battery MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 669 of 1449

MPI -On-vehicle Service13A-137

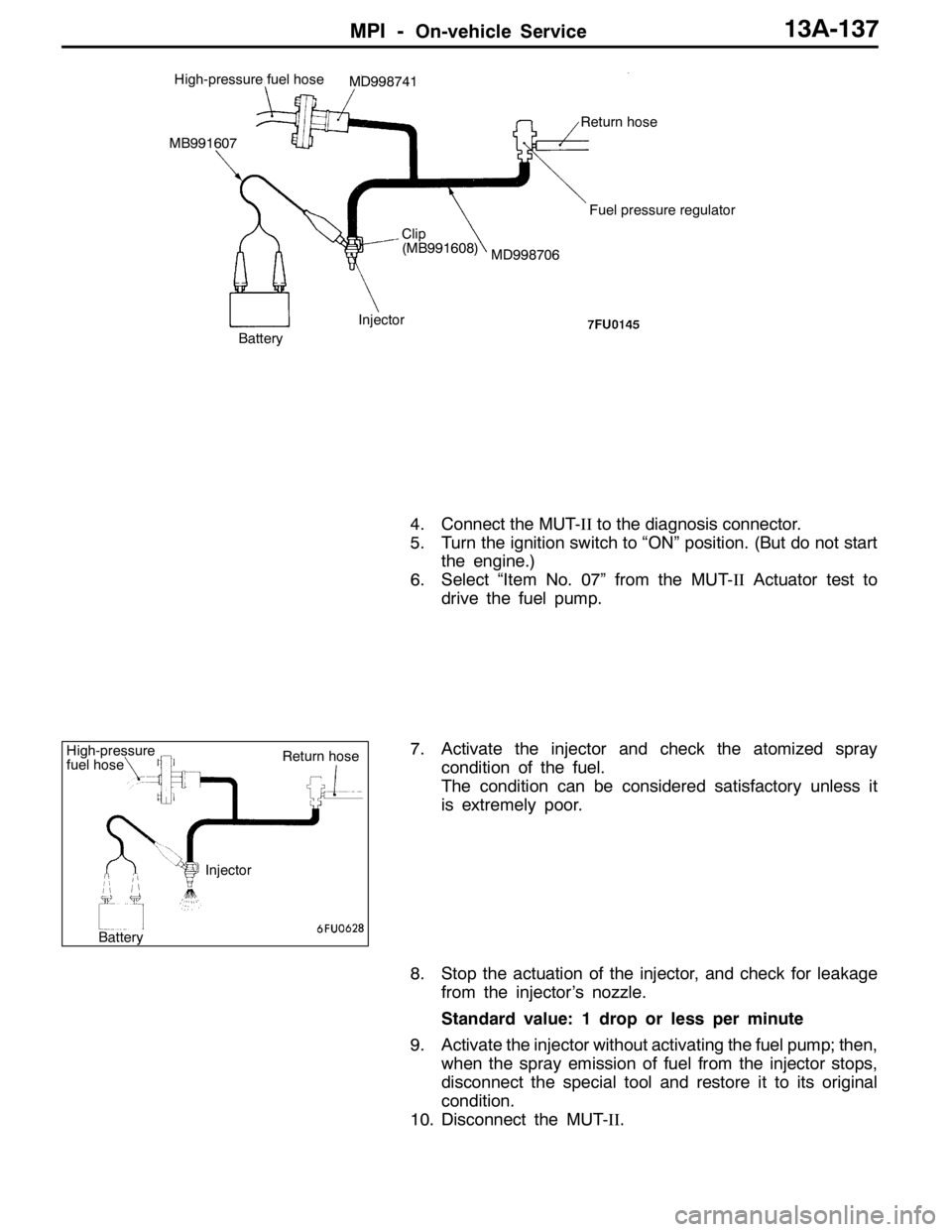

MB991607

High-pressure fuel hoseMD998741

MD998706Return hose

BatteryInjectorFuel pressure regulator

Clip

(MB991608)

4. Connect the MUT-IIto the diagnosis connector.

5. Turn the ignition switch to “ON” position. (But do not start

the engine.)

6. Select “Item No. 07” from the MUT-IIActuator test to

drive the fuel pump.

7. Activate the injector and check the atomized spray

condition of the fuel.

The condition can be considered satisfactory unless it

is extremely poor.

8. Stop the actuation of the injector, and check for leakage

from the injector’s nozzle.

Standard value: 1 drop or less per minute

9. Activate the injector without activating the fuel pump; then,

when the spray emission of fuel from the injector stops,

disconnect the special tool and restore it to its original

condition.

10. Disconnect the MUT-II.

High-pressure

fuel hose

BatteryInjectorReturn hose

Page 672 of 1449

MPI -On-vehicle Service13A-140

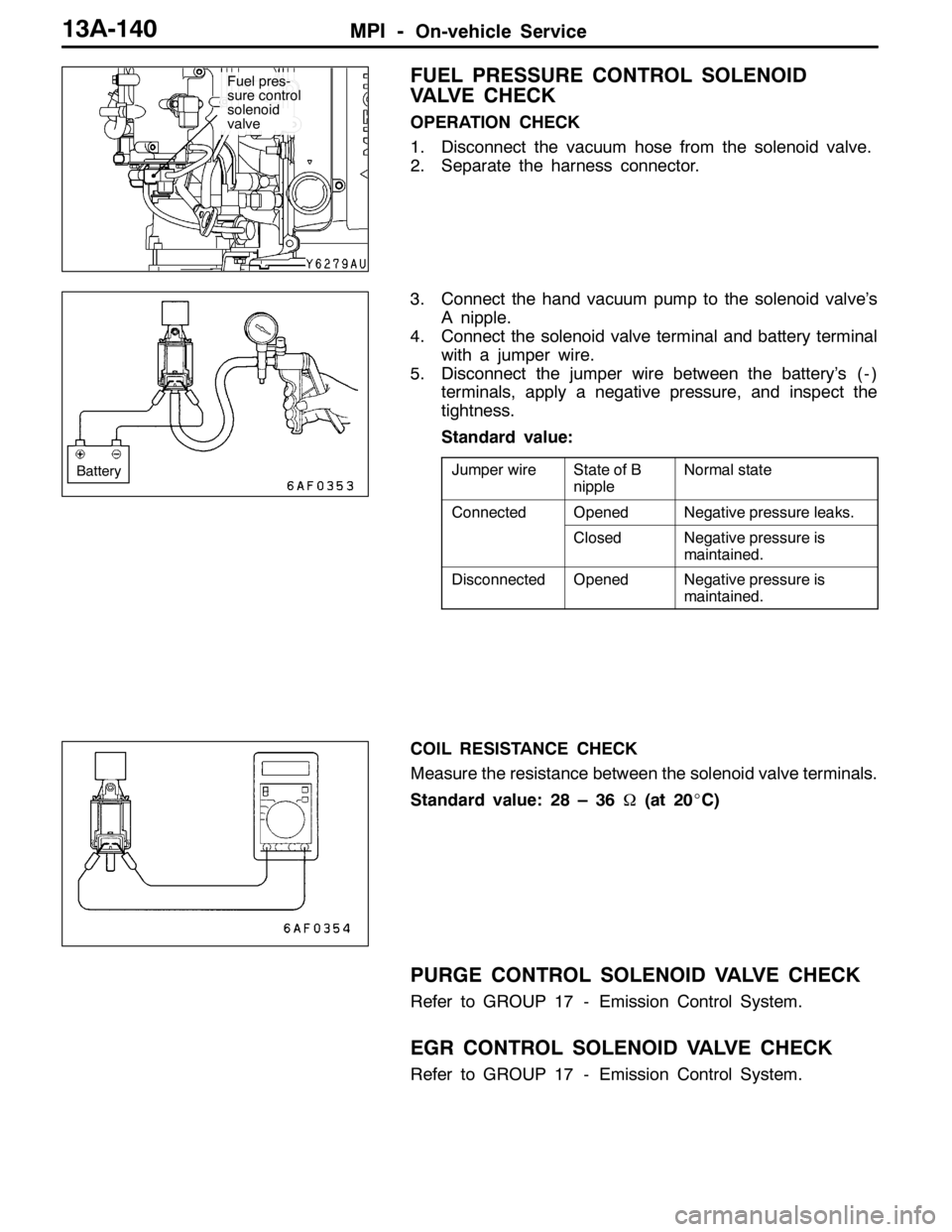

FUEL PRESSURE CONTROL SOLENOID

VALVE CHECK

OPERATION CHECK

1. Disconnect the vacuum hose from the solenoid valve.

2. Separate the harness connector.

3. Connect the hand vacuum pump to the solenoid valve’s

A nipple.

4. Connect the solenoid valve terminal and battery terminal

with a jumper wire.

5. Disconnect the jumper wire between the battery’s ( - )

terminals, apply a negative pressure, and inspect the

tightness.

Standard value:

Jumper wireState of B

nippleNormal state

ConnectedOpenedNegative pressure leaks.

ClosedNegative pressure is

maintained.

DisconnectedOpenedNegative pressure is

maintained.

COIL RESISTANCE CHECK

Measure the resistance between the solenoid valve terminals.

Standard value: 28 – 36Ω(at 20_C)

PURGE CONTROL SOLENOID VALVE CHECK

Refer to GROUP 17 - Emission Control System.

EGR CONTROL SOLENOID VALVE CHECK

Refer to GROUP 17 - Emission Control System.

Fuel pres-

sure control

solenoid

valve

Battery

Page 692 of 1449

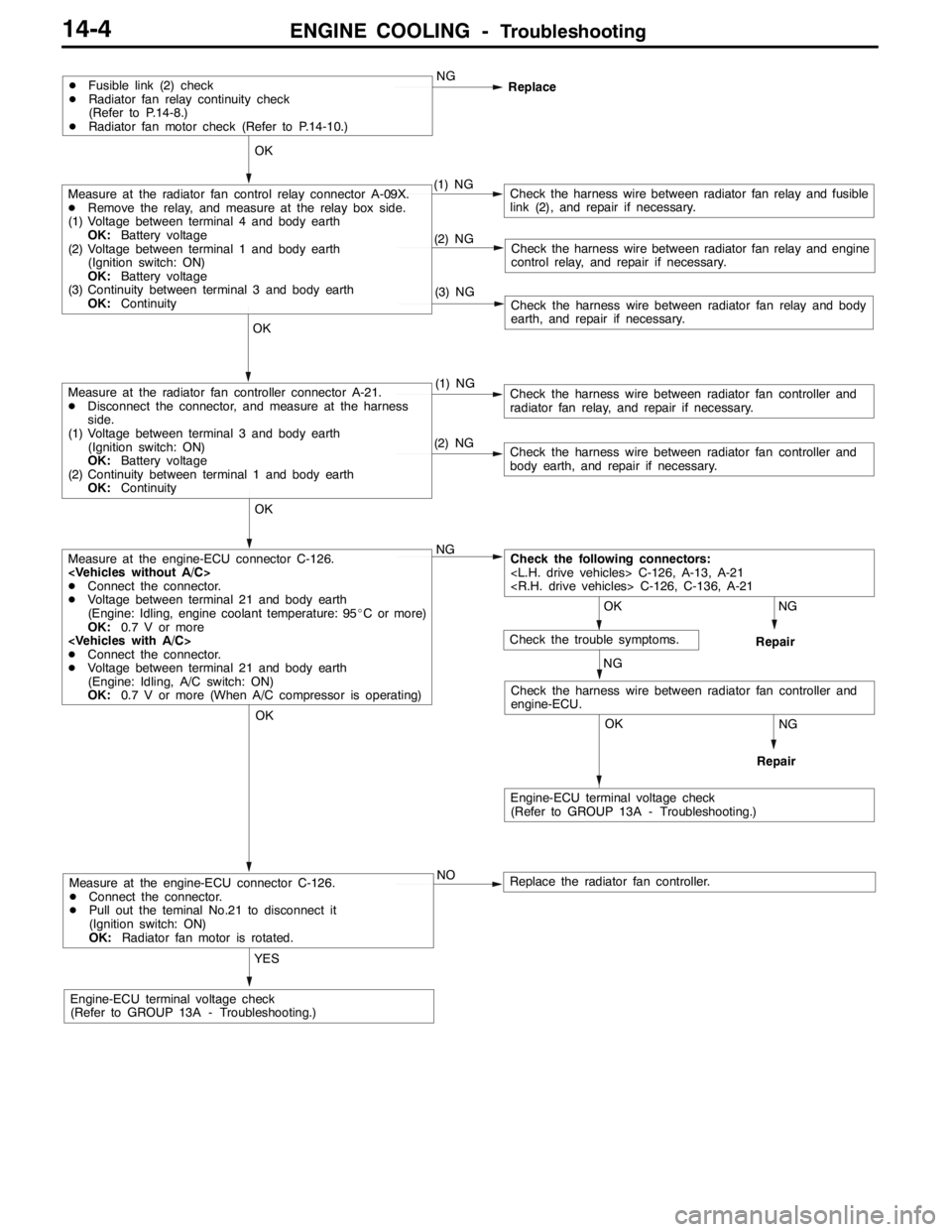

ENGINE COOLING -Troubleshooting14-4

Measure at the engine-ECU connector C-126.

DConnect the connector.

DPull out the teminal No.21 to disconnect it

(Ignition switch: ON)

OK:Radiator fan motor is rotated.

YES

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)NO

Replace the radiator fan controller.

NG

Repair

OK

NG

Repair

OK

Check the harness wire between radiator fan controller and

engine-ECU.

Measure at the engine-ECU connector C-126.

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, engine coolant temperature: 95_C or more)

OK:0.7 V or more

DConnect the connector.

DVoltage between terminal 21 and body earth

(Engine: Idling, A/C switch: ON)

OK:0.7 V or more (When A/C compressor is operating)NG

(2) NGCheck the harness wire between radiator fan controller and

body earth, and repair if necessary.

OK

Measure at the radiator fan controller connector A-21.

DDisconnect the connector, and measure at the harness

side.

(1) Voltage between terminal 3 and body earth

(Ignition switch: ON)

OK:Battery voltage

(2) Continuity between terminal 1 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan controller and

radiator fan relay, and repair if necessary.

(3) NGCheck the harness wire between radiator fan relay and body

earth, and repair if necessary.

(2) NGCheck the harness wire between radiator fan relay and engine

control relay, and repair if necessary.

OK

Measure at the radiator fan control relay connector A-09X.

DRemove the relay, and measure at the relay box side.

(1) Voltage between terminal 4 and body earth

OK:Battery voltage

(2) Voltage between terminal 1 and body earth

(Ignition switch: ON)

OK:Battery voltage

(3) Continuity between terminal 3 and body earth

OK:Continuity(1) NGCheck the harness wire between radiator fan relay and fusible

link (2), and repair if necessary.

DFusible link (2) check

DRadiator fan relay continuity check

(Refer to P.14-8.)

DRadiator fan motor check (Refer to P.14-10.)NG

Replace

OK

OK

Engine-ECU terminal voltage check

(Refer to GROUP 13A - Troubleshooting.)

Check the following connectors:

NG

Check the trouble symptoms.

Page 696 of 1449

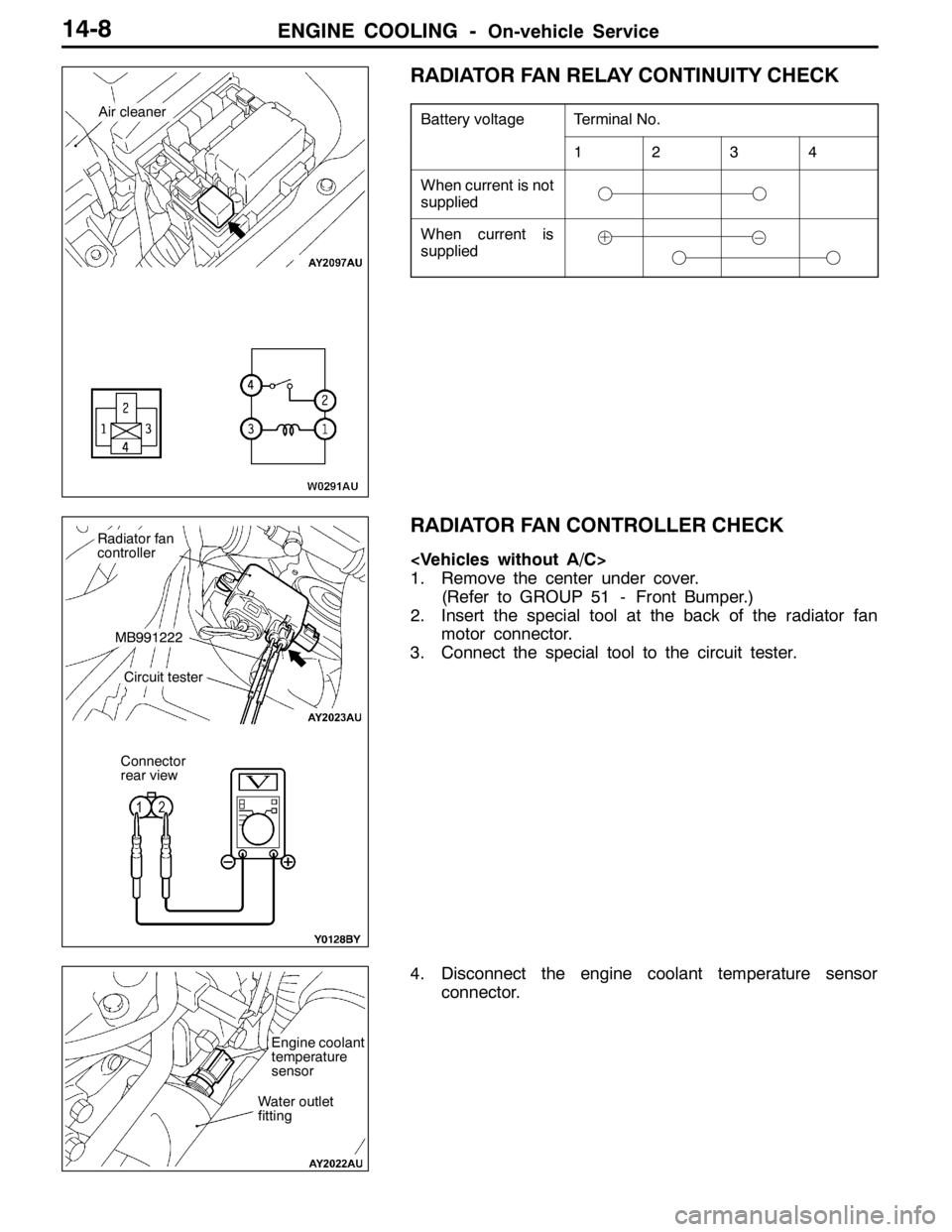

ENGINE COOLING -On-vehicle Service14-8

RADIATOR FAN RELAY CONTINUITY CHECK

Battery voltageTerminal No.

1234

When current is not

supplied

When current is

supplied

RADIATOR FAN CONTROLLER CHECK

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Disconnect the engine coolant temperature sensor

connector.

Air cleaner

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Water outlet

fitting

Engine coolant

temperature

sensor

Page 697 of 1449

![MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the](/img/19/57084/w960_57084-696.png)

ENGINE COOLING -On-vehicle Service14-9

5. Connect the special tool (MB991658) to the harness side

of the engine coolant temperature sensor connector.

6. Connect the special tool [MB991791(APS)] to the special

tool (MB991658).

7. Start the engine and let it run at idle.

NOTE

Since the resistance value of the special tool (APS)

indicates a low engine coolant temperature, engine speed

increases.

8. When the lever of the special tool (APS) is turned to

the end, check that the engine speed decreases and

the radiator fan motor rotates.

9. When the lever of the special tool (APS) is turned to

the reverse direction, check that the voltage between

terminals of the radiator fan motor connector gradually

decreases from the battery voltage to 0 V.

10. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

11. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

12. Connect the engine coolant temperature sensor

connector.

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Insert the special tool at the back of the radiator fan

motor connector.

3. Connect the special tool to the circuit tester.

4. Start the engine and run it at idle.

5. Turn the A/C switch to the ON position and hold the

engine coolant temperature at 80_C or lower.

6. When the voltage between the terminals of the radiator

fan motor connector, the following values of (1) - (3)

can be detected at random.

(1) 0 V

(2) 8.22.6 V

(3) Battery voltage2.6 V

7. If inoperable, replace the radiator fan controller.

(Refer to P.14-15.)

8. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)

Engine coolant

temperature sensor

connector

(harness side)

MB991791(APS)

MB991658

MB991658Lever

MB991791(APS)

Radiator fan

controller

MB991222

Circuit tester

Connector

rear view

Page 698 of 1449

ENGINE COOLING -On - vehicle Service14-10

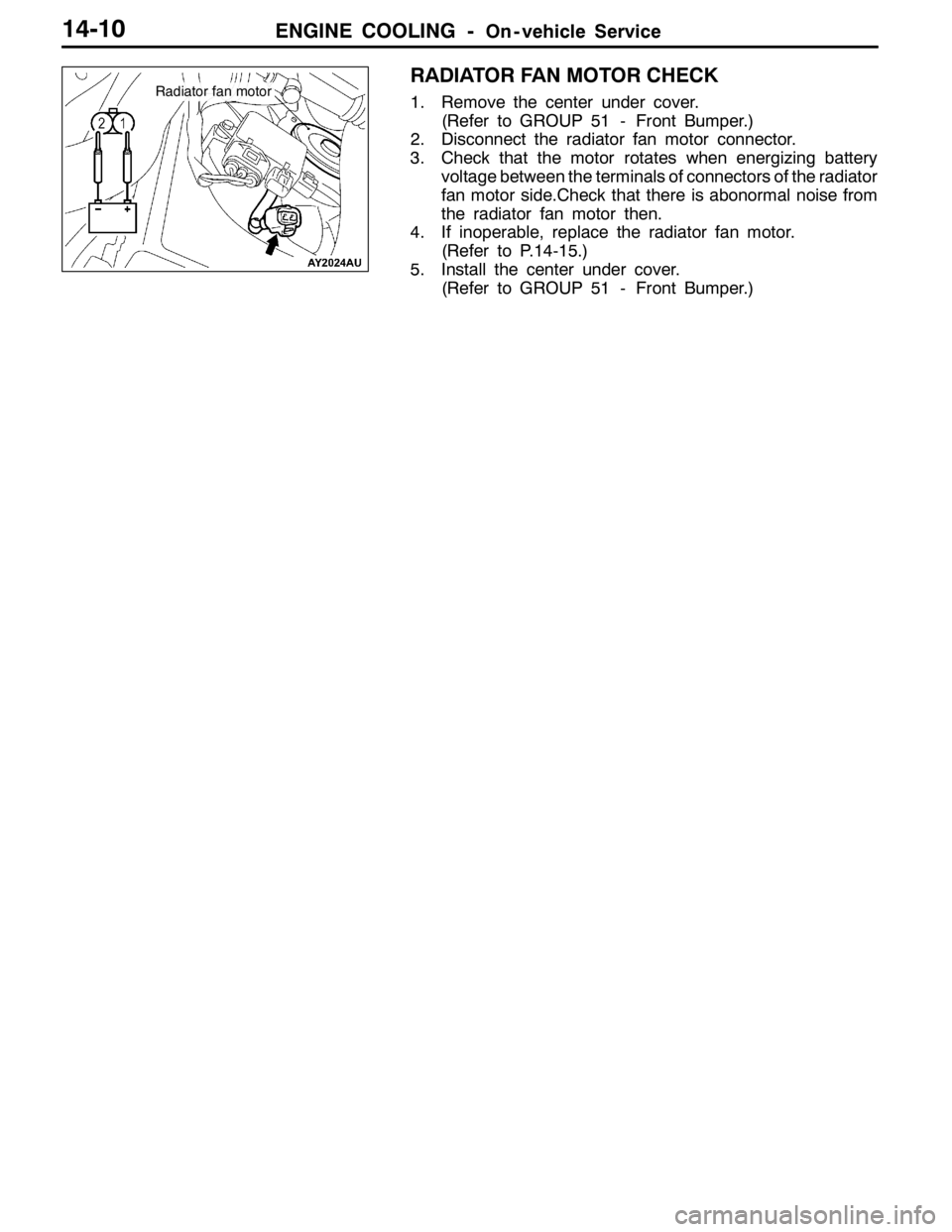

RADIATOR FAN MOTOR CHECK

1. Remove the center under cover.

(Refer to GROUP 51 - Front Bumper.)

2. Disconnect the radiator fan motor connector.

3. Check that the motor rotates when energizing battery

voltage between the terminals of connectors of the radiator

fan motor side.Check that there is abonormal noise from

the radiator fan motor then.

4. If inoperable, replace the radiator fan motor.

(Refer to P.14-15.)

5. Install the center under cover.

(Refer to GROUP 51 - Front Bumper.)Radiator fan motor

Page 702 of 1449

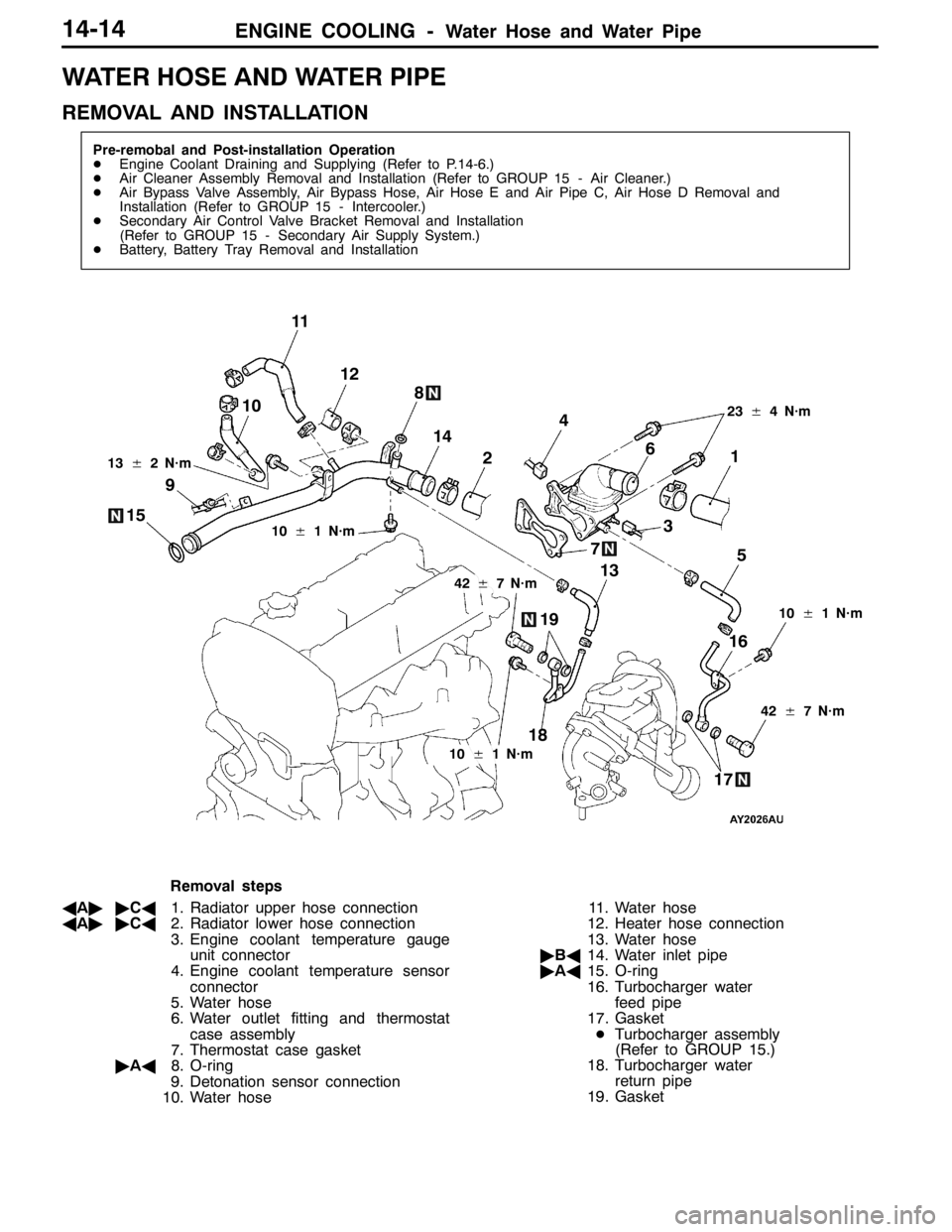

ENGINE COOLING -Water Hose and Water Pipe14-14

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15 - Air Cleaner.)

DAir Bypass Valve Assembly, Air Bypass Hose, Air Hose E and Air Pipe C, Air Hose D Removal and

Installation (Refer to GROUP 15 - Intercooler.)

DSecondary Air Control Valve Bracket Removal and Installation

(Refer to GROUP 15 - Secondary Air Supply System.)

DBattery, Battery Tray Removal and Installation

3 4

5 6

7 8

9

1012

10±1 N·m

42±7 N·m 13±2 N·m

11

1

2

23±4 N·m

18

1716 1514

13

19

10±1 N·m

42±7 N·m

10±1 N·m

Removal steps

AA""CA1. Radiator upper hose connection

AA""CA2. Radiator lower hose connection

3. Engine coolant temperature gauge

unit connector

4. Engine coolant temperature sensor

connector

5. Water hose

6. Water outlet fitting and thermostat

case assembly

7. Thermostat case gasket

"AA8. O-ring

9. Detonation sensor connection

10. Water hose11. Water hose

12. Heater hose connection

13. Water hose

"BA14. Water inlet pipe

"AA15. O-ring

16. Turbocharger water

feed pipe

17. Gasket

DTurbocharger assembly

(Refer to GROUP 15.)

18. Turbocharger water

return pipe

19. Gasket

Page 703 of 1449

ENGINE COOLING -Water Hose and Water Pipe/Radiator14-15

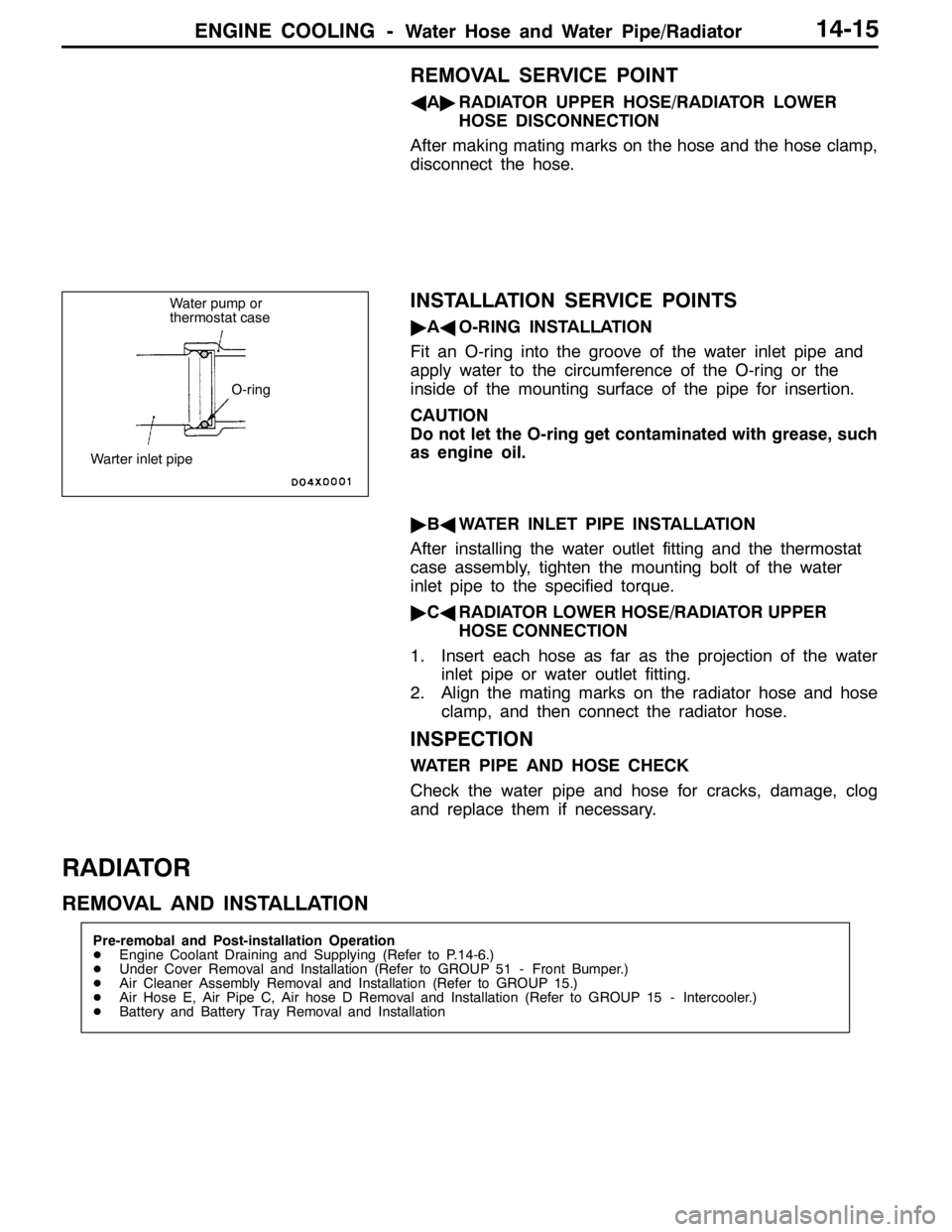

REMOVAL SERVICE POINT

AA"RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

After making mating marks on the hose and the hose clamp,

disconnect the hose.

INSTALLATION SERVICE POINTS

"AAO-RING INSTALLATION

Fit an O-ring into the groove of the water inlet pipe and

apply water to the circumference of the O-ring or the

inside of the mounting surface of the pipe for insertion.

CAUTION

Do not let the O-ring get contaminated with grease, such

as engine oil.

"BAWATER INLET PIPE INSTALLATION

After installing the water outlet fitting and the thermostat

case assembly, tighten the mounting bolt of the water

inlet pipe to the specified torque.

"CARADIATOR LOWER HOSE/RADIATOR UPPER

HOSE CONNECTION

1. Insert each hose as far as the projection of the water

inlet pipe or water outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

WATER PIPE AND HOSE CHECK

Check the water pipe and hose for cracks, damage, clog

and replace them if necessary.

RADIATOR

REMOVAL AND INSTALLATION

Pre-remobal and Post-installation Operation

DEngine Coolant Draining and Supplying (Refer to P.14-6.)

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DAir Cleaner Assembly Removal and Installation (Refer to GROUP 15.)

DAir Hose E, Air Pipe C, Air hose D Removal and Installation (Refer to GROUP 15 - Intercooler.)

DBattery and Battery Tray Removal and Installation

Water pump or

thermostat case

O-ring

Warter inlet pipe

Page 711 of 1449

INTAKE AND EXHAUST -On-vehicle Service15-5

3. If there is a significant deviation from the standard value,

check the actuator or the waste gate valve: replace

actuator or turbocharger assembly if necessary.

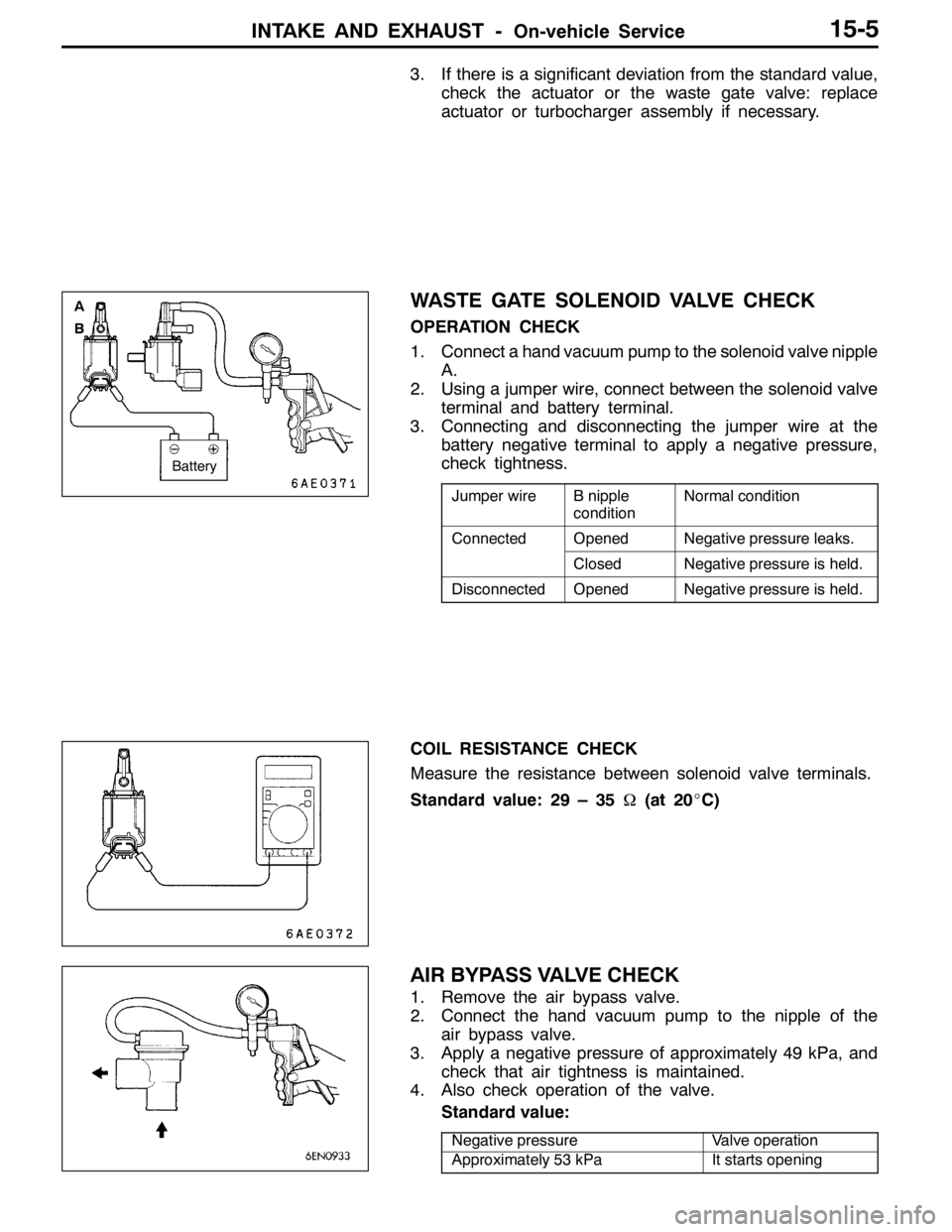

WASTE GATE SOLENOID VALVE CHECK

OPERATION CHECK

1. Connect a hand vacuum pump to the solenoid valve nipple

A.

2. Using a jumper wire, connect between the solenoid valve

terminal and battery terminal.

3. Connecting and disconnecting the jumper wire at the

battery negative terminal to apply a negative pressure,

check tightness.

Jumper wireB nipple

conditionNormal condition

ConnectedOpenedNegative pressure leaks.

ClosedNegative pressure is held.

DisconnectedOpenedNegative pressure is held.

COIL RESISTANCE CHECK

Measure the resistance between solenoid valve terminals.

Standard value: 29 – 35Ω(at 20_C)

AIR BYPASS VALVE CHECK

1. Remove the air bypass valve.

2. Connect the hand vacuum pump to the nipple of the

air bypass valve.

3. Apply a negative pressure of approximately 49 kPa, and

check that air tightness is maintained.

4. Also check operation of the valve.

Standard value:

Negative pressureValve operation

Approximately 53 kPaIt starts opening

Battery B A

Page 712 of 1449

INTAKE AND EXHAUST -On-vehicle Service15-6

INTAKE MANIFOLD PRESSURE CHECK

Refer to GROUP 11A – On-vehicle Service.

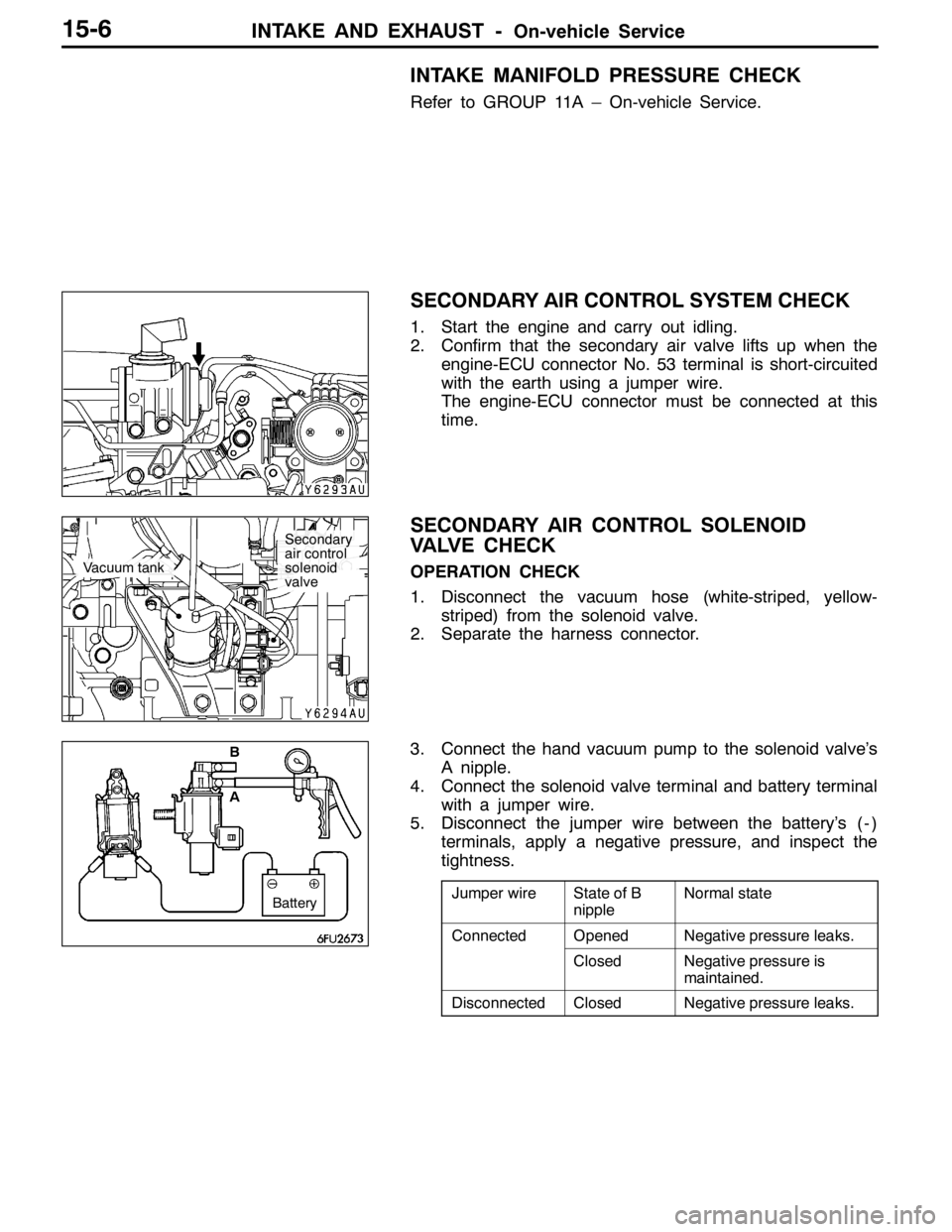

SECONDARY AIR CONTROL SYSTEM CHECK

1. Start the engine and carry out idling.

2. Confirm that the secondary air valve lifts up when the

engine-ECU connector No. 53 terminal is short-circuited

with the earth using a jumper wire.

The engine-ECU connector must be connected at this

time.

SECONDARY AIR CONTROL SOLENOID

VALVE CHECK

OPERATION CHECK

1. Disconnect the vacuum hose (white-striped, yellow-

striped) from the solenoid valve.

2. Separate the harness connector.

3. Connect the hand vacuum pump to the solenoid valve’s

A nipple.

4. Connect the solenoid valve terminal and battery terminal

with a jumper wire.

5. Disconnect the jumper wire between the battery’s ( - )

terminals, apply a negative pressure, and inspect the

tightness.

Jumper wireState of B

nippleNormal state

ConnectedOpenedNegative pressure leaks.

ClosedNegative pressure is

maintained.

DisconnectedClosedNegative pressure leaks.

Vacuum tank

Secondary

air control

solenoid

valve

Battery A B