air condition MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 42 of 241

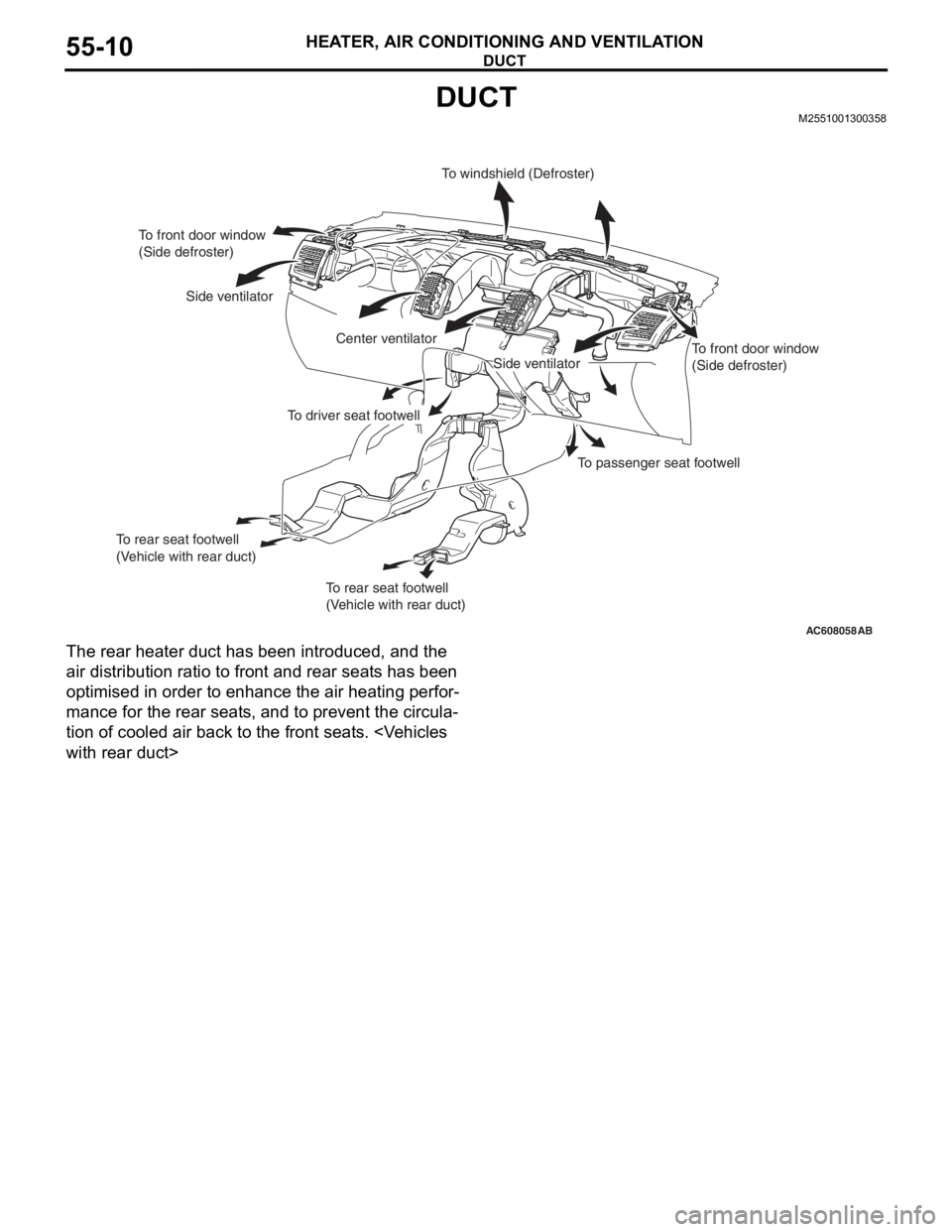

DUCT

HEATER, AIR CONDITIONING AND VENTILATION55-10

DUCTM2551001300358

The rear heater duct has been introduced, and the

air distribution ratio to front and rear seats has been

optimised in order to enhance the air heating perfor

-

mance for the rear seats, and to prevent the circula-

tion of cooled air back to the front seats.

AC608058

To front door window

(Side defroster)

Side ventilator

Center ventilatorTo windshield (Defroster)

To front door window

(Side defroster)

To passenger seat footwell

To driver seat footwell

To rear seat footwell

(Vehicle with rear duct)

To rear seat footwell

(Vehicle with rear duct)

Side ventilator

AB

Page 43 of 241

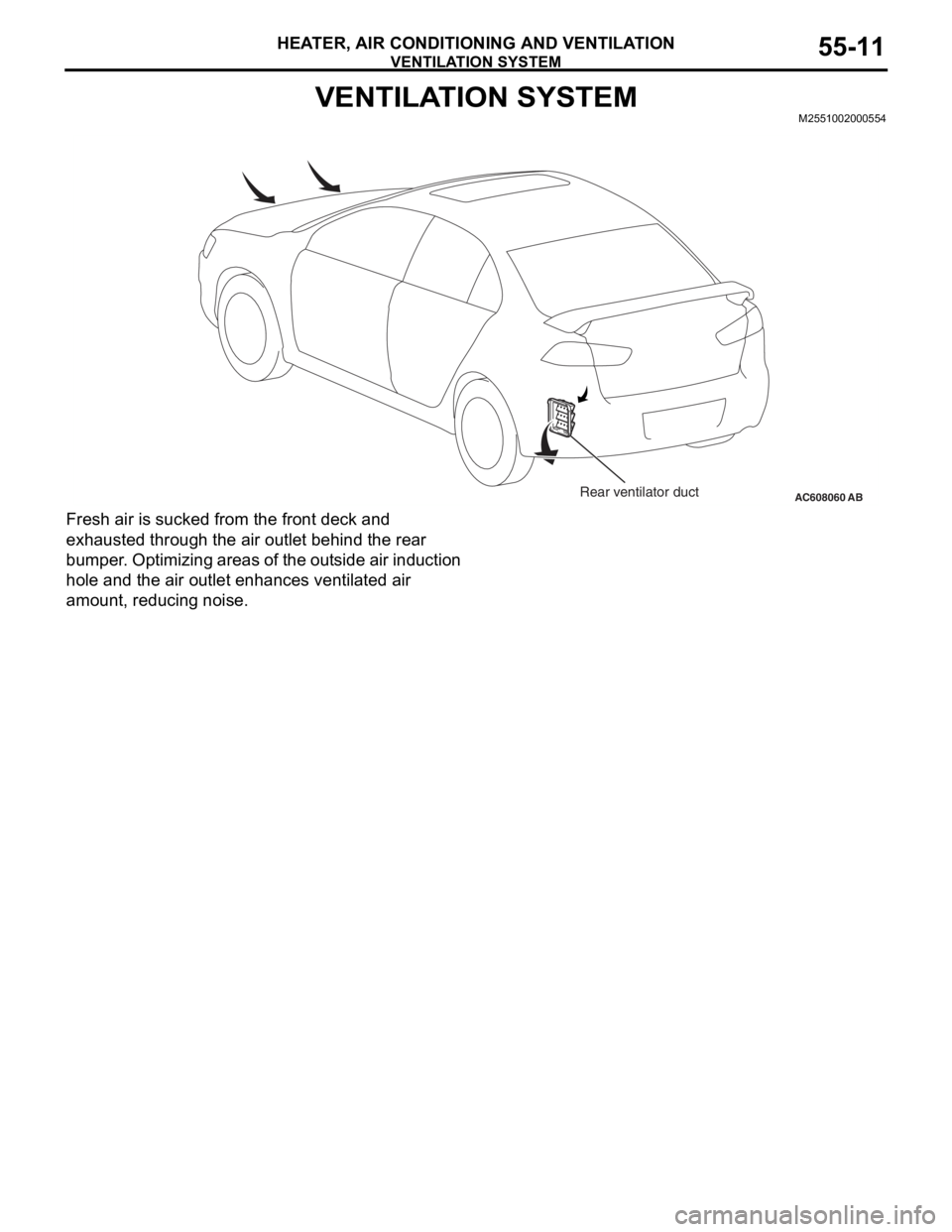

VENTILATION SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-11

VENTILATION SYSTEMM2551002000554

Fresh air is sucked from the front deck and

exhausted through the air outlet behind the rear

bumper. Optimizing areas of the outside air induction

hole and the air outlet enhances ventilated air

amount, reducing noise.

AC608060Rear ventilator ductAB

Page 72 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-10

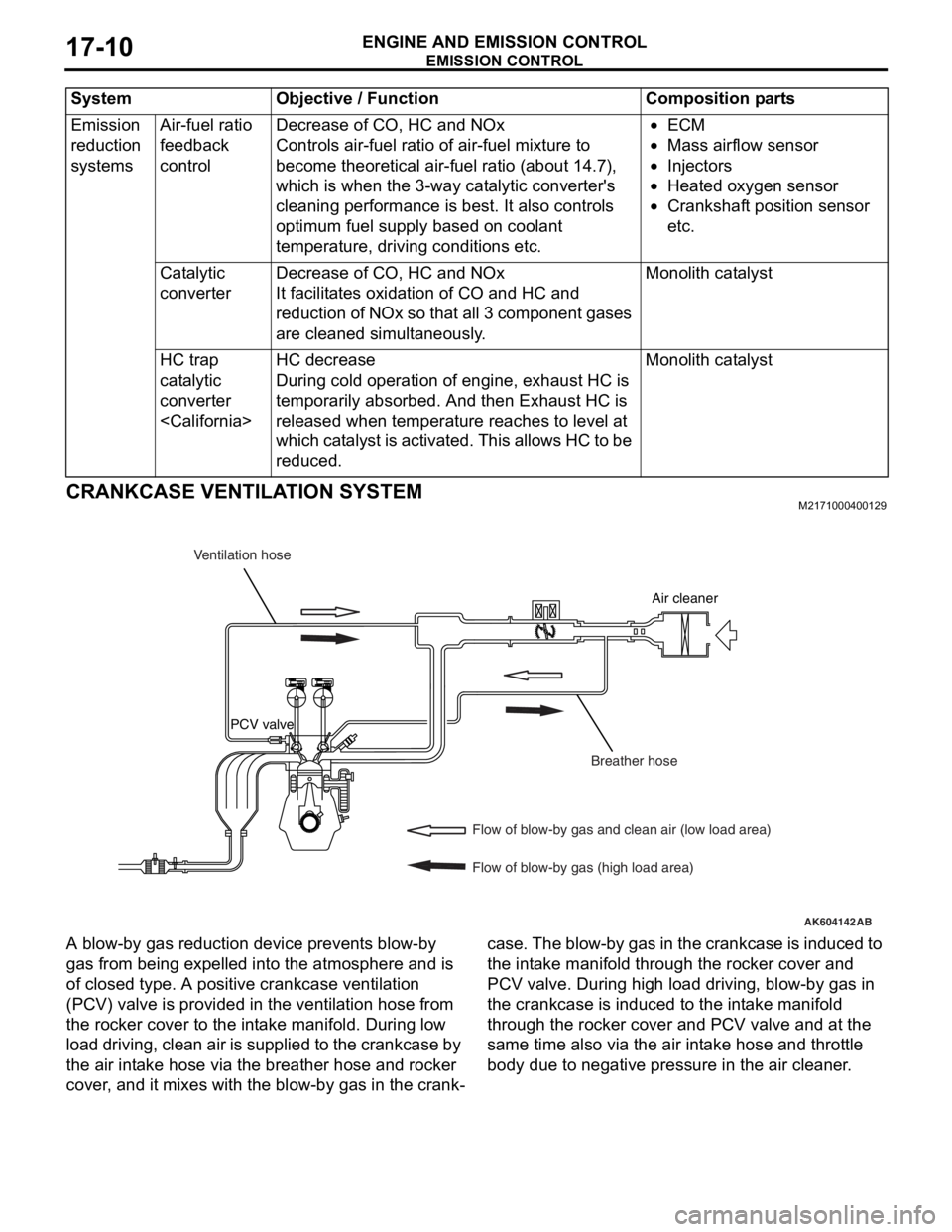

CRANKCASE VENTILATION SYSTEMM2171000400129

A blow-by gas reduction device prevents blow-by

gas from being expelled into the atmosphere and is

of closed type. A positive crankcase ventilation

(PCV) valve is provided in the ventilation hose from

the rocker cover to the intake manifold. During low

load driving, clean air is supplied to the crankcase by

the air intake hose via the breather hose and rocker

cover, and it mixes with the blow-by gas in the crank

-

case. The blow-by gas in the crankcase is induced to

the intake manifold through the rocker cover and

PCV valve. During high load driving, blow-by gas in

the crankcase is induced to the intake manifold

through the rocker cover and PCV valve and at the

same time also via the air intake hose and throttle

body due to negative pressure in the air cleaner.

Emission

reduction

systemsAir-fuel ratio

feedback

controlDecrease of CO, HC and NOx

Controls air-fuel ratio of air-fuel mixture to

become theoretical air-fuel ratio (about 14.7),

which is when the 3-way catalytic converter's

cleaning performance is best. It also controls

optimum fuel supply based on coolant

temperature, driving conditions etc.

•ECM

•Mass airflow sensor

•Injectors

•Heated oxygen sensor

•Crankshaft position sensor

etc.

Catalytic

converterDecrease of CO, HC and NOx

It facilitates oxidation of CO and HC and

reduction of NOx so that all 3 component gases

are cleaned simultaneously.

Monolith catalyst

HC trap

catalytic

converter

During cold operation of engine, exhaust HC is

temporarily absorbed. And then Exhaust HC is

released when temperature reaches to level at

which catalyst is activated. This allows HC to be

reduced.

Monolith catalyst

System Objective / Function Composition parts

AK604142

Air cleaner

PCV valve

AB

Ventilation hose

Breather hose

Flow of blow-by gas and clean air (low load area)

Flow of blow-by gas (high load area)

Page 74 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

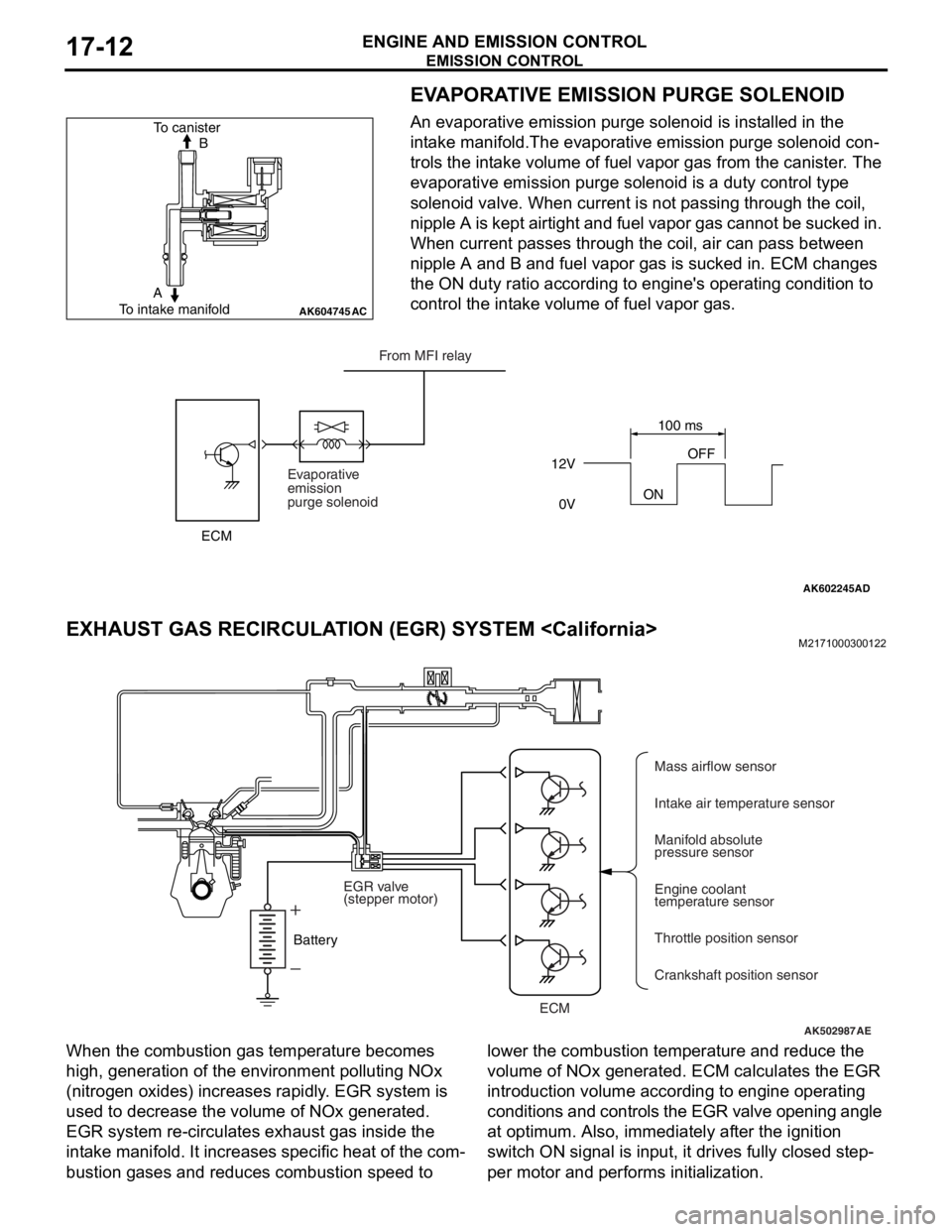

EVAPORATIVE EMISSION PURGE SOLENOID

An evaporative emission purge solenoid is installed in the

intake manifold.The evaporative emission purge solenoid con

-

trols the intake volume of fuel vapor gas from the canister. The

evaporative emission purge solenoid is a duty control type

solenoid valve. When current is not passing through the coil,

nipple A is kept airtight and fuel vapor gas cannot be sucked in.

When current passes through the coil, air can pass between

nipple A and B and fuel vapor gas is sucked in. ECM changes

the ON duty ratio according to engine's operating condition to

control the intake volume of fuel vapor gas.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

When the combustion gas temperature becomes

high, generation of the environment polluting NOx

(nitrogen oxides) increases rapidly. EGR system is

used to decrease the volume of NOx generated.

EGR system re-circulates exhaust gas inside the

intake manifold. It increases specific heat of the com

-

bustion gases and reduces combustion speed to lower the combustion temperature and reduce the

volume of NOx generated. ECM calculates the EGR

introduction volume according to engine operating

conditions and controls the EGR valve opening angle

at optimum. Also, immediately after the ignition

switch ON signal is input, it drives fully closed step

-

per motor and performs initialization.

AK604745AC

B To canister

To intake manifoldA

AK602245AD

12V

ONOFF

0V100 ms

Evaporative

emission

purge solenoidFrom MFI relay

ECM

AK502987AE

ECMMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Throttle position sensor

Crankshaft position sensor BatteryEGR valve

(stepper motor)

Page 120 of 241

ACTUATOR

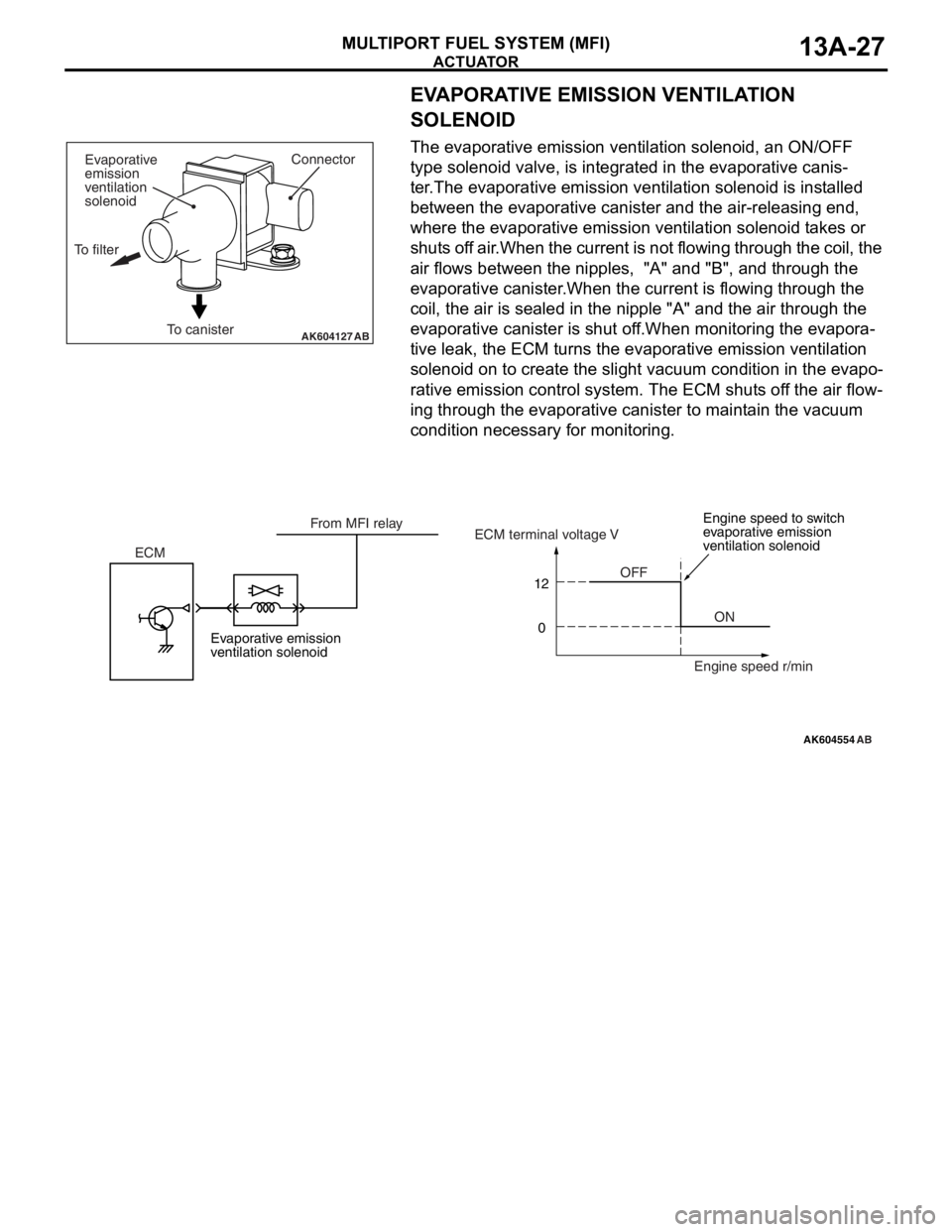

MULTIPORT FUEL SYSTEM (MFI)13A-27

EVAPORATIVE EMISSION VENTILATION

SOLENOID

The evaporative emission ventilation solenoid, an ON/OFF

type solenoid valve, is integrated in the evaporative canis

-

ter.The evaporative emission ventilation solenoid is installed

between the evaporative canister and the air-releasing end,

where the evaporative emission ventilation solenoid takes or

shuts off air.When the current is not flowing through the coil, the

air flows between the nipples, "A" and "B", and through the

evaporative canister.When the current is flowing through the

coil, the air is sealed in the nipple "A" and the air through the

evaporative canister is shut off.When monitoring the evapora

-

tive leak, the ECM turns the evaporative emission ventilation

solenoid on to create the slight vacuum condition in the evapo

-

rative emission control system. The ECM shuts off the air flow-

ing through the evaporative canister to maintain the vacuum

condition necessary for monitoring.

AK604127ABTo canisterConnector

Evaporative

emission

ventilation

solenoid

To filter

AK604554

12

0

AB

OFF

ON ECMECM terminal voltage V

Engine speed r/min From MFI relay

Evaporative emission

ventilation solenoidEngine speed to switch

evaporative emission

ventilation solenoid

Page 122 of 241

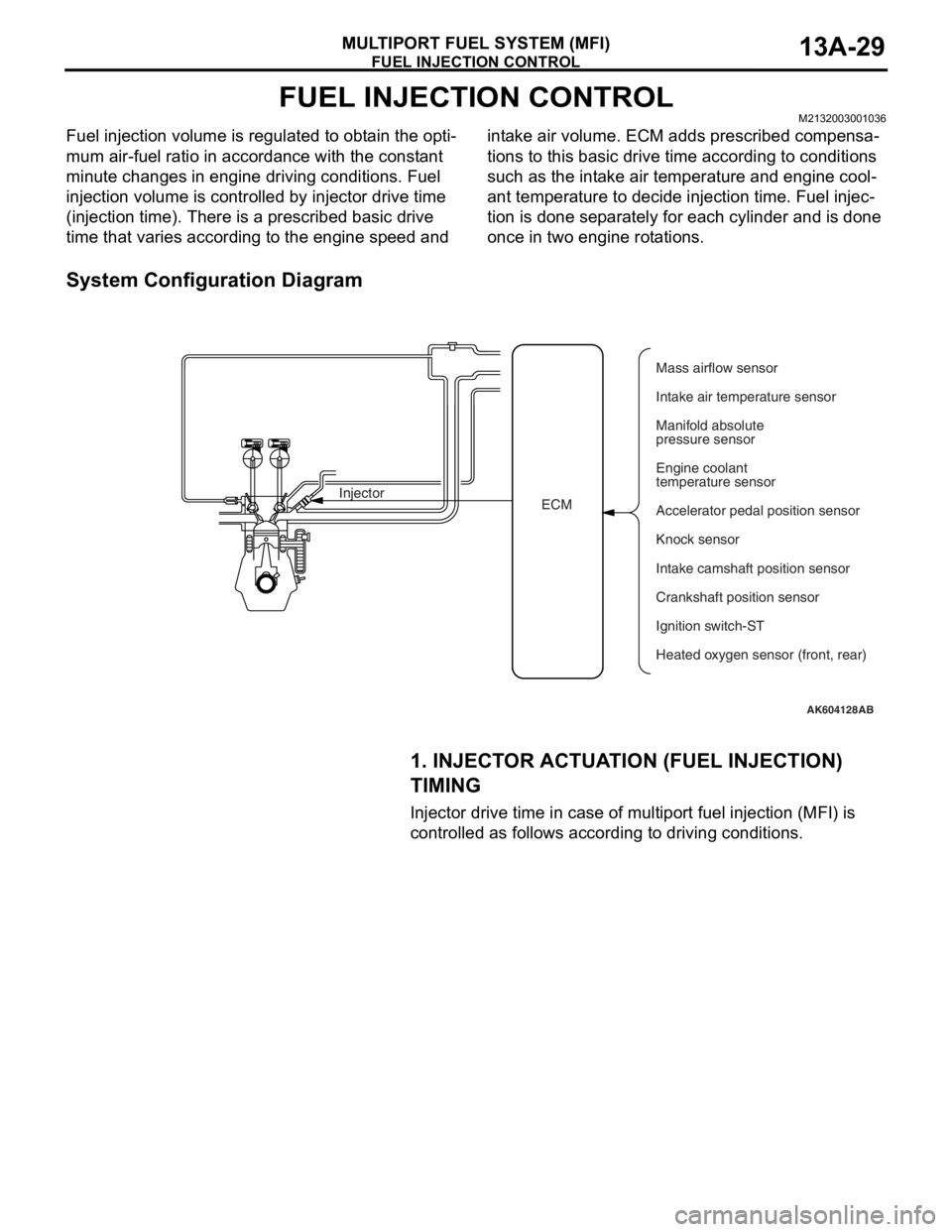

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-29

FUEL INJECTION CONTROLM2132003001036

Fuel injection volume is regulated to obtain the opti-

mum air-fuel ratio in accordance with the constant

minute changes in engine driving conditions. Fuel

injection volume is controlled by injector drive time

(injection time). There is a prescribed basic drive

time that varies according to the engine speed and intake air volume. ECM adds prescribed compensa

-

tions to this basic drive time according to conditions

such as the intake air temperature and engine cool

-

ant temperature to decide injection time. Fuel injec-

tion is done separately for each cylinder and is done

once in two engine rotations.

System Configuration Diagram

1. INJECTOR ACTUATION (FUEL INJECTION)

TIMING

Injector drive time in case of multiport fuel injection (MFI) is

controlled as follows according to driving conditions.

AK604128AB

ECM InjectorMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Accelerator pedal position sensor

Knock sensor

Intake camshaft position sensor

Ignition switch-ST

Heated oxygen sensor (front, rear) Crankshaft position sensor

Page 124 of 241

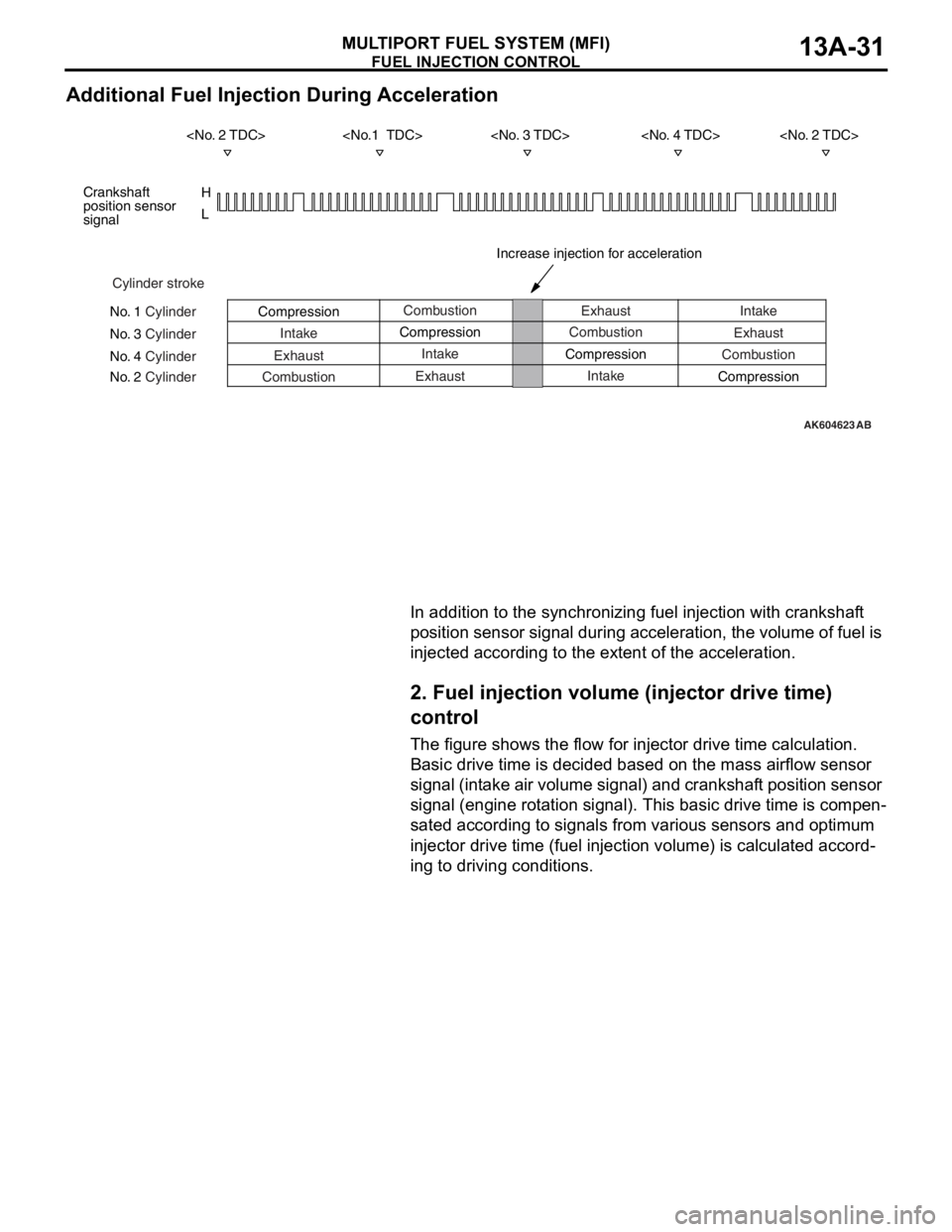

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-31

Additional Fuel Injection During Acceleration

In addition to the synchronizing fuel injection with crankshaft

position sensor signal during acceleration, the volume of fuel is

injected according to the extent of the acceleration.

2. Fuel injection volume (injector drive time)

control

The figure shows the flow for injector drive time calculation.

Basic drive time is decided based on the mass airflow sensor

signal (intake air volume signal) and crankshaft position sensor

signal (engine rotation signal). This basic drive time is compen

-

sated according to signals from various sensors and optimum

injector drive time (fuel injection volume) is calculated accord

-

ing to driving conditions.

AK604623

H

L

AB

Cylinder stroke

No. 1 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 2 CylinderCombustion

Intake

Exhaust

CombustionExhaust

Compression

Intake

Exhaust CompressionCombustion

Intake CompressionIntake

Exhaust

Combustion

Compression Crankshaft

position sensor

signal

Increase injection for acceleration

Page 127 of 241

![MITSUBISHI LANCER EVOLUTION X 2008 User Guide FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the o MITSUBISHI LANCER EVOLUTION X 2008 User Guide FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the o](/img/19/57326/w960_57326-126.png)

FUEL INJECTION CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-34

[Injector drive time compensation]

After calculating the injector basic drive time, the ECM makes

the following compensations to control the optimum fuel injec

-

tion volume according to driving conditions.

List of main compensations for fuel injection control

.

[Fuel limit control during deceleration]

ECM limits fuel when decelerating downhill to prevent exces-

sive rise of catalytic converter temperature and to improve fuel

efficiency.

.

[Fuel-cut control when over-run]

When engine speed exceeds a prescribed limit (6,600 r/min),

ECM cuts fuel supply to prevent overrunning and thus protect

the engine. Also, if engine speed exceeds 4,000 r/min for 15

seconds while vehicle is stationary (no load), it cuts fuel supply

and controls the throttle valve opening angle to protect the

engine.

CompensationsContent

Heated oxygen sensor feedback compensationThe heated oxygen sensor signal is used for

making the compensation to get air-fuel ratio with

best cleaning efficiency of the 3-way catalytic

converter. This compensation might not be made

sometimes in order to improve drivability,

depending on driving conditions. (Air-fuel ratio

compensation is made.)

Air-fuel ratio compensationUnder driving conditions where heated oxygen

sensor feedback compensation is not performed,

compensation is made based on pre-set map

values that vary according to engine speed and

intake air volume.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature, the greater the fuel injection volume.

Acceleration/ Deceleration compensationCompensation is made according to change in

intake air volume. During acceleration, fuel injection

volume is increased. Also, during deceleration, fuel

injection volume is decreased.

Fuel injection compensationCompensation is made according to the pressure

difference between atmospheric pressure and

manifold absolute pressure. The greater the

difference in pressure, the shorter the injector drive

time.

Battery voltage compensationCompensation is made depending on battery

voltage. The lower the battery voltage, the greater

the injector drive signal time.

Learning value for fuel compensationCompensation amount is learned to compensate

feedback of heated oxygen sensor. This allows

system to compensate in accordance with engine

characteristics.

Page 128 of 241

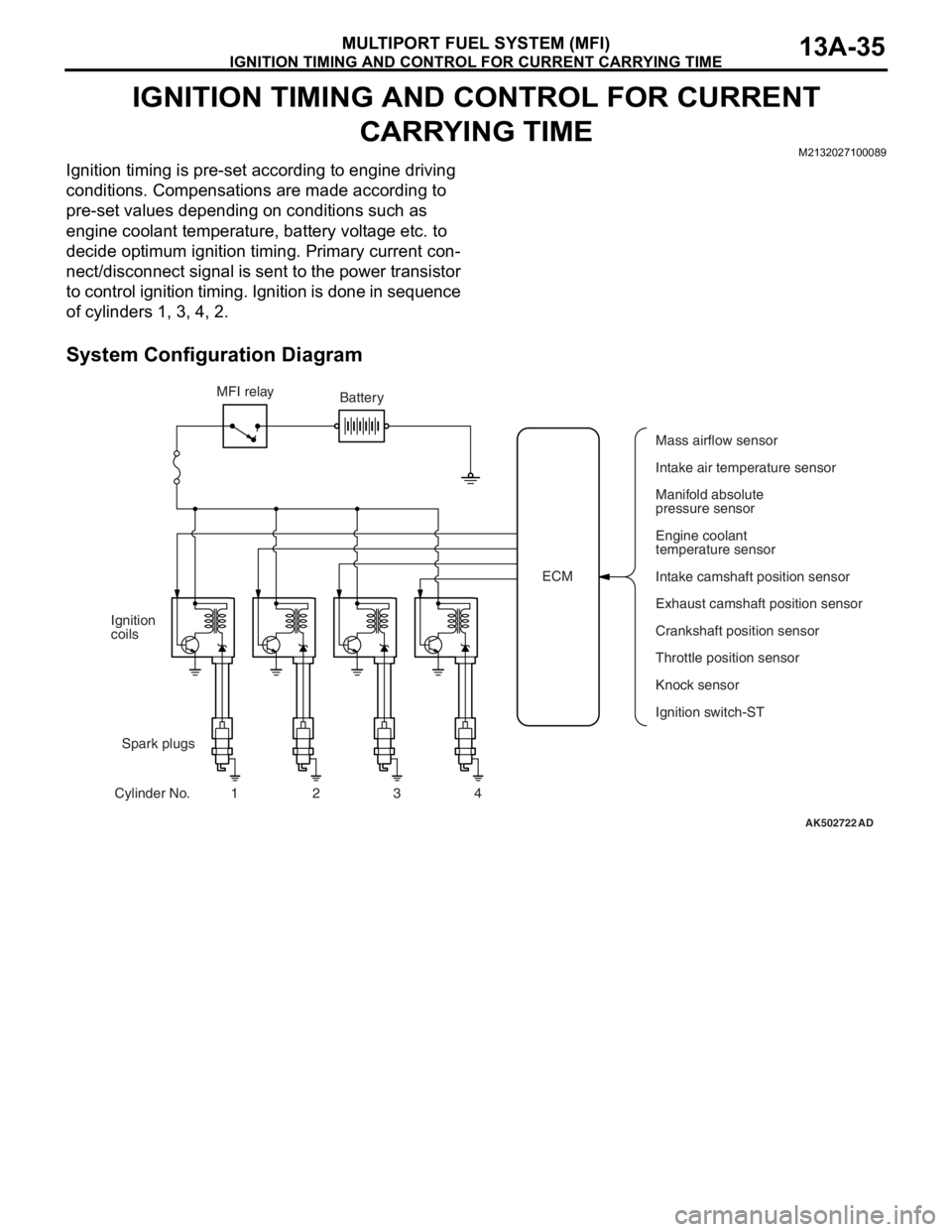

IGNITION TIMING AND CONTROL FOR CURRENT CARRYING TIME

MULTIPORT FUEL SYSTEM (MFI)13A-35

IGNITION TIMING AND CONTROL FOR CURRENT

CARRYING TIME

M2132027100089

Ignition timing is pre-set according to engine driving

conditions. Compensations are made according to

pre-set values depending on conditions such as

engine coolant temperature, battery voltage etc. to

decide optimum ignition timing. Primary current con

-

nect/disconnect signal is sent to the power transistor

to control ignition timing. Ignition is done in sequence

of cylinders 1, 3, 4, 2.

System Configuration Diagram

AK502722AD

ECM MFI relay

Spark plugs Ignition

coils

Cylinder No. 1 2 3 4Battery

Mass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Intake camshaft position sensor

Exhaust camshaft position sensor

Crankshaft position sensor

Knock sensor

Ignition switch-ST Throttle position sensor

Page 137 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-44

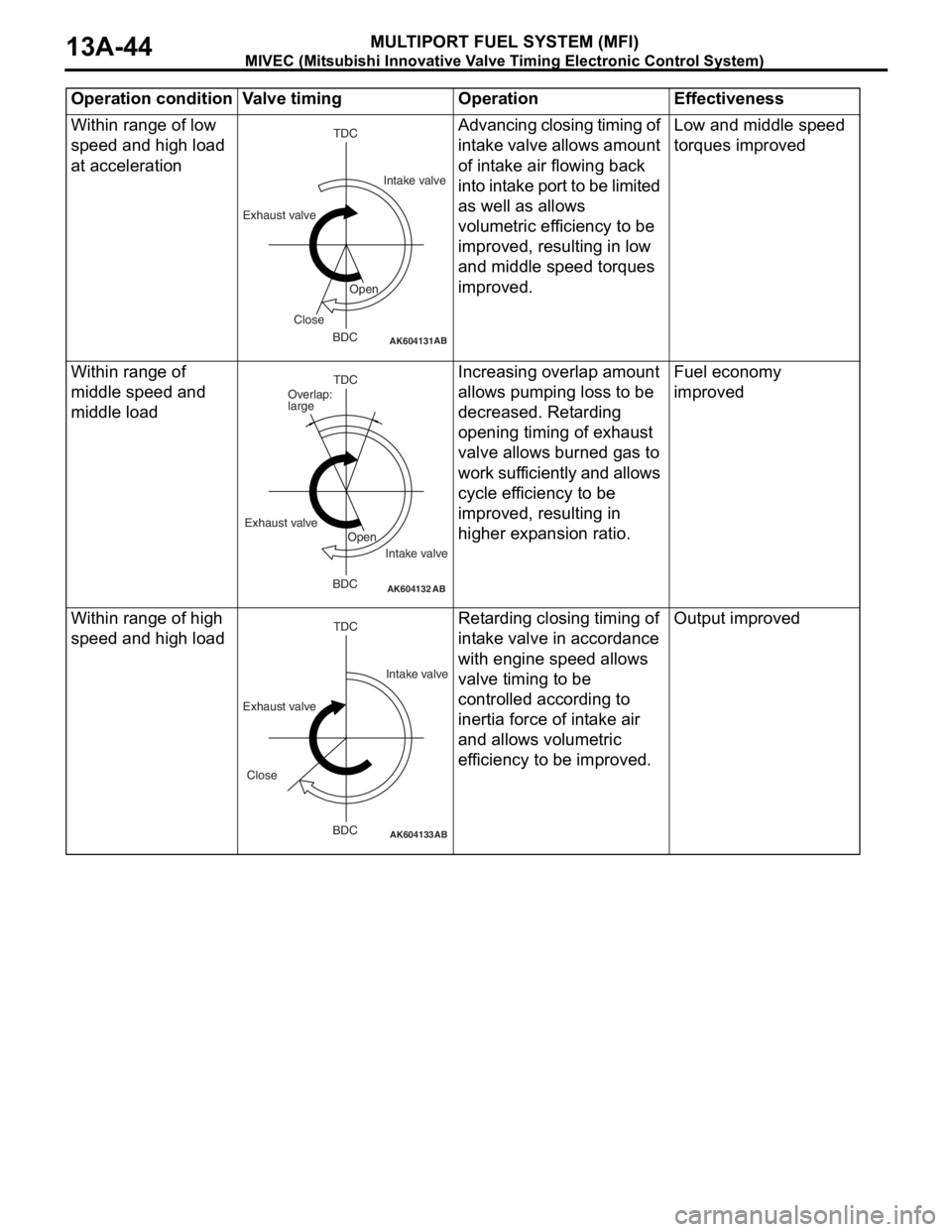

Within range of low

speed and high load

at accelerationAdvancing closing timing of

intake valve allows amount

of intake air flowing back

into intake port to be limited

as well as allows

volumetric efficiency to be

improved, resulting in low

and middle speed torques

improved.Low and middle speed

torques improved

Within range of

middle speed and

middle loadIncreasing overlap amount

allows pumping loss to be

decreased. Retarding

opening timing of exhaust

valve allows burned gas to

work sufficiently and allows

cycle efficiency to be

improved, resulting in

higher expansion ratio.Fuel economy

improved

Within range of high

speed and high loadRetarding closing timing of

intake valve in accordance

with engine speed allows

valve timing to be

controlled according to

inertia force of intake air

and allows volumetric

efficiency to be improved.Output improved

Operation condition Valve timing Operation Effectiveness

AK604131AB

TDC

BDC Exhaust valveIntake valve

Open

Close

AK604132AB

TDC

BDC Exhaust valve

Intake valve Overlap:

large

Open

AK604133

TDC

BDC

AB

Exhaust valveIntake valve

Close