MITSUBISHI MONTERO 1987 1.G Owner's Manual

Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 22 of 284

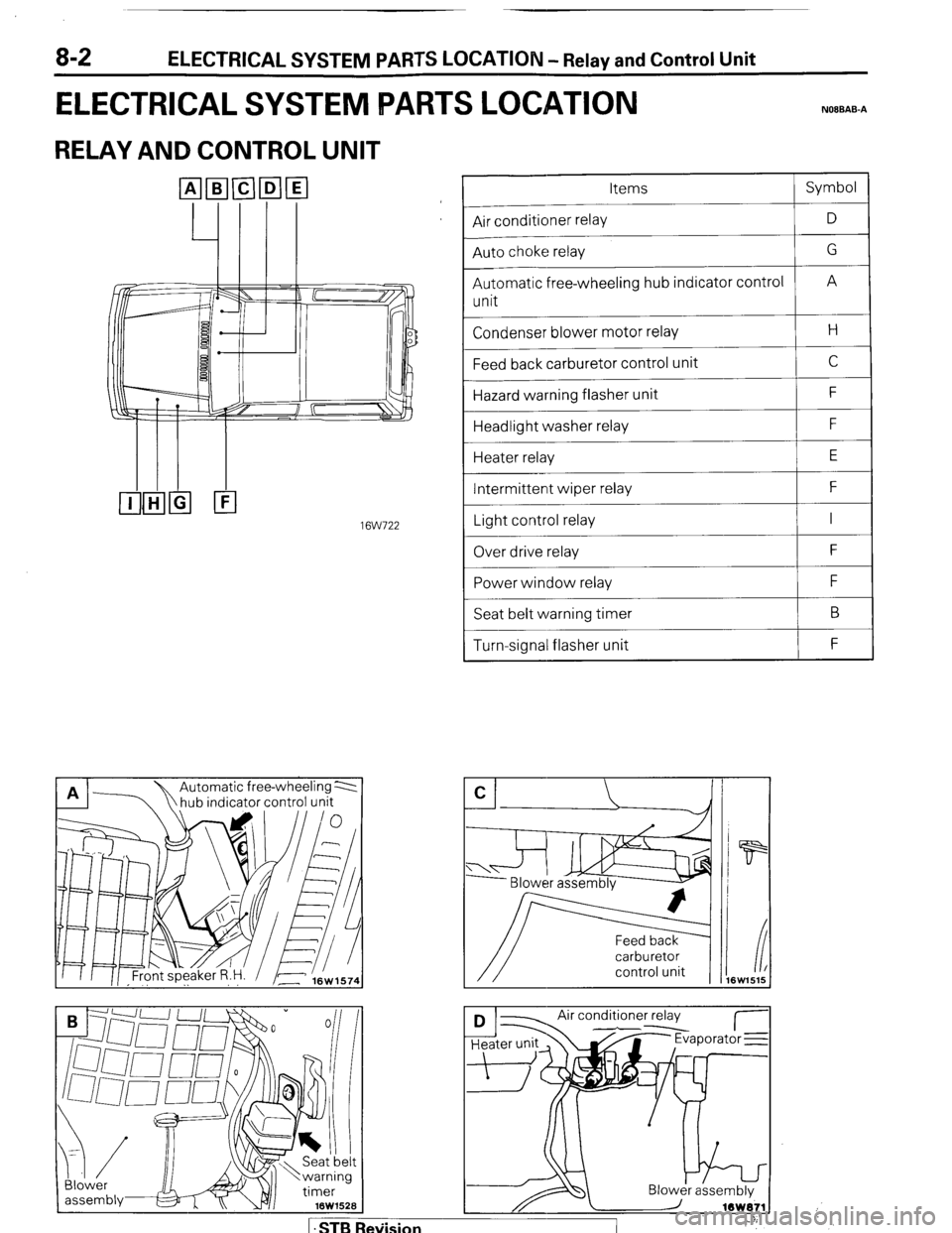

8-2 ELECTRICAL SYSTEM PARTS LOCATION - Relay and Control Unit

ELECTRICAL SYSTEM IPARTS LOCATION NOIBAB-A

RELAY AND CONTROL UNIT

16W722

n 17

hub indicator control unit A A Automatic free-wheeling 2

Blower

assembiy& x v/i 16W152B Items Symbol

--

Air conditioner relay D

--

Auto choke relay G

--

Automatic free-wheeling hub indicator control

A

unit

Condenser blower motor relay H

Feed back carburetor control unit C

Hazard warning flasher unit F

Headlight washer relay F

Heater relay E

Intermittent wiper relay F

~___

Light control relay I

~___

Over drive relay F

Power window relay F

Seat belt warning timer B

Turn-signal flasher unit F

carburetor

control unit

Air conditioner relay

d--- I- Jr Evaporator E

1 .STB Re\iision

Page 23 of 284

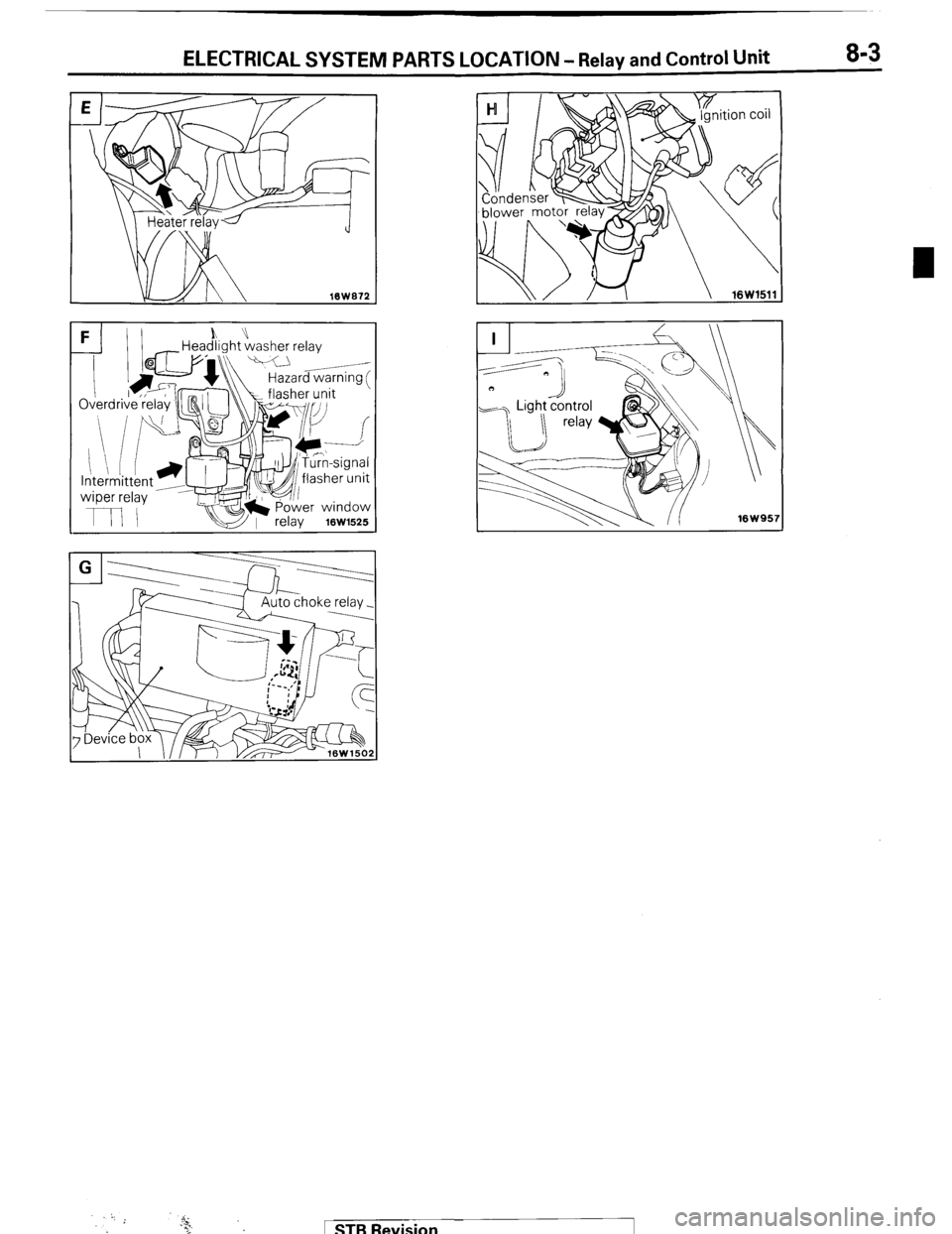

ELECTRICAL SYSTEM PARTS LOCATION - Relay and Control Unit 8-3

FI)I h” -Headlight washer relay

k\\ Hazard warnina f

1 STB Revision

Page 24 of 284

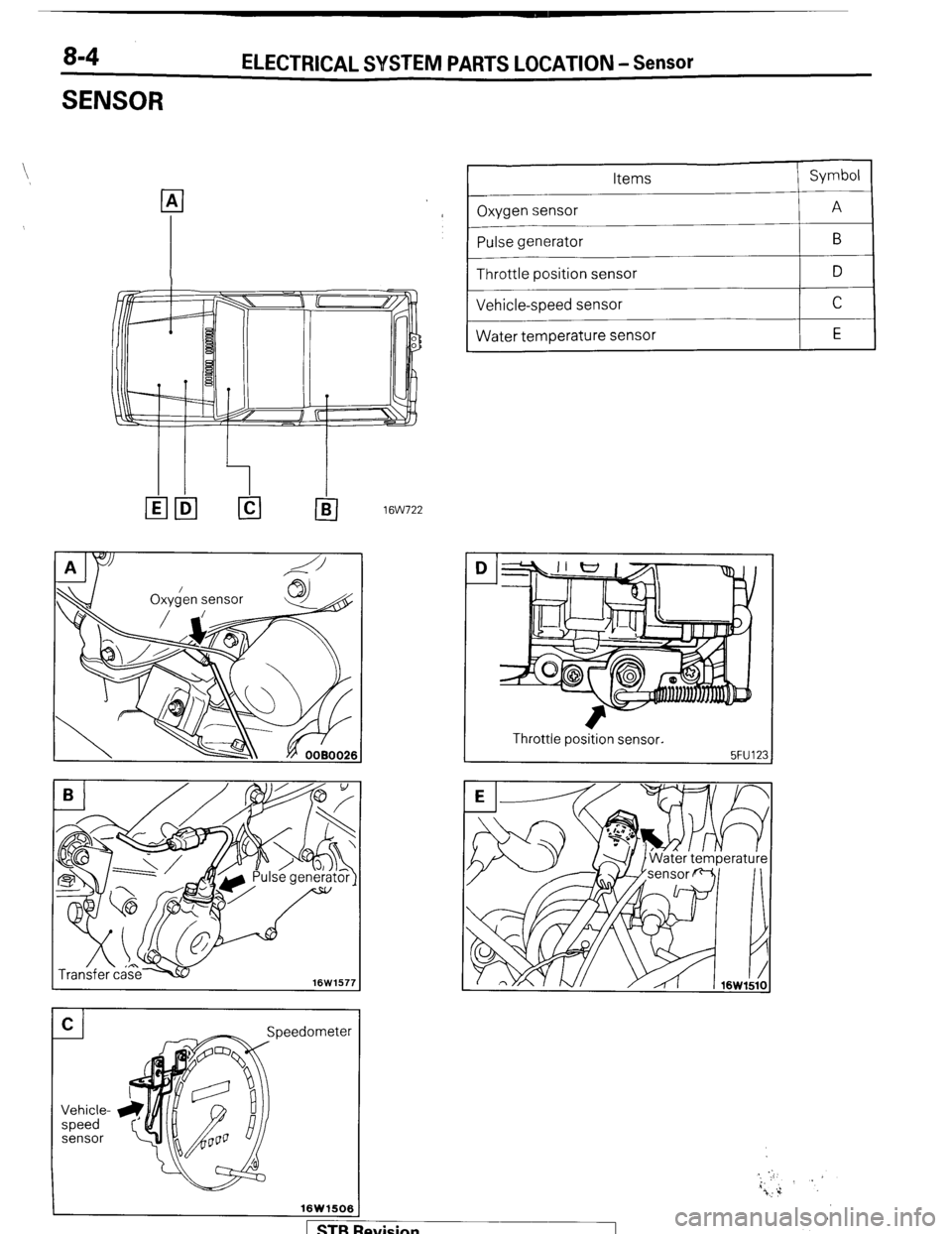

8-4

SENSOR ELECTRICAL SYSTEM PARTS LOCATION - Sensor

I leedometer

16W1506

p

Items

Oxygen sensor

-

Pulse generator --

Throttle position sensor

_____

Vehicle-speed sensor

~~

Water temperature sensor Symbol

A B

D C

E

ltw722

I Throttle position sensor.

I

Revision

Page 25 of 284

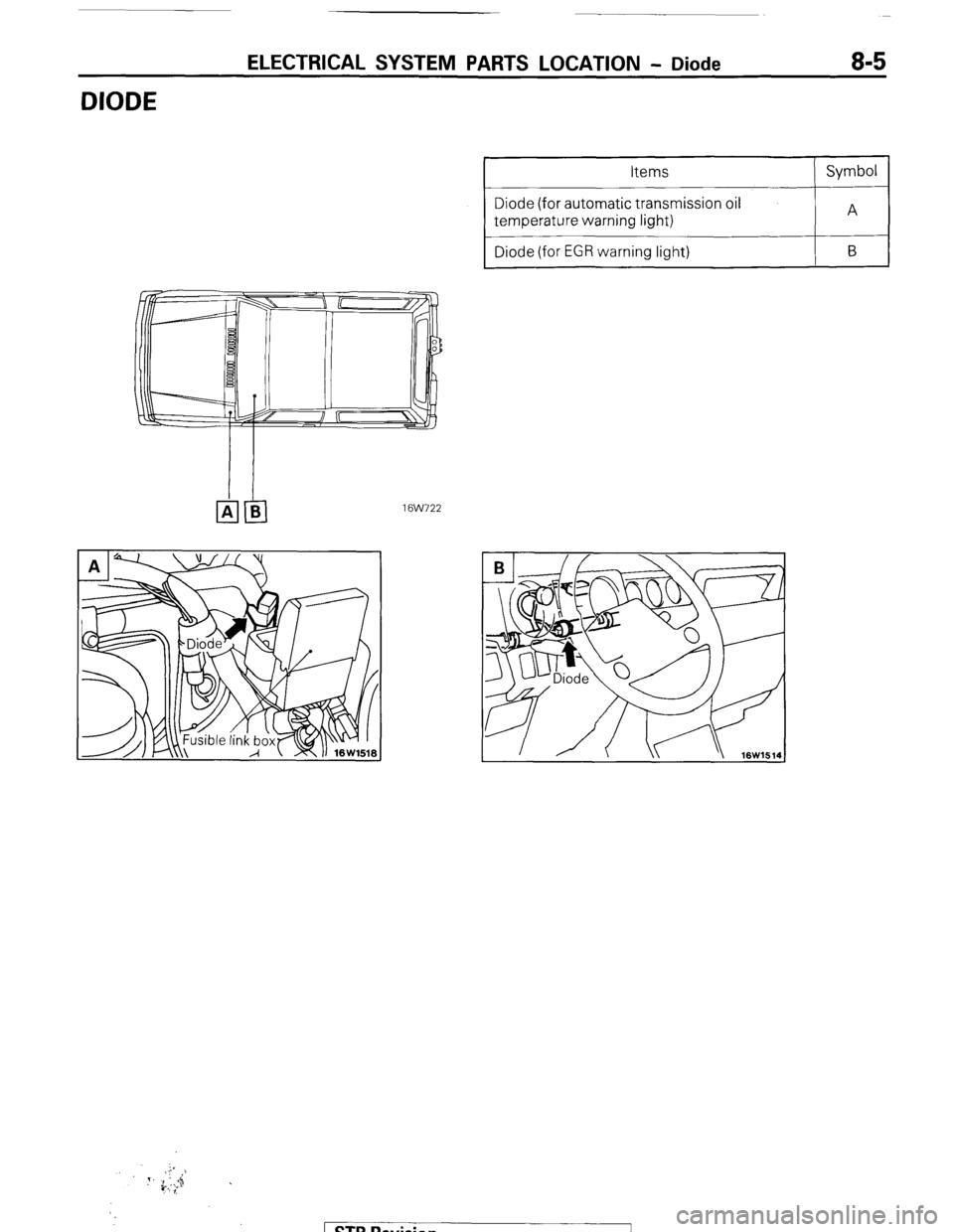

DIODE

ELECTRICAL SYSTEM PARTS LOCATION - Diode 8-5

Diode (for automatic transmission oil

Diode (for EGR warning light)

1 @NJ22

STB Revision

Page 26 of 284

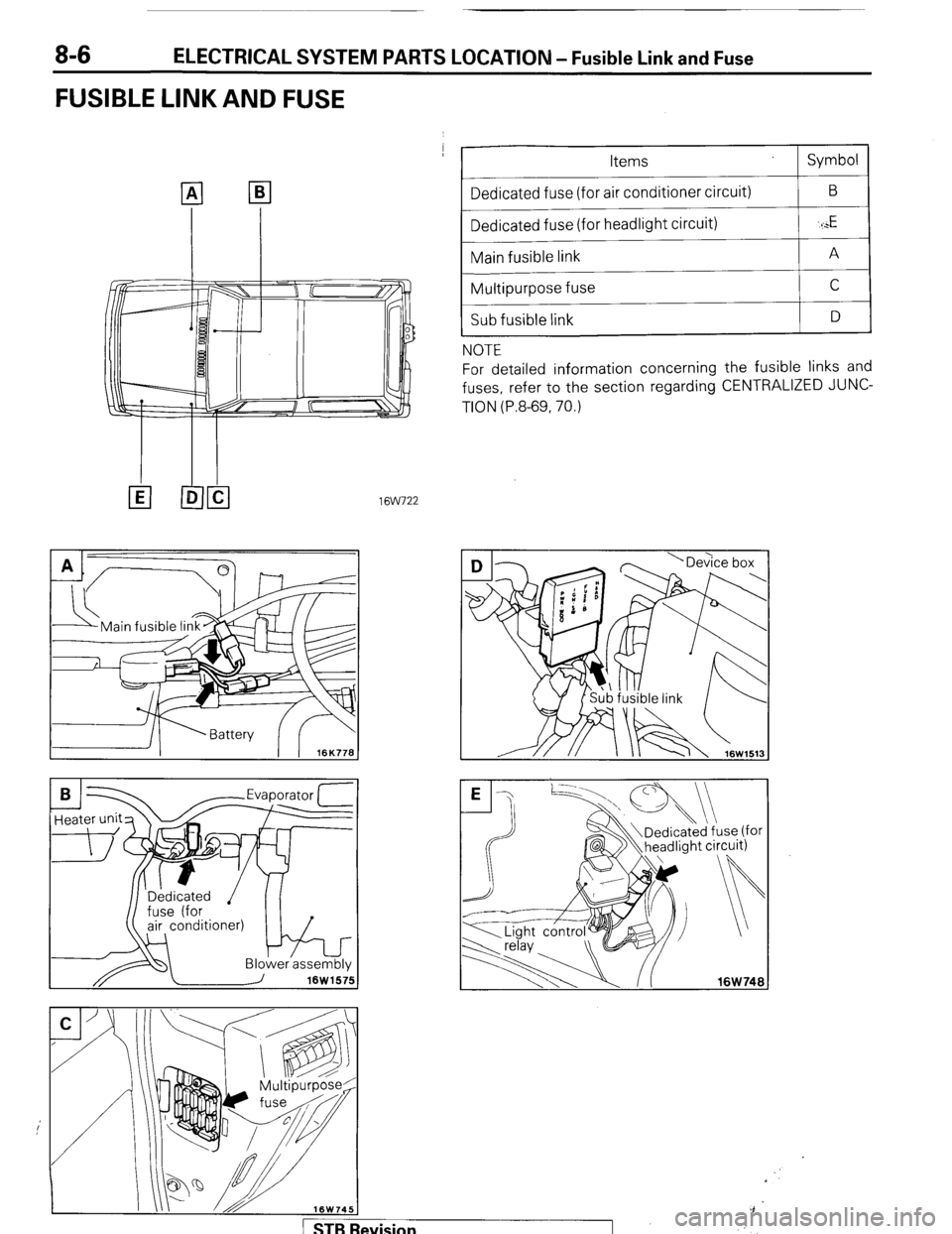

ELECTRICAL SYSTEM PARTS LOCATION - Fusible Link and Fuse

FUSIBLE LINK AND FUSE

--

Items

Dedicated fuse (for air conditioner circuit)

Dedicated fuse (for headlight circuit)

Main fusible link

Multipurpose fuse

Sub fusible link

NOTE Symbol

B

‘I

E

A

C

D

For detailed information concerning the fusible links and

fuses, refer to the section regarding CENTRALIZED JUNC-

TION (P.8-69, 70.)

16W722

-Evaoorator 1

/ STBI levision

Page 27 of 284

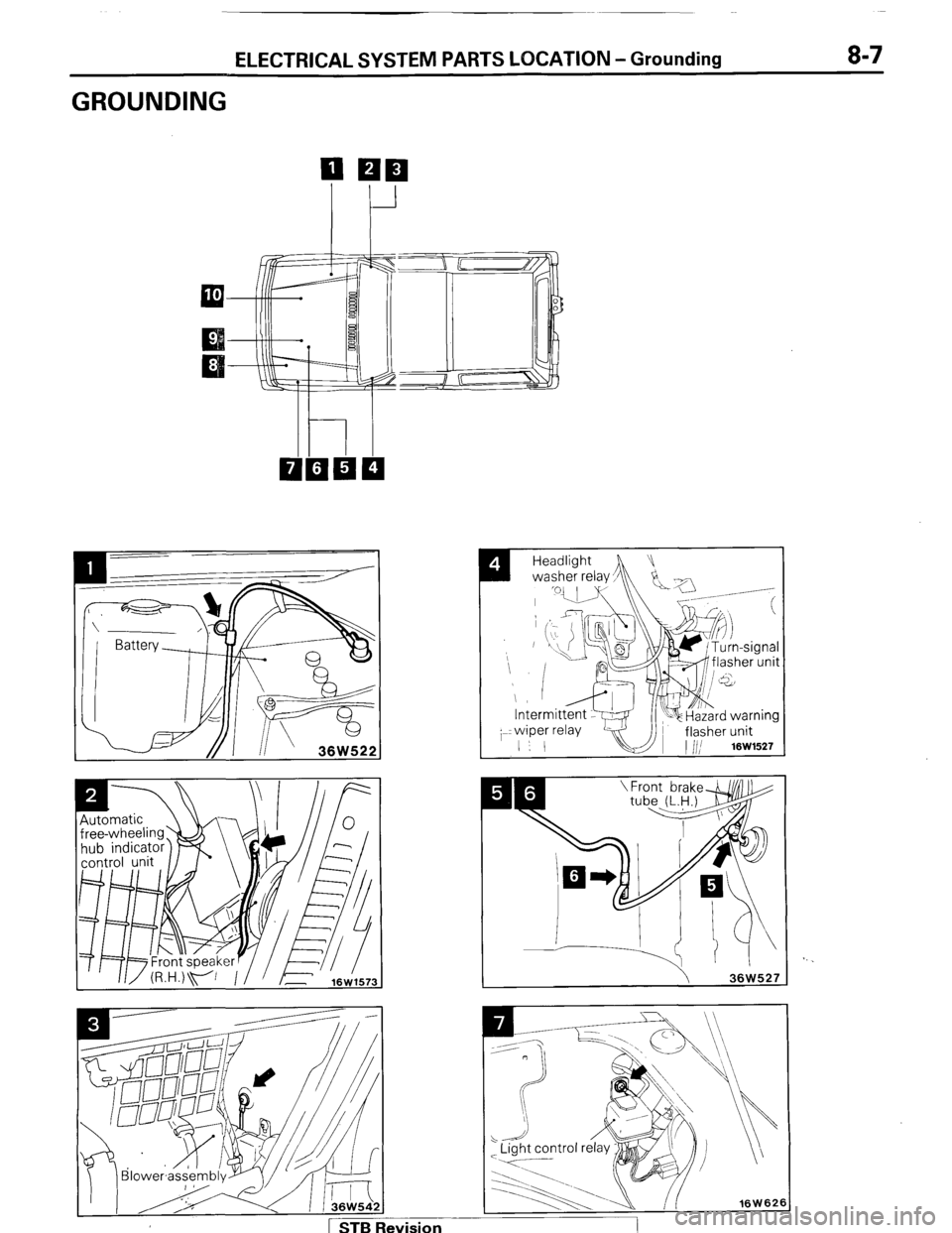

ELECTRICAL SYSTEM PARTS LOCATION -Grounding 8-7

GROUNDING

I

Headlight

washer relay,

h !Ja -/

_ .-----

/ 1 STB Revision

Page 28 of 284

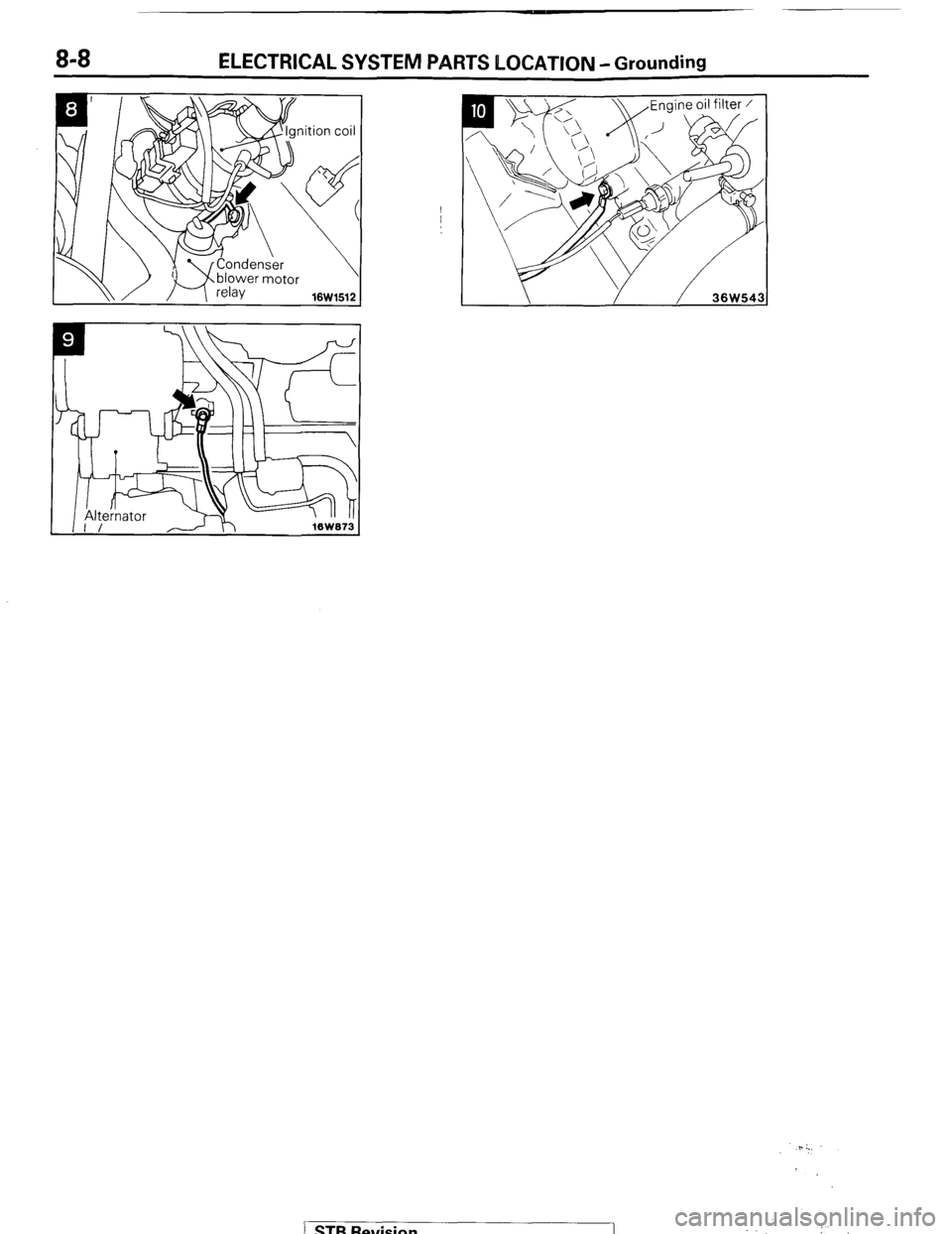

8-8 ELECTRICAL SYSTEM PARTS LOCATION -Grounding

\\/ / 16W1512 1

5. :.,

STB Revision 1 i

Page 29 of 284

INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector 8-9

Connect to

harness

16UO500

16R1317

8; 4 16R1319

INSPECTION OF HARNESS

CONNECTOR

NOECAM

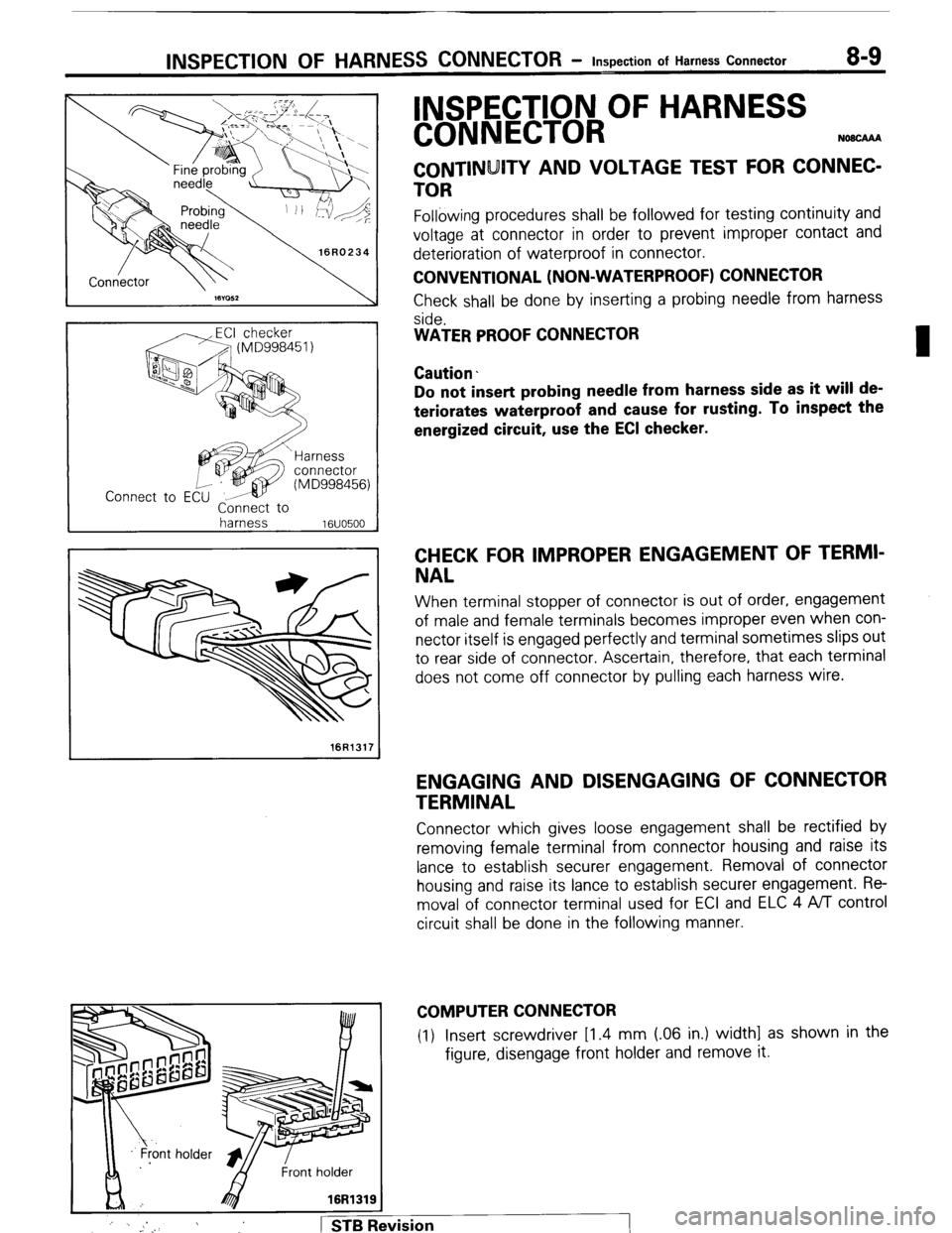

CONTINUITY AND VOLTAGE TEST FOR CONNEC-

TOR

Following procedures shall be followed for testing continuity and

voltage at connector in order to prevent improper contact and

deterioration of waterproof in connector.

CONVENTIONAL (NON-WATERPROOF) CONNECTOR

Check shall be done by inserting a probing needle from harness

side.

WATER PROOF CONNECTOR

Caution.

Do not insert probing needle from harness side as it will de-

teriorates waterproof and cause for rusting. To inspect the

energized circuit, use the ECI checker.

CHECK FOR IMPROPER ENGAGEMENT OF TERMI-

NAL

When terminal stopper of connector is out of order, engagement

of male and female terminals becomes improper even when con-

nector itself is engaged perfectly and terminal sometimes slips out

to rear side of connector. Ascertain, therefore, that each terminal

does not come off connector by pulling each harness wire.

ENGAGING AND DISENGAGING OF CONNECTOR

TERMINAL

Connector which gives loose engagement shall be rectified by

removing female terminal from connector housing and raise its

lance to establish securer engagement. Removal of connector

housing and raise its lance to establish securer engagement. Re-

moval of connector terminal used for ECI and ELC 4 ,4/l control

circuit shall be done in the following manner.

COMPUTER CONNECTOR

(1) Insert screwdriver [1.4 mm (06 in.) width] as shown in the

figure, disengage front holder and remove it.

:

j ’ . _. 1 STB Revision

Page 30 of 284

8-10 INSPECTION OF HARNESS CONNECTOR - Inspection of Harness Connector

Housing lance

-5

1 16R1321

’ Needle

16Ffi322

Housing lance

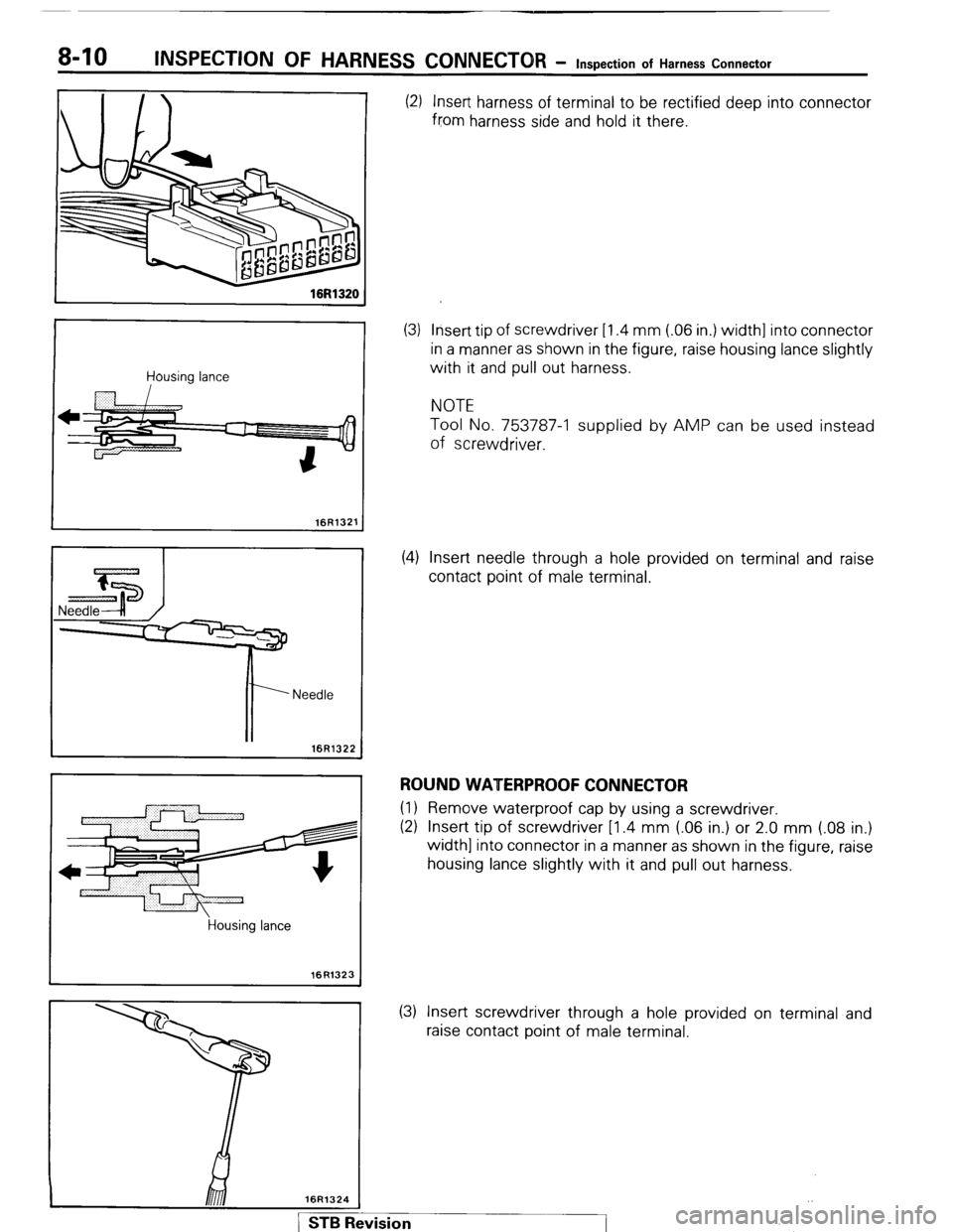

16R1323 (2) Insert harness of terminal to be rectified deep into connector

from harness side and hold it there.

(3) Insert tip of screwdriver [1.4 mm (.06 in.) width] into connector

in a manner as shown in the figure, raise housing lance slightly

with it and pull out harness.

NOTE

Tool No. 753787-l supplied by AMP can be used instead

of screwdriver.

(4) Insert needle through a hole provided on terminal and raise

contact point of male terminal.

ROUND WATERPROOF CONNECTOR (1) Remove waterproof cap by using a screwdriver.

(2) Insert tip of screwdriver [1.4 mm (.06 in.) or 2.0 mm (.08 in.)

width] into connector in a manner as shown in the figure, raise

housing lance slightly with it and pull out harness.

(3) Insert screwdriver through a hole provided on terminal and

raise contact point of male terminal.