fuel consumption MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 39 of 241

A/C-ECU

HEATER, AIR CONDITIONING AND VENTILATION55-7

A/C-ECUM2551001200265

CONTROL

.

FORCED DEF CONTROL

When air outlet position is switched to DEF, A/C is

automatically turned ON, and outside/inside air

selection damper is set to the fresh air position to

quickly defrost the windshield screen.

.

MAX A/C CONTROL

When the temperature adjustment knob is turned to

the maximum A/C position with the blower knob at

position other than OFF, the following controls are

made by the A/C-ECU.

NOTE: "*" Manual operation is disabled during max

A/C control.

.

MAX COOL, MAX HOT CONTROL

When the set temperature is at 18.0 °C <61°F>

(MAX COOL) or at 32.0

°C <89°F> (MAX HOT) with

the air outlet and air volume at the AUTO positions,

the following controls are made automatically by the

A/C-ECU.

NOTE: "*" indicates that when the automatic control

is not cancelled using the customise function, the

manual operation is disabled.

.

REAR WINDOW DEFOGGER TIMER

CONTROL

In order to prevent battery consumption, the defog-

ger is automatically turned OFF, 20 minutes after it is

turned ON.

.

IDLE-UP CONTROL

A/C-ECU and the engine ECU communicate with

each other through the CAN communication. The

idle-up speed of the engine is controlled in two steps

depending on the A/C load to secure the air cooling

performance during summer and to enhance fuel

economy in seasons with moderate temperature.

.

DETECTION CONTROL FOR

REFRIGERANT LEAKS

A/C-ECU determines if the refrigerant amount is less

than specified or refrigerant pressure is abnormal by

using the ambient temperature (ambient temperature

sensor to measure refrigerant inflation rate) and

refrigerant pressure (measured by the A/C pressure

sensor). When refrigerant amount or refrigerant pres

-

sure is judged abnormal, the compressor is cut-off to

protect the A/C system.

NOTE: When abnormality occurs, the A/C indicator

flashes.

.

PROTECTION CONTROL AT AIR BAG

DEPLOYMENT (DURING COLLISION)

When the air bag deployment is detected, the A/C

system is stopped.

.

CUSTOMISE FUNCTION

Depending on the user's preference, the following

functions can be selected. The programmed informa

-

tion is held even when the battery is disconnected.

•Automatic control for inside/outside air selection

Press and hold (approximately for 10 seconds)

the inside/outside air selection switch to cancel

the automatic control for inside/outside air selec

-

tion.

•A/C automatic control

Press and hold (approximately for 10 seconds)

the A/C switch to cancel the A/C automatic con

-

trol.

Subject to controlMAX COOL

Air mix damperMAX COOL position

Air outlet modeSelected position

Air volumeSelected position

Outside/inside air

selection damperAir recirculation position*

Air conditioner switchON*

Subject to

controlMAX COOLMAX HOT

Air mix

damperMAX COOL

positionMAX HOT

position

Air outlet

modeFACE positionFOOT position

Air volumeMaximumMaximum

Outside/insid

e air

selection

damperAir recirculation

position*Fresh air

position*

Air

conditioner

switchON*OFF*

Page 75 of 241

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-13

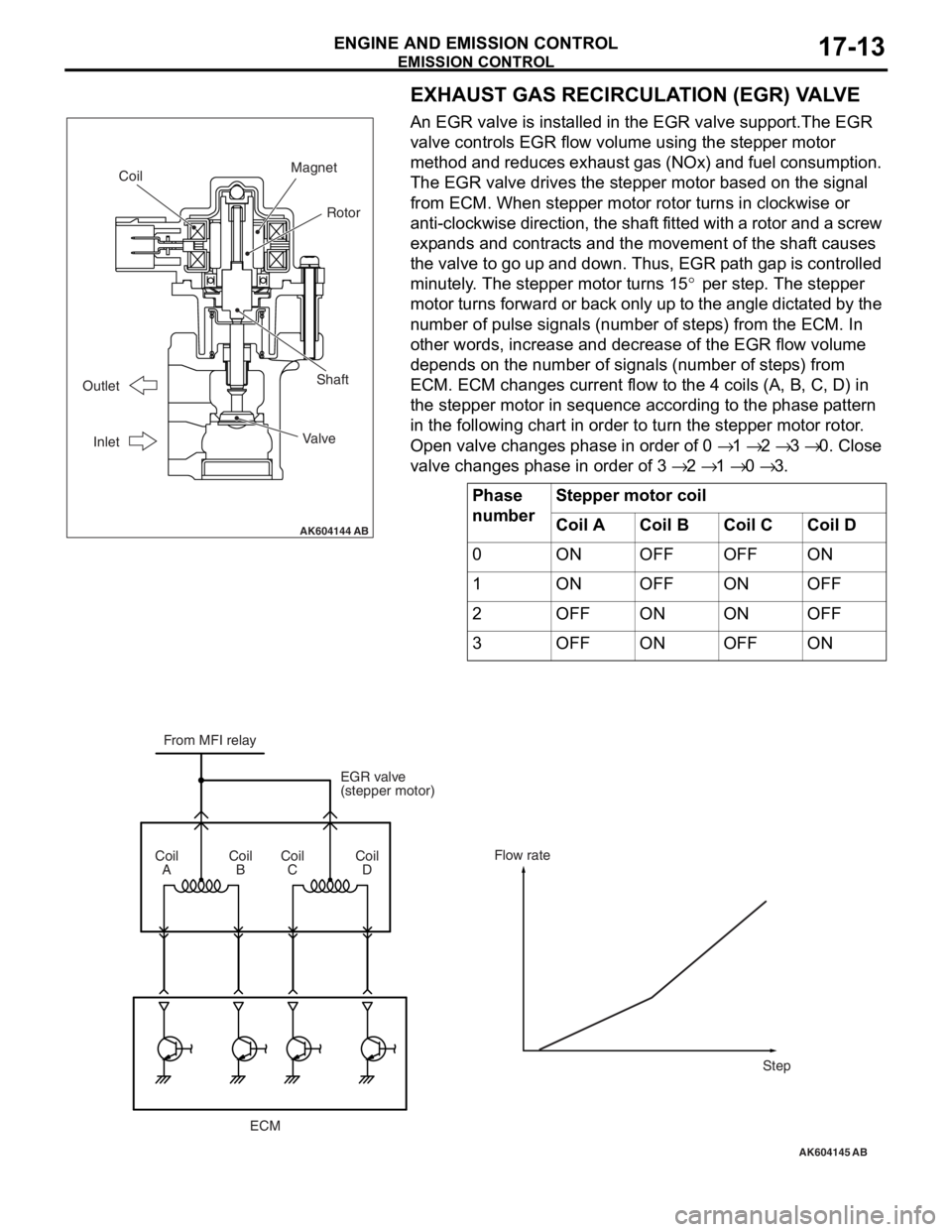

EXHAUST GAS RECIRCULATION (EGR) VALVE

An EGR valve is installed in the EGR valve support.The EGR

valve controls EGR flow volume using the stepper motor

method and reduces exhaust gas (NOx) and fuel consumption.

The EGR valve drives the stepper motor based on the signal

from ECM. When stepper motor rotor turns in clockwise or

anti-clockwise direction, the shaft fitted with a rotor and a screw

expands and contracts and the movement of the shaft causes

the valve to go up and down. Thus, EGR path gap is controlled

minutely. The stepper motor turns 15

° per step. The stepper

motor turns forward or back only up to the angle dictated by the

number of pulse signals (number of steps) from the ECM. In

other words, increase and decrease of the EGR flow volume

depends on the number of signals (number of steps) from

ECM. ECM changes current flow to the 4 coils (A, B, C, D) in

the stepper motor in sequence according to the phase pattern

in the following chart in order to turn the stepper motor rotor.

Open valve changes phase in order of 0

→ 1 → 2 → 3 → 0. Close

valve changes phase in order of 3

→ 2 → 1 → 0 → 3.

Phase

numberStepper motor coil

Coil ACoil BCoil CCoil D

0ONOFFOFFON

1ONOFFONOFF

2OFFONONOFF

3OFFONOFFON

AK604144

Coil

Shaft

Valve Outlet

Inlet

Rotor

Magnet

AB

AK604145

From MFI relay

EGR valve

(stepper motor)

ECM Coil

ACoil

BCoil

CCoil

DFlow rate

Step

AB

Page 135 of 241

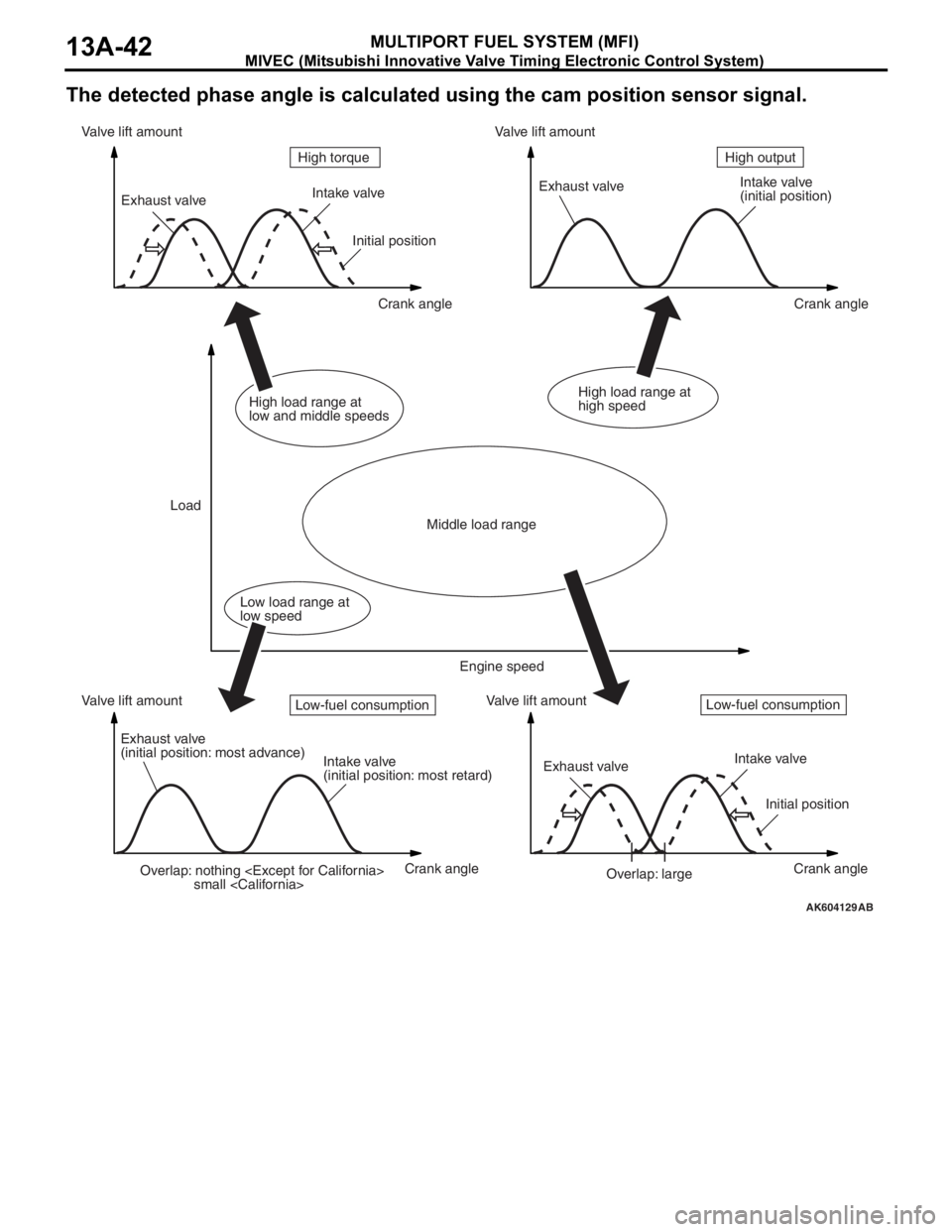

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-42

The detected phase angle is calculated using the cam position sensor signal.

AK604129AB

Overlap: nothing

small

(initial position)

Exhaust valve

(initial position: most advance)

Intake valve

(initial position: most retard)Exhaust valveIntake valve

Initial position

Overlap: large Initial position

Crank angle Crank angle

Crank angle Crank angle Valve lift amount Valve lift amountValve lift amount Valve lift amount

LoadHigh output High torque

Middle load range

Low load range at

low speedHigh load range at

low and middle speedsHigh load range at

high speed

Engine speed

Low-fuel consumptionLow-fuel consumption