battery MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 620 of 1449

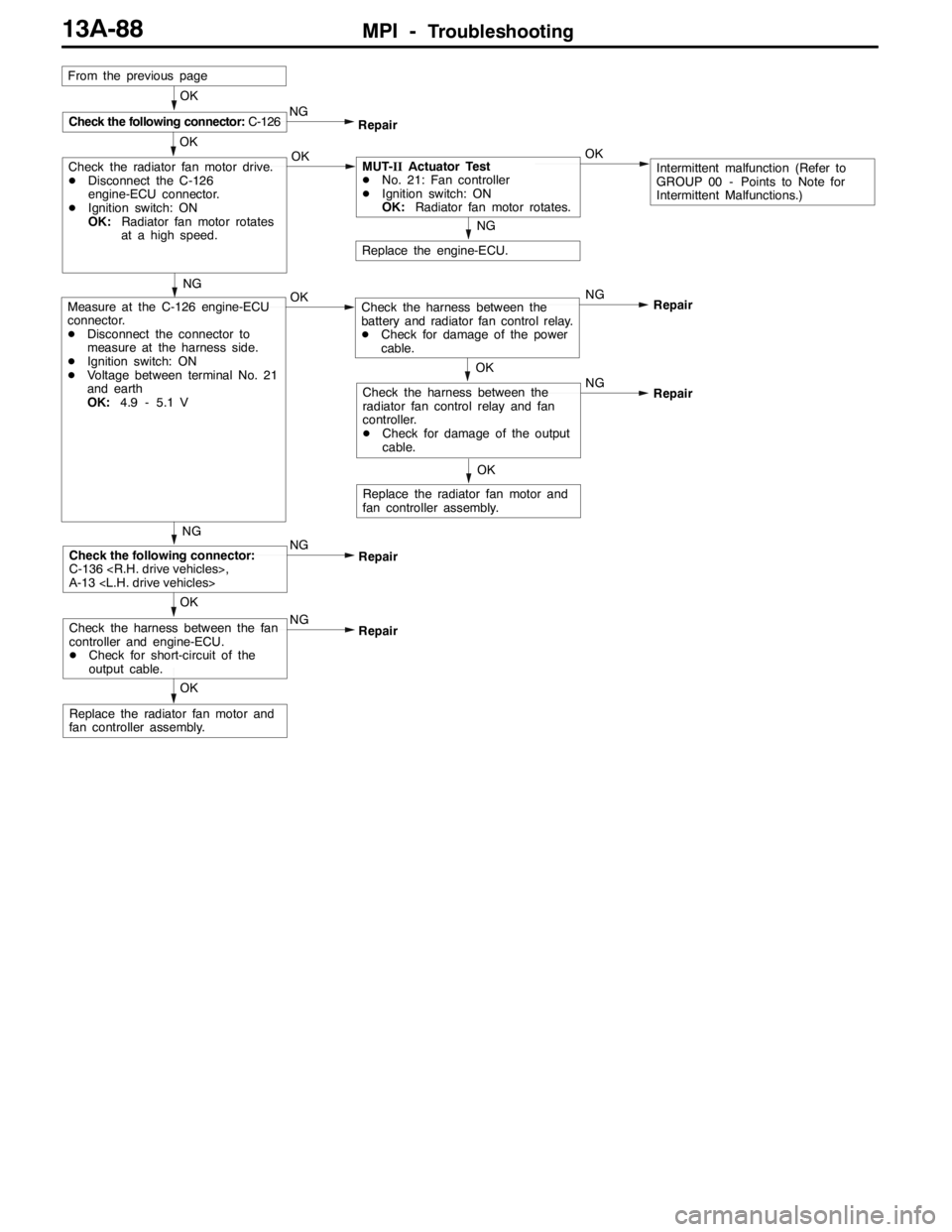

MPI -Troubleshooting13A-88

NGRepair

NG

Repair NG

From the previous page

OK

OK

Replace the engine-ECU.

NG

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan motor rotates.

NG

Check the radiator fan motor drive.

DDisconnect the C-126

engine-ECU connector.

DIgnition switch: ON

OK:Radiator fan motor rotates

at a high speed.OK

OK

Check the harness between the

battery and radiator fan control relay.

DCheck for damage of the power

cable.RepairMeasure at the C-126 engine-ECU

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 21

and earth

OK:4.9 - 5.1 VOK

OK

Check the harness between the

radiator fan control relay and fan

controller.

DCheck for damage of the output

cable.

Replace the radiator fan motor and

fan controller assembly.NG

NG

OK

Check the following connector:

C-136

A-13

OK

Replace the radiator fan motor and

fan controller assembly.

Check the harness between the fan

controller and engine-ECU.

DCheck for short-circuit of the

output cable.Repair NG

OK

Check the following connector:C-126

Repair

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

Page 621 of 1449

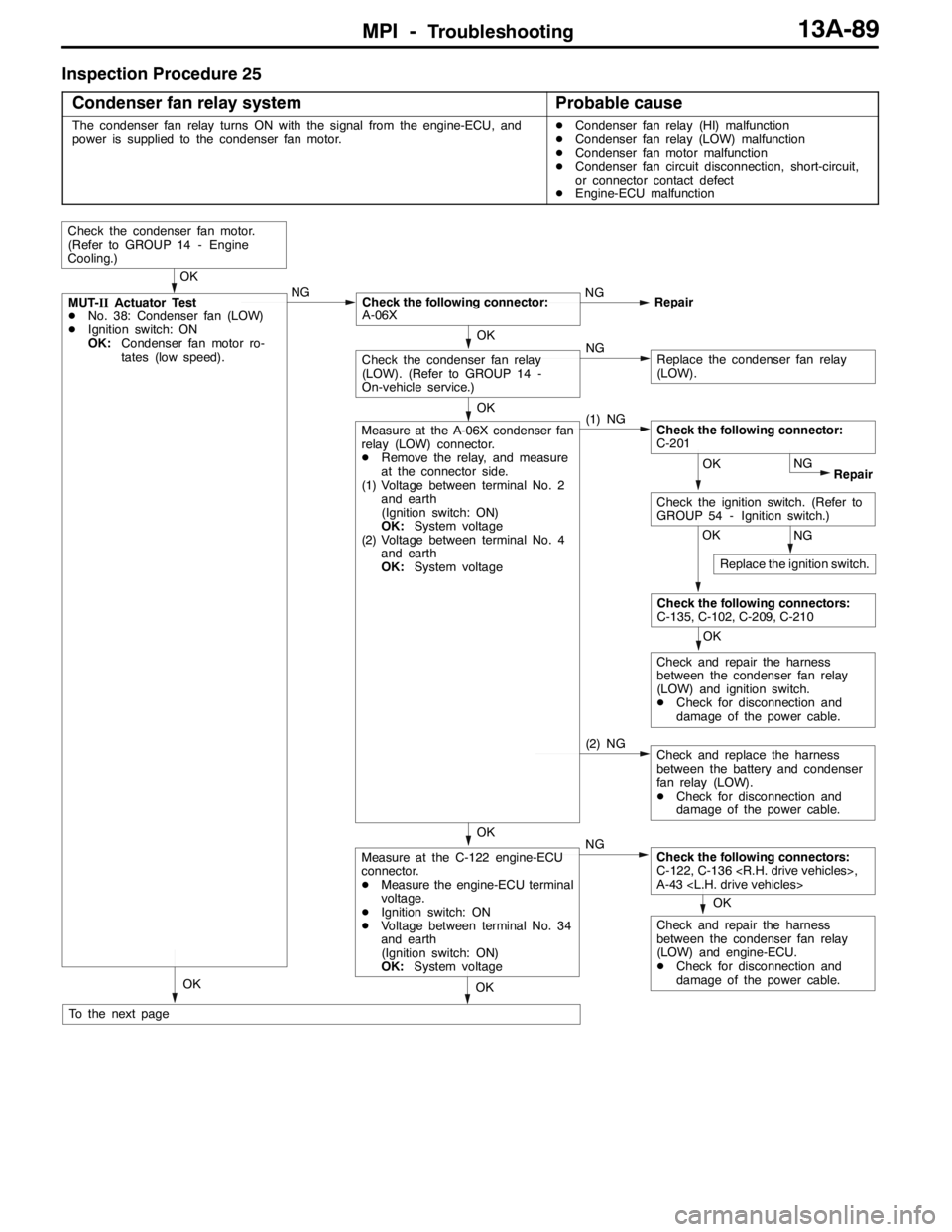

MPI -Troubleshooting13A-89

Inspection Procedure 25

Condenser fan relay system

Probable cause

The condenser fan relay turns ON with the signal from the engine-ECU, and

power is supplied to the condenser fan motor.DCondenser fan relay (HI) malfunction

DCondenser fan relay (LOW) malfunction

DCondenser fan motor malfunction

DCondenser fan circuit disconnection, short-circuit,

or connector contact defect

DEngine-ECU malfunction

OK

Check and repair the harness

between the condenser fan relay

(LOW) and engine-ECU.

DCheck for disconnection and

damage of the power cable.

(2) NG

OK

OK

Check the condenser fan motor.

(Refer to GROUP 14 - Engine

Cooling.)

OK

NG

OK

Check the following connector:

A-06X

OK

MUT-IIActuator Test

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan motor ro-

tates (low speed).NG

OK

Measure at the C-122 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 34

and earth

(Ignition switch: ON)

OK:System voltageRepair

NG

To the next page

NGReplace the condenser fan relay

(LOW).

OK

Check the condenser fan relay

(LOW). (Refer to GROUP 14 -

On-vehicle service.)

(1) NGMeasure at the A-06X condenser fan

relay (LOW) connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair OK

OK

Check the following connectors:

C-135, C-102, C-209, C-210

Check and repair the harness

between the condenser fan relay

(LOW) and ignition switch.

DCheck for disconnection and

damage of the power cable.

Check the following connectors:

C-122, C-136

A-43

Check the following connector:

C-201

NG

Check the ignition switch. (Refer to

GROUP 54 - Ignition switch.)

Replace the ignition switch.

Check and replace the harness

between the battery and condenser

fan relay (LOW).

DCheck for disconnection and

damage of the power cable.

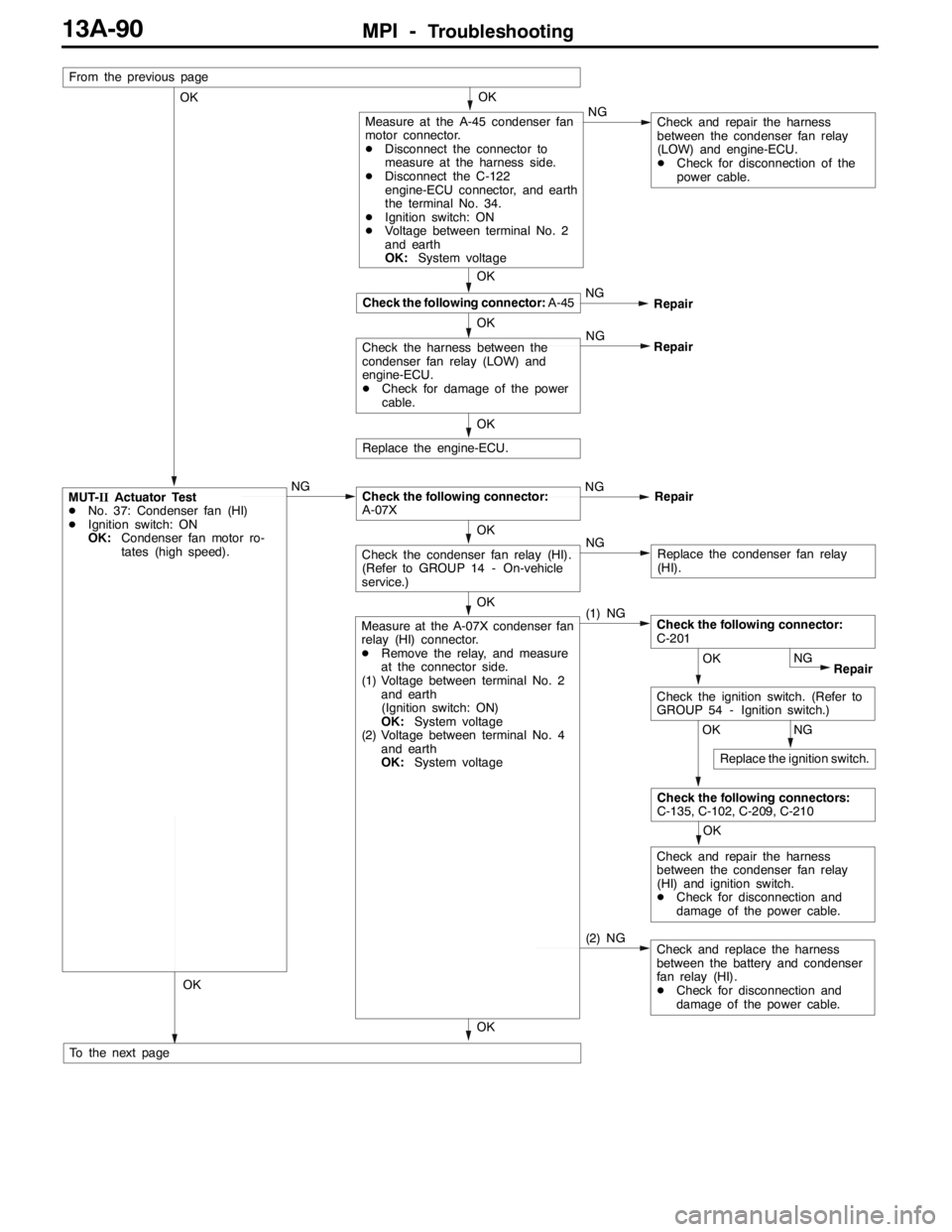

Page 622 of 1449

MPI -Troubleshooting13A-90

(2) NG

OK

OK

OK

NG

OK

Check the following connector:

A-07X

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DIgnition switch: ON

OK:Condenser fan motor ro-

tates (high speed).NG

Repair

NGReplace the condenser fan relay

(HI).

OK

Check the condenser fan relay (HI).

(Refer to GROUP 14 - On-vehicle

service.)

(1) NGMeasure at the A-07X condenser fan

relay (HI) connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 4

and earth

OK:System voltage

NG

Repair OK

OK

Check the following connectors:

C-135, C-102, C-209, C-210

Check and repair the harness

between the condenser fan relay

(HI) and ignition switch.

DCheck for disconnection and

damage of the power cable.

Check the following connector:

C-201

NG

Check the ignition switch. (Refer to

GROUP 54 - Ignition switch.)

Replace the ignition switch.

Check and replace the harness

between the battery and condenser

fan relay (HI).

DCheck for disconnection and

damage of the power cable.

NGCheck the following connector:A-45

OK

Replace the engine-ECU.

OK

To the next page

NG

OK

Check the harness between the

condenser fan relay (LOW) and

engine-ECU.

DCheck for damage of the power

cable.Repair Repair

NGOK

Measure at the A-45 condenser fan

motor connector.

DDisconnect the connector to

measure at the harness side.

DDisconnect the C-122

engine-ECU connector, and earth

the terminal No. 34.

DIgnition switch: ON

DVoltage between terminal No. 2

and earth

OK:System voltageCheck and repair the harness

between the condenser fan relay

(LOW) and engine-ECU.

DCheck for disconnection of the

power cable.

From the previous page

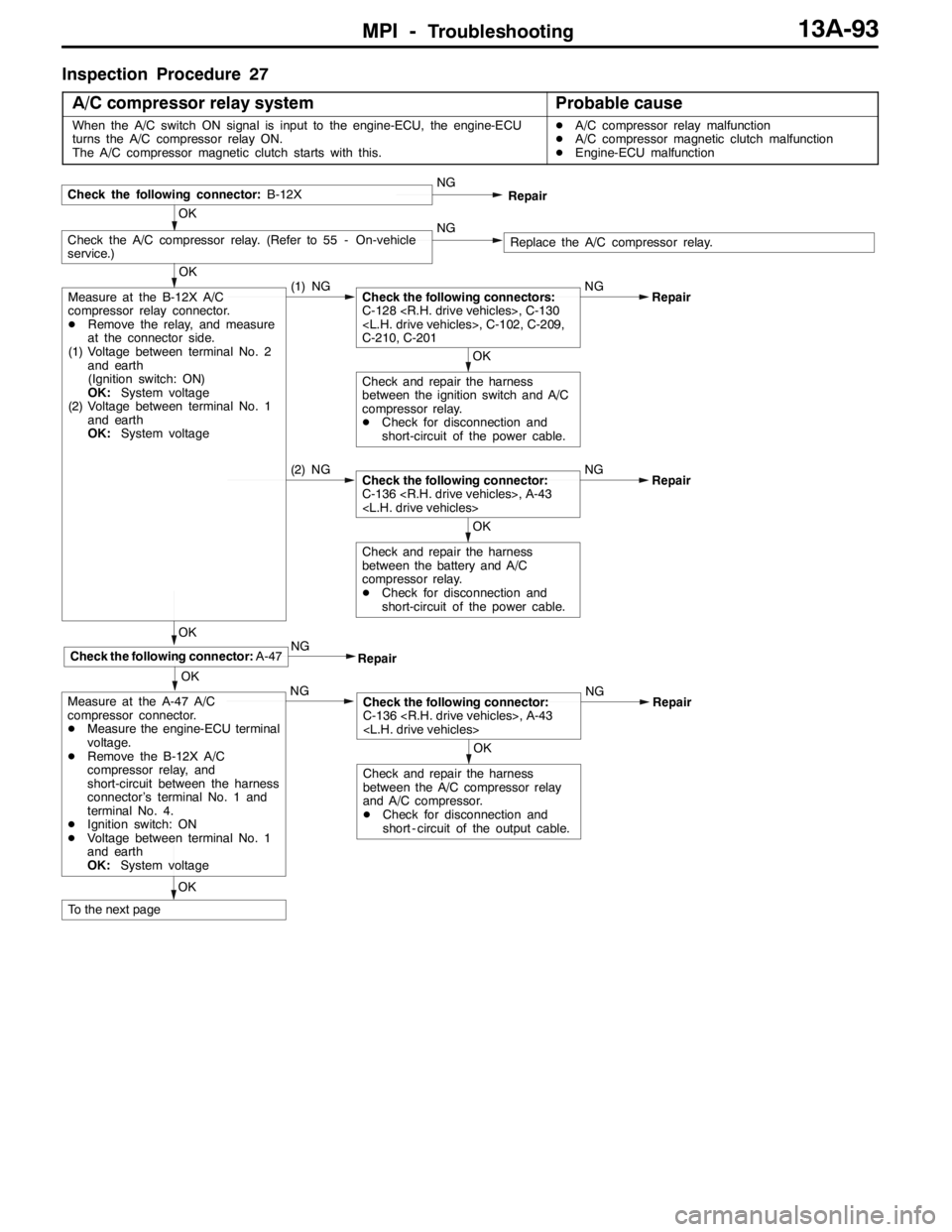

Page 625 of 1449

MPI -Troubleshooting13A-93

Inspection Procedure 27

A/C compressor relay system

Probable cause

When the A/C switch ON signal is input to the engine-ECU, the engine-ECU

turns the A/C compressor relay ON.

The A/C compressor magnetic clutch starts with this.DA/C compressor relay malfunction

DA/C compressor magnetic clutch malfunction

DEngine-ECU malfunction

OK

(2) NGCheck the following connector:

C-136

Check and repair the harness

between the battery and A/C

compressor relay.

DCheck for disconnection and

short-circuit of the power cable.

OK

Check the A/C compressor relay. (Refer to 55 - On-vehicle

service.)NGReplace the A/C compressor relay.

Check the following connector:B-12XNG

Repair

OK

OK

Measure at the B-12X A/C

compressor relay connector.

DRemove the relay, and measure

at the connector side.

(1) Voltage between terminal No. 2

and earth

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 1

and earth

OK:System voltage(1) NGCheck the following connectors:

C-128

C-210, C-201NG

OK

Check and repair the harness

between the ignition switch and A/C

compressor relay.

DCheck for disconnection and

short-circuit of the power cable.Repair

OKNG

Measure at the A-47 A/C

compressor connector.

DMeasure the engine-ECU terminal

voltage.

DRemove the B-12X A/C

compressor relay, and

short-circuit between the harness

connector’s terminal No. 1 and

terminal No. 4.

DIgnition switch: ON

DVoltage between terminal No. 1

and earth

OK:System voltage

To the next pageRepair

NG

OK

Check the following connector:A-47

Repair

OK

Check the following connector:

C-136

Check and repair the harness

between the A/C compressor relay

and A/C compressor.

DCheck for disconnection and

short - circuit of the output cable.Repair

Page 626 of 1449

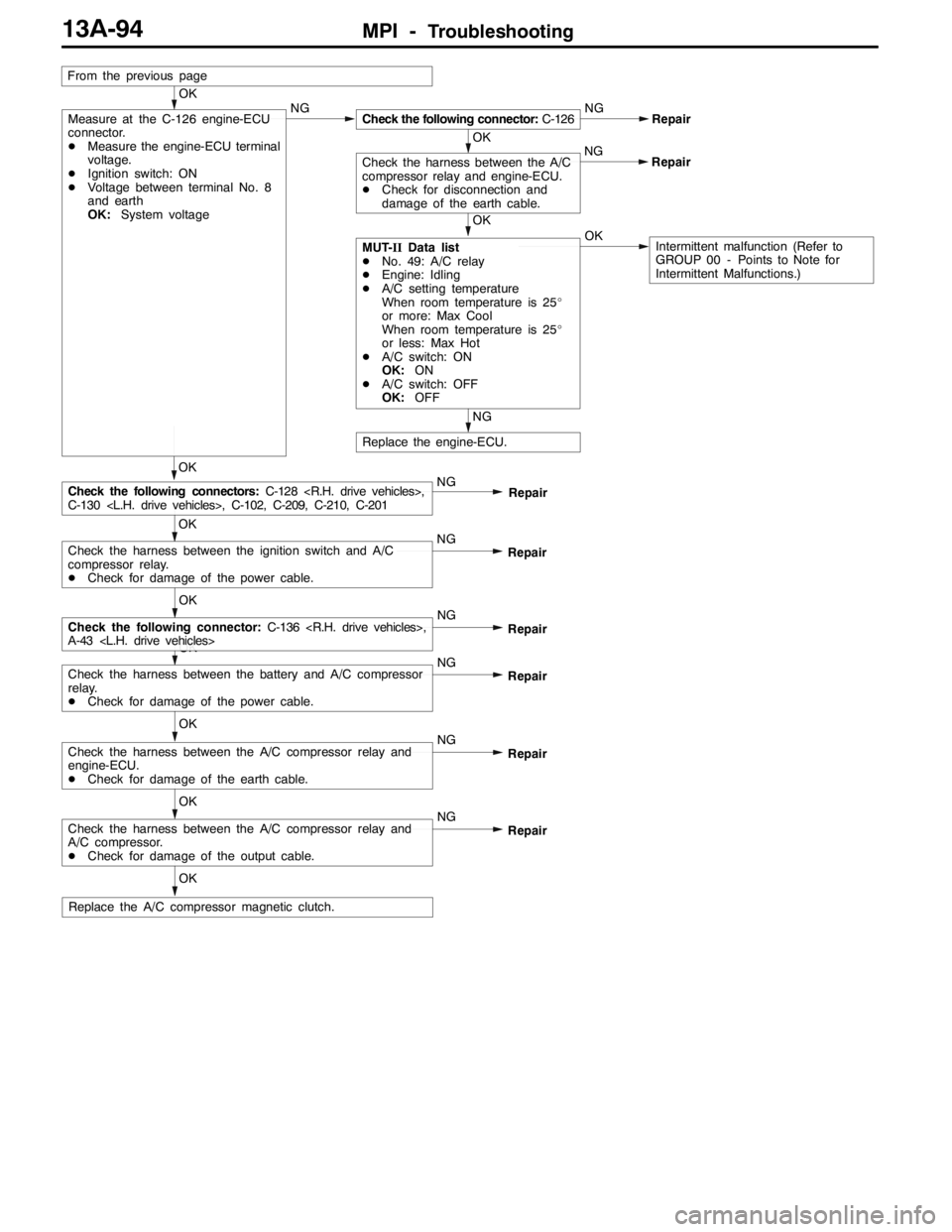

MPI -Troubleshooting13A-94

OK

OK

Check the harness between the battery and A/C compressor

relay.

DCheck for damage of the power cable.NG

Repair

OK

Check the following connector:C-136

A-43

Repair

NG

Replace the engine-ECU.

NG

Repair

OK

OKMUT-IIData list

DNo. 49: A/C relay

DEngine: Idling

DA/C setting temperature

When room temperature is 25_

or more: Max Cool

When room temperature is 25_

or less: Max Hot

DA/C switch: ON

OK:ON

DA/C switch: OFF

OK:OFF

OK

OK

Measure at the C-126 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 8

and earth

OK:System voltageNGCheck the following connector:C-126NG

OK

Check the harness between the A/C

compressor relay and engine-ECU.

DCheck for disconnection and

damage of the earth cable.Repair

OK

Check the harness between the ignition switch and A/C

compressor relay.

DCheck for damage of the power cable.NG

Check the following connectors:C-128

C-130

From the previous page

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

Repair NG

OK

Check the harness between the A/C compressor relay and

engine-ECU.

DCheck for damage of the earth cable.NG

Repair

OK

Check the harness between the A/C compressor relay and

A/C compressor.

DCheck for damage of the output cable.NG

Repair

Replace the A/C compressor magnetic clutch.

Page 635 of 1449

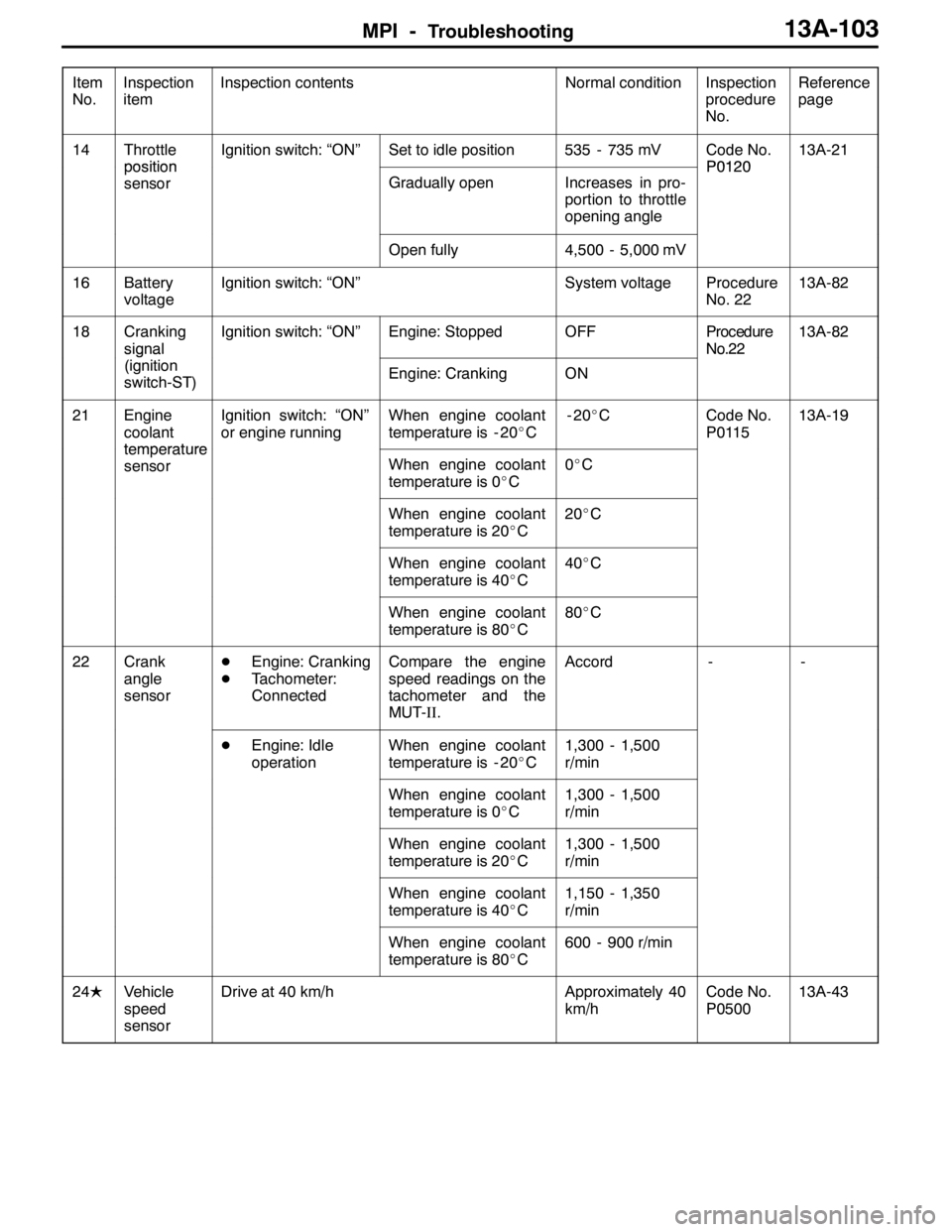

MPI -Troubleshooting13A-103

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

14Throttle

position

Ignition switch: “ON”Set to idle position535 - 735 mVCode No.

P0120

13A-21

position

sensor

Gradually openIncreases in pro-

portion to throttle

opening angle

P0120

Open fully4,500 - 5,000 mV

16Battery

voltageIgnition switch: “ON”System voltageProcedure

No. 2213A-82

18Cranking

signalIgnition switch: “ON”Engine: StoppedOFFProcedure

No.2213A-82

signal

(ignition

switch-ST)Engine: CrankingON

No.22

21Engine

coolant

temperature

Ignition switch: “ON”

or engine runningWhen engine coolant

temperature is - 20_C-20_CCode No.

P011513A-19

temperature

sensorWhen engine coolant

temperature is 0_C0_C

When engine coolant

temperature is 20_C20_C

When engine coolant

temperature is 40_C40_C

When engine coolant

temperature is 80_C80_C

22Crank

angle

sensorDEngine: Cranking

DTachometer:

ConnectedCompare the engine

speed readings on the

tachometer and the

MUT-II.Accord--

DEngine: Idle

operationWhen engine coolant

temperature is - 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 0_C1,300 - 1,500

r/min

When engine coolant

temperature is 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 40_C1,150 - 1,350

r/min

When engine coolant

temperature is 80_C600 - 900 r/min

24LVehicle

speed

sensorDrive at 40 km/hApproximately 40

km/hCode No.

P050013A-43

Page 657 of 1449

MPI -On-vehicle Service13A-125

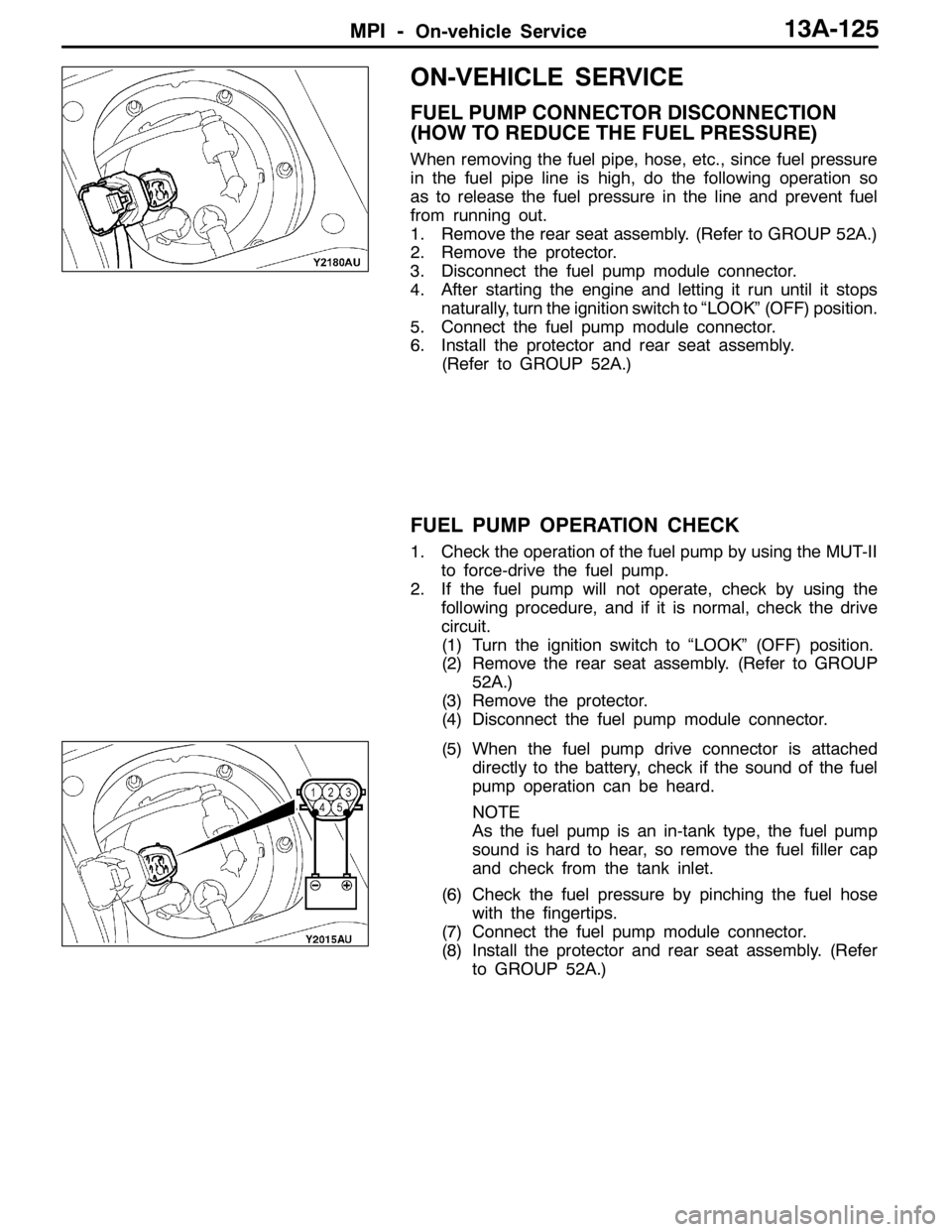

ON-VEHICLE SERVICE

FUEL PUMP CONNECTOR DISCONNECTION

(HOW TO REDUCE THE FUEL PRESSURE)

When removing the fuel pipe, hose, etc., since fuel pressure

in the fuel pipe line is high, do the following operation so

as to release the fuel pressure in the line and prevent fuel

from running out.

1. Remove the rear seat assembly. (Refer to GROUP 52A.)

2. Remove the protector.

3. Disconnect the fuel pump module connector.

4. After starting the engine and letting it run until it stops

naturally, turn the ignition switch to “LOOK” (OFF) position.

5. Connect the fuel pump module connector.

6. Install the protector and rear seat assembly.

(Refer to GROUP 52A.)

FUEL PUMP OPERATION CHECK

1. Check the operation of the fuel pump by using the MUT-II

to force-drive the fuel pump.

2. If the fuel pump will not operate, check by using the

following procedure, and if it is normal, check the drive

circuit.

(1) Turn the ignition switch to “LOOK” (OFF) position.

(2) Remove the rear seat assembly. (Refer to GROUP

52A.)

(3) Remove the protector.

(4) Disconnect the fuel pump module connector.

(5) When the fuel pump drive connector is attached

directly to the battery, check if the sound of the fuel

pump operation can be heard.

NOTE

As the fuel pump is an in-tank type, the fuel pump

sound is hard to hear, so remove the fuel filler cap

and check from the tank inlet.

(6) Check the fuel pressure by pinching the fuel hose

with the fingertips.

(7) Connect the fuel pump module connector.

(8) Install the protector and rear seat assembly. (Refer

to GROUP 52A.)

Page 659 of 1449

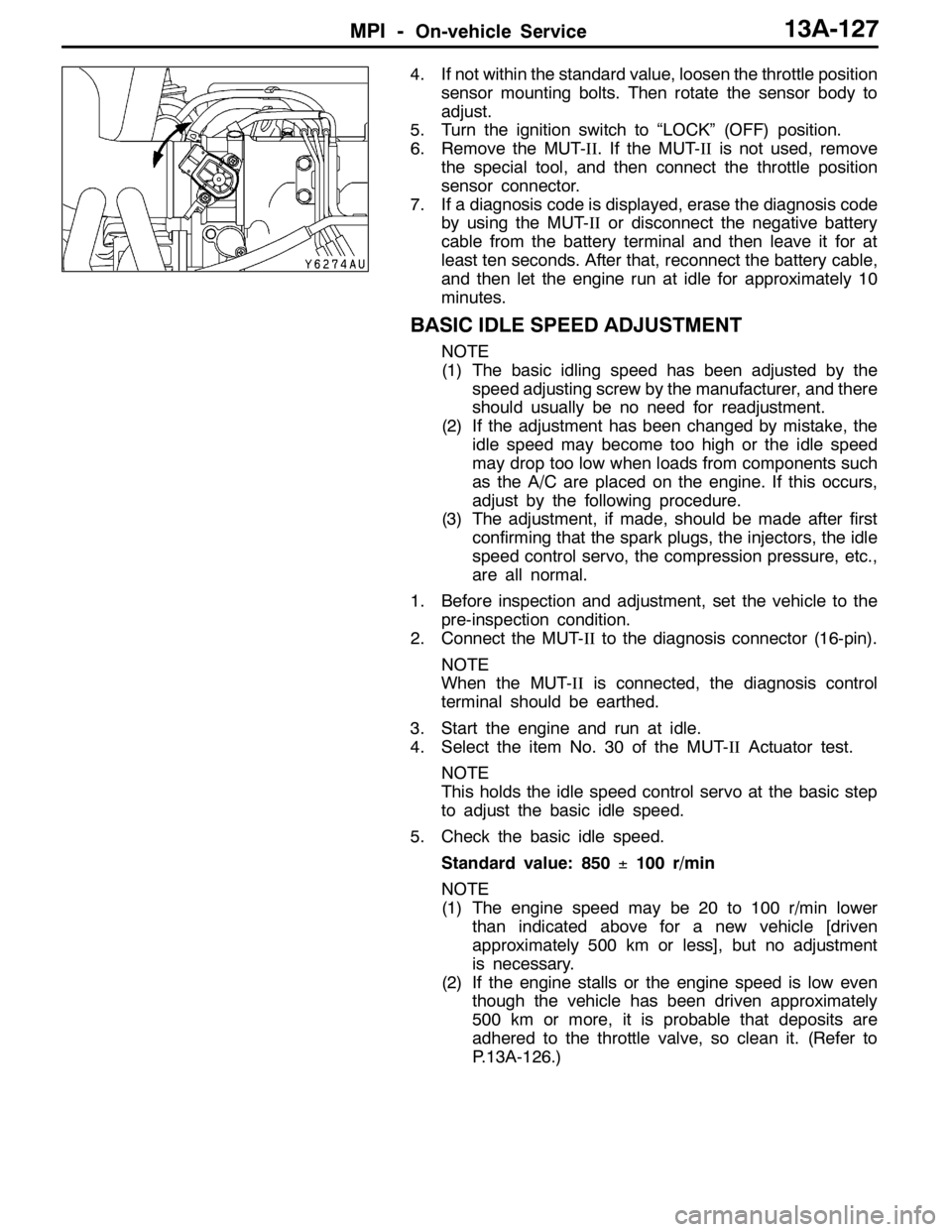

MPI -On-vehicle Service13A-127

4. If not within the standard value, loosen the throttle position

sensor mounting bolts. Then rotate the sensor body to

adjust.

5. Turn the ignition switch to “LOCK” (OFF) position.

6. Remove the MUT-II. If the MUT-IIis not used, remove

the special tool, and then connect the throttle position

sensor connector.

7. If a diagnosis code is displayed, erase the diagnosis code

by using the MUT-IIor disconnect the negative battery

cable from the battery terminal and then leave it for at

least ten seconds. After that, reconnect the battery cable,

and then let the engine run at idle for approximately 10

minutes.

BASIC IDLE SPEED ADJUSTMENT

NOTE

(1) The basic idling speed has been adjusted by the

speed adjusting screw by the manufacturer, and there

should usually be no need for readjustment.

(2) If the adjustment has been changed by mistake, the

idle speed may become too high or the idle speed

may drop too low when loads from components such

as the A/C are placed on the engine. If this occurs,

adjust by the following procedure.

(3) The adjustment, if made, should be made after first

confirming that the spark plugs, the injectors, the idle

speed control servo, the compression pressure, etc.,

are all normal.

1. Before inspection and adjustment, set the vehicle to the

pre-inspection condition.

2. Connect the MUT-IIto the diagnosis connector (16-pin).

NOTE

When the MUT-IIis connected, the diagnosis control

terminal should be earthed.

3. Start the engine and run at idle.

4. Select the item No. 30 of the MUT-IIActuator test.

NOTE

This holds the idle speed control servo at the basic step

to adjust the basic idle speed.

5. Check the basic idle speed.

Standard value: 850±100 r/min

NOTE

(1) The engine speed may be 20 to 100 r/min lower

than indicated above for a new vehicle [driven

approximately 500 km or less], but no adjustment

is necessary.

(2) If the engine stalls or the engine speed is low even

though the vehicle has been driven approximately

500 km or more, it is probable that deposits are

adhered to the throttle valve, so clean it. (Refer to

P.13A-126.)

Page 664 of 1449

MPI -On-vehicle Service13A-132

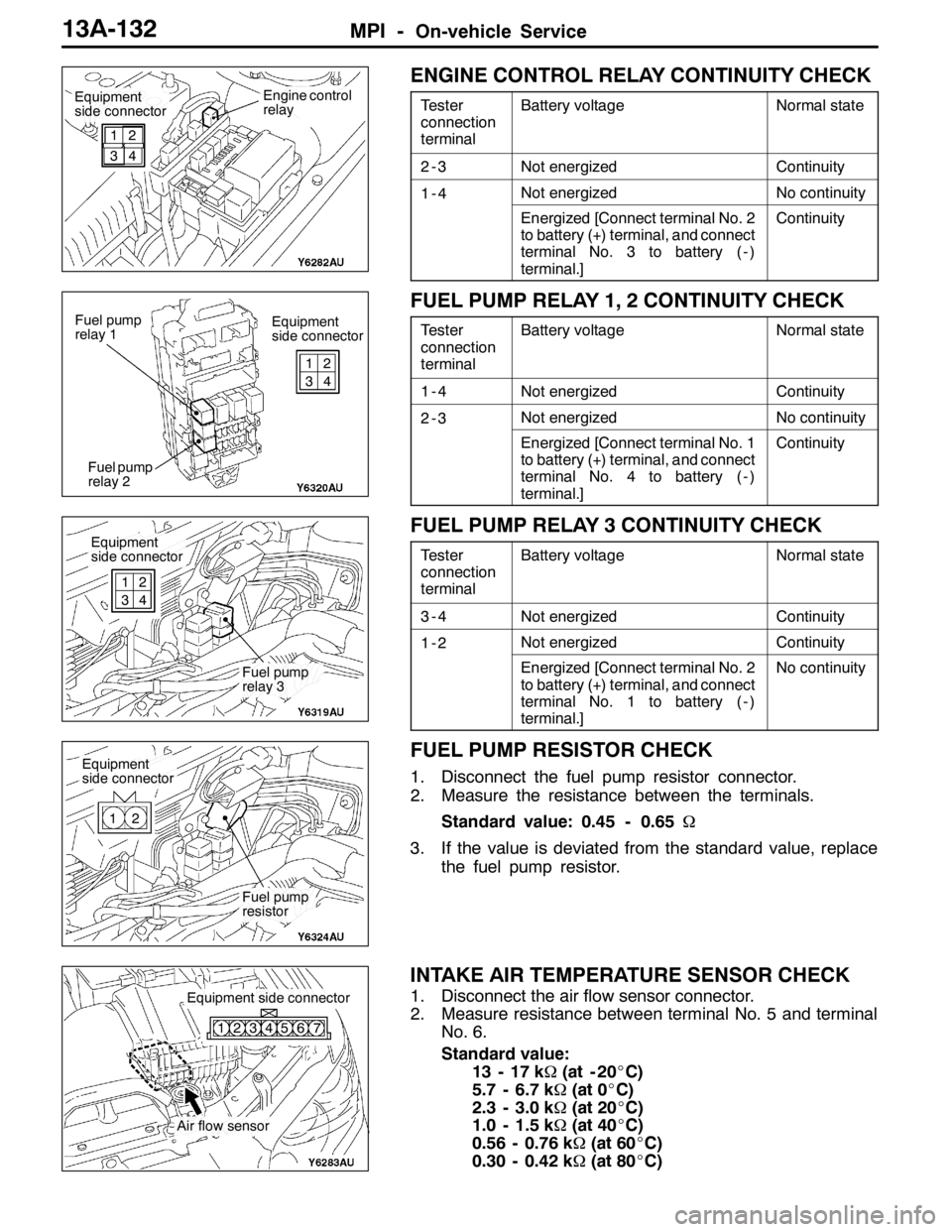

ENGINE CONTROL RELAY CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

2-3Not energizedContinuity

1-4Not energizedNo continuity

Energized [Connect terminal No. 2

to battery (+) terminal, and connect

terminal No. 3 to battery ( - )

terminal.]Continuity

FUEL PUMP RELAY 1, 2 CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

1-4Not energizedContinuity

2-3Not energizedNo continuity

Energized [Connect terminal No. 1

to battery (+) terminal, and connect

terminal No. 4 to battery ( - )

terminal.]Continuity

FUEL PUMP RELAY 3 CONTINUITY CHECK

Tester

connection

terminalBattery voltageNormal state

3-4Not energizedContinuity

1-2Not energizedContinuity

Energized [Connect terminal No. 2

to battery (+) terminal, and connect

terminal No. 1 to battery ( - )

terminal.]No continuity

FUEL PUMP RESISTOR CHECK

1. Disconnect the fuel pump resistor connector.

2. Measure the resistance between the terminals.

Standard value: 0.45 - 0.65Ω

3. If the value is deviated from the standard value, replace

the fuel pump resistor.

INTAKE AIR TEMPERATURE SENSOR CHECK

1. Disconnect the air flow sensor connector.

2. Measure resistance between terminal No. 5 and terminal

No. 6.

Standard value:

13 - 17 kΩ(at - 20_C)

5.7 - 6.7 kΩ(at 0_C)

2.3 - 3.0 kΩ(at 20_C)

1.0 - 1.5 kΩ(at 40_C)

0.56 - 0.76 kΩ(at 60_C)

0.30 - 0.42 kΩ(at 80_C)

Equipment

side connectorEngine control

relay

1

32

4

Equipment

side connector Fuel pump

relay 1

Fuel pump

relay 21

32

4

Equipment

side connector

Fuel pump

relay 3 1

32

4

Equipment

side connector

Fuel pump

resistor 12

Air flow sensor

Equipment side connector

123456 7

Page 667 of 1449

MPI -On-vehicle Service13A-135

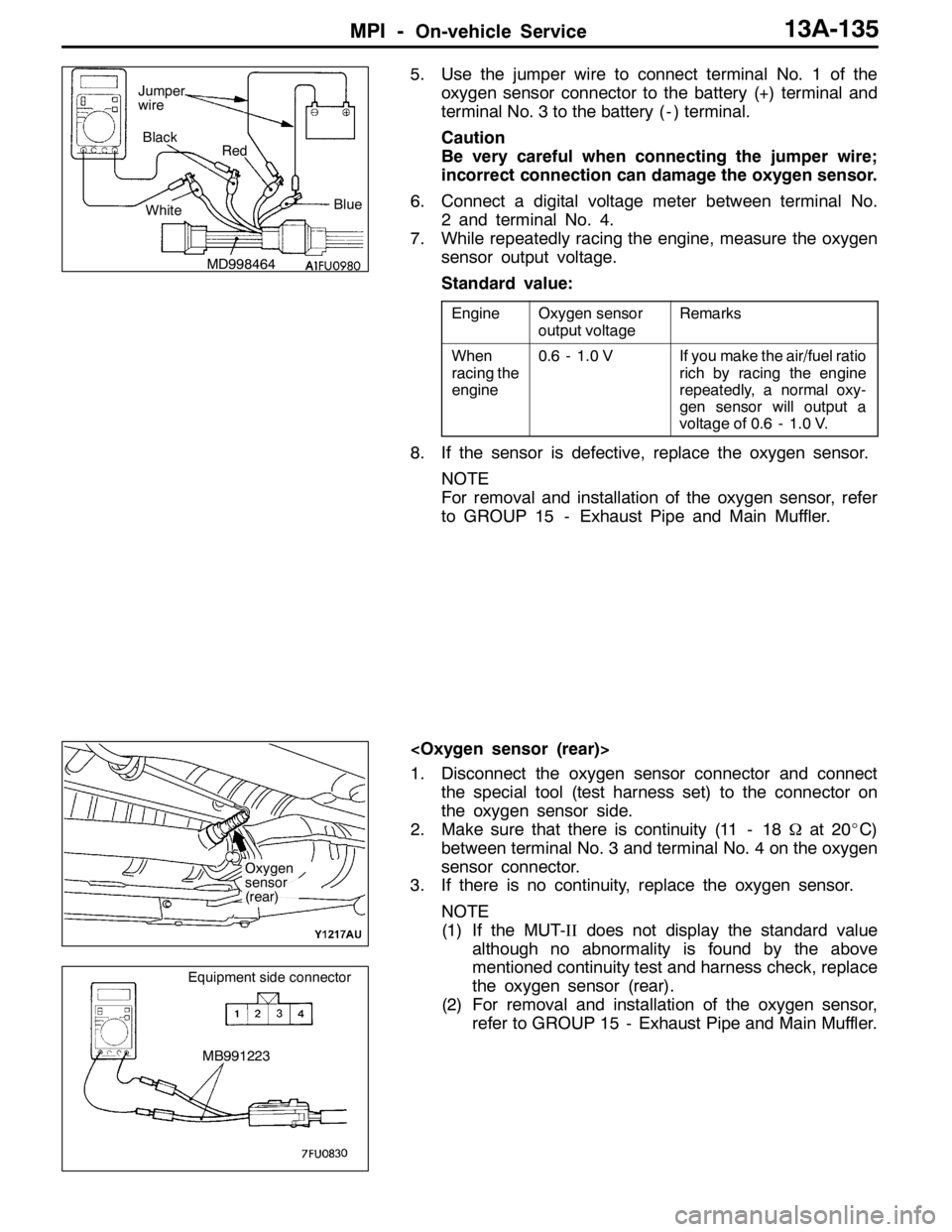

5. Use the jumper wire to connect terminal No. 1 of the

oxygen sensor connector to the battery (+) terminal and

terminal No. 3 to the battery ( - ) terminal.

Caution

Be very careful when connecting the jumper wire;

incorrect connection can damage the oxygen sensor.

6. Connect a digital voltage meter between terminal No.

2 and terminal No. 4.

7. While repeatedly racing the engine, measure the oxygen

sensor output voltage.

Standard value:

EngineOxygen sensor

output voltageRemarks

When

racing the

engine0.6 - 1.0 VIf you make the air/fuel ratio

rich by racing the engine

repeatedly, a normal oxy-

gen sensor will output a

voltage of 0.6 - 1.0 V.

8. If the sensor is defective, replace the oxygen sensor.

NOTE

For removal and installation of the oxygen sensor, refer

to GROUP 15 - Exhaust Pipe and Main Muffler.

1. Disconnect the oxygen sensor connector and connect

the special tool (test harness set) to the connector on

the oxygen sensor side.

2. Make sure that there is continuity (11 - 18Ωat 20_C)

between terminal No. 3 and terminal No. 4 on the oxygen

sensor connector.

3. If there is no continuity, replace the oxygen sensor.

NOTE

(1) If the MUT-IIdoes not display the standard value

although no abnormality is found by the above

mentioned continuity test and harness check, replace

the oxygen sensor (rear).

(2) For removal and installation of the oxygen sensor,

refer to GROUP 15 - Exhaust Pipe and Main Muffler.

MD998464Blue Black

Red

White Jumper

wire

Oxygen

sensor

(rear)

MB991223

Equipment side connector