wheel MITSUBISHI LANCER EVOLUTION 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 376 of 1449

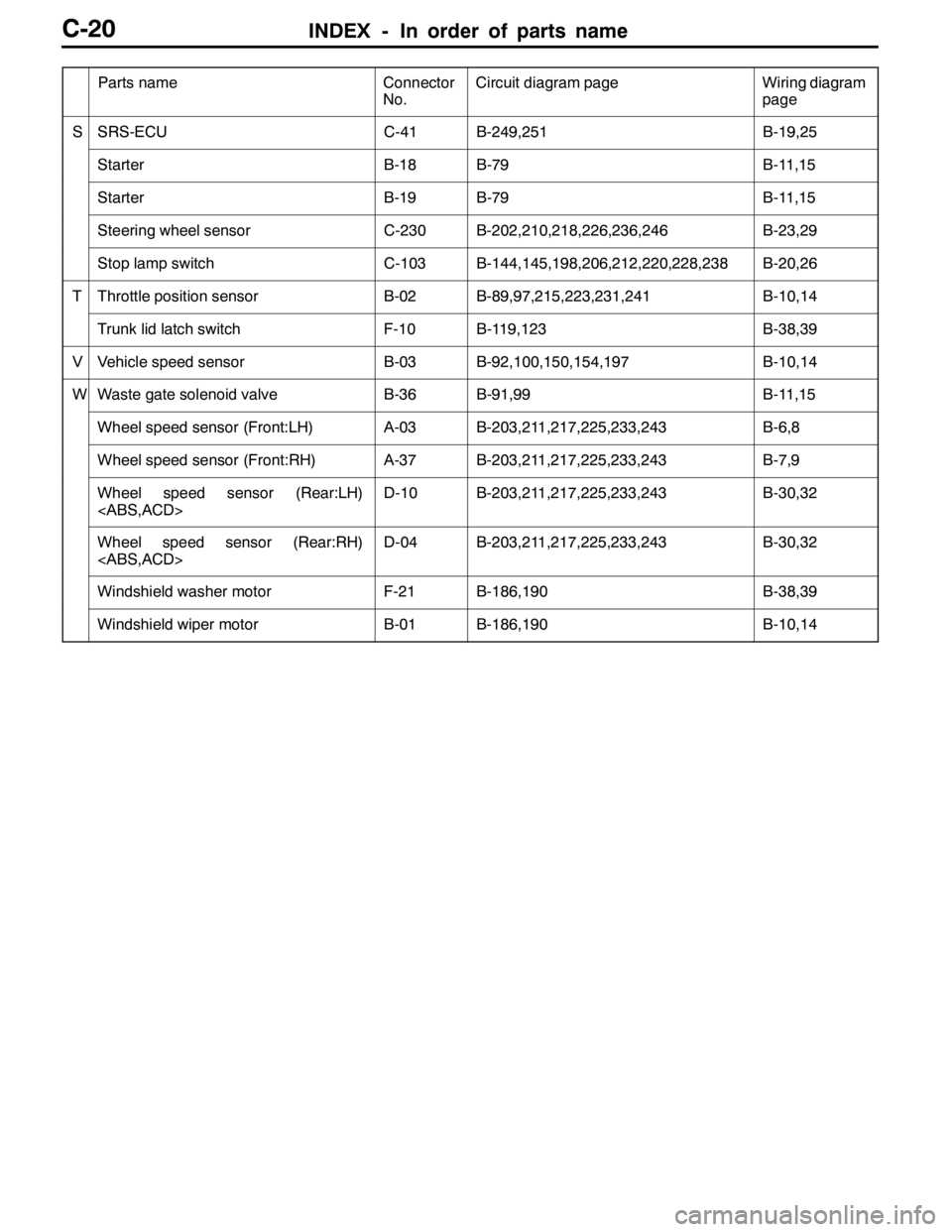

INDEX - In order of parts nameC-20

Wiring diagram

page Circuit diagram page Connector

No. Parts name

SSRS-ECUC-41B-249,251B-19,25

StarterB-18B-79B-11,15

StarterB-19B-79B-11,15

Steering wheel sensorC-230B-202,210,218,226,236,246B-23,29

Stop lamp switchC-103B-144,145,198,206,212,220,228,238B-20,26

TThrottle position sensorB-02B-89,97,215,223,231,241B-10,14

Trunk lid latch switchF-10B-119,123B-38,39

VVehicle speed sensorB-03B-92,100,150,154,197B-10,14

WWaste gate solenoid valveB-36B-91,99B-11,15

Wheel speed sensor (Front:LH)A-03B-203,211,217,225,233,243B-6,8

Wheel speed sensor (Front:RH)A-37B-203,211,217,225,233,243B-7,9

Wheel speed sensor (Rear:LH)

Wheel speed sensor (Rear:RH)

Windshield washer motorF-21B-186,190B-38,39

Windshield wiper motorB-01B-186,190B-10,14

Page 393 of 1449

GENERAL -Vehicle Identification00-15

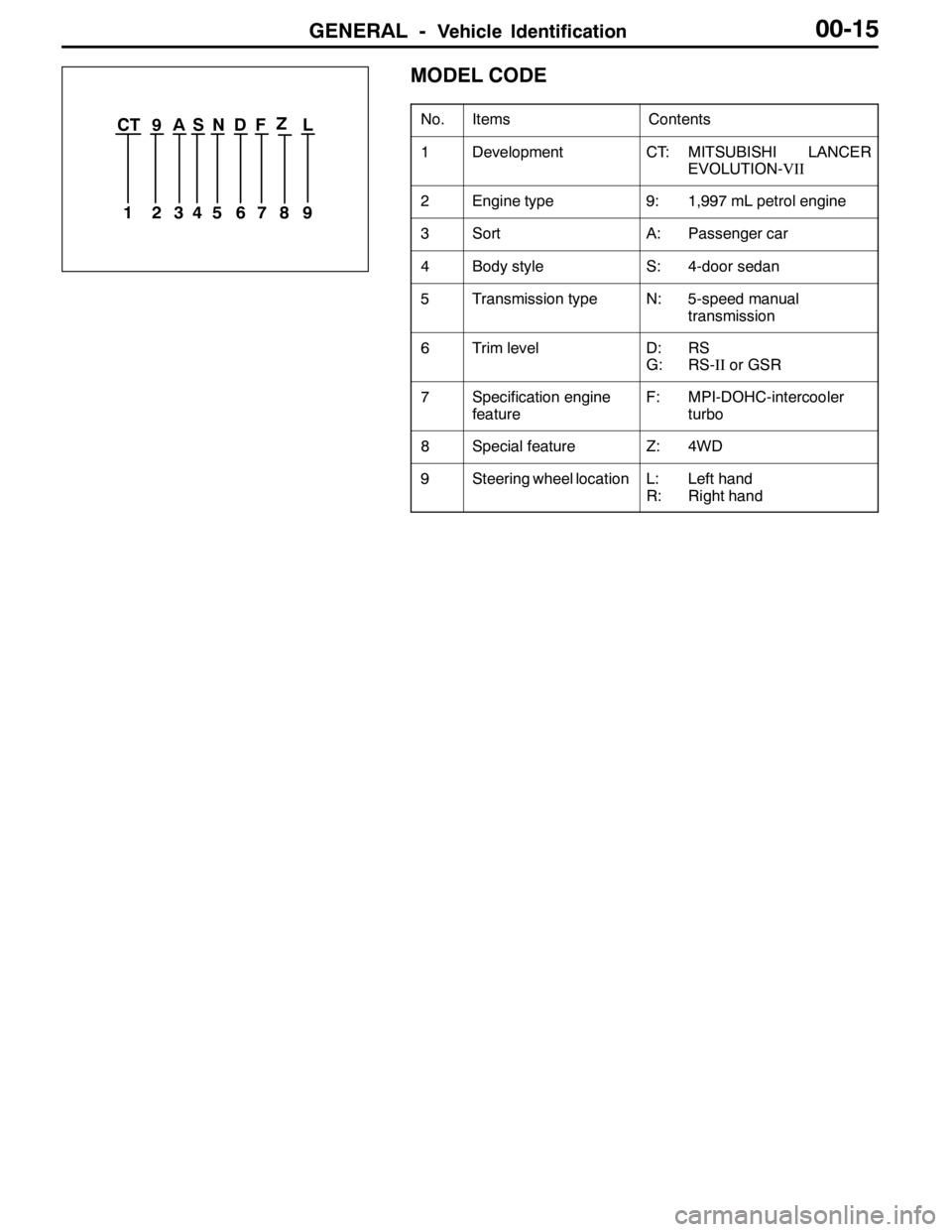

MODEL CODE

No.ItemsContents

1DevelopmentCT: MITSUBISHI LANCER

EVOLUTION-VII

2Engine type9: 1,997 mL petrol engine

3SortA: Passenger car

4Body styleS: 4-door sedan

5Transmission typeN: 5-speed manual

transmission

6Trim levelD: RS

G: RS-IIor GSR

7Specification engine

featureF: MPI-DOHC-intercooler

turbo

8Special featureZ: 4WD

9Steering wheel locationL: Left hand

R: Right hand

123456789 CT 9 A S N D F L

Z

Page 395 of 1449

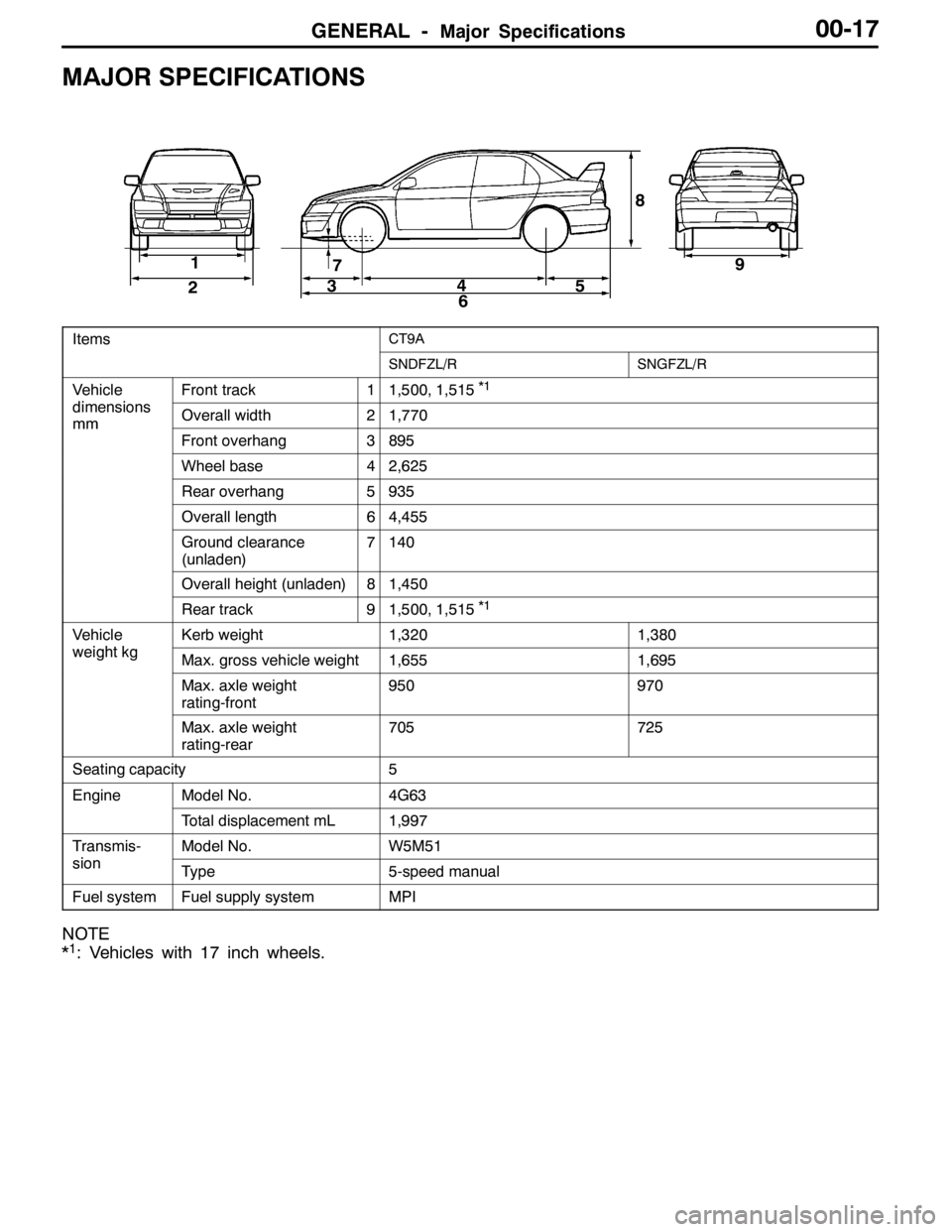

GENERAL -Major Specifications00-17

MAJOR SPECIFICATIONS

1

234

5

6 78

9

ItemsCT9A

SNDFZL/RSNGFZL/R

Vehicle

di i

Front track11,500, 1,515*1

dimensions

mmOverall width21,770mm

Front overhang3895

Wheel base42,625

Rear overhang5935

Overall length64,455

Ground clearance

(unladen)7140

Overall height (unladen)81,450

Rear track91,500, 1,515*1

Vehicle

ihtk

Kerb weight1,3201,380

weight kgMax. gross vehicle weight1,6551,695

Max. axle weight

rating-front950970

Max. axle weight

rating-rear705725

Seating capacity5

EngineModel No.4G63g

Total displacement mL1,997

Transmis-

i

Model No.W5M51

sionType5-speed manual

Fuel systemFuel supply systemMPI

NOTE

*1: Vehicles with 17 inch wheels.

Page 396 of 1449

GENERAL -Precautions Before Service00-18

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

1. Items to follow when servicing SRS

(1) Be sure to read GROUP 52B - Supplemental Restraint System (SRS).

For safe operations, please follow the directions and heed all warnings.

(2) Wait at least 60 seconds after disconnecting the battery cable before doing any further work.

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the battery cable is disconnected.

(3) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

DSun visor

DGlove box

DSRS-ECU

DSteering wheel

DSteering Joint Cover

DAir bag module (driver’s side and front passenger’s side)

DClock spring

DSeat belt with pre-tensioner

(4) Always use the designated special tools and test equipment.

(5) Store components removed from the SRS in a clean and dry place.

The air bag module should be stored on a flat surface and placed so that the pad surface is

facing upward.

Do not place anything on top of it.

(6) Never attempt to disassemble or repair the SRS components (SRS-ECU, air bag module, clock

spring and seat belt with pre-tensioner).

(7) Whenever you finish servicing the SRS, check the SRS warning lamp operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing of the air bag module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP 52B - Air Bag Module Disposal Procedures.)

2. Observe the following when carrying out operations on places where SRS components are installed,

including operations not directly related to the SRS air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat, so remove the SRS components before drying

or baking the vehicle after painting.

DSRS-ECU, air bag module, clock spring: 93_C or more

DSeat belt with pre-tensioner: 90_C or more

After re-installing them, check the SRS warning lamp operation to make sure that the system

functions properly.

Page 399 of 1449

GENERAL -Supplemental Restraint System (SRS)00-21

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

To improve safety, the SRS and seat belts with

pre-tensioner. These systems enhance collision

safety by restraining the front passengers in case

of an accident. The SRS works with the

pre-tensioner simultaneously when a collision is

detected.

The SRS consists of two air bag modules, SRS

air bag control unit (SRS-ECU), SRS warning lamp

and clock spring. The air bags are located in the

center of the steering wheel, above the glove box.

Each air bag has a folded air bag and an inflator

unit. The SRS-ECU under the floor console monitors

the system and has a safing G-sensor and an

analog G-sensor. The warning lamp on theinstrument panel indicates the operational status

of the SRS. The clock spring is installed in the

steering column. The seat belt pre-tensioner is built

into the front seat belt retractor. Only authorized

service personnel should do work on or around

the SRS components and seat belt with

pre-tensioner. Those service personnel should read

this manual carefully before starting any such work.

Extreme care must be used when servicing the

SRS to avoid injury to the service personnel (by

inadvertent deployment of the air bags or

inadvertent operation of the seat belt with

pre-tensioner) or the driver (by rendering the SRS

or the seat belt with pre-tensioner inoperative).

Diagnosis

connectorFront passenger’s

air bag module

Clock spring Driver’s air bag

module

SRS-ECU

SRS warning lamp

Driver’s air bag

Front

passenger’s

air bag

Seat belt with

pre-tensioner

Page 411 of 1449

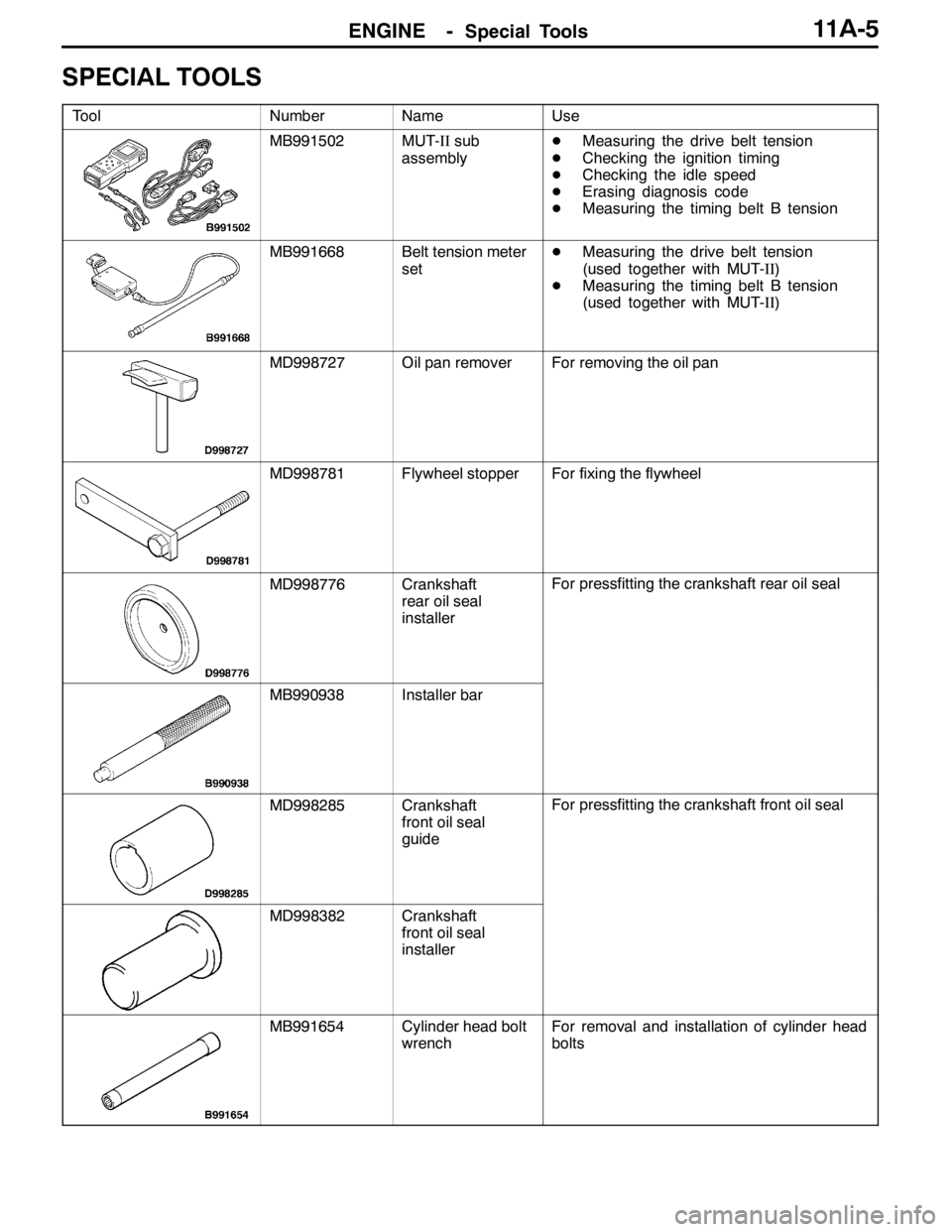

ENGINE -Special Tools11A-5

SPECIAL TOOLS

ToolNumberNameUse

MB991502MUT-IIsub

assemblyDMeasuring the drive belt tension

DChecking the ignition timing

DChecking the idle speed

DErasing diagnosis code

DMeasuring the timing belt B tension

MB991668Belt tension meter

setDMeasuring the drive belt tension

(used together with MUT-II)

DMeasuring the timing belt B tension

(used together with MUT-II)

MD998727Oil pan removerFor removing the oil pan

MD998781Flywheel stopperFor fixing the flywheel

MD998776Crankshaft

rear oil seal

installerFor pressfitting the crankshaft rear oil seal

MB990938Installer bar

MD998285Crankshaft

front oil seal

guideFor pressfitting the crankshaft front oil seal

MD998382Crankshaft

front oil seal

installer

MB991654Cylinder head bolt

wrenchFor removal and installation of cylinder head

bolts

Page 432 of 1449

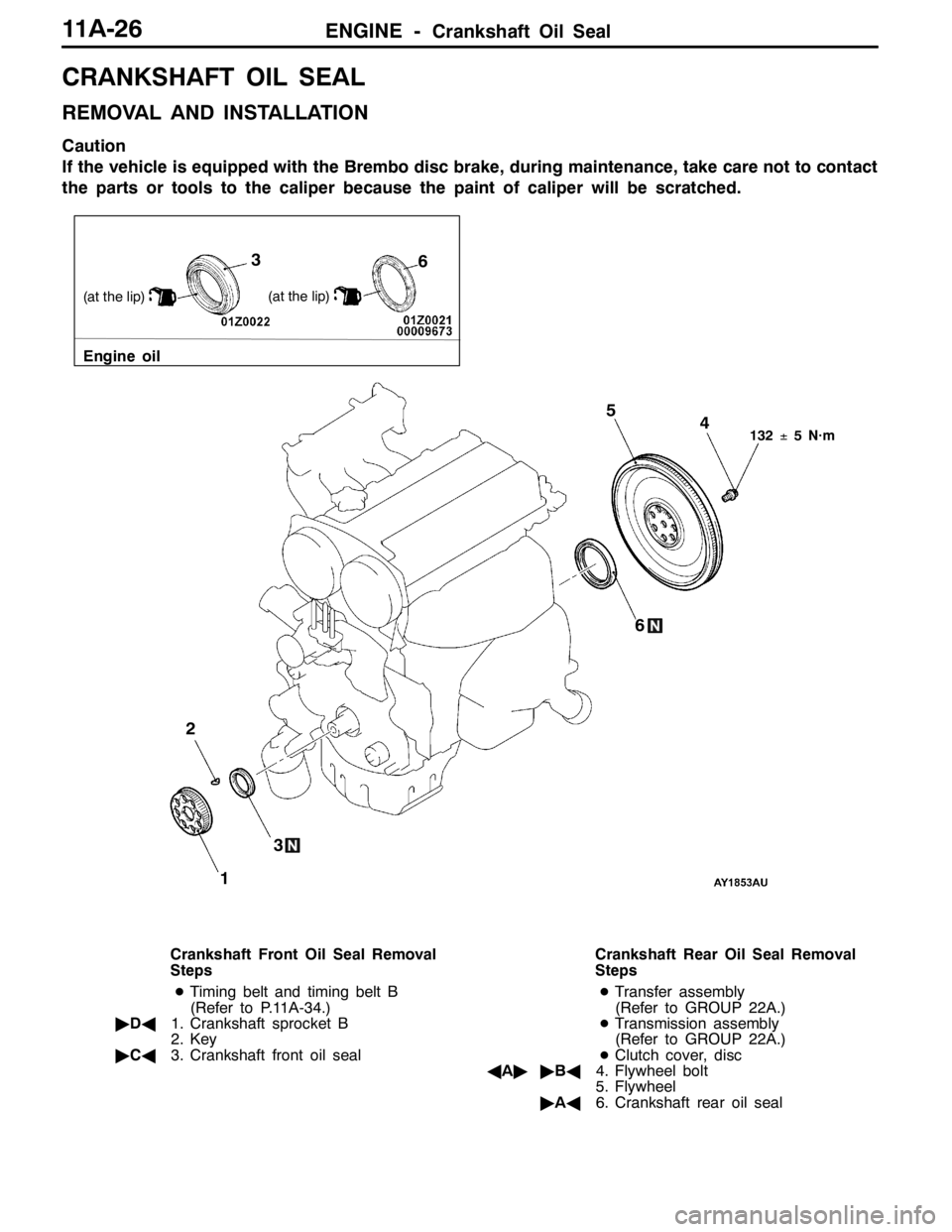

ENGINE -Crankshaft Oil Seal11A-26

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Caution

If the vehicle is equipped with the Brembo disc brake, during maintenance, take care not to contact

the parts or tools to the caliper because the paint of caliper will be scratched.

1 2

34 5

6

Engine oil

(at the lip)

(at the lip)

3

6

132±5 N·m

Crankshaft Front Oil Seal Removal

Steps

DTiming belt and timing belt B

(Refer to P.11A-34.)

"DA1. Crankshaft sprocket B

2. Key

"CA3. Crankshaft front oil sealCrankshaft Rear Oil Seal Removal

Steps

DTransfer assembly

(Refer to GROUP 22A.)

DTransmission assembly

(Refer to GROUP 22A.)

DClutch cover, disc

AA""BA4. Flywheel bolt

5. Flywheel

"AA6. Crankshaft rear oil seal

Page 433 of 1449

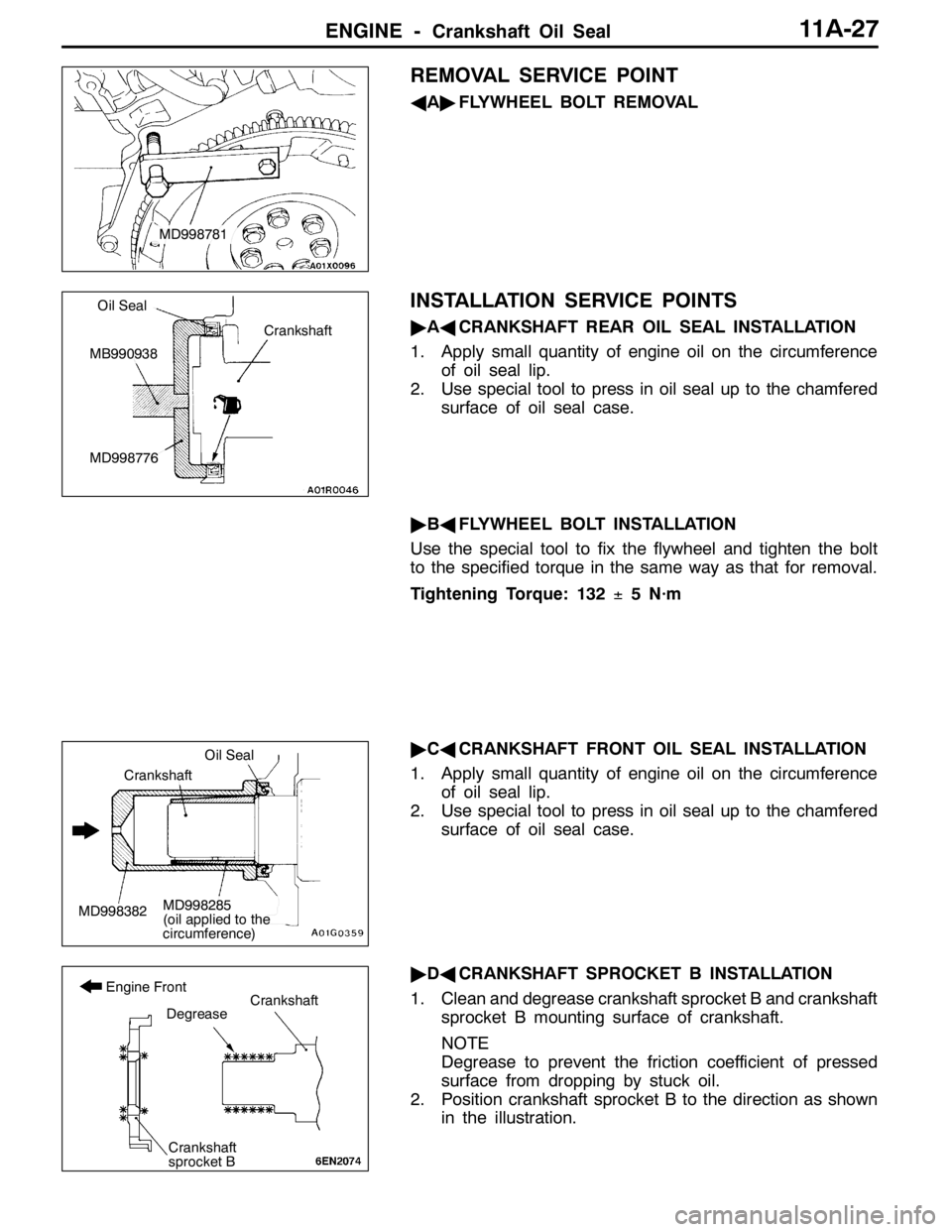

ENGINE -Crankshaft Oil Seal11A-27

REMOVAL SERVICE POINT

AA"FLYWHEEL BOLT REMOVAL

INSTALLATION SERVICE POINTS

"AACRANKSHAFT REAR OIL SEAL INSTALLATION

1. Apply small quantity of engine oil on the circumference

of oil seal lip.

2. Use special tool to press in oil seal up to the chamfered

surface of oil seal case.

"BAFLYWHEEL BOLT INSTALLATION

Use the special tool to fix the flywheel and tighten the bolt

to the specified torque in the same way as that for removal.

Tightening Torque: 132±5 N·m

"CACRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Apply small quantity of engine oil on the circumference

of oil seal lip.

2. Use special tool to press in oil seal up to the chamfered

surface of oil seal case.

"DACRANKSHAFT SPROCKET B INSTALLATION

1. Clean and degrease crankshaft sprocket B and crankshaft

sprocket B mounting surface of crankshaft.

NOTE

Degrease to prevent the friction coefficient of pressed

surface from dropping by stuck oil.

2. Position crankshaft sprocket B to the direction as shown

in the illustration.

MD998781

Crankshaft

Oil Seal

MB990938

MD998776

MD998382

Oil Seal

Crankshaft

MD998285

(oil applied to the

circumference)

Crankshaft

sprocket B

Degrease

Engine FrontCrankshaft

Page 461 of 1449

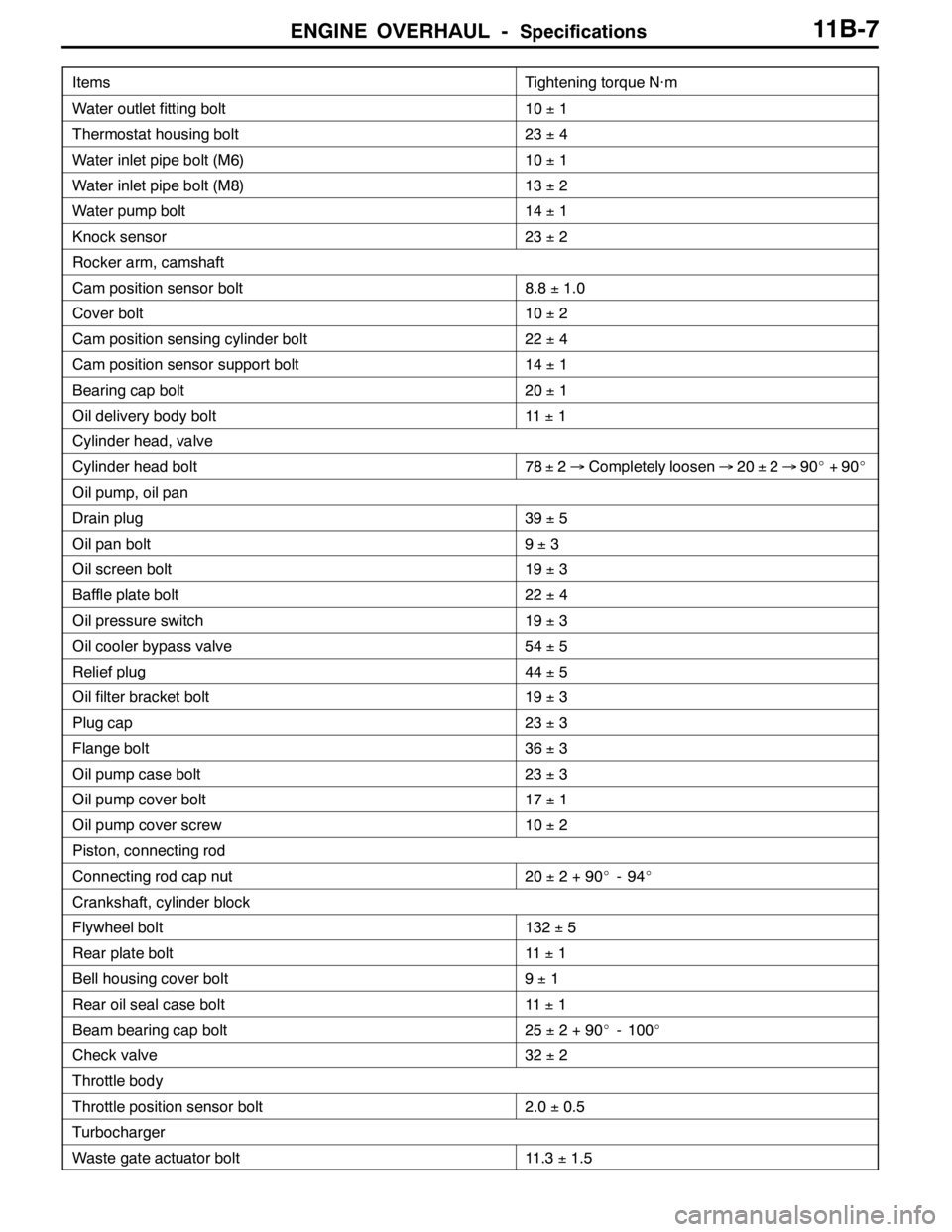

ENGINE OVERHAUL -Specifications11B-7

Items Tightening torque N·m

Water outlet fitting bolt10±1

Thermostat housing bolt23±4

Water inlet pipe bolt (M6)10±1

Water inlet pipe bolt (M8)13±2

Water pump bolt14±1

Knock sensor23±2

Rocker arm, camshaft

Cam position sensor bolt8.8±1.0

Cover bolt10±2

Cam position sensing cylinder bolt22±4

Cam position sensor support bolt14±1

Bearing cap bolt20±1

Oil delivery body bolt11±1

Cylinder head, valve

Cylinder head bolt78±2→Completely loosen→20±2→90_+90_

Oil pump, oil pan

Drain plug39±5

Oil pan bolt9±3

Oil screen bolt19±3

Baffle plate bolt22±4

Oil pressure switch19±3

Oil cooler bypass valve54±5

Relief plug44±5

Oil filter bracket bolt19±3

Plug cap23±3

Flange bolt36±3

Oil pump case bolt23±3

Oil pump cover bolt17±1

Oil pump cover screw10±2

Piston, connecting rod

Connecting rod cap nut20±2+90_-94_

Crankshaft, cylinder block

Flywheel bolt132±5

Rear plate bolt11±1

Bell housing cover bolt9±1

Rear oil seal case bolt11±1

Beam bearing cap bolt25±2+90_- 100_

Check valve32±2

Throttle body

Throttle position sensor bolt2.0±0.5

Turbocharger

Waste gate actuator bolt11.3±1.5

Page 463 of 1449

ENGINE OVERHAUL -Special Tools11B-9

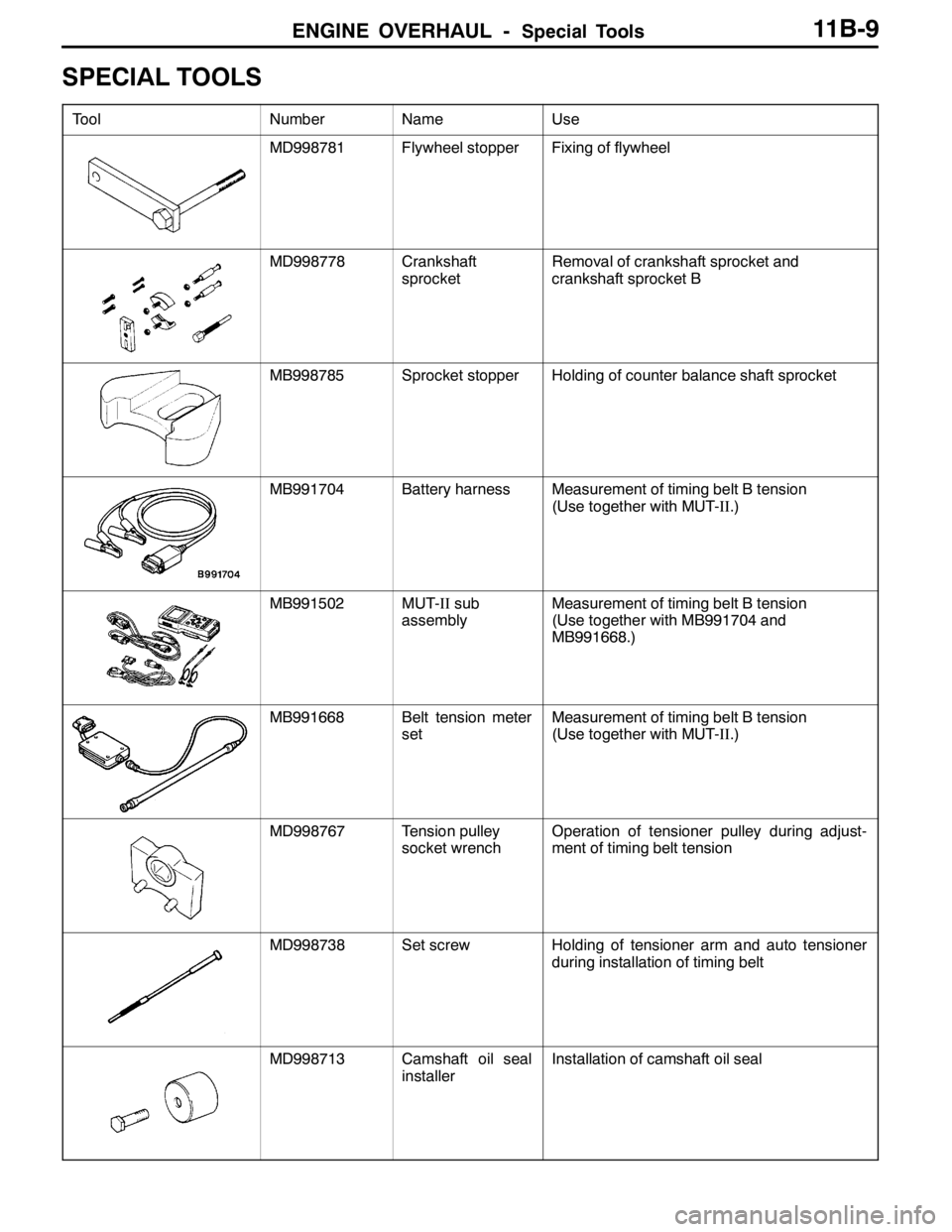

SPECIAL TOOLS

ToolNumberNameUse

MD998781Flywheel stopperFixing of flywheel

MD998778Crankshaft

sprocketRemoval of crankshaft sprocket and

crankshaft sprocket B

MB998785Sprocket stopperHolding of counter balance shaft sprocket

MB991704Battery harnessMeasurement of timing belt B tension

(Use together with MUT-II.)

MB991502MUT-IIsub

assemblyMeasurement of timing belt B tension

(Use together with MB991704 and

MB991668.)

MB991668Belt tension meter

setMeasurement of timing belt B tension

(Use together with MUT-II.)

MD998767Tension pulley

socket wrenchOperation of tensioner pulley during adjust-

ment of timing belt tension

MD998738Set screwHolding of tensioner arm and auto tensioner

during installation of timing belt

MD998713Camshaft oil seal

installerInstallation of camshaft oil seal