wheel MITSUBISHI LANCER IX 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER IX, Model: MITSUBISHI LANCER IX 2006Pages: 800, PDF Size: 45.03 MB

Page 222 of 800

GENERAL INFORMATION

PARKING BRAKES36-2

GENERAL INFORMATION

M1361000100496

The parking brake is of a mechanical rear-wheel act-

ing type, and its operation utilises a parking brake

lever.

SPECIFICATIONS

ItemSpecification

Ty p eDrum-in disc

Clearance adjustmentManual

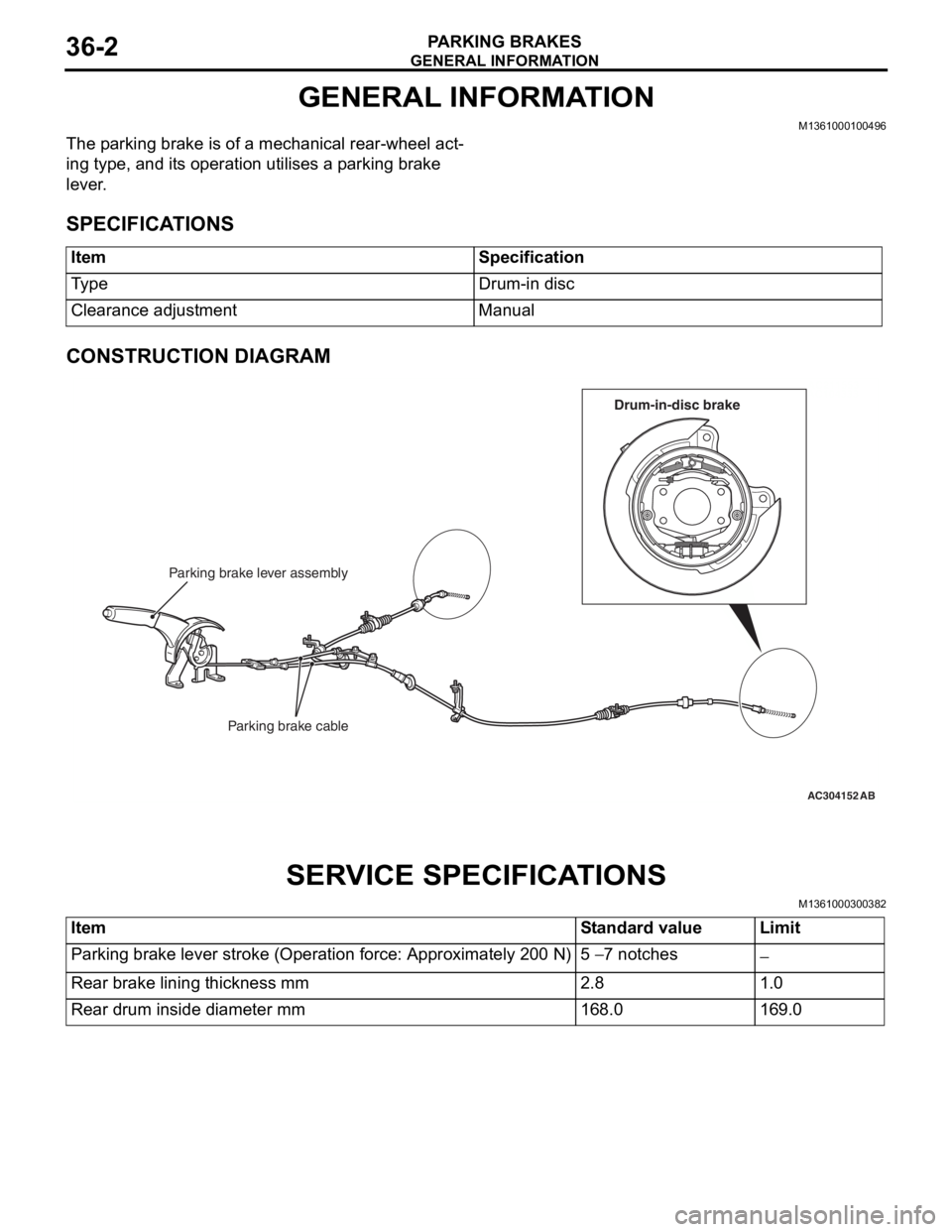

CONSTRUCTION DIAGRAM

AC211553

AC104333

AC304152

Parking brake lever assembly

Parking brake cable

AB

Drum-in-disc brake

SERV ICE SPECI F ICA T IONS

M13610003 0038 2

ItemStandard valueLimit

Parking brake lever stroke (Operation force: Approximately 200 N)5 − 7 notches−

Rear brake lining thickness mm2.81.0

Rear drum inside diameter mm168.0169.0

Page 223 of 800

LUBRICANTS

PARKING BRAKES36-3

LUBRICANTS

M1361000400293

ItemSpecified lubricant

Rear brake shoe and backing plate contact surfaceBrake grease SAE J310, NLGI No.1

Rear brake shoe assembly

Rear brake shoe slack adjuster

ON-VEHIC LE SER VI CE

PARKING BRAKE LE VER STROKE

CHECK AND ADJUSTMENT

M13610009 0033 9

1.Pull the p a rkin g brake le ver wit h a force of

ap proxima t ely 200 N an d co unt the number of

no tche s.

St andard va lue: 5 − 7 notches

2.If the p a rking b r ake leve r stro ke is no t the

st a ndard valu e, adjust as de scribed below .

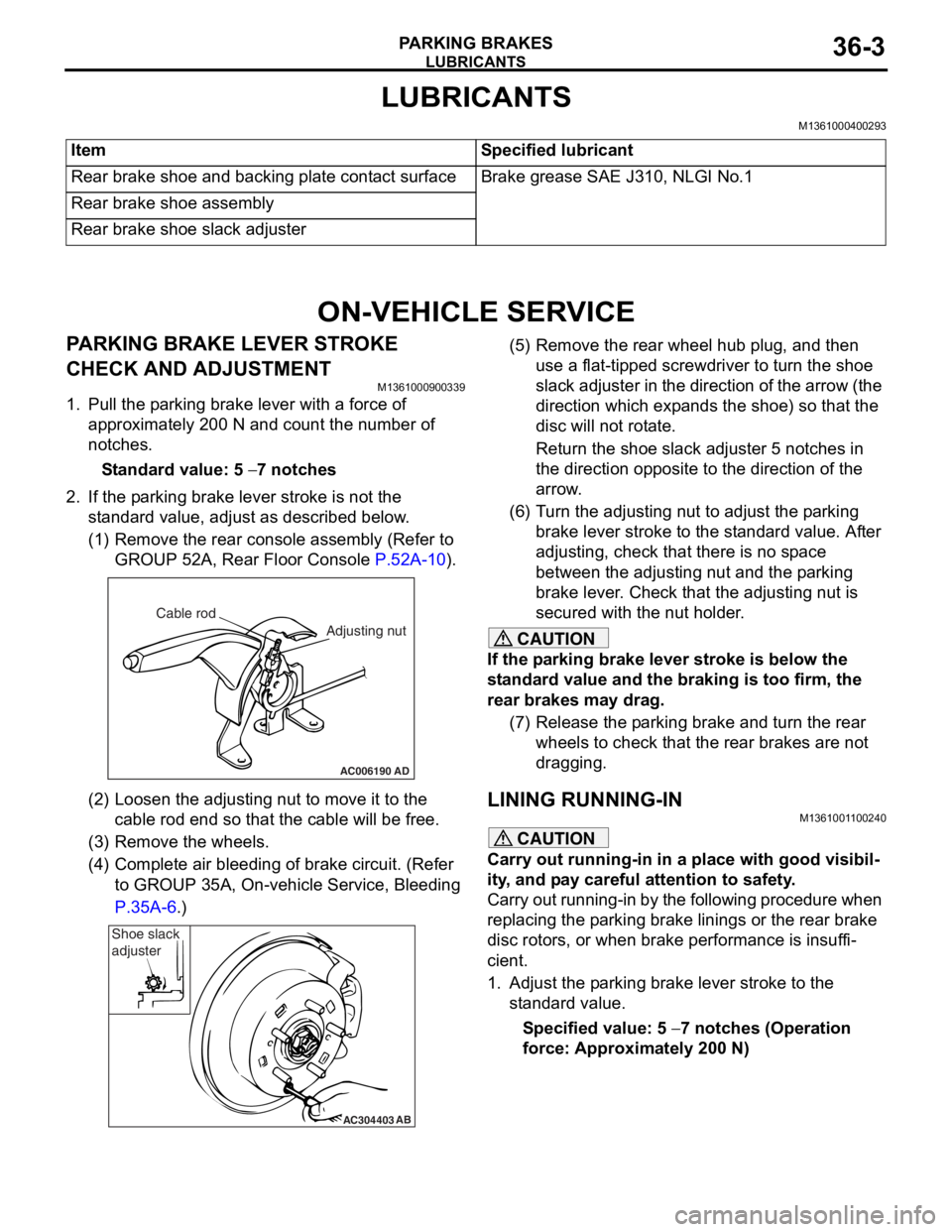

(1)R emove the rear console a sse mbly (Refer to

GROUP 5 2 A, Rear Floor Console

P.52A-10).

AC006190

Cable rod

Adjusting nut

AD

(2)Loosen th e adjusting nu t to move it to th e

cab l e rod end so tha t the cable will be fre e .

(3)R emove the wheels.

(4)C omplete a i r bleedin g of b r ake circuit. (Re f er

to GROUP 35A, On-ve h icle Service, Blee ding

P.35A-6.)

AC304403AB

Shoe slack

adjuster

(5

) R emove the rear whee l hub plug , and then

use a flat-tipped screwdriver to turn the shoe

slack ad juster in the direction of the arrow (the

dire ctio n which exp a nds the shoe) so that the

disc will no t rot a te.

Return the sh oe slack adjust e r 5 not ches in

the d

i rection opposite t o the d i rection of the

arrow

.

(6) T urn th e adjusting nut to adjust the p a rking

brake le ver stroke to the st anda rd value. Af ter

adjusting, check that there is n o sp ace

between the a d justing nut an d the p a rking

brake le ver . Che ck that th e adjusting nut is

secured with the nut ho lder .

CAUTION

If the parking brake lever stroke is below the

standard value and the braking is too firm, the

rear brakes may drag.

(7) Release the parking brake and turn the rear wheels to check that t he rear brakes are not

dragging.

LINING RUNNING-INM1361001100240

CAUTION

Carry out running-in in a place with good visibil-

ity, and pay careful attention to safety.

Carry out running-in by the following procedure when

replacing the parking brake linings or the rear brake

disc rotors, or when brake performance is insuffi

-

cient.

1. Adjust the parking brake lever stroke to the standard value.

Specified value: 5 − 7 notches (Operation

force: Approximately 200 N)

Page 228 of 800

Page 229 of 800

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-9

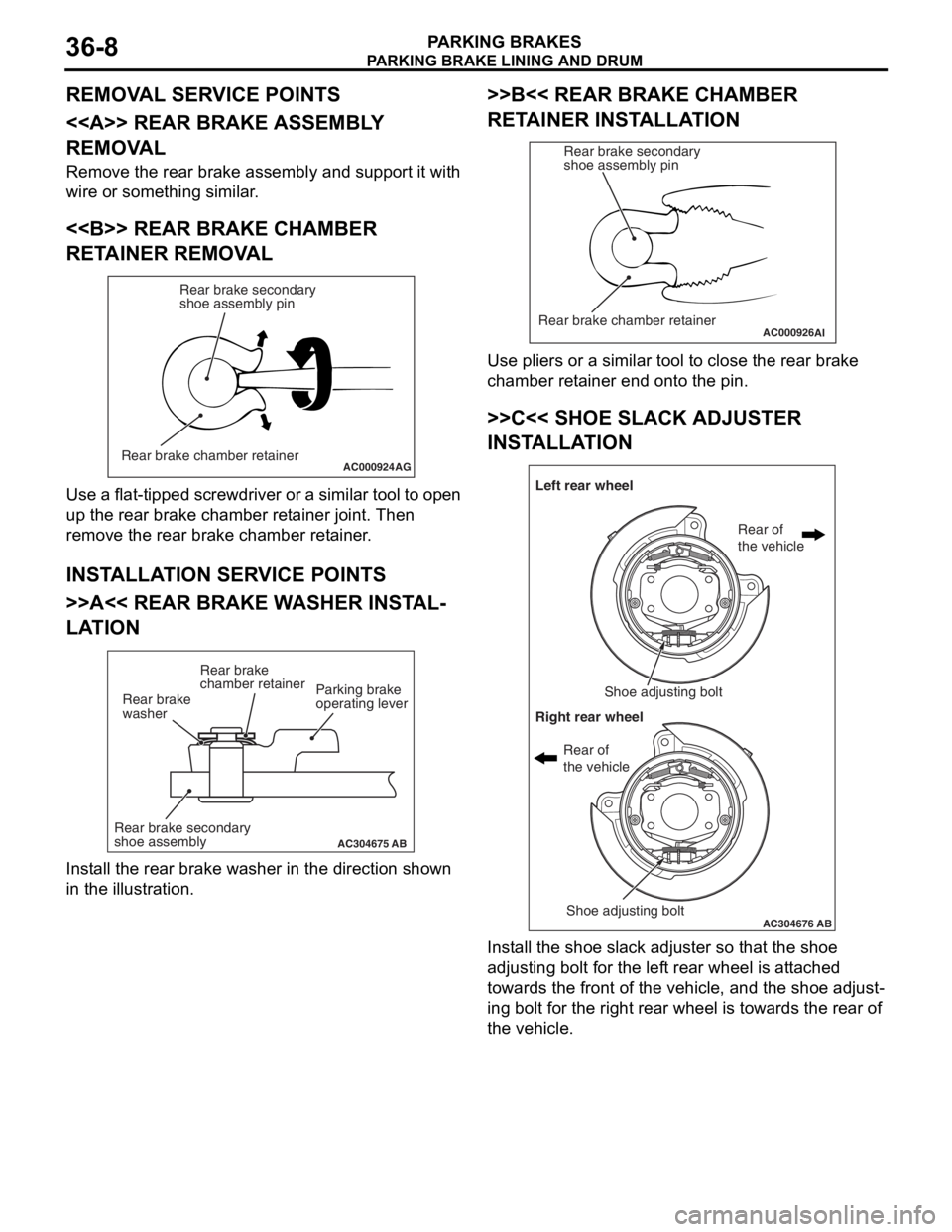

>>D<< SHOE RETURN SPRINGS

INSTALLATION

AC202302AC

Front of the vehicleBlue paint Yellow paint

The shoe ret u rn sp rings are n o t in tercha ngeab le as

their const

a nt s are d i f f e r ent. Th e one with blue p a in t

mark

should be inst a ll at t he fron t o f th e vehicle, and

the oth

e r with yellow p a int a t the re ar of th e ve hicle,

respectively

.

NOTE: The ill ustratio n sh ows th e lef t rear whee l. T he

right re

ar wheel is symme trical to that.

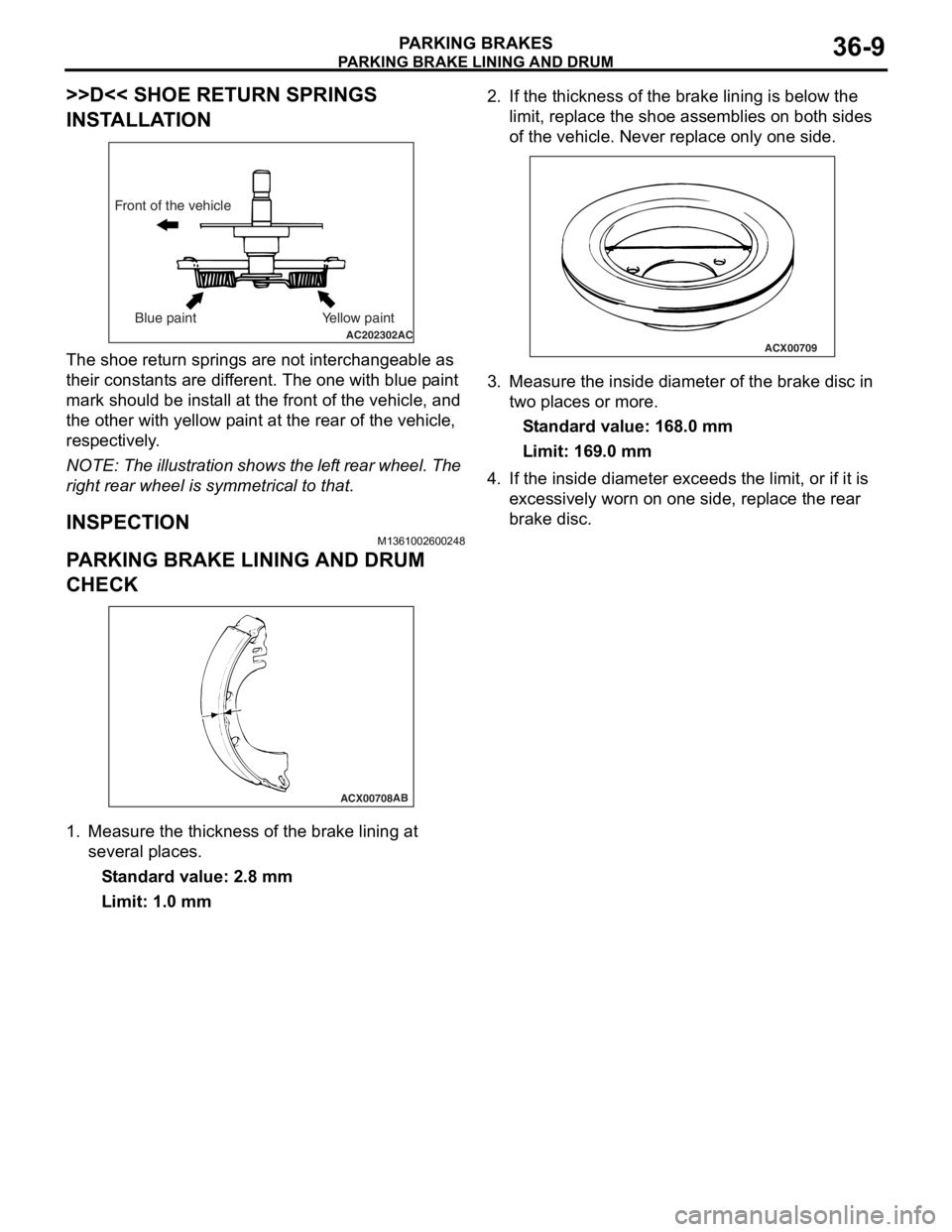

INSPECTION

M13610026 0024 8

PARKING BRAKE LI NING AND DRUM

CHECK

ACX00708AB

1.

Measure the thickne ss of the b r ake lining at

seve ral place s .

St andard va lue: 2.8 mm

Limit: 1.0 mm

2.If the thickness of t he brake linin g is belo w the

limit, rep l ace the shoe a s semblies on bo th sides

o f the vehicle. Ne ver re place only on e side.

ACX00709

3.Measure the inside d i ameter of the bra k e d i sc in

two p l aces o r more .

St andard va lue: 16 8.0 mm

Limit: 169.0 mm

4.If the inside diamete r exceeds the limit, or if it is

e xce ssively worn on one side, rep l ace the re ar

b r ake d i sc.

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 233 of 800

GENERAL INFORMATION

POWER STEERING37-3

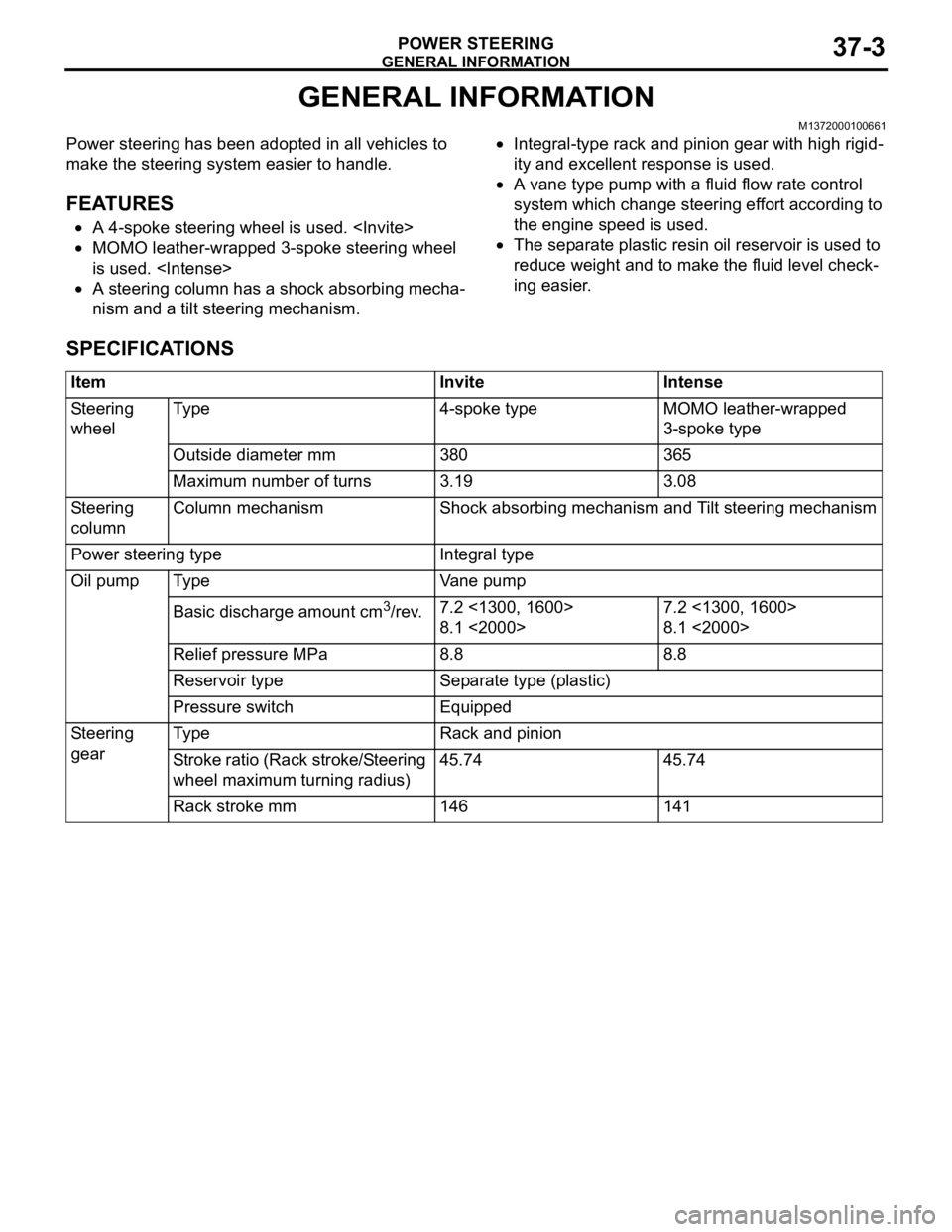

GENERAL INFORMATION

M1372000100661

Power steering has been adopted in all vehicles to

make the steering system easier to handle.

FEATURES

•A 4-spoke steering wheel is used.

•MOMO leather-wrapped 3-spoke steering wheel

is used.

•A steering column has a shock absorbing mecha-

nism and a tilt steering mechanism.

•Integral-type rack and pinion gear with high rigid-

ity and excellent response is used.

•A vane type pump with a fluid flow rate control

system which change steering effort according to

the engine speed is used.

•The separate plastic resin oil reservoir is used to

reduce weight and to make the fluid level check

-

ing easier.

SPECIFICATIONS

ItemInviteIntense

Steering

wheelTy p e4-spoke typeMOMO leather-wrapped

3-spoke type

Outside diameter mm380365

Maximum number of turns3.193.08

Steering

columnColumn mechanismShock absorbing mechanism and Tilt steering mechanism

Power steering typeIntegral type

Oil pumpTy p eVane pump

Basic discharge amount cm3/rev.7.2 <1300, 1600>

8.1 <2000>

7.2 <1300, 1600>

8.1 <2000>

Relief pressure MPa8.88.8

Reservoir typeSeparate type (plastic)

Pressure switchEquipped

Steering

gearTy p eRack and pinion

Stroke ratio (Rack stroke/Steering

wheel maximum turning radius)45.7445.74

Rack stroke mm146141

Page 234 of 800

GENERAL INFORMATION

POWER STEERING37-4

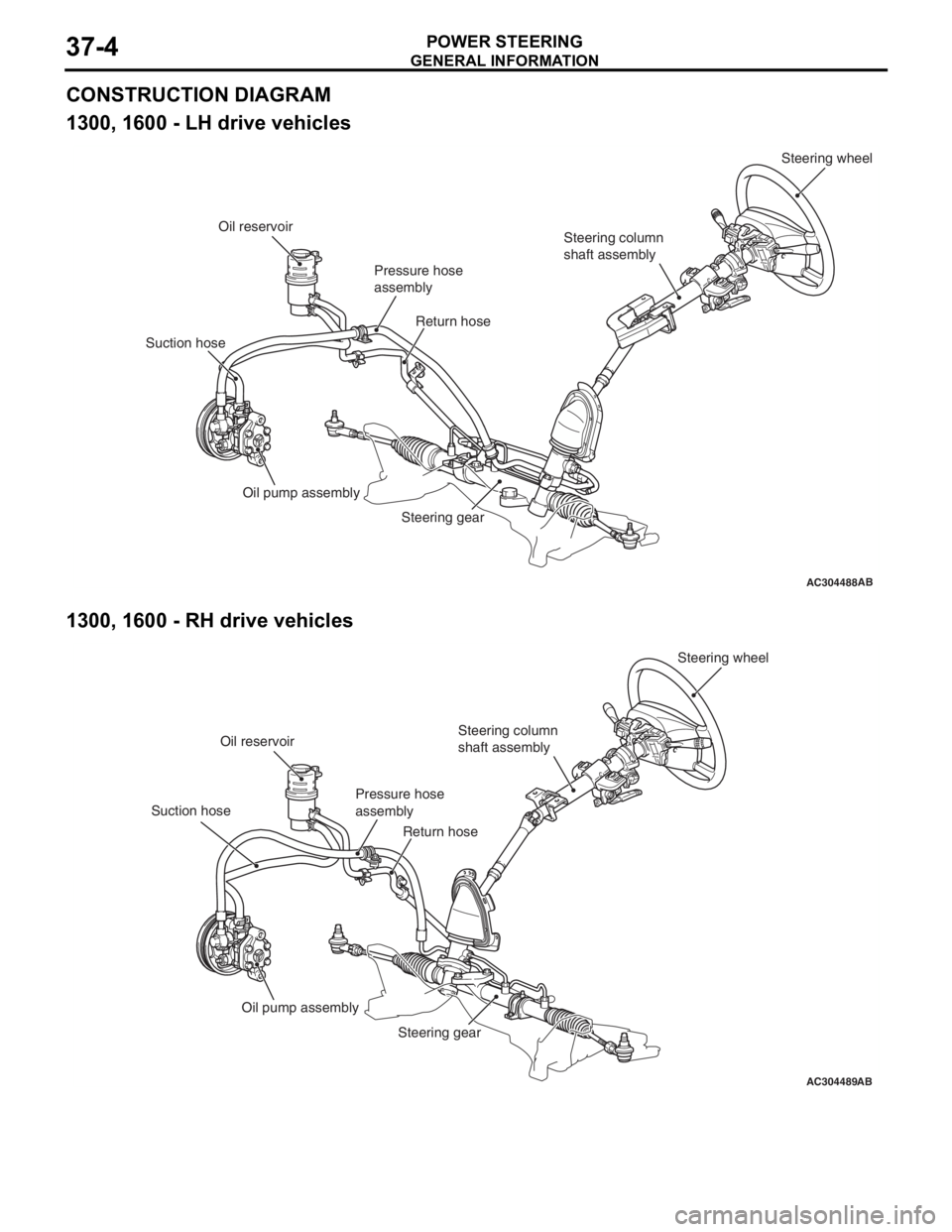

CONSTRUCTION DIAGRAM

1300, 1600 - LH drive vehicles

AC304488AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

1300, 1600 - RH drive vehicl es

AC304489AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

Page 235 of 800

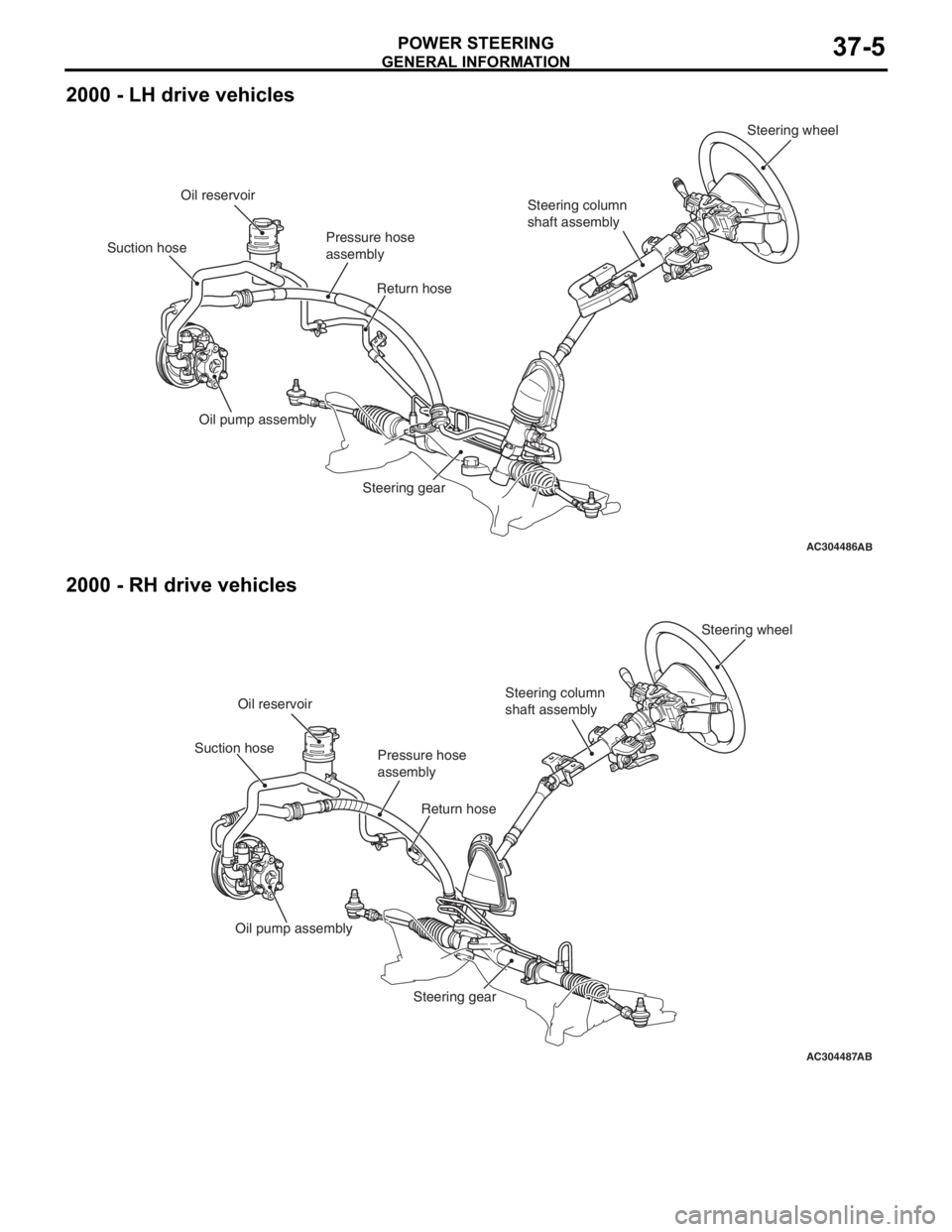

GENERAL INFORMATION

POWER STEERING37-5

2000 - LH drive vehicles

AC304486AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose Return hose

Oil pump assembly Steering gear

2000 - RH drive vehicles

AC304487AB

Steering wheel

Steering column

shaft assembly

Pressure hose

assembly

Oil reservoir

Suction hose

Return hose

Oil pump assembly Steering gear

Page 236 of 800

SERVICE SPECIFICATIONS

POWER STEERING37-6

SERVICE SPECIFICATIONS

M1372000300795

ItemStandard valueLimit

Steering wheel free

play mmWith engine running−30

With engine stopped10 or less−

Steering angleInner wheelInvite39°30' ± 1°30'−

Intense (LH drive vehicles)33°40' +1°00'/-2°00'−

Intense (RH drive vehicles)37°00' +1°00'/-2°00'−

Outer wheel

(reference)Invite32°30'−

Intense (LH drive vehicles)28°46'−

Intense (RH drive vehicles)30°00'−

Toe-inAt the centre of tyre tread mm1 ± 2−

Toe-angle (per wheel)0°03' ± 06'−

Tie rod end ball joint turning torque N⋅m0.5 − 2.5−

Tie rod swing resistance N [Tie rod swing torque N⋅m]8 − 27 [1.5 − 4.9]−

Stationary steering effort N [Fluctuation allowance N]29 or less [5.9 or less]−

Oil pump pressure

MPa (750

± 100 r/min.)

Oil pump relief pressure8.8 − 9.5−

Pressure under no-load conditions0.2 − 0.7−

Steering gear retention hydraulic pressure8.8 − 9.5−

Oil pressure switch operating pressure

MPaOFF → ON1.5 − 2.0−

ON → OFF0.7 − 2.0−

Steering gear total pinion torque N⋅m

[Change in torque N

⋅m]

Invite0.8 − 2.1 [0.6 or less]−

Intense0.7 − 2.1 [0.6 or less]−

Opening dimension of special tool boot band crimping tool (MB991561)

mm2.9−

Band crimped width mm2.4 − 2.8−

Page 241 of 800

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set the front wheels straight ahead.

ACX01122 AB

2.Measure the play on th e ste e ring wh eel

circumfer ence before the whee ls st a r t to move

when slightly moving the stee ring whe e l in both

direct ions.

Limit: 30 mm

3.Wh en the play exceed s the limit, check fo r the

play on the stee ring shaf t and stee ring linkage

connectio n . Correct or replace .

4.If th e free play still exceeds the limit valu e, set t he

steering wheel stra ight ahead with the engine

stoppe d. Loa d 5 N towards the steer ing whee l

circumfer ence and check the play .

St andard value (steering whee l pla y with the

engine s

t opped): 1 0 mm o r l ess

5.If the play e xce eds the st an dard value , remove

th e ste e ring gear (Refe r to

P.37-23) and check

the tot a l p i nion torqu e (Refer to P.37-26).

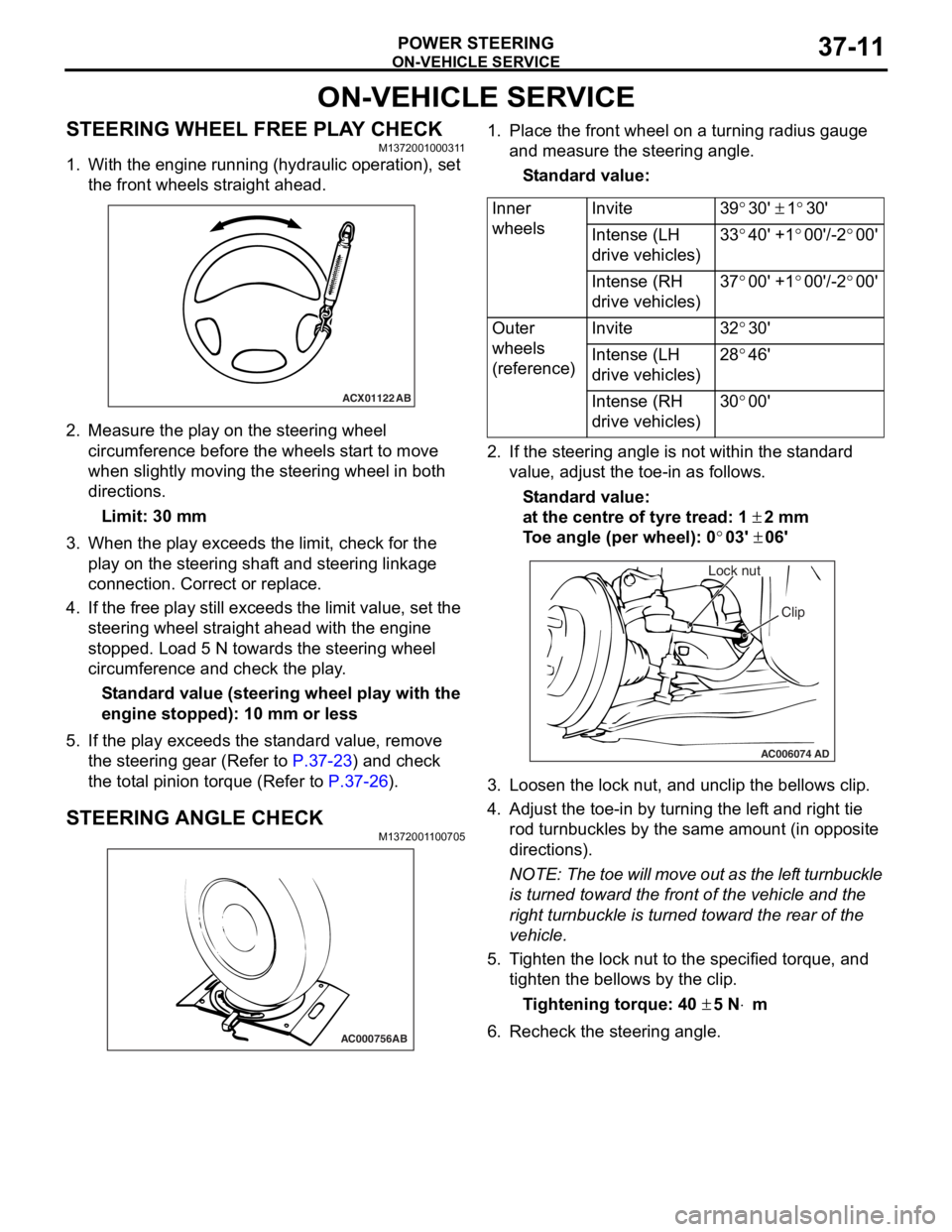

STEERING ANGLE CHECKM137200 1 1 0070 5

AC000756AB

1.Place t he fron t wh eel on a tu rning radiu s gau ge

a nd me asure the steering ang le.

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/-2°00'

Intense (RH

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

2.If the steerin g ang le is not within the st a ndard

value , adjust t he toe-in as follows.

St andard va lue:

at the centre of tyre trea d: 1 ± 2 mm

To e angle (p er whee l): 0°03' ± 06'

AC006074 AD

Lock nut

Clip

3.L oose n the lock nut, and un clip the bellows clip .

4.Adjust the toe - in by turning th e lef t an d righ t tie

ro d turnb u ckles by th e sa me a m oun t (in o pposite

directions).

NOTE: The to e will move out as th e lef t turnbuckle

is tur

ned toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned toward the rear of the

vehicle.

5. T i ghten the lo ck nut to the specified torque , and

tighten the be llo ws by the clip .

Ti ghte n ing torque: 40 ± 5 N⋅m

6.Recheck the stee ring a ngle .