check engine MITSUBISHI LANCER EVOLUTION 2007 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 489 of 1449

ENGINE OVERHAUL -Rocker Arm and Camshaft11B-35

REMOVAL SERVICE POINT

AA"LASH ADJUSTER REMOVAL

Caution

When reusing the lash adjuster, always clean and inspect

it before installing. (Refer to the section on checking the

lash adjuster.)

INSTALLATION SERVICE POINTS

"AALASH ADJUSTER INSTALLATION

Caution

When reusing the lash adjuster, always clean and inspect

it before installing. (Refer to the section on checking the

lash adjuster.)

Assembly the lash adjuster onto the rocker arm while taking

care not to spill out diesel oil in it.

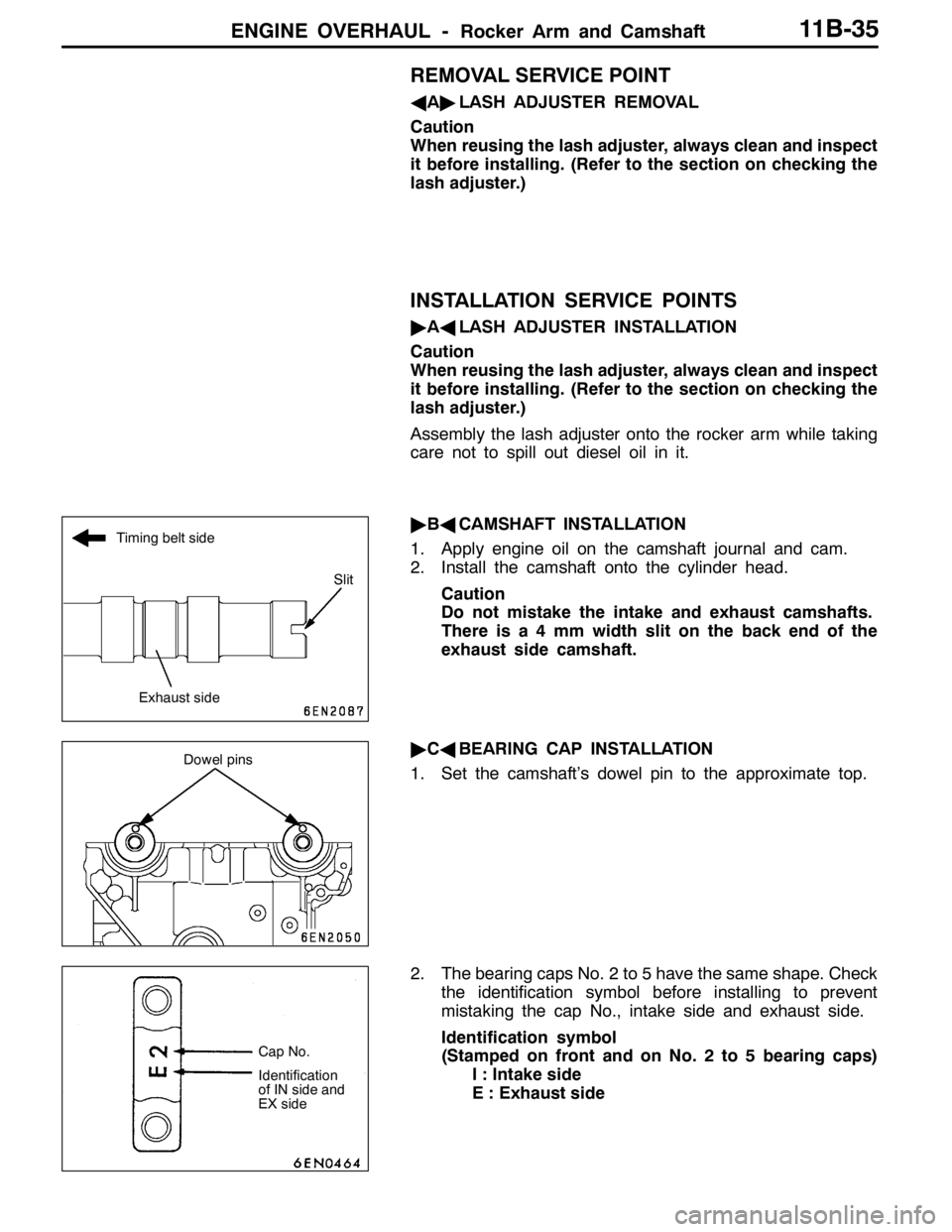

"BACAMSHAFT INSTALLATION

1. Apply engine oil on the camshaft journal and cam.

2. Install the camshaft onto the cylinder head.

Caution

Do not mistake the intake and exhaust camshafts.

There is a 4 mm width slit on the back end of the

exhaust side camshaft.

"CABEARING CAP INSTALLATION

1. Set the camshaft’s dowel pin to the approximate top.

2. The bearing caps No. 2 to 5 have the same shape. Check

the identification symbol before installing to prevent

mistaking the cap No., intake side and exhaust side.

Identification symbol

(Stamped on front and on No. 2 to 5 bearing caps)

I : Intake side

E : Exhaust side

Timing belt side

Slit

Exhaust side

Dowel pins

Cap No.

Identification

of IN side and

EX side

Page 497 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-43

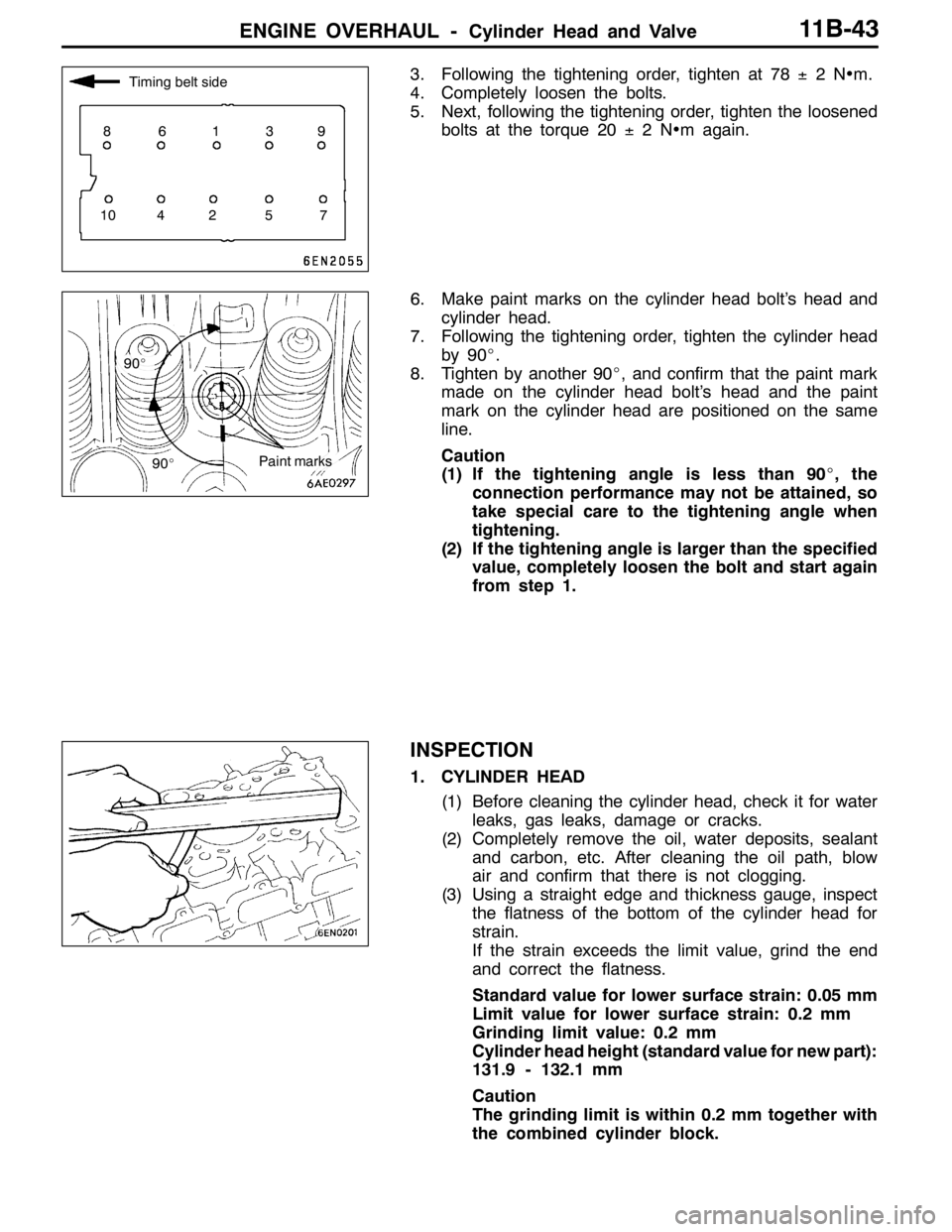

3. Following the tightening order, tighten at 78±2N•m.

4. Completely loosen the bolts.

5. Next, following the tightening order, tighten the loosened

bolts at the torque 20±2N•m again.

6. Make paint marks on the cylinder head bolt’s head and

cylinder head.

7. Following the tightening order, tighten the cylinder head

by 90_.

8. Tighten by another 90_, and confirm that the paint mark

made on the cylinder head bolt’s head and the paint

mark on the cylinder head are positioned on the same

line.

Caution

(1) If the tightening angle is less than 90_, the

connection performance may not be attained, so

take special care to the tightening angle when

tightening.

(2) If the tightening angle is larger than the specified

value, completely loosen the bolt and start again

from step 1.

INSPECTION

1. CYLINDER HEAD

(1) Before cleaning the cylinder head, check it for water

leaks, gas leaks, damage or cracks.

(2) Completely remove the oil, water deposits, sealant

and carbon, etc. After cleaning the oil path, blow

air and confirm that there is not clogging.

(3) Using a straight edge and thickness gauge, inspect

the flatness of the bottom of the cylinder head for

strain.

If the strain exceeds the limit value, grind the end

and correct the flatness.

Standard value for lower surface strain: 0.05 mm

Limit value for lower surface strain: 0.2 mm

Grinding limit value: 0.2 mm

Cylinder head height (standard value for new part):

131.9 - 132.1 mm

Caution

The grinding limit is within 0.2 mm together with

the combined cylinder block.

Timing belt side

86139

10 4 2 5 7

90_

90_

Paint marks

Page 508 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-54

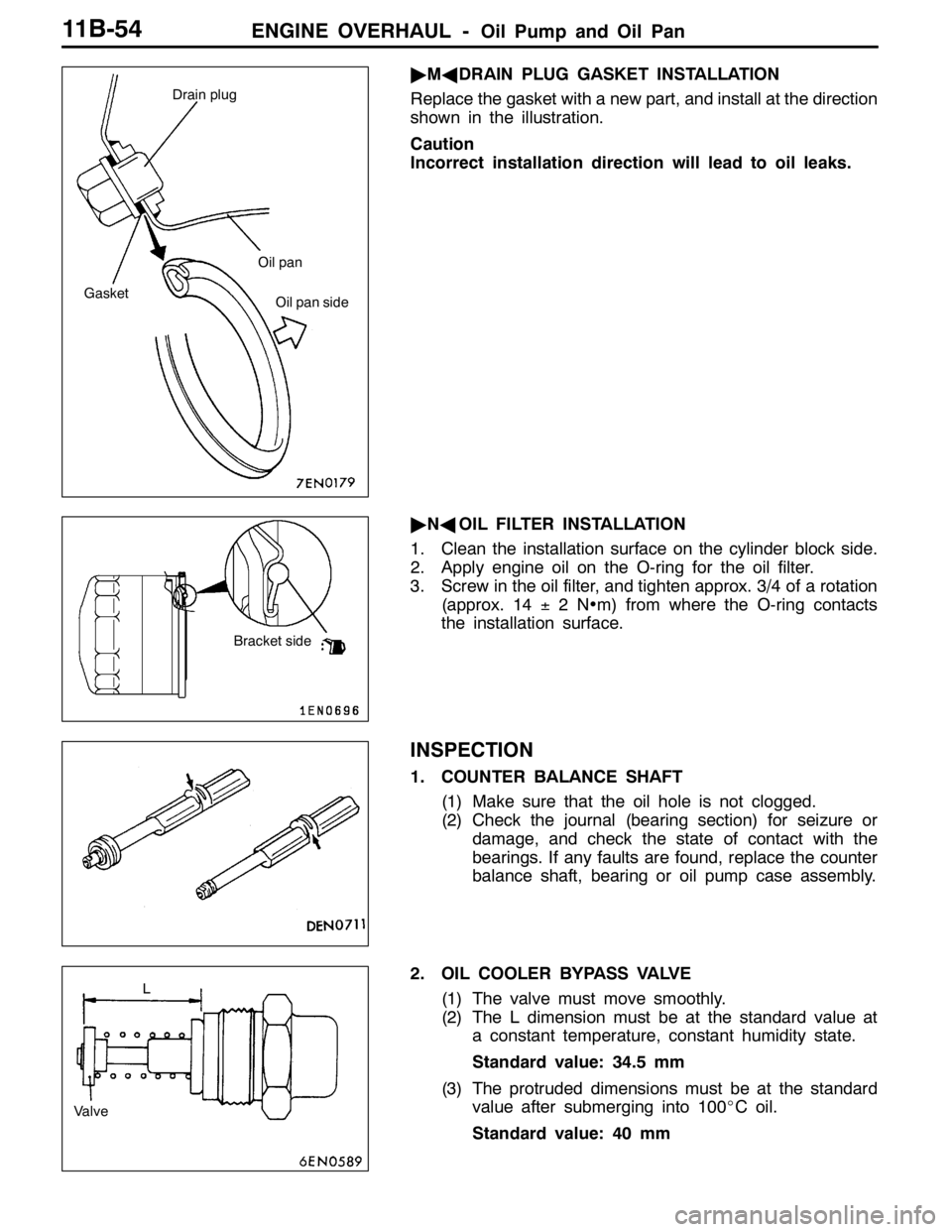

"MADRAIN PLUG GASKET INSTALLATION

Replace the gasket with a new part, and install at the direction

shown in the illustration.

Caution

Incorrect installation direction will lead to oil leaks.

"NAOIL FILTER INSTALLATION

1. Clean the installation surface on the cylinder block side.

2. Apply engine oil on the O-ring for the oil filter.

3. Screw in the oil filter, and tighten approx. 3/4 of a rotation

(approx. 14±2N•m) from where the O-ring contacts

the installation surface.

INSPECTION

1. COUNTER BALANCE SHAFT

(1) Make sure that the oil hole is not clogged.

(2) Check the journal (bearing section) for seizure or

damage, and check the state of contact with the

bearings. If any faults are found, replace the counter

balance shaft, bearing or oil pump case assembly.

2. OIL COOLER BYPASS VALVE

(1) The valve must move smoothly.

(2) The L dimension must be at the standard value at

a constant temperature, constant humidity state.

Standard value: 34.5 mm

(3) The protruded dimensions must be at the standard

value after submerging into 100_C oil.

Standard value: 40 mm

Drain plug

Oil pan

Oil pan side Gasket

Bracket side

L

Valve

Page 513 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-59

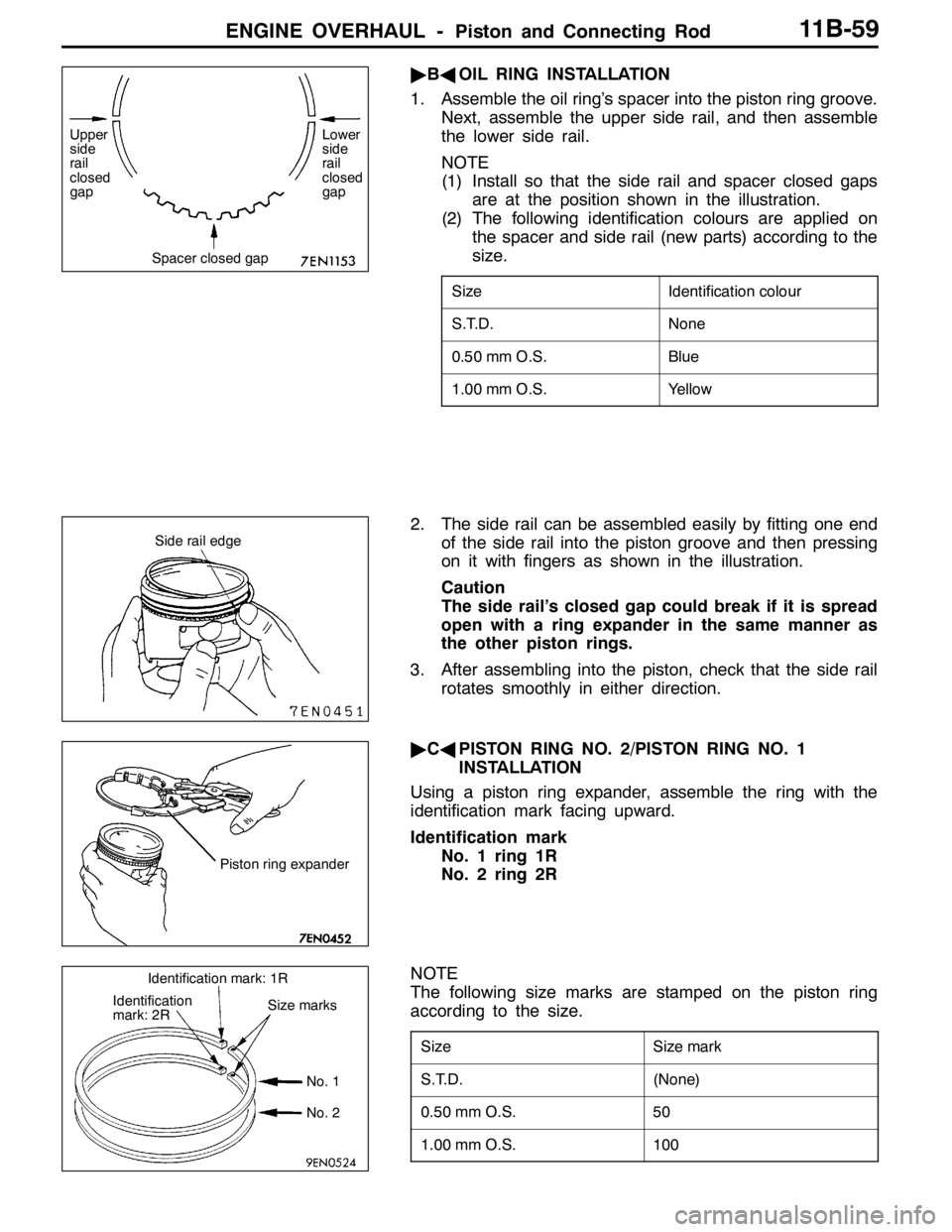

"BAOIL RING INSTALLATION

1. Assemble the oil ring’s spacer into the piston ring groove.

Next, assemble the upper side rail, and then assemble

the lower side rail.

NOTE

(1) Install so that the side rail and spacer closed gaps

are at the position shown in the illustration.

(2) The following identification colours are applied on

the spacer and side rail (new parts) according to the

size.

SizeIdentification colour

S.T.D.None

0.50 mm O.S.Blue

1.00 mm O.S.Yellow

2. The side rail can be assembled easily by fitting one end

of the side rail into the piston groove and then pressing

on it with fingers as shown in the illustration.

Caution

The side rail’s closed gap could break if it is spread

open with a ring expander in the same manner as

the other piston rings.

3. After assembling into the piston, check that the side rail

rotates smoothly in either direction.

"CAPISTON RING NO. 2/PISTON RING NO. 1

INSTALLATION

Using a piston ring expander, assemble the ring with the

identification mark facing upward.

Identification mark

No. 1 ring 1R

No. 2 ring 2R

NOTE

The following size marks are stamped on the piston ring

according to the size.

SizeSize mark

S.T.D.(None)

0.50 mm O.S.50

1.00 mm O.S.100

Spacer closed gap Upper

side

rail

closed

gapLower

side

rail

closed

gap

Side rail edge

Piston ring expander

Identification

mark: 2RSize marks

No. 1

No. 2 Identification mark: 1R

Page 516 of 1449

ENGINE OVERHAUL -Piston and Connecting Rod11B-62

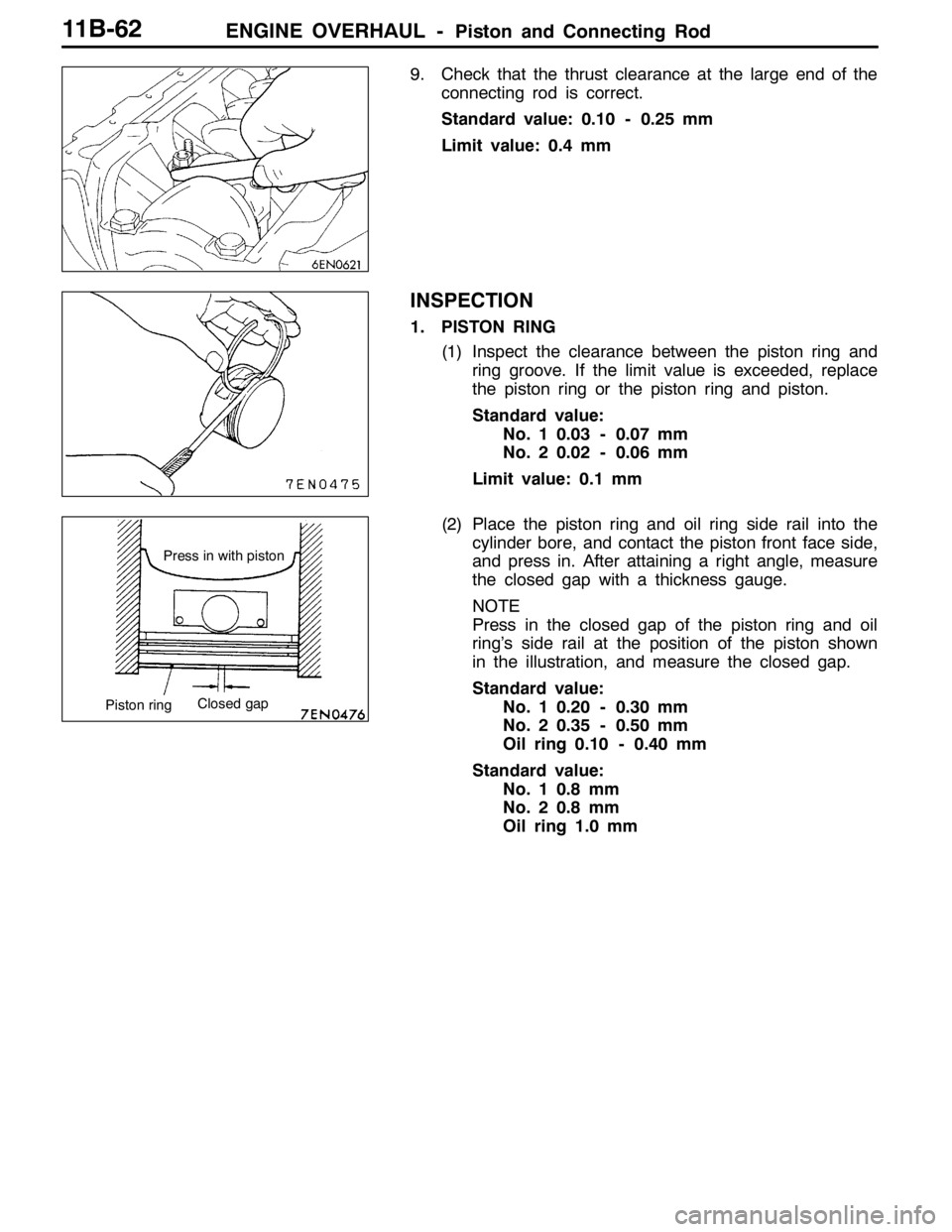

9. Check that the thrust clearance at the large end of the

connecting rod is correct.

Standard value: 0.10 - 0.25 mm

Limit value: 0.4 mm

INSPECTION

1. PISTON RING

(1) Inspect the clearance between the piston ring and

ring groove. If the limit value is exceeded, replace

the piston ring or the piston ring and piston.

Standard value:

No. 1 0.03 - 0.07 mm

No. 2 0.02 - 0.06 mm

Limit value: 0.1 mm

(2) Place the piston ring and oil ring side rail into the

cylinder bore, and contact the piston front face side,

and press in. After attaining a right angle, measure

the closed gap with a thickness gauge.

NOTE

Press in the closed gap of the piston ring and oil

ring’s side rail at the position of the piston shown

in the illustration, and measure the closed gap.

Standard value:

No. 1 0.20 - 0.30 mm

No. 2 0.35 - 0.50 mm

Oil ring 0.10 - 0.40 mm

Standard value:

No. 1 0.8 mm

No. 2 0.8 mm

Oil ring 1.0 mm

Press in with piston

Piston ringClosed gap

Page 518 of 1449

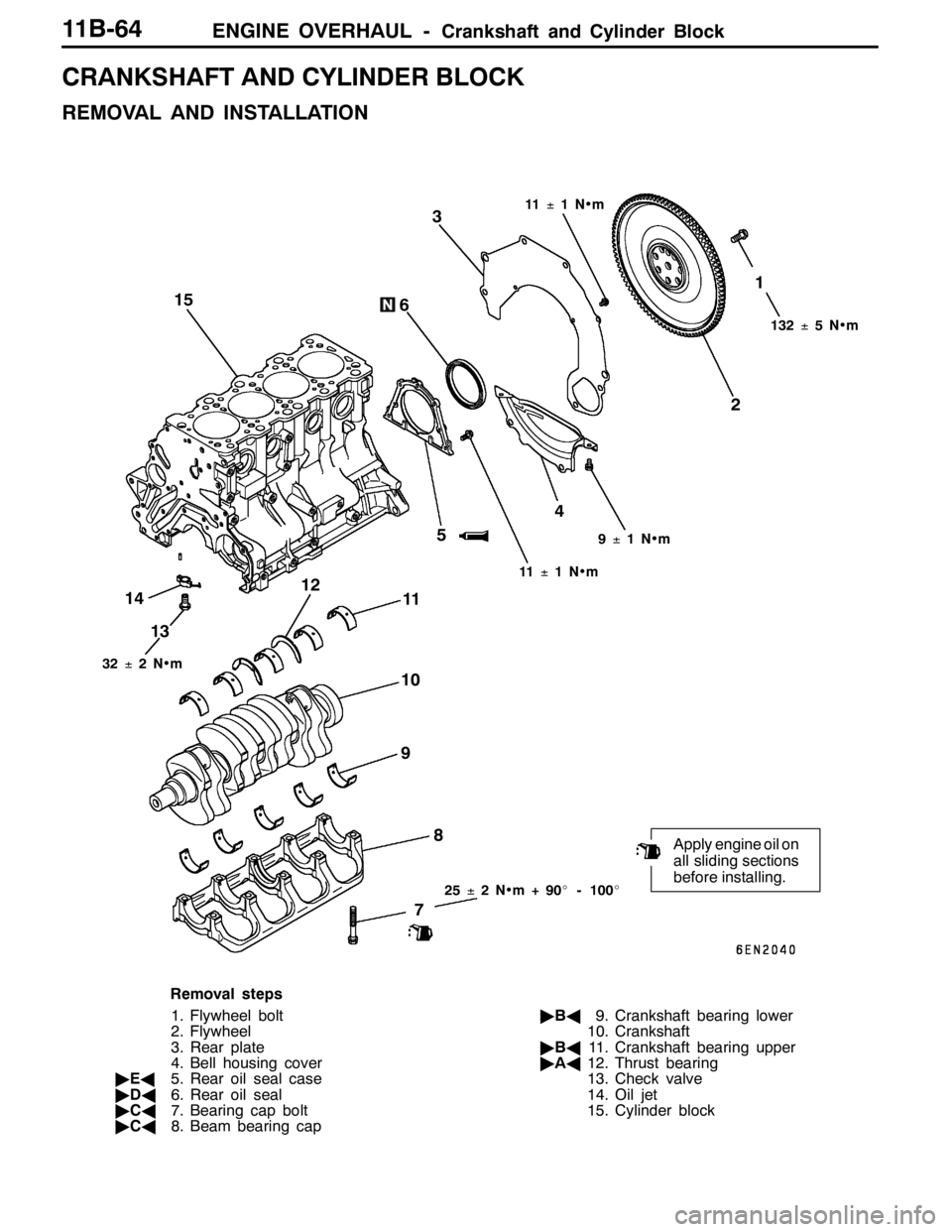

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-64

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

25±2N•m+90_- 100_

21

Apply engine oil on

all sliding sections

before installing.

4

5 6

73

8 9 1011

132±5N•m 11±1N•m

11±1N•m9±1N•m

32±2N•m

14

1312 15

Removal steps

1. Flywheel bolt

2. Flywheel

3. Rear plate

4. Bell housing cover

"EA5. Rear oil seal case

"DA6. Rear oil seal

"CA7. Bearing cap bolt

"CA8. Beam bearing cap"BA9. Crankshaft bearing lower

10. Crankshaft

"BA11. Crankshaft bearing upper

"AA12. Thrust bearing

13. Check valve

14. Oil jet

15. Cylinder block

Page 522 of 1449

ENGINE OVERHAUL -Crankshaft and Cylinder Block11B-68

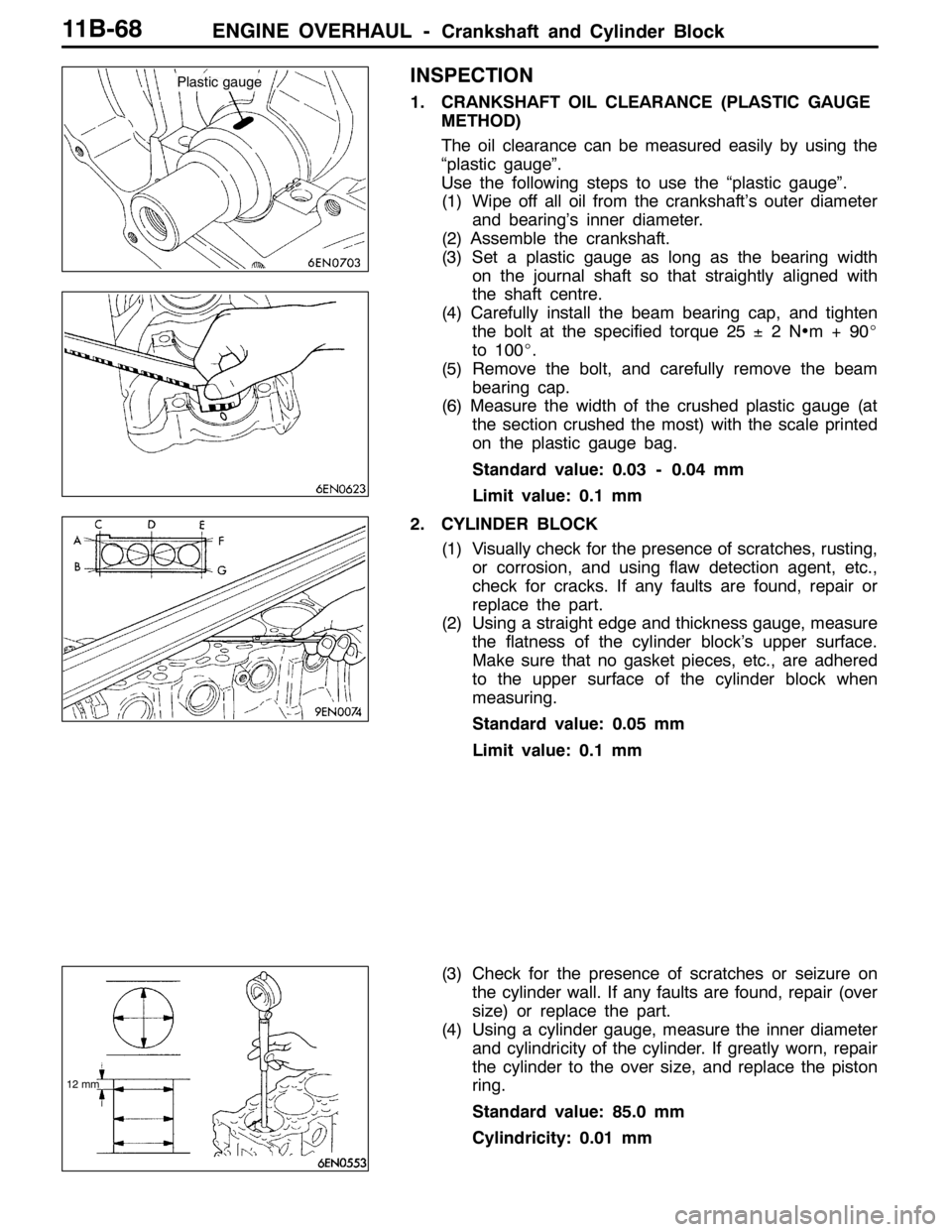

INSPECTION

1. CRANKSHAFT OIL CLEARANCE (PLASTIC GAUGE

METHOD)

The oil clearance can be measured easily by using the

“plastic gauge”.

Use the following steps to use the “plastic gauge”.

(1) Wipe off all oil from the crankshaft’s outer diameter

and bearing’s inner diameter.

(2) Assemble the crankshaft.

(3) Set a plastic gauge as long as the bearing width

on the journal shaft so that straightly aligned with

the shaft centre.

(4) Carefully install the beam bearing cap, and tighten

the bolt at the specified torque 25±2N•m+90_

to 100_.

(5) Remove the bolt, and carefully remove the beam

bearing cap.

(6) Measure the width of the crushed plastic gauge (at

the section crushed the most) with the scale printed

on the plastic gauge bag.

Standard value: 0.03 - 0.04 mm

Limit value: 0.1 mm

2. CYLINDER BLOCK

(1) Visually check for the presence of scratches, rusting,

or corrosion, and using flaw detection agent, etc.,

check for cracks. If any faults are found, repair or

replace the part.

(2) Using a straight edge and thickness gauge, measure

the flatness of the cylinder block’s upper surface.

Make sure that no gasket pieces, etc., are adhered

to the upper surface of the cylinder block when

measuring.

Standard value: 0.05 mm

Limit value: 0.1 mm

(3) Check for the presence of scratches or seizure on

the cylinder wall. If any faults are found, repair (over

size) or replace the part.

(4) Using a cylinder gauge, measure the inner diameter

and cylindricity of the cylinder. If greatly worn, repair

the cylinder to the over size, and replace the piston

ring.

Standard value: 85.0 mm

Cylindricity: 0.01 mm

Plastic gauge

12 mm

Page 525 of 1449

12-1

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

LUBRICANTS 3..............................

SPECIAL TOOL 3............................ON-VEHICLE SERVICE 4.....................

Engine Oil Check 4............................

Engine Oil Replacement 4.......................

Oil Filter Replacement 5........................

Oil Pressure Check 5..........................

ENGINE OIL COOLER 7......................

Page 528 of 1449

ENGINE LUBRICATION -On-vehicle Service12-4

ON-VEHICLE SERVICE

ENGINE OIL CHECK

1. Pull out the level gauge slowly and check that the oil

level is in the illustrated range.

2. Check that the oil is not excessively dirty, that there is

no coolant or petrol mixed in, and that it has sufficient

viscosity.

ENGINE OIL REPLACEMENT

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

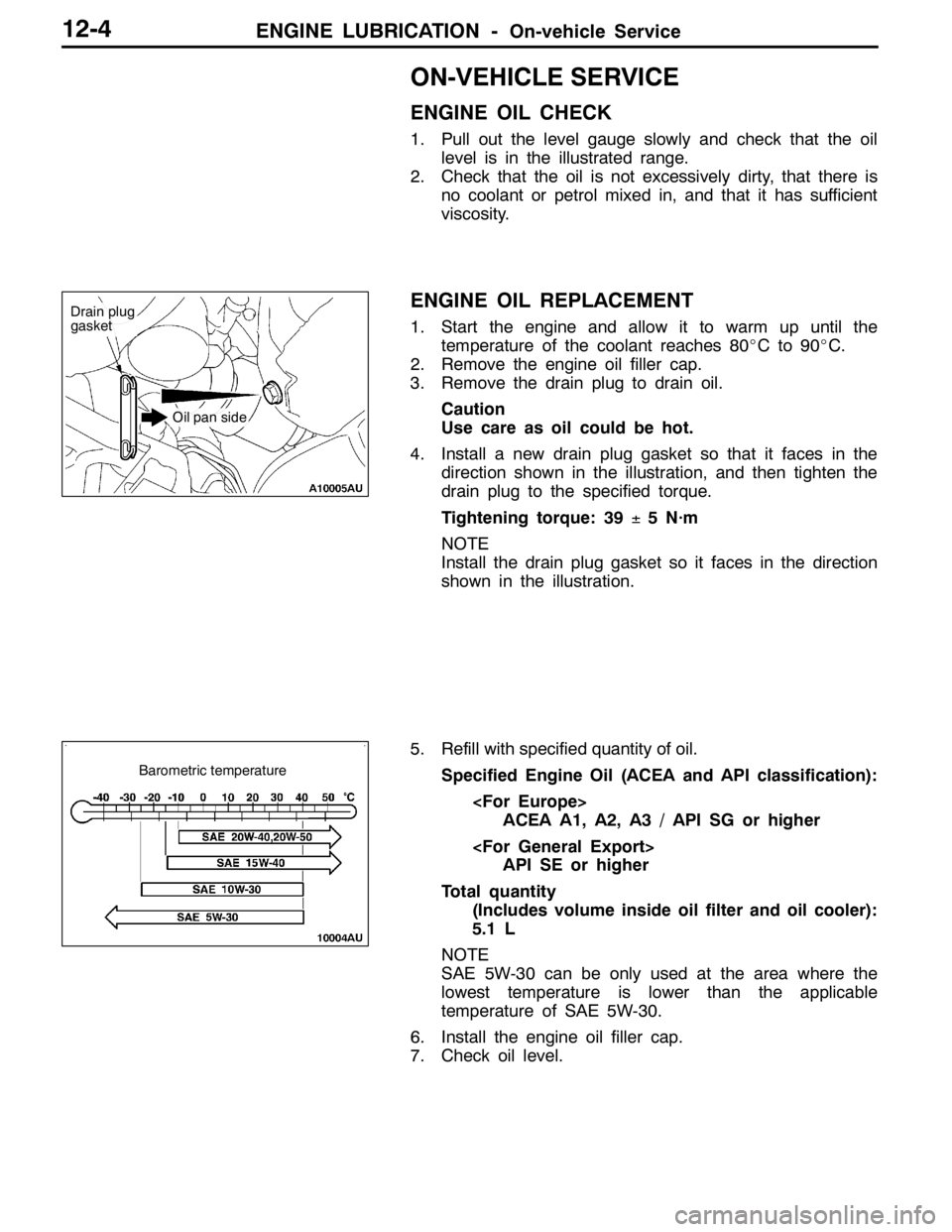

4. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the

drain plug to the specified torque.

Tightening torque: 39±5 N·m

NOTE

Install the drain plug gasket so it faces in the direction

shown in the illustration.

5. Refill with specified quantity of oil.

Specified Engine Oil (ACEA and API classification):

ACEA A1, A2, A3 / API SG or higher

API SE or higher

Total quantity

(Includes volume inside oil filter and oil cooler):

5.1 L

NOTE

SAE 5W-30 can be only used at the area where the

lowest temperature is lower than the applicable

temperature of SAE 5W-30.

6. Install the engine oil filler cap.

7. Check oil level.

Drain plug

gasket

Oil pan side

Barometric temperature

Page 529 of 1449

ENGINE LUBRICATION -On-vehicle Service12-5

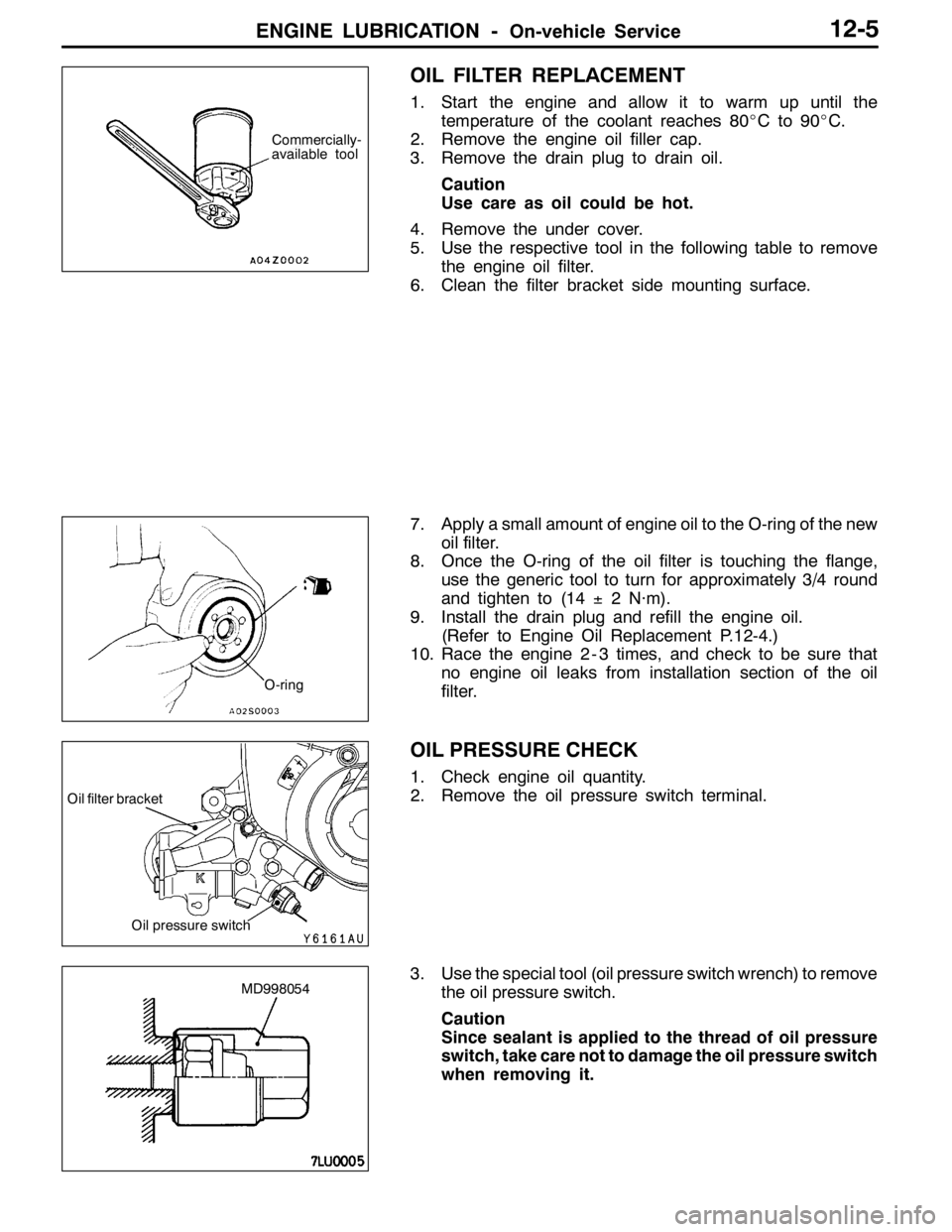

OIL FILTER REPLACEMENT

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

4. Remove the under cover.

5. Use the respective tool in the following table to remove

the engine oil filter.

6. Clean the filter bracket side mounting surface.

7. Apply a small amount of engine oil to the O-ring of the new

oil filter.

8. Once the O-ring of the oil filter is touching the flange,

use the generic tool to turn for approximately 3/4 round

and tighten to (14±2 N·m).

9. Install the drain plug and refill the engine oil.

(Refer to Engine Oil Replacement P.12-4.)

10. Race the engine 2 - 3 times, and check to be sure that

no engine oil leaks from installation section of the oil

filter.

OIL PRESSURE CHECK

1. Check engine oil quantity.

2. Remove the oil pressure switch terminal.

3. Use the special tool (oil pressure switch wrench) to remove

the oil pressure switch.

Caution

Since sealant is applied to the thread of oil pressure

switch, take care not to damage the oil pressure switch

when removing it.

Commercially-

available tool

O-ring

Oil pressure switch

Oil filter bracket

MD998054