relay MITSUBISHI LANCER EVOLUTION X 2008 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 95 of 241

13A-1

GROUP 13A

MULTIPORT FUEL

SYSTEM (MFI)

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .13A-2

CONTROL UNIT. . . . . . . . . . . . . . . . .13A-6

SENSOR. . . . . . . . . . . . . . . . . . . . . . .13A-8

ACTUATOR . . . . . . . . . . . . . . . . . . . .13A-23

FUEL INJECTION CONTROL . . . . . .13A-29

IGNITION TIMING AND CONTROL FOR

CURRENT CARRYING TIME . . . . . .13A-35

THROTTLE VALVE OPENING ANGLE

CONTROL AND IDLE SPEED

CONTROL . . . . . . . . . . . . . . . . . . . . .13A-38

MIVEC (Mitsubishi Innovative Valve

Timing Electronic Control System) .13A-40

MULTIPORT FUEL INJECTION (MFI)

RELAY CONTROL . . . . . . . . . . . . . . .13A-45

FUEL PUMP RELAY CONTROL . . . .13A-46

STARTER RELAY CONTROL . . . . . .13A-47

HEATED OXYGEN SENSOR HEATER

CONTROL . . . . . . . . . . . . . . . . . . . . . .13A-49

A/C COMPRESSOR RELAY

CONTROL . . . . . . . . . . . . . . . . . . . . . .13A-50

GENERATOR CONTROL . . . . . . . . . .13A-51

EVAPORATIVE EMISSION CONTROL

SYSTEM INCORRECT PURGE FLOW

MONITOR . . . . . . . . . . . . . . . . . . . . . .13A-52

EXHAUST GAS RECIRCULATION

CONTROL . . . . . . . . . . . . . . . . . . . . . .13A-53

CONTROLLER AREA NETWORK

(CAN) . . . . . . . . . . . . . . . . . . . . . . . . .13A-53

EVAPORATIVE EMISSION PURGE

CONTROL . . . . . . . . . . . . . . . . . . . . . .13A-53

HC TRAP CATALYTIC CONVERTER

DETERIORATION MONITOR . . . . . . .13A-53

ON-BOARD DIAGNOSTICS . . . . . . . .13A-53

Page 97 of 241

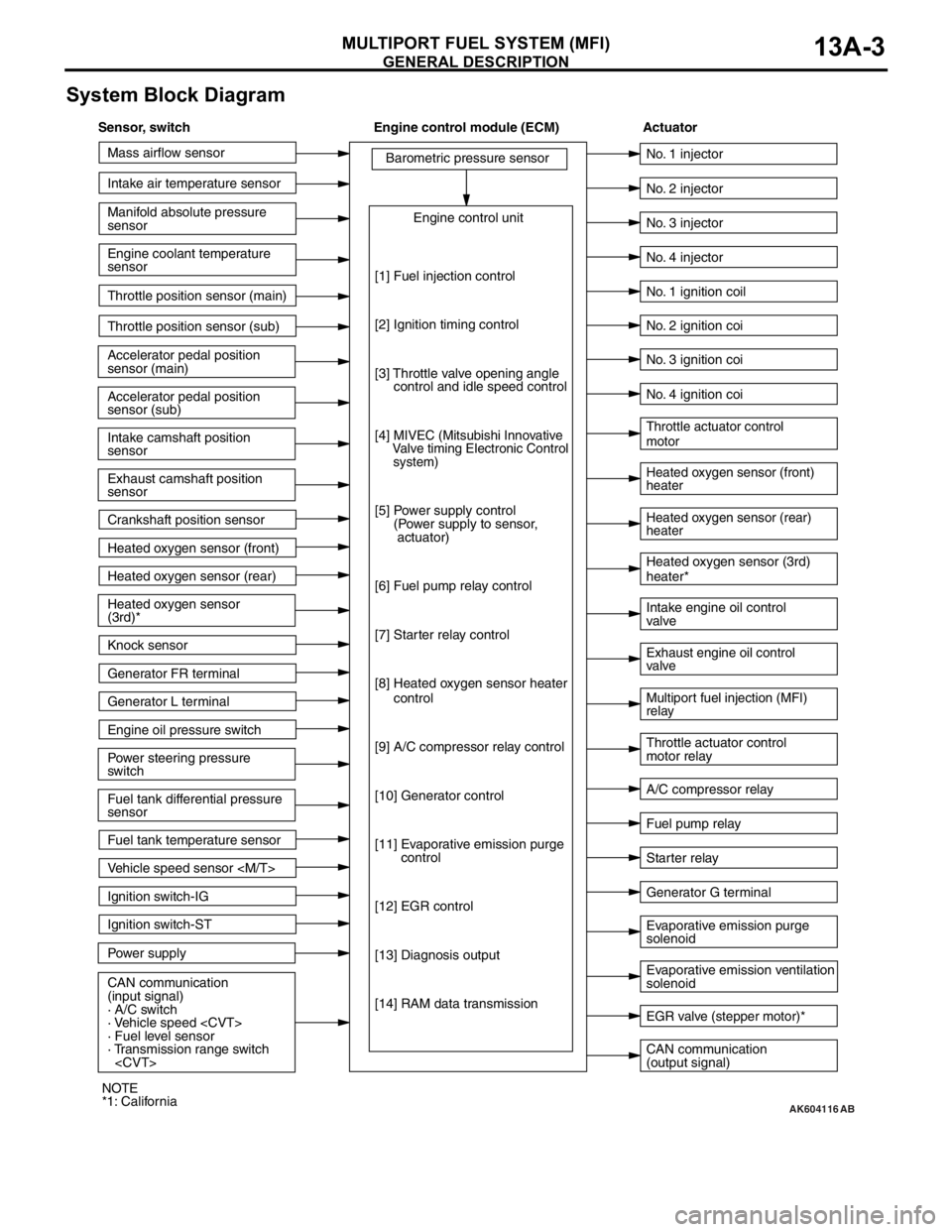

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-3

System Block Diagram

AK604116

Mass airflow sensor

Intake air temperature sensor

Intake camshaft position

sensor

Exhaust camshaft position

sensor

Crankshaft position sensor Throttle position sensor (main)

Throttle position sensor (sub)

Accelerator pedal position

sensor (sub) Accelerator pedal position

sensor (main) Engine coolant temperature

sensor Manifold absolute pressure

sensor

Heated oxygen sensor (front)

Heated oxygen sensor (rear)

Power steering pressure

switch Engine oil pressure switch Generator L terminal

Ignition switch-ST

Power supply Ignition switch-IG

CAN communication

(input signal)

· A/C switch

· Vehicle speed

· Fuel level sensor

· Transmission range switch

sensor Heated oxygen sensor

(3rd)*

Knock sensor

Generator FR terminal

Fuel tank temperature sensor

Vehicle speed sensor

[1] Fuel injection control

[2] Ignition timing control

[3] Throttle valve opening angle

control and idle speed control

[4]

MIVEC (Mitsubishi Innovative

Valve timing Electronic Control

system)

[5] Power supply control

(Power supply to sensor,

actuator)

[6] Fuel pump relay control

[7] Starter relay control

[8] Heated oxygen sensor heater

control

[9] A/C compressor relay control

[10] Generator control

[11] Evaporative emission purge

control

[12] EGR control

[13] Diagnosis output

[14] RAM data transmission

CAN communication

(output signal) Intake engine oil control

valve

A/C compressor relay No. 2 injector

No. 3 injector

No. 4 injector

Heated oxygen sensor (front)

heater

Heated oxygen sensor (rear)

heater Throttle actuator control

motor

Throttle actuator control

motor relay No. 1 injector

No. 1 ignition coil

No. 2 ignition coi

No. 3 ignition coi

No. 4 ignition coi

Fuel pump relay

Generator G terminal Heated oxygen sensor (3rd)

heater*

Multiport fuel injection (MFI)

relay Exhaust engine oil control

valve

Evaporative emission ventilation

solenoid Evaporative emission purge

solenoid

EGR valve (stepper motor)*

Starter relay

AB

Sensor, switch Engine control module (ECM) Actuator

NOTE

*1: California

Page 98 of 241

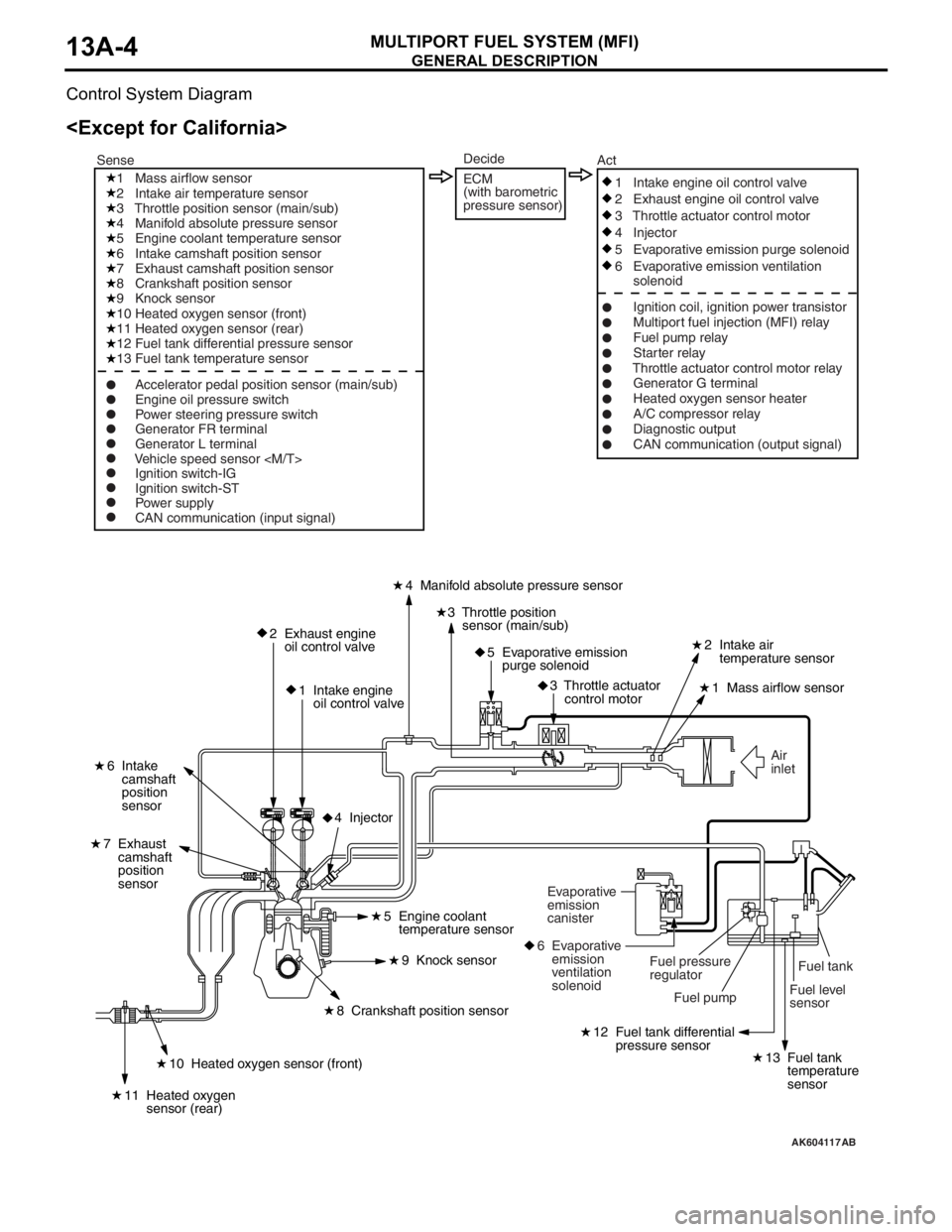

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-4

Control System Diagram

AK604117

Fuel level

sensorFuel tank Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor10 Heated oxygen sensor (front)

11 Heated oxygen

sensor (rear)

8 Crankshaft position sensor5 Engine coolant

temperature sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Fuel tank differential pressure sensor

13 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB

Page 99 of 241

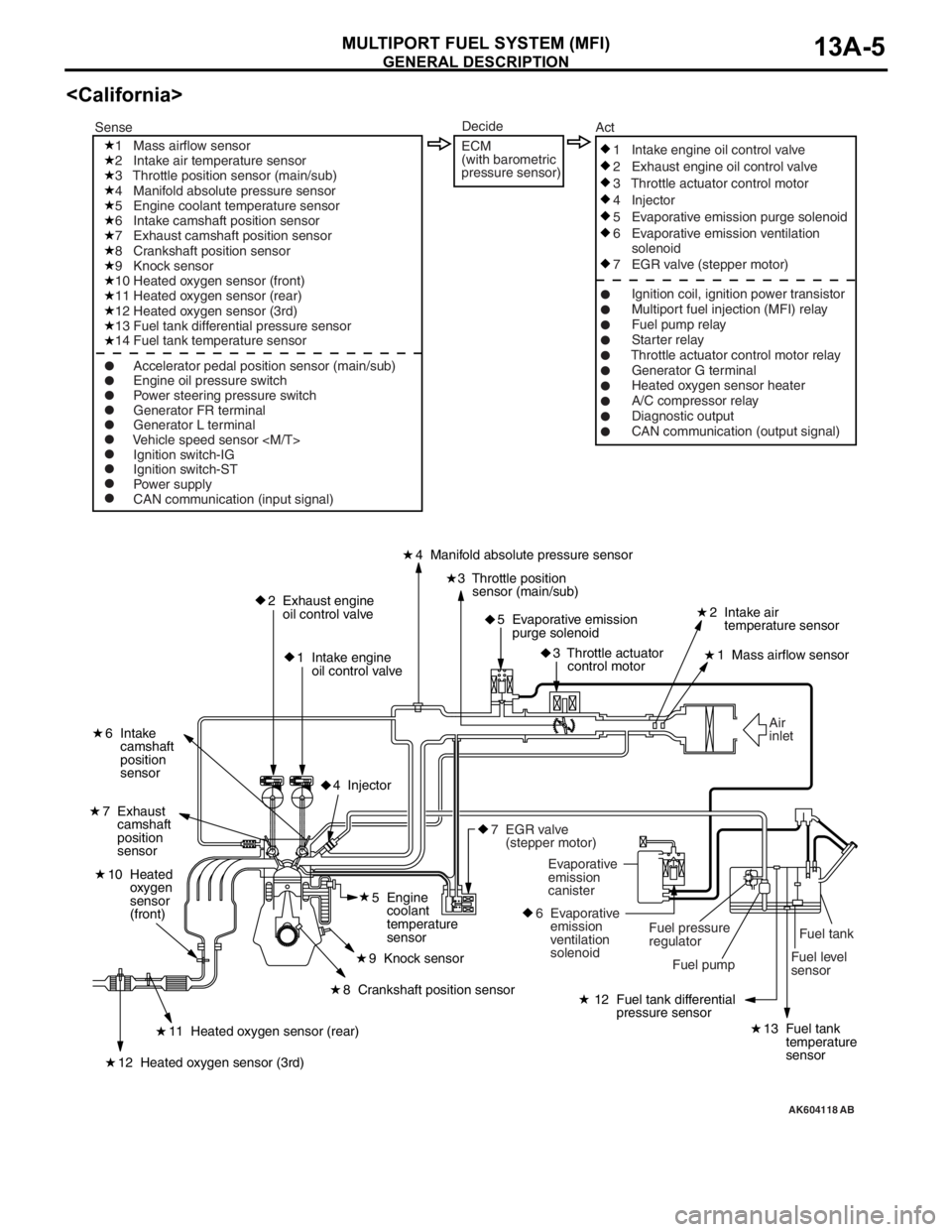

GENERAL DESCRIPTION

MULTIPORT FUEL SYSTEM (MFI)13A-5

AK604118

Fuel tank

Fuel level

sensor Air

inlet

2 Exhaust engine

oil control valve

1 Intake engine

oil control valve4 Manifold absolute pressure sensor

2 Intake air

temperature sensor

1 Mass airflow sensor

6 Intake

camshaft

position

sensor

7 Exhaust

camshaft

position

sensor

3 Throttle position

sensor (main/sub)

5 Evaporative emission

purge solenoid

3 Throttle actuator

control motor

12 Fuel tank differential

pressure sensor

13 Fuel tank

temperature

sensor11 Heated oxygen sensor (rear)

10 Heated

oxygen

sensor

(front)

12 Heated oxygen sensor (3rd)

8 Crankshaft position sensor5 Engine

coolant

temperature

sensor

9 Knock sensor

4 Injector

Fuel pump Fuel pressure

regulator Evaporative

emission

canister

6 Evaporative

emission

ventilation

solenoid

7 EGR valve

(stepper motor)

1 Mass airflow sensor

2 Intake air temperature sensor

3 Throttle position sensor (main/sub)

4 Manifold absolute pressure sensor

5 Engine coolant temperature sensor

6 Intake camshaft position sensor

7 Exhaust camshaft position sensor

8 Crankshaft position sensor

9 Knock sensor

10 Heated oxygen sensor (front)

11 Heated oxygen sensor (rear)

12 Heated oxygen sensor (3rd)

13 Fuel tank differential pressure sensor

14 Fuel tank temperature sensor

Ignition switch-IG

Ignition switch-ST

Power supply

CAN communication (input signal)1 Intake engine oil control valve

2 Exhaust engine oil control valve

3 Throttle actuator control motor

4 Injector

5 Evaporative emission purge solenoid

6 Evaporative emission ventilation

solenoid

7 EGR valve (stepper motor)

Ignition coil, ignition power transistor

Multiport fuel injection (MFI) relay

Fuel pump relay

Starter relay

Throttle actuator control motor relay

Generator G terminal

Heated oxygen sensor heater

A/C compressor relay

Diagnostic output

CAN communication (output signal) SenseAct

Engine oil pressure switch

Power steering pressure switch

Generator FR terminal

Generator L terminal

Vehicle speed sensor

Decide

ECM

(with barometric

pressure sensor)

AB

Page 101 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-8

SENSORM2132001000565.

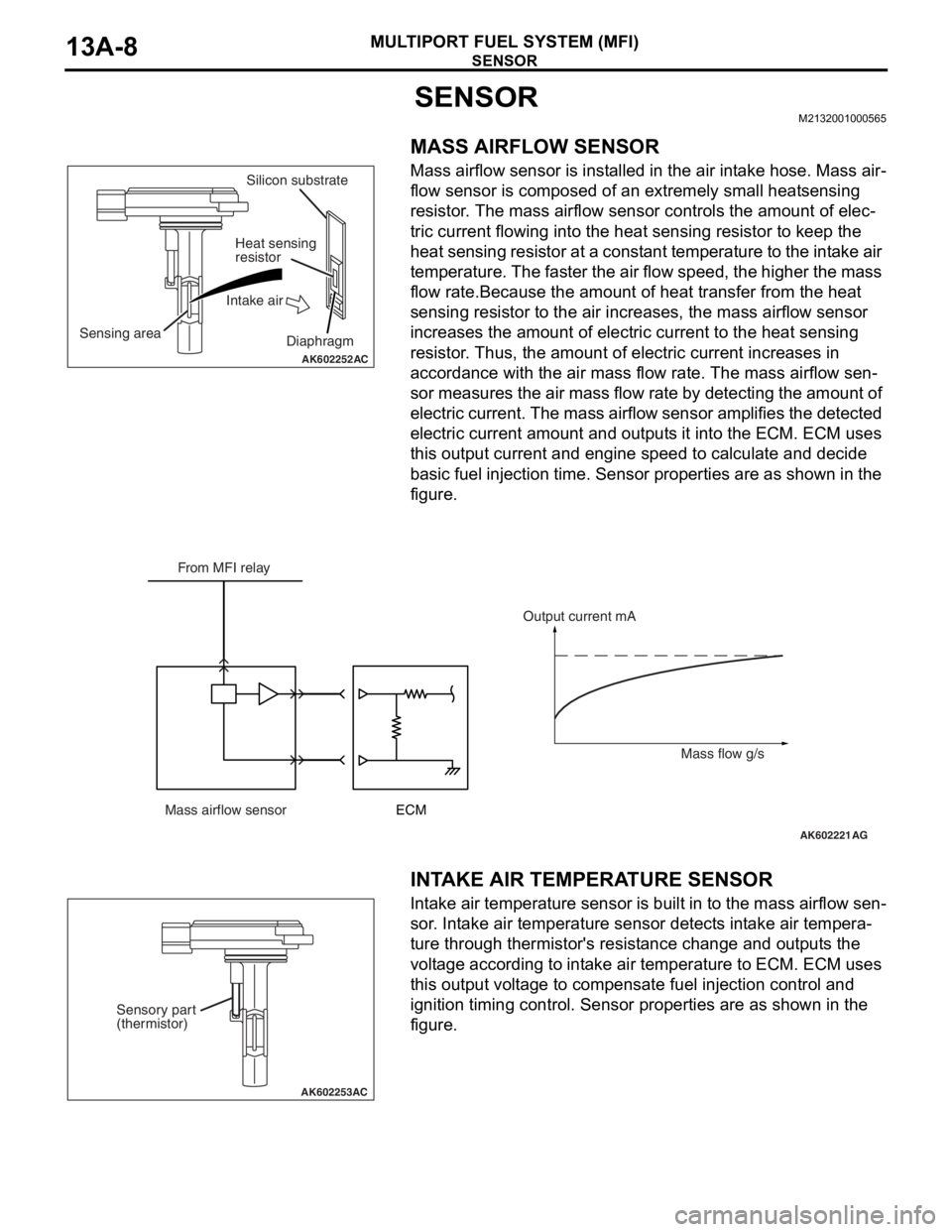

MASS AIRFLOW SENSOR

Mass airflow sensor is installed in the air intake hose. Mass air-

flow sensor is composed of an extremely small heatsensing

resistor. The mass airflow sensor controls the amount of elec

-

tric current flowing into the heat sensing resistor to keep the

heat sensing resistor at a constant temperature to the intake air

temperature. The faster the air flow speed, the higher the mass

flow rate.Because the amount of heat transfer from the heat

sensing resistor to the air increases, the mass airflow sensor

increases the amount of electric current to the heat sensing

resistor. Thus, the amount of electric current increases in

accordance with the air mass flow rate. The mass airflow sen

-

sor measures the air mass flow rate by detecting the amount of

electric current. The mass airflow sensor amplifies the detected

electric current amount and outputs it into the ECM. ECM uses

this output current and engine speed to calculate and decide

basic fuel injection time. Sensor properties are as shown in the

figure.

.

INTAKE AIR TEMPERATURE SENSOR

Intake air temperature sensor is built in to the mass airflow sen-

sor. Intake air temperature sensor detects intake air tempera-

ture through thermistor's resistance change and outputs the

voltage according to intake air temperature to ECM. ECM uses

this output voltage to compensate fuel injection control and

ignition timing control. Sensor properties are as shown in the

figure.

AK602252AC

Sensing areaSilicon substrate

Heat sensing

resistor

Intake air

Diaphragm

AK602221AG

From MFI relay

Mass airflow sensorECMOutput current mA

Mass flow g/s

AK602253AC

Sensory part

(thermistor)

Page 108 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-15

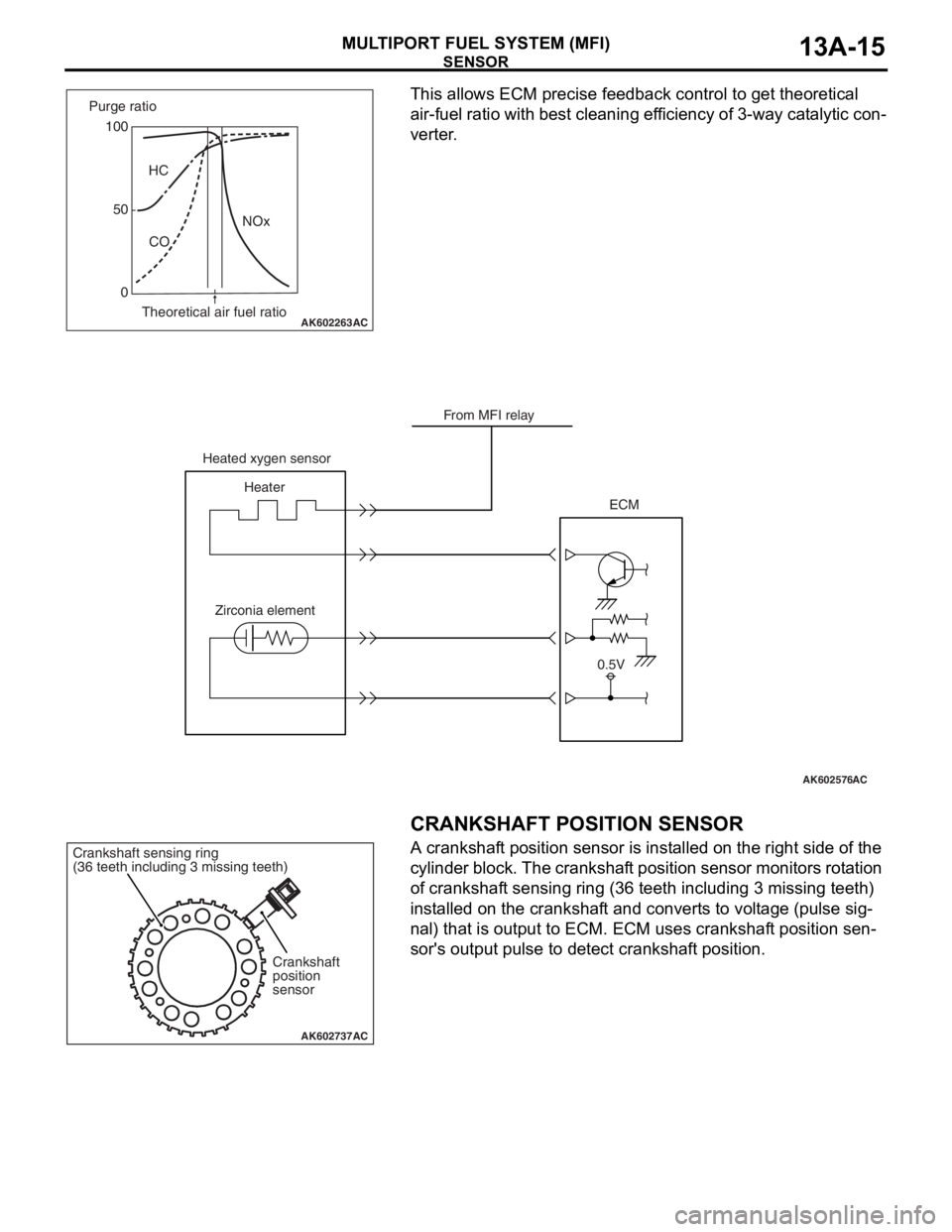

This allows ECM precise feedback control to get theoretical

air-fuel ratio with best cleaning efficiency of 3-way catalytic con

-

verter.

.

CRANKSHAFT POSITION SENSOR

A crankshaft position sensor is installed on the right side of the

cylinder block. The crankshaft position sensor monitors rotation

of crankshaft sensing ring (36 teeth including 3 missing teeth)

installed on the crankshaft and converts to voltage (pulse sig

-

nal) that is output to ECM. ECM uses crankshaft position sen-

sor's output pulse to detect crankshaft position.

.

AK602263AC

100

0HC

CONOx 50 Purge ratio

Theoretical air fuel ratio

AK602576AC

From MFI relay

Heated xygen sensor

Heater

Zirconia elementECM

0.5V

AK602737AC

Crankshaft

position

sensor Crankshaft sensing ring

(36 teeth including 3 missing teeth)

Page 116 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-23

ACTUATORM2132002000353

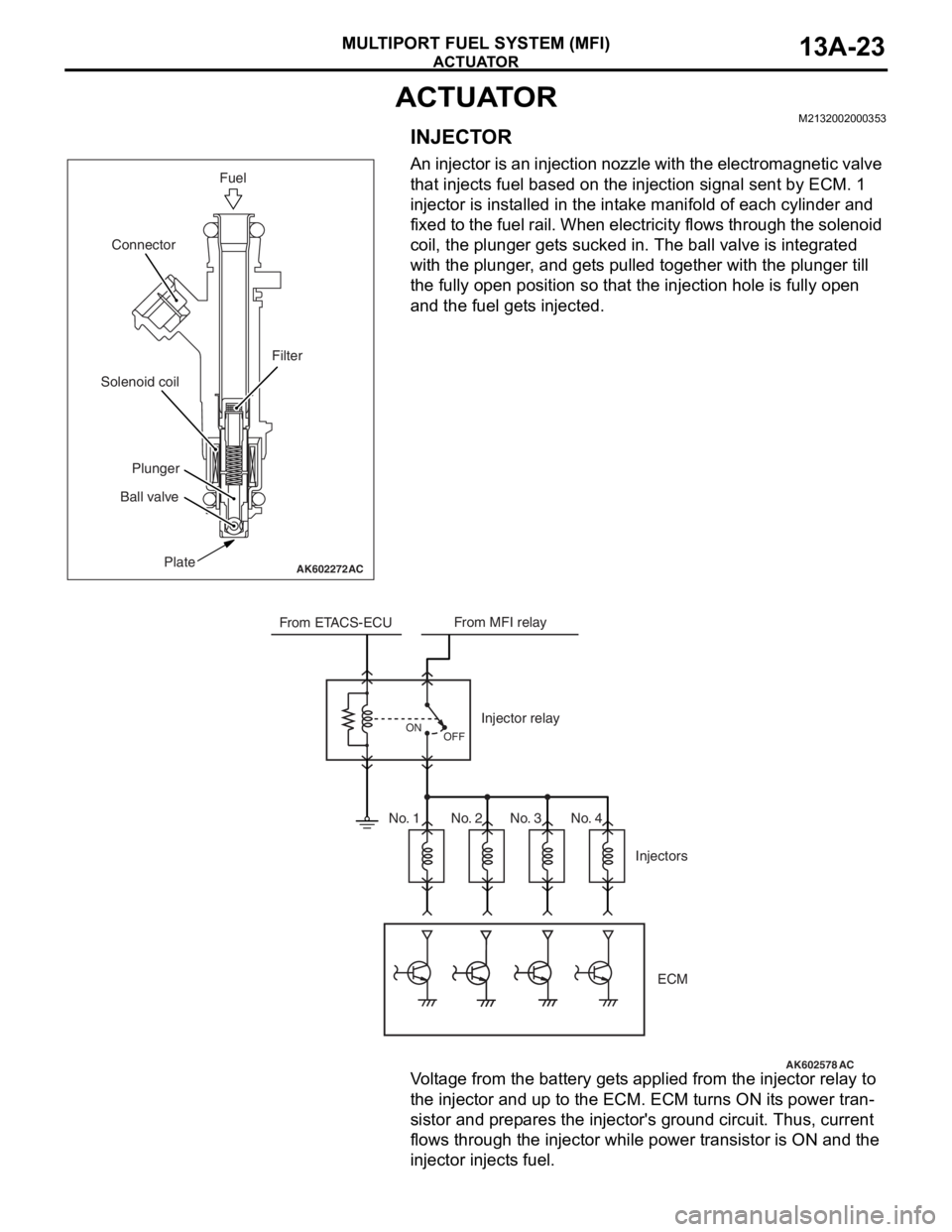

INJECTOR

An injector is an injection nozzle with the electromagnetic valve

that injects fuel based on the injection signal sent by ECM. 1

injector is installed in the intake manifold of each cylinder and

fixed to the fuel rail. When electricity flows through the solenoid

coil, the plunger gets sucked in. The ball valve is integrated

with the plunger, and gets pulled together with the plunger till

the fully open position so that the injection hole is fully open

and the fuel gets injected.

Voltage from the battery gets applied from the injector relay to

the injector and up to the ECM. ECM turns ON its power tran

-

sistor and prepares the injector's ground circuit. Thus, current

flows through the injector while power transistor is ON and the

injector injects fuel.

AK602272AC

Fuel

Plate Ball valvePlunger Solenoid coilConnector

Filter

AK602578

From ETACS-ECUFrom MFI relay

Injector relay

Injectors

OFF ON

ECM

AC

No. 1 No. 2 No. 3 No. 4

Page 117 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-24

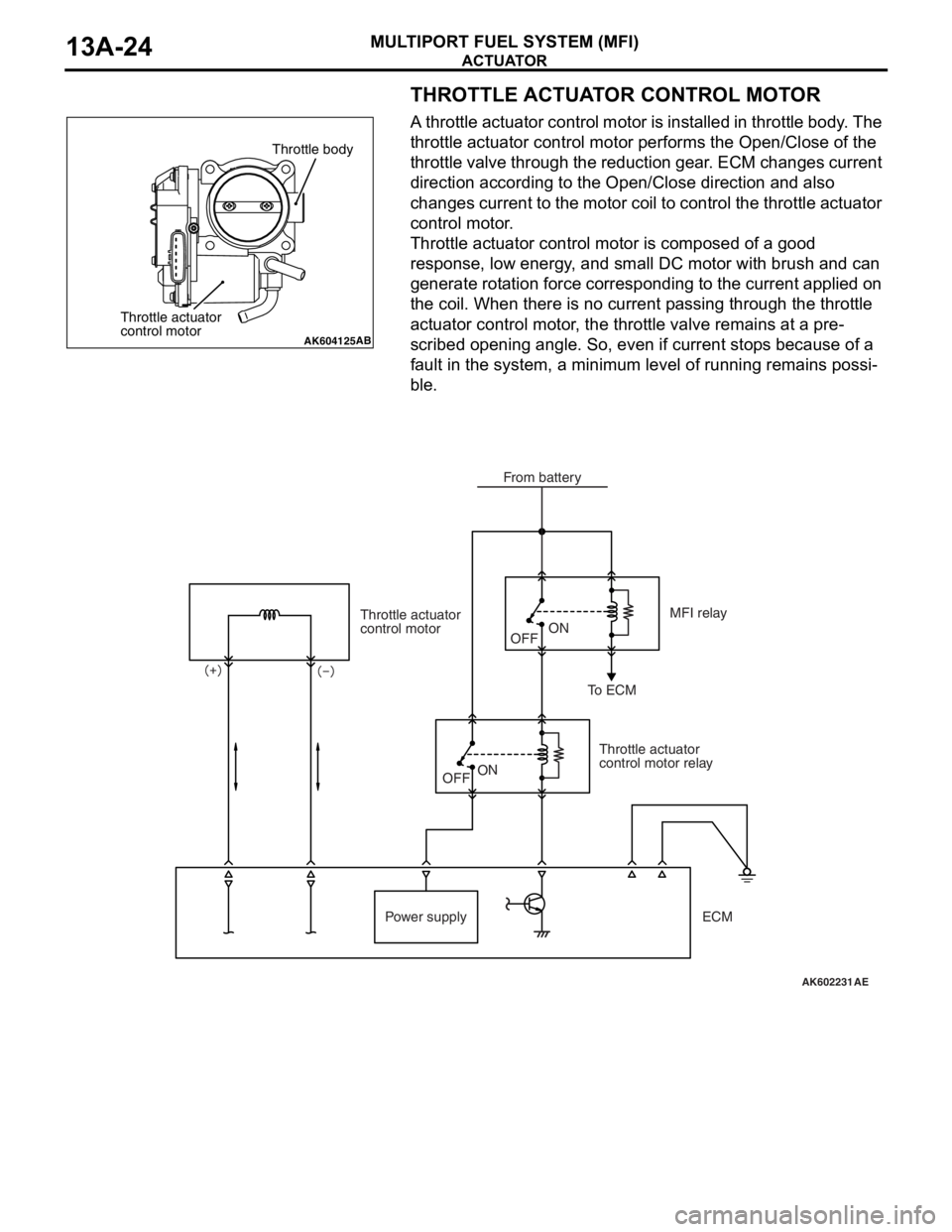

THROTTLE ACTUATOR CONTROL MOTOR

A throttle actuator control motor is installed in throttle body. The

throttle actuator control motor performs the Open/Close of the

throttle valve through the reduction gear. ECM changes current

direction according to the Open/Close direction and also

changes current to the motor coil to control the throttle actuator

control motor.

Throttle actuator control motor is composed of a good

response, low energy, and small DC motor with brush and can

generate rotation force corresponding to the current applied on

the coil. When there is no current passing through the throttle

actuator control motor, the throttle valve remains at a pre

-

scribed opening angle. So, even if current stops because of a

fault in the system, a minimum level of running remains possi

-

ble.

AK604125AB

Throttle body

Throttle actuator

control motor

AK602231

Throttle actuator

control motor

Throttle actuator

control motor relayMFI relay

To ECM

Power supplyOFFON

OFF

ON

AE

From battery

ECM

Page 118 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-25

IGNITION COIL

Refer to GROUP 16 − Ignition Coil P.16-2.

EXHAUST GAS RECIRCULATION (EGR) VALVE

Refer to GROUP 17 − Emission Control − Exhaust Gas Recircu-

lation (EGR) System P.17-12.

EVAPORATIVE EMISSION PURGE SOLENOID

Refer to GROUP 17 − Emission Control − Evaporative Emission

Control System

P.17-11.

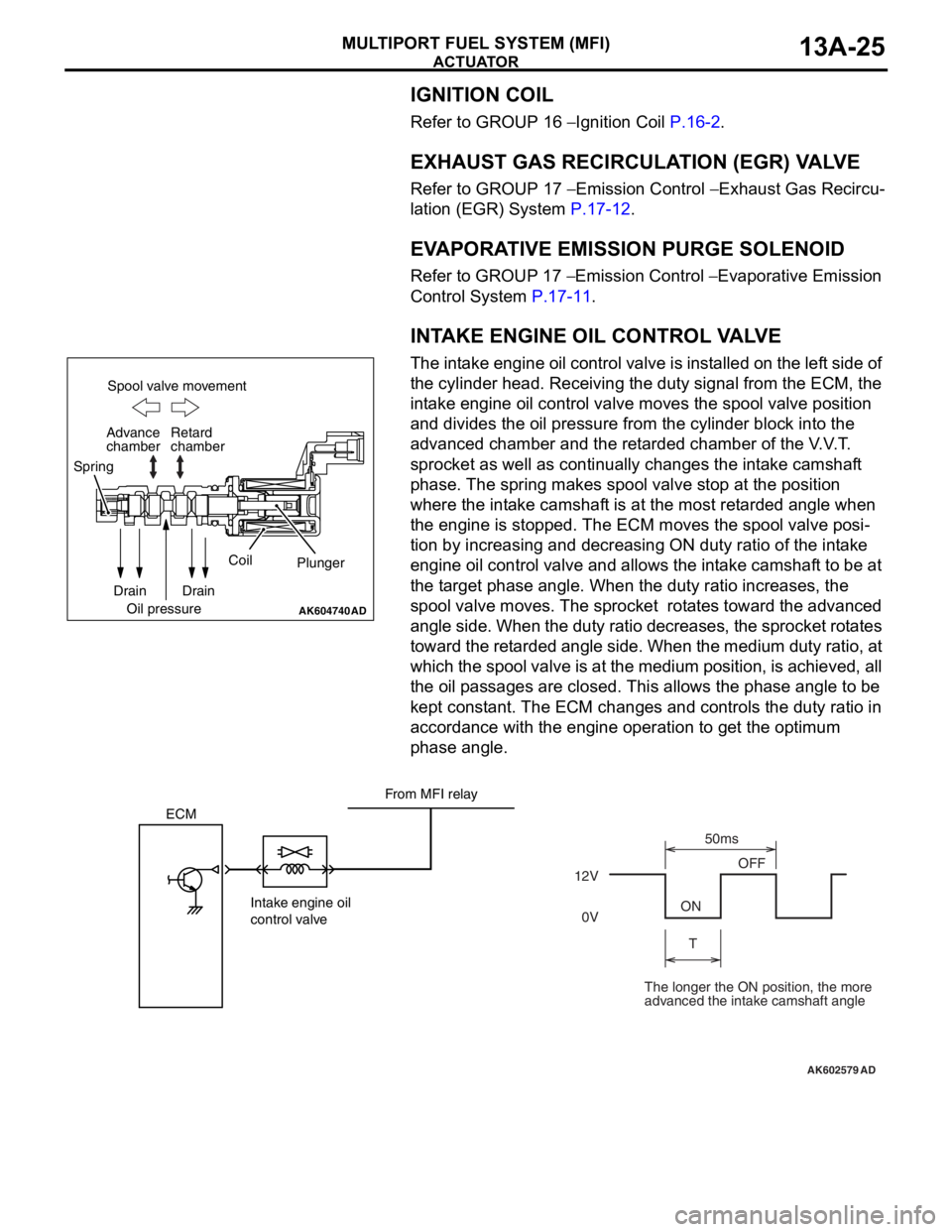

INTAKE ENGINE OIL CONTROL VALVE

The intake engine oil control valve is installed on the left side of

the cylinder head. Receiving the duty signal from the ECM, the

intake engine oil control valve moves the spool valve position

and divides the oil pressure from the cylinder block into the

advanced chamber and the retarded chamber of the V.V.T.

sprocket as well as continually changes the intake camshaft

phase. The spring makes spool valve stop at the position

where the intake camshaft is at the most retarded angle when

the engine is stopped. The ECM moves the spool valve posi

-

tion by increasing and decreasing ON duty ratio of the intake

engine oil control valve and allows the intake camshaft to be at

the target phase angle. When the duty ratio increases, the

spool valve moves. The sprocket rotates toward the advanced

angle side. When the duty ratio decreases, the sprocket rotates

toward the retarded angle side. When the medium duty ratio, at

which the spool valve is at the medium position, is achieved, all

the oil passages are closed. This allows the phase angle to be

kept constant. The ECM changes and controls the duty ratio in

accordance with the engine operation to get the optimum

phase angle.

AK604740AD

Spool valve movement

Retard

chamber

Spring

Drain

Oil pressureCoil

Plunger

Drain Advance

chamber

AK602579

ECM

Intake engine oil

control valve12VOFF

ON

T50ms

0V

AD

From MFI relay

The longer the ON position, the more

advanced the intake camshaft angle

Page 119 of 241

ACTUATOR

MULTIPORT FUEL SYSTEM (MFI)13A-26

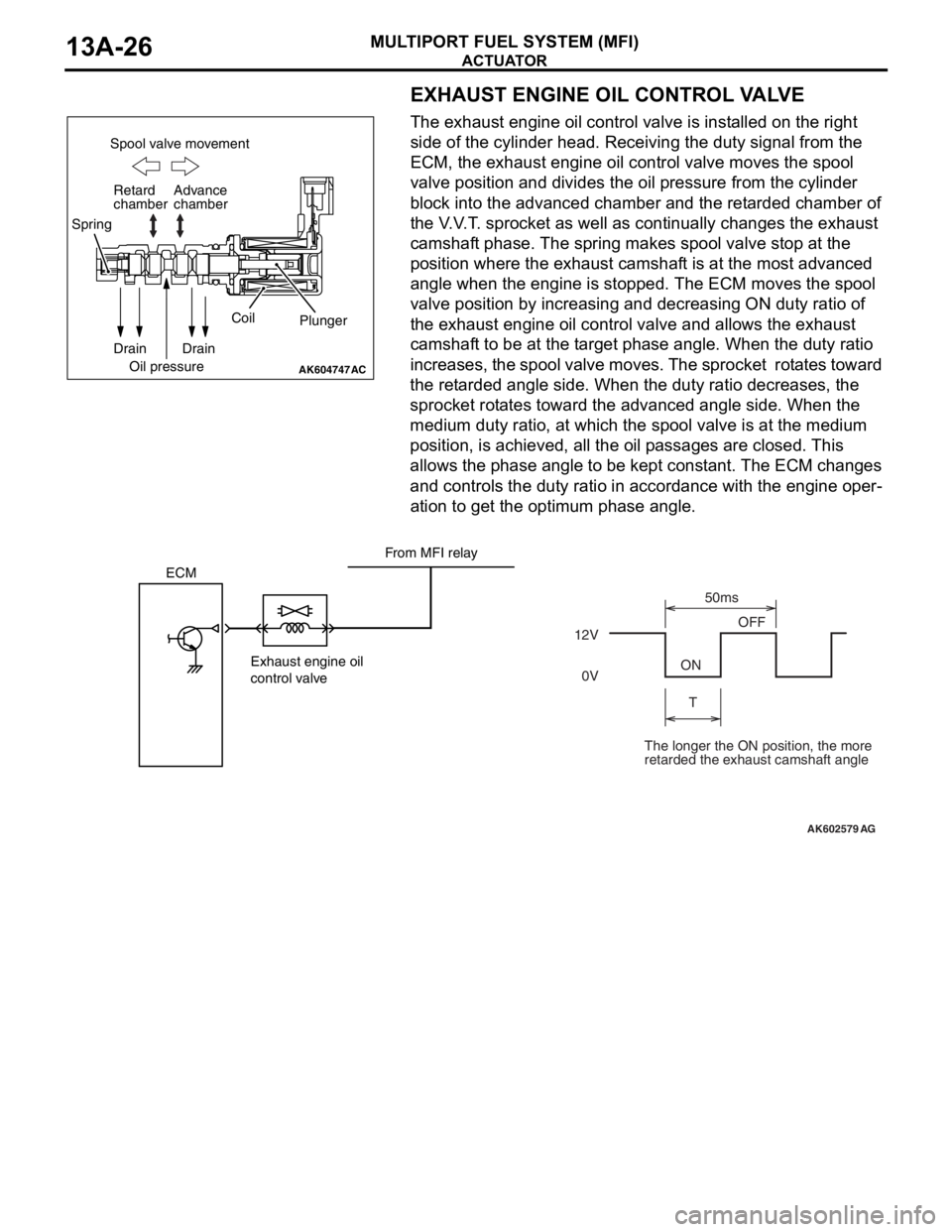

EXHAUST ENGINE OIL CONTROL VALVE

The exhaust engine oil control valve is installed on the right

side of the cylinder head. Receiving the duty signal from the

ECM, the exhaust engine oil control valve moves the spool

valve position and divides the oil pressure from the cylinder

block into the advanced chamber and the retarded chamber of

the V.V.T. sprocket as well as continually changes the exhaust

camshaft phase. The spring makes spool valve stop at the

position where the exhaust camshaft is at the most advanced

angle when the engine is stopped. The ECM moves the spool

valve position by increasing and decreasing ON duty ratio of

the exhaust engine oil control valve and allows the exhaust

camshaft to be at the target phase angle. When the duty ratio

increases, the spool valve moves. The sprocket rotates toward

the retarded angle side. When the duty ratio decreases, the

sprocket rotates toward the advanced angle side. When the

medium duty ratio, at which the spool valve is at the medium

position, is achieved, all the oil passages are closed. This

allows the phase angle to be kept constant. The ECM changes

and controls the duty ratio in accordance with the engine oper

-

ation to get the optimum phase angle.

AK604747

Spool valve movement

Retard

chamber

Spring

Drain

Oil pressureCoil

Plunger

Drain Advance

chamber

AC

AK602579

ECM

Exhaust engine oil

control valve12VOFF

ON

T50ms

0V

AG

From MFI relay

The longer the ON position, the more

retarded the exhaust camshaft angle