key MITSUBISHI LANCER EVOLUTION 2007 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 432 of 1449

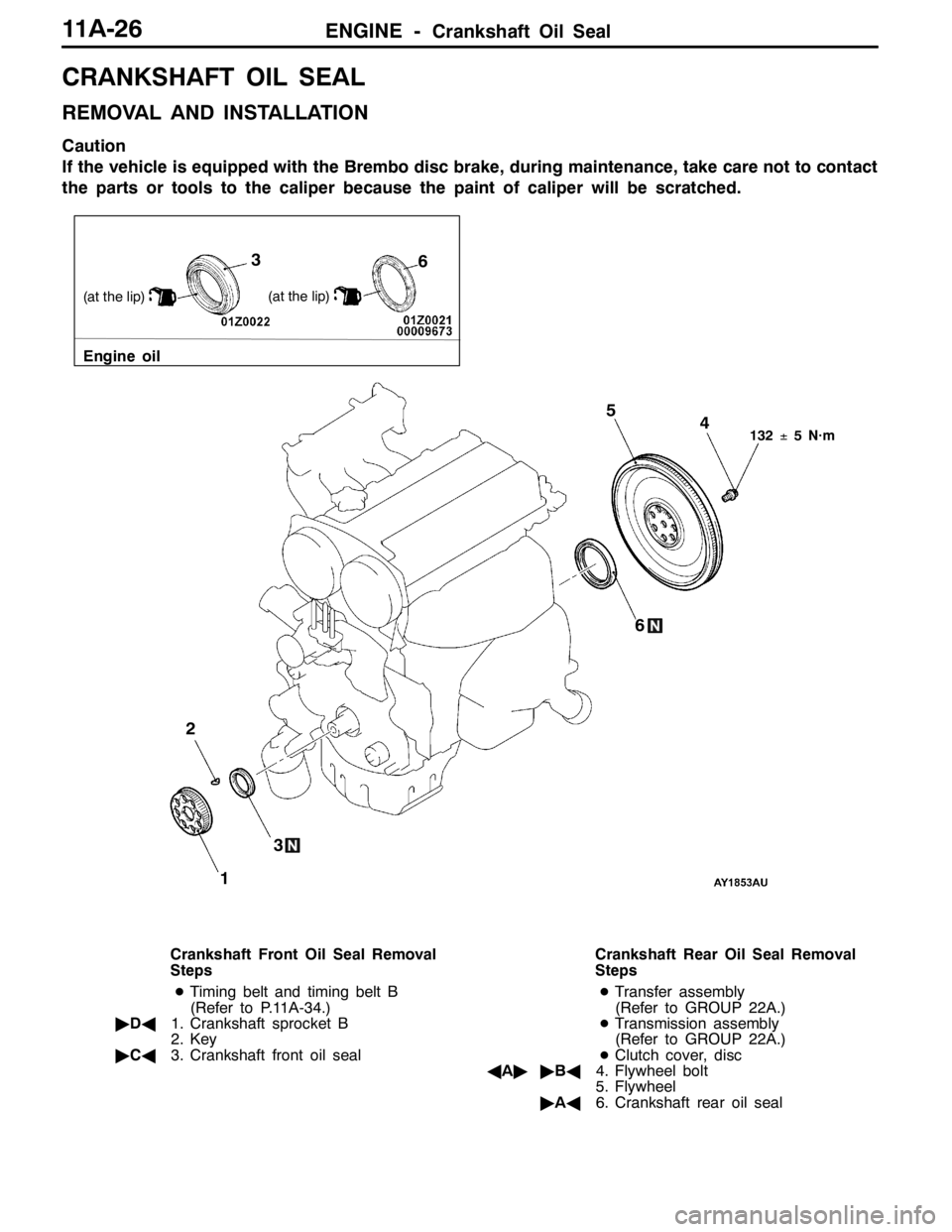

ENGINE -Crankshaft Oil Seal11A-26

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

1 2

34 5

6

Engine oil

(at the lip)

(at the lip)

3

6

132±5 N·m

Crankshaft Front Oil Seal Removal

Steps

DTiming belt and timing belt B

(Refer to P.11A-34.)

"DA1. Crankshaft sprocket B

2. Key

"CA3. Crankshaft front oil sealCrankshaft Rear Oil Seal Removal

Steps

DTransfer assembly

(Refer to GROUP 22A.)

DTransmission assembly

(Refer to GROUP 22A.)

DClutch cover, disc

AA""BA4. Flywheel bolt

5. Flywheel

"AA6. Crankshaft rear oil seal

Page 467 of 1449

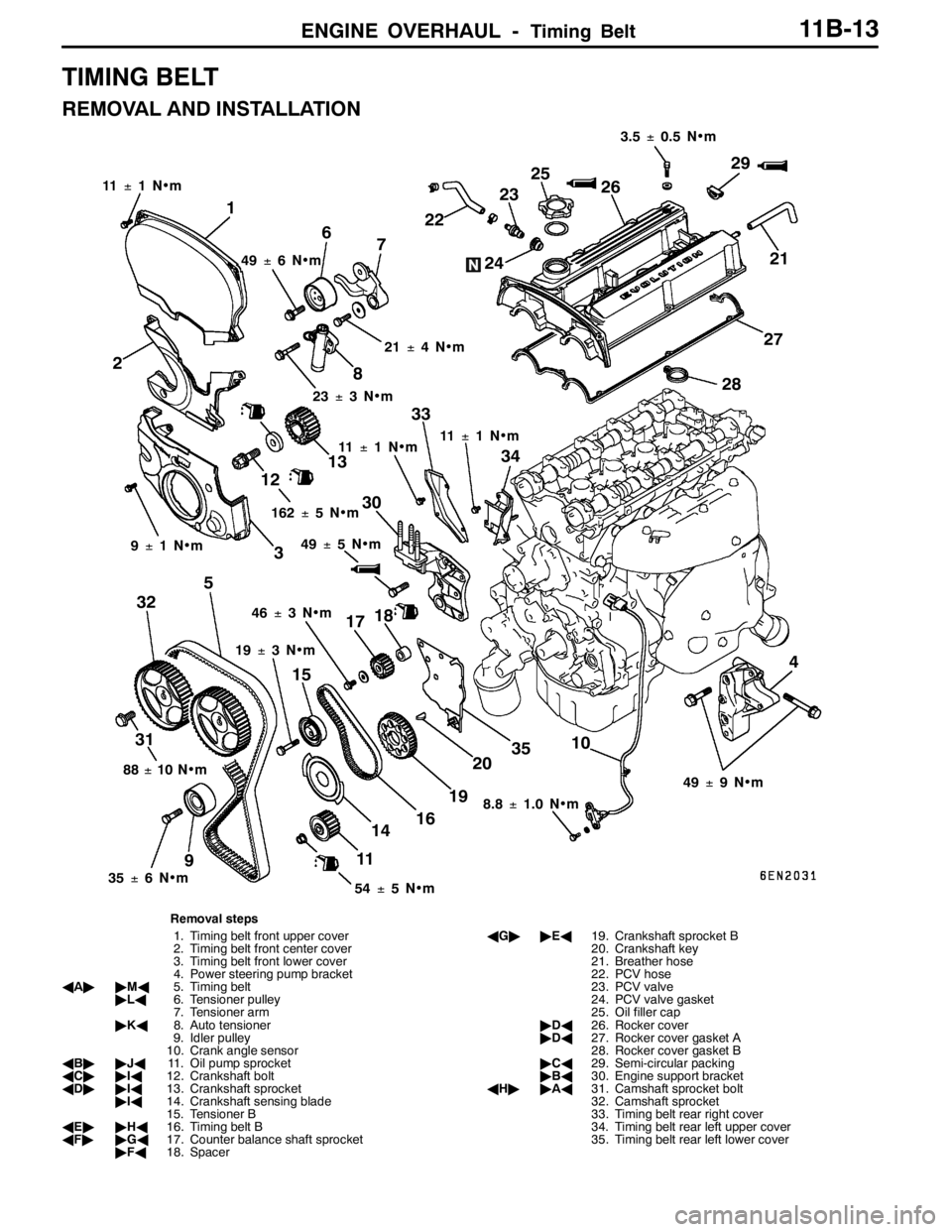

ENGINE OVERHAUL -Timing Belt11B-13

TIMING BELT

REMOVAL AND INSTALLATION

1

11±1N•m

2

3

4 56

7

8

910

11 1213

14 15

16 1718

192021 2223

2425

26

27

2829

30

313233

34

35

49±6N•m

21±4N•m

23±3N•m

11±1N•m11±1N•m

88±10 N•m

35±6N•m

54±5N•m 19±3N•m 46±3N•m 9±1N•m162±5N•m3.5±0.5 N•m

49±9N•m

8.8±1.0 N•m 49±5N•m

Removal steps

1. Timing belt front upper cover

2. Timing belt front center cover

3. Timing belt front lower cover

4. Power steering pump bracket

AA""MA5. Timing belt

"LA6. Tensioner pulley

7. Tensioner arm

"KA8. Auto tensioner

9. Idler pulley

10. Crank angle sensor

AB""JA11. Oil pump sprocket

AC""IA12. Crankshaft bolt

AD""IA13. Crankshaft sprocket

"IA14. Crankshaft sensing blade

15. Tensioner B

AE""HA16. Timing belt B

AF""GA17. Counter balance shaft sprocket

"FA18. SpacerAG""EA19. Crankshaft sprocket B

20. Crankshaft key

21. Breather hose

22. PCV hose

23. PCV valve

24. PCV valve gasket

25. Oil filler cap

"DA26. Rocker cover

"DA27. Rocker cover gasket A

28. Rocker cover gasket B

"CA29. Semi-circular packing

"BA30. Engine support bracket

AH""AA31. Camshaft sprocket bolt

32. Camshaft sprocket

33. Timing belt rear right cover

34. Timing belt rear left upper cover

35. Timing belt rear left lower cover

Page 541 of 1449

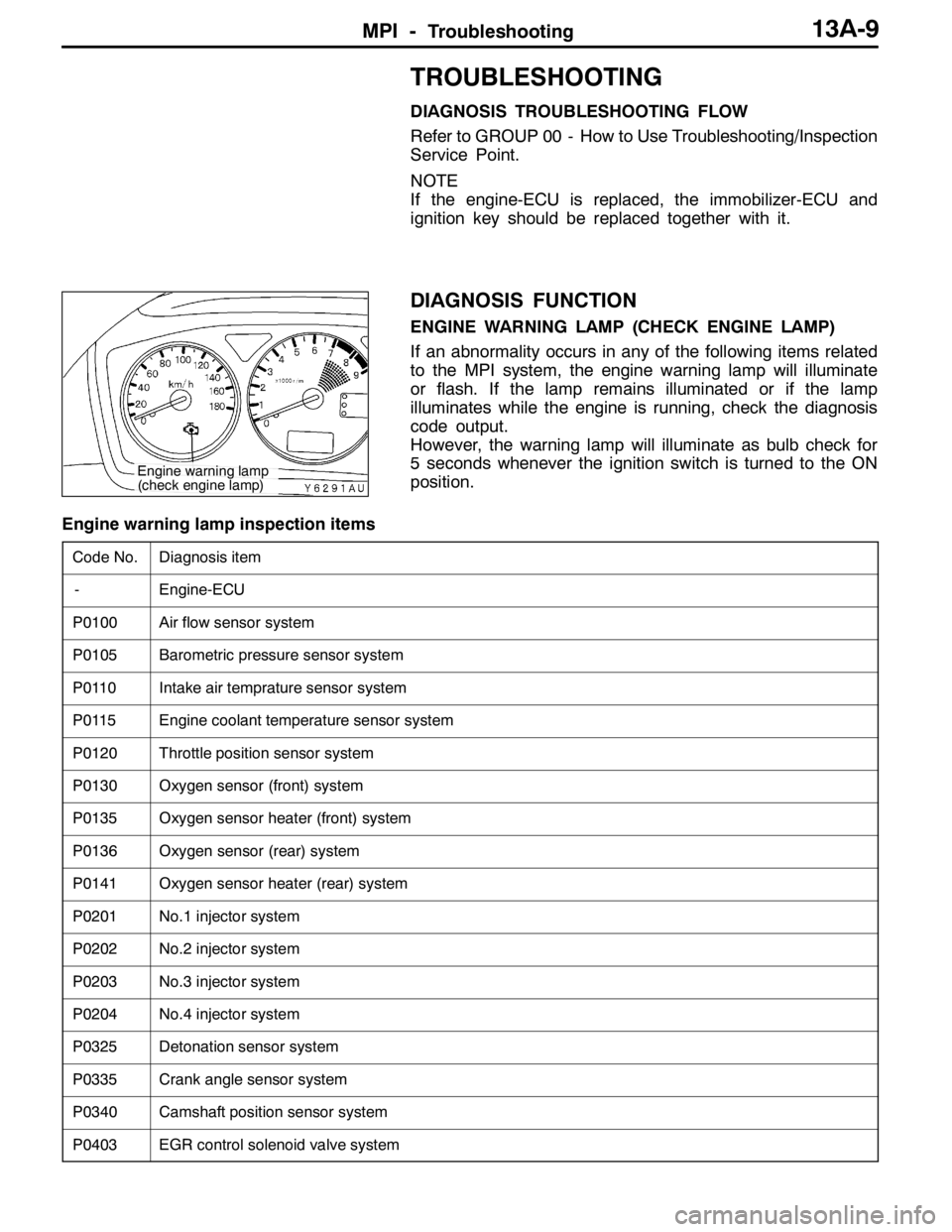

MPI -Troubleshooting13A-9

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOW

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Point.

NOTE

If the engine-ECU is replaced, the immobilizer-ECU and

ignition key should be replaced together with it.

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the MPI system, the engine warning lamp will illuminate

or flash. If the lamp remains illuminated or if the lamp

illuminates while the engine is running, check the diagnosis

code output.

However, the warning lamp will illuminate as bulb check for

5 seconds whenever the ignition switch is turned to the ON

position.

Engine warning lamp inspection items

Code No.Diagnosis item

-Engine-ECU

P0100Air flow sensor system

P0105Barometric pressure sensor system

P0110Intake air temprature sensor system

P0115Engine coolant temperature sensor system

P0120Throttle position sensor system

P0130Oxygen sensor (front) system

P0135Oxygen sensor heater (front) system

P0136Oxygen sensor (rear) system

P0141Oxygen sensor heater (rear) system

P0201No.1 injector system

P0202No.2 injector system

P0203No.3 injector system

P0204No.4 injector system

P0325Detonation sensor system

P0335Crank angle sensor system

P0340Camshaft position sensor system

P0403EGR control solenoid valve system

Engine warning lamp

(check engine lamp)

Page 583 of 1449

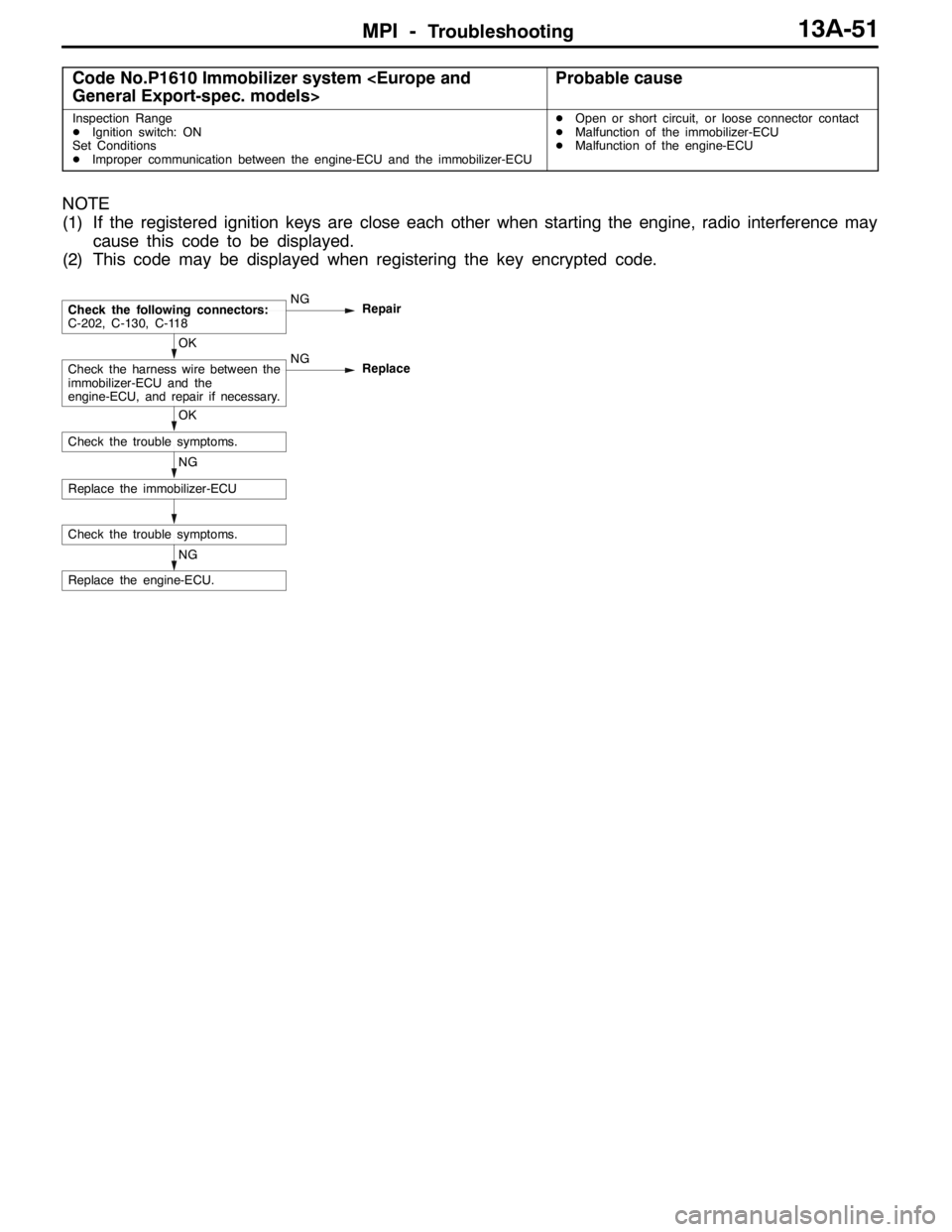

MPI -Troubleshooting13A-51

Code No.P1610 Immobilizer system

Inspection Range

DIgnition switch: ON

Set Conditions

DImproper communication between the engine-ECU and the immobilizer-ECUDOpen or short circuit, or loose connector contact

DMalfunction of the immobilizer-ECU

DMalfunction of the engine-ECU

NOTE

(1) If the registered ignition keys are close each other when starting the engine, radio interference may

cause this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

NG

Replace the engine-ECU.

Check the trouble symptoms.

NG

Replace the immobilizer-ECU

OK

Check the trouble symptoms.

OK

Check the harness wire between the

immobilizer-ECU and the

engine-ECU, and repair if necessary.NG

Replace

Check the following connectors:

C-202, C-130, C-118NG

Repair

Page 660 of 1449

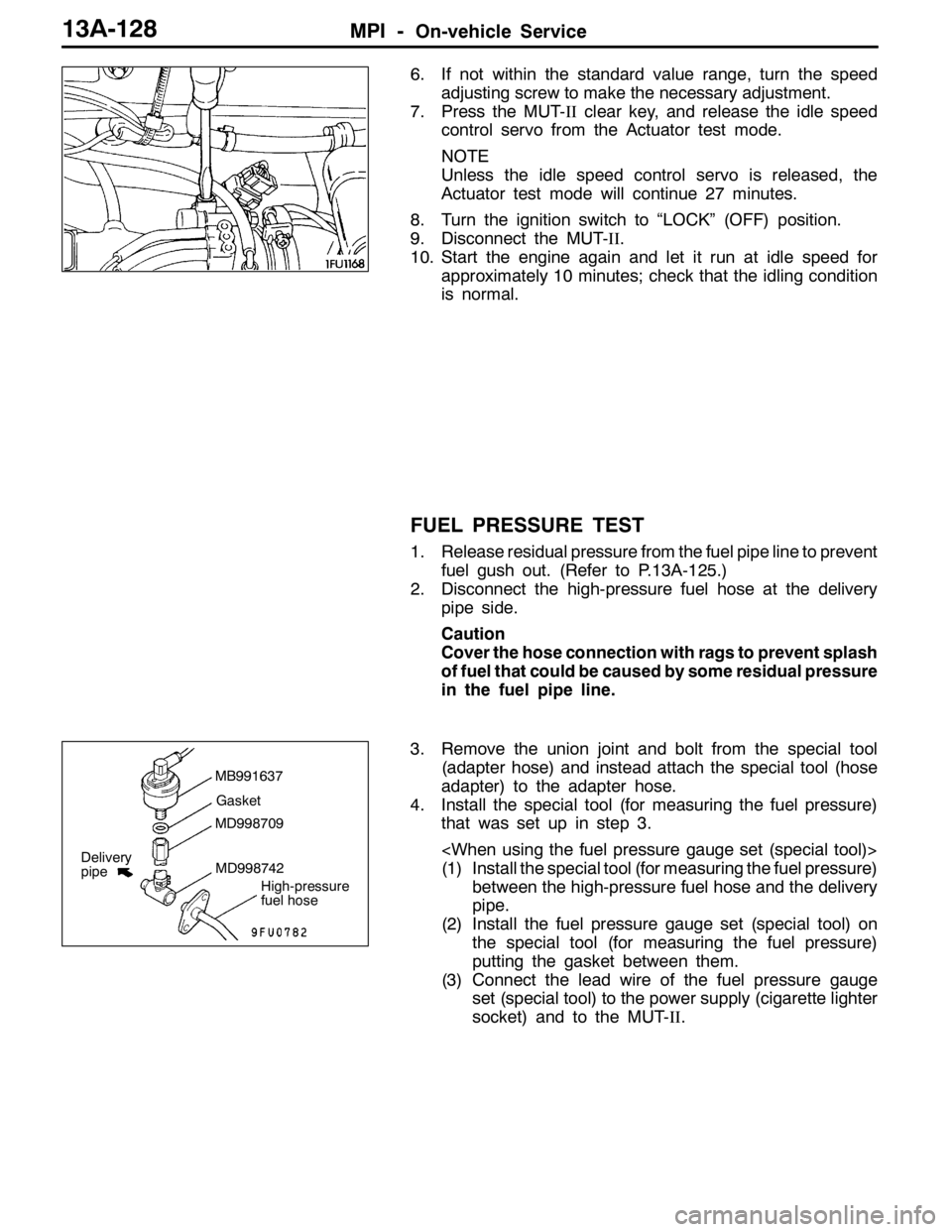

MPI -On-vehicle Service13A-128

6. If not within the standard value range, turn the speed

adjusting screw to make the necessary adjustment.

7. Press the MUT-IIclear key, and release the idle speed

control servo from the Actuator test mode.

NOTE

Unless the idle speed control servo is released, the

Actuator test mode will continue 27 minutes.

8. Turn the ignition switch to “LOCK” (OFF) position.

9. Disconnect the MUT-II.

10. Start the engine again and let it run at idle speed for

approximately 10 minutes; check that the idling condition

is normal.

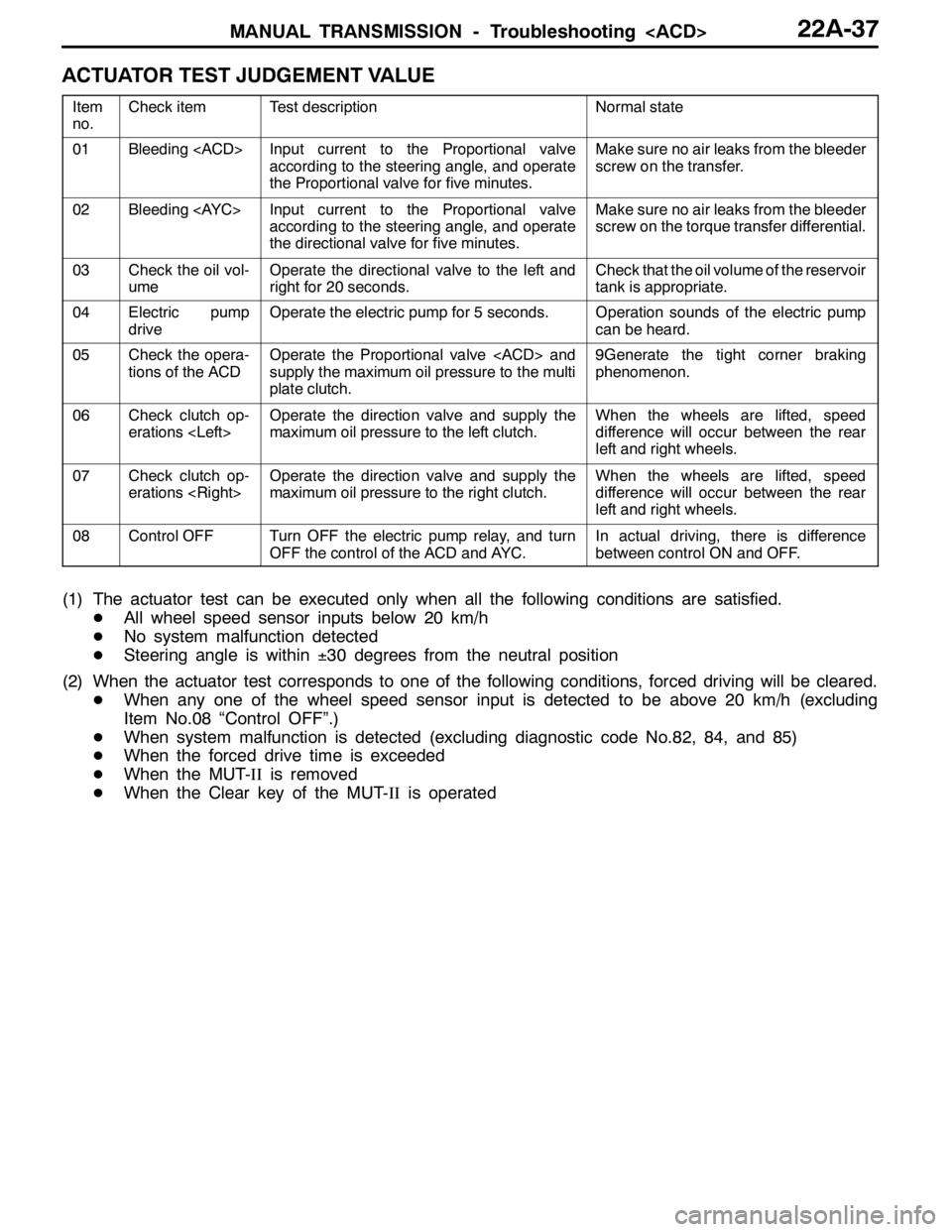

FUEL PRESSURE TEST

1. Release residual pressure from the fuel pipe line to prevent

fuel gush out. (Refer to P.13A-125.)

2. Disconnect the high-pressure fuel hose at the delivery

pipe side.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressure

in the fuel pipe line.

3. Remove the union joint and bolt from the special tool

(adapter hose) and instead attach the special tool (hose

adapter) to the adapter hose.

4. Install the special tool (for measuring the fuel pressure)

that was set up in step 3.

(1) Install the special tool (for measuring the fuel pressure)

between the high-pressure fuel hose and the delivery

pipe.

(2) Install the fuel pressure gauge set (special tool) on

the special tool (for measuring the fuel pressure)

putting the gasket between them.

(3) Connect the lead wire of the fuel pressure gauge

set (special tool) to the power supply (cigarette lighter

socket) and to the MUT-II.

MB991637

Gasket

MD998709

MD998742

High-pressure

fuel hose

Delivery

pipe

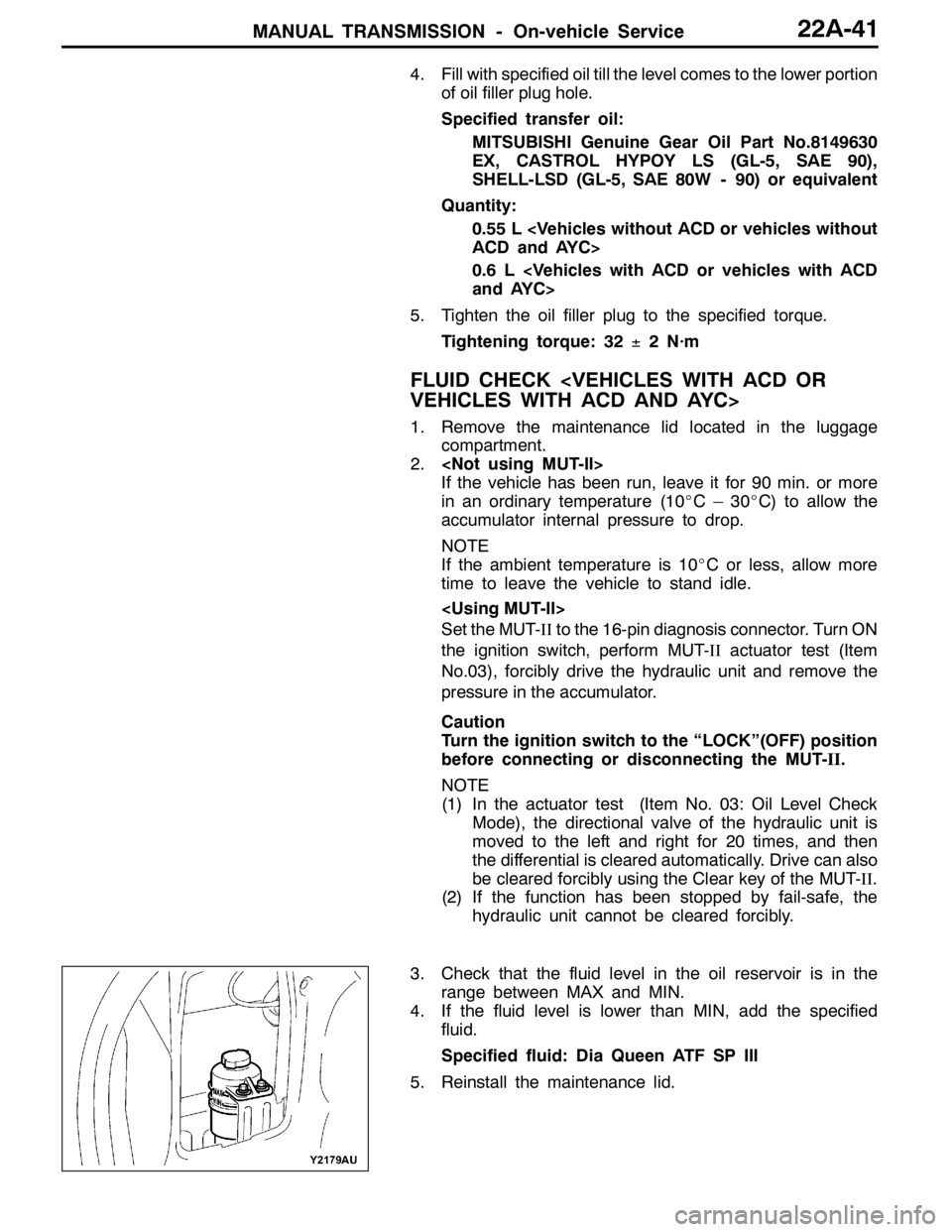

Page 845 of 1449

MANUAL TRANSMISSION - Troubleshooting

ACTUATOR TEST JUDGEMENT VALUE

Item

no.Check itemTest descriptionNormal state

01Bleeding

according to the steering angle, and operate

the Proportional valve for five minutes.Make sure no air leaks from the bleeder

screw on the transfer.

02Bleeding

according to the steering angle, and operate

the directional valve for five minutes.Make sure no air leaks from the bleeder

screw on the torque transfer differential.

03Check the oil vol-

umeOperate the directional valve to the left and

right for 20 seconds.Check that the oil volume of the reservoir

tank is appropriate.

04Electric pump

driveOperate the electric pump for 5 seconds.Operation sounds of the electric pump

can be heard.

05Check the opera-

tions of the ACDOperate the Proportional valve

supply the maximum oil pressure to the multi

plate clutch.9Generate the tight corner braking

phenomenon.

06Check clutch op-

erations

maximum oil pressure to the left clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

07Check clutch op-

erations

maximum oil pressure to the right clutch.When the wheels are lifted, speed

difference will occur between the rear

left and right wheels.

08Control OFFTurn OFF the electric pump relay, and turn

OFF the control of the ACD and AYC.In actual driving, there is difference

between control ON and OFF.

(1) The actuator test can be executed only when all the following conditions are satisfied.

DAll wheel speed sensor inputs below 20 km/h

DNo system malfunction detected

DSteering angle is within±30 degrees from the neutral position

(2) When the actuator test corresponds to one of the following conditions, forced driving will be cleared.

DWhen any one of the wheel speed sensor input is detected to be above 20 km/h (excluding

Item No.08 “Control OFF”.)

DWhen system malfunction is detected (excluding diagnostic code No.82, 84, and 85)

DWhen the forced drive time is exceeded

DWhen the MUT-IIis removed

DWhen the Clear key of the MUT-IIis operated

Page 849 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-41

4. Fill with specified oil till the level comes to the lower portion

of oil filler plug hole.

Specified transfer oil:

MITSUBISHI Genuine Gear Oil Part No.8149630

EX, CASTROL HYPOY LS (GL-5, SAE 90),

SHELL-LSD (GL-5, SAE 80W - 90) or equivalent

Quantity:

0.55 L

0.6 L

5. Tighten the oil filler plug to the specified torque.

Tightening torque: 32±2 N·m

FLUID CHECK

1. Remove the maintenance lid located in the luggage

compartment.

2.

If the vehicle has been run, leave it for 90 min. or more

in an ordinary temperature (10_C–30_C) to allow the

accumulator internal pressure to drop.

NOTE

If the ambient temperature is 10_C or less, allow more

time to leave the vehicle to stand idle.

Set the MUT-IIto the 16-pin diagnosis connector. Turn ON

the ignition switch, perform MUT-IIactuator test (Item

No.03), forcibly drive the hydraulic unit and remove the

pressure in the accumulator.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

NOTE

(1) In the actuator test (Item No. 03: Oil Level Check

Mode), the directional valve of the hydraulic unit is

moved to the left and right for 20 times, and then

the differential is cleared automatically. Drive can also

be cleared forcibly using the Clear key of the MUT-II.

(2) If the function has been stopped by fail-safe, the

hydraulic unit cannot be cleared forcibly.

3. Check that the fluid level in the oil reservoir is in the

range between MAX and MIN.

4. If the fluid level is lower than MIN, add the specified

fluid.

Specified fluid: Dia Queen ATF SP III

5. Reinstall the maintenance lid.

Page 850 of 1449

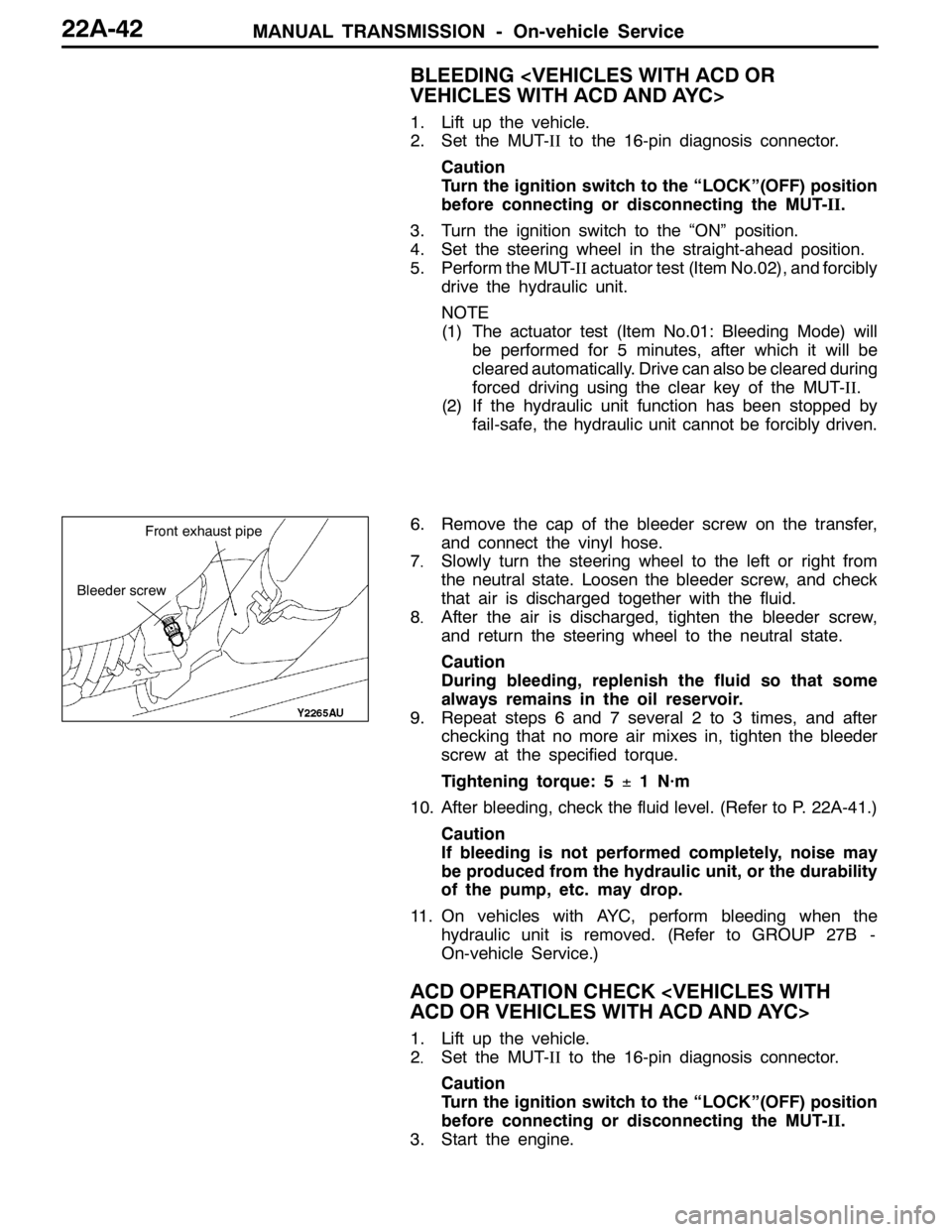

MANUAL TRANSMISSION - On-vehicle Service22A-42

BLEEDING

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Turn the ignition switch to the “ON” position.

4. Set the steering wheel in the straight-ahead position.

5. Perform the MUT-IIactuator test (Item No.02), and forcibly

drive the hydraulic unit.

NOTE

(1) The actuator test (Item No.01: Bleeding Mode) will

be performed for 5 minutes, after which it will be

cleared automatically. Drive can also be cleared during

forced driving using the clear key of the MUT-II.

(2) If the hydraulic unit function has been stopped by

fail-safe, the hydraulic unit cannot be forcibly driven.

6. Remove the cap of the bleeder screw on the transfer,

and connect the vinyl hose.

7

.Slowly turn the steering wheel to the left or right from

the neutral state. Loosen the bleeder screw, and check

that air is discharged together with the fluid.

8

.After the air is discharged, tighten the bleeder screw,

and return the steering wheel to the neutral state.

Caution

During bleeding, replenish the fluid so that some

always remains in the oil reservoir.

9. Repeat steps 6 and 7 several 2 to 3 times, and after

checking that no more air mixes in, tighten the bleeder

screw at the specified torque.

Tightening torque: 5±1 N·m

10. After bleeding, check the fluid level. (Refer to P. 22A-41.)

Caution

If bleeding is not performed completely, noise may

be produced from the hydraulic unit, or the durability

of the pump, etc. may drop.

11. On vehicles with AYC, perform bleeding when the

hydraulic unit is removed. (Refer to GROUP 27B -

On-vehicle Service.)

ACD OPERATION CHECK

1. Lift up the vehicle.

2

.Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Start the engine.

Bleeder screw

Front exhaust pipe

Page 851 of 1449

MANUAL TRANSMISSION - On-vehicle Service22A-43

4. Set the gear to the 2nd gear or above, operate the MUT-II,

and check from the service data (Item No.09) that the

wheel speed is within 10 km/h to 20 km/h.

NOTE

(1) Set the steering wheel to the neutral position

(2) The ACD may continue operating (operation sounds

can be heard) when the steering wheel is steered,

this is not a system fault. In this case, set the steering

wheel to the neutral position, and perform the following

operations to stop the ACD.

DRelease the clutch.

DSet the gear to “N”.

DStop the engine

5. Perform the MUT-IIactuator test (Item No.05), and forcibly

drive the transfer.

NOTE

(1) The actuator test (Item No. 05: ACD Operation Check

Mode) is performed for 1 minute, after which it will

be cleared automatically. Drive can also be cleared

during forced driving using the clear key of the MUT-II.

(2) If the hydraulic unit function has been stopped by

fail-safe, the transfer cannot be forcibly driven.

6. Check that the front and rear wheel speeds satisfy the

following in the MUT-IIactuator test (Item No.05).

The front wheel will be faster than the back wheels by

more than 2 km/h.

NOTE

If the above are not satisfied, check the oil pressure as

the system may be faulty.

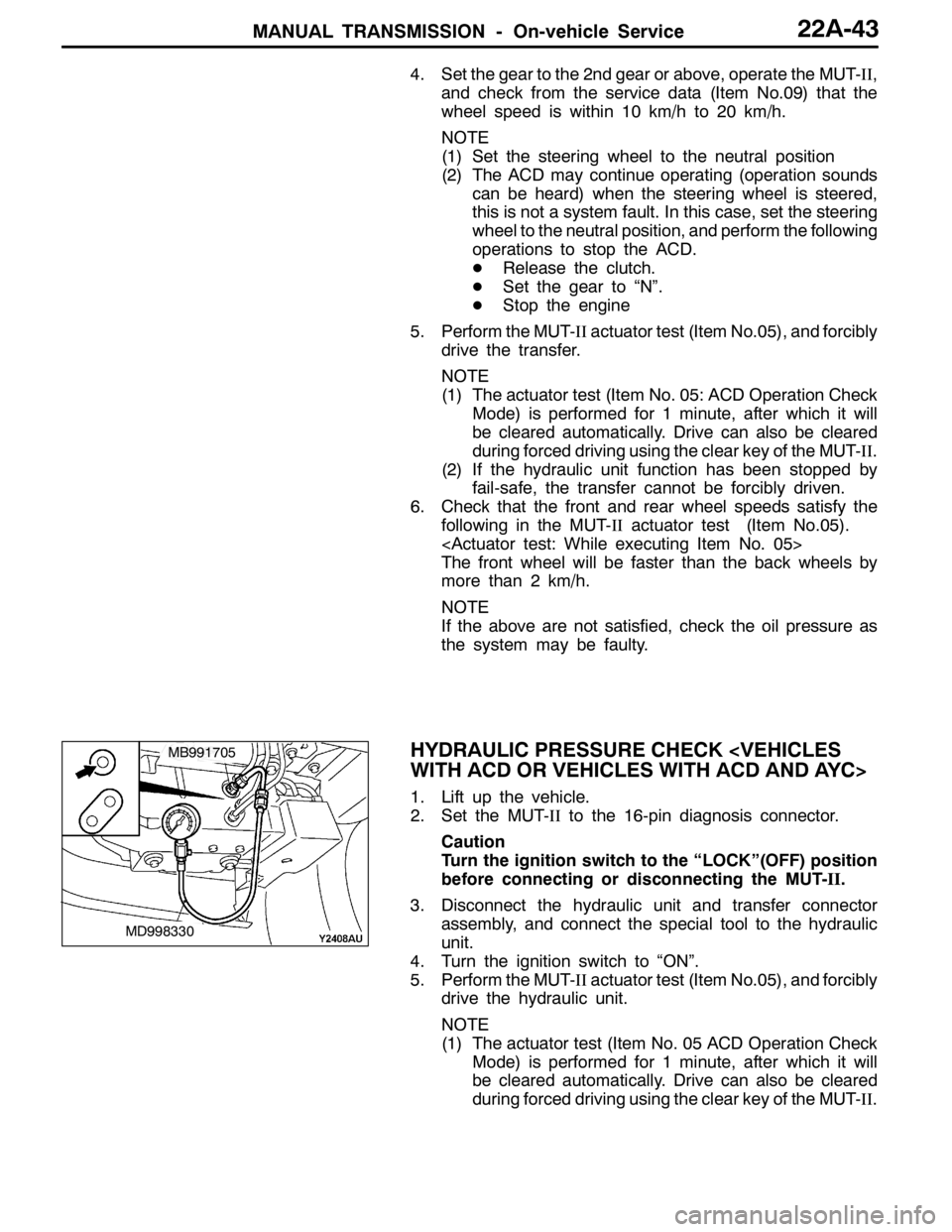

HYDRAULIC PRESSURE CHECK

1. Lift up the vehicle.

2. Set the MUT-IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the “LOCK”(OFF) position

before connecting or disconnecting the MUT-II.

3. Disconnect the hydraulic unit and transfer connector

assembly, and connect the special tool to the hydraulic

unit.

4. Turn the ignition switch to “ON”.

5. Perform the MUT-IIactuator test (Item No.05), and forcibly

drive the hydraulic unit.

NOTE

(1) The actuator test (Item No. 05 ACD Operation Check

Mode) is performed for 1 minute, after which it will

be cleared automatically. Drive can also be cleared

during forced driving using the clear key of the MUT-II.

MD998330

MB991705

Page 960 of 1449

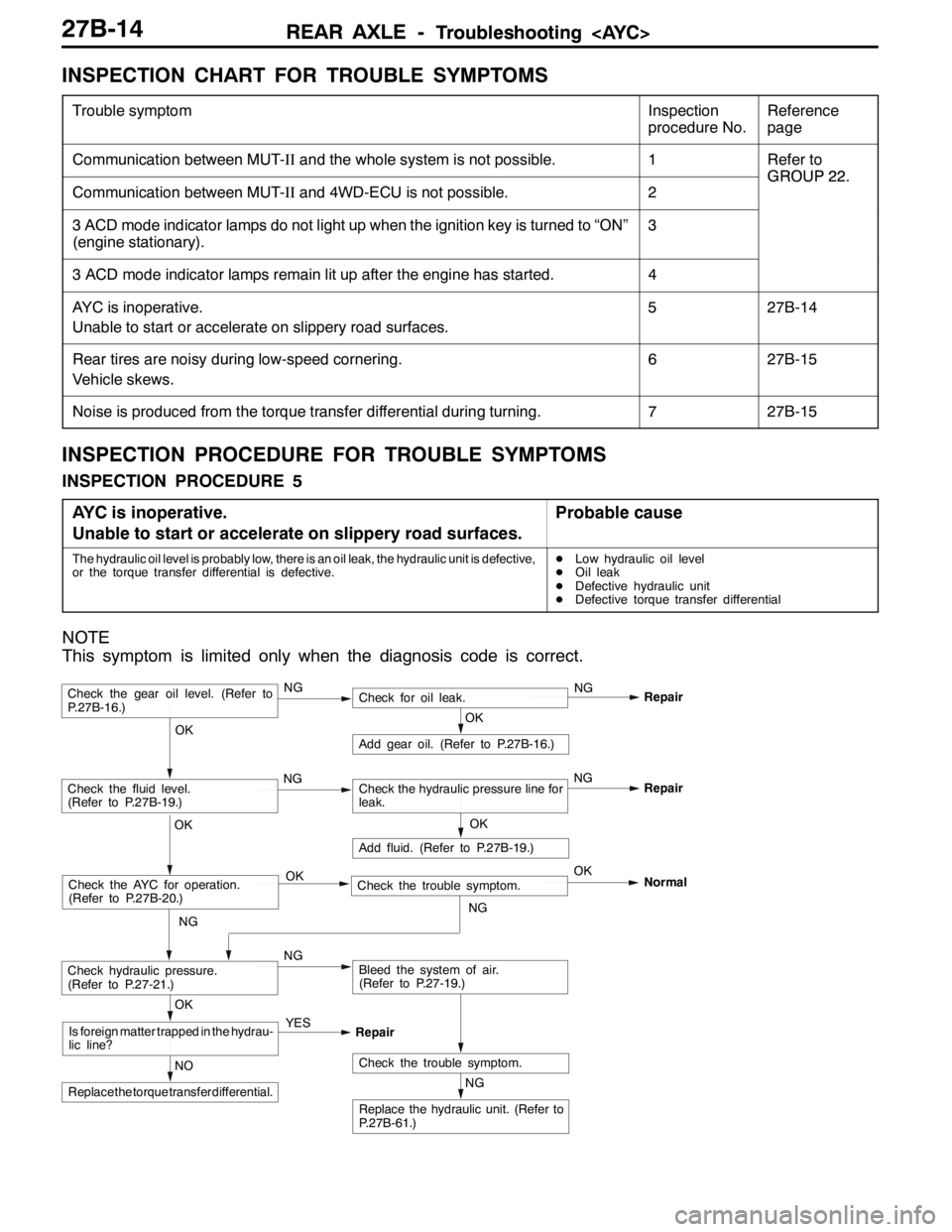

REAR AXLE -Troubleshooting

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure No.Reference

page

Communication between MUT-IIand the whole system is not possible.1Refer to

GROUP22

Communication between MUT-IIand 4WD-ECU is not possible.2

GROUP22.

3 ACD mode indicator lamps do not light up when the ignition key is turned to “ON”

(engine stationary).3

3 ACD mode indicator lamps remain lit up after the engine has started.4

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.527B-14

Rear tires are noisy during low-speed cornering.

Vehicle skews.627B-15

Noise is produced from the torque transfer differential during turning.727B-15

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

INSPECTION PROCEDURE 5

AYC is inoperative.

Unable to start or accelerate on slippery road surfaces.

Probable cause

The hydraulic oil level is probably low, there is an oil leak, the hydraulic unit is defective,

or the torque transfer differential is defective.DLow hydraulic oil level

DOil leak

DDefective hydraulic unit

DDefective torque transfer differential

NOTE

This symptom is limited only when the diagnosis code is correct.

NG

Replace the hydraulic unit. (Refer to

P.27B-61.)

NG

Add fluid. (Refer to P.27B-19.)

OKRepair

Check the trouble symptom.NO

Replace the torque transfer differential.

OK

Is foreign matter trapped in the hydrau-

lic line?YES

Repair

OK

Check the fluid level.

(Refer to P.27B-19.)Check the hydraulic pressure line for

leak.

OK

Add gear oil. (Refer to P.27B-16.)

OK

Check hydraulic pressure.

(Refer to P.27-21.)NGBleed the system of air.

(Refer to P.27-19.)

Check the gear oil level. (Refer to

P.27B-16.)NGCheck for oil leak.NG

Repair

Check the AYC for operation.

(Refer to P.27B-20.)Check the trouble symptom. OKOK

NGNormal

NGNG