torque MITSUBISHI MONTERO 1987 1.G User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 185 of 284

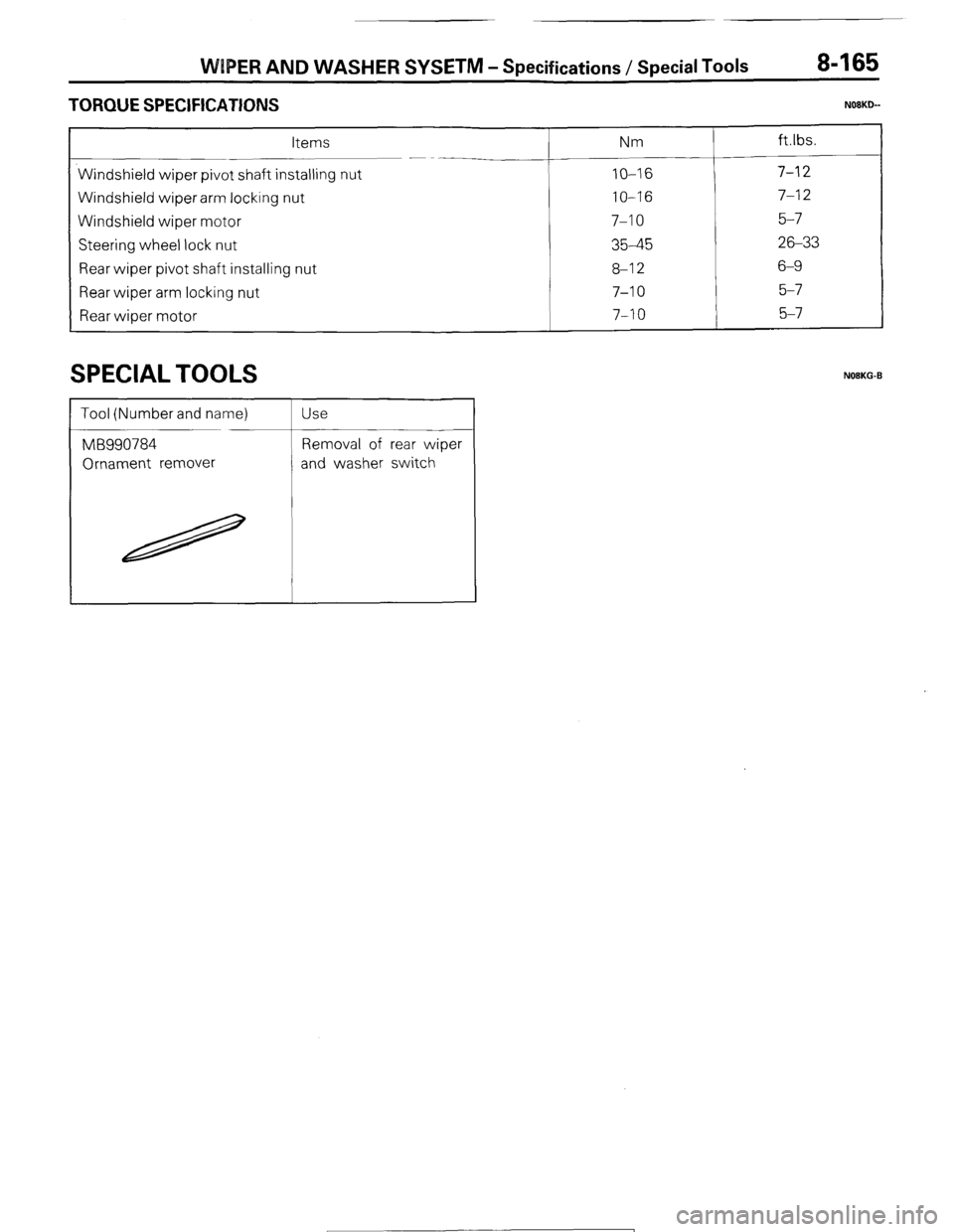

WIPER AND WASHER SYSETM - Specifications / Special TOOIS 8-165

TORQUE SPECIFICATIONS N08KLb-

Items Nm

Windshield wiper pivot shaft installing nut

IO-16 Windshield wiper arm locking nut

IO-16 Windshield wiper motor

7-10 Steering wheel lock nut

35-45 Rear wiper pivot shaft installing nut

8-12 Rear wiper arm locking nut

7-10 Rear wioer motor

7-10

SPECIAL TOOLS NOEKG-B

1 STB Revision

Page 204 of 284

8-184

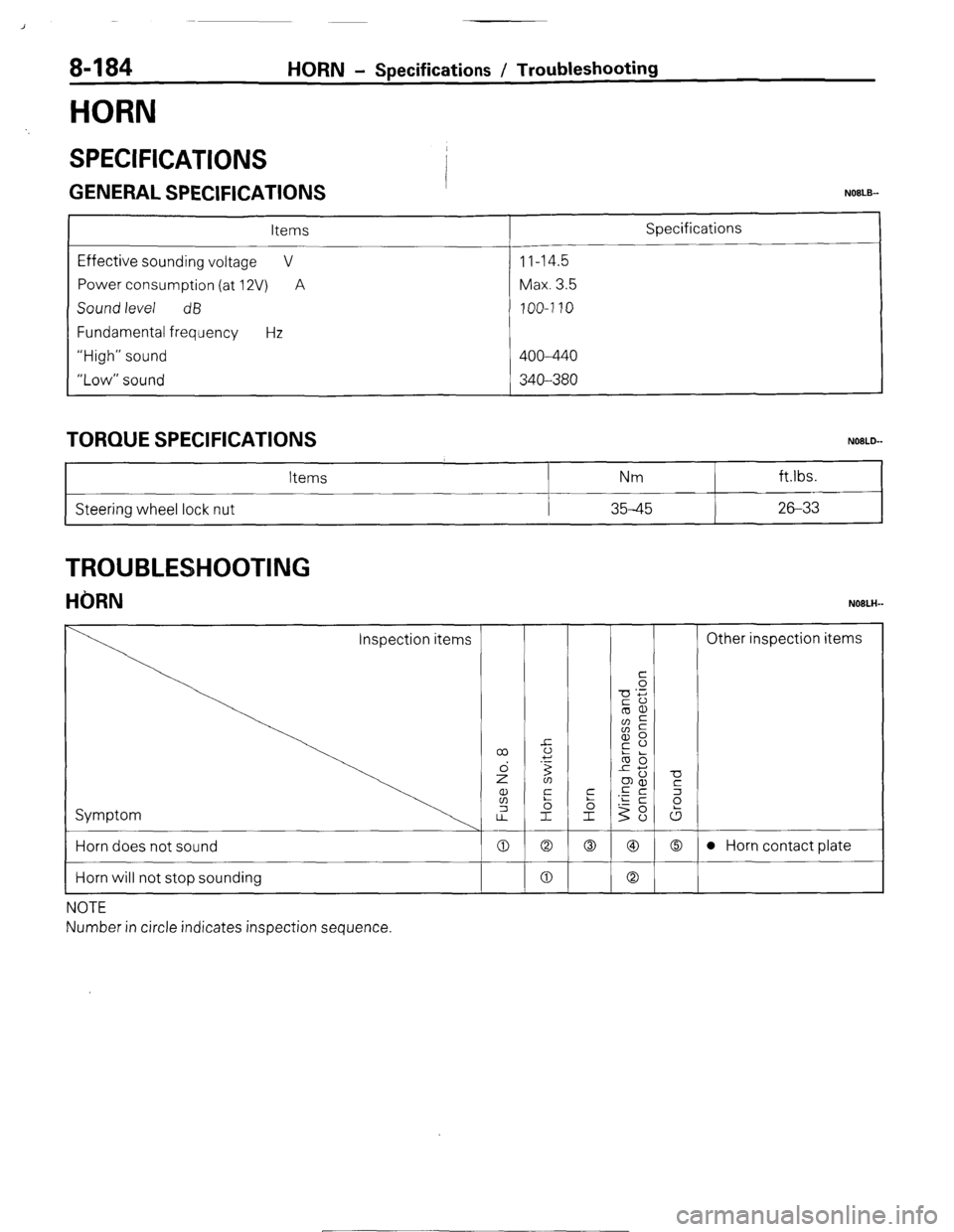

HORN

HORN - Specifications / Troubleshooting

SPECIFICATIONS

GENERAL SPECIFICATIONS I NOBLE--

Items

Effective sounding voltage V

Power consumption (at 12V) A

Sound level dB

Fundamental frequency Hz

“High” sound

“Low” sound 11-14.5

Max. 3.5

100-7 10

400--440

340--380 Specifications

TORQUE SPECIFICATIONS

Steering wheel lock nut Items

i Nm ft.lbs.

35-45 26-33

TROUBLESHOOTING

HORN NOBLH-

Horn does not sound

Horn will not stop sounding

NOTE

Number in circle indicates inspection sequence. 0 Q 0 @I 0 l Horn contact plate

0 0

1 STB Revision

~-1

Page 237 of 284

24-1

AIR-CO IONING

CONTENTS

AIR-CONDITIONING

AIR CONDITIONER SWITCH ......................... 42

CIRCUIT DIAGRAM ...................................... . . 26

COMPRESSOR ............................................... 46

EVAPORATOR ............................................ . ... 43

GENERAL INFORMATION .............. . ....... . . . .... 19

RECEIVER DRIER, CONDENSER,

COMPRESSOR CLUTCH ASSEMBLY .......... 45

SAFETY PRECAUTIONS ................................ 28

SERVICE ADJUSTMENT PROCEDURES ...... 29

Compressor Drive Belt Adjustment ...........

40

Compressor Noise ..................................... 41

Handling Tubing and Fittings ..................... 39

Manifold Gauge Set Installation ................ 29

Performance Test ...................................... 34

Refrigerant Leak Repair Procedure ........... 34

Test Procedures ......................................... 29

Testing System for Leaks .......................... 33

SPECIAL TOOLS ............................................ 22

SPECIFICATIONS ...... . .

.. . ................................ 21

General Specifications ...............................

21

Service Specifications ................................

21

Torque Specifications ................................

21

TROUBLESHOOTING .................................... 22 Air is Emitted but Is Not Cool

Cool Air Flow Is Intermittent

Insufficient Air Flow

Insufficient Cooling

HEATERS

BLOWER ASSEMBLY . . . . . . . . . . . . . . . . . . ..a............... 14

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

HEATER CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

HEATER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SERVICE ADJUSTMENT PROCEDURES . . . . . . 5

Temperature Control System

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Blower Motor Inoperative

Blower Motor Operates on High

Speed Only

Improper Heat

No Ventilation Even When Mode

Selection Lever Is Operated

VENTILATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . ..a..... . . . . . . . . . . . .

16

Page 257 of 284

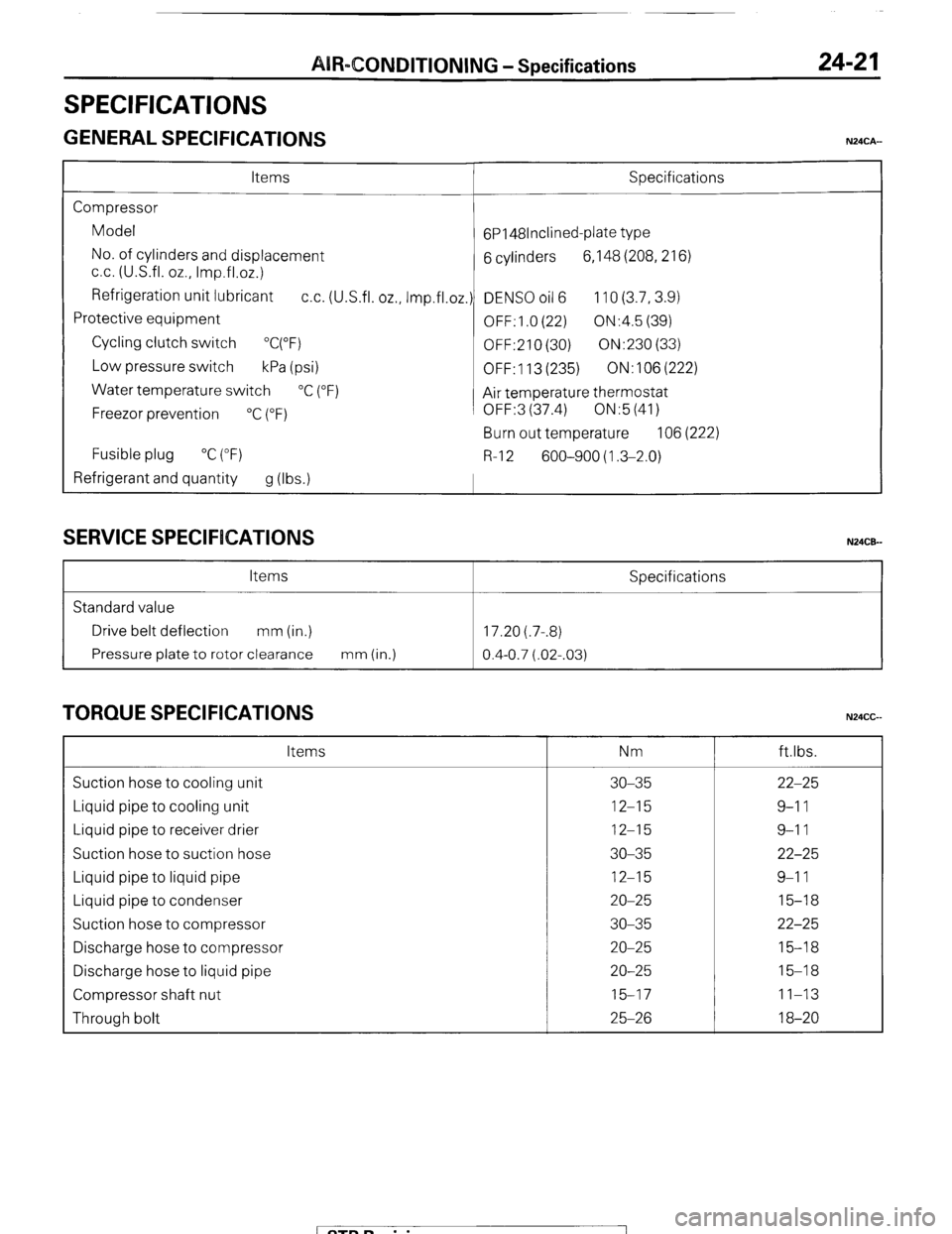

AIR-CONDITIONING -Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

24-2 1

N24CA-

Items Specifications

Compressor

Model

6P148lnclined-plate type

No. of cylinders and displacement

6 cylinders 6,148 (208,216)

cc. (U.S.fl. oz., Imp.fl.02.)

Refrigeration unit lubricant

cc. (U.S.fl. oz., Imp.fl.oz.) DENS0 oil 6 110 (3.7,3.9)

Protective equipment

OFF: 1 .O (22) ON:4.5 (39)

Cycling clutch switch

“C(“F)

OFF:210 (30) ON:230 (33)

Low pressure switch

kPa (psi)

OFF: 113 (235) ON:106(222)

Water temperature switch

“C (“F)

Air temperature thermostat

Freezor prevention

“C (“F) OFF:3 (37.4) ON:5 (41)

Burn out temperature 106 (222)

Fusible plug “C (“F)

R-l 2 600-900 (1.3-2.0)

Refrigerant and quantity

g (Ibs.1

SERVICE SPECIFICATIONS N24CE-

Items Specifications

Standard value

Drive belt deflection mm (in.) 17.20 (.7-.8)

Pressure plate to rotor clearance mm (in.)

0.4-0.7 (.02-.03)

TORQUE SPECIFICATIONS N24CG Items Nm ftlbs.

Suction hose to cooling unit 30-35 22-25

Liquid pipe to cooling unit 12-15 9-l 1

Liquid pipe to receiver drier 12-15 9-l 1

Suction hose to suction hose 30-35 22-25

Liquid pipe to liquid pipe 12-15 9-l 1

Liquid pipe to condenser 20-25 15-18

Suction hose to compressor 30-35 22-25

Discharge hose to compressor 20-25 15-18

Discharge hose to liquid pipe 20-25 15-18

Compressor shaft nut 15-17 11-13

Through bolt 25-26 18-20

/ STB Revision I

Page 276 of 284

24-40 AIR-CONDITIONING-Service Adjustment Procedures

Nut

I Union

20110267

Tension pulley IOON (22 Ibs.1 Compressor

Crankshaft

pulley

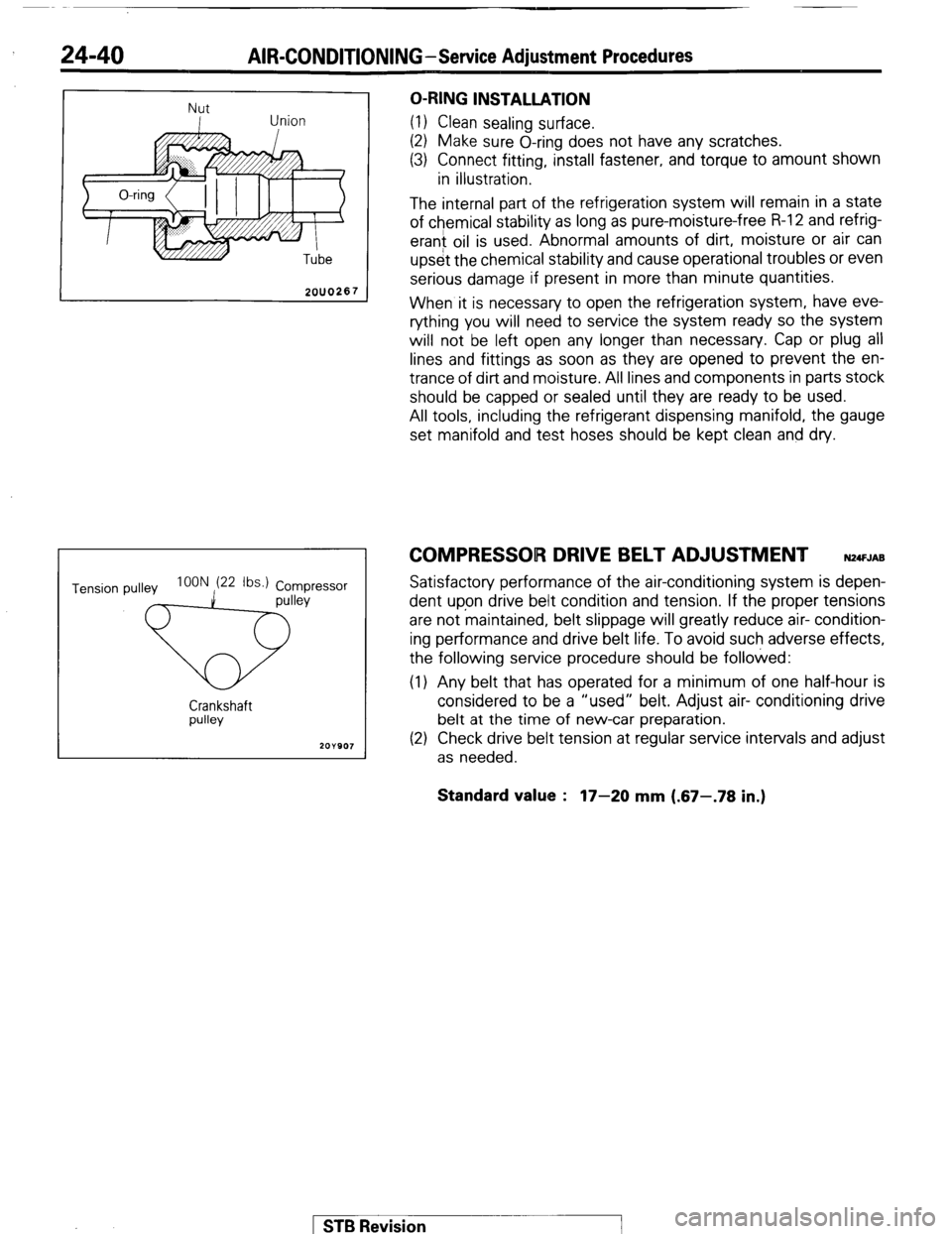

I 2OY907 1 O-RING INSTALLATION

(1) Clean sealing surface.

(2) Make sure O-ring does not have any scratches.

(3) Connect fitting, install fastener, and torque to amount shown

in illustration.

The internal part of the refrigeration system will remain in a state

of chemical stability as long as pure-moisture-free R-l 2 and refrig-

erant oil is used. Abnormal amounts of dirt, moisture or air can

upset the chemical stability and cause operational troubles or even

serious damage if present in more than minute quantities.

When it is necessary to open the refrigeration system, have eve-

rything you will need to service the system ready so the system

will not be left open any longer than necessary. Cap or plug all

lines and fittings as soon as they are opened to prevent the en-

trance of dirt and moisture. All lines and components in parts stock

should be capped or sealed until they are ready to be used.

All tools, including the refrigerant dispensing manifold, the gauge

set manifold and test hoses should be kept clean and dry.

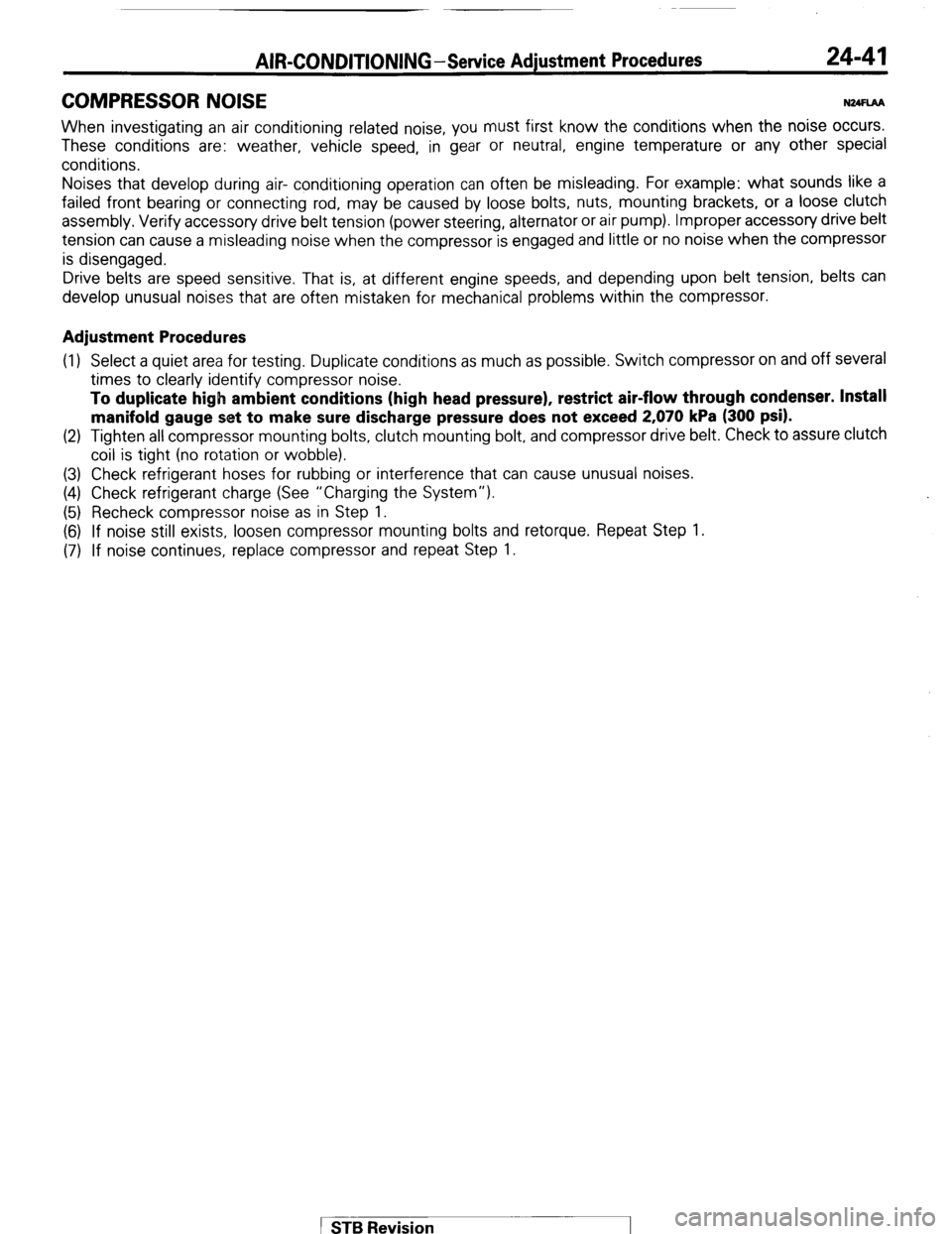

COMPRESSOR DRIVE BELT ADJUSTMENT N24FJAE

Satisfactory performance of the air-conditioning system is depen-

dent upon drive belt condition and tension. If the proper tensions

are not maintained, belt slippage will greatly reduce air- condition-

ing performance and drive belt life. To avoid such adverse effects,

the following service procedure should be followed:

(1) Any belt that has operated for a minimum of one half-hour is

considered to be a “used” belt. Adjust air- conditioning drive

belt at the time of new-car preparation.

(2) Check drive belt tension at regular service intervals and adjust

as needed.

Standard value :

17-20 mm (.67-.78 in.)

1 STB Revision

-7

Page 277 of 284

AIR-CONDITIONING -Service Adjustment Procedures 24-41

COMPRESSOR NOISE NWLM

When investigating an air conditioning related noise, you must first know the conditions when the noise occurs.

These conditions are: weather, vehicle speed, in gear or neutral, engine temperature or any other special

conditions.

Noises that develop during air- conditioning operation can often be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be caused by loose bolts, nuts, mounting brackets, or a loose clutch

assembly. Verify accessory drive belt tension (power

steering, alternator or air pump). Improper accessory drive belt

tension can cause a misleading noise when the compressor is engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed sensitive. That is, at different engine speeds, and depending upon belt tension, belts can

develop unusual noises that are often mistaken for mechanical problems within the compressor.

Adjustment Procedures

(1) Select a quiet area for testing. Duplicate conditions as much as possible. Switch compressor on and off several

times to clearly identify compressor noise.

To duplicate high ambient conditions (high head pressure), restrict air-flow through

condenser. Install

manifold gauge set to make sure discharge pressure does not exceed 2,070 kPa (300 psi).

(2) Tighten all compressor mounting bolts, clutch mounting bolt, and compressor drive belt. Check to assure clutch

coil is tight (no rotation or wobble).

(3) Check refrigerant hoses for rubbing or interference that can cause unusual noises.

(4) Check refrigerant charge (See “Charging the System”).

(5) Recheck compressor noise as in Step 1.

(6) If noise still exists, loosen compressor mounting bolts and retorque. Repeat Step 1.

(7) If noise continues, replace compressor and repeat Step 1.

1 STB Revision