catalytic converter MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 537 of 1449

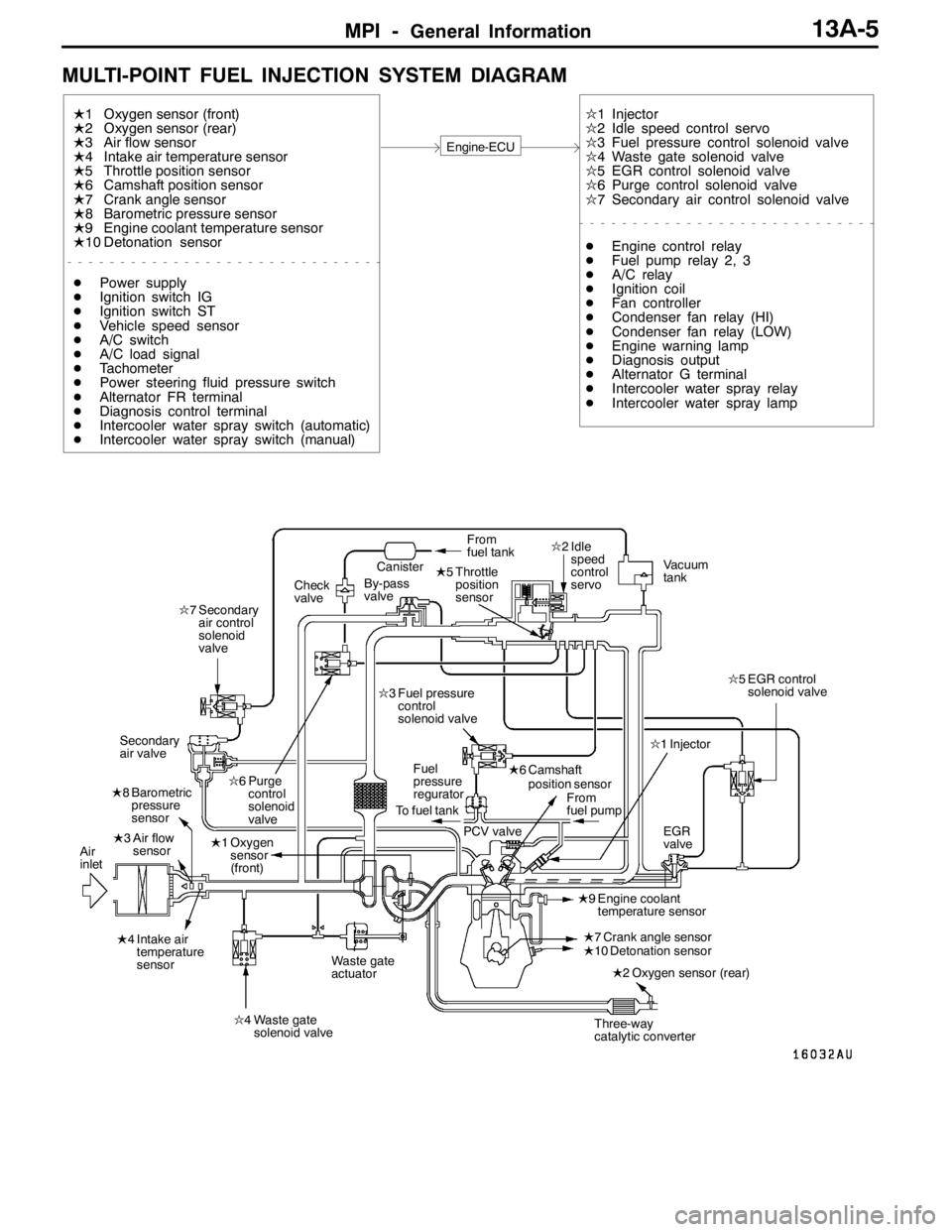

MPI -General Information13A-5

MULTI-POINT FUEL INJECTION SYSTEM DIAGRAM

L1 Oxygen sensor (front)

L2 Oxygen sensor (rear)

L3 Air flow sensor

L4 Intake air temperature sensor

L5 Throttle position sensor

L6 Camshaft position sensor

L7 Crank angle sensor

L8 Barometric pressure sensor

L9 Engine coolant temperature sensor

L10 Detonation sensor

Engine-ECU

l1 Injector

l2 Idle speed control servo

l3 Fuel pressure control solenoid valve

l4 Waste gate solenoid valve

l5 EGR control solenoid valve

l6 Purge control solenoid valve

l7 Secondary air control solenoid valve

DPower supply

DIgnition switch IG

DIgnition switch ST

DVehicle speed sensor

DA/C switch

DA/C load signal

DTachometer

DPower steering fluid pressure switch

DAlternator FR terminal

DDiagnosis control terminal

DIntercooler water spray switch (automatic)

DIntercooler water spray switch (manual)DEngine control relay

DFuel pump relay 2, 3

DA/C relay

DIgnition coil

DFan controller

DCondenser fan relay (HI)

DCondenser fan relay (LOW)

DEngine warning lamp

DDiagnosis output

DAlternator G terminal

DIntercooler water spray relay

DIntercooler water spray lamp

L1 Oxygen

sensor

(front)

L4 Intake air

temperature

sensorL5 Throttle

position

sensor

L6 Camshaft

position sensorl1 Injector l2 Idle

speed

control

servo

l6 Purge

control

solenoid

valve

Three-way

catalytic converter Canister

Air

inletVacuum

tank

Fuel

pressure

reguratorFrom

fuel tank

To fuel tank

PCV valveFrom

fuel pump

Waste gate

actuatorL2 Oxygen sensor (rear) Check

valveBy-pass

valve

l5 EGR control

solenoid valve

l4 Waste gate

solenoid valve L8 Barometric

pressure

sensor

L3 Air flow

sensorl7 Secondary

air control

solenoid

valve

Secondary

air valvel3 Fuel pressure

control

solenoid valve

EGR

valve

L9 Engine coolant

temperature sensor

L7 Crank angle sensor

L10 Detonation sensor

Page 707 of 1449

15-1

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATION 3..................

SPECIAL TOOL 3............................

ON-VEHICLE SERVICE 3.....................

Turbocharger Supercharging Pressure Check 3...

Supercharging Pressure Control System

Check 4.......................................

Waste Gate Actuator Check 4...................

Waste Gate Solenoid Valve Check 5.............

Air Bypass Valve Check 5......................

Intake Manifold Pressure Check 6...............

Secondary Air Control System Check 6..........

Secondary Air Control Solenoid Valve Check 6...

Secondary Air Valve Check 7...................Vacuum Tank Check 7.........................

AIR CLEANER 8.............................

INTERCOOLER 9............................

INTERCOOLER WATER SPRAY 10............

SECONDARY AIR SUPPLY SYSTEM 14.......

INTAKE MANIFOLD 16.......................

EXHAUST MANIFOLD 19.....................

TURBOCHARGER 22.........................

EXHAUST PIPE AND MAIN MUFFLER 26.....

CATALYTIC CONVERTER

(REFER TO GROUP 17.) ....................

Page 771 of 1449

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2.........

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2...............

ON-VEHICLE SERVICE 2...................

Accelerator Cable Check and

Adjustment 2................................

ACCELERATOR CABLE AND PEDAL 3......

EMISSION CONTROL SYSTEM 4......

GENERAL INFORMATION 4................

Emission Control Device Reference

Table 4.....................................

SERVICE SPECIFICATIONS 5..............

VACUUM HOSE 5..........................

Vacuum Hose Piping Diagram 5..............

Vacuum Circuit Diagram 6....................

Vacuum Hose Check 7......................

Vacuum Hose Installation 7..................

CRANKCASE EMISSION CONTROL

SYSTEM 8................................

General Information 8........................

System Diagram 8..........................

Component Location 9.......................

Positive Crankcase Ventilation System Check 9....

PCV Valve Check 9.........................

EVAPORATIVE EMISSION CONTROL

SYSTEM 10...............................

General Information 10.......................

System Diagram 10..........................

Component Location 10......................

Purge Control System Check 11...............

Purge Port Vacuum Check 11.................

Purge Control Solenoid Valve Check 12.........

Check Valve Check 12.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 13...............................

General Information 13.......................

Operation 13................................

System Diagram 13..........................

Component Location 14......................

Exhaust Gas Recirculation (EGR) Control System

Check 14...................................

EGR Valve Check 15.........................

EGR Port Vacuum Check 15..................

EGR Control Solenoid Valve Check 16..........

EGR VALVE 17............................

CANISTER 18.............................

CATALYTIC CONVERTER 19................

General Information 19.......................

Page 774 of 1449

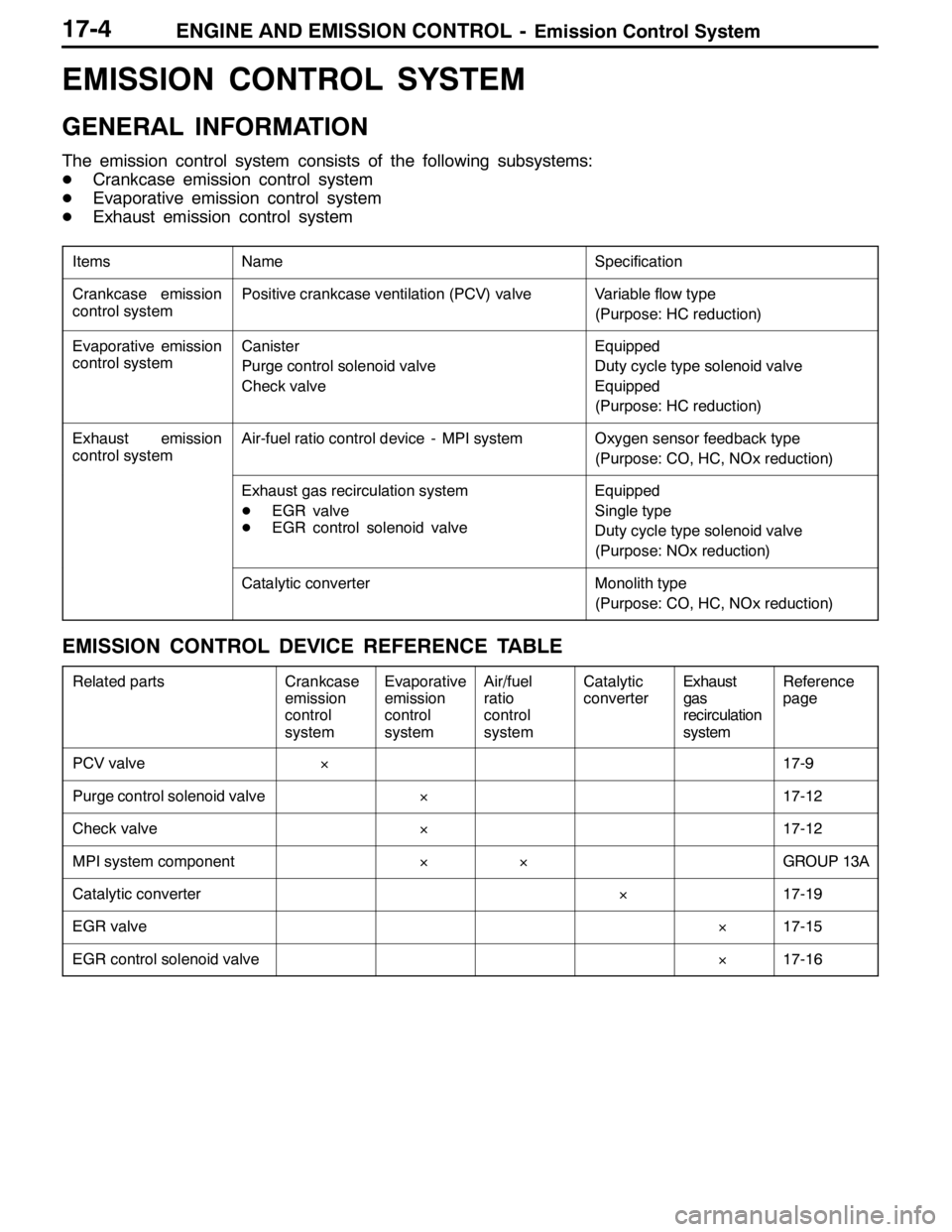

ENGINE AND EMISSION CONTROL -Emission Control System17-4

EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The emission control system consists of the following subsystems:

DCrankcase emission control system

DEvaporative emission control system

DExhaust emission control system

ItemsNameSpecification

Crankcase emission

control systemPositive crankcase ventilation (PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission

control systemCanister

Purge control solenoid valve

Check valveEquipped

Duty cycle type solenoid valve

Equipped

(Purpose: HC reduction)

Exhaust emission

control systemAir-fuel ratio control device - MPI systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

DEGR valve

DEGR control solenoid valveEquipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE REFERENCE TABLE

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel

ratio

control

systemCatalytic

converterExhaust

gas

recirculation

systemReference

page

PCV valve×17-9

Purge control solenoid valve×17-12

Check valve×17-12

MPI system component××GROUP 13A

Catalytic converter×17-19

EGR valve×17-15

EGR control solenoid valve×17-16

Page 775 of 1449

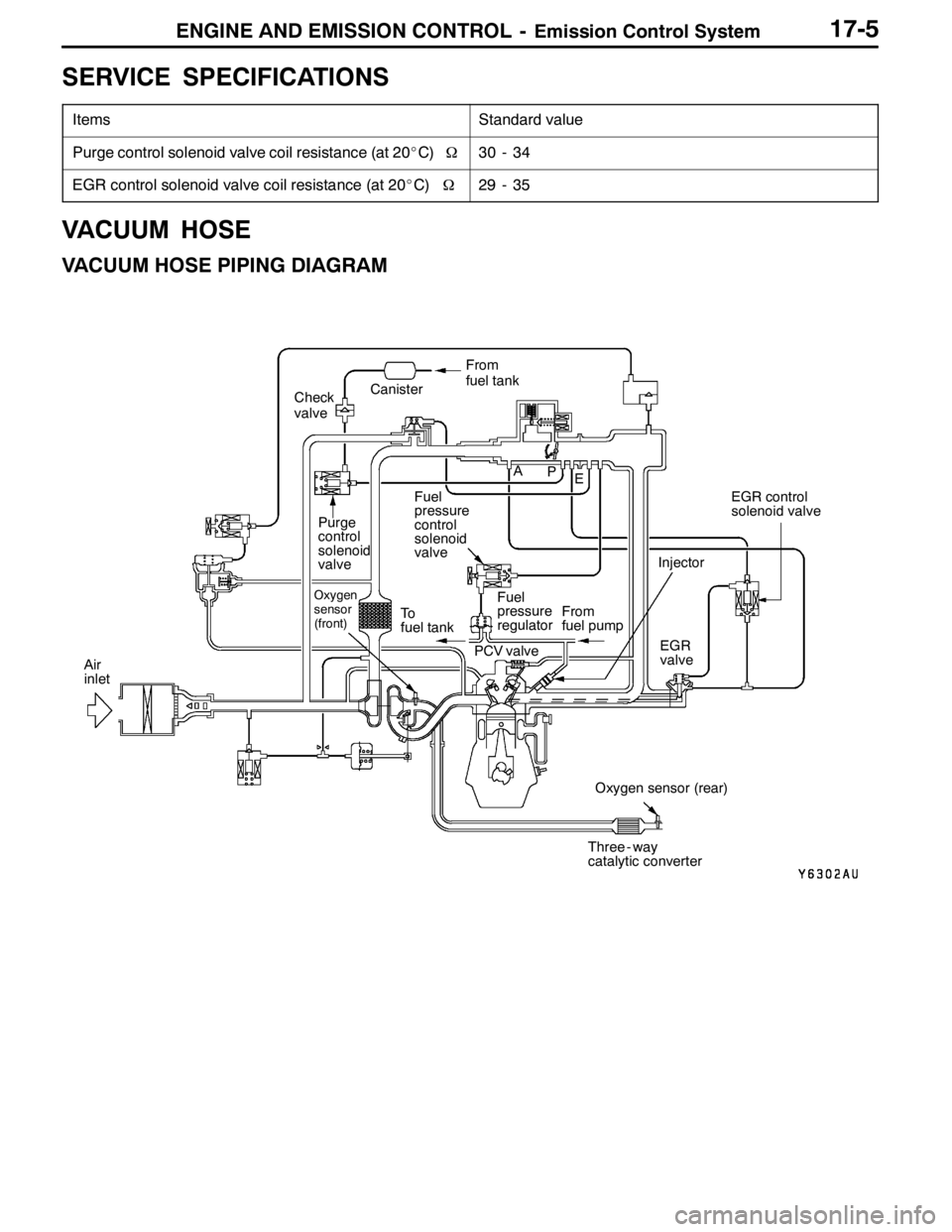

ENGINE AND EMISSION CONTROL -Emission Control System17-5

SERVICE SPECIFICATIONS

ItemsStandard value

Purge control solenoid valve coil resistance (at 20_C)Ω30 - 34

EGR control solenoid valve coil resistance (at 20_C)Ω29 - 35

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAM

Fuel

pressure

control

solenoid

valve

Oxygen

sensor

(front)

Check

valve

Fuel

pressure

regulator

PCV valve To

fuel tank

Oxygen sensor (rear) From

fuel pump

Air

inletEGR control

solenoid valve

Purge

control

solenoid

valveCanisterFrom

fuel tank

EGR

valve Injector

Three - way

catalytic converter A

P

E

Page 789 of 1449

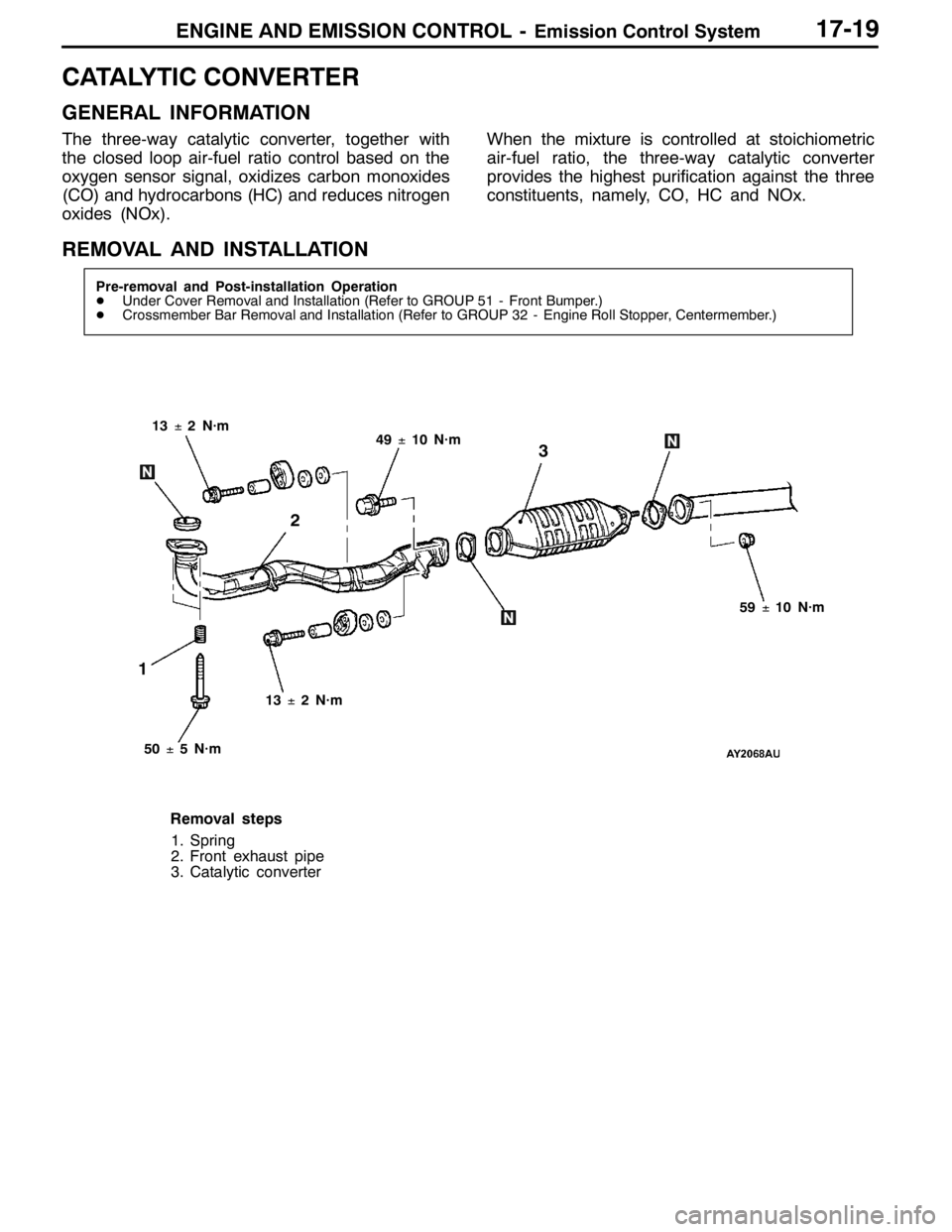

ENGINE AND EMISSION CONTROL -Emission Control System17-19

CATALYTIC CONVERTER

GENERAL INFORMATION

The three-way catalytic converter, together with

the closed loop air-fuel ratio control based on the

oxygen sensor signal, oxidizes carbon monoxides

(CO) and hydrocarbons (HC) and reduces nitrogen

oxides (NOx).When the mixture is controlled at stoichiometric

air-fuel ratio, the three-way catalytic converter

provides the highest purification against the three

constituents, namely, CO, HC and NOx.

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DUnder Cover Removal and Installation (Refer to GROUP 51 - Front Bumper.)

DCrossmember Bar Removal and Installation (Refer to GROUP 32 - Engine Roll Stopper, Centermember.)

123

49±10N·m

13±2N·m 13±2N·m

59±10N·m

50±5N·m

Removal steps

1. Spring

2. Front exhaust pipe

3. Catalytic converter