battery MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 593 of 1449

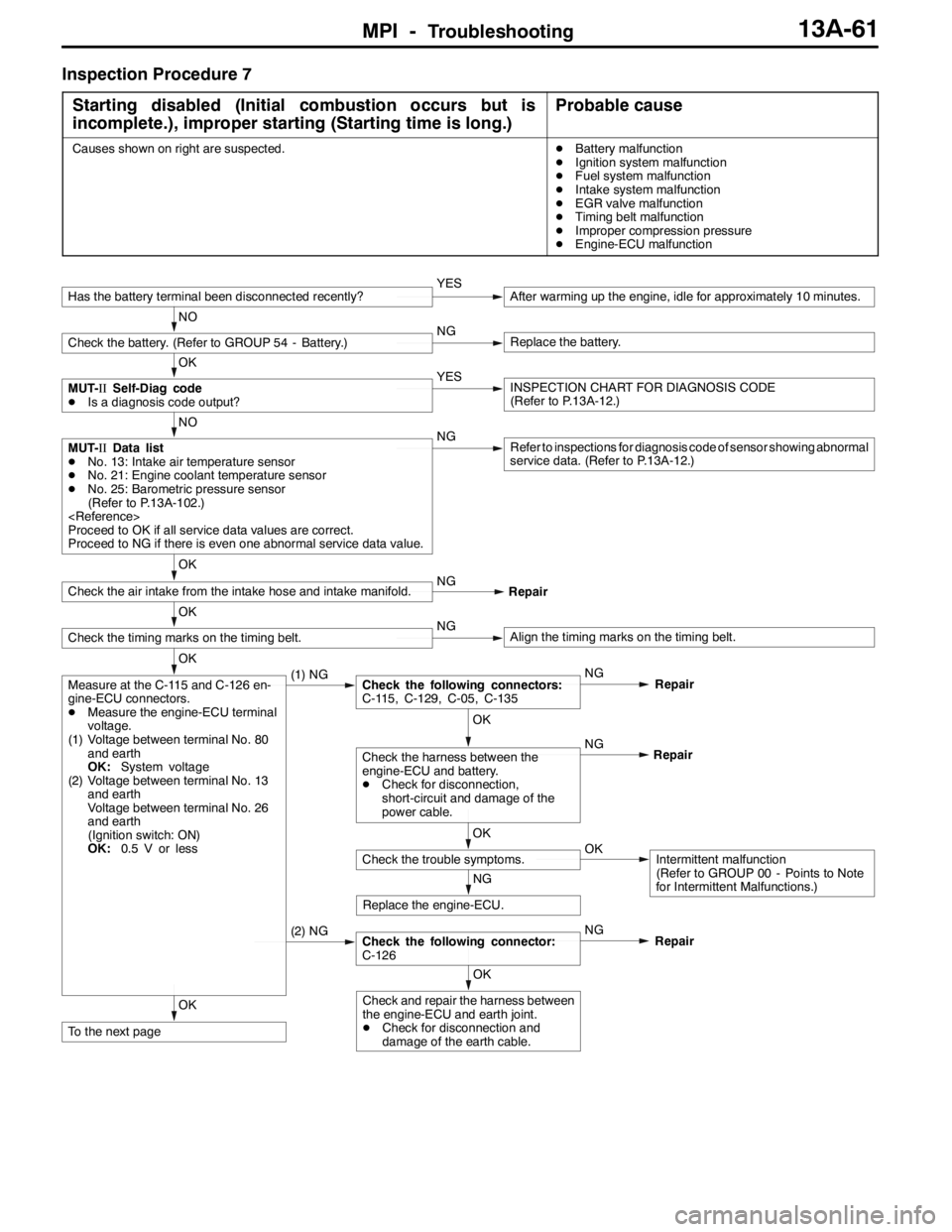

MPI -Troubleshooting13A-61

Inspection Procedure 7

Starting disabled (Initial combustion occurs but is

incomplete.), improper starting (Starting time is long.)

Probable cause

Causes shown on right are suspected.DBattery malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake system malfunction

DEGR valve malfunction

DTiming belt malfunction

DImproper compression pressure

DEngine-ECU malfunction

OK

To the next page

OK

Check and repair the harness between

the engine-ECU and earth joint.

DCheck for disconnection and

damage of the earth cable.

(2) NGCheck the following connector:

C-126NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

engine-ECU and battery.

DCheck for disconnection,

short-circuit and damage of the

power cable.Repair

OK

Measure at the C-115 and C-126 en-

gine-ECU connectors.

DMeasure the engine-ECU terminal

voltage.

(1) Voltage between terminal No. 80

and earth

OK:System voltage

(2) Voltage between terminal No. 13

and earth

Voltage between terminal No. 26

and earth

(Ignition switch: ON)

OK:0.5 V or less(1) NGCheck the following connectors:

C-115, C-129, C-05, C-135NG

Repair

OK

Check the timing marks on the timing belt.NGAlign the timing marks on the timing belt.

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

NO

MUT-IIData list

DNo. 13: Intake air temperature sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing abnormal

service data. (Refer to P.13A-12.)

OK

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

NO

Check the battery. (Refer to GROUP 54 - Battery.)NGReplace the battery.

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.

Page 595 of 1449

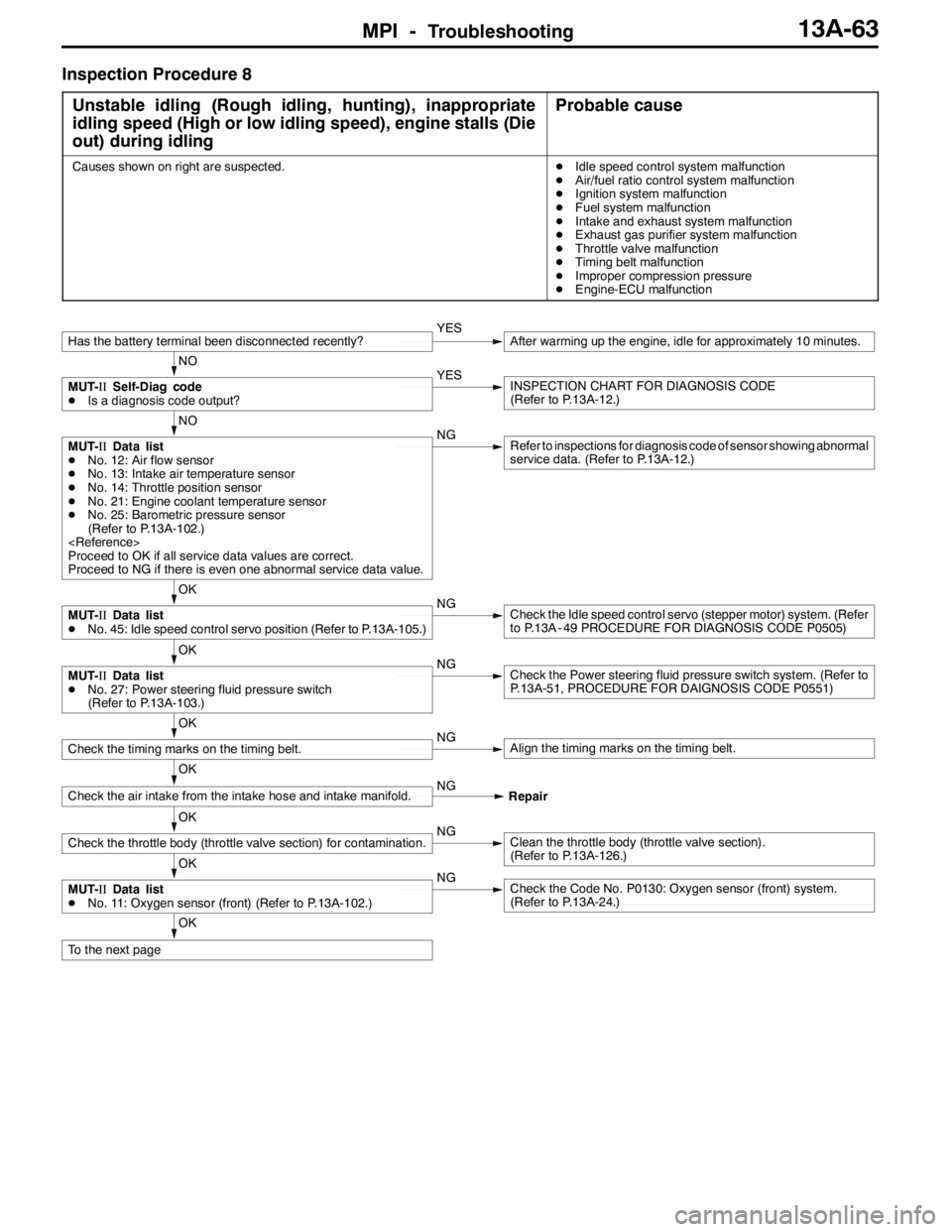

MPI -Troubleshooting13A-63

Inspection Procedure 8

Unstable idling (Rough idling, hunting), inappropriate

idling speed (High or low idling speed), engine stalls (Die

out) during idling

Probable cause

Causes shown on right are suspected.DIdle speed control system malfunction

DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DThrottle valve malfunction

DTiming belt malfunction

DImproper compression pressure

DEngine-ECU malfunction

OK

To the next page

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check the throttle body (throttle valve section) for contamination.NGClean the throttle body (throttle valve section).

(Refer to P.13A-126.)

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

Check the timing marks on the timing belt.NGAlign the timing marks on the timing belt.

OK

MUT-IIData list

DNo. 27: Power steering fluid pressure switch

(Refer to P.13A-103.)NGCheck the Power steering fluid pressure switch system. (Refer to

P.13A-51, PROCEDURE FOR DAIGNOSIS CODE P0551)

OK

MUT-IIData list

DNo. 45: Idle speed control servo position (Refer to P.13A-105.)NGCheck the Idle speed control servo (stepper motor) system. (Refer

to P.13A - 49 PROCEDURE FOR DIAGNOSIS CODE P0505)

NO

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 14: Throttle position sensor

DNo. 21: Engine coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing abnormal

service data. (Refer to P.13A-12.)

NO

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.

Page 596 of 1449

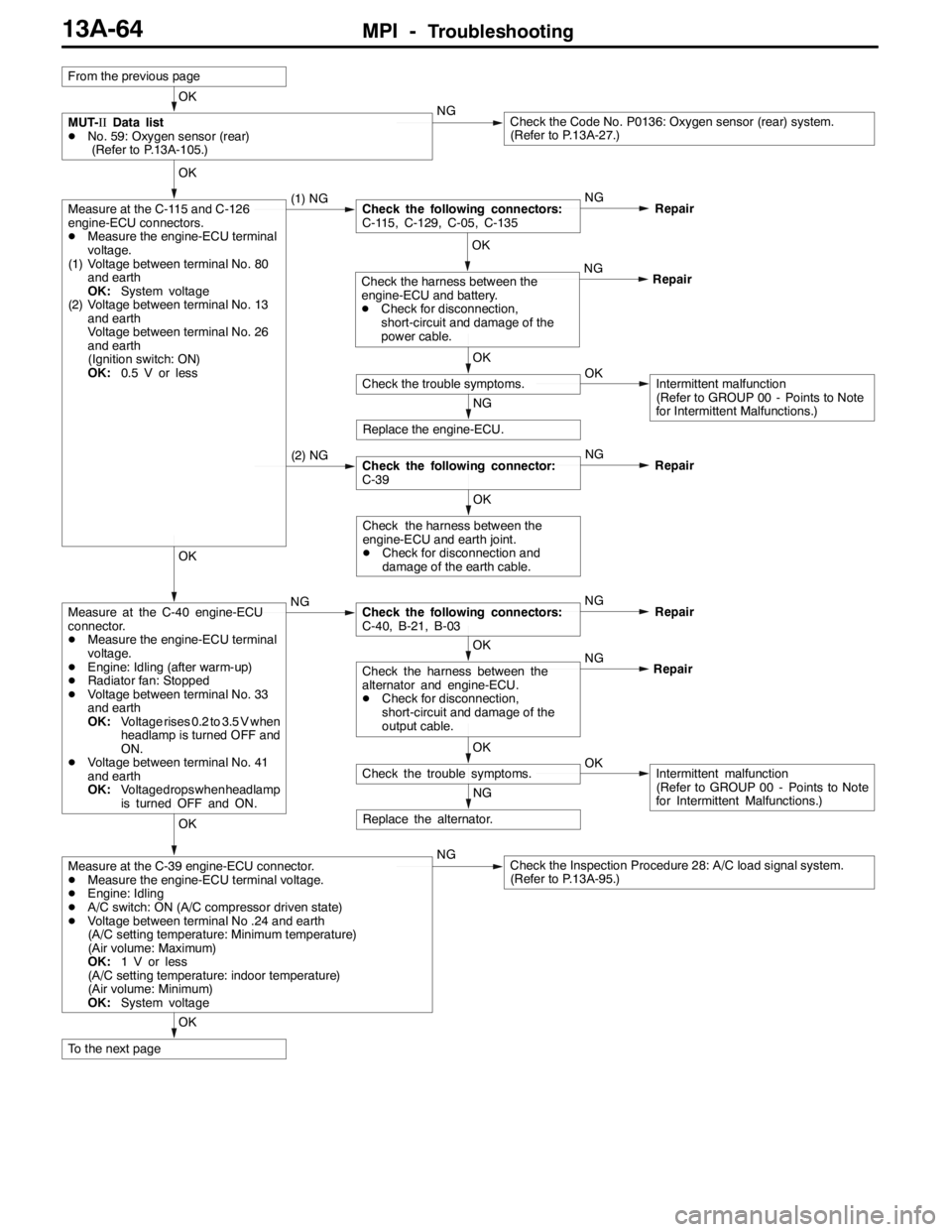

MPI -Troubleshooting13A-64

OK

To the next page

OK

Measure at the C-39 engine-ECU connector.

DMeasure the engine-ECU terminal voltage.

DEngine: Idling

DA/C switch: ON (A/C compressor driven state)

DVoltage between terminal No .24 and earth

(A/C setting temperature: Minimum temperature)

(Air volume: Maximum)

OK:1 V or less

(A/C setting temperature: indoor temperature)

(Air volume: Minimum)

OK:System voltageNGCheck the Inspection Procedure 28: A/C load signal system.

(Refer to P.13A-95.)

NG

Replace the alternator.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

alternator and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.Repair

OK

Measure at the C-40 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling (after warm-up)

DRadiator fan: Stopped

DVoltage between terminal No. 33

and earth

OK:Voltage rises 0.2 to 3.5 V when

headlamp is turned OFF and

ON.

DVoltage between terminal No. 41

and earth

OK:Voltage drops whenheadlamp

is turned OFF and ON.NGCheck the following connectors:

C-40, B-21, B-03NG

Repair

OK

Check the harness between the

engine-ECU and earth joint.

DCheck for disconnection and

damage of the earth cable.

(2) NGCheck the following connector:

C-39NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.) NG

OK

Check the harness between the

engine-ECU and battery.

DCheck for disconnection,

short-circuit and damage of the

power cable.Repair

OK

Measure at the C-115 and C-126

engine-ECU connectors.

DMeasure the engine-ECU terminal

voltage.

(1) Voltage between terminal No. 80

and earth

OK:System voltage

(2) Voltage between terminal No. 13

and earth

Voltage between terminal No. 26

and earth

(Ignition switch: ON)

OK:0.5 V or less(1) NGCheck the following connectors:

C-115, C-129, C-05, C-135NG

Repair

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

From the previous page

Page 598 of 1449

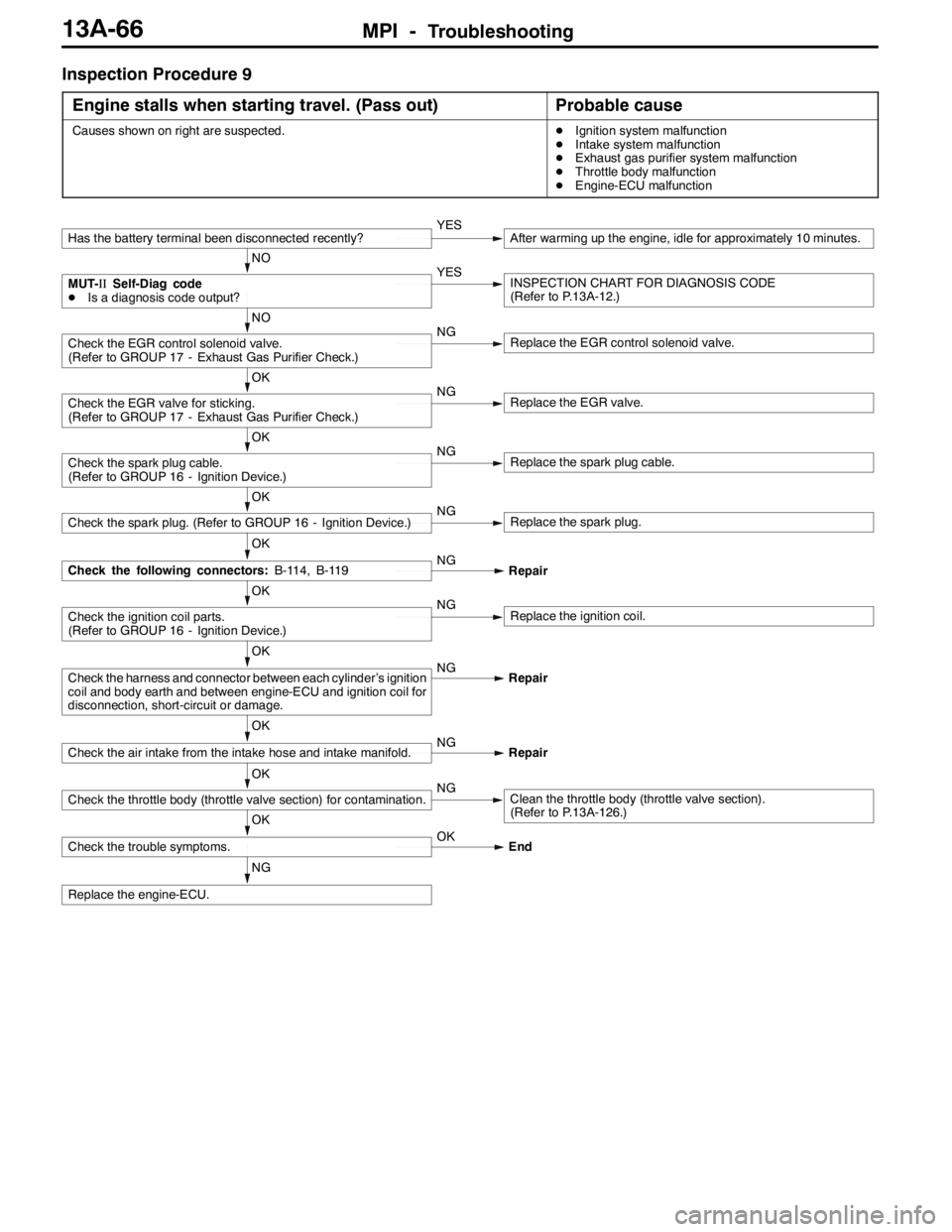

MPI -Troubleshooting13A-66

Inspection Procedure 9

Engine stalls when starting travel. (Pass out)

Probable cause

Causes shown on right are suspected.DIgnition system malfunction

DIntake system malfunction

DExhaust gas purifier system malfunction

DThrottle body malfunction

DEngine-ECU malfunction

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OK

End

OK

Check the throttle body (throttle valve section) for contamination.NGClean the throttle body (throttle valve section).

(Refer to P.13A-126.)

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

Check the harness and connector between each cylinder’s ignition

coil and body earth and between engine-ECU and ignition coil for

disconnection, short-circuit or damage.NG

Repair

OK

Check the ignition coil parts.

(Refer to GROUP 16 - Ignition Device.)NGReplace the ignition coil.

OK

Check the following connectors:B-114, B-119NG

Repair

OK

Check the spark plug. (Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug.

OK

Check the spark plug cable.

(Refer to GROUP 16 - Ignition Device.)NGReplace the spark plug cable.

OK

Check the EGR valve for sticking.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR valve.

NO

Check the EGR control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR control solenoid valve.

NO

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.

Page 599 of 1449

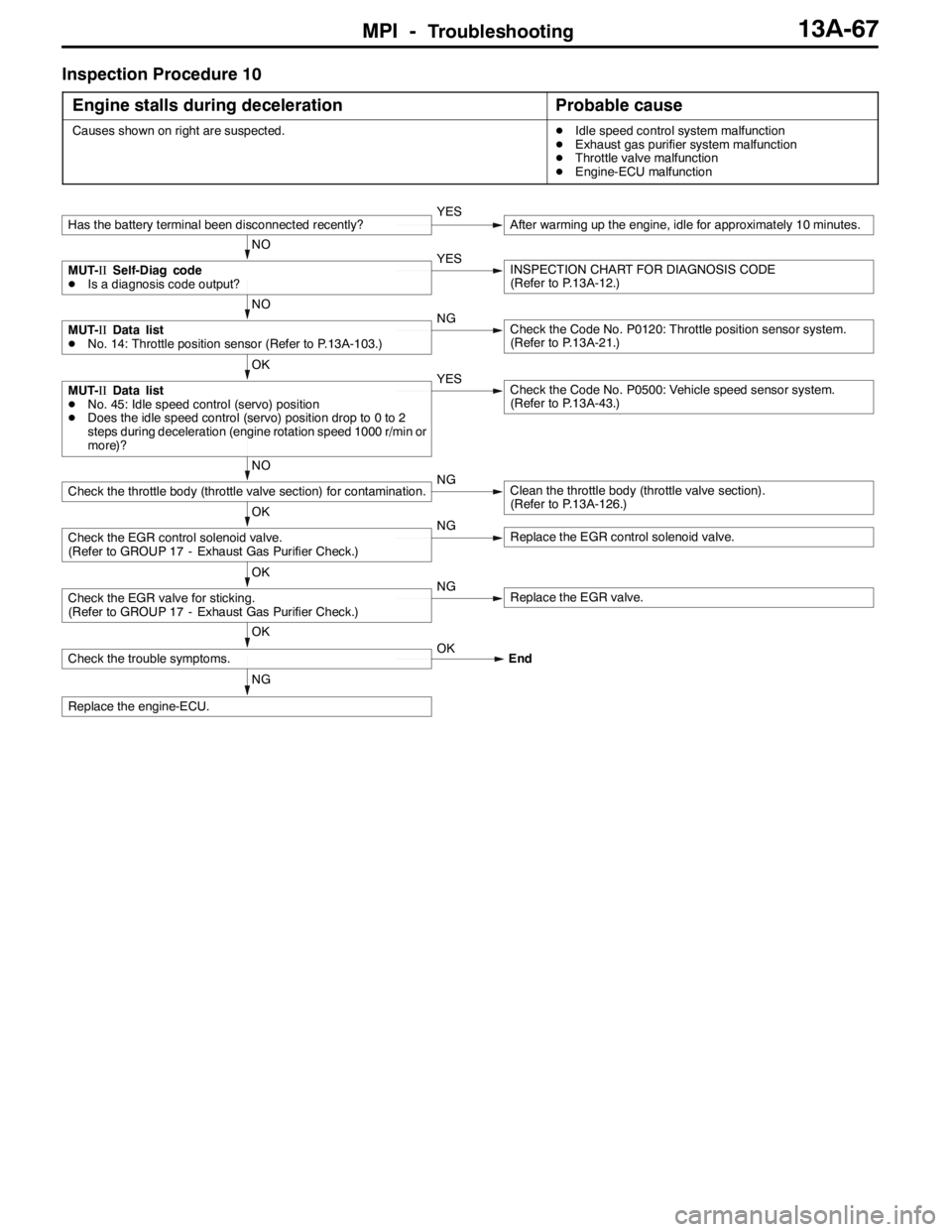

MPI -Troubleshooting13A-67

Inspection Procedure 10

Engine stalls during deceleration

Probable cause

Causes shown on right are suspected.DIdle speed control system malfunction

DExhaust gas purifier system malfunction

DThrottle valve malfunction

DEngine-ECU malfunction

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.OK

End

OK

Check the EGR valve for sticking.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR valve.

OK

Check the EGR control solenoid valve.

(Refer to GROUP 17 - Exhaust Gas Purifier Check.)NGReplace the EGR control solenoid valve.

NO

Check the throttle body (throttle valve section) for contamination.NGClean the throttle body (throttle valve section).

(Refer to P.13A-126.)

OK

MUT-IIData list

DNo. 45: Idle speed control (servo) position

DDoes the idle speed control (servo) position drop to 0 to 2

steps during deceleration (engine rotation speed 1000 r/min or

more)?YESCheck the Code No. P0500: Vehicle speed sensor system.

(Refer to P.13A-43.)

NO

MUT-IIData list

DNo. 14: Throttle position sensor (Refer to P.13A-103.)NGCheck the Code No. P0120: Throttle position sensor system.

(Refer to P.13A-21.)

NO

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Has the battery terminal been disconnected recently?YESAfter warming up the engine, idle for approximately 10 minutes.

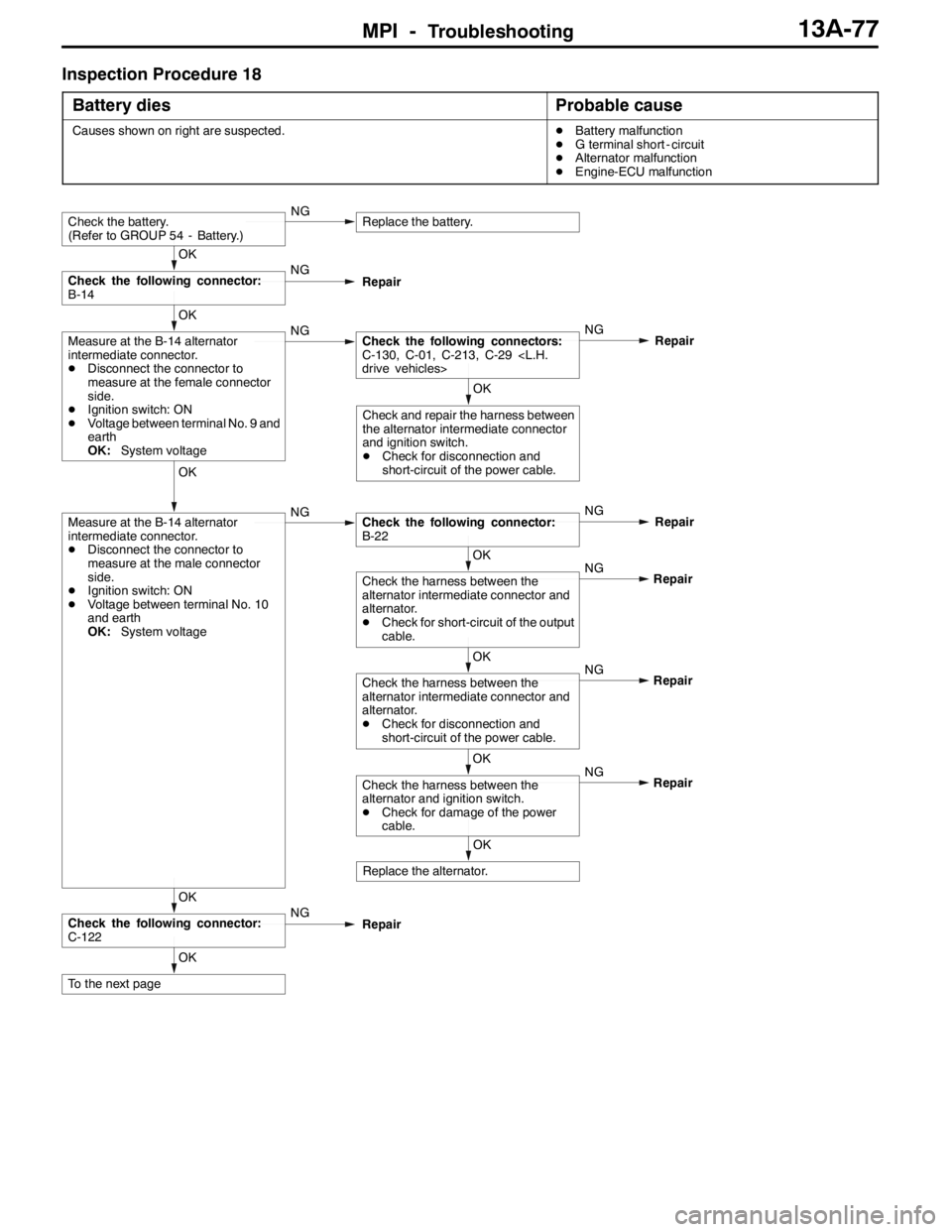

Page 609 of 1449

MPI -Troubleshooting13A-77

Inspection Procedure 18

Battery dies

Probable cause

Causes shown on right are suspected.DBattery malfunction

DG terminal short - circuit

DAlternator malfunction

DEngine-ECU malfunction

OK

To the next page

OK

Check the following connector:

C-122NG

Repair

OK

Replace the alternator.NG

OK

Check the harness between the

alternator and ignition switch.

DCheck for damage of the power

cable.Repair NG

OK

Check the harness between the

alternator intermediate connector and

alternator.

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the harness between the

alternator intermediate connector and

alternator.

DCheck for short-circuit of the output

cable.Repair

OK

Measure at the B-14 alternator

intermediate connector.

DDisconnect the connector to

measure at the male connector

side.

DIgnition switch: ON

DVoltage between terminal No. 10

and earth

OK:System voltageNGCheck the following connector:

B-22NG

Repair

OK

Check and repair the harness between

the alternator intermediate connector

and ignition switch.

DCheck for disconnection and

short-circuit of the power cable.

OK

Measure at the B-14 alternator

intermediate connector.

DDisconnect the connector to

measure at the female connector

side.

DIgnition switch: ON

DVoltage between terminal No. 9 and

earth

OK:System voltageNGCheck the following connectors:

C-130, C-01, C-213, C-29

Repair

OK

Check the following connector:

B-14NG

Repair

Check the battery.

(Refer to GROUP 54 - Battery.)NGReplace the battery.

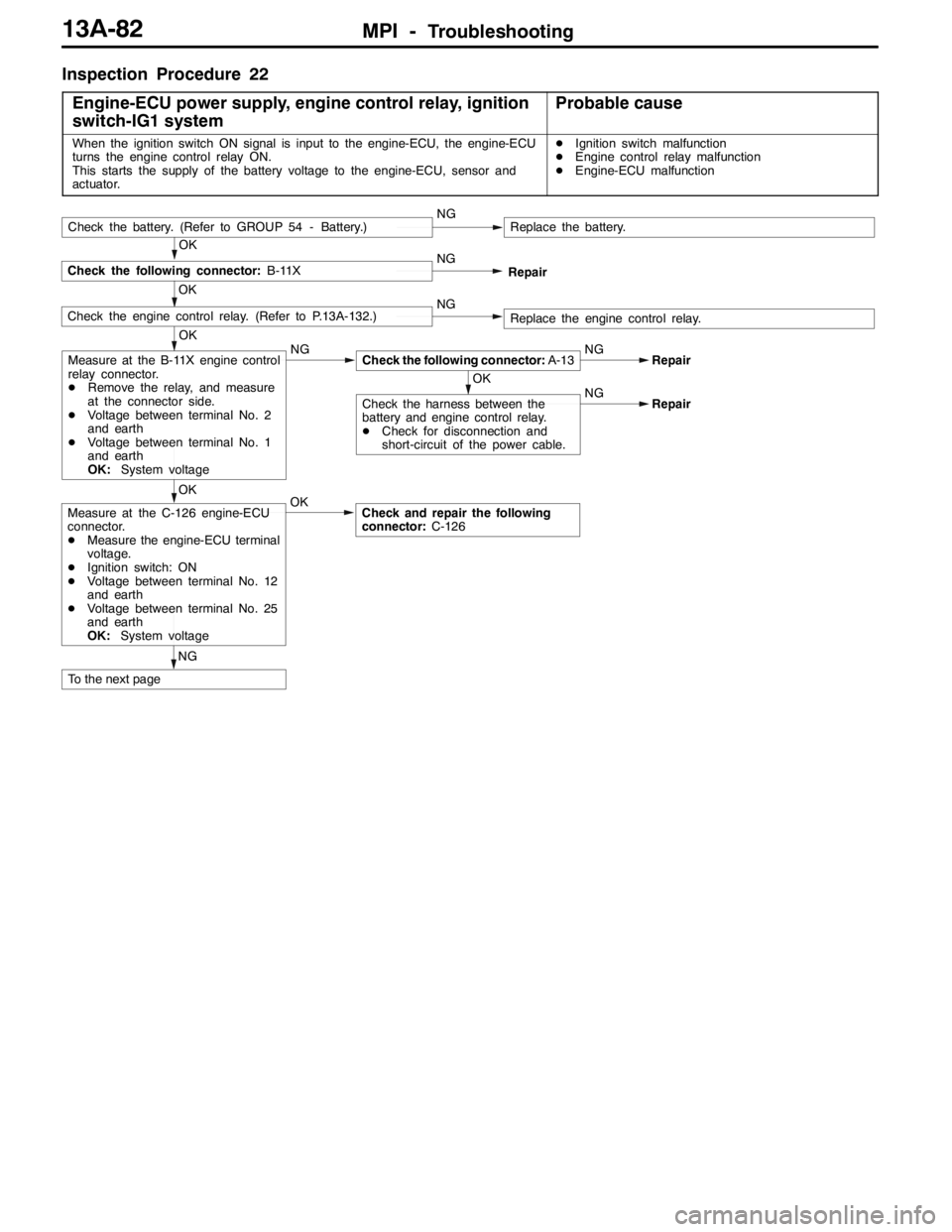

Page 614 of 1449

MPI -Troubleshooting13A-82

Inspection Procedure 22

Engine-ECU power supply, engine control relay, ignition

switch-IG1 system

Probable cause

When the ignition switch ON signal is input to the engine-ECU, the engine-ECU

turns the engine control relay ON.

This starts the supply of the battery voltage to the engine-ECU, sensor and

actuator.DIgnition switch malfunction

DEngine control relay malfunction

DEngine-ECU malfunction

OK

Check the engine control relay. (Refer to P.13A-132.)NGReplace the engine control relay.

OK

Check the following connector:B-11XNG

Check the battery. (Refer to GROUP 54 - Battery.)NGReplace the battery.

Repair

OK

OK

Measure at the B-11X engine control

relay connector.

DRemove the relay, and measure

at the connector side.

DVoltage between terminal No. 2

and earth

DVoltage between terminal No. 1

and earth

OK:System voltageNGCheck the following connector:A-13NG

OK

Check the harness between the

battery and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.NGRepair

Repair

NGOK

Check and repair the following

connector:C-126Measure at the C-126 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 12

and earth

DVoltage between terminal No. 25

and earth

OK:System voltage

To the next page

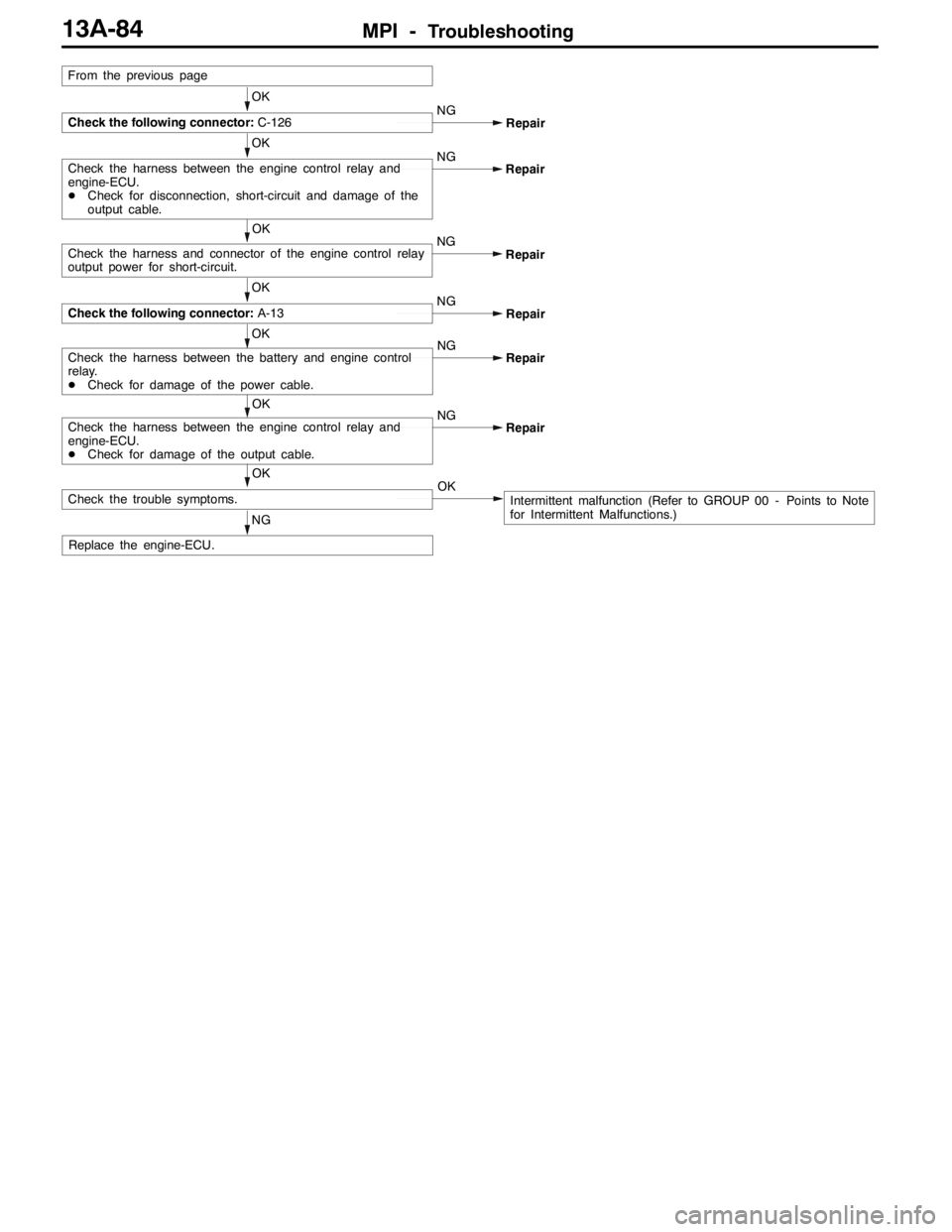

Page 616 of 1449

MPI -Troubleshooting13A-84

Check the harness and connector of the engine control relay

output power for short-circuit.NG

NG

OK

Check the harness between the engine control relay and

engine-ECU.

DCheck for disconnection, short-circuit and damage of the

output cable.NG

OK

Check the following connector:C-126NG

Intermittent malfunction (Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

From the previous page

Repair

OKRepair

Repair

OK

OK

Check the following connector:A-13NG

Repair

Check the harness between the battery and engine control

relay.

DCheck for damage of the power cable.NG

OKRepair

Check the harness between the engine control relay and

engine-ECU.

DCheck for damage of the output cable.NG

OKRepair

OKCheck the trouble symptoms.

Replace the engine-ECU.

Page 617 of 1449

MPI -Troubleshooting13A-85

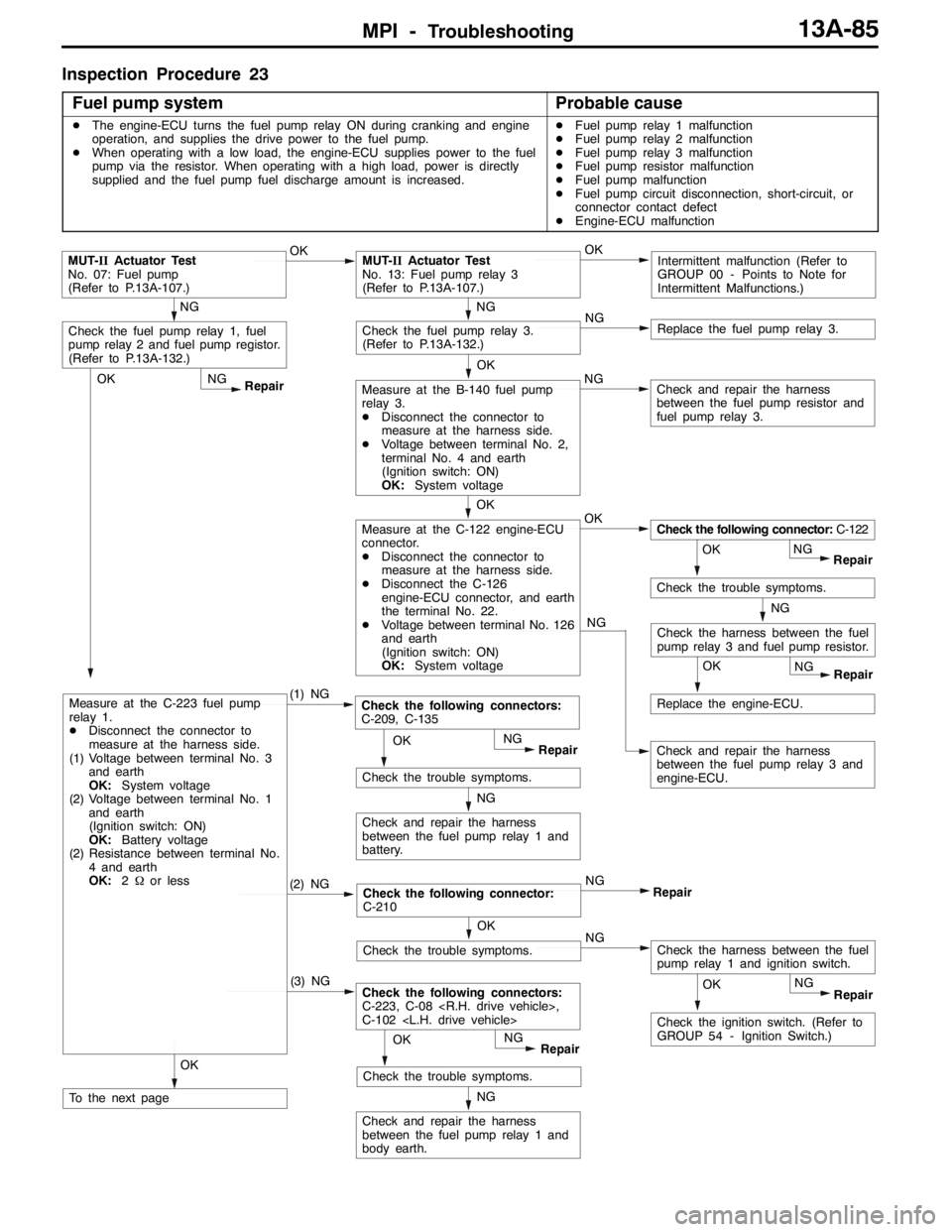

Inspection Procedure 23

Fuel pump system

Probable cause

DThe engine-ECU turns the fuel pump relay ON during cranking and engine

operation, and supplies the drive power to the fuel pump.

DWhen operating with a low load, the engine-ECU supplies power to the fuel

pump via the resistor. When operating with a high load, power is directly

supplied and the fuel pump fuel discharge amount is increased.DFuel pump relay 1 malfunction

DFuel pump relay 2 malfunction

DFuel pump relay 3 malfunction

DFuel pump resistor malfunction

DFuel pump malfunction

DFuel pump circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

NG

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)OKMUT-IIActuator Test

No. 07: Fuel pump

(Refer to P.13A-107.)

NGMUT-IIActuator Test

No. 13: Fuel pump relay 3

(Refer to P.13A-107.)OK

NG

Replace the fuel pump relay 3.NG

NG

Repair

Check the fuel pump relay 1, fuel

pump relay 2 and fuel pump registor.

(Refer to P.13A-132.)

OK

Measure at the B-140 fuel pump

relay 3.

DDisconnect the connector to

measure at the harness side.

DVoltage between terminal No. 2,

terminal No. 4 and earth

(Ignition switch: ON)

OK:System voltageNG

OK

Check the fuel pump relay 3.

(Refer to P.13A-132.)

OK

Check and repair the harness

between the fuel pump resistor and

fuel pump relay 3. OK

NG

Repair OK

NG

Check the trouble symptoms.

RepairOK

Check the harness between the fuel

pump relay 3 and fuel pump resistor.

Replace the engine-ECU.

Check and repair the harness

between the fuel pump relay 3 and

engine-ECU.

Check the following connector:C-122Measure at the C-122 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DDisconnect the C-126

engine-ECU connector, and earth

the terminal No. 22.

DVoltage between terminal No. 126

and earth

(Ignition switch: ON)

OK:System voltageNG

OK

Check the following connectors:

C-209, C-135(1) NG

Repair NG

NG

Check the trouble symptoms.

Check and repair the harness

between the fuel pump relay 1 and

battery.

(2) NGNG

OK

Check the following connector:

C-210Repair

NGCheck the trouble symptoms.

OK

Check the following connectors:

C-223, C-08

C-102

NG

Repair

NG

Check and repair the harness

between the fuel pump relay 1 and

body earth.

Check the trouble symptoms.OK

To the next page

Measure at the C-223 fuel pump

relay 1.

DDisconnect the connector to

measure at the harness side.

(1) Voltage between terminal No. 3

and earth

OK:System voltage

(2) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK:Battery voltage

(2) Resistance between terminal No.

4 and earth

OK:2Ωor less

Repair OK

Check the ignition switch. (Refer to

GROUP 54 - Ignition Switch.)

Check the harness between the fuel

pump relay 1 and ignition switch.

NG

Page 619 of 1449

MPI -Troubleshooting13A-87

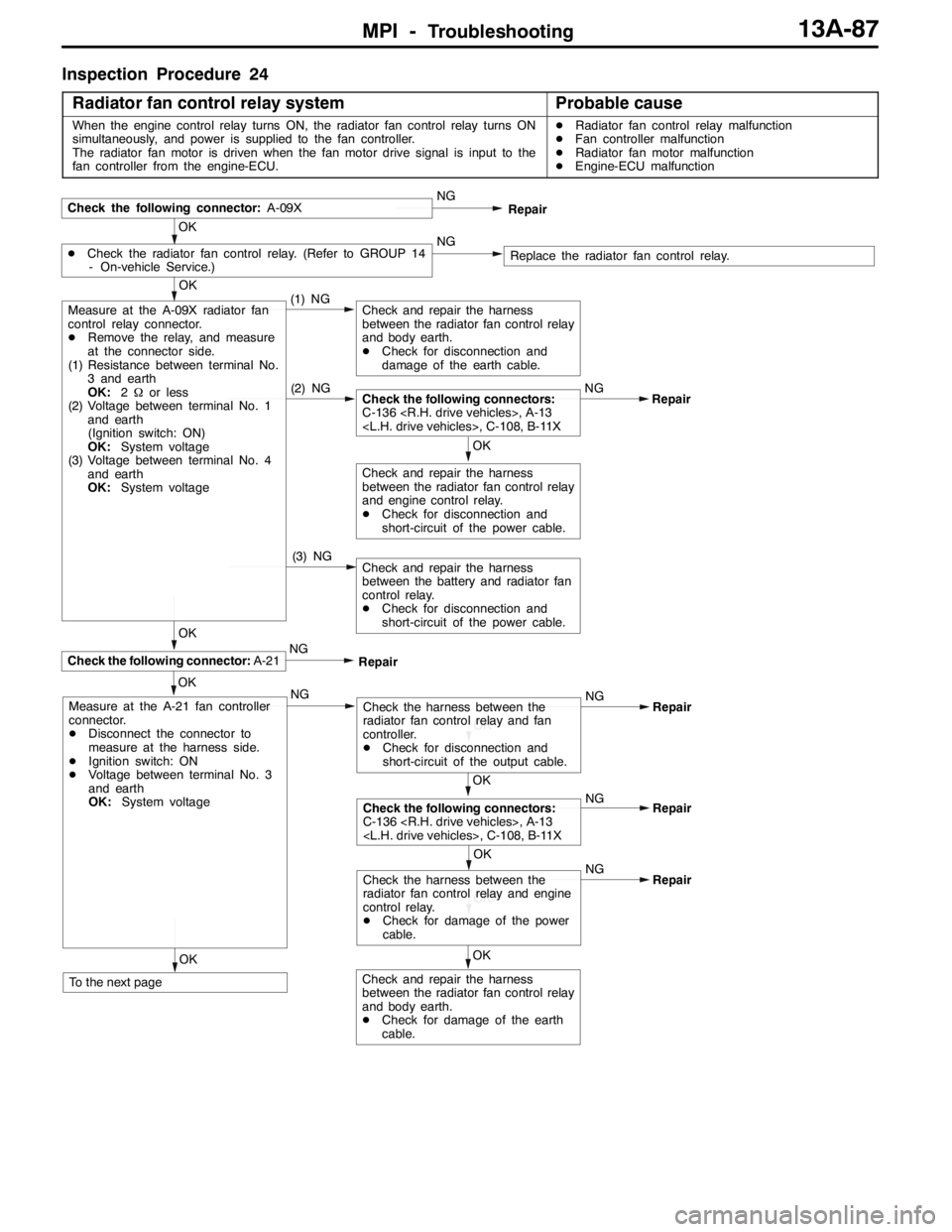

Inspection Procedure 24

Radiator fan control relay system

Probable cause

When the engine control relay turns ON, the radiator fan control relay turns ON

simultaneously, and power is supplied to the fan controller.

The radiator fan motor is driven when the fan motor drive signal is input to the

fan controller from the engine-ECU.DRadiator fan control relay malfunction

DFan controller malfunction

DRadiator fan motor malfunction

DEngine-ECU malfunction

OK

(1) NG

OK

DCheck the radiator fan control relay. (Refer to GROUP 14

- On-vehicle Service.)NGReplace the radiator fan control relay.

Check the following connector:A-09XNG

Repair

OK

OK

(2) NGCheck the following connectors:

C-136

OK

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for disconnection and

damage of the earth cable.

Repair

OK

Check the following connector:A-21

Check and repair the harness

between the radiator fan control relay

and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.

(3) NGCheck and repair the harness

between the battery and radiator fan

control relay.

DCheck for disconnection and

short-circuit of the power cable.

Measure at the A-09X radiator fan

control relay connector.

DRemove the relay, and measure

at the connector side.

(1) Resistance between terminal No.

3 and earth

OK:2Ωor less

(2) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK:System voltage

(3) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair

OK

Measure at the A-21 fan controller

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltage

To the next pageNG

OK

Check the harness between the

radiator fan control relay and fan

controller.

DCheck for disconnection and

short-circuit of the output cable.NG

Repair

OK

Check the following connectors:

C-136

Repair

OK

OK

Check the harness between the

radiator fan control relay and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

Check and repair the harness

between the radiator fan control relay

and body earth.

DCheck for damage of the earth

cable.