warning MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 29 of 241

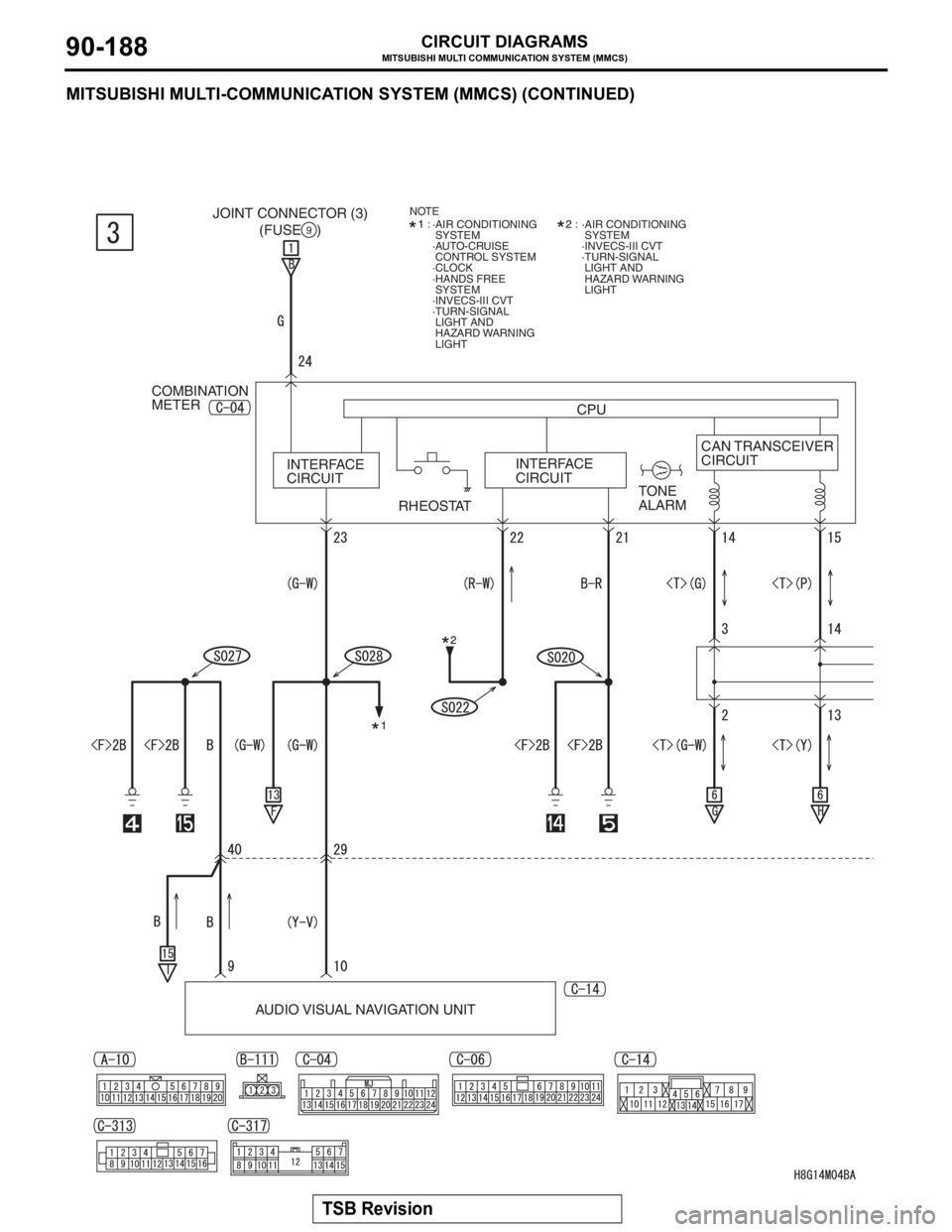

MITSUBISHI MULTI COMMUNICATION SYSTEM (MMCS)

TSB Revision

CIRCUIT DIAGRAMS90-188

MITSUBISHI MULTI-COMMUNICATION SYSTEM (MMCS) (CONTINUED)

COMBINATION

METER

INTERFACE

CIRCUITCAN TRANSCEIVER

CIRCUIT CPU (FUSE )

9

RHEOSTATTONE

ALARM INTERFACE

CIRCUIT

AUDIO VISUAL NAVIGATION UNIT

·AIR CONDITIONING

SYSTEM

·AUTO-CRUISE

CONTROL SYSTEM

·CLOCK

·HANDS FREE

SYSTEM

·INVECS-III CVT

·TURN-SIGNAL

LIGHT AND

HAZARD WARNING

LIGHT:

·AIR CONDITIONING

SYSTEM

·INVECS-III CVT

·TURN-SIGNAL

LIGHT AND

HAZARD WARNING

LIGHT: NOTEJOINT CONNECTOR (3)

Page 111 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-18

.

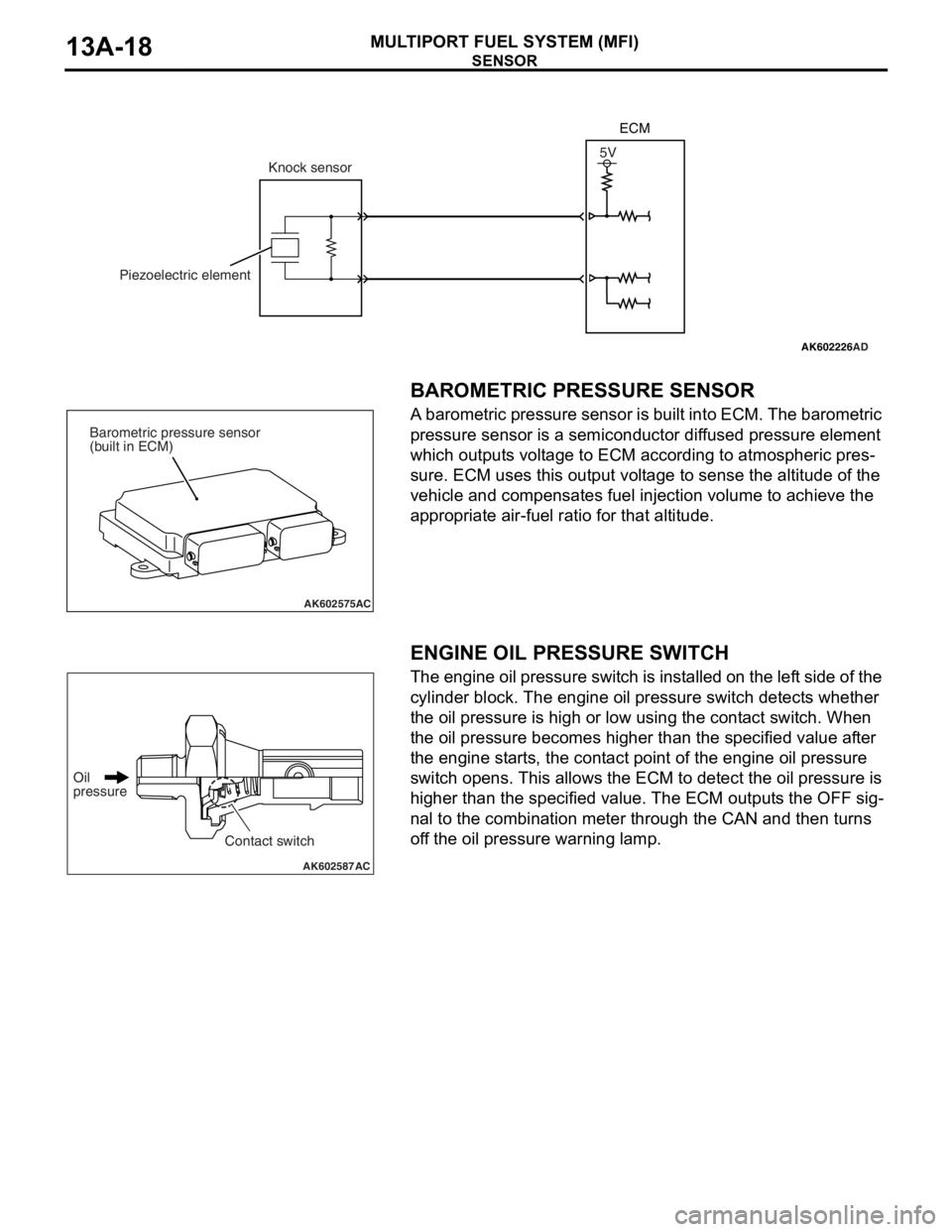

BAROMETRIC PRESSURE SENSOR

A barometric pressure sensor is built into ECM. The barometric

pressure sensor is a semiconductor diffused pressure element

which outputs voltage to ECM according to atmospheric pres

-

sure. ECM uses this output voltage to sense the altitude of the

vehicle and compensates fuel injection volume to achieve the

appropriate air-fuel ratio for that altitude.

.

ENGINE OIL PRESSURE SWITCH

The engine oil pressure switch is installed on the left side of the

cylinder block. The engine oil pressure switch detects whether

the oil pressure is high or low using the contact switch. When

the oil pressure becomes higher than the specified value after

the engine starts, the contact point of the engine oil pressure

switch opens. This allows the ECM to detect the oil pressure is

higher than the specified value. The ECM outputs the OFF sig

-

nal to the combination meter through the CAN and then turns

off the oil pressure warning lamp.

AK602226AD

5V

Knock sensor

Piezoelectric elementECM

AK602575AC

Barometric pressure sensor

(built in ECM)

AK602587AC

Oil

pressure

Contact switch

Page 157 of 241

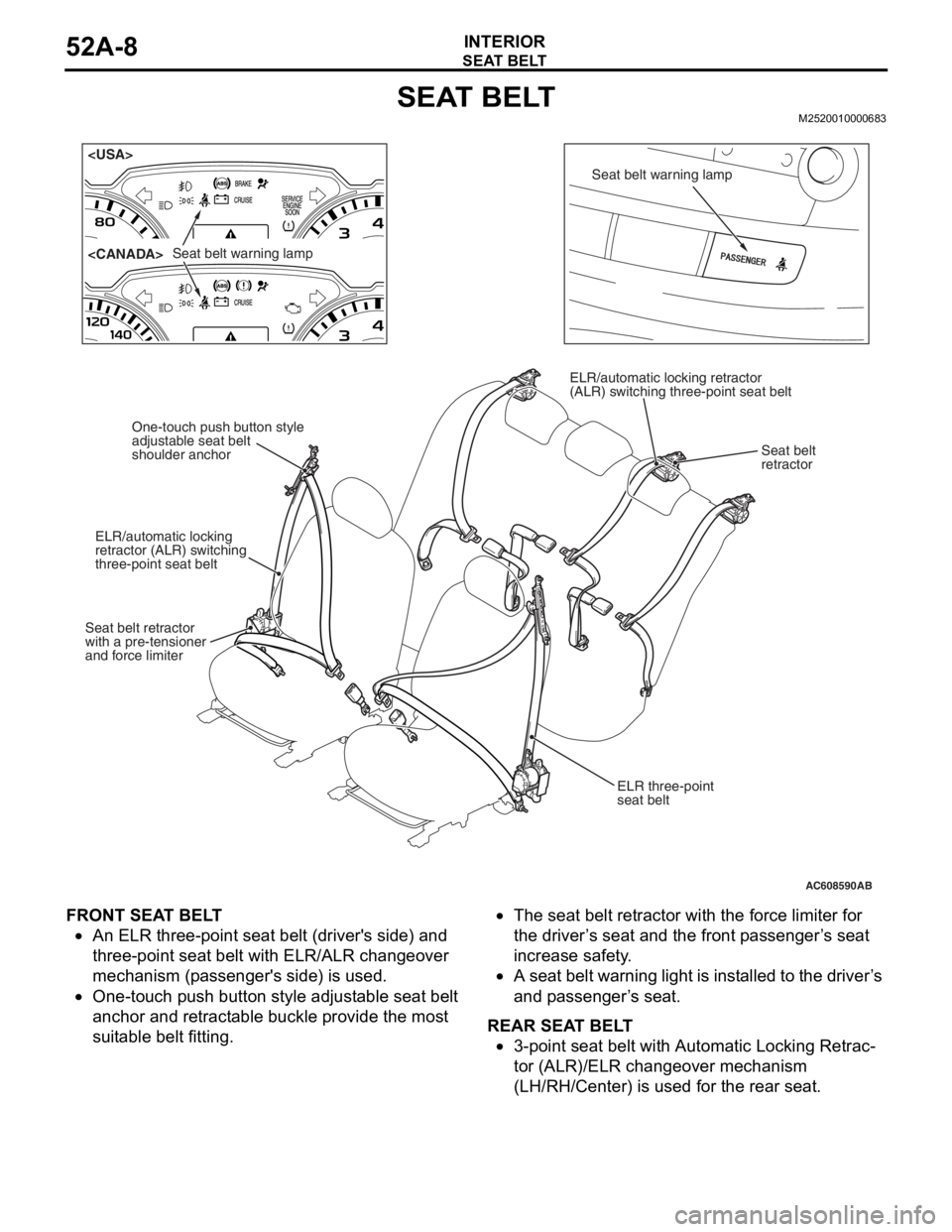

SEAT BELT

INTERIOR52A-8

SEAT BELTM2520010000683

FRONT SEAT BELT

•An ELR three-point seat belt (driver's side) and

three-point seat belt with ELR/ALR changeover

mechanism (passenger's side) is used.

•One-touch push button style adjustable seat belt

anchor and retractable buckle provide the most

suitable belt fitting.

•The seat belt retractor with the force limiter for

the driver’s seat and the front passenger’s seat

increase safety.

•A seat belt warning light is installed to the driver’s

and passenger’s seat.

REAR SEAT BELT

•3-point seat belt with Automatic Locking Retrac-

tor (ALR)/ELR changeover mechanism

(LH/RH/Center) is used for the rear seat.

AC608590

Seat belt warning lamp

Seat belt warning lamp

ELR three-point

seat belt

One-touch push button style

adjustable seat belt

shoulder anchor

ELR/automatic locking

retractor (ALR) switching

three-point seat belt

Seat belt retractor

with a pre-tensioner

and force limiter ELR/automatic locking retractor

(ALR) switching three-point seat belt

Seat belt

retractor

AB

Page 162 of 241

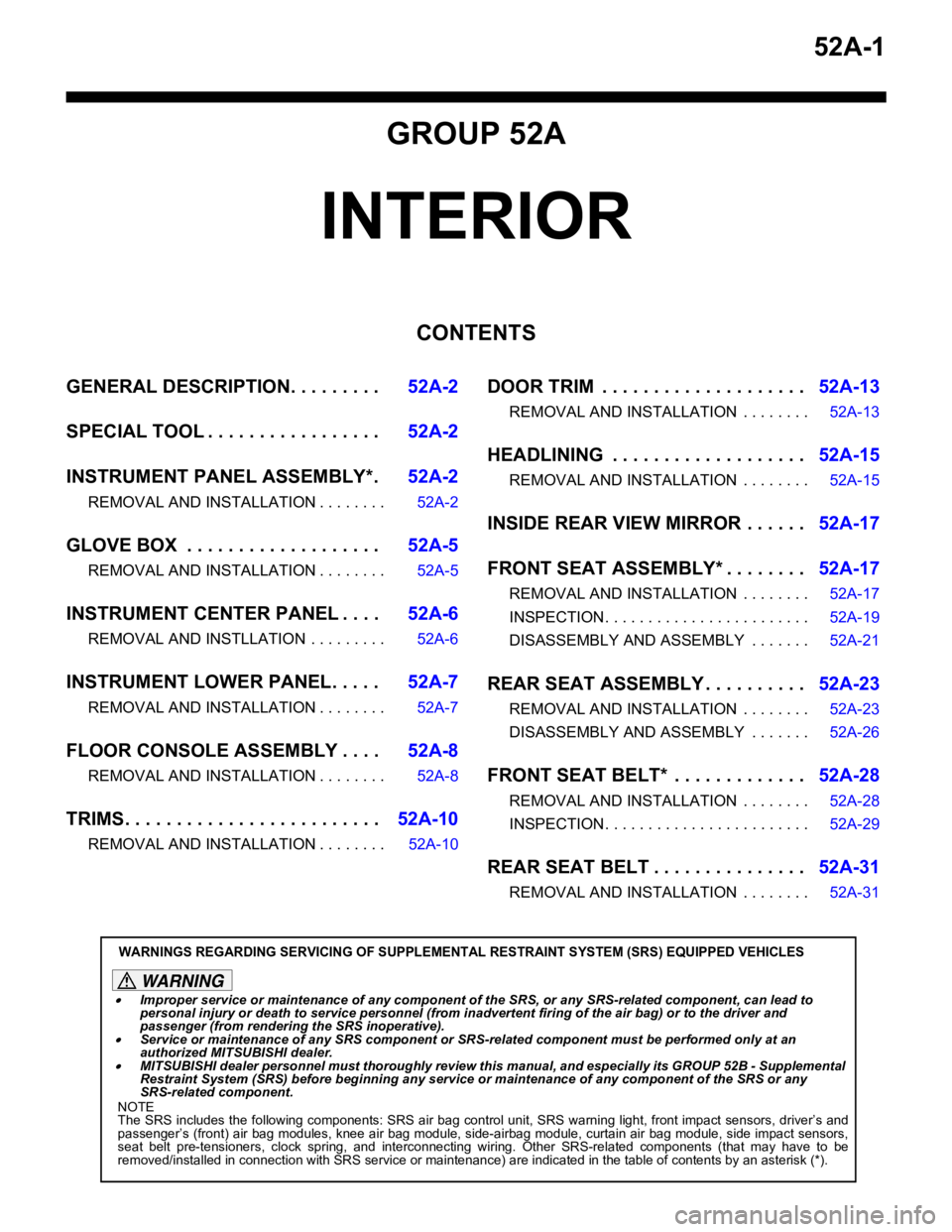

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .52A-2

SPECIAL TOOL . . . . . . . . . . . . . . . . .52A-2

INSTRUMENT PANEL ASSEMBLY*.52A-2

REMOVAL AND INSTALLATION . . . . . . . . 52A-2

GLOVE BOX . . . . . . . . . . . . . . . . . . .52A-5

REMOVAL AND INSTALLATION . . . . . . . . 52A-5

INSTRUMENT CENTER PANEL . . . .52A-6

REMOVAL AND INSTLLATION . . . . . . . . . 52A-6

INSTRUMENT LOWER PANEL. . . . .52A-7

REMOVAL AND INSTALLATION . . . . . . . . 52A-7

FLOOR CONSOLE ASSEMBLY . . . .52A-8

REMOVAL AND INSTALLATION . . . . . . . . 52A-8

TRIMS. . . . . . . . . . . . . . . . . . . . . . . . .52A-10

REMOVAL AND INSTALLATION . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . .52A-13

REMOVAL AND INSTALLATION . . . . . . . . 52A-13

HEADLINING . . . . . . . . . . . . . . . . . . .52A-15

REMOVAL AND INSTALLATION . . . . . . . . 52A-15

INSIDE REAR VIEW MIRROR . . . . . .52A-17

FRONT SEAT ASSEMBLY* . . . . . . . .52A-17

REMOVAL AND INSTALLATION . . . . . . . . 52A-17

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-19

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-21

REAR SEAT ASSEMBLY . . . . . . . . . .52A-23

REMOVAL AND INSTALLATION . . . . . . . . 52A-23

DISASSEMBLY AND ASSEMBLY . . . . . . . 52A-26

FRONT SEAT BELT* . . . . . . . . . . . . .52A-28

REMOVAL AND INSTALLATION . . . . . . . . 52A-28

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 52A-29

REAR SEAT BELT . . . . . . . . . . . . . . .52A-31

REMOVAL AND INSTALLATION . . . . . . . . 52A-31

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of an y component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

passenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, driver’s and

passenger’s (front) air bag modules, knee air bag module, side-airbag module, curtain air bag module, side impact sensors,

seat belt pre-tensioners, clock spring, and interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 163 of 241

GENERAL DESCRIPTION

TSB Revision

INTERIOR52A-2

GENERAL DESCRIPTIONM1521000100429

OPERATION

.

SEAT BELT WARNING SYSTEM

If the driver turns the ignition switch to the "ON" posi-

tion without fastening the seat belt, the seat belt

warning light illuminates.

SPECIAL TOOLM1521000600576

INSTRUMENT PANEL ASSEMBLY

REMOVAL AND INSTALLATIONM1521001701591

WARNING

For removal and installation of the passenger's side air bag module, always observe the ser-

vice procedures described in GROUP 52B, Air Bag Module and Clock Spring P.52B-367.

The following bolts and screws are used for installing the in strument panel. Bolts and screws are indicated as

marks shown in the illustration in the sections of "R emoval and Installation" and "Disassembly and Assem

-

bly."

D: Thread diameter, L: Effective thread length

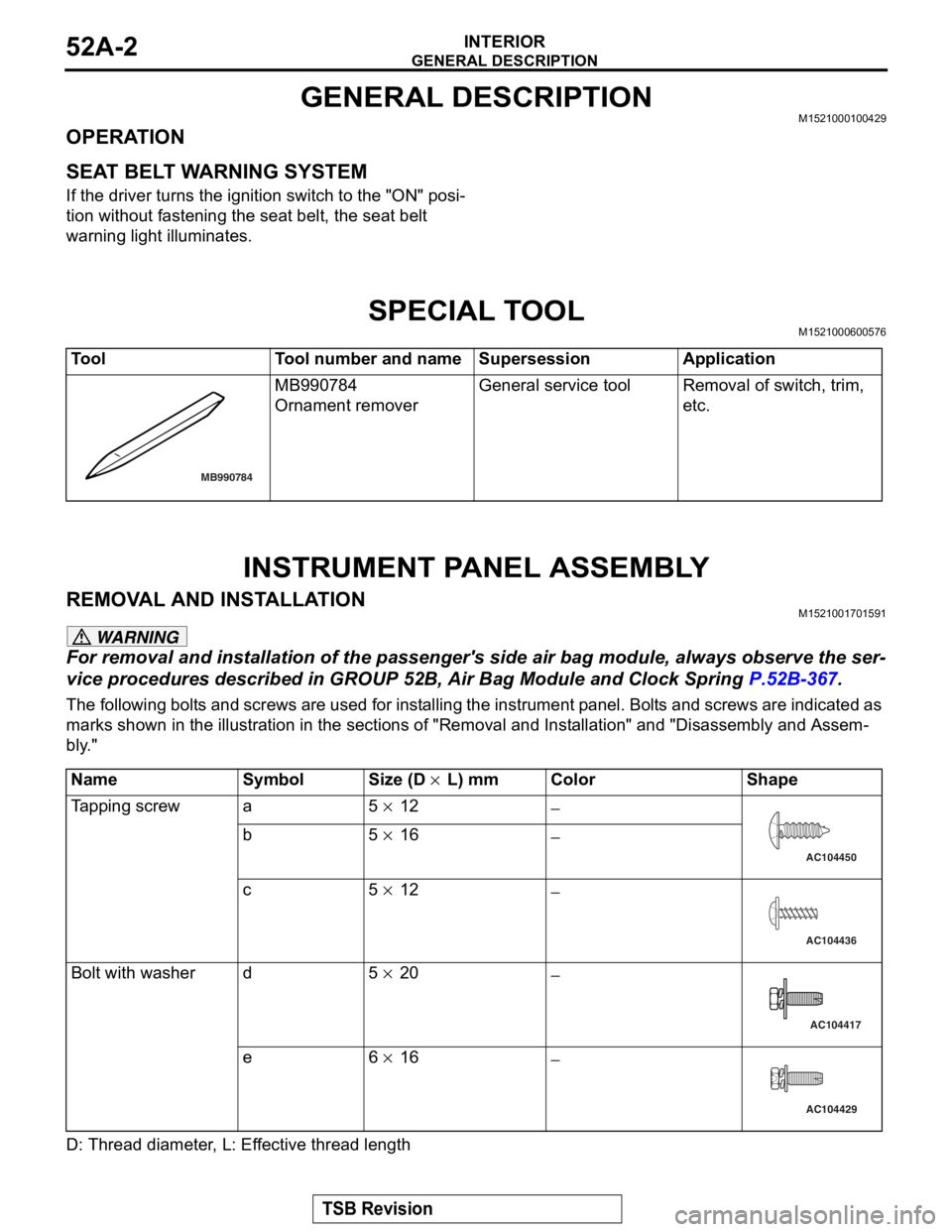

ToolTool number and nameSupersessionApplication

MB990784

Ornament remover

General service toolRemoval of switch, trim,

etc.

MB990784

NameSymbolSize (D × L) mmColorShape

Tapping screwa5 × 12−

b5 × 16−

c5 × 12−

Bolt with washerd5 × 20−

e6 × 16−

AC104450

AC104436

AC104417

AC104429

Page 178 of 241

INSIDE REAR VIEW MIRROR

TSB Revision

INTERIOR52A-17

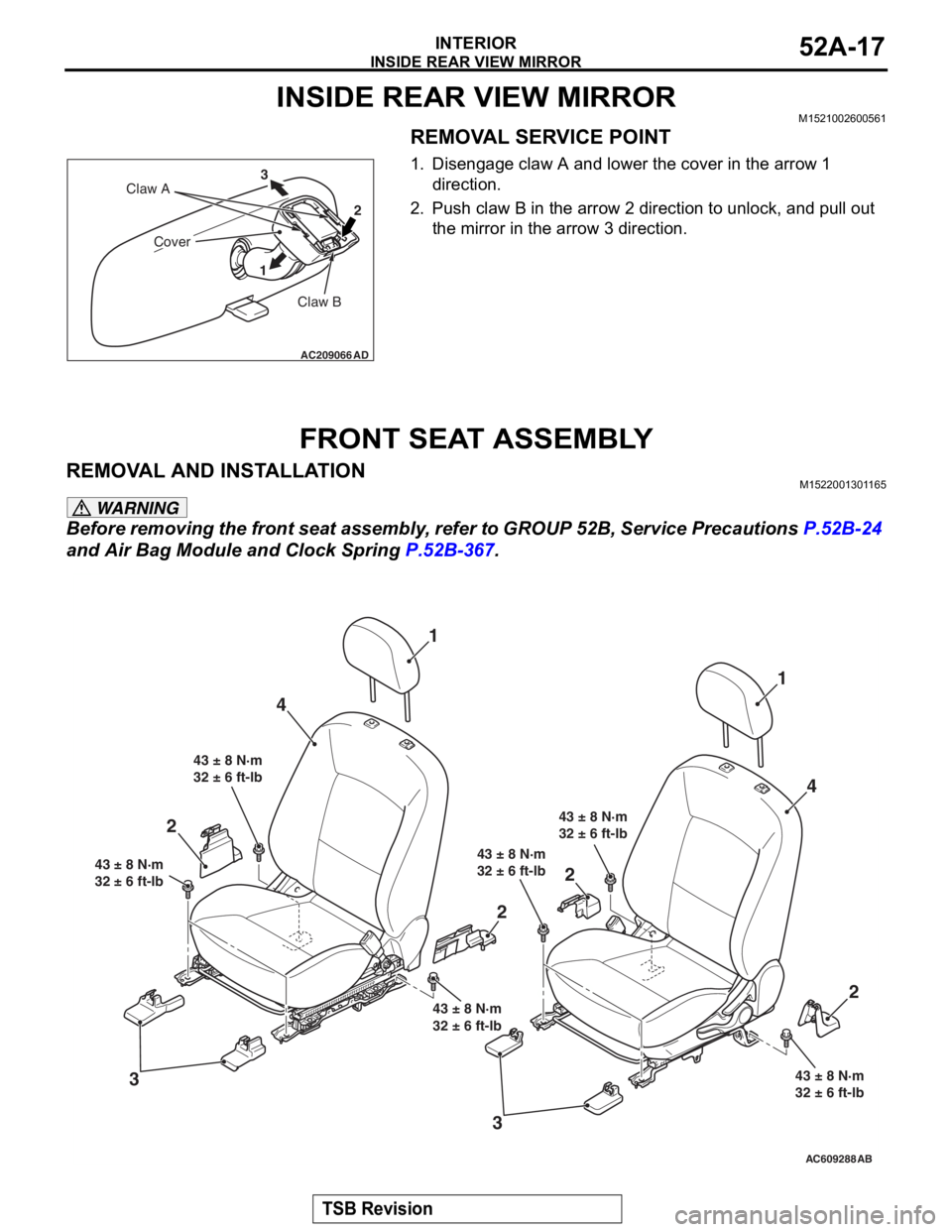

INSIDE REAR VIEW MIRRORM1521002600561

REMOVAL SERVICE POINT

1. Disengage claw A and lower the cover in the arrow 1 direction.

2. Push claw B in the arrow 2 direction to unlock, and pull out the mirror in the arrow 3 direction.

FRONT SEAT ASSEMBLY

REMOVAL AND INSTALLATIONM1522001301165

WARNING

Before removing the front seat assembly, refer to GROUP 52B, Service Precautions P.52B-24

and Air Bag Module and Clock Spring P.52B-367.

AC209066

Claw B

Claw A

Cover

12

3

AD

AC609288AB

4

3 1

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb 43 ± 8 N·m

32 ± 6 ft-lb

43 ± 8 N·m

32 ± 6 ft-lb

1

4

2

2

2

3

2

Page 212 of 241

GENERAL INFORMATION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-3

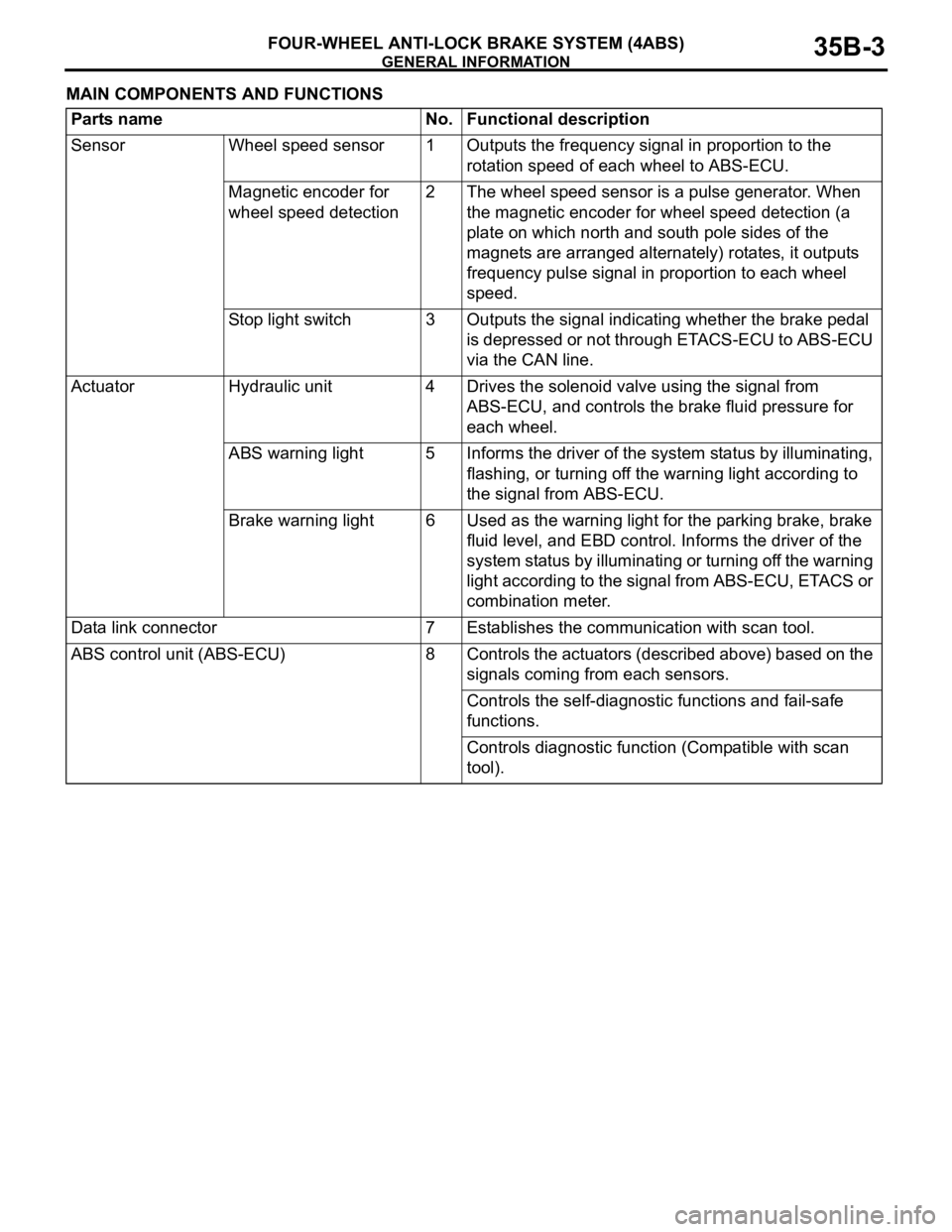

MAIN COMPONENTS AND FUNCTIONS

.

Parts nameNo.Functional description

SensorWheel speed sensor1Outputs the frequency signal in proportion to the

rotation speed of each wheel to ABS-ECU.

Magnetic encoder for

wheel speed detection2The wheel speed sensor is a pulse generator. When

the magnetic encoder for wheel speed detection (a

plate on which north and south pole sides of the

magnets are arranged alternately) rotates, it outputs

frequency pulse signal in proportion to each wheel

speed.

Stop light switch3Outputs the signal indicating whether the brake pedal

is depressed or not through ETACS-ECU to ABS-ECU

via the CAN line.

ActuatorHydraulic unit4Drives the solenoid valve using the signal from

ABS-ECU, and controls the brake fluid pressure for

each wheel.

ABS warning light5Informs the driver of the system status by illuminating,

flashing, or turning off the warning light according to

the signal from ABS-ECU.

Brake warning light6Used as the warning light for the parking brake, brake

fluid level, and EBD control. Informs the driver of the

system status by illuminating or turning off the warning

light according to the signal from ABS-ECU, ETACS or

combination meter.

Data link connector7Establishes the communication with scan tool.

ABS control unit (ABS-ECU)8Controls the actuators (described above) based on the

signals coming from each sensors.

Controls the self-diagnostic functions and fail-safe

functions.

Controls diagnostic function (Compatible with scan

tool).

Page 213 of 241

GENERAL INFORMATION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-4

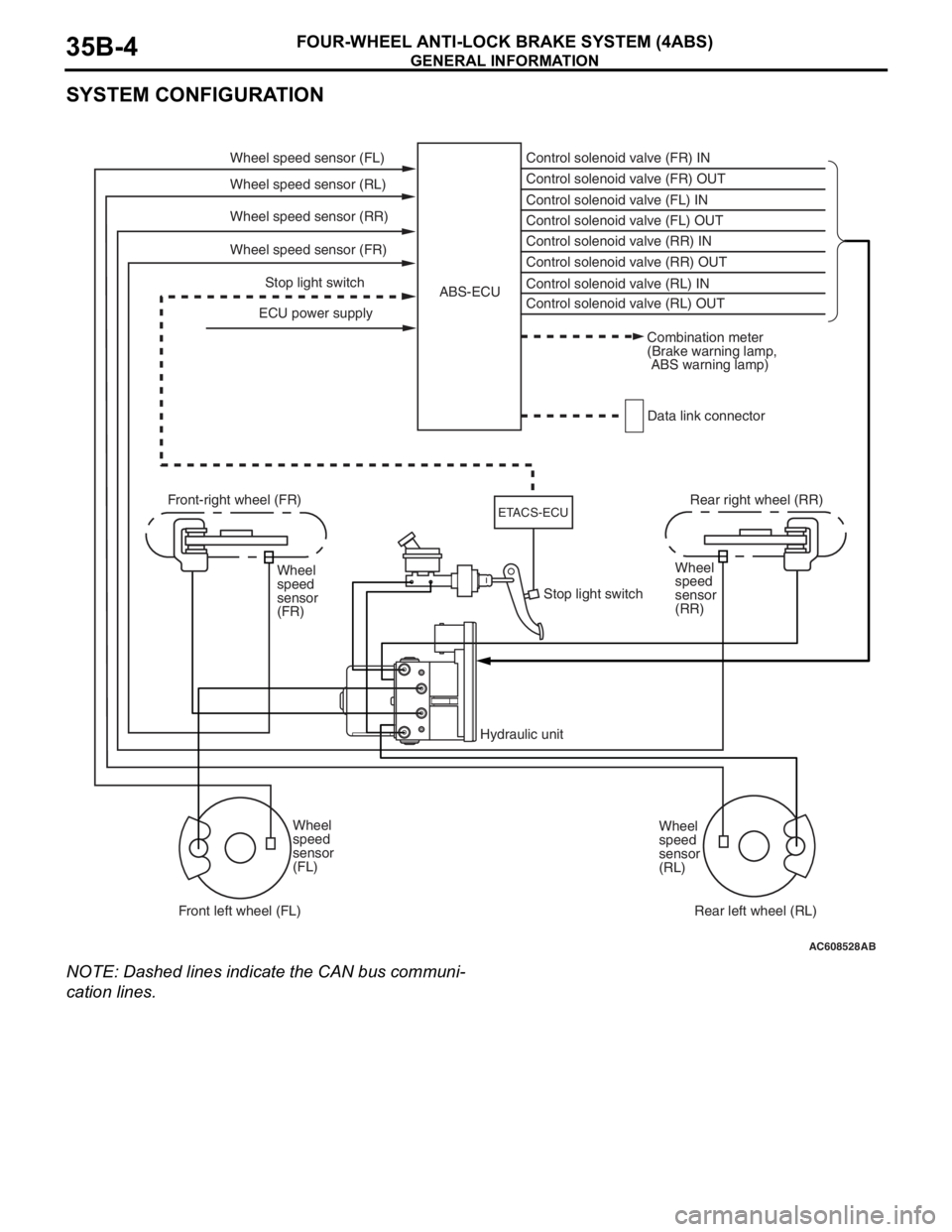

SYSTEM CONFIGURATION

NOTE: Dashed lines indicate the CAN bus communi-

cation lines.

.

AC608528AB

Wheel speed sensor (FL)

ECU power supplyABS-ECU

Combination meter

(Brake warning lamp,

ABS warning lamp)

Data link connector Wheel speed sensor (RL)

Wheel speed sensor (RR)

Wheel speed sensor (FR)

Stop light switch Front-right wheel (FR)

Hydraulic unit Stop light switch

ETACS-ECU

Wheel

speed

sensor

(FL) Wheel

speed

sensor

(FR)Wheel

speed

sensor

(RR)

Wheel

speed

sensor

(RL) Control solenoid valve (RL) OUT Control solenoid valve (RR) OUT Control solenoid valve (FL) OUT Control solenoid valve (FR) OUT Control solenoid valve (FR) IN

Control solenoid valve (FL) IN

Control solenoid valve (RR) IN

Control solenoid valve (RL) IN

Rear right wheel (RR)

Rear left wheel (RL) Front left wheel (FL)

Page 215 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-6

CONSTRUCTION DESCRIPTION

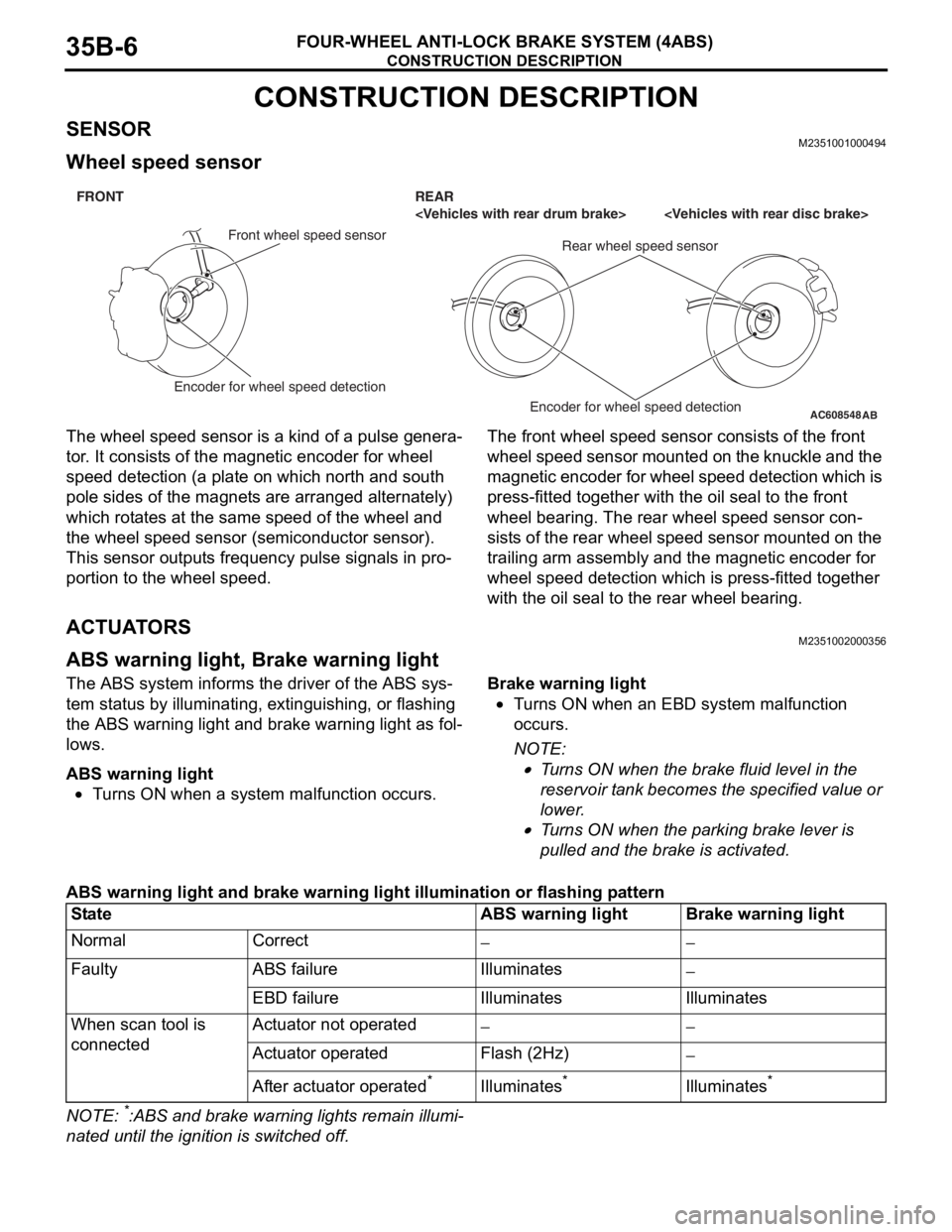

SENSORM2351001000494

Wheel speed sensor

The wheel speed sensor is a kind of a pulse genera-

tor. It consists of the magnetic encoder for wheel

speed detection (a plate on which north and south

pole sides of the magnets are arranged alternately)

which rotates at the same speed of the wheel and

the wheel speed sensor (semiconductor sensor).

This sensor outputs frequency pulse signals in pro

-

portion to the wheel speed.

The front wheel speed sensor consists of the front

wheel speed sensor mounted on the knuckle and the

magnetic encoder for wheel speed detection which is

press-fitted together with the oil seal to the front

wheel bearing. The rear wheel speed sensor con

-

sists of the rear wheel speed sensor mounted on the

trailing arm assembly and the magnetic encoder for

wheel speed detection which is press-fitted together

with the oil seal to the rear wheel bearing.

ACTUATORSM2351002000356

ABS warning light, Brake warning light

The ABS system informs the driver of the ABS sys-

tem status by illuminating, extinguishing, or flashing

the ABS warning light and brake warning light as fol

-

lows.

ABS warning light

•Turns ON when a system malfunction occurs.

Brake warning light

•Turns ON when an EBD system malfunction

occurs.

NOTE: .

•Turns ON when the brake fluid level in the

reservoir tank becomes the specified value or

lower.

•Turns ON when the parking brake lever is

pulled and the brake is activated.

ABS warning light and brake warning light illumination or flashing pattern

NOTE: *:ABS and brake warning lights remain illumi-

nated until the ignition is switched off.

AC608548

AB

FRONT REAR

Front wheel speed sensor

Rear wheel speed sensor

Encoder for wheel speed detection

Encoder for wheel speed detection

StateABS warning lightBrake warning light

NormalCorrect−−

FaultyABS failureIlluminates−

EBD failureIlluminatesIlluminates

When scan tool is

connectedActuator not operated−−

Actuator operatedFlash (2Hz)−

After actuator operated*Illuminates*Illuminates*

Page 216 of 241

CONSTRUCTION DESCRIPTION

FOUR-WHEEL ANTI-LOCK BRAKE SYSTEM (4ABS)35B-7

ABS-ECUM2351003000520

•By integrating ABS-ECU into the hydraulic unit,

no wiring harness for sending drive signal of the

solenoid valve and pump motor is required,

assuring higher reliability.

•Self-diagnostic and memory functions are inte-

grated into ABS-ECU. If any malfunction is

detected by the self-diagnostic function,

ABS-ECU activates a fail-safe function and illumi

-

nates the ABS warning light and brake warning

light

*.

NOTE: *: The brake warning light is used as the

EBD control warning light.

•ABS-ECU detects vehicle speed from the signals

of the wheel speed sensor and its recognizes the

wheel rotation status, estimates the wheel slip

condition based on the preprogrammed algo

-

rithm, and then controls the solenoid valve in the

hydraulic unit so that the wheels do not lock.

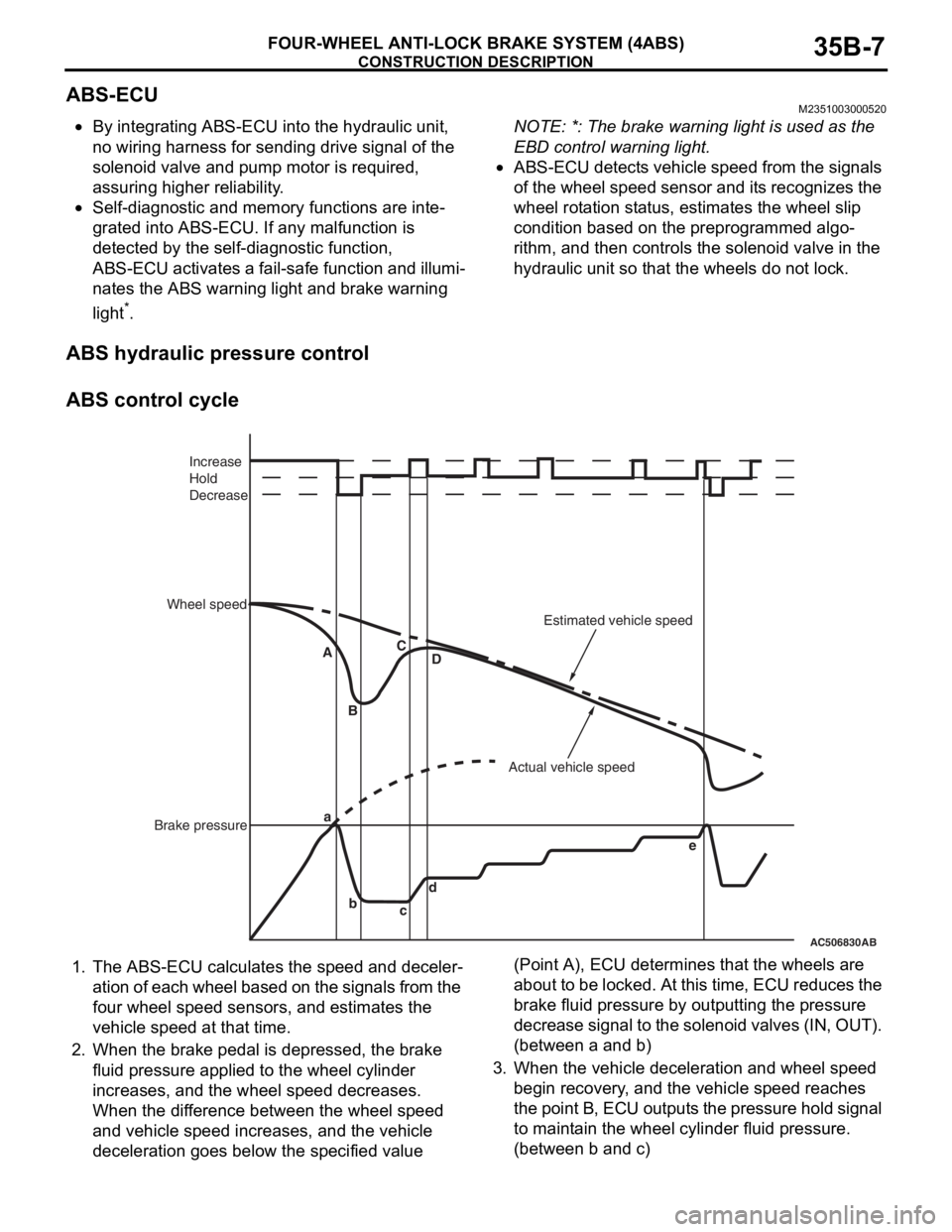

ABS hydraulic pressure control

ABS control cycle

1. The ABS-ECU calculates the speed and deceler-

ation of each wheel based on the signals from the

four wheel speed sensors, and estimates the

vehicle speed at that time.

2. When the brake pedal is depressed, the brake

fluid pressure applied to the wheel cylinder

increases, and the wheel speed decreases.

When the difference between the wheel speed

and vehicle speed increases, and the vehicle

deceleration goes below the specified value (Point A), ECU determines that the wheels are

about to be locked. At this time, ECU reduces the

brake fluid pressure by outputting the pressure

decrease signal to the solenoid valves (IN, OUT).

(between a and b)

3. When the vehicle deceleration and wheel speed

begin recovery, and the vehicle speed reaches

the point B, ECU outputs the pressure hold signal

to maintain the wheel cylinder fluid pressure.

(between b and c)

AC506830AB

a

b

cd A

BC

D

e Increase

Hold

Decrease

Wheel speed

Brake pressureActual vehicle speedEstimated vehicle speed