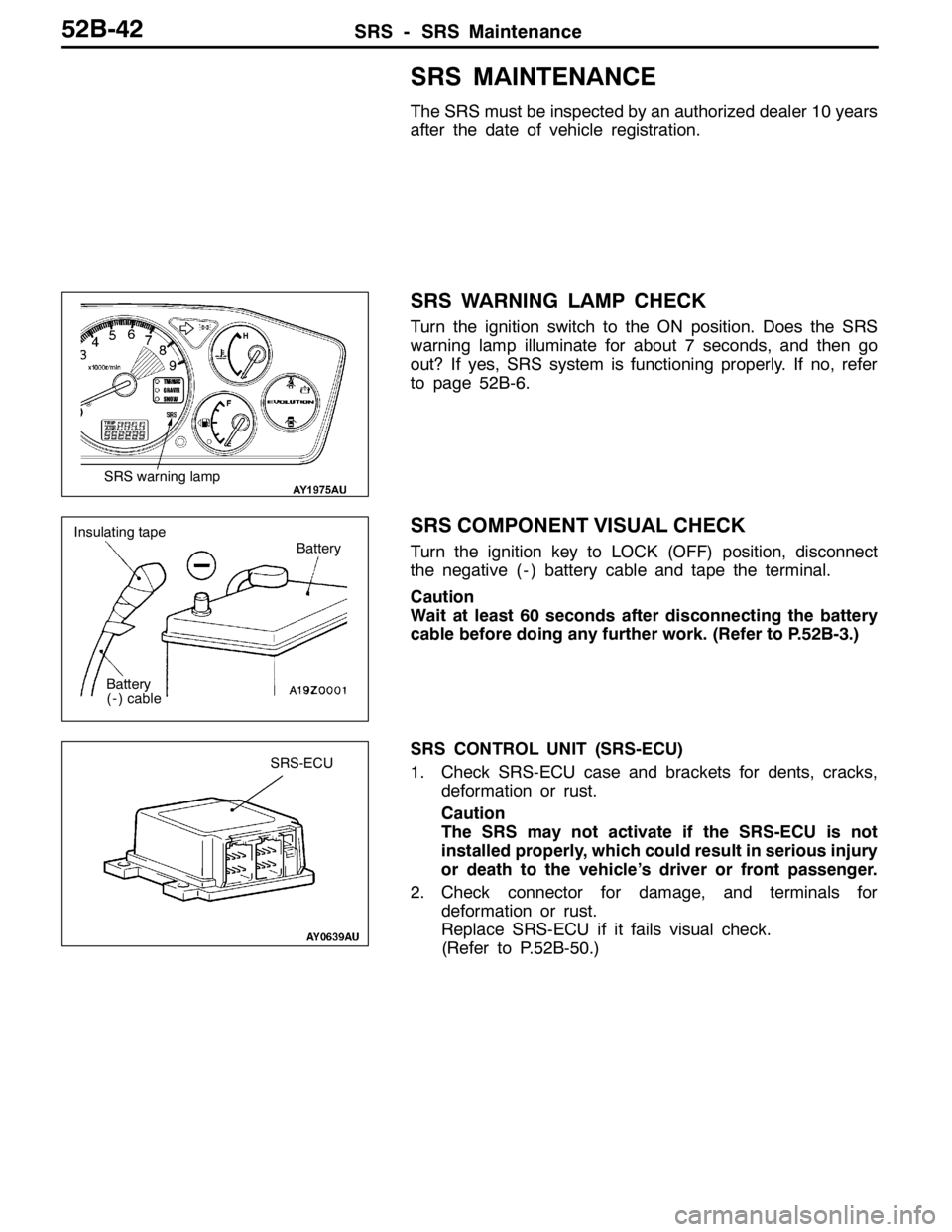

SRS WARNING LAMP CHECK

Turn the ignition switch to the ON position. Does the SRS

warning lamp illuminate for about 7 seconds, and then go

out? If yes, SRS system is functioning properly. If no, refer

to page 52B-6.

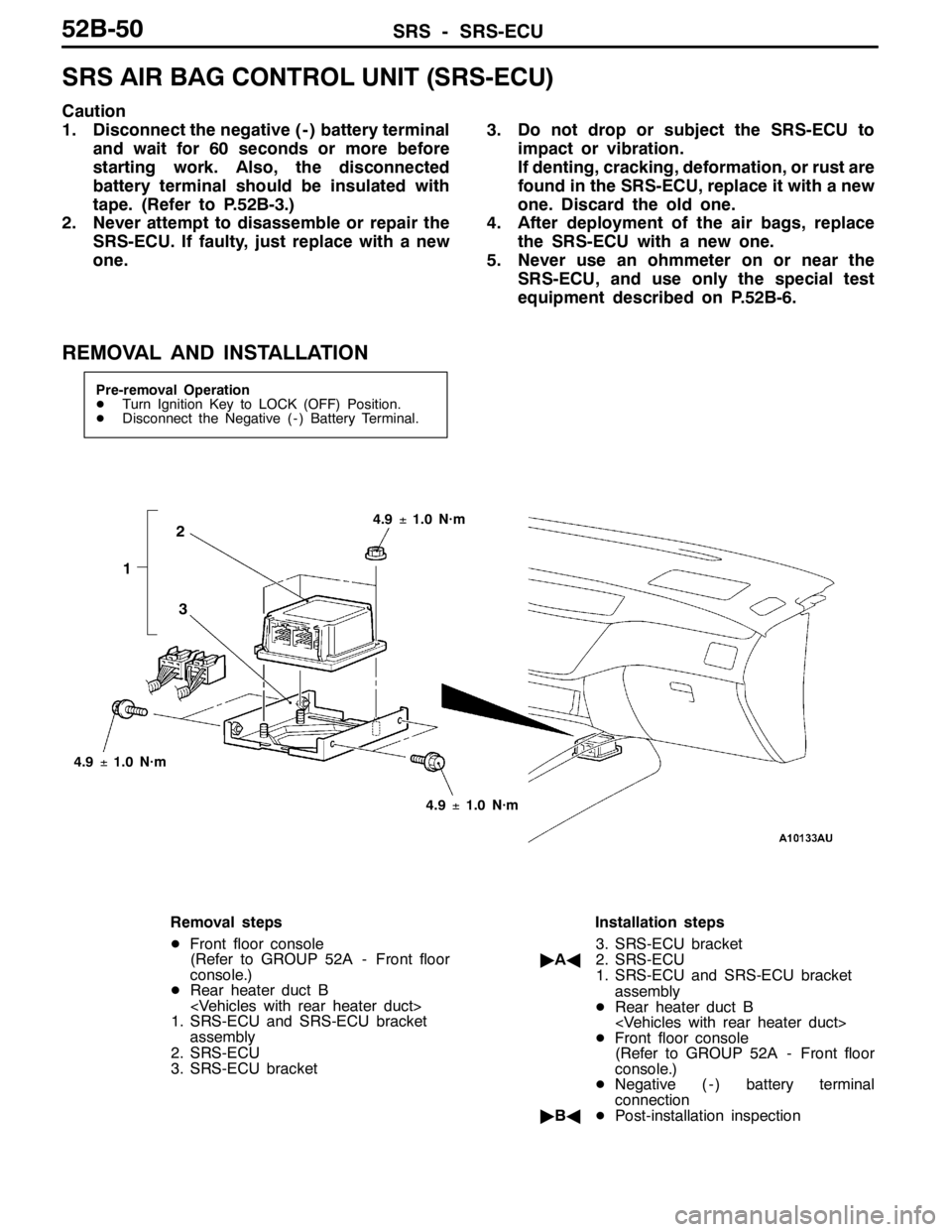

SRS COMPONENT VISUAL CHECK

Turn the ignition key to LOCK (OFF) position, disconnect

the negative ( - ) battery cable and tape the terminal.

Caution

Wait at least 60 seconds after disconnecting the battery

cable before doing any further work. (Refer to P.52B-3.)

SRS CONTROL UNIT (SRS-ECU)

1. Check SRS-ECU case and brackets for dents, cracks,

deformation or rust.

Caution

The SRS may not activate if the SRS-ECU is not

installed properly, which could result in serious injury

or death to the vehicle’s driver or front passenger.

2. Check connector for damage, and terminals for

deformation or rust.

Replace SRS-ECU if it fails visual check.

(Refer to P.52B-50.)

SRS warning lamp

Insulating tape

Battery

Battery

( - ) cable

SRS-ECU

Page 1294 of 1449

SRS - SRS-ECU52B-50

SRS AIR BAG CONTROL UNIT (SRS-ECU)

Caution

1. Disconnect the negative ( - ) battery terminal

and wait for 60 seconds or more before

starting work. Also, the disconnected

battery terminal should be insulated with

tape. (Refer to P.52B-3.)

2. Never attempt to disassemble or repair the

SRS-ECU. If faulty, just replace with a new

one.3. Do not drop or subject the SRS-ECU to

impact or vibration.

If denting, cracking, deformation, or rust are

found in the SRS-ECU, replace it with a new

one. Discard the old one.

4. After deployment of the air bags, replace

the SRS-ECU with a new one.

5. Never use an ohmmeter on or near the

SRS-ECU, and use only the special test

equipment described on P.52B-6.

REMOVAL AND INSTALLATION

Pre-removal Operation

DTurn Ignition Key to LOCK (OFF) Position.

DDisconnect the Negative ( - ) Battery Terminal.

12

4.9±1.0 N·m

4.9±1.0 N·m

4.9±1.0 N·m

3

Removal steps

DFront floor console

(Refer to GROUP 52A - Front floor

console.)

DRear heater duct B

1. SRS-ECU and SRS-ECU bracket

assembly

2. SRS-ECU

3. SRS-ECU bracketInstallation steps

3. SRS-ECU bracket

"AA2. SRS-ECU

1. SRS-ECU and SRS-ECU bracket

assembly

DRear heater duct B

DFront floor console

(Refer to GROUP 52A - Front floor

console.)

DNegative ( - ) battery terminal

connection

"BADPost-installation inspection

Page 1305 of 1449

SRS -Seat Belt with Pre-tensioner52B-61

SEAT BELT WITH PRE-TENSIONER

Caution:

1. Wait for at least 60 seconds after

disconnecting the negative ( - ) terminal of

the battery before starting any operation.The

removed negative ( - ) terminal must be

protected by wrapping the tape. (Refer to

P.52B-3.)

2. Never disassemble or repair the seat belt

with pre-tensioner. Replace the part with a

new one when it malfunctions.

3. Take an extra care to deal with the seat belt

with pre-tensioner by avoiding dropping or

wetting it with water or oil. If any dent, crack,

or deformation is found, be sure to replace

the seat belt with pre-tensioner with a new

part.4. Do not place a heavy object on top of the

seat belt pre-tensioner.

5. Never keep the seat belt with pre-tensioner

in a place where the temperature can exceed

over 90_C.

6. Replace the seat belt with pre-tensioner with

a new one after operating the seat belt

pre-tensioner.

7. Wear gloves or protective glasses when

handling the seat belt with pre-tensioner

after operation.

8. If the seat belt with pre-tensioner before

operation needs to be discarded, be sure

to do so after operating the seat belt

pre-tensioner. (Refer to P.52B-64.)

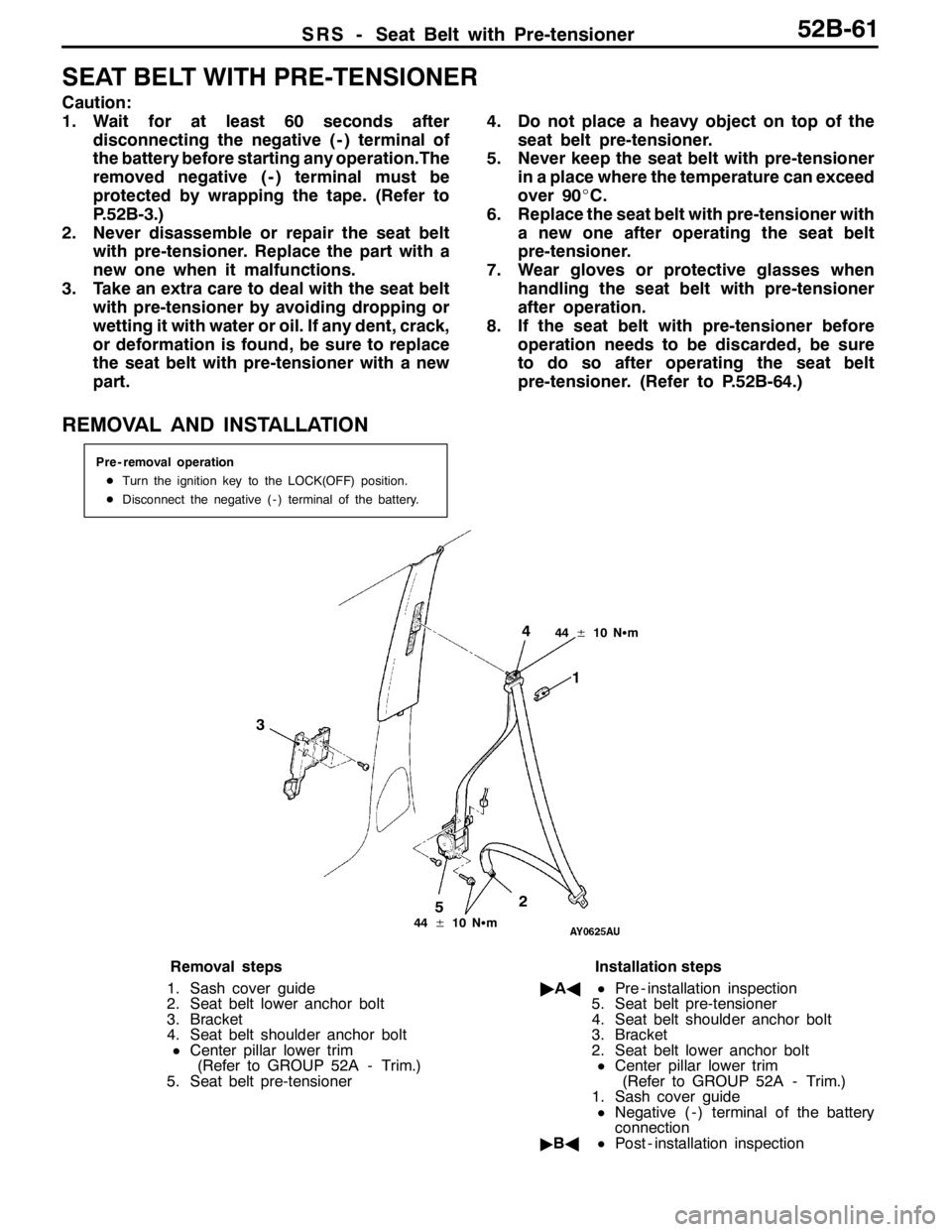

REMOVAL AND INSTALLATION

Pre - removal operation

DTurn the ignition key to the LOCK(OFF) position.

DDisconnect the negative ( - ) terminal of the battery.

1 4

3

2

44±10 NSm

44±10 NSm

5

Removal steps

1. Sash cover guide

2. Seat belt lower anchor bolt

3. Bracket

4. Seat belt shoulder anchor bolt

DCenter pillar lower trim

(Refer to GROUP 52A - Trim.)

5. Seat belt pre-tensionerInstallation steps

"AA

DPre - installation inspection

5. Seat belt pre-tensioner

4. Seat belt shoulder anchor bolt

3. Bracket

2. Seat belt lower anchor bolt

DCenter pillar lower trim

(Refer to GROUP 52A - Trim.)

1. Sash cover guide

DNegative ( - ) terminal of the battery

connection

"BADPost - installation inspection

Page 1306 of 1449

SRS -Seat Belt with Pre-tensioner52B-62

INSTALLATION SERVICE POINTS

"AAPRE-INSTALLATION INSPECTION

1. Pre-installation inspection must be carried out even when

installing a new seat belt with pre-tensioner. (Refer to

Inspections.)

Caution

If the seat belt with pre-tensioner is discarded, discard

it after operating the seat belt pre-tensioner according

to the specified procedure. (Refer to P.52B-64.)

2. Connect the negative ( - ) terminal of the battery.

3. Connect the MUT-II to the diagnosis connector (16 pin).

Caution

Connection and disconnection of the MUT-II must be

carried out after turning the ignition switch to the

LOCK (OFF) position.

4. Turn the ignition switch to ON position.

5. Check that there is no abnormality except for open circuit

in the seat belt pre-tensioner after reading diagnostic

codes.

6. Turn the ignition key to LOCK (OFF) position.

7. Release the negative ( - ) terminal cable of the battery

and wrap a tape around it for insulation.

Caution

Wait for at least 60 seconds after disconnecting the

negative ( - ) battery cable before starting any

operation. (Refer to P.52B-3.)

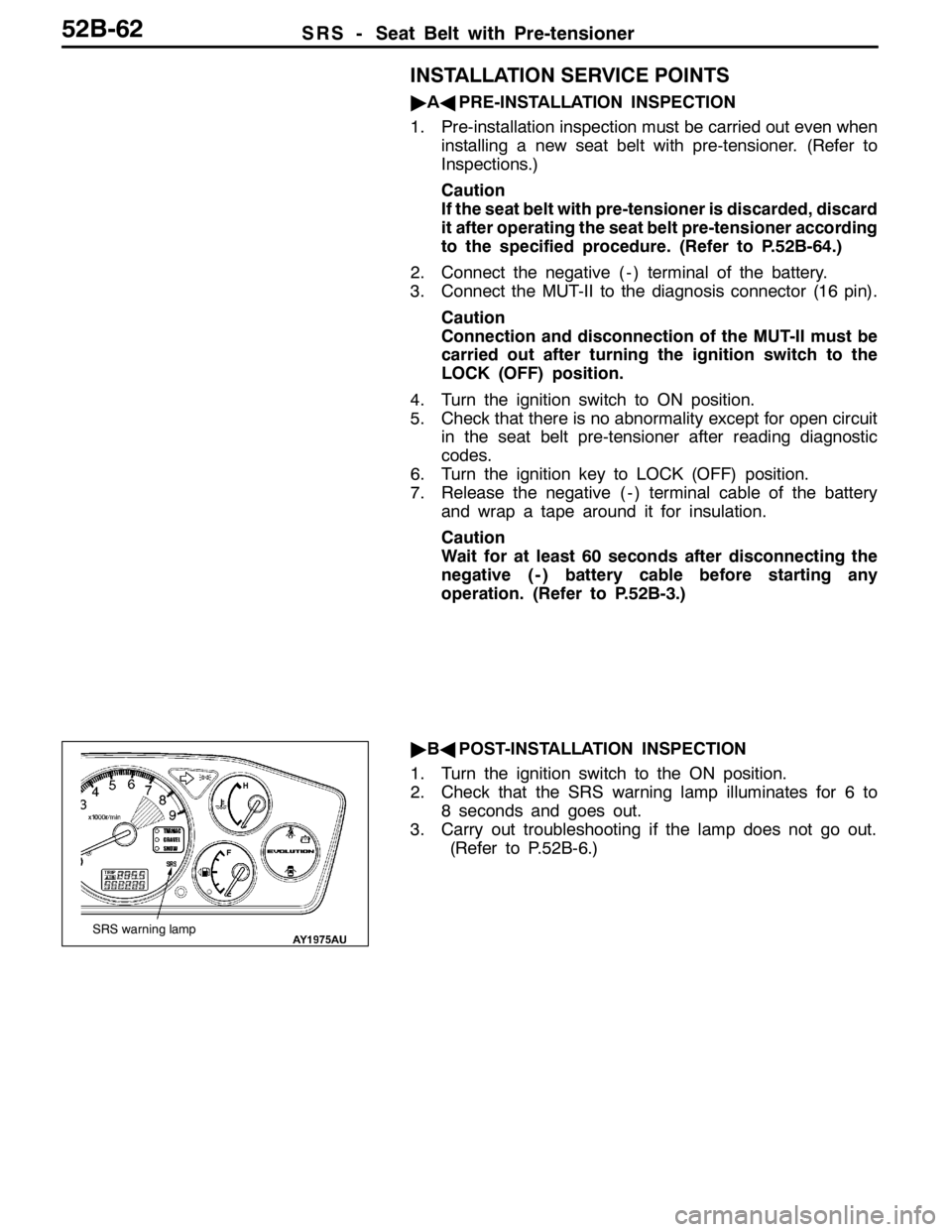

"BAPOST-INSTALLATION INSPECTION

1. Turn the ignition switch to the ON position.

2. Check that the SRS warning lamp illuminates for 6 to

8 seconds and goes out.

3. Carry out troubleshooting if the lamp does not go out.

(Refer to P.52B-6.)

SRS warning lamp

Page 1326 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-6

IGNITION SWITCH AND IMMOBILIZER SYSTEM

SPECIAL TOOLS

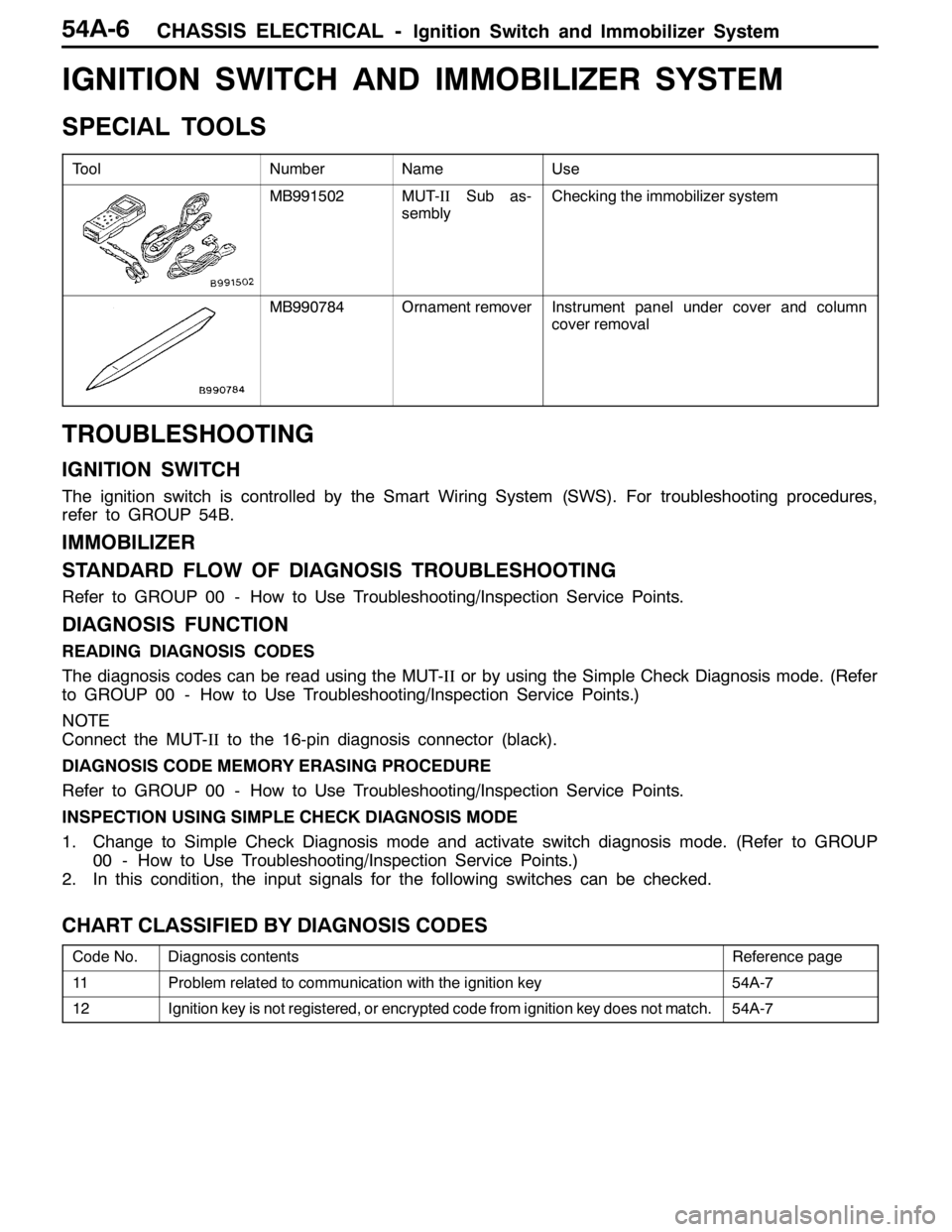

ToolNumberNameUse

MB991502MUT-IISub as-

semblyChecking the immobilizer system

MB990784Ornament removerInstrument panel under cover and column

cover removal

TROUBLESHOOTING

IGNITION SWITCH

The ignition switch is controlled by the Smart Wiring System (SWS). For troubleshooting procedures,

refer to GROUP 54B.

IMMOBILIZER

STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

DIAGNOSIS FUNCTION

READING DIAGNOSIS CODES

The diagnosis codes can be read using the MUT-IIor by using the Simple Check Diagnosis mode. (Refer

to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.)

NOTE

Connect the MUT-IIto the 16-pin diagnosis connector (black).

DIAGNOSIS CODE MEMORY ERASING PROCEDURE

Refer to GROUP 00 - How to Use Troubleshooting/Inspection Service Points.

INSPECTION USING SIMPLE CHECK DIAGNOSIS MODE

1. Change to Simple Check Diagnosis mode and activate switch diagnosis mode. (Refer to GROUP

00 - How to Use Troubleshooting/Inspection Service Points.)

2. In this condition, the input signals for the following switches can be checked.

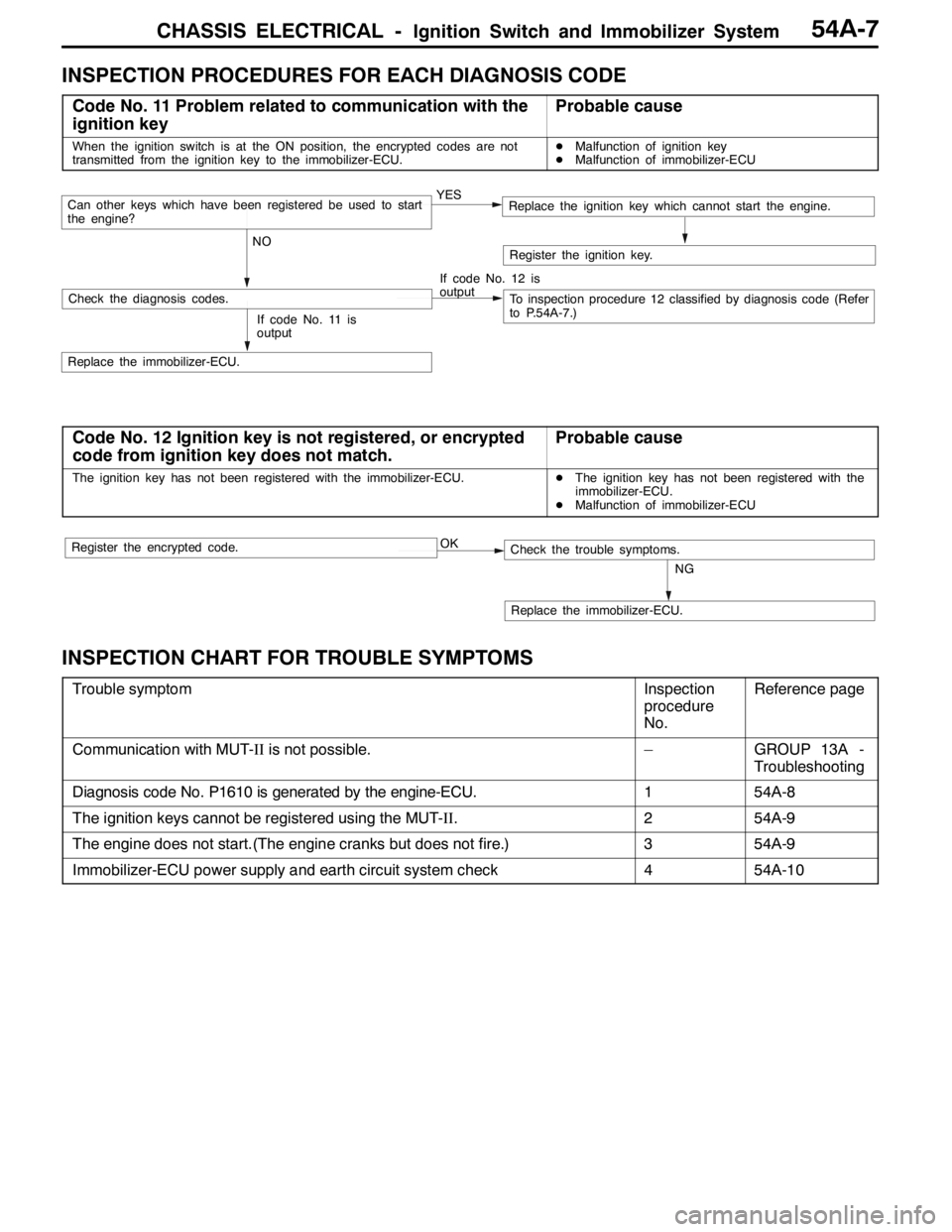

CHART CLASSIFIED BY DIAGNOSIS CODES

Code No.Diagnosis contentsReference page

11Problem related to communication with the ignition key54A-7

12Ignition key is not registered, or encrypted code from ignition key does not match.54A-7

Page 1327 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-7

INSPECTION PROCEDURES FOR EACH DIAGNOSIS CODE

Code No. 11 Problem related to communication with the

ignition keyProbable cause

When the ignition switch is at the ON position, the encrypted codes are not

transmitted from the ignition key to the immobilizer-ECU.DMalfunction of ignition key

DMalfunction of immobilizer-ECU

YES

NOCan other keys which have been registered be used to start

the engine?Replace the ignition key which cannot start the engine.

If code No. 12 is

output

Check the diagnosis codes.To inspection procedure 12 classified by diagnosis code (Refer

to P.54A-7.)

Replace the immobilizer-ECU.

Register the ignition key.

If code No. 11 is

output

Code No. 12 Ignition key is not registered, or encrypted

code from ignition key does not match.Probable cause

The ignition key has not been registered with the immobilizer-ECU.DThe ignition key has not been registered with the

immobilizer-ECU.

DMalfunction of immobilizer-ECU

OK

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.Register the encrypted code.

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure

No.Reference page

Communication with MUT-IIis not possible.–GROUP 13A -

Troubleshooting

Diagnosis code No. P1610 is generated by the engine-ECU.154A-8

The ignition keys cannot be registered using the MUT-II.254A-9

The engine does not start.(The engine cranks but does not fire.)354A-9

Immobilizer-ECU power supply and earth circuit system check454A-10

Page 1328 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-8

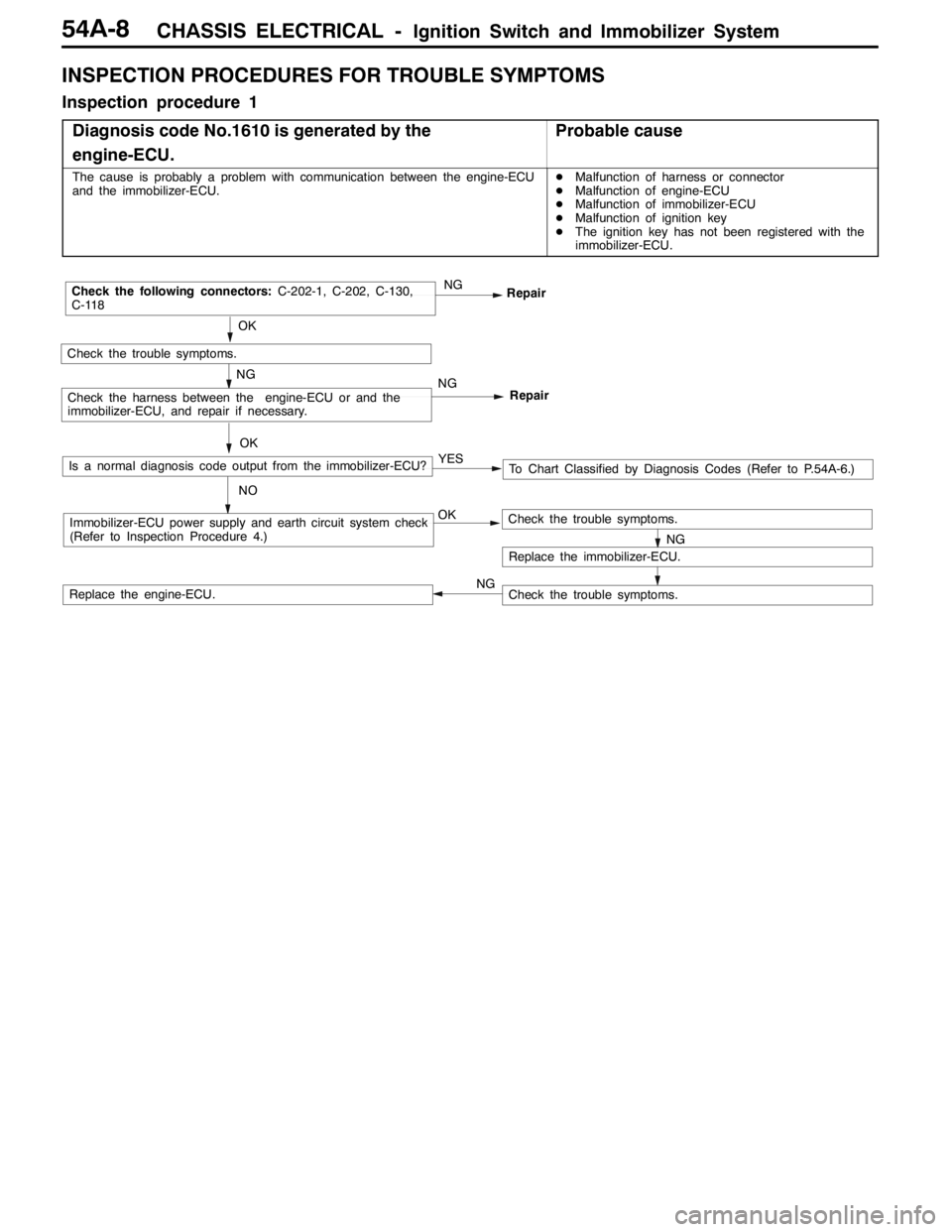

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

Diagnosis code No.1610 is generated by the

engine-ECU.

Probable cause

The cause is probably a problem with communication between the engine-ECU

and the immobilizer-ECU.DMalfunction of harness or connector

DMalfunction of engine-ECU

DMalfunction of immobilizer-ECU

DMalfunction of ignition key

DThe ignition key has not been registered with the

immobilizer-ECU.

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

OK

Check the trouble symptoms.

NGRepair

NGCheck the following connectors:C-202-1, C-202, C-130,

C-118

Repair

NGCheck the harness between the engine-ECU or and the

immobilizer-ECU, and repair if necessary.

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Check the trouble symptoms.Replace the engine-ECU.OK

Is a normal diagnosis code output from the immobilizer-ECU?

NOTo Chart Classified by Diagnosis Codes (Refer to P.54A-6.) YES

NG

Page 1329 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-9

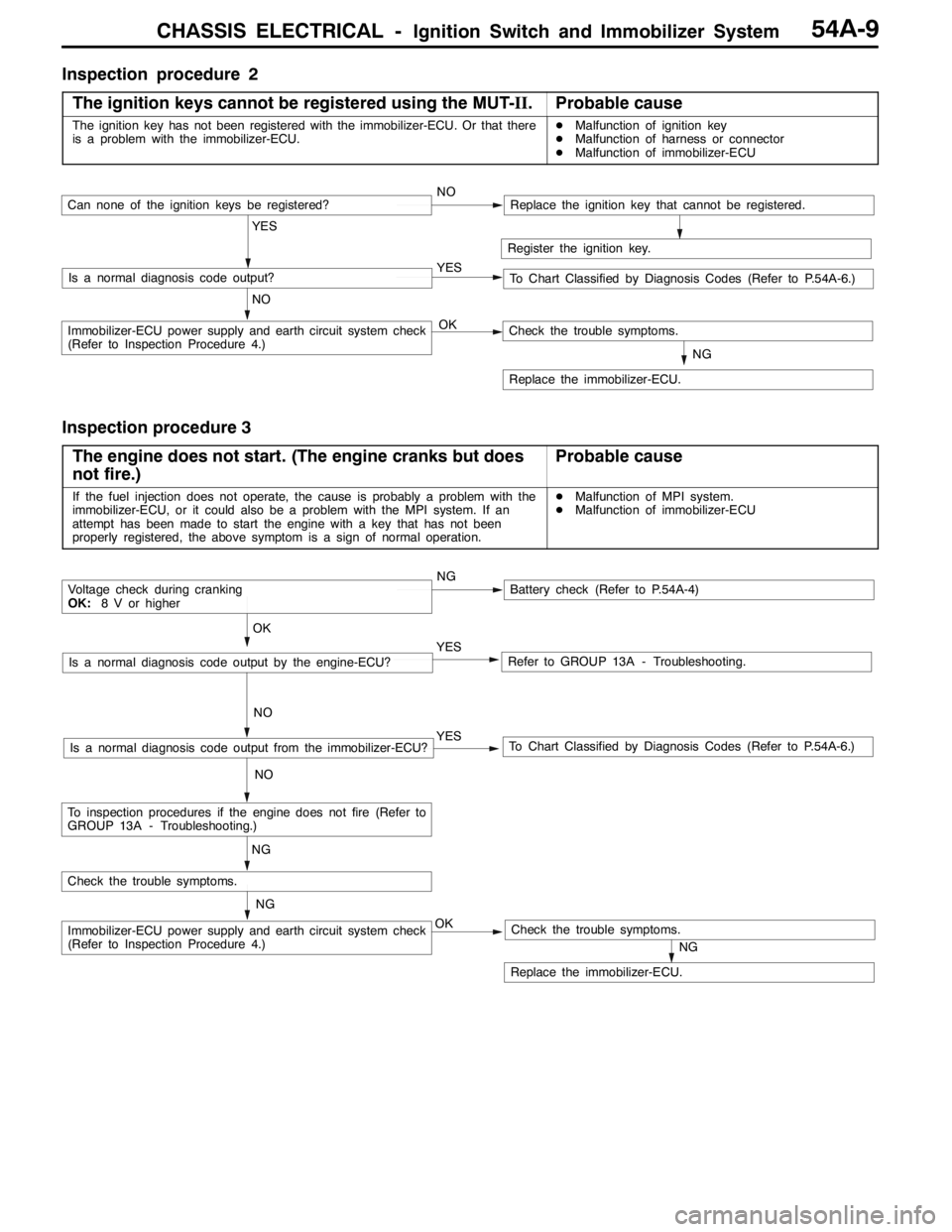

Inspection procedure 2

The ignition keys cannot be registered using the MUT-II.

Probable cause

The ignition key has not been registered with the immobilizer-ECU. Or that there

is a problem with the immobilizer-ECU.DMalfunction of ignition key

DMalfunction of harness or connector

DMalfunction of immobilizer-ECU

Register the ignition key.

YES

NO YESIs a normal diagnosis code output?

NOCan none of the ignition keys be registered?Replace the ignition key that cannot be registered.

To Chart Classified by Diagnosis Codes (Refer to P.54A-6.)

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Inspection procedure 3

The engine does not start. (The engine cranks but does

not fire.)

Probable cause

If the fuel injection does not operate, the cause is probably a problem with the

immobilizer-ECU, or it could also be a problem with the MPI system. If an

attempt has been made to start the engine with a key that has not been

properly registered, the above symptom is a sign of normal operation.DMalfunction of MPI system.

DMalfunction of immobilizer-ECU

NGBattery check (Refer to P.54A-4)

YES

NO

Refer to GROUP 13A - Troubleshooting.YES

NO

To Chart Classified by Diagnosis Codes (Refer to P.54A-6.)Is a normal diagnosis code output from the immobilizer-ECU?

OK

Voltage check during cranking

OK:8 V or higher

Is a normal diagnosis code output by the engine-ECU?

NG

OKImmobilizer-ECU power supply and earth circuit system check

(Refer to Inspection Procedure 4.)

NG

Replace the immobilizer-ECU.

Check the trouble symptoms.

Check the trouble symptoms.

NG

To inspection procedures if the engine does not fire (Refer to

GROUP 13A - Troubleshooting.)

Page 1331 of 1449

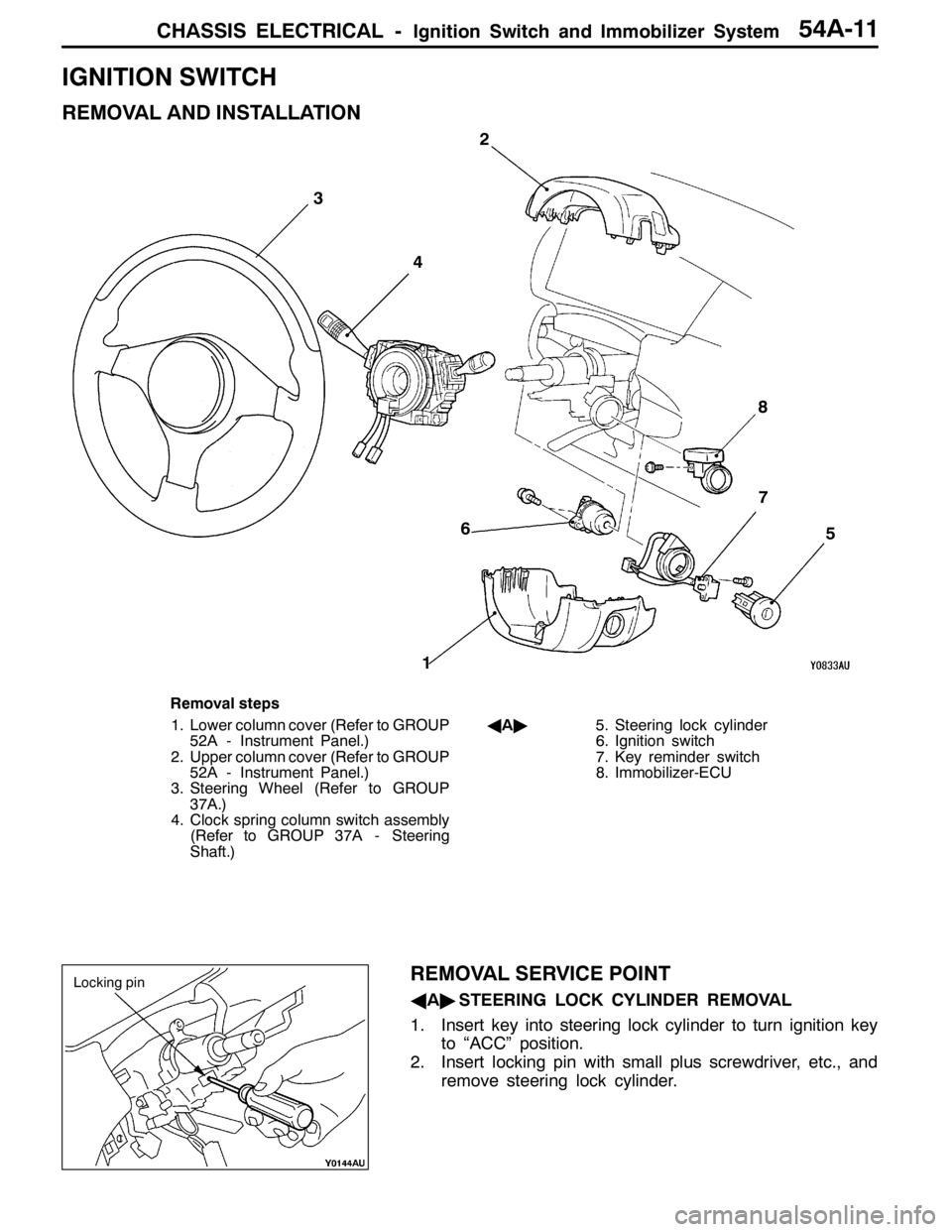

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-11

IGNITION SWITCH

REMOVAL AND INSTALLATION

7

6

15 32

4

8

Removal steps

1. Lower column cover (Refer to GROUP

52A - Instrument Panel.)

2. Upper column cover (Refer to GROUP

52A - Instrument Panel.)

3. Steering Wheel (Refer to GROUP

37A.)

4. Clock spring column switch assembly

(Refer to GROUP 37A - Steering

Shaft.)AA"5. Steering lock cylinder

6. Ignition switch

7. Key reminder switch

8. Immobilizer-ECU

REMOVAL SERVICE POINT

AA"STEERING LOCK CYLINDER REMOVAL

1. Insert key into steering lock cylinder to turn ignition key

to “ACC” position.

2. Insert locking pin with small plus screwdriver, etc., and

remove steering lock cylinder.

Locking pin

Page 1332 of 1449

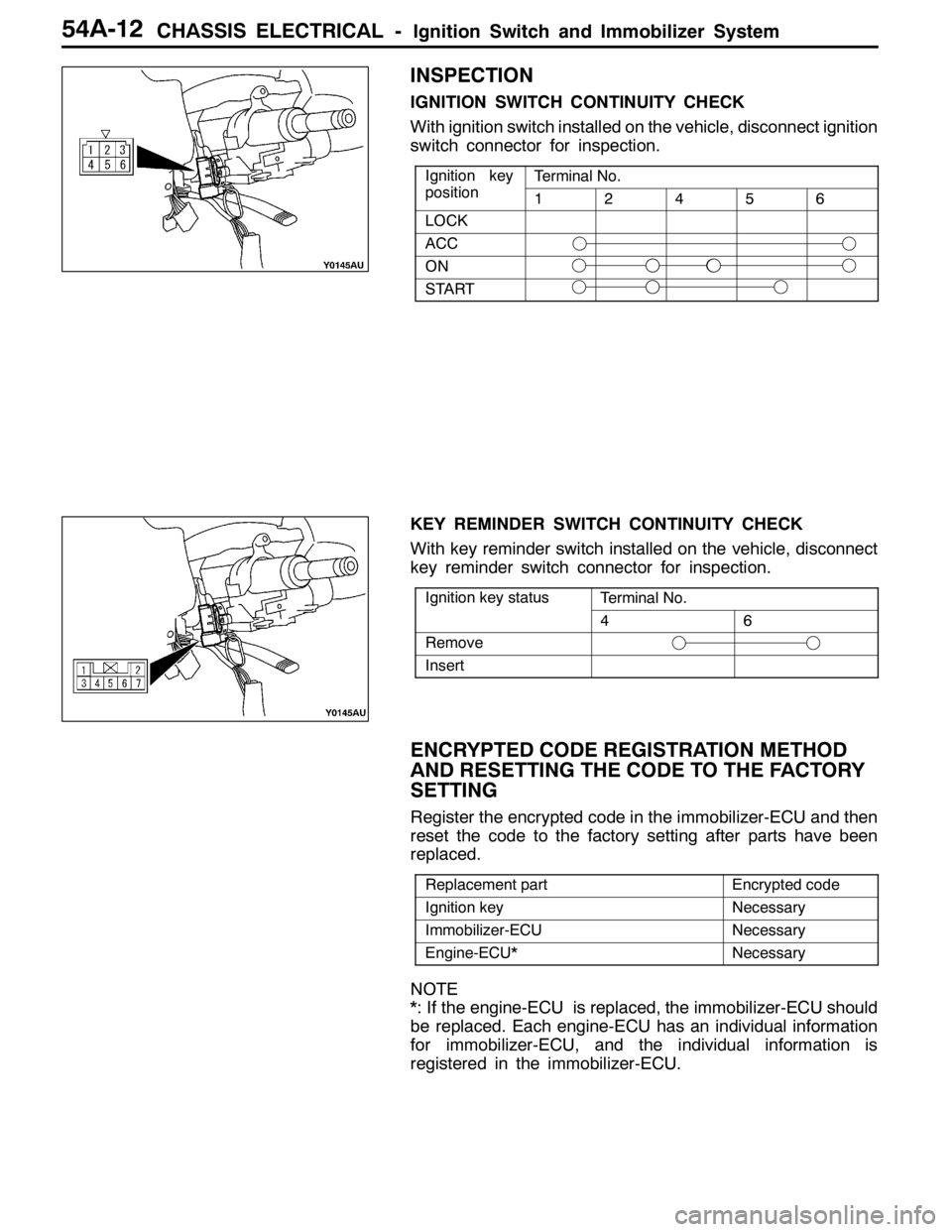

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-12

INSPECTION

IGNITION SWITCH CONTINUITY CHECK

With ignition switch installed on the vehicle, disconnect ignition

switch connector for inspection.

Ignition key

iti

Terminal No.gy

position12456

LOCK

ACC

ON

START

KEY REMINDER SWITCH CONTINUITY CHECK

With key reminder switch installed on the vehicle, disconnect

key reminder switch connector for inspection.

Ignition key statusTerminal No.gy

46

Remove

Insert

ENCRYPTED CODE REGISTRATION METHOD

AND RESETTING THE CODE TO THE FACTORY

SETTING

Register the encrypted code in the immobilizer-ECU and then

reset the code to the factory setting after parts have been

replaced.

Replacement partEncrypted code

Ignition keyNecessary

Immobilizer-ECUNecessary

Engine-ECU*Necessary

NOTE

*: If the engine-ECU is replaced, the immobilizer-ECU should

be replaced. Each engine-ECU has an individual information

for immobilizer-ECU, and the individual information is

registered in the immobilizer-ECU.