relay MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 10 of 241

AUDIO SYSTEM

TSB Revision

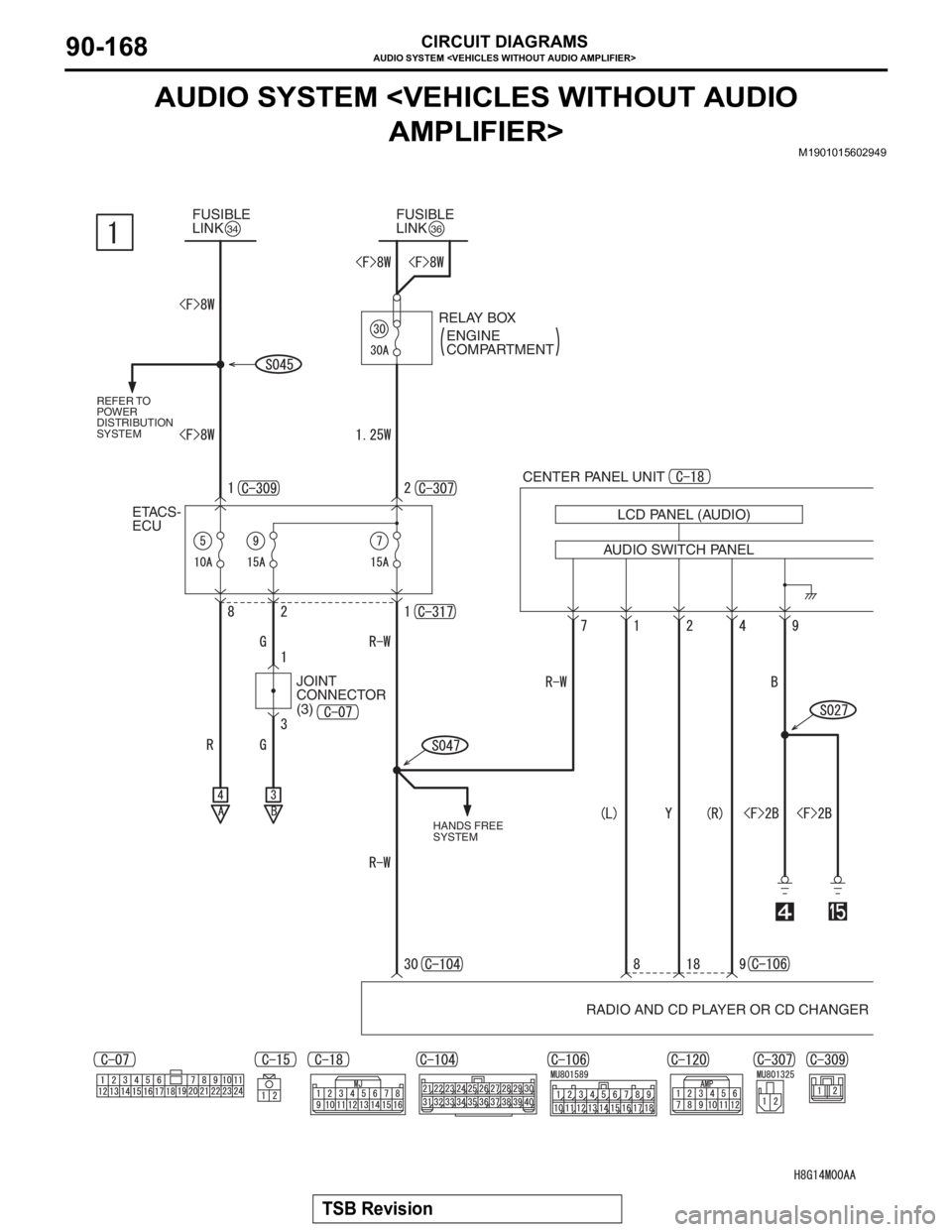

CIRCUIT DIAGRAMS90-168

AUDIO SYSTEM

M1901015602949

FUSIBLE

LINK34FUSIBLE

LINK36

REFER TO

POWER

DISTRIBUTION

SYSTEM

CENTER PANEL UNIT

ETACS-

ECU

AUDIO SWITCH PANELLCD PANEL (AUDIO)

RADIO AND CD PLAYER OR CD CHANGER RELAY BOX

ENGINE

COMPARTMENT

HANDS FREE

SYSTEM

JOINT

CONNECTOR

(3)

Page 11 of 241

AUDIO SYSTEM

TSB Revision

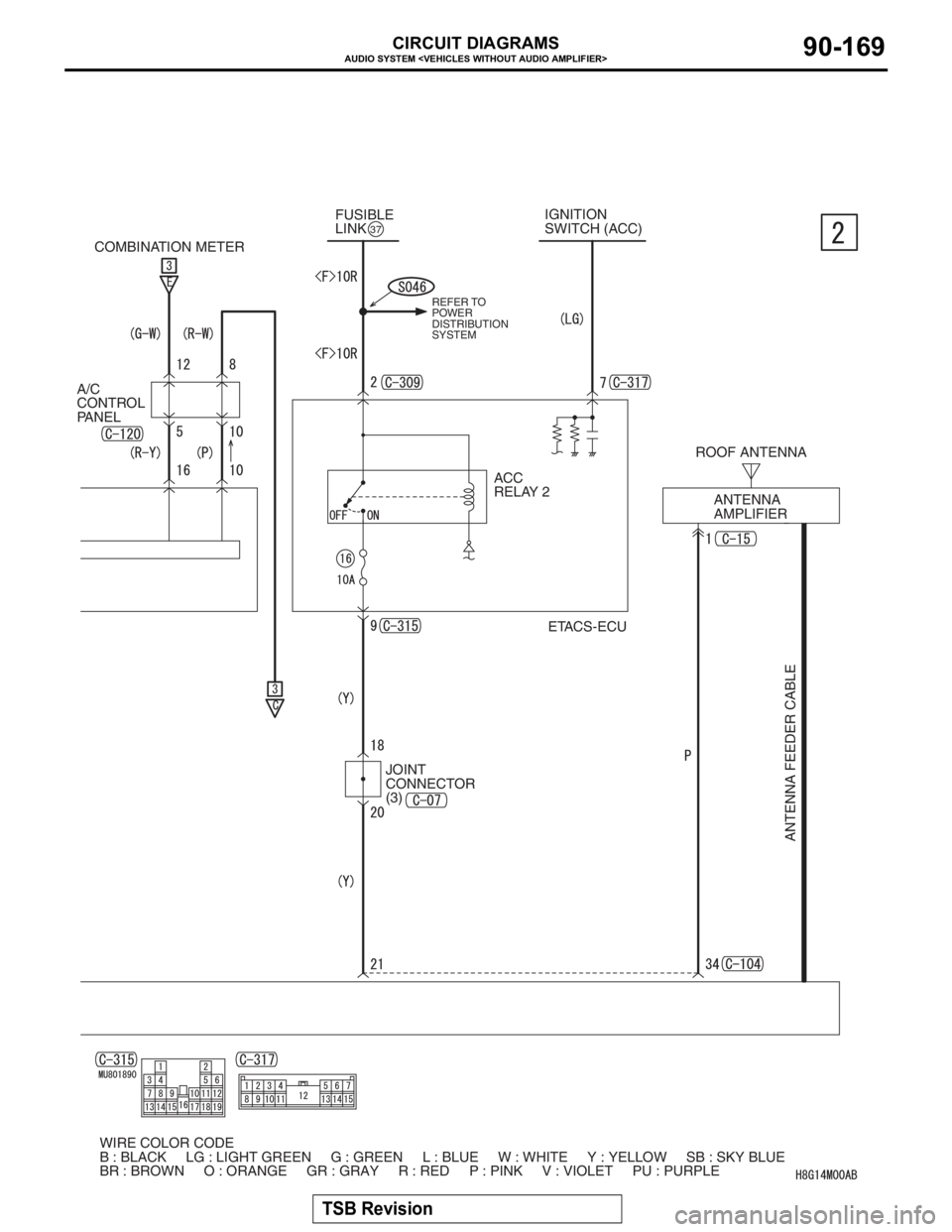

CIRCUIT DIAGRAMS90-169

FUSIBLE

LINK37

ACC

RELAY 2ROOF ANTENNA

ANTENNA

AMPLIFIER

ANTENNA FEEDER CABLE

ETACS-ECU IGNITION

SWITCH (ACC)

REFER TO

POWER

DISTRIBUTION

SYSTEM

WIRE COLOR CODE

B : BLACK LG : LIGHT GREEN G : GREEN L : BLUE W : WHITE Y : YELLOW SB : SKY BLUE

BR : BROWN O : ORANGE GR : GRAY R : RED P : PINK V : VIOLET PU : PURPLE COMBINATION METER

A/C

CONTROL

PANEL

JOINT

CONNECTOR

(3)

Page 17 of 241

AUDIO SYSTEM

TSB Revision

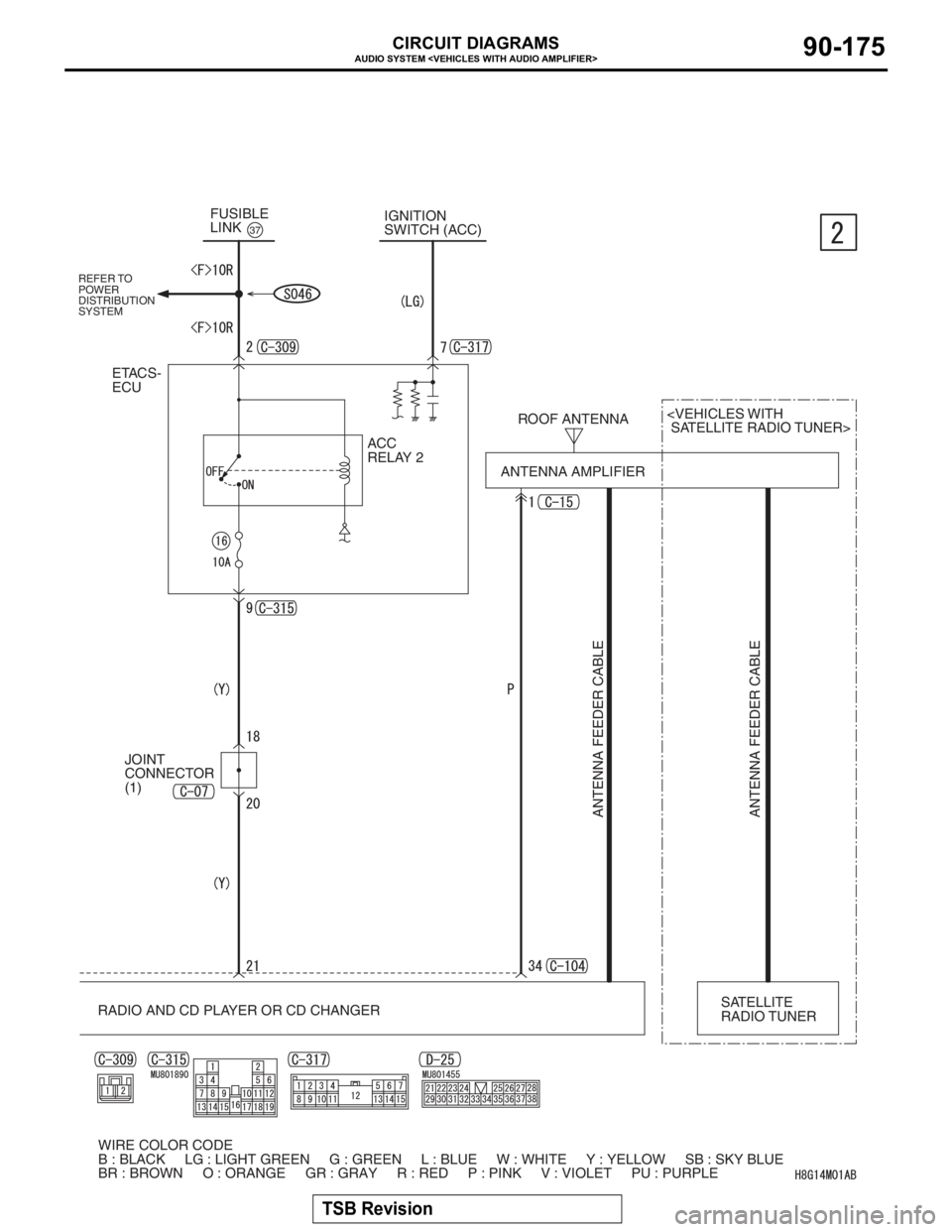

CIRCUIT DIAGRAMS90-175

ACC

RELAY 2 FUSIBLE

LINK

37

ROOF ANTENNA

ANTENNA AMPLIFIER

ANTENNA FEEDER CABLE ANTENNA FEEDER CABLE

ETACS-

ECU

RADIO AND CD PLAYER OR CD CHANGER

SWITCH (ACC)

SATELLITE

RADIO TUNER

WIRE COLOR CODE

B : BLACK LG : LIGHT GREEN G : GREEN L : BLUE W : WHITE Y : YELLOW SB : SKY BLUE

BR : BROWN O : ORANGE GR : GRAY R : RED P : PINK V : VIOLET PU : PURPLEJOINT

CONNECTOR

(1)

REFER TO

POWER

DISTRIBUTION

SYSTEM

Page 26 of 241

CLOCK

TSB Revision

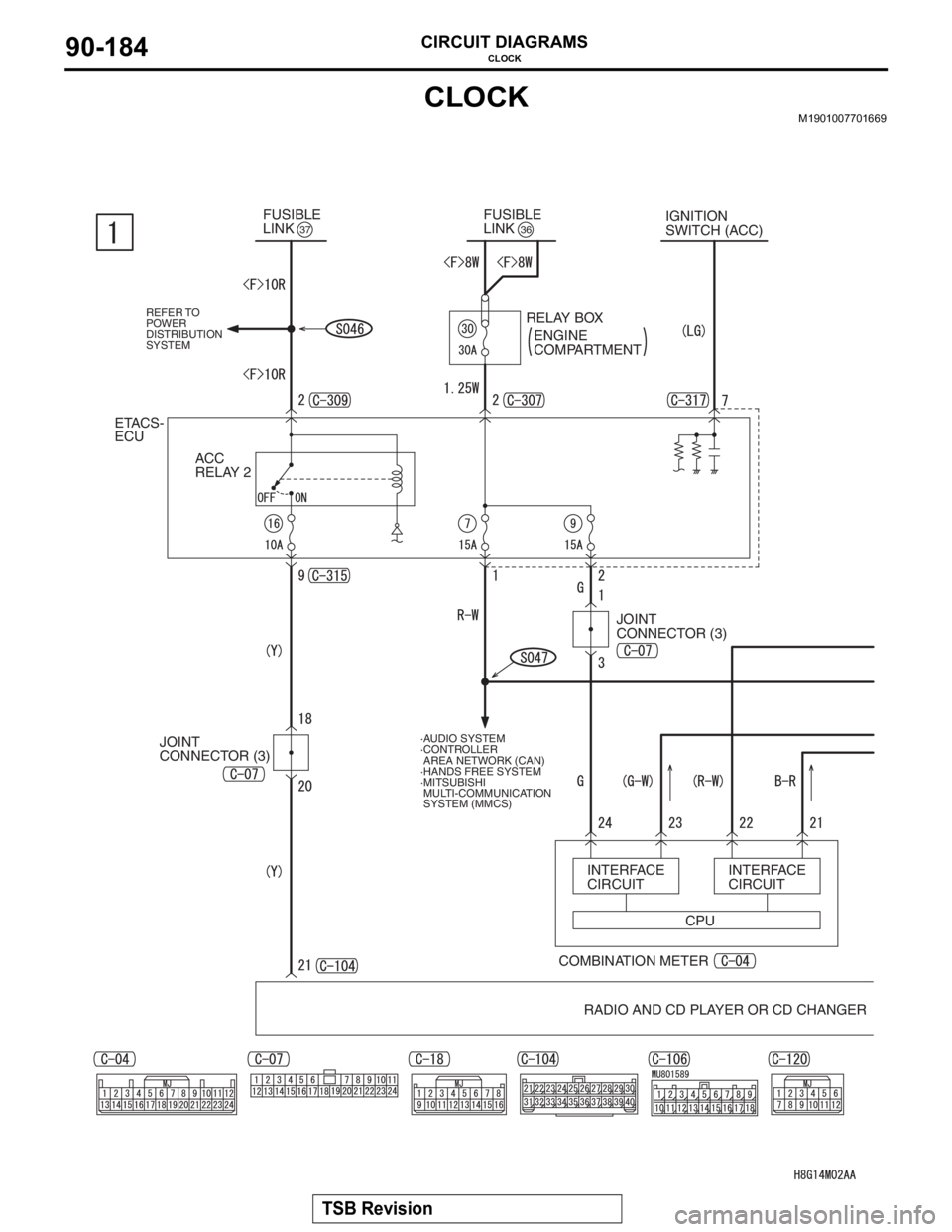

CIRCUIT DIAGRAMS90-184

CLOCKM1901007701669

ETACS-

ECU

ACC

RELAY 2

37FUSIBLE

LINK36FUSIBLE

LINK

RELAY BOX

ENGINE

COMPARTMENTIGNITION

SWITCH (ACC)

RADIO AND CD PLAYER OR CD CHANGER COMBINATION METERINTERFACE

CIRCUIT

·AUDIO SYSTEM

·CONTROLLER

AREA NETWORK (CAN)

·HANDS FREE SYSTEM

·MITSUBISHI

MULTI-COMMUNICATION

SYSTEM (MMCS)

CPUINTERFACE

CIRCUIT JOINT

CONNECTOR (3)

REFER TO

POWER

DISTRIBUTION

SYSTEM

JOINT

CONNECTOR (3)

Page 27 of 241

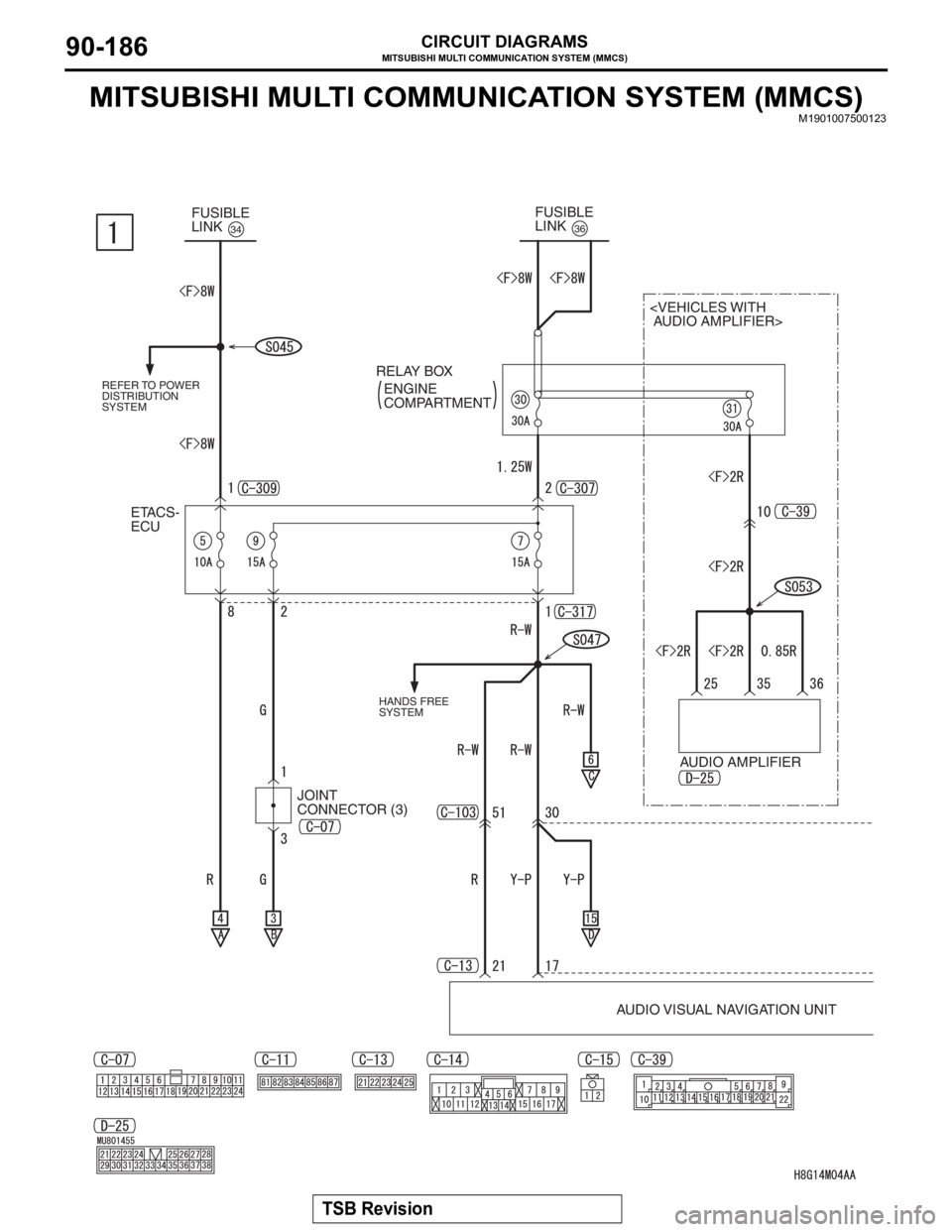

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

TSB Revision

CIRCUIT DIAGRAMS90-186

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)M1901007500123

FUSIBLE

LINK34

ETACS-

ECUFUSIBLE

LINK

36

AUDIO AMPLIFIER

AUDIO VISUAL NAVIGATION UNIT RELAY BOX

ENGINE

COMPARTMENT

HANDS FREE

SYSTEM REFER TO POWER

DISTRIBUTION

SYSTEM

JOINT

CONNECTOR (3)

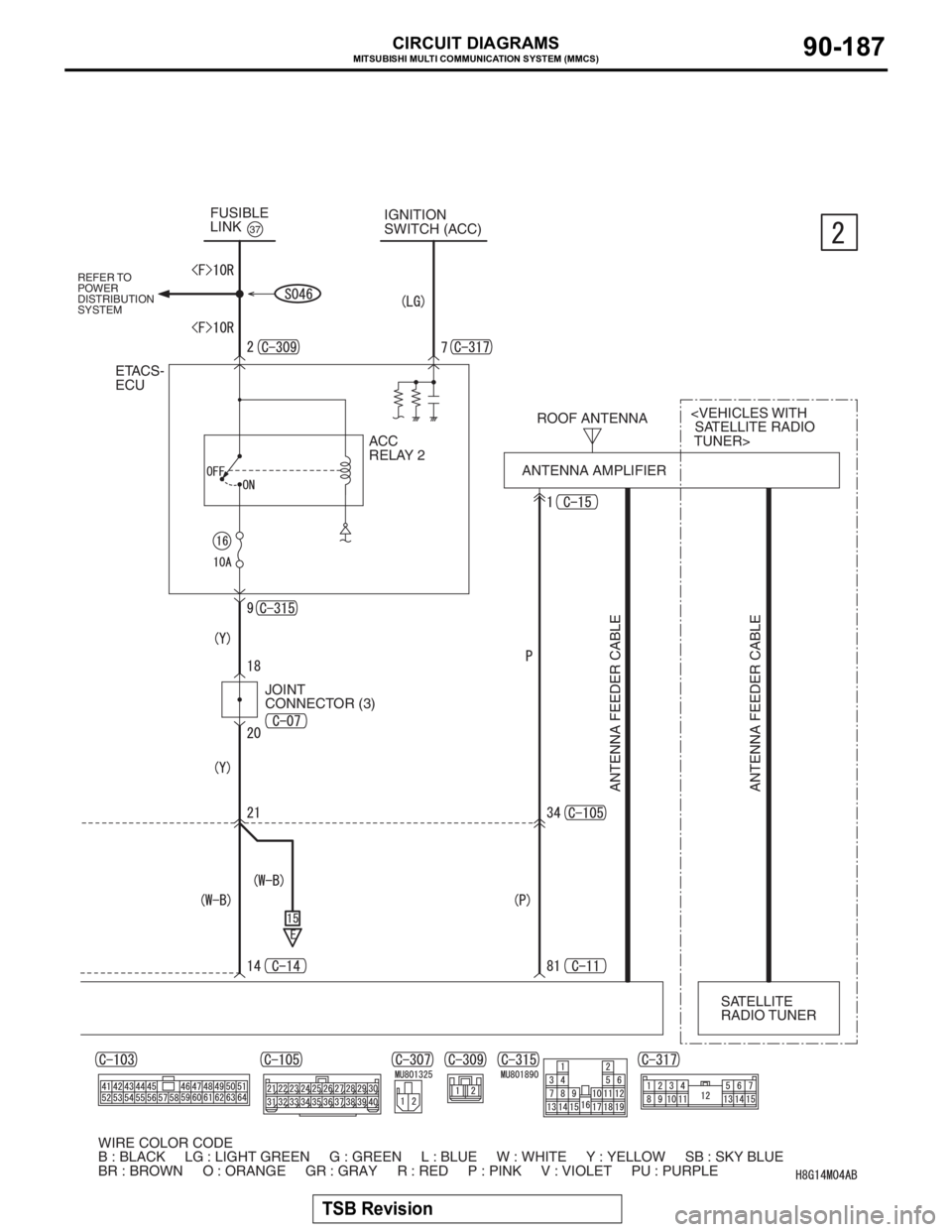

Page 28 of 241

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

TSB Revision

CIRCUIT DIAGRAMS90-187

ACC

RELAY 2 FUSIBLE

LINK

37

ROOF ANTENNA

ANTENNA AMPLIFIER

ANTENNA FEEDER CABLE ANTENNA FEEDER CABLE

ETACS-

ECU

TUNER> IGNITION

SWITCH (ACC)

SATELLITE

RADIO TUNER

WIRE COLOR CODE

B : BLACK LG : LIGHT GREEN G : GREEN L : BLUE W : WHITE Y : YELLOW SB : SKY BLUE

BR : BROWN O : ORANGE GR : GRAY R : RED P : PINK V : VIOLET PU : PURPLE

REFER TO

POWER

DISTRIBUTION

SYSTEM

JOINT

CONNECTOR (3)

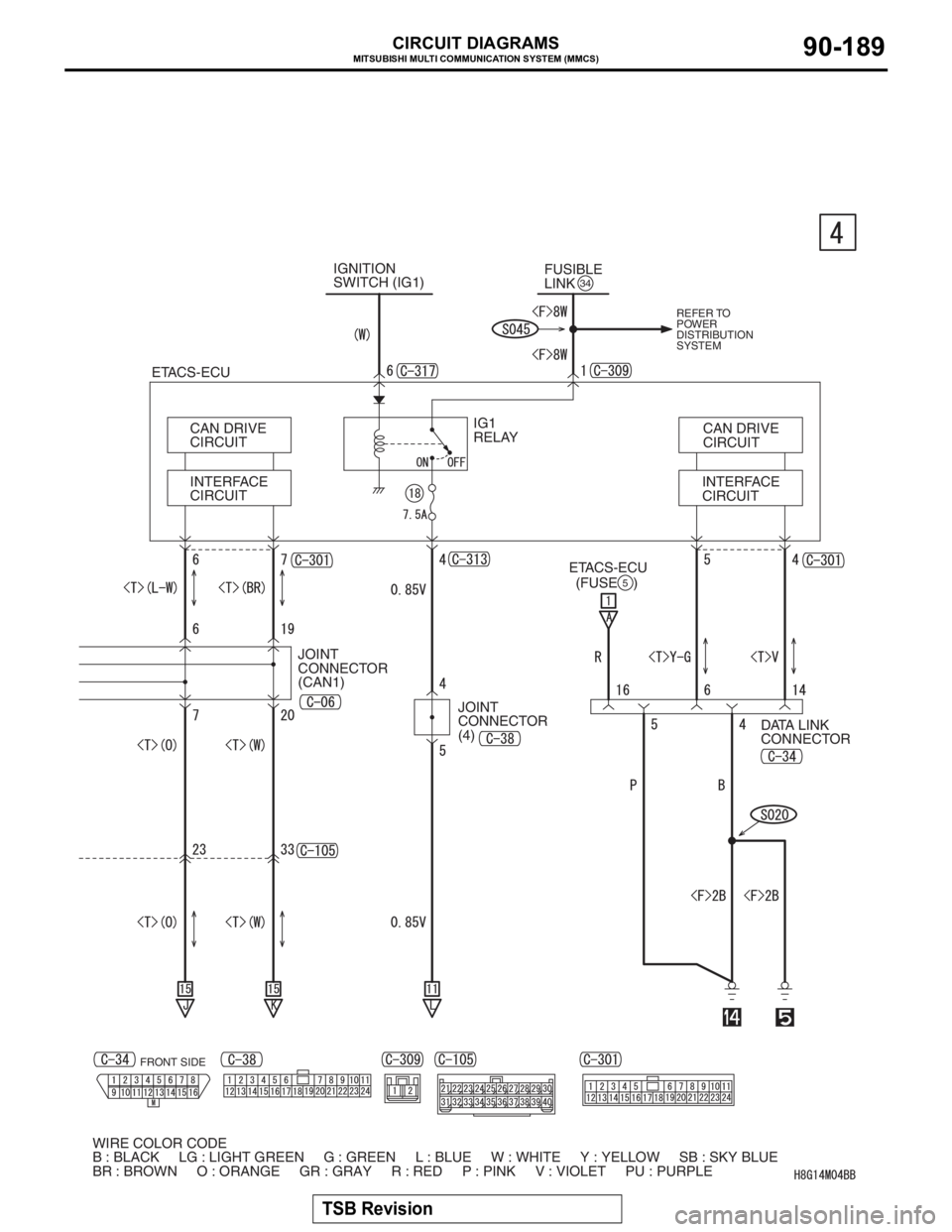

Page 30 of 241

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

TSB Revision

CIRCUIT DIAGRAMS90-189

INTERFACE

CIRCUITCAN DRIVE

CIRCUIT

DATA LINK

CONNECTOR ETACS-ECU

INTERFACE

CIRCUIT CAN DRIVE

CIRCUIT

ETACS-ECU

(FUSE )

5

WIRE COLOR CODE

B : BLACK LG : LIGHT GREEN G : GREEN L : BLUE W : WHITE Y : YELLOW SB : SKY BLUE

BR : BROWN O : ORANGE GR : GRAY R : RED P : PINK V : VIOLET PU : PURPLEJOINT

CONNECTOR

(CAN1)FUSIBLE

LINK

34IGNITION

SWITCH (IG1)

IG1

RELAY

REFER TO

POWER

DISTRIBUTION

SYSTEM

JOINT

CONNECTOR

(4)

FRONT SIDE

Page 73 of 241

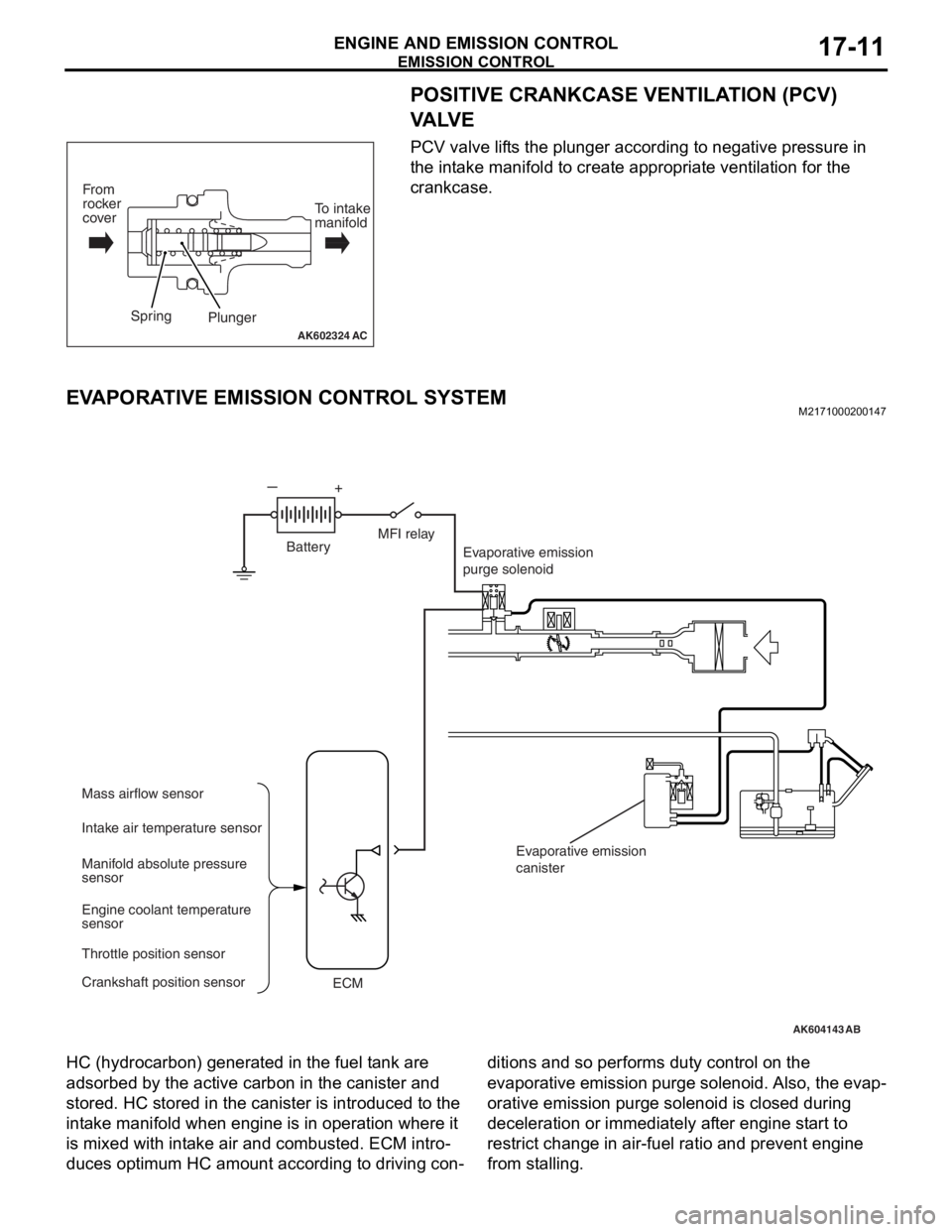

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-11

POSITIVE CRANKCASE VENTILATION (PCV)

VA LV E

PCV valve lifts the plunger according to negative pressure in

the intake manifold to create appropriate ventilation for the

crankcase.

EVAPORATIVE EMISSION CONTROL SYSTEMM2171000200147

HC (hydrocarbon) generated in the fuel tank are

adsorbed by the active carbon in the canister and

stored. HC stored in the canister is introduced to the

intake manifold when engine is in operation where it

is mixed with intake air and combusted. ECM intro

-

duces optimum HC amount according to driving con-

ditions and so performs duty control on the

evaporative emission purge solenoid. Also, the evap

-

orative emission purge solenoid is closed during

deceleration or immediately after engine start to

restrict change in air-fuel ratio and prevent engine

from stalling.

AK602324AC

Plunger

From

rocker

coverTo intake

manifold

Spring

AK604143

Evaporative emission

purge solenoid

Mass airflow sensor

ECM Intake air temperature sensor

Manifold absolute pressure

sensor

Engine coolant temperature

sensor

Throttle position sensor

Crankshaft position sensorEvaporative emission

canister

AB

MFI relay

Battery

Page 74 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-12

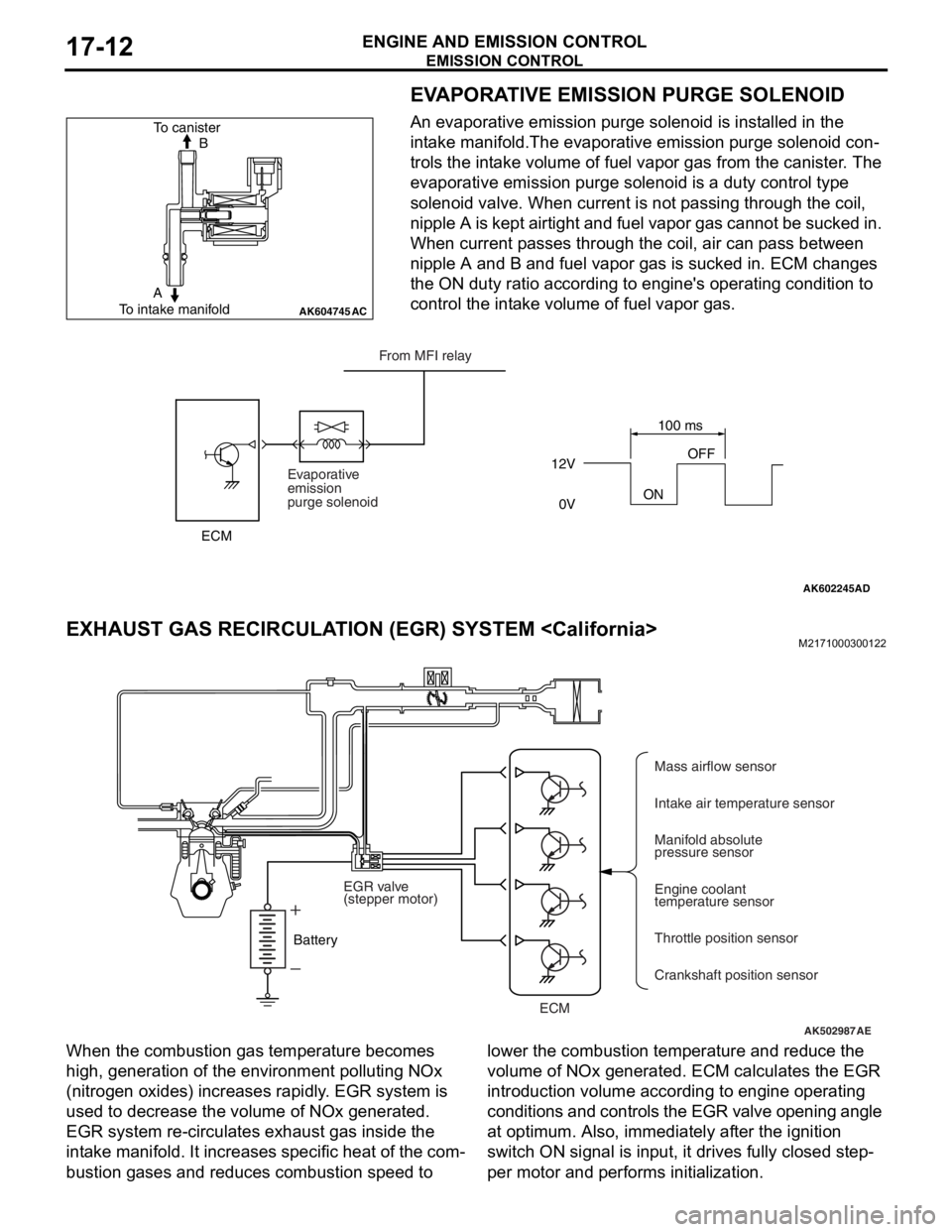

EVAPORATIVE EMISSION PURGE SOLENOID

An evaporative emission purge solenoid is installed in the

intake manifold.The evaporative emission purge solenoid con

-

trols the intake volume of fuel vapor gas from the canister. The

evaporative emission purge solenoid is a duty control type

solenoid valve. When current is not passing through the coil,

nipple A is kept airtight and fuel vapor gas cannot be sucked in.

When current passes through the coil, air can pass between

nipple A and B and fuel vapor gas is sucked in. ECM changes

the ON duty ratio according to engine's operating condition to

control the intake volume of fuel vapor gas.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

When the combustion gas temperature becomes

high, generation of the environment polluting NOx

(nitrogen oxides) increases rapidly. EGR system is

used to decrease the volume of NOx generated.

EGR system re-circulates exhaust gas inside the

intake manifold. It increases specific heat of the com

-

bustion gases and reduces combustion speed to lower the combustion temperature and reduce the

volume of NOx generated. ECM calculates the EGR

introduction volume according to engine operating

conditions and controls the EGR valve opening angle

at optimum. Also, immediately after the ignition

switch ON signal is input, it drives fully closed step

-

per motor and performs initialization.

AK604745AC

B To canister

To intake manifoldA

AK602245AD

12V

ONOFF

0V100 ms

Evaporative

emission

purge solenoidFrom MFI relay

ECM

AK502987AE

ECMMass airflow sensor

Intake air temperature sensor

Manifold absolute

pressure sensor

Engine coolant

temperature sensor

Throttle position sensor

Crankshaft position sensor BatteryEGR valve

(stepper motor)

Page 75 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-13

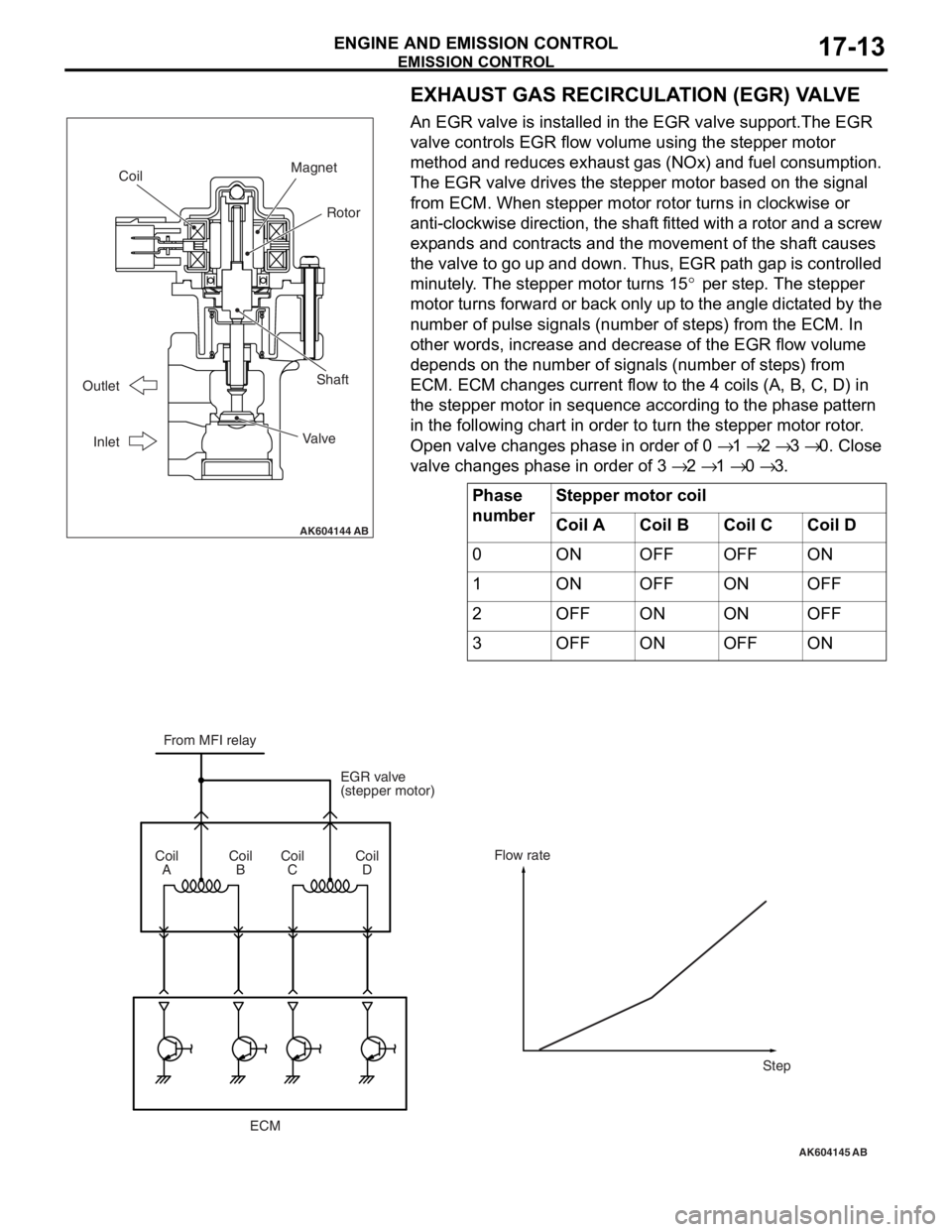

EXHAUST GAS RECIRCULATION (EGR) VALVE

An EGR valve is installed in the EGR valve support.The EGR

valve controls EGR flow volume using the stepper motor

method and reduces exhaust gas (NOx) and fuel consumption.

The EGR valve drives the stepper motor based on the signal

from ECM. When stepper motor rotor turns in clockwise or

anti-clockwise direction, the shaft fitted with a rotor and a screw

expands and contracts and the movement of the shaft causes

the valve to go up and down. Thus, EGR path gap is controlled

minutely. The stepper motor turns 15

° per step. The stepper

motor turns forward or back only up to the angle dictated by the

number of pulse signals (number of steps) from the ECM. In

other words, increase and decrease of the EGR flow volume

depends on the number of signals (number of steps) from

ECM. ECM changes current flow to the 4 coils (A, B, C, D) in

the stepper motor in sequence according to the phase pattern

in the following chart in order to turn the stepper motor rotor.

Open valve changes phase in order of 0

→ 1 → 2 → 3 → 0. Close

valve changes phase in order of 3

→ 2 → 1 → 0 → 3.

Phase

numberStepper motor coil

Coil ACoil BCoil CCoil D

0ONOFFOFFON

1ONOFFONOFF

2OFFONONOFF

3OFFONOFFON

AK604144

Coil

Shaft

Valve Outlet

Inlet

Rotor

Magnet

AB

AK604145

From MFI relay

EGR valve

(stepper motor)

ECM Coil

ACoil

BCoil

CCoil

DFlow rate

Step

AB