belt MITSUBISHI LANCER EVOLUTION 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 473 of 1449

ENGINE OVERHAUL -Timing Belt11B-19

Caution

(1) Measure when the belt’s surface temperature is

close to room temperature.

(2) Make sure that water or oil, etc., do not get on

the mike.

(3) If strong winds contact the mike or if noise is

generated in the area while measuring, a value

that differs from the actual value may be indicated.

(4) If the measurement is carried out with the mike

contacted against the belt, a value that differs

from the actual value may be indicated.

(5) Do not measure while the engine is running.

11. Disconnect MUT-II.

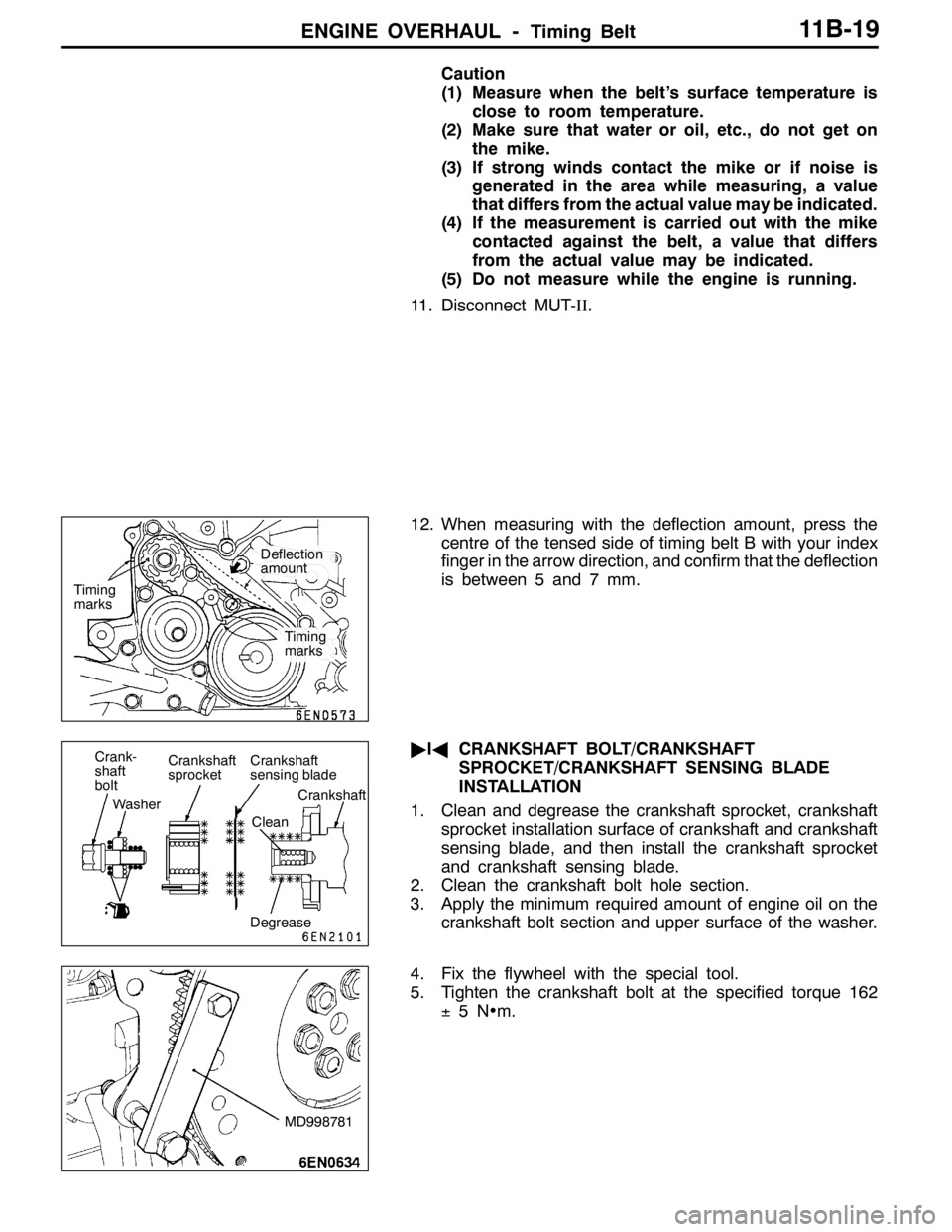

12. When measuring with the deflection amount, press the

centre of the tensed side of timing belt B with your index

finger in the arrow direction, and confirm that the deflection

is between 5 and 7 mm.

"IACRANKSHAFT BOLT/CRANKSHAFT

SPROCKET/CRANKSHAFT SENSING BLADE

INSTALLATION

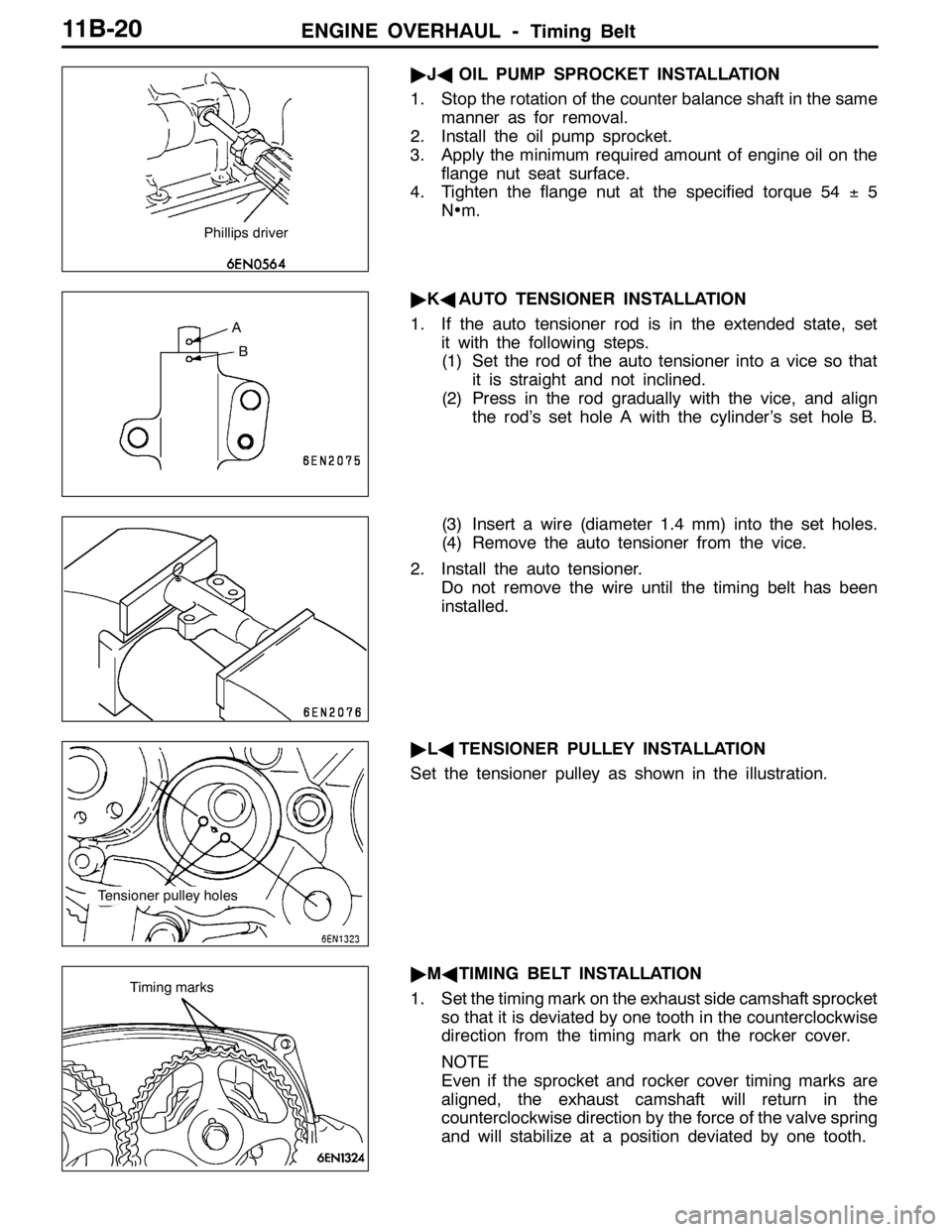

1. Clean and degrease the crankshaft sprocket, crankshaft

sprocket installation surface of crankshaft and crankshaft

sensing blade, and then install the crankshaft sprocket

and crankshaft sensing blade.

2. Clean the crankshaft bolt hole section.

3. Apply the minimum required amount of engine oil on the

crankshaft bolt section and upper surface of the washer.

4. Fix the flywheel with the special tool.

5. Tighten the crankshaft bolt at the specified torque 162

±5N•m.

Timing

marks

Timing

marks

Deflection

amount

Crank-

shaft

bolt

WasherCrankshaft

sprocketCrankshaft

sensing blade

Crankshaft

Clean

Degrease

MD998781

Page 474 of 1449

ENGINE OVERHAUL -Timing Belt11B-20

"JAOIL PUMP SPROCKET INSTALLATION

1. Stop the rotation of the counter balance shaft in the same

manner as for removal.

2. Install the oil pump sprocket.

3. Apply the minimum required amount of engine oil on the

flange nut seat surface.

4. Tighten the flange nut at the specified torque 54±5

N•m.

"KAAUTO TENSIONER INSTALLATION

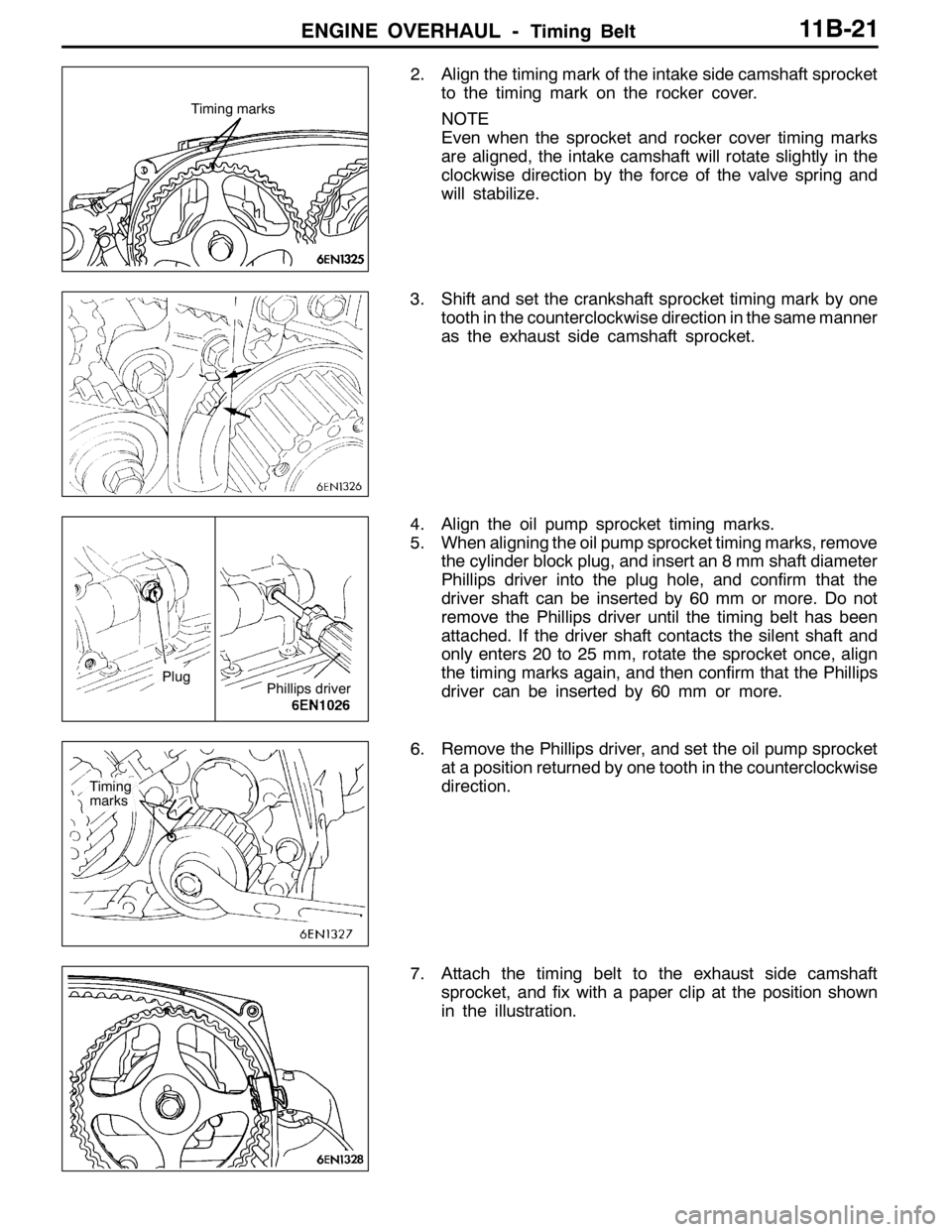

1. If the auto tensioner rod is in the extended state, set

it with the following steps.

(1) Set the rod of the auto tensioner into a vice so that

it is straight and not inclined.

(2) Press in the rod gradually with the vice, and align

the rod’s set hole A with the cylinder’s set hole B.

(3) Insert a wire (diameter 1.4 mm) into the set holes.

(4) Remove the auto tensioner from the vice.

2. Install the auto tensioner.

Do not remove the wire until the timing belt has been

installed.

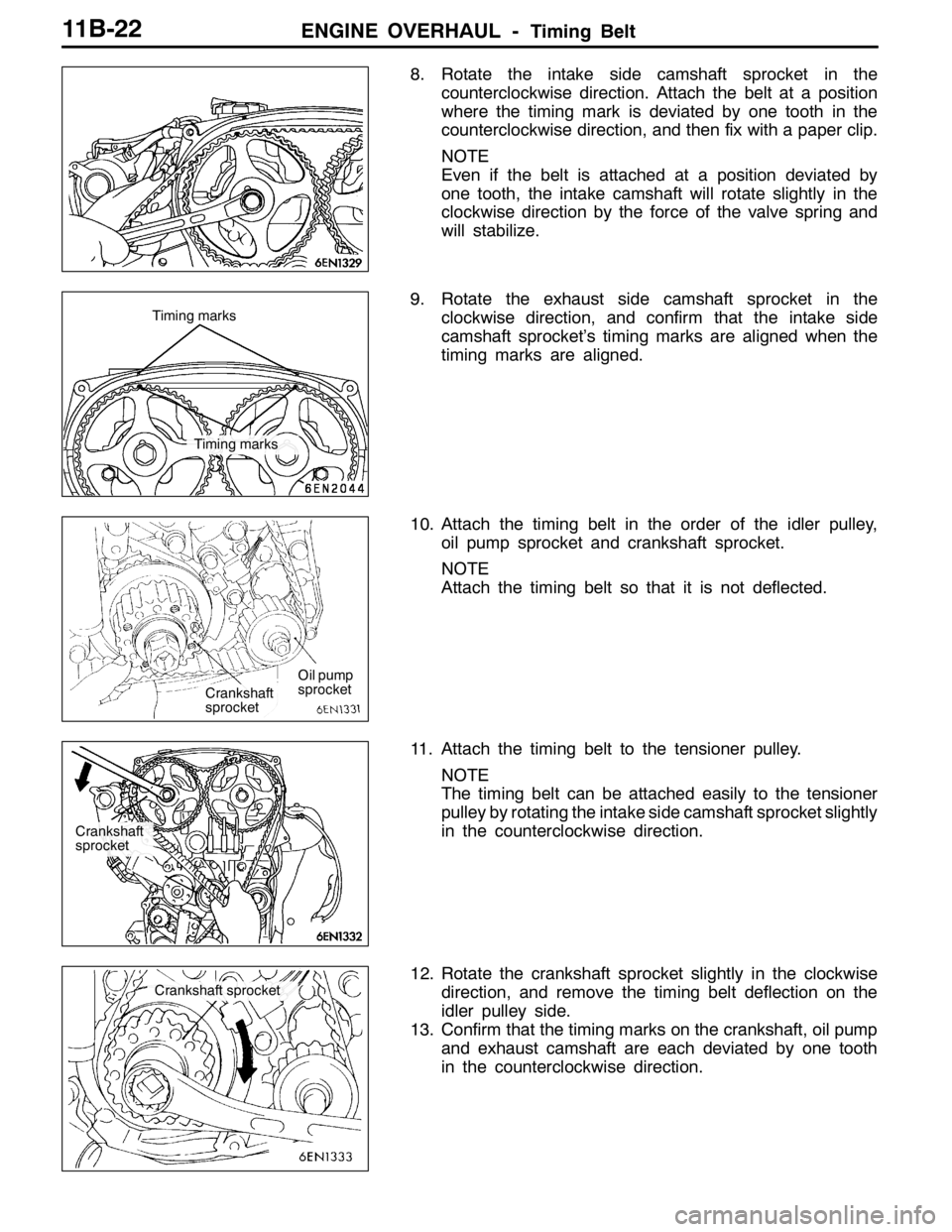

"LATENSIONER PULLEY INSTALLATION

Set the tensioner pulley as shown in the illustration.

"MATIMING BELT INSTALLATION

1. Set the timing mark on the exhaust side camshaft sprocket

so that it is deviated by one tooth in the counterclockwise

direction from the timing mark on the rocker cover.

NOTE

Even if the sprocket and rocker cover timing marks are

aligned, the exhaust camshaft will return in the

counterclockwise direction by the force of the valve spring

and will stabilize at a position deviated by one tooth.

Phillips driver

A

B

Tensioner pulley holes

Timing marks

Page 475 of 1449

ENGINE OVERHAUL -Timing Belt11B-21

2. Align the timing mark of the intake side camshaft sprocket

to the timing mark on the rocker cover.

NOTE

Even when the sprocket and rocker cover timing marks

are aligned, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

3. Shift and set the crankshaft sprocket timing mark by one

tooth in the counterclockwise direction in the same manner

as the exhaust side camshaft sprocket.

4. Align the oil pump sprocket timing marks.

5. When aligning the oil pump sprocket timing marks, remove

the cylinder block plug, and insert an 8 mm shaft diameter

Phillips driver into the plug hole, and confirm that the

driver shaft can be inserted by 60 mm or more. Do not

remove the Phillips driver until the timing belt has been

attached. If the driver shaft contacts the silent shaft and

only enters 20 to 25 mm, rotate the sprocket once, align

the timing marks again, and then confirm that the Phillips

driver can be inserted by 60 mm or more.

6. Remove the Phillips driver, and set the oil pump sprocket

at a position returned by one tooth in the counterclockwise

direction.

7. Attach the timing belt to the exhaust side camshaft

sprocket, and fix with a paper clip at the position shown

in the illustration.

Timing marks

Phillips driverPlug

Timing

marks

Page 476 of 1449

ENGINE OVERHAUL -Timing Belt11B-22

8. Rotate the intake side camshaft sprocket in the

counterclockwise direction. Attach the belt at a position

where the timing mark is deviated by one tooth in the

counterclockwise direction, and then fix with a paper clip.

NOTE

Even if the belt is attached at a position deviated by

one tooth, the intake camshaft will rotate slightly in the

clockwise direction by the force of the valve spring and

will stabilize.

9. Rotate the exhaust side camshaft sprocket in the

clockwise direction, and confirm that the intake side

camshaft sprocket’s timing marks are aligned when the

timing marks are aligned.

10. Attach the timing belt in the order of the idler pulley,

oil pump sprocket and crankshaft sprocket.

NOTE

Attach the timing belt so that it is not deflected.

11. Attach the timing belt to the tensioner pulley.

NOTE

The timing belt can be attached easily to the tensioner

pulley by rotating the intake side camshaft sprocket slightly

in the counterclockwise direction.

12. Rotate the crankshaft sprocket slightly in the clockwise

direction, and remove the timing belt deflection on the

idler pulley side.

13. Confirm that the timing marks on the crankshaft, oil pump

and exhaust camshaft are each deviated by one tooth

in the counterclockwise direction.

Timing marks Timing marks

Crankshaft

sprocketOil pump

sprocket

Crankshaft

sprocket

Crankshaft sprocket

Page 477 of 1449

ENGINE OVERHAUL -Timing Belt11B-23

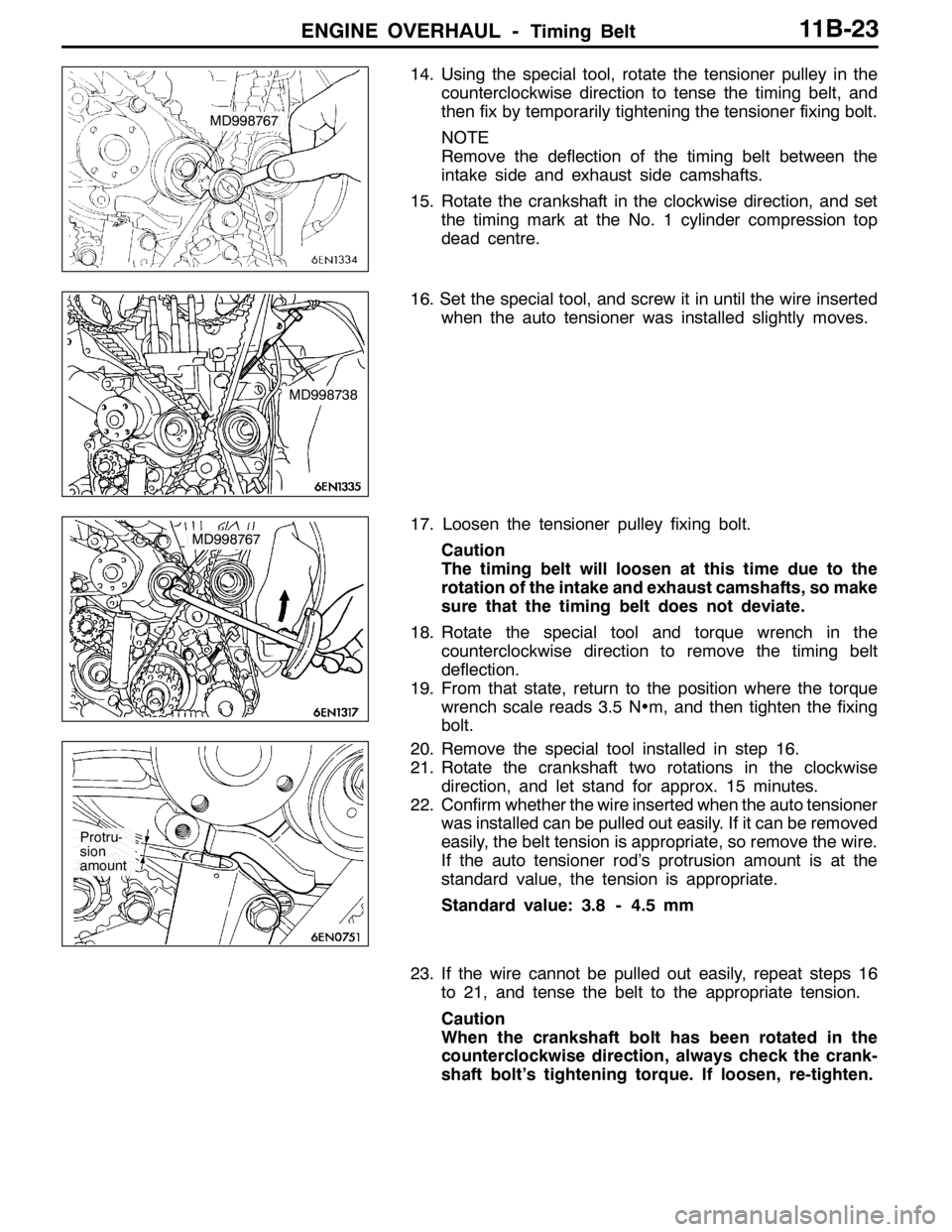

14. Using the special tool, rotate the tensioner pulley in the

counterclockwise direction to tense the timing belt, and

then fix by temporarily tightening the tensioner fixing bolt.

NOTE

Remove the deflection of the timing belt between the

intake side and exhaust side camshafts.

15. Rotate the crankshaft in the clockwise direction, and set

the timing mark at the No. 1 cylinder compression top

dead centre.

16. Set the special tool, and screw it in until the wire inserted

when the auto tensioner was installed slightly moves.

17. Loosen the tensioner pulley fixing bolt.

Caution

The timing belt will loosen at this time due to the

rotation of the intake and exhaust camshafts, so make

sure that the timing belt does not deviate.

18. Rotate the special tool and torque wrench in the

counterclockwise direction to remove the timing belt

deflection.

19. From that state, return to the position where the torque

wrench scale reads 3.5 N•m, and then tighten the fixing

bolt.

20. Remove the special tool installed in step 16.

21. Rotate the crankshaft two rotations in the clockwise

direction, and let stand for approx. 15 minutes.

22. Confirm whether the wire inserted when the auto tensioner

was installed can be pulled out easily. If it can be removed

easily, the belt tension is appropriate, so remove the wire.

If the auto tensioner rod’s protrusion amount is at the

standard value, the tension is appropriate.

Standard value: 3.8 - 4.5 mm

23. If the wire cannot be pulled out easily, repeat steps 16

to 21, and tense the belt to the appropriate tension.

Caution

When the crankshaft bolt has been rotated in the

counterclockwise direction, always check the crank-

shaft bolt’s tightening torque. If loosen, re-tighten.

MD998767

MD998738

MD998767

Protru-

sion

amount

Page 478 of 1449

ENGINE OVERHAUL -Timing Belt11B-24

INSPECTION

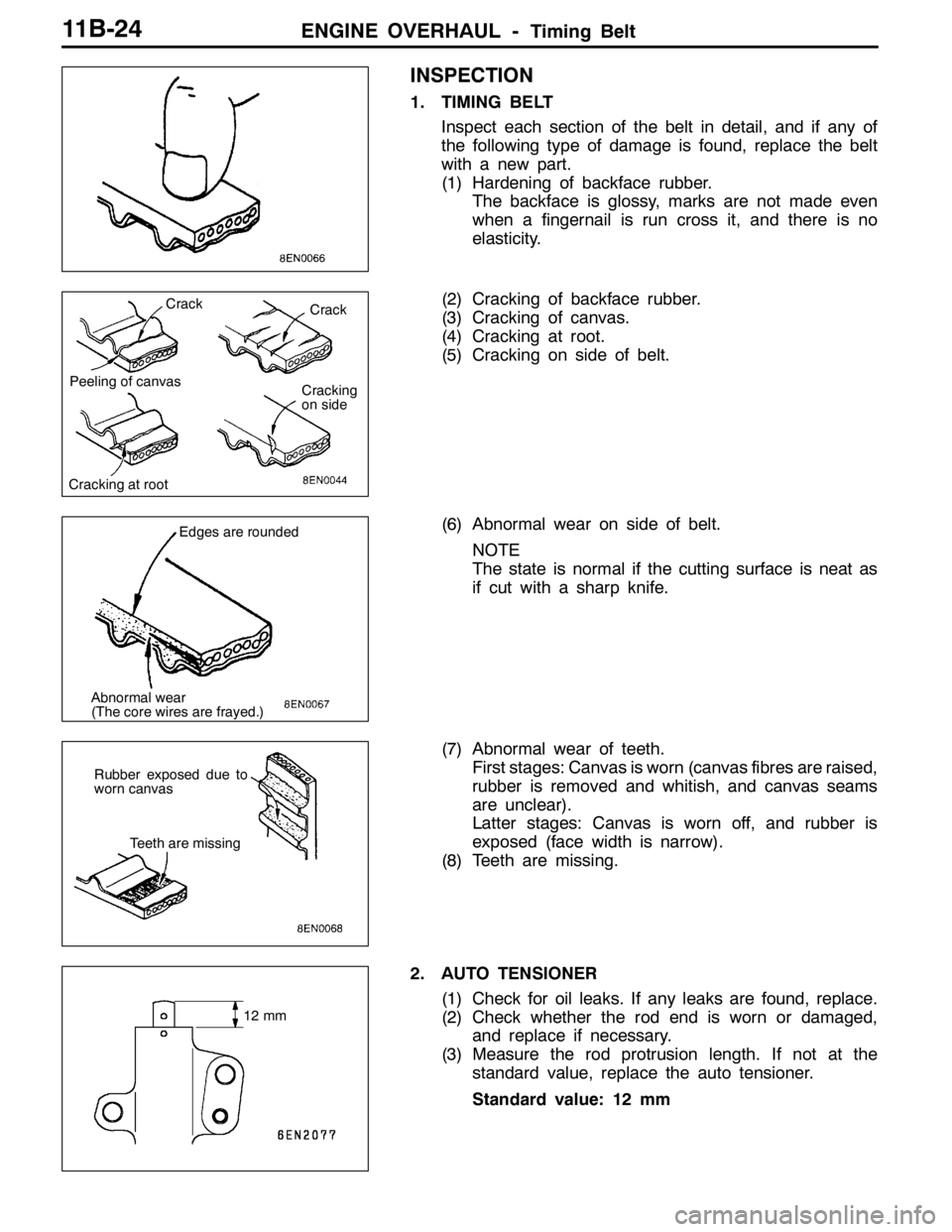

1. TIMING BELT

Inspect each section of the belt in detail, and if any of

the following type of damage is found, replace the belt

with a new part.

(1) Hardening of backface rubber.

The backface is glossy, marks are not made even

when a fingernail is run cross it, and there is no

elasticity.

(2) Cracking of backface rubber.

(3) Cracking of canvas.

(4) Cracking at root.

(5) Cracking on side of belt.

(6) Abnormal wear on side of belt.

NOTE

The state is normal if the cutting surface is neat as

if cut with a sharp knife.

(7) Abnormal wear of teeth.

First stages: Canvas is worn (canvas fibres are raised,

rubber is removed and whitish, and canvas seams

are unclear).

Latter stages: Canvas is worn off, and rubber is

exposed (face width is narrow).

(8) Teeth are missing.

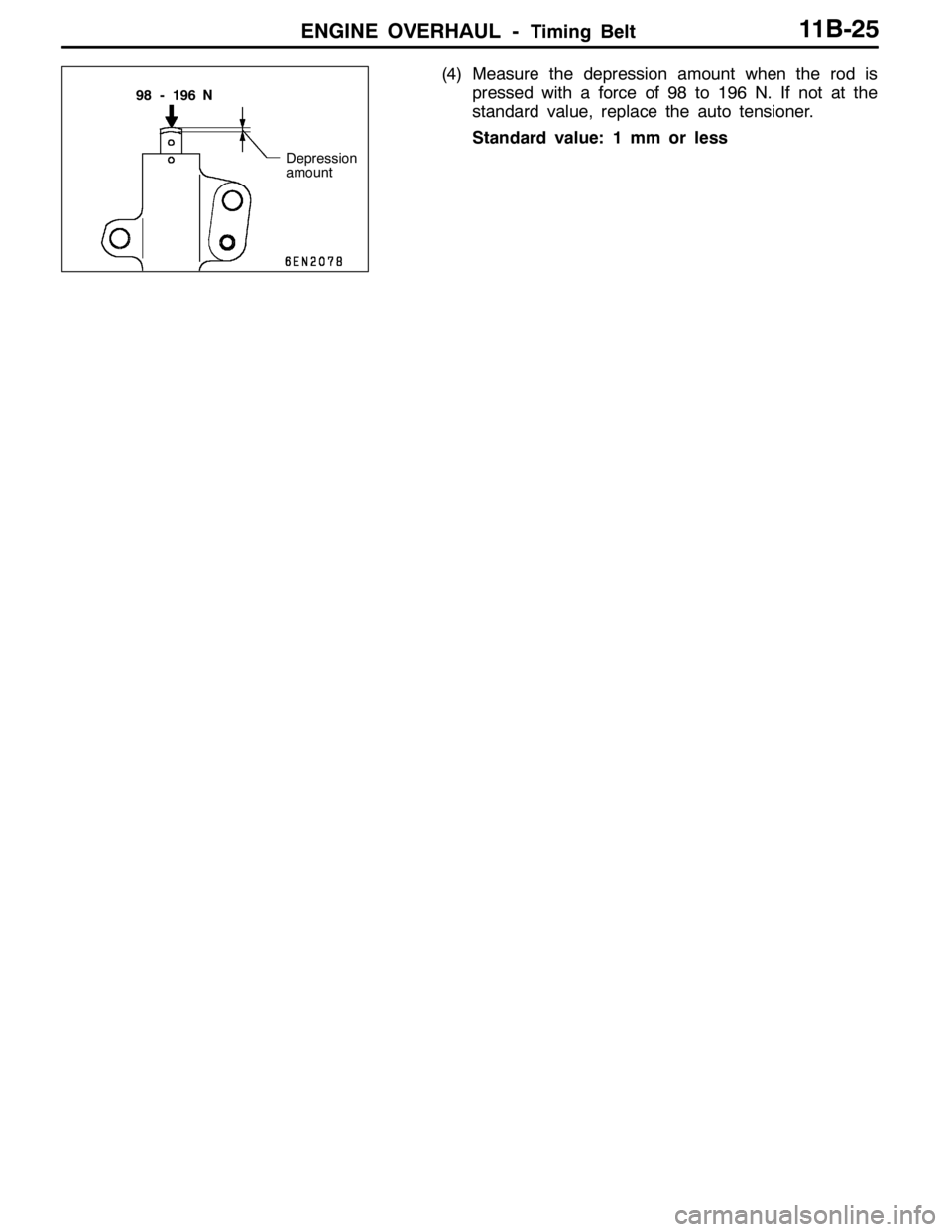

2. AUTO TENSIONER

(1) Check for oil leaks. If any leaks are found, replace.

(2) Check whether the rod end is worn or damaged,

and replace if necessary.

(3) Measure the rod protrusion length. If not at the

standard value, replace the auto tensioner.

Standard value: 12 mm

Crack

Crack

Peeling of canvas

Cracking

on side

Cracking at root

Edges are rounded

Abnormal wear

(The core wires are frayed.)

Rubber exposed due to

worn canvas

Teeth are missing

12 mm

Page 479 of 1449

ENGINE OVERHAUL -Timing Belt11B-25

(4) Measure the depression amount when the rod is

pressed with a force of 98 to 196 N. If not at the

standard value, replace the auto tensioner.

Standard value: 1 mm or less

Depression

amount 98 - 196 N

Page 489 of 1449

ENGINE OVERHAUL -Rocker Arm and Camshaft11B-35

REMOVAL SERVICE POINT

AA"LASH ADJUSTER REMOVAL

Caution

When reusing the lash adjuster, always clean and inspect

it before installing. (Refer to the section on checking the

lash adjuster.)

INSTALLATION SERVICE POINTS

"AALASH ADJUSTER INSTALLATION

Caution

When reusing the lash adjuster, always clean and inspect

it before installing. (Refer to the section on checking the

lash adjuster.)

Assembly the lash adjuster onto the rocker arm while taking

care not to spill out diesel oil in it.

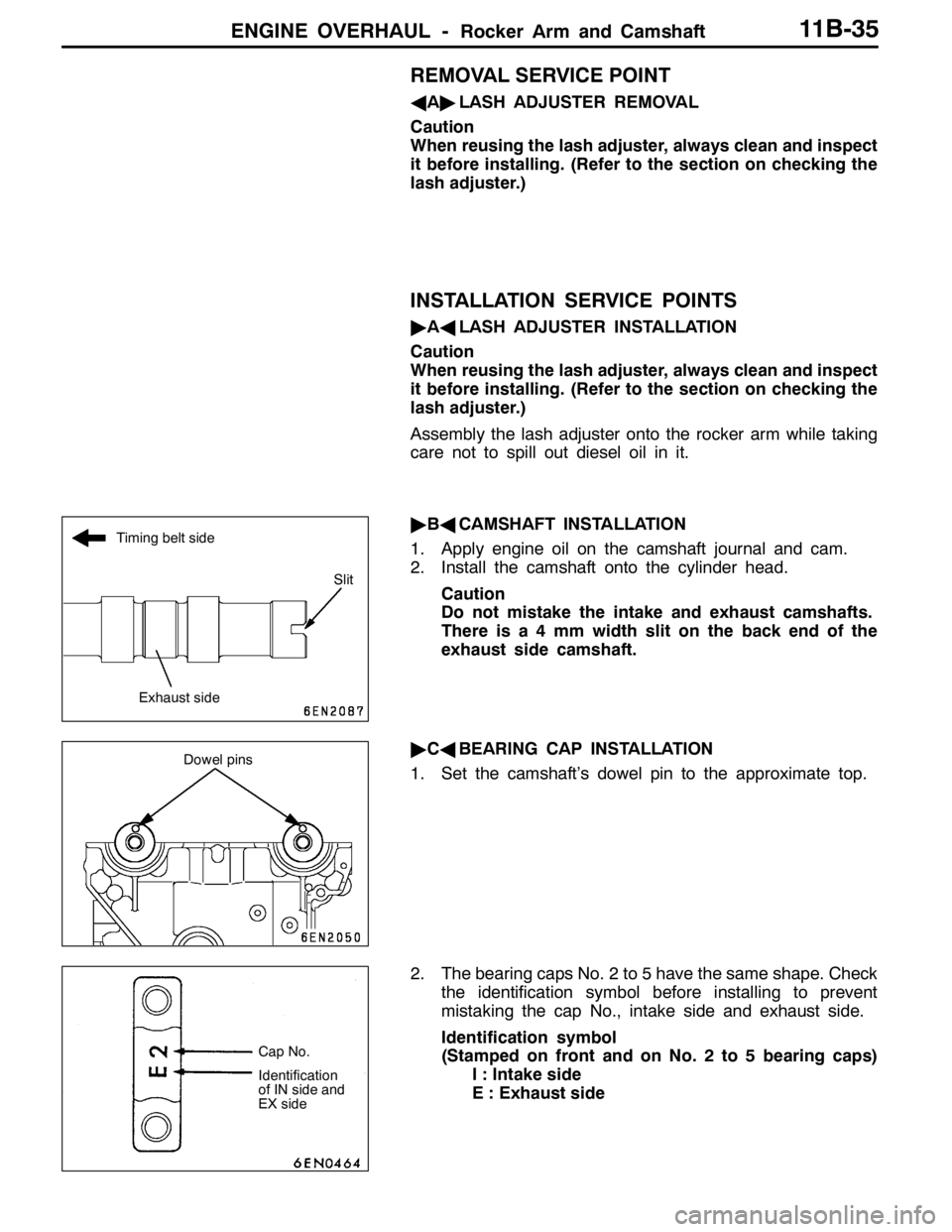

"BACAMSHAFT INSTALLATION

1. Apply engine oil on the camshaft journal and cam.

2. Install the camshaft onto the cylinder head.

Caution

Do not mistake the intake and exhaust camshafts.

There is a 4 mm width slit on the back end of the

exhaust side camshaft.

"CABEARING CAP INSTALLATION

1. Set the camshaft’s dowel pin to the approximate top.

2. The bearing caps No. 2 to 5 have the same shape. Check

the identification symbol before installing to prevent

mistaking the cap No., intake side and exhaust side.

Identification symbol

(Stamped on front and on No. 2 to 5 bearing caps)

I : Intake side

E : Exhaust side

Timing belt side

Slit

Exhaust side

Dowel pins

Cap No.

Identification

of IN side and

EX side

Page 497 of 1449

ENGINE OVERHAUL -Cylinder Head and Valve11B-43

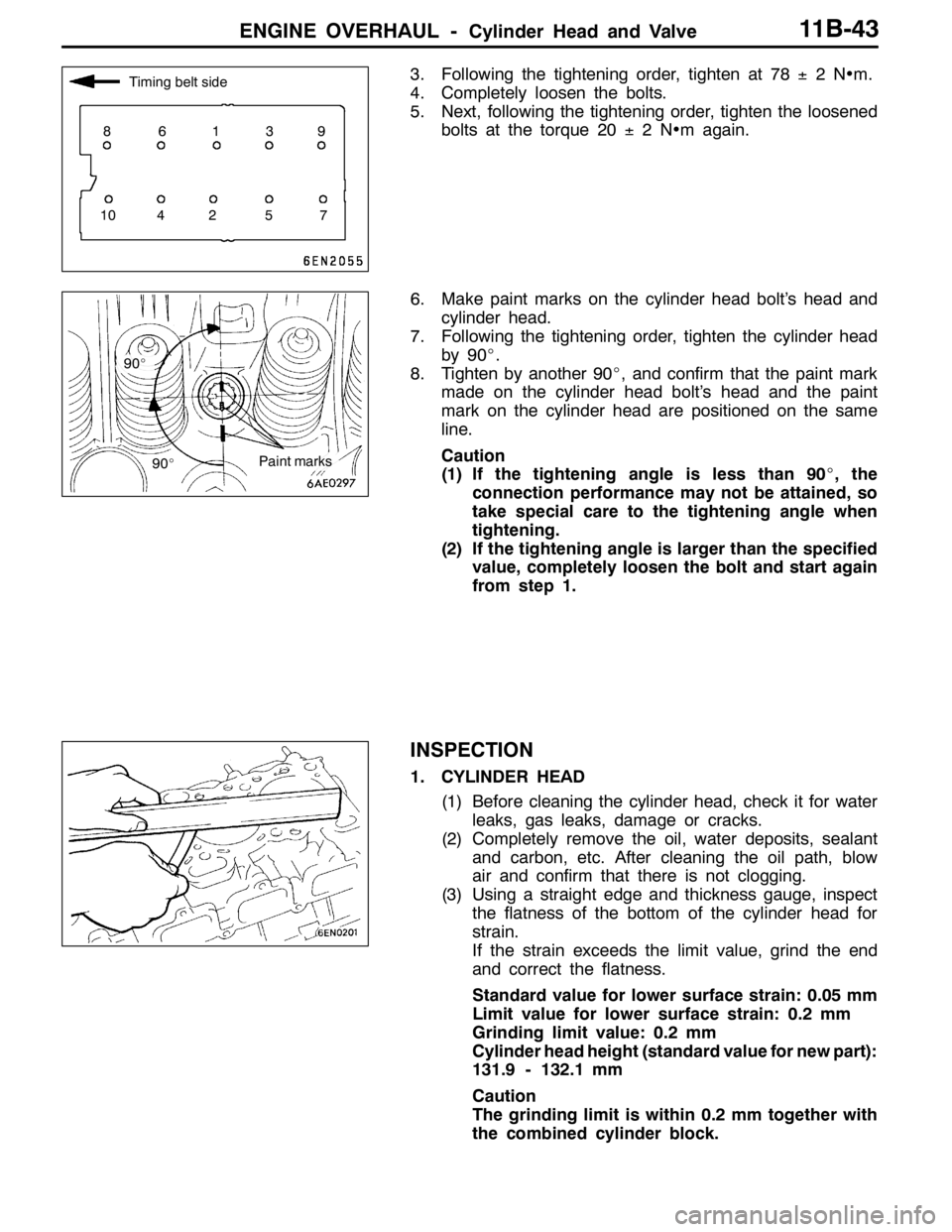

3. Following the tightening order, tighten at 78±2N•m.

4. Completely loosen the bolts.

5. Next, following the tightening order, tighten the loosened

bolts at the torque 20±2N•m again.

6. Make paint marks on the cylinder head bolt’s head and

cylinder head.

7. Following the tightening order, tighten the cylinder head

by 90_.

8. Tighten by another 90_, and confirm that the paint mark

made on the cylinder head bolt’s head and the paint

mark on the cylinder head are positioned on the same

line.

Caution

(1) If the tightening angle is less than 90_, the

connection performance may not be attained, so

take special care to the tightening angle when

tightening.

(2) If the tightening angle is larger than the specified

value, completely loosen the bolt and start again

from step 1.

INSPECTION

1. CYLINDER HEAD

(1) Before cleaning the cylinder head, check it for water

leaks, gas leaks, damage or cracks.

(2) Completely remove the oil, water deposits, sealant

and carbon, etc. After cleaning the oil path, blow

air and confirm that there is not clogging.

(3) Using a straight edge and thickness gauge, inspect

the flatness of the bottom of the cylinder head for

strain.

If the strain exceeds the limit value, grind the end

and correct the flatness.

Standard value for lower surface strain: 0.05 mm

Limit value for lower surface strain: 0.2 mm

Grinding limit value: 0.2 mm

Cylinder head height (standard value for new part):

131.9 - 132.1 mm

Caution

The grinding limit is within 0.2 mm together with

the combined cylinder block.

Timing belt side

86139

10 4 2 5 7

90_

90_

Paint marks

Page 507 of 1449

ENGINE OVERHAUL -Oil Pump and Oil Pan11B-53

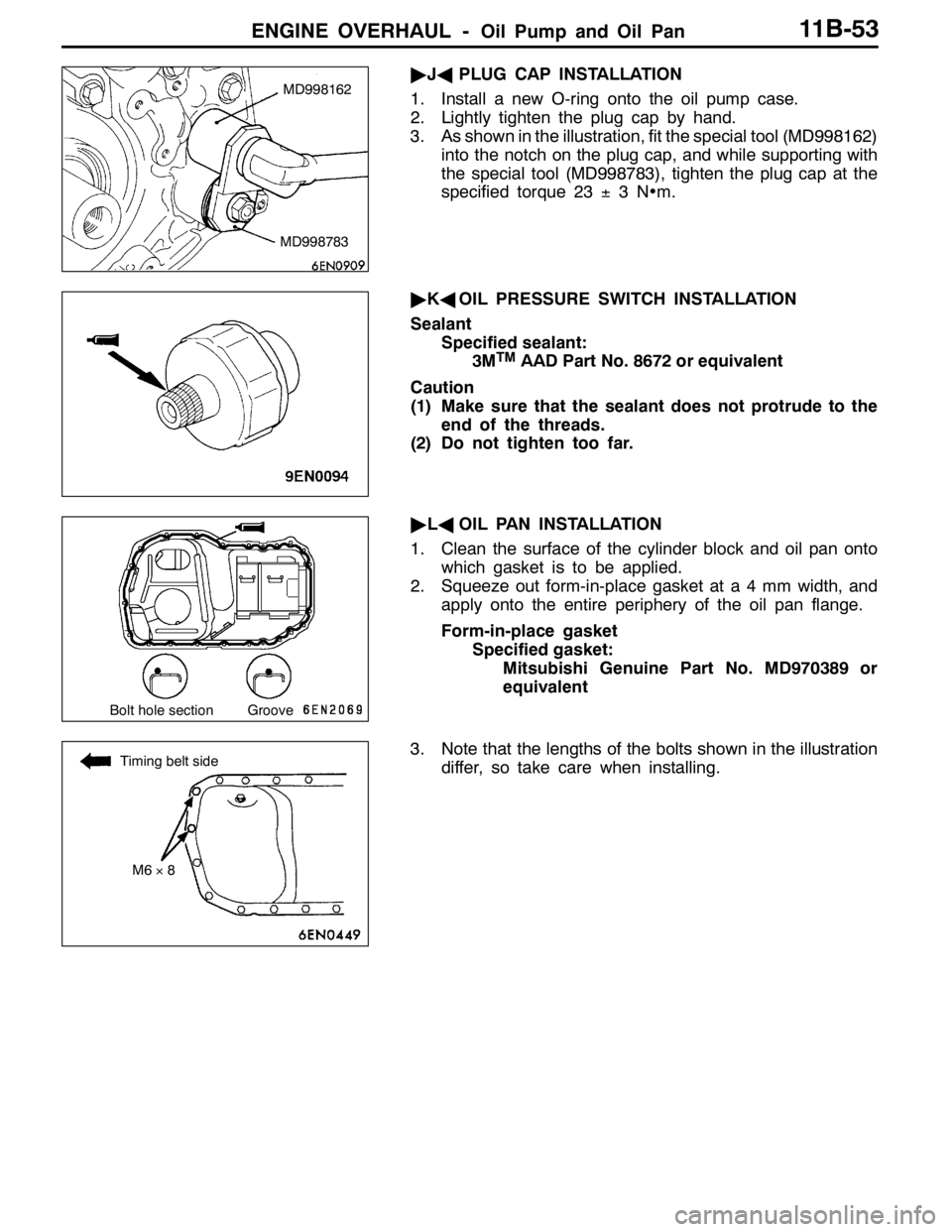

"JAPLUG CAP INSTALLATION

1. Install a new O-ring onto the oil pump case.

2. Lightly tighten the plug cap by hand.

3. As shown in the illustration, fit the special tool (MD998162)

into the notch on the plug cap, and while supporting with

the special tool (MD998783), tighten the plug cap at the

specified torque 23±3N•m.

"KAOIL PRESSURE SWITCH INSTALLATION

Sealant

Specified sealant:

3M

TMAAD Part No. 8672 or equivalent

Caution

(1) Make sure that the sealant does not protrude to the

end of the threads.

(2) Do not tighten too far.

"LAOIL PAN INSTALLATION

1. Clean the surface of the cylinder block and oil pan onto

which gasket is to be applied.

2. Squeeze out form-in-place gasket at a 4 mm width, and

apply onto the entire periphery of the oil pan flange.

Form-in-place gasket

Specified gasket:

Mitsubishi Genuine Part No. MD970389 or

equivalent

3. Note that the lengths of the bolts shown in the illustration

differ, so take care when installing.

MD998162

MD998783

Bolt hole section Groove

Timing belt side

M6×8