key MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 1333 of 1449

CHASSIS ELECTRICAL -Ignition Switch and Immobilizer System54A-13

ENCRYPTED CODE REGISTRATION METHOD

If using an ignition key that has just been newly purchased,

or if the immobilizer-ECU has been replaced, you will need

to register the encrypted codes for each ignition key being

used into the immobilizer-ECU. (A maximum of eight different

encrypted codes can be registered.)

Moreover, when the immobilizer-ECU has been replaced, you

will need to use the MUT-IIto register the password that

the user specifies into the immobilizer-ECU. (Refer to the

MUT-IIinstruction manual for instructions on using the MUT-II.)

Caution

Because registering of the encrypted codes is carried

out after all previously-registered codes have been

erased, you should have ready all of the ignition keys

that have already been registered.

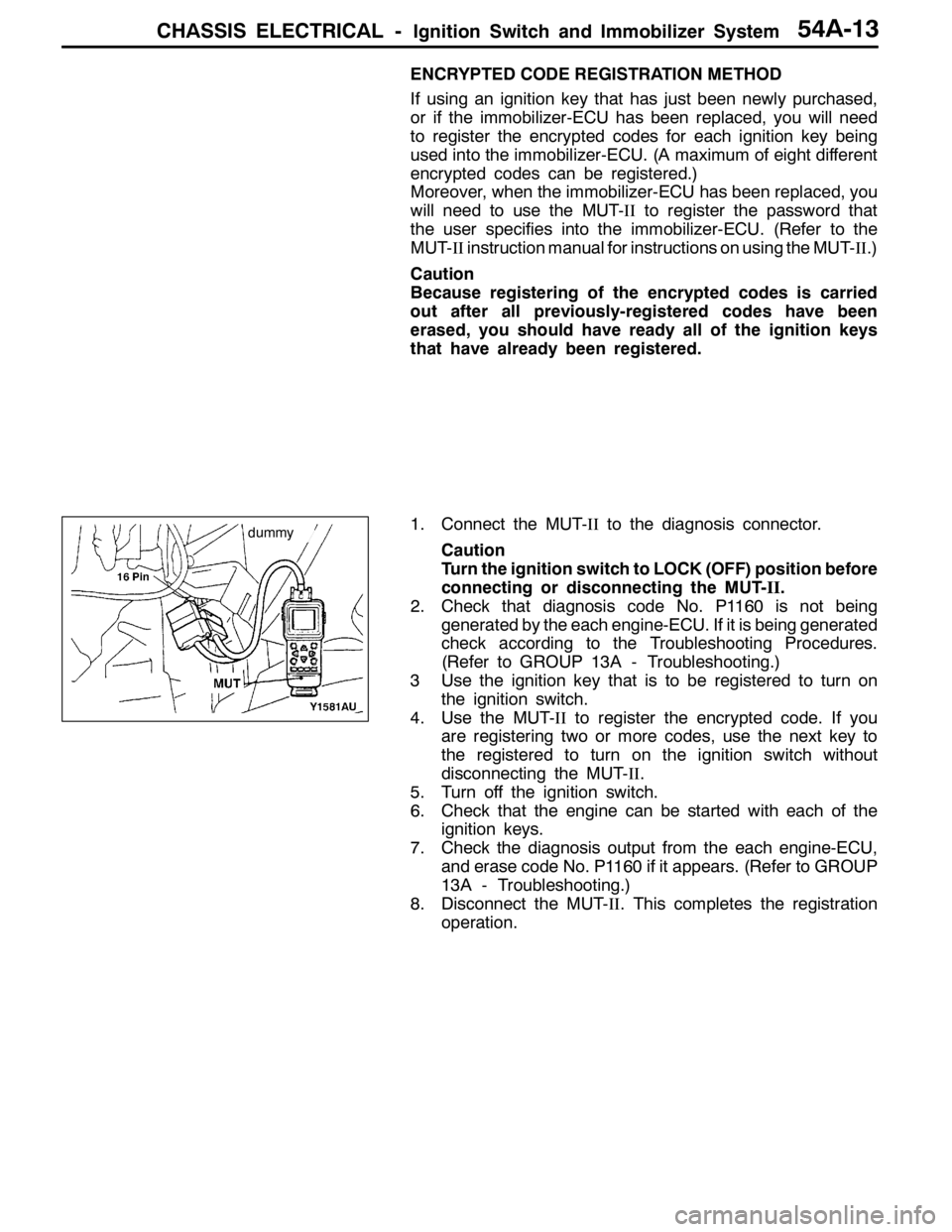

1. Connect the MUT-IIto the diagnosis connector.

Caution

Turn the ignition switch to LOCK (OFF) position before

connecting or disconnecting the MUT-II.

2. Check that diagnosis code No. P1160 is not being

generated by the each engine-ECU. If it is being generated

check according to the Troubleshooting Procedures.

(Refer to GROUP 13A - Troubleshooting.)

3 Use the ignition key that is to be registered to turn on

the ignition switch.

4. Use the MUT-IIto register the encrypted code. If you

are registering two or more codes, use the next key to

the registered to turn on the ignition switch without

disconnecting the MUT-II.

5. Turn off the ignition switch.

6. Check that the engine can be started with each of the

ignition keys.

7. Check the diagnosis output from the each engine-ECU,

and erase code No. P1160 if it appears. (Refer to GROUP

13A - Troubleshooting.)

8. Disconnect the MUT-II. This completes the registration

operation.

dummy

Page 1349 of 1449

CHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp AssemblyCHASSIS ELECTRICAL -Headlamp Assembly54A-29

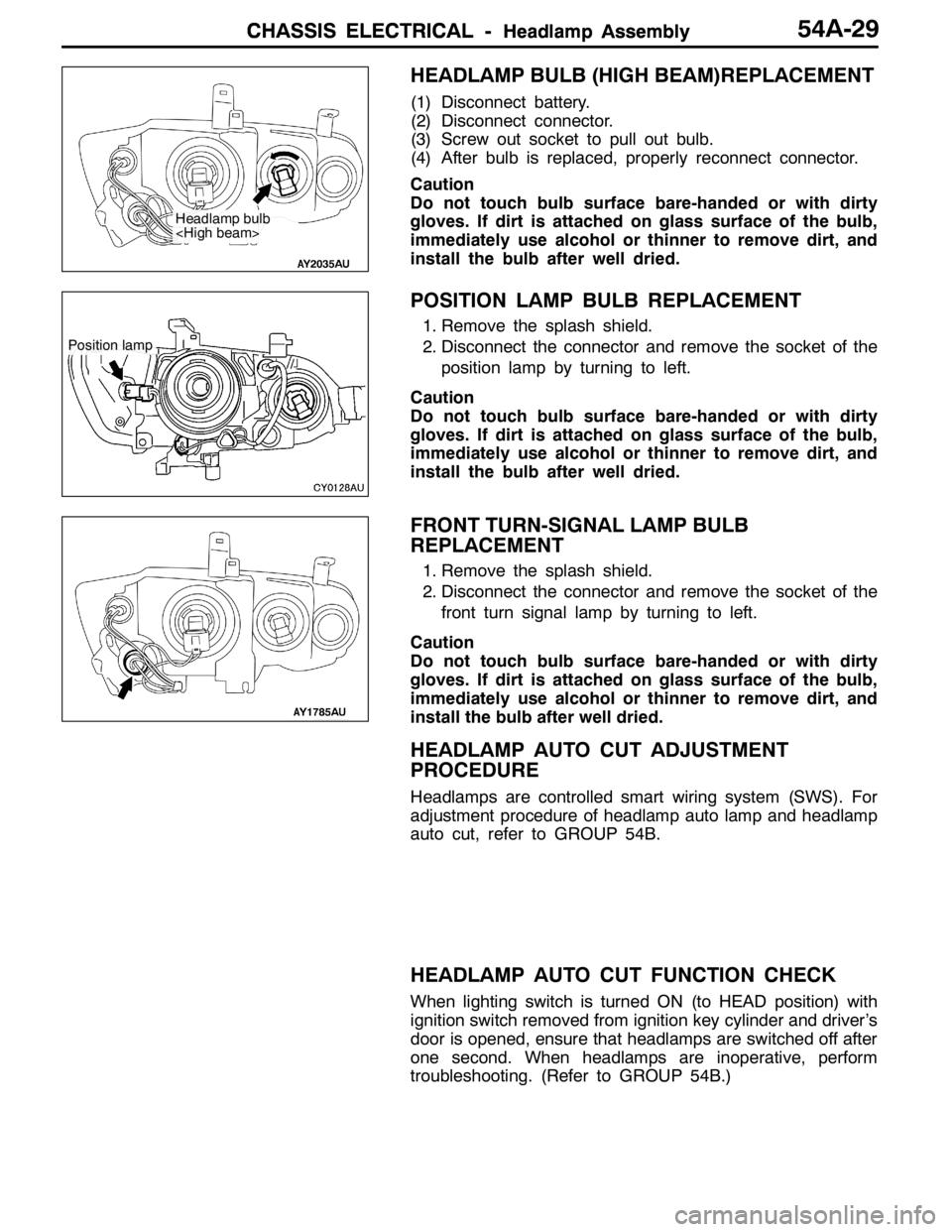

HEADLAMP BULB (HIGH BEAM)REPLACEMENT

(1) Disconnect battery.

(2) Disconnect connector.

(3) Screw out socket to pull out bulb.

(4) After bulb is replaced, properly reconnect connector.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

POSITION LAMP BULB REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

position lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

FRONT TURN-SIGNAL LAMP BULB

REPLACEMENT

1. Remove the splash shield.

2. Disconnect the connector and remove the socket of the

front turn signal lamp by turning to left.

Caution

Do not touch bulb surface bare-handed or with dirty

gloves. If dirt is attached on glass surface of the bulb,

immediately use alcohol or thinner to remove dirt, and

install the bulb after well dried.

HEADLAMP AUTO CUT ADJUSTMENT

PROCEDURE

Headlamps are controlled smart wiring system (SWS). For

adjustment procedure of headlamp auto lamp and headlamp

auto cut, refer to GROUP 54B.

HEADLAMP AUTO CUT FUNCTION CHECK

When lighting switch is turned ON (to HEAD position) with

ignition switch removed from ignition key cylinder and driver’s

door is opened, ensure that headlamps are switched off after

one second. When headlamps are inoperative, perform

troubleshooting. (Refer to GROUP 54B.)

Headlamp bulb

Position lamp

Page 1367 of 1449

SWS -Troubleshooting54B-3

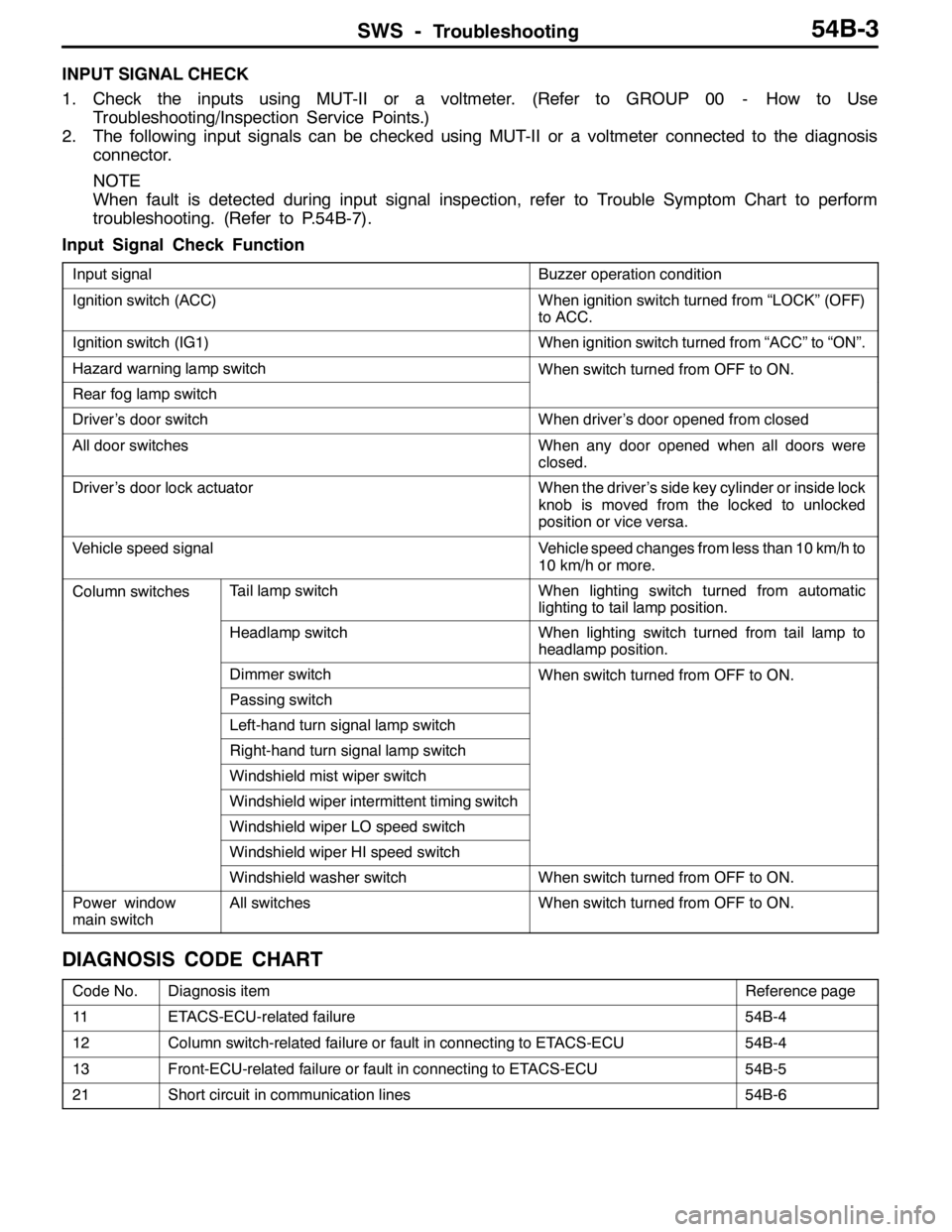

INPUT SIGNAL CHECK

1. Check the inputs using MUT-II or a voltmeter. (Refer to GROUP 00 - How to Use

Troubleshooting/Inspection Service Points.)

2. The following input signals can be checked using MUT-II or a voltmeter connected to the diagnosis

connector.

NOTE

When fault is detected during input signal inspection, refer to Trouble Symptom Chart to perform

troubleshooting. (Refer to P.54B-7).

Input Signal Check Function

Input signalBuzzer operation condition

Ignition switch (ACC)When ignition switch turned from “LOCK” (OFF)

to ACC.

Ignition switch (IG1)When ignition switch turned from “ACC” to “ON”.

Hazard warning lamp switchWhen switch turned from OFF to ON.

Rear fog lamp switch

Driver’s door switchWhen driver’s door opened from closed

All door switchesWhen any door opened when all doors were

closed.

Driver’s door lock actuatorWhen the driver’s side key cylinder or inside lock

knob is moved from the locked to unlocked

position or vice versa.

Vehicle speed signalVehicle speed changes from less than 10 km/h to

10 km/h or more.

Column switchesTail lamp switchWhen lighting switch turned from automatic

lighting to tail lamp position.

Headlamp switchWhen lighting switch turned from tail lamp to

headlamp position.

Dimmer switchWhen switch turned from OFF to ON.

Passing switch

Left-hand turn signal lamp switch

Right-hand turn signal lamp switch

Windshield mist wiper switch

Windshield wiper intermittent timing switch

Windshield wiper LO speed switch

Windshield wiper HI speed switch

Windshield washer switchWhen switch turned from OFF to ON.

Power window

main switchAll switchesWhen switch turned from OFF to ON.

DIAGNOSIS CODE CHART

Code No.Diagnosis itemReference page

11ETACS-ECU-related failure54B-4

12Column switch-related failure or fault in connecting to ETACS-ECU54B-4

13Front-ECU-related failure or fault in connecting to ETACS-ECU54B-5

21Short circuit in communication lines54B-6

Page 1398 of 1449

SWS -Troubleshooting54B-34

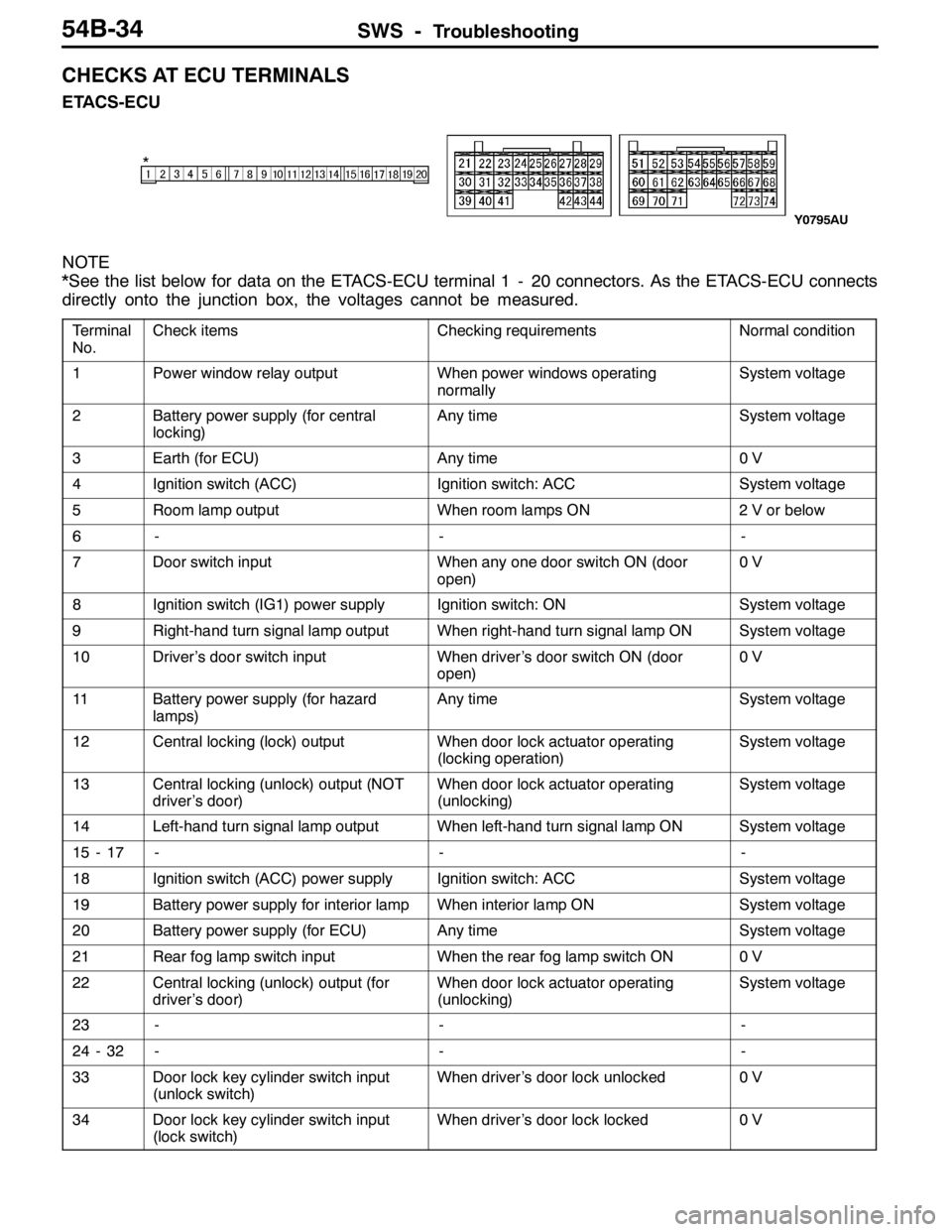

CHECKS AT ECU TERMINALS

ETACS-ECU

*

Y0795AU

NOTE

*See the list below for data on the ETACS-ECU terminal 1 - 20 connectors. As the ETACS-ECU connects

directly onto the junction box, the voltages cannot be measured.

Terminal

No.Check itemsChecking requirementsNormal condition

1Power window relay outputWhen power windows operating

normallySystem voltage

2Battery power supply (for central

locking)Any timeSystem voltage

3Earth (for ECU)Any time0V

4Ignition switch (ACC)Ignition switch: ACCSystem voltage

5Room lamp outputWhen room lamps ON2 V or below

6---

7Door switch inputWhen any one door switch ON (door

open)0V

8Ignition switch (IG1) power supplyIgnition switch: ONSystem voltage

9Right-hand turn signal lamp outputWhen right-hand turn signal lamp ONSystem voltage

10Driver’s door switch inputWhen driver’s door switch ON (door

open)0V

11Battery power supply (for hazard

lamps)Any timeSystem voltage

12Central locking (lock) outputWhen door lock actuator operating

(locking operation)System voltage

13Central locking (unlock) output (NOT

driver’s door)When door lock actuator operating

(unlocking)System voltage

14Left-hand turn signal lamp outputWhen left-hand turn signal lamp ONSystem voltage

15 - 17---

18Ignition switch (ACC) power supplyIgnition switch: ACCSystem voltage

19Battery power supply for interior lampWhen interior lamp ONSystem voltage

20Battery power supply (for ECU)Any timeSystem voltage

21Rear fog lamp switch inputWhen the rear fog lamp switch ON0V

22Central locking (unlock) output (for

driver’s door)When door lock actuator operating

(unlocking)System voltage

23---

24 - 32---

33Door lock key cylinder switch input

(unlock switch)When driver’s door lock unlocked0V

34Door lock key cylinder switch input

(lock switch)When driver’s door lock locked0V

Page 1399 of 1449

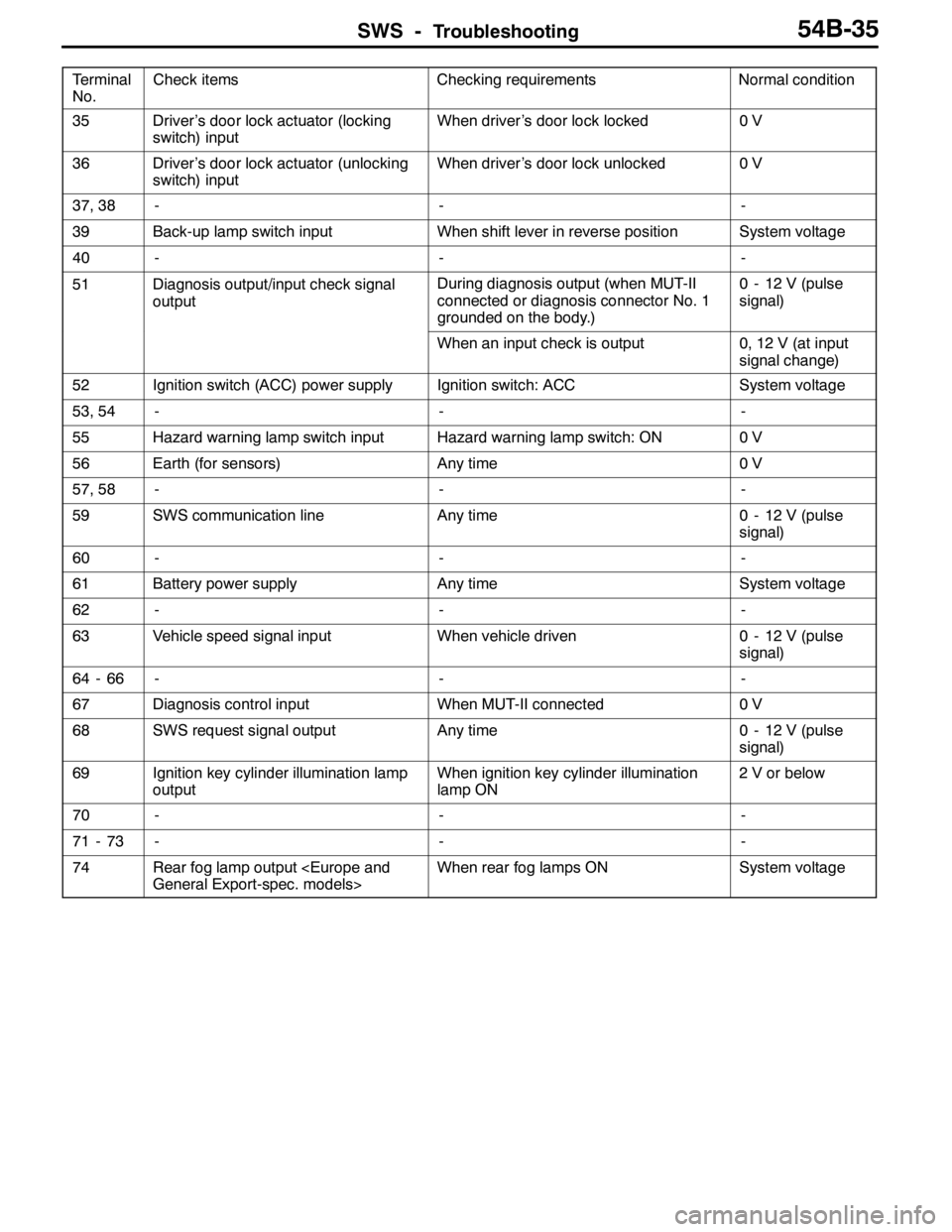

SWS -Troubleshooting54B-35

Terminal

No.Normal condition Checking requirements Check items

35Driver’s door lock actuator (locking

switch) inputWhen driver’s door lock locked0V

36Driver’s door lock actuator (unlocking

switch) inputWhen driver’s door lock unlocked0V

37, 38---

39Back-up lamp switch inputWhen shift lever in reverse positionSystem voltage

40---

51Diagnosis output/input check signal

outputDuring diagnosis output (when MUT-II

connected or diagnosis connector No. 1

grounded on the body.)0 - 12 V (pulse

signal)

When an input check is output0, 12 V (at input

signal change)

52Ignition switch (ACC) power supplyIgnition switch: ACCSystem voltage

53, 54---

55Hazard warning lamp switch inputHazard warning lamp switch: ON0V

56Earth (for sensors)Any time0V

57, 58---

59SWS communication lineAny time0 - 12 V (pulse

signal)

60---

61Battery power supplyAny timeSystem voltage

62---

63Vehicle speed signal inputWhen vehicle driven0 - 12 V (pulse

signal)

64 - 66---

67Diagnosis control inputWhen MUT-II connected0V

68SWS request signal outputAny time0 - 12 V (pulse

signal)

69Ignition key cylinder illumination lamp

outputWhen ignition key cylinder illumination

lamp ON2 V or below

70---

71 - 73---

74Rear fog lamp output