wheel MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 468 of 1449

ENGINE OVERHAUL -Timing Belt11B-14

REMOVAL SERVICE POINTS

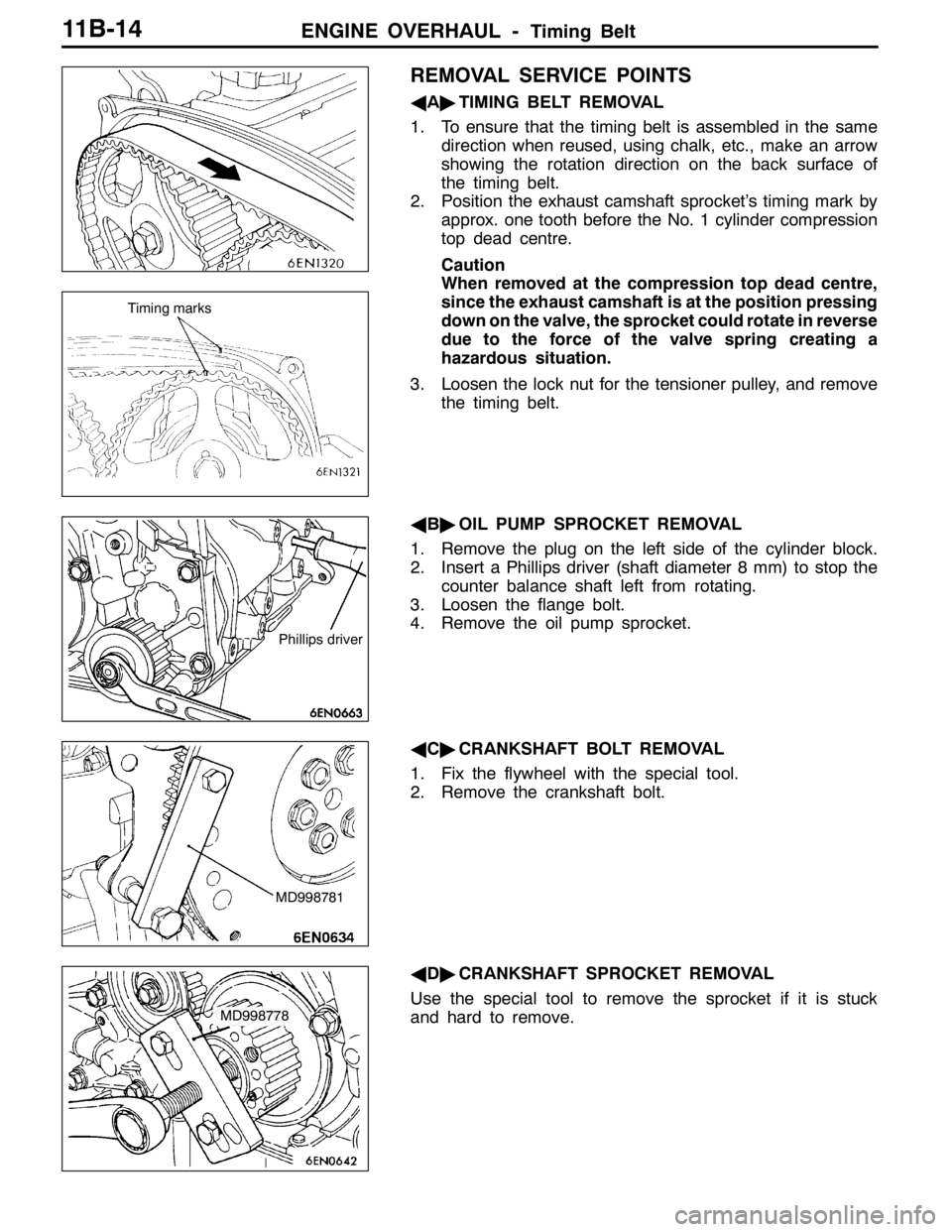

AA"TIMING BELT REMOVAL

1. To ensure that the timing belt is assembled in the same

direction when reused, using chalk, etc., make an arrow

showing the rotation direction on the back surface of

the timing belt.

2. Position the exhaust camshaft sprocket’s timing mark by

approx. one tooth before the No. 1 cylinder compression

top dead centre.

Caution

When removed at the compression top dead centre,

since the exhaust camshaft is at the position pressing

down on the valve, the sprocket could rotate in reverse

due to the force of the valve spring creating a

hazardous situation.

3. Loosen the lock nut for the tensioner pulley, and remove

the timing belt.

AB"OIL PUMP SPROCKET REMOVAL

1. Remove the plug on the left side of the cylinder block.

2. Insert a Phillips driver (shaft diameter 8 mm) to stop the

counter balance shaft left from rotating.

3. Loosen the flange bolt.

4. Remove the oil pump sprocket.

AC"CRANKSHAFT BOLT REMOVAL

1. Fix the flywheel with the special tool.

2. Remove the crankshaft bolt.

AD"CRANKSHAFT SPROCKET REMOVAL

Use the special tool to remove the sprocket if it is stuck

and hard to remove.

Timing marks

Phillips driver

MD998781

MD998778

Page 473 of 1449

ENGINE OVERHAUL -Timing Belt11B-19

Caution

(1) Measure when the belt’s surface temperature is

close to room temperature.

(2) Make sure that water or oil, etc., do not get on

the mike.

(3) If strong winds contact the mike or if noise is

generated in the area while measuring, a value

that differs from the actual value may be indicated.

(4) If the measurement is carried out with the mike

contacted against the belt, a value that differs

from the actual value may be indicated.

(5) Do not measure while the engine is running.

11. Disconnect MUT-II.

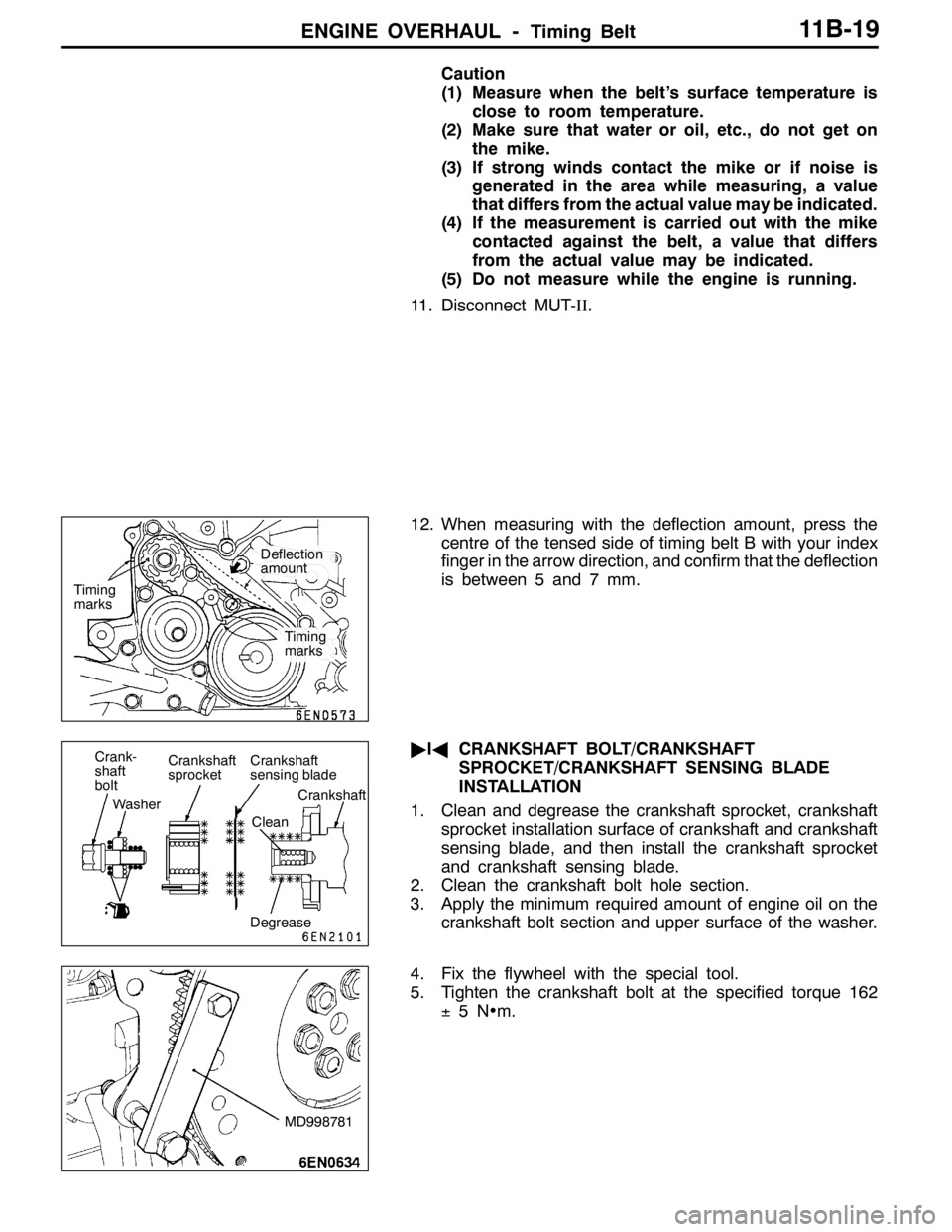

12. When measuring with the deflection amount, press the

centre of the tensed side of timing belt B with your index

finger in the arrow direction, and confirm that the deflection

is between 5 and 7 mm.

"IACRANKSHAFT BOLT/CRANKSHAFT

SPROCKET/CRANKSHAFT SENSING BLADE

INSTALLATION

1. Clean and degrease the crankshaft sprocket, crankshaft

sprocket installation surface of crankshaft and crankshaft

sensing blade, and then install the crankshaft sprocket

and crankshaft sensing blade.

2. Clean the crankshaft bolt hole section.

3. Apply the minimum required amount of engine oil on the

crankshaft bolt section and upper surface of the washer.

4. Fix the flywheel with the special tool.

5. Tighten the crankshaft bolt at the specified torque 162

±5N•m.

Timing

marks

Timing

marks

Deflection

amount

Crank-

shaft

bolt

WasherCrankshaft

sprocketCrankshaft

sensing blade

Crankshaft

Clean

Degrease

MD998781

Page 518 of 1449

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-64

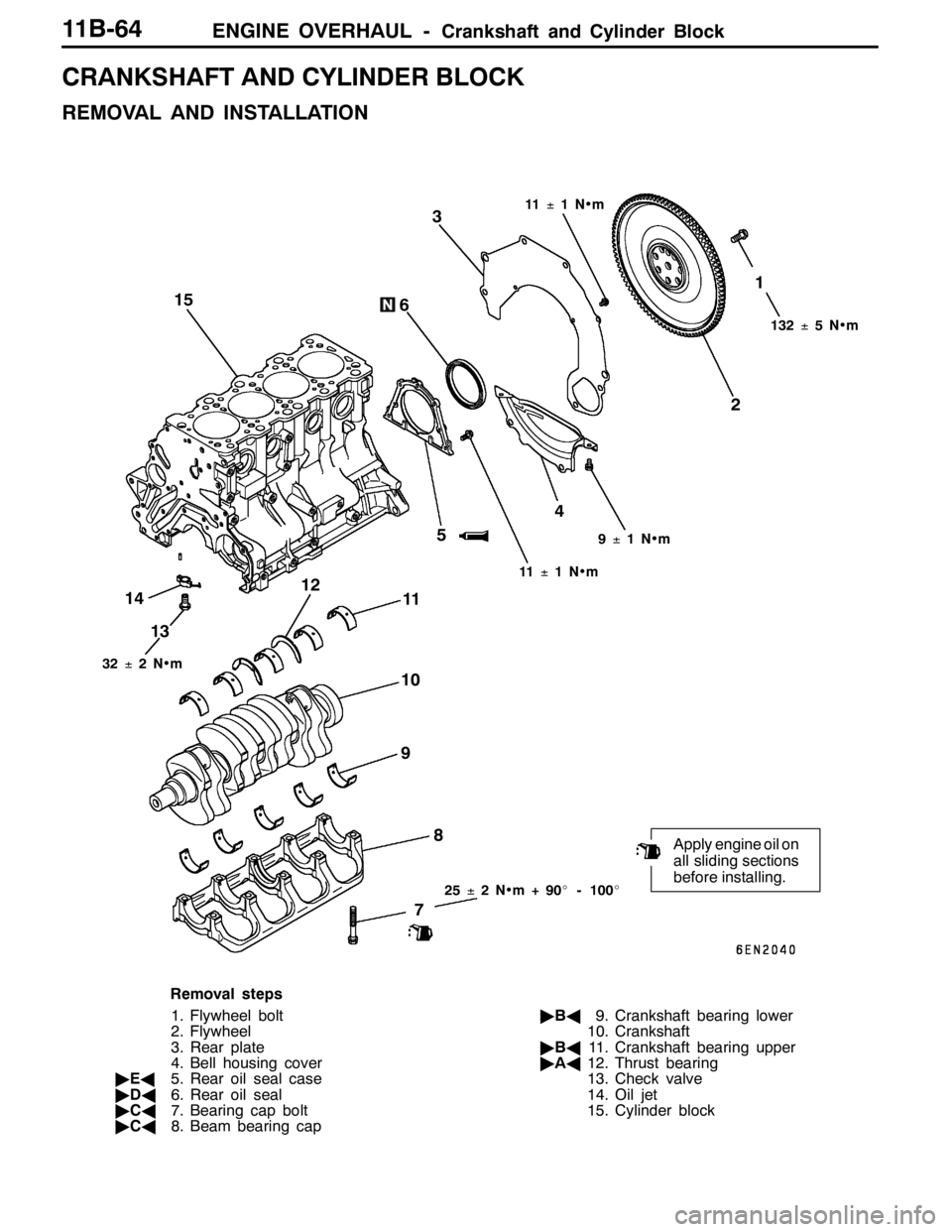

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

25±2N•m+90_- 100_

21

Apply engine oil on

all sliding sections

before installing.

4

5 6

73

8 9 1011

132±5N•m 11±1N•m

11±1N•m9±1N•m

32±2N•m

14

1312 15

Removal steps

1. Flywheel bolt

2. Flywheel

3. Rear plate

4. Bell housing cover

"EA5. Rear oil seal case

"DA6. Rear oil seal

"CA7. Bearing cap bolt

"CA8. Beam bearing cap"BA9. Crankshaft bearing lower

10. Crankshaft

"BA11. Crankshaft bearing upper

"AA12. Thrust bearing

13. Check valve

14. Oil jet

15. Cylinder block

Page 578 of 1449

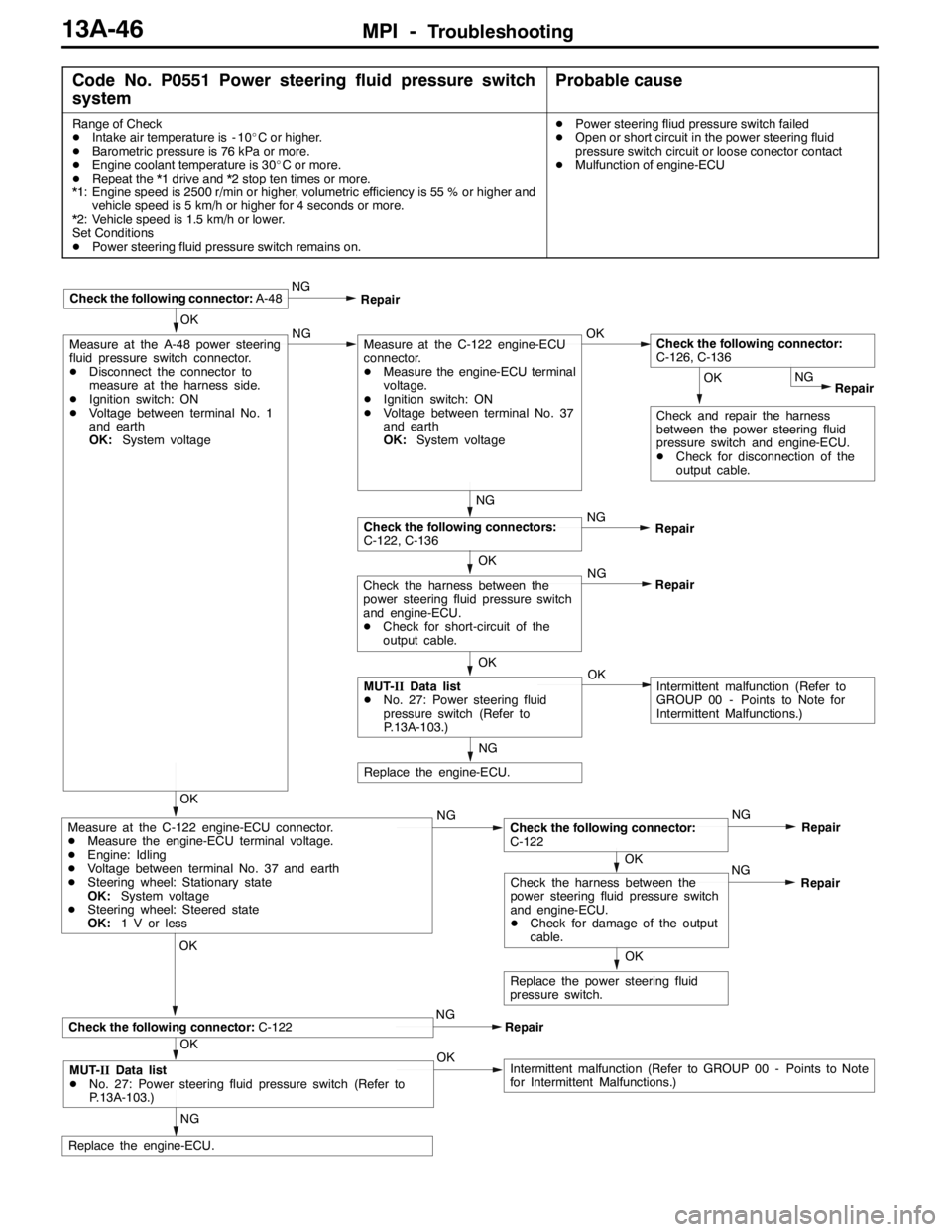

MPI -Troubleshooting13A-46

Code No. P0551 Power steering fluid pressure switch

systemProbable cause

Range of Check

DIntake air temperature is - 10_C or higher.

DBarometric pressure is 76 kPa or more.

DEngine coolant temperature is 30_C or more.

DRepeat the *1 drive and *2 stop ten times or more.

*1: Engine speed is 2500 r/min or higher, volumetric efficiency is 55 % or higher and

vehicle speed is 5 km/h or higher for 4 seconds or more.

*2: Vehicle speed is 1.5 km/h or lower.

Set Conditions

DPower steering fluid pressure switch remains on.DPower steering fliud pressure switch failed

DOpen or short circuit in the power steering fluid

pressure switch circuit or loose conector contact

DMulfunction of engine-ECU

NG

OKOK

NGCheck the following connectors:

C-122, C-136

NG

OKNG

OK

Check the harness between the

power steering fluid pressure switch

and engine-ECU.

DCheck for short-circuit of the

output cable.Repair Repair

OKIntermittent malfunction (Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

NG

OK

Measure at the A-48 power steering

fluid pressure switch connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltageNGMeasure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 37

and earth

OK:System voltage

OK

NG

Replace the engine-ECU.

MUT-IIData list

DNo. 27: Power steering fluid pressure switch (Refer to

P.13A-103.)

OK

Check the following connector:A-48NG

Repair

NG

Repair OK

Check the following connector:

C-126, C-136

Check and repair the harness

between the power steering fluid

pressure switch and engine-ECU.

DCheck for disconnection of the

output cable.

Replace the engine-ECU.

OK

NG

MUT-IIData list

DNo. 27: Power steering fluid

pressure switch (Refer to

P.13A-103.)Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

Measure at the C-122 engine-ECU connector.

DMeasure the engine-ECU terminal voltage.

DEngine: Idling

DVoltage between terminal No. 37 and earth

DSteering wheel: Stationary state

OK:System voltage

DSteering wheel: Steered state

OK:1 V or less

OK

Replace the power steering fluid

pressure switch.Repair

Check the following connector:

C-122NG

Repair

Check the following connector:C-122

Check the harness between the

power steering fluid pressure switch

and engine-ECU.

DCheck for damage of the output

cable.OK

Repair NG

Page 585 of 1449

MPI -Troubleshooting

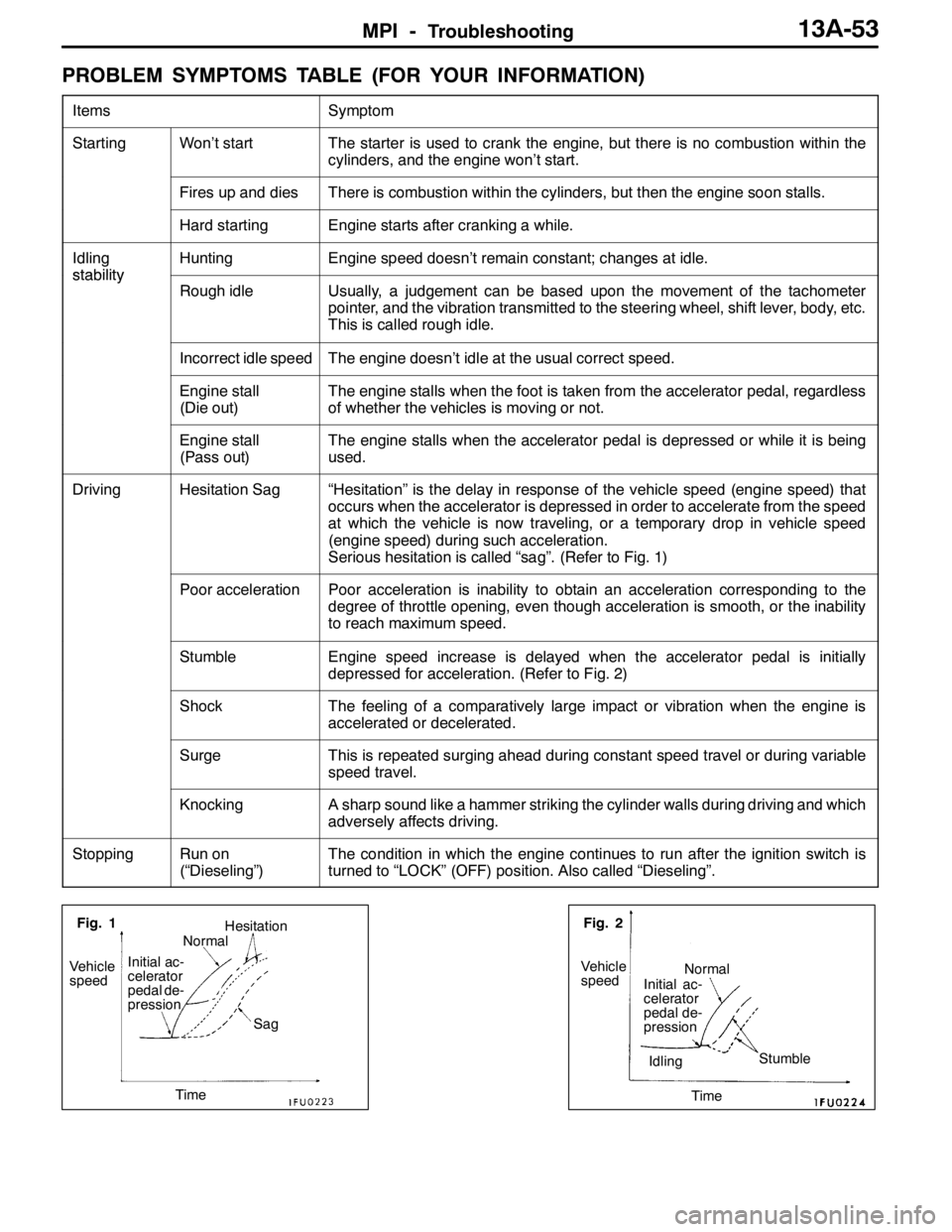

Fig. 1

Vehicle

speedInitial ac-

celerator

pedal de-

pressionNormalHesitation

Sag

TimeFig. 2

Normal

Initial ac-

celerator

pedal de-

pression

IdlingStumble

Time Vehicle

speed

13A-53

PROBLEM SYMPTOMS TABLE (FOR YOUR INFORMATION)

ItemsSymptom

StartingWon’t startThe starter is used to crank the engine, but there is no combustion within the

cylinders, and the engine won’t start.

Fires up and diesThere is combustion within the cylinders, but then the engine soon stalls.

Hard startingEngine starts after cranking a while.

Idling

stability

HuntingEngine speed doesn’t remain constant; changes at idle.

stability

Rough idleUsually, a judgement can be based upon the movement of the tachometer

pointer, and the vibration transmitted to the steering wheel, shift lever, body, etc.

This is called rough idle.

Incorrect idle speedThe engine doesn’t idle at the usual correct speed.

Engine stall

(Die out)The engine stalls when the foot is taken from the accelerator pedal, regardless

of whether the vehicles is moving or not.

Engine stall

(Pass out)The engine stalls when the accelerator pedal is depressed or while it is being

used.

DrivingHesitation Sag“Hesitation” is the delay in response of the vehicle speed (engine speed) that

occurs when the accelerator is depressed in order to accelerate from the speed

at which the vehicle is now traveling, or a temporary drop in vehicle speed

(engine speed) during such acceleration.

Serious hesitation is called “sag”. (Refer to Fig. 1)

Poor accelerationPoor acceleration is inability to obtain an acceleration corresponding to the

degree of throttle opening, even though acceleration is smooth, or the inability

to reach maximum speed.

StumbleEngine speed increase is delayed when the accelerator pedal is initially

depressed for acceleration. (Refer to Fig. 2)

ShockThe feeling of a comparatively large impact or vibration when the engine is

accelerated or decelerated.

SurgeThis is repeated surging ahead during constant speed travel or during variable

speed travel.

KnockingA sharp sound like a hammer striking the cylinder walls during driving and which

adversely affects driving.

StoppingRun on

(“Dieseling”)The condition in which the engine continues to run after the ignition switch is

turned to “LOCK” (OFF) position. Also called “Dieseling”.

Page 636 of 1449

MPI -Troubleshooting13A-104

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

25Barometric

pressure

Ignition switch: ONAltitude: 0 m101 kPaCode No.

P0105

13A-15

pressure

sensor

Altitude: 0 m95 kPa

P0105

Altitude: 0 m88 kPa

Altitude: 0 m81 kPa

27Power

steering

fluidEngine: Idle operationSteering wheel

stationaryOFFCode No.

P055113A-46

fluid

pressure

switchSteering wheel turningON

28A/C switchEngine: Idle operation

(When A/C switch isA/C switch: OFFOFFProcedure

No. 2613A-92

(WhenA/Cswitchis

ON, A/C compressor

should be operating.)A/C switch: ONON

No.26

34Air flow

sensorEngine: After

warm-upIdle operationONCode No.

P010013A-13

sensor

reset

signal

warm up

3,000 r/minOFF

P0100

37Volumetric

efficiency

DEngine coolant

temperature:

Idle operation15 - 35%--

efficiencytemperature:

85 - 95_C

DLightningand

2,500 r/min15 - 35%

DLightning and

accessories:

OFFExcessive

accellerationAccording to ac-

celeration, volu-

metric efficiency

is increased.

41Injectors*1Engine: CrankingWhen engine coolant

temperature is 0_C

(injection is carried out

for all cylinders simulta-

neously)25 - 37 ms--

When engine coolant

temperature is 20_C15 - 22 ms

When engine coolant

temperature is 80_C4.2 - 6.3 ms

Injectors*2DEngine coolant

temperature:

80–95_C

Engine: Idle operation1.5 - 2.7 ms--

80–95_C

DLamps, electric

cooling fan and

allaccessories:

2,500 r/min1.2 - 2.4 ms

allaccessories:

OFF

DTransmission:

Neutral

When engine is sud-

denly racedIncreases

Page 643 of 1449

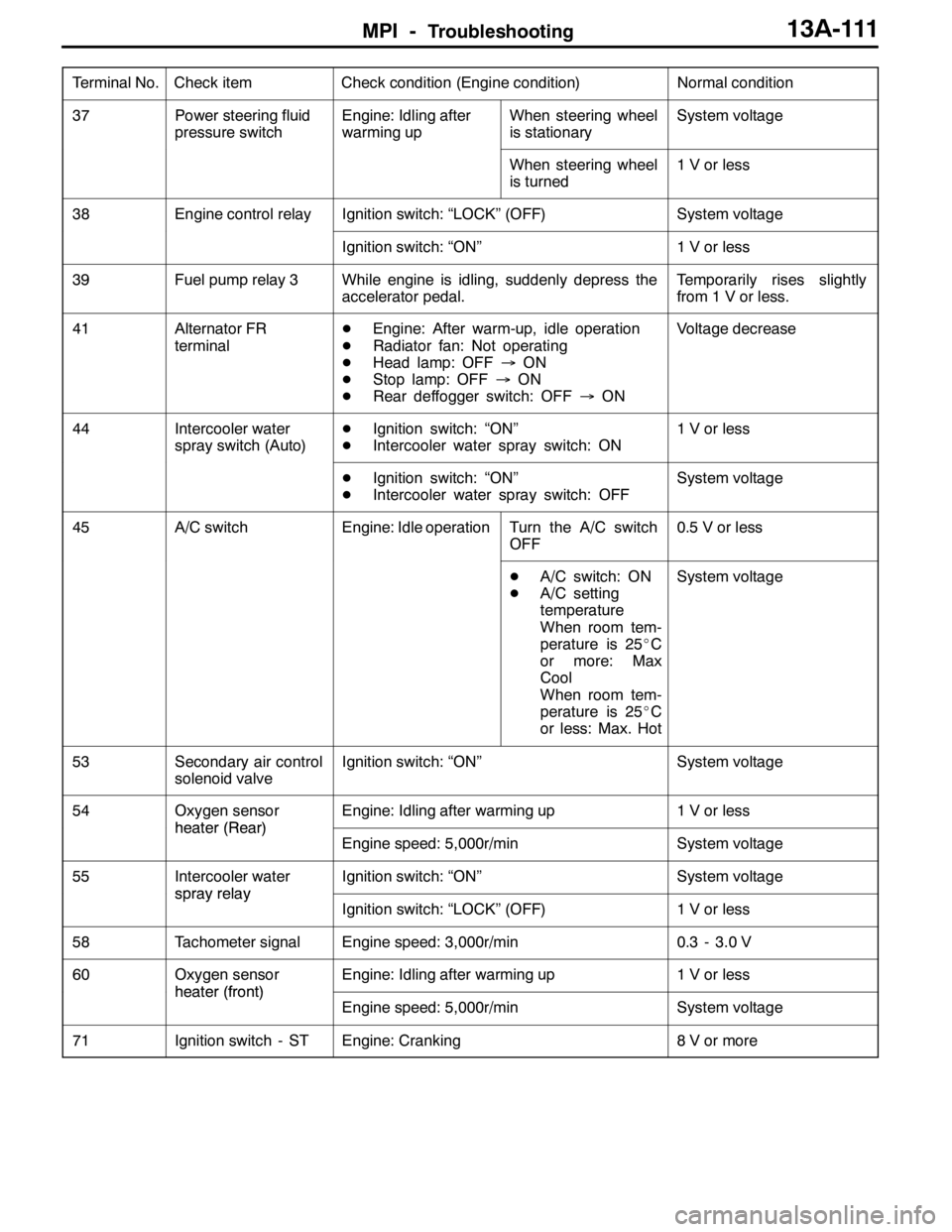

MPI -Troubleshooting13A-111

Terminal No.Normal condition Check condition (Engine condition) Check item

37Power steering fluid

pressure switchEngine: Idling after

warming upWhen steering wheel

is stationarySystem voltage

When steering wheel

is turned1 V or less

38Engine control relayIgnition switch: “LOCK” (OFF)System voltage

Ignition switch: “ON”1 V or less

39Fuel pump relay 3While engine is idling, suddenly depress the

accelerator pedal.Temporarily rises slightly

from 1 V or less.

41Alternator FR

terminalDEngine: After warm-up, idle operation

DRadiator fan: Not operating

DHead lamp: OFF→ON

DStop lamp: OFF→ON

DRear deffogger switch: OFF→ONVoltage decrease

44Intercooler water

spray switch (Auto)DIgnition switch: “ON”

DIntercooler water spray switch: ON1 V or less

DIgnition switch: “ON”

DIntercooler water spray switch: OFFSystem voltage

45A/C switchEngine: Idle operationTurn the A/C switch

OFF0.5 V or less

DA/C switch: ON

DA/C setting

temperature

When room tem-

perature is 25_C

or more: Max

Cool

When room tem-

perature is 25_C

or less: Max. HotSystem voltage

53Secondary air control

solenoid valveIgnition switch: “ON”System voltage

54Oxygen sensor

heater(Rear)

Engine: Idling after warming up1 V or less

heater(Rear)

Engine speed: 5,000r/minSystem voltage

55Intercooler water

sprayrelay

Ignition switch: “ON”System voltage

spray relay

Ignition switch: “LOCK” (OFF)1 V or less

58Tachometer signalEngine speed: 3,000r/min0.3 - 3.0 V

60Oxygen sensor

heater(front)

Engine: Idling after warming up1 V or less

heater(front)

Engine speed: 5,000r/minSystem voltage

71Ignition switch - STEngine: Cranking8 V or more

Page 684 of 1449

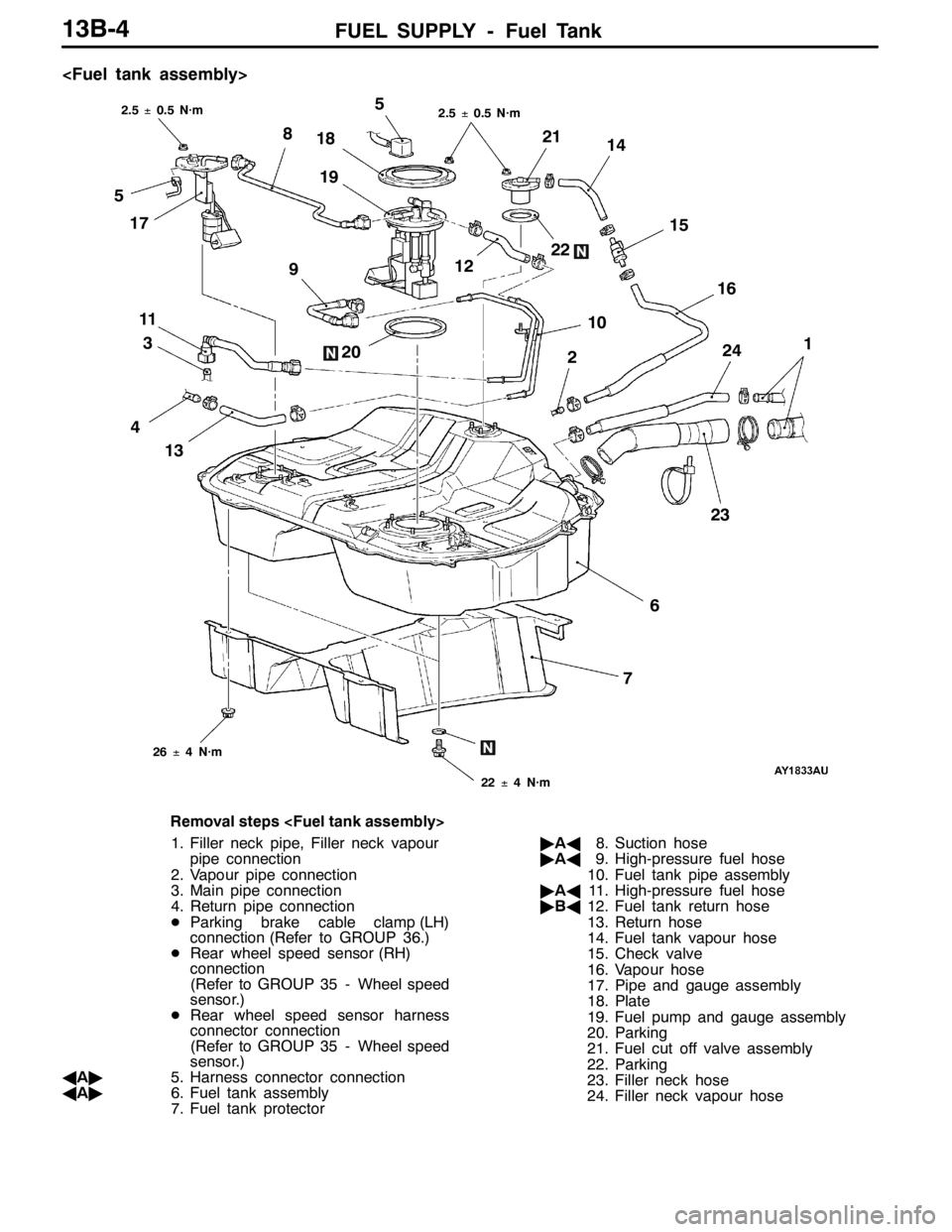

FUEL SUPPLY - Fuel Tank13B-4

12

10

6 21

1

2

4

7 8

915 18

23 20

13 314

22

24 1119

5

16 175

2.5±0.5 N·m

2.5±0.5 N·m

26±4 N·m

22±4 N·m

Removal steps

1. Filler neck pipe, Filler neck vapour

pipe connection

2. Vapour pipe connection

3. Main pipe connection

4. Return pipe connection

DParking brake cable clamp (LH)

connection (Refer to GROUP 36.)

DRear wheel speed sensor (RH)

connection

(Refer to GROUP 35 - Wheel speed

sensor.)

DRear wheel speed sensor harness

connector connection

(Refer to GROUP 35 - Wheel speed

sensor.)

AA"5. Harness connector connection

AA"6. Fuel tank assembly

7. Fuel tank protector"AA8. Suction hose

"AA9. High-pressure fuel hose

10. Fuel tank pipe assembly

"AA11. High-pressure fuel hose

"BA12. Fuel tank return hose

13. Return hose

14. Fuel tank vapour hose

15. Check valve

16. Vapour hose

17. Pipe and gauge assembly

18. Plate

19. Fuel pump and gauge assembly

20. Parking

21. Fuel cut off valve assembly

22. Parking

23. Filler neck hose

24. Filler neck vapour hose

Page 727 of 1449

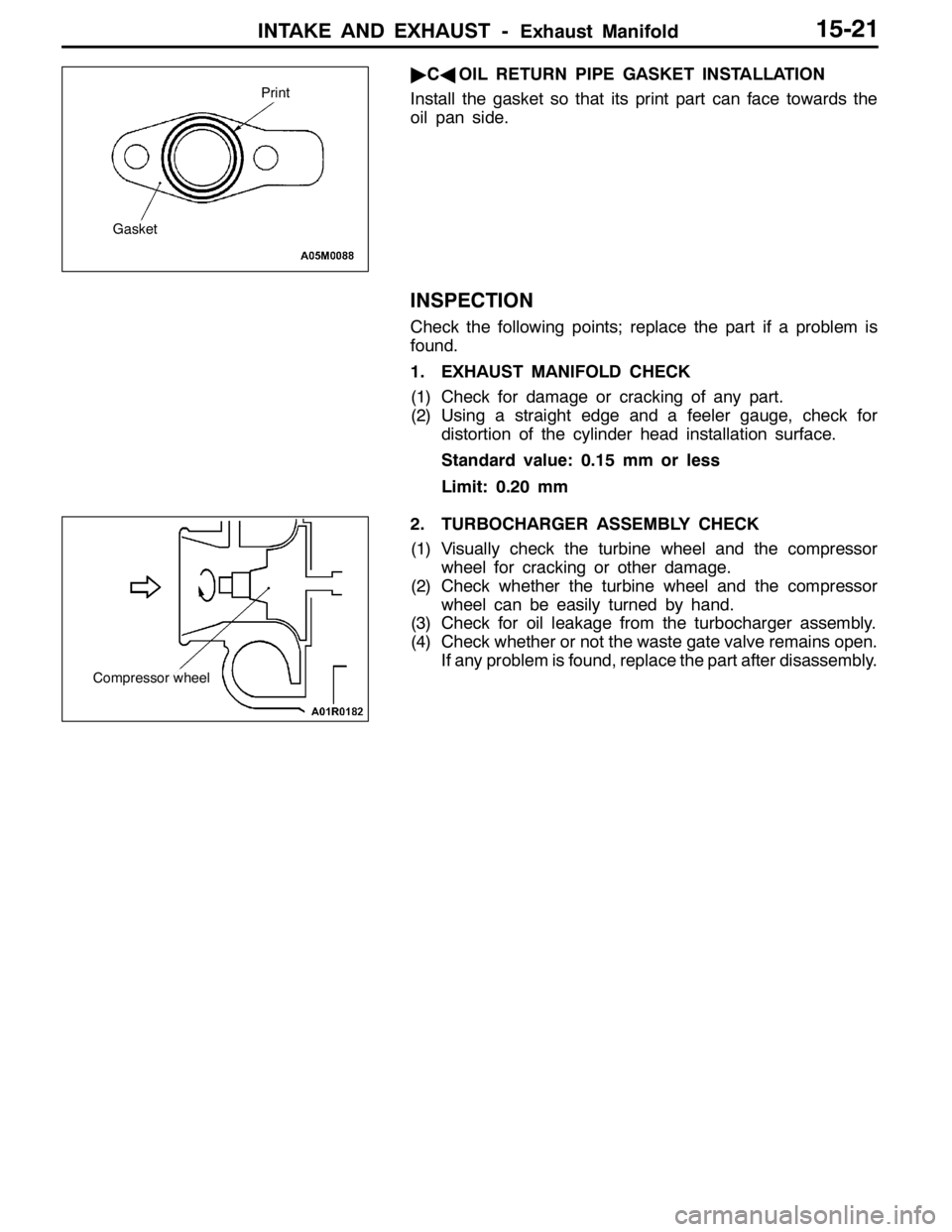

INTAKE AND EXHAUST -Exhaust Manifold15-21

"CAOIL RETURN PIPE GASKET INSTALLATION

Install the gasket so that its print part can face towards the

oil pan side.

INSPECTION

Check the following points; replace the part if a problem is

found.

1. EXHAUST MANIFOLD CHECK

(1) Check for damage or cracking of any part.

(2) Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

2. TURBOCHARGER ASSEMBLY CHECK

(1) Visually check the turbine wheel and the compressor

wheel for cracking or other damage.

(2) Check whether the turbine wheel and the compressor

wheel can be easily turned by hand.

(3) Check for oil leakage from the turbocharger assembly.

(4) Check whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

Gasket

Print

Compressor wheel

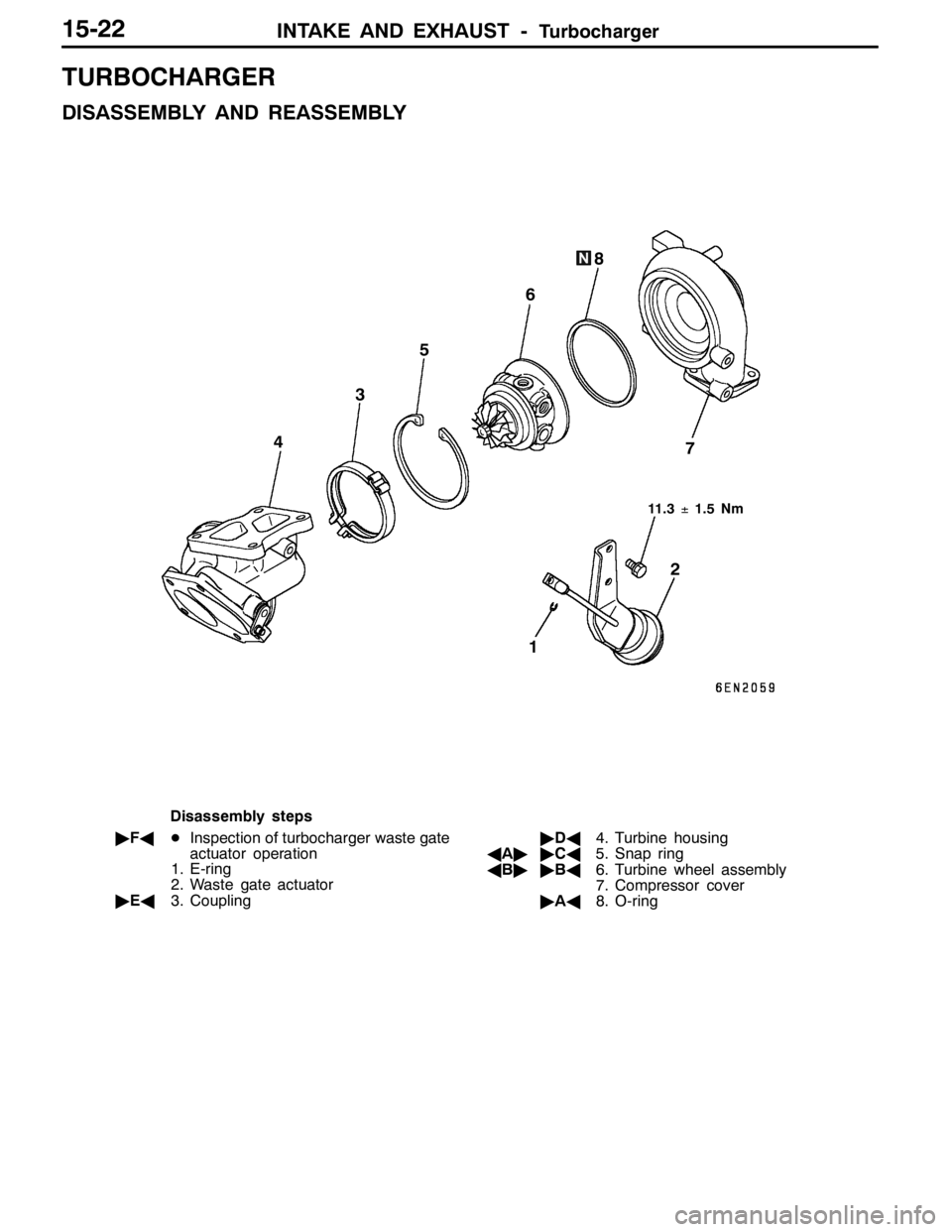

Page 728 of 1449

INTAKE AND EXHAUST -Turbocharger15-22

TURBOCHARGER

DISASSEMBLY AND REASSEMBLY

5

11.3±1.5 Nm

4368

2

17

Disassembly steps

"FADInspection of turbocharger waste gate

actuator operation

1. E-ring

2. Waste gate actuator

"EA3. Coupling"DA4. Turbine housing

AA""CA5. Snap ring

AB""BA6. Turbine wheel assembly

7. Compressor cover

"AA8. O-ring