MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 231 of 241

GENERAL INFORMATION

WHEEL AND TIRE31-2

GENERAL INFORMATIONM2310000100941

•The wheels and tires of the following specifica-

tions have been established.

•Adopt the Tire Pressure Monitoring System

(TPMS).

•Warns driver of low tire pressure by illuminat-

ing the TPMS warning light on the combina-

tion meter.

•Warns driver of TPMS probrems by flashing*

the TPMS warning light on the combination

meter.

NOTE: *: Change to continuous illumination

after flashing for about 1 minute.

SPECIFICATIONS

.

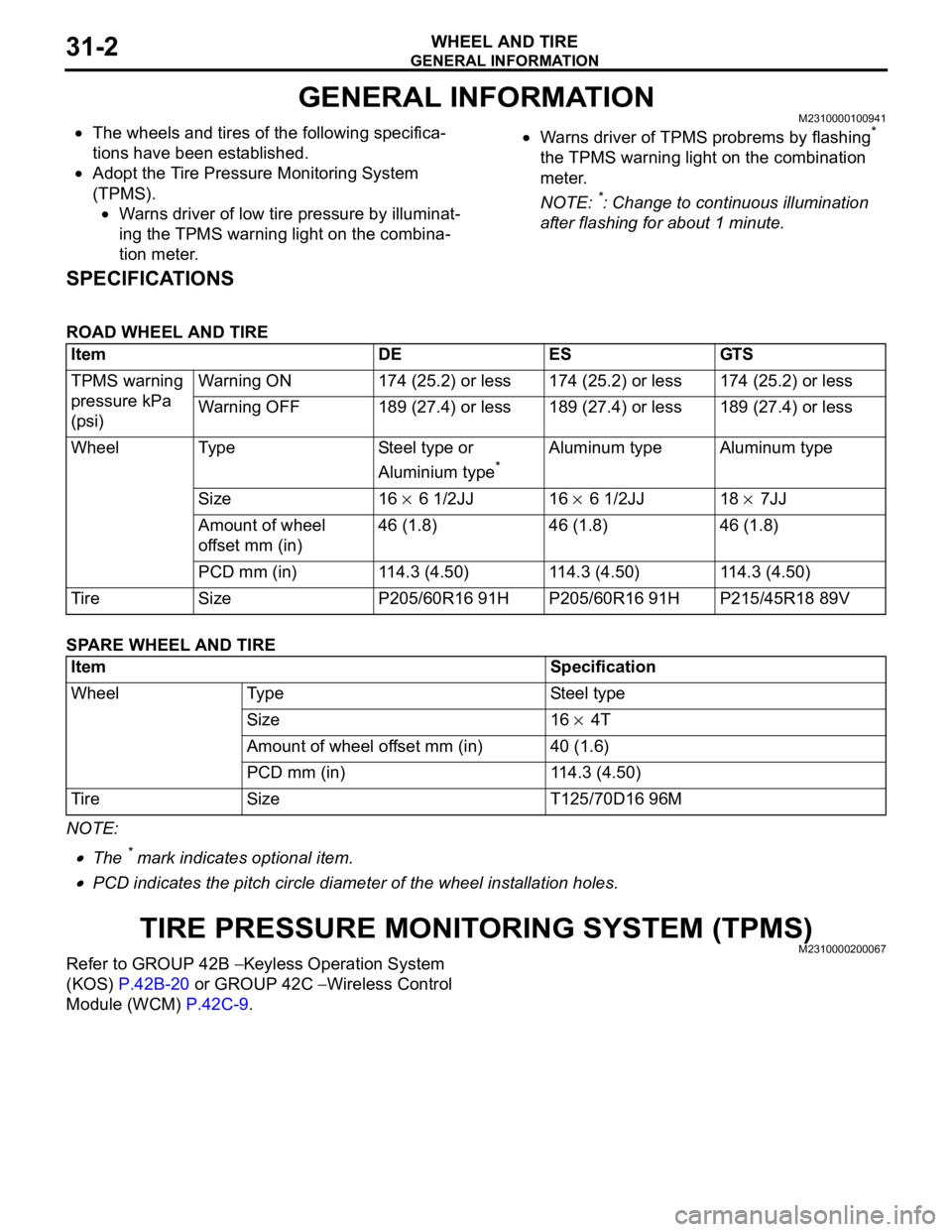

ROAD WHEEL AND TIRE

SPARE WHEEL AND TIRE

NOTE: .

•The * mark indicates optional item.

•PCD indicates the pitch circle diameter of the wheel installation holes.

TIRE PRESSURE MONITORING SYSTEM (TPMS)M2310000200067

Refer to GROUP 42B − Keyless Operation System

(KOS)

P.42B-20 or GROUP 42C − Wireless Control

Module (WCM) P.42C-9.

ItemDEESGT S

TPMS warning

pressure kPa

(psi)Warning ON174 (25.2) or less174 (25.2) or less174 (25.2) or less

Warning OFF189 (27.4) or less189 (27.4) or less189 (27.4) or less

WheelTy p eSteel type or

Aluminium type

*

Aluminum typeAluminum type

Size16 × 6 1/2JJ16 × 6 1/2JJ18 × 7JJ

Amount of wheel

offset mm (in)46 (1.8)46 (1.8)46 (1.8)

PCD mm (in)114.3 (4.50)114.3 (4.50)114.3 (4.50)

TireSizeP205/60R16 91HP205/60R16 91HP215/45R18 89V

ItemSpecification

WheelTy p eSteel type

Size16 × 4T

Amount of wheel offset mm (in)40 (1.6)

PCD mm (in)114.3 (4.50)

TireSizeT125/70D16 96M

Page 232 of 241

27-1

GROUP 27

REAR AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . .27-2

Page 233 of 241

GENERAL INFORMATION

REAR AXLE27-2

GENERAL INFORMATIONM2270000100478

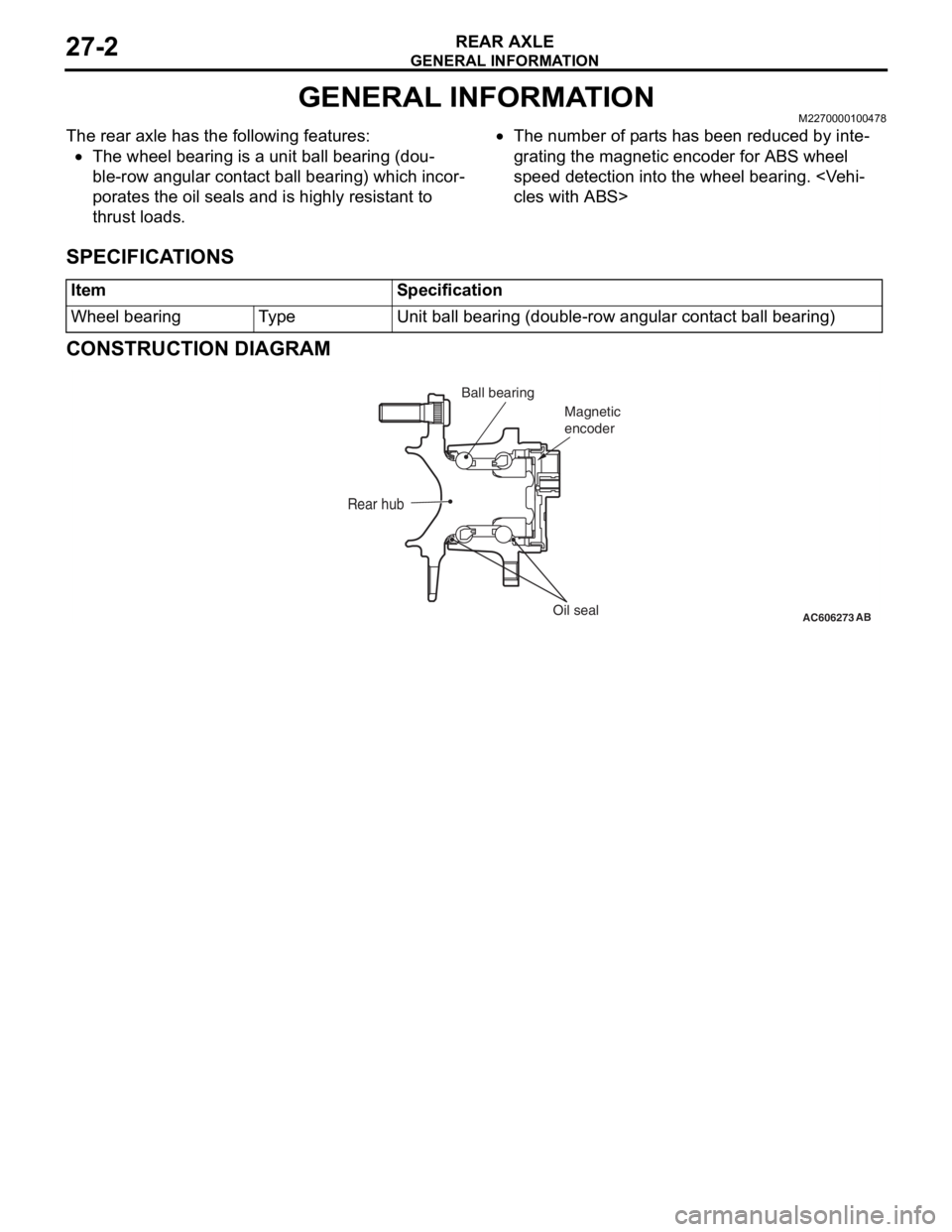

The rear axle has the following features:

•The wheel bearing is a unit ball bearing (dou-

ble-row angular contact ball bearing) which incor-

porates the oil seals and is highly resistant to

thrust loads.

•The number of parts has been reduced by inte-

grating the magnetic encoder for ABS wheel

speed detection into the wheel bearing.

cles with ABS>

SPECIFICATIONS

CONSTRUCTION DIAGRAM

ItemSpecification

Wheel bearingTy p eUnit ball bearing (double-row angular contact ball bearing)

AC606273

Rear hub

Oil seal Ball bearing

Magnetic

encoderAB

Page 234 of 241

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-2

STEERING WHEEL . . . . . . . . . . . . . .37-3

STEERING SHAFT AND COLUMN . .37-4

OIL PUMP . . . . . . . . . . . . . . . . . . . . . .37-6

STEERING GEAR . . . . . . . . . . . . . . . .37-7

OIL RESERVOIR . . . . . . . . . . . . . . . .37-8

Page 235 of 241

GENERAL INFORMATION

POWER STEERING37-2

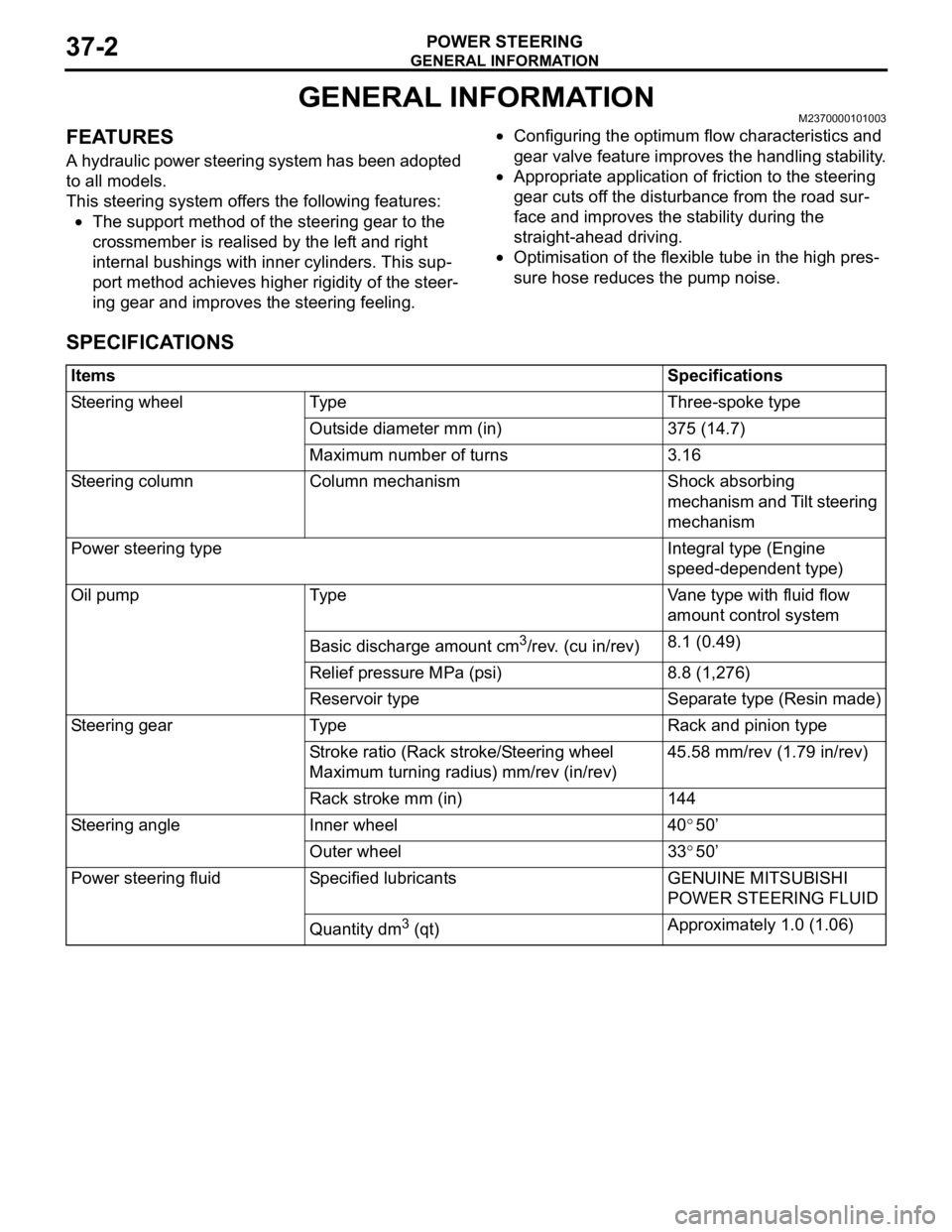

GENERAL INFORMATIONM2370000101003

FEATURES

A hydraulic power steering system has been adopted

to all models.

This steering system offers the following features:

•The support method of the steering gear to the

crossmember is realised by the left and right

internal bushings with inner cylinders. This sup

-

port method achieves higher rigidity of the steer-

ing gear and improves the steering feeling.

•Configuring the optimum flow characteristics and

gear valve feature improves the handling stability.

•Appropriate application of friction to the steering

gear cuts off the disturbance from the road sur

-

face and improves the stability during the

straight-ahead driving.

•Optimisation of the flexible tube in the high pres-

sure hose reduces the pump noise.

SPECIFICATIONS

ItemsSpecifications

Steering wheelTy p eThree-spoke type

Outside diameter mm (in)375 (14.7)

Maximum number of turns3.16

Steering columnColumn mechanismShock absorbing

mechanism and Tilt steering

mechanism

Power steering typeIntegral type (Engine

speed-dependent type)

Oil pumpTy p eVane type with fluid flow

amount control system

Basic discharge amount cm3/rev. (cu in/rev)8.1 (0.49)

Relief pressure MPa (psi)8.8 (1,276)

Reservoir typeSeparate type (Resin made)

Steering gearTy p eRack and pinion type

Stroke ratio (Rack stroke/Steering wheel

Maximum turning radius) mm/rev (in/rev)45.58 mm/rev (1.79 in/rev)

Rack stroke mm (in)144

Steering angleInner wheel40°50’

Outer wheel33°50’

Power steering fluidSpecified lubricantsGENUINE MITSUBISHI

POWER STEERING FLUID

Quantity dm3 (qt)Approximately 1.0 (1.06)

Page 236 of 241

STEERING WHEEL

POWER STEERING37-3

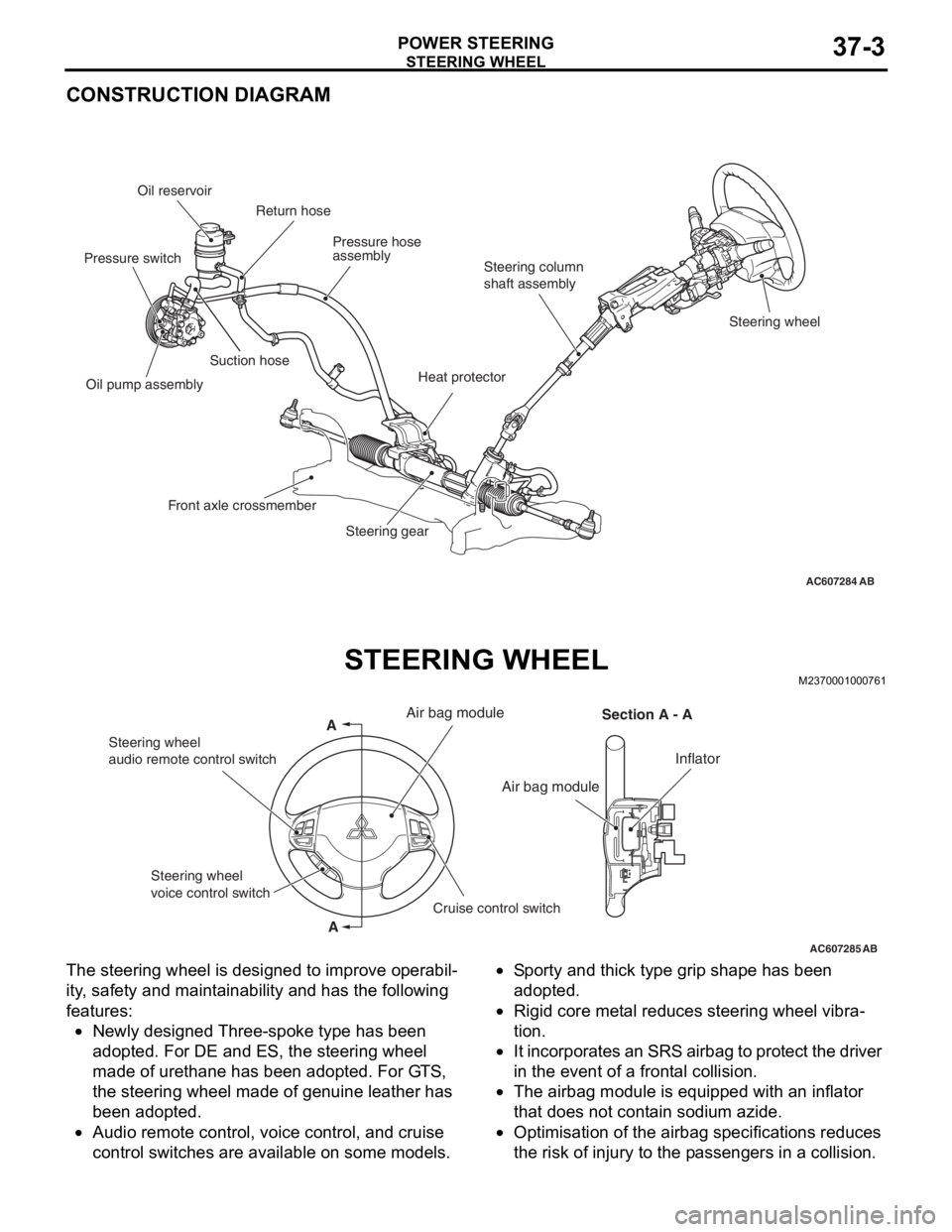

CONSTRUCTION DIAGRAM

STEERING WHEELM2370001000761

The steering wheel is designed to improve operabil-

ity, safety and maintainability and has the following

features:

•Newly designed Three-spoke type has been

adopted. For DE and ES, the steering wheel

made of urethane has been adopted. For GTS,

the steering wheel made of genuine leather has

been adopted.

•Audio remote control, voice control, and cruise

control switches are available on some models.

•Sporty and thick type grip shape has been

adopted.

•Rigid core metal reduces steering wheel vibra-

tion.

•It incorporates an SRS airbag to protect the driver

in the event of a frontal collision.

•The airbag module is equipped with an inflator

that does not contain sodium azide.

•Optimisation of the airbag specifications reduces

the risk of injury to the passengers in a collision.

AC607284AB

Steering wheel Steering column

shaft assembly Pressure hose

assembly Oil reservoir

Suction hose

Oil pump assembly

Steering gear Return hose

Front axle crossmember

Heat protector

Pressure switch

AC607285

A

AAir bag module

Section A - A

Inflator

Steering wheel

audio remote control switch

Cruise control switch Steering wheel

voice control switch

Air bag module

AB

Page 237 of 241

STEERING SHAFT AND COLUMN

POWER STEERING37-4

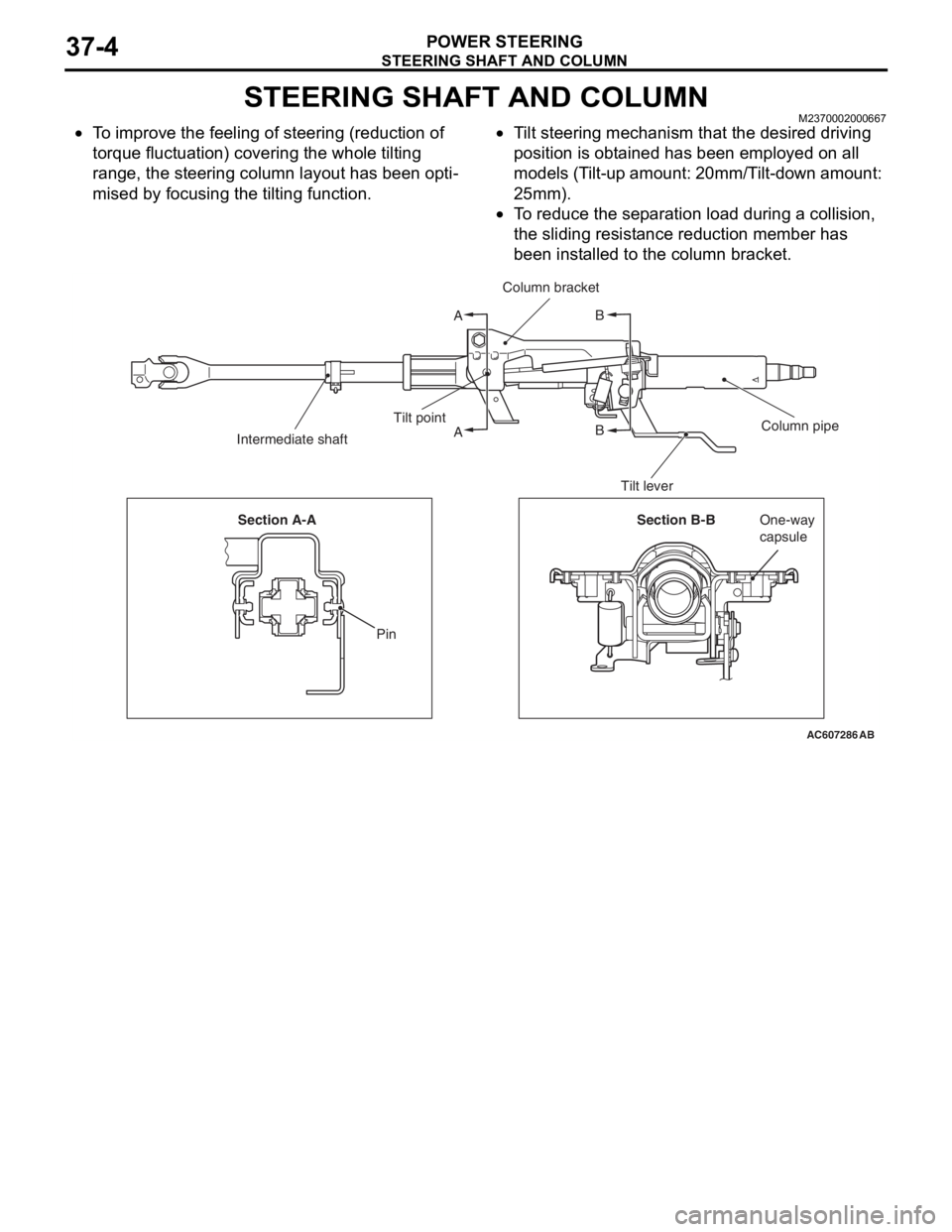

STEERING SHAFT AND COLUMNM2370002000667

•To improve the feeling of steering (reduction of

torque fluctuation) covering the whole tilting

range, the steering column layout has been opti

-

mised by focusing the tilting function.

•Tilt steering mechanism that the desired driving

position is obtained has been employed on all

models (Tilt-up amount: 20mm/Tilt-down amount:

25mm).

•To reduce the separation load during a collision,

the sliding resistance reduction member has

been installed to the column bracket.

AC607286

A

AB

B

AB

Column bracket

Column pipe Tilt point

Intermediate shaft

Tilt lever

Section B-BOne-way

capsule Section A-A

Pin

Page 238 of 241

STEERING SHAFT AND COLUMN

POWER STEERING37-5

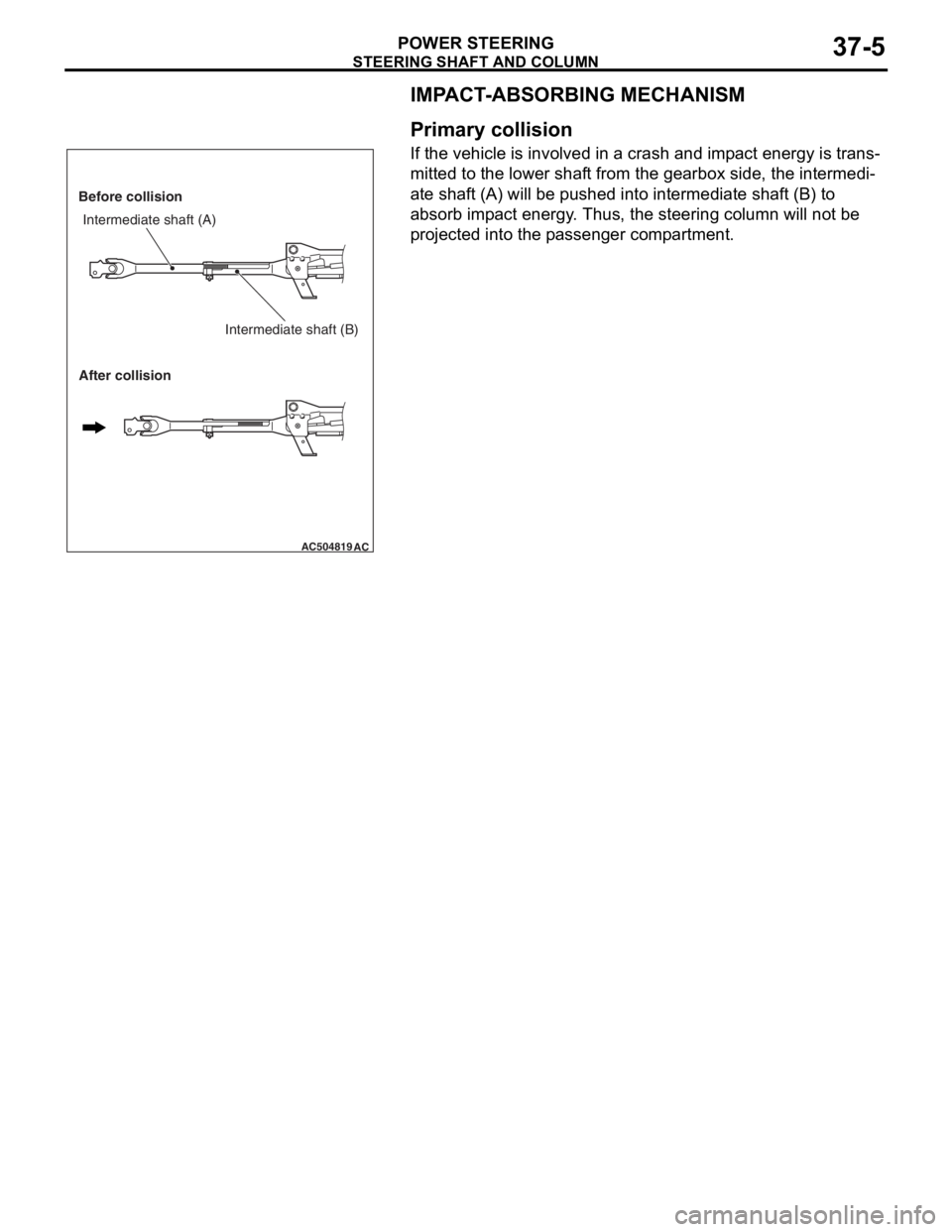

IMPACT-ABSORBING MECHANISM

.

Primary collision

If the vehicle is involved in a crash and impact energy is trans-

mitted to the lower shaft from the gearbox side, the intermedi-

ate shaft (A) will be pushed into intermediate shaft (B) to

absorb impact energy. Thus, the steering column will not be

projected into the passenger compartment.

.

AC504819AC

Before collision

After collisionIntermediate shaft (A)

Intermediate shaft (B)

Page 239 of 241

OIL PUMP

POWER STEERING37-6

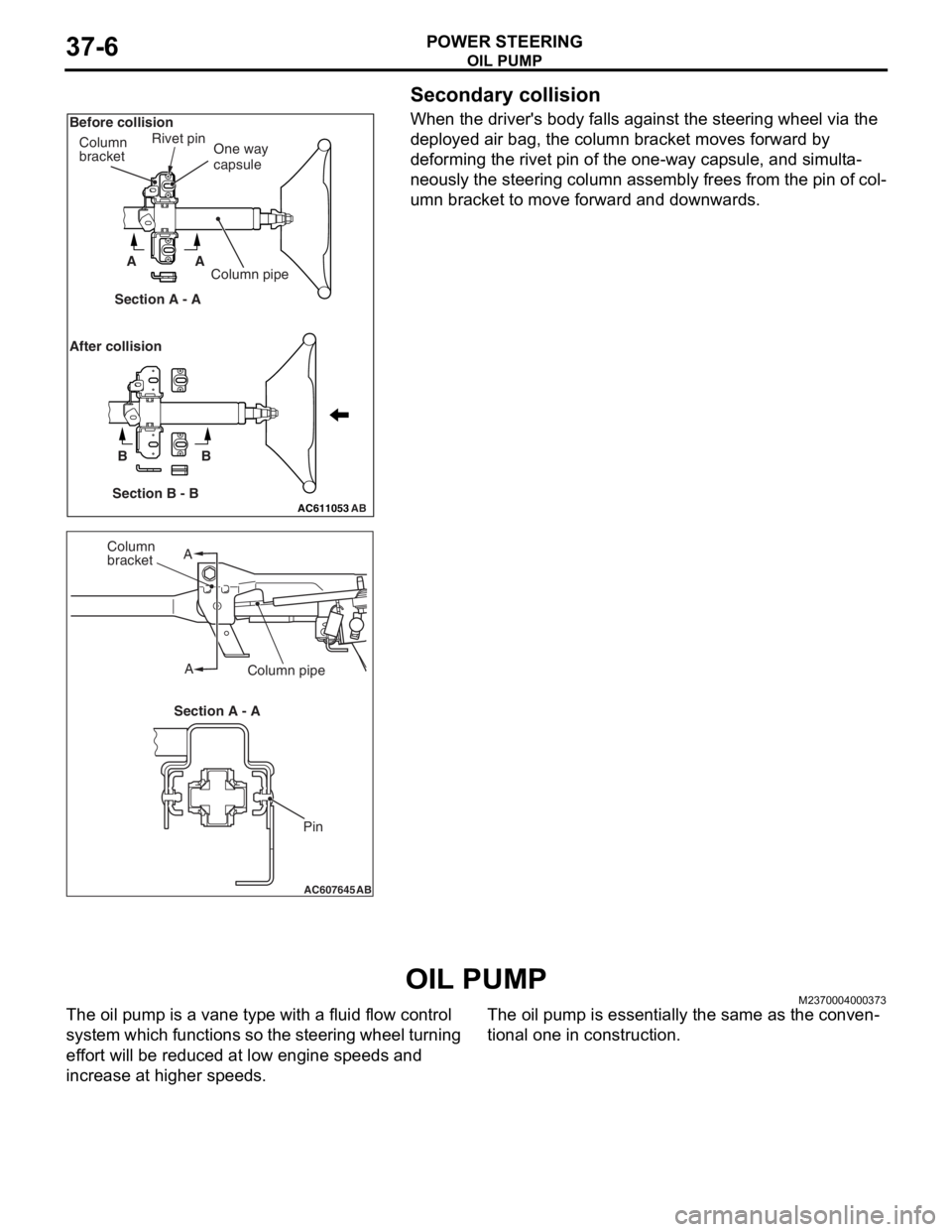

Secondary collision

When the driver's body falls against the steering wheel via the

deployed air bag, the column bracket moves forward by

deforming the rivet pin of the one-way capsule, and simulta

-

neously the steering column assembly frees from the pin of col-

umn bracket to move forward and downwards.

OIL PUMPM2370004000373

The oil pump is a vane type with a fluid flow control

system which functions so the steering wheel turning

effort will be reduced at low engine speeds and

increase at higher speeds. The oil pump is essentially the same as the conven-

tional one in construction.

AC611053AB

AA

BB

One way

capsule

Section B - BSection A - A Column

bracketRivet pin

Column pipe Before collision

After collision

AC607645AB

A

AColumn

bracket

Column pipe

Pin Section A - A

Page 240 of 241

STEERING GEAR

POWER STEERING37-7

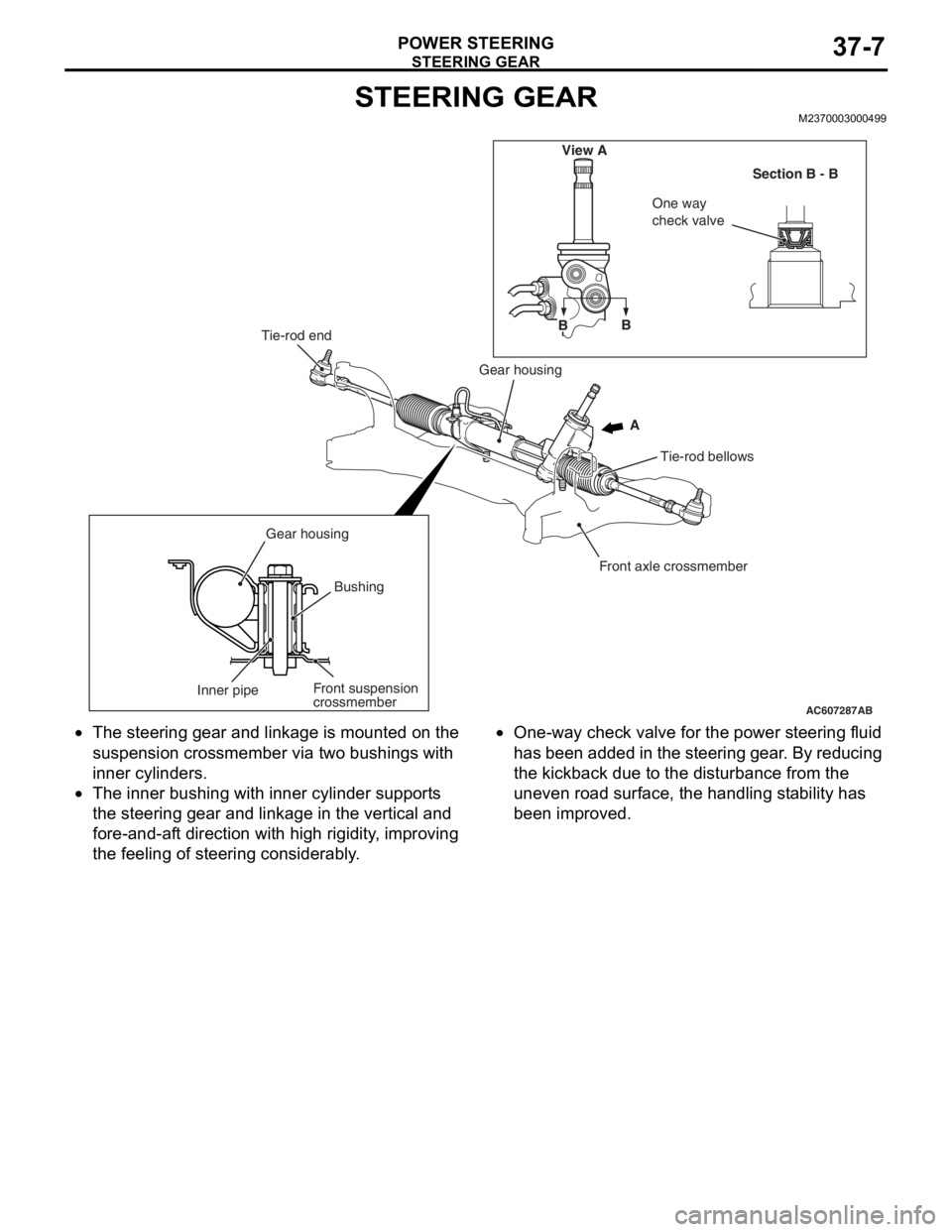

STEERING GEARM2370003000499

•The steering gear and linkage is mounted on the

suspension crossmember via two bushings with

inner cylinders.

•The inner bushing with inner cylinder supports

the steering gear and linkage in the vertical and

fore-and-aft direction with high rigidity, improving

the feeling of steering considerably.

•One-way check valve for the power steering fluid

has been added in the steering gear. By reducing

the kickback due to the disturbance from the

uneven road surface, the handling stability has

been improved.

AC607287AB

Tie-rod end

Gear housing

Gear housingTie-rod bellows

Front axle crossmember

Inner pipeBushing

Front suspension

crossmemberB

BView A

ASection B - B

One way

check valve