Circuit diagram MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 21 of 284

8-1

ELECTRICAL

CONTENTS

NOBAA-

ACCESSORY ......................................................

188

Cigarette Lighter ............................................

,190

Clock ...............................................................

,191

AUDIO SYSTEM ................................................

.192

AUTOMATIC FREE-WHEELING HUB

INDICATOR SYSTEM ........................................

208

Automatic Free-wheeling Hub

Indicator Control Unit

..................................... ,216

Pulse Generator ..............................................

215

BACK DOOR WINDOW DEFOGGER

................ .203

Defogger switch ............................................

,206

Printed Heater Lines

...................................... ,207

CHARGING SYSTEM .........................................

71

Alternator ........................................................

83

Service Adjustment Procedures

..................... 77

Battery Charging ........................................

82

Inspection of Battery ..................................

81

Output Current Test ...................................

78

Regulated Voltage Test ..............................

79

Voltage Drop Test of Alternator Output

Wire ............................................................

77

ELECTRICAL SYSTEM PARTS LOCATION

...... 2

Diode ...............................................................

5

Fusible Link and Fuse

..................................... 6

Grounding .......................................................

7

Relay and Control Unit ....................................

2

Sensor .............................................................

4

HORN ..................................................................

184

Horn Switch

.................................................... 187

IGNITION SYSTEM ............................................

105

Ignition Switch

................................................ 122

Ignition System ...............................................

1 14

Service Adjustment Procedures

.................... .l 1 1

Checking Ignition System

..........................

11 1

Checking Ignition Timing

...........................

11 1

Spark Plug Cable Test

................................

1 12

Spark Plug Test

.......................................... 1 12 INSPECTION OF HARNESS CONNECTOR ...... 9

Check for Improper Engagement of

Terminal .......................................................... 9

Continuity and Voltage Test for Connector .... 9

Engaging and Disengaging of Connector

Terminal ..........................................................

9

LIGHTING SYSTEM ........................................... 143

Column Switch

................................ .

.............. .I59

Dimmer Control Switch

................................. .I62

Hazard Warning Switch

................................. .I61

Headlight ........................................................ ,158

Service Adjustment Procedures

.................... .I57

Headlight Aiming .......................................

157

METERS AND GAUGES .................................... 123

Service Adjustment Procedures

.................... .I30

Fuel Gauge Simple Test ................................. .I31

Fuel Gauge Unit Inspection ........................... .I31

Oil Pressure Gauge Simple Test

.................... .I32

Oil Pressure Gauge Unit Simple Test

............ ,132

Speedometer Inspection

............................... .I30

Tachometer Inspection .................................. ,130

Voltage Meter Simple Test

............................ .I33

Water Temperature Gauge Simple Test

....... ..I3 1

Water Temperature Gauge Unit Inspection

. ..I3 2

STARTING SYSTEM .......................................... 91

Starter Motor ............ ....................................... 97

WIPER AND WASHER SYSTEM

....................... .163

WIRING HARNESS ............................................ 13

Centralized Junction ....................................... 69

Circuit Diagram ............................................... 34

Configuration Diagram .................................... 27

How to Read Wiring Diagrams ....................... 20

Troubleshooting .............................................. 13

Page 33 of 284

WIRING HARNESS - Troubleshooting 8-13

WIRING HARNESS

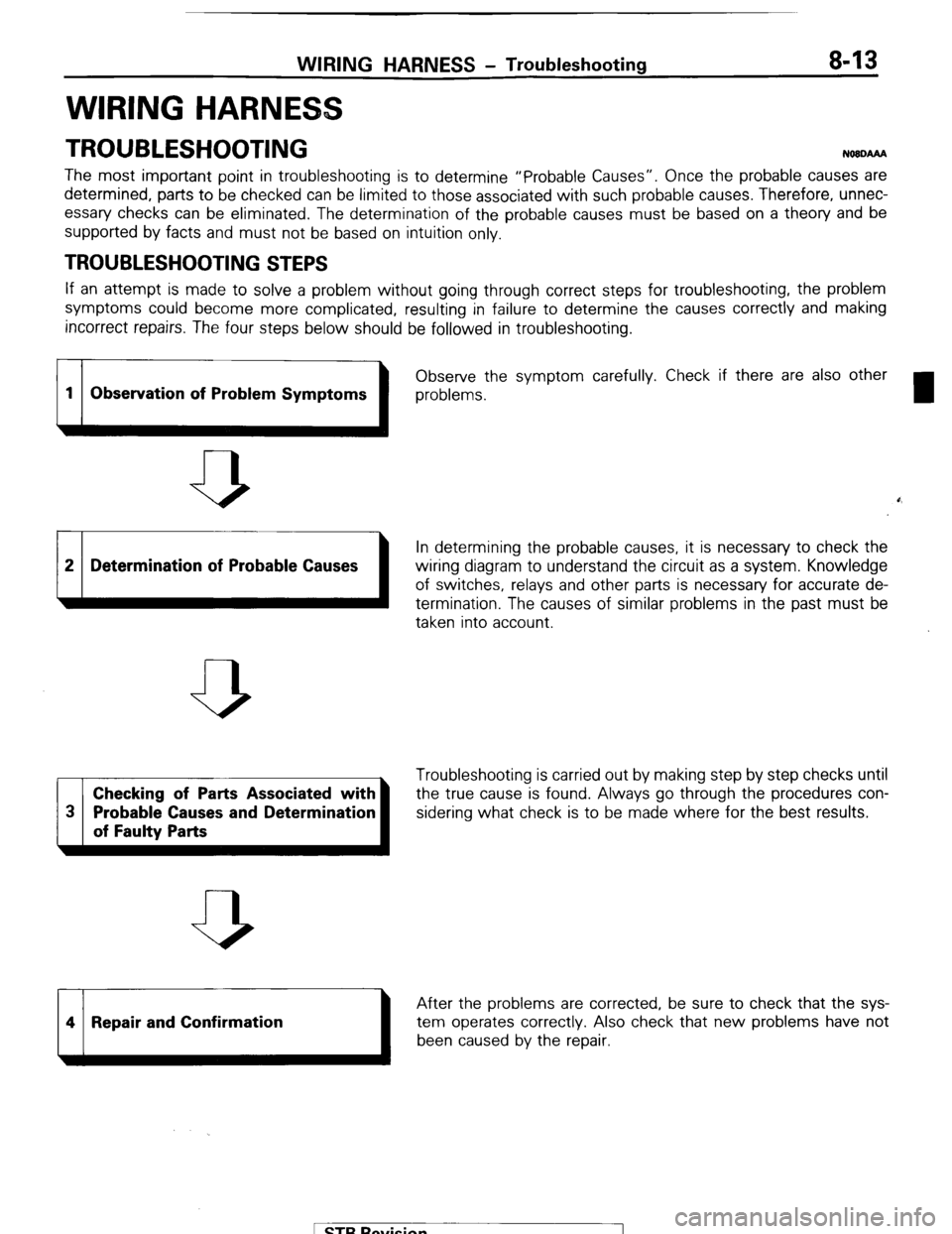

TROUBLESHOOTING NO8DAAA

The most important point in troubleshooting is to determine “Probable Causes”. Once the probable causes are

determined, parts to be checked can be limited to those associated with such probable causes. Therefore, unnec-

essary checks can be eliminated. The determination of the probable causes must be based on a theory and be

supported by facts and must not be based on intuition only.

TROUBLESHOOTING STEPS

If an attempt is made to solve a problem without going through correct steps for troubleshooting, the problem

symptoms could become more complicated, resulting in failure to determine the causes correctly and making

incorrect repairs. The four steps below should be followed in troubleshooting.

1 1 Observe the

1 problems. symptom carefully. Check if there are also other

1 Observation of Problem Symptoms

b

0,

2 Determination of Probable Causes

In determining the probable causes, it is necessary to check the

wiring diagram to understand the circuit as a system. Knowledge

of switches, relays and other parts is necessary for accurate de-

termination. The causes of similar problems in the past must be

taken into account.

Checking of Parts Associated with Troubleshooting is carried out by making step by step checks until

the true cause is found. Always go through the procedures con-

sidering what check is to be made where for the best results.

14 1 Repair and Confirmation

After the problems are corrected, be sure to check that the sys-

1 been caused by the repair, tem operates correctly Also check that new problems have not

1 STB Revision

1

Page 35 of 284

WIRING HARNESS - Troubleshooting 8-15

1660227

Black lead wire

Ground y

1680228

Normal open (NO) type

OFF

ax

Current does not flow ON

Current flows

Normal close (NC) type

OFF

l-2

Current flows ON

-op--

IX

Current does not flow

1680229

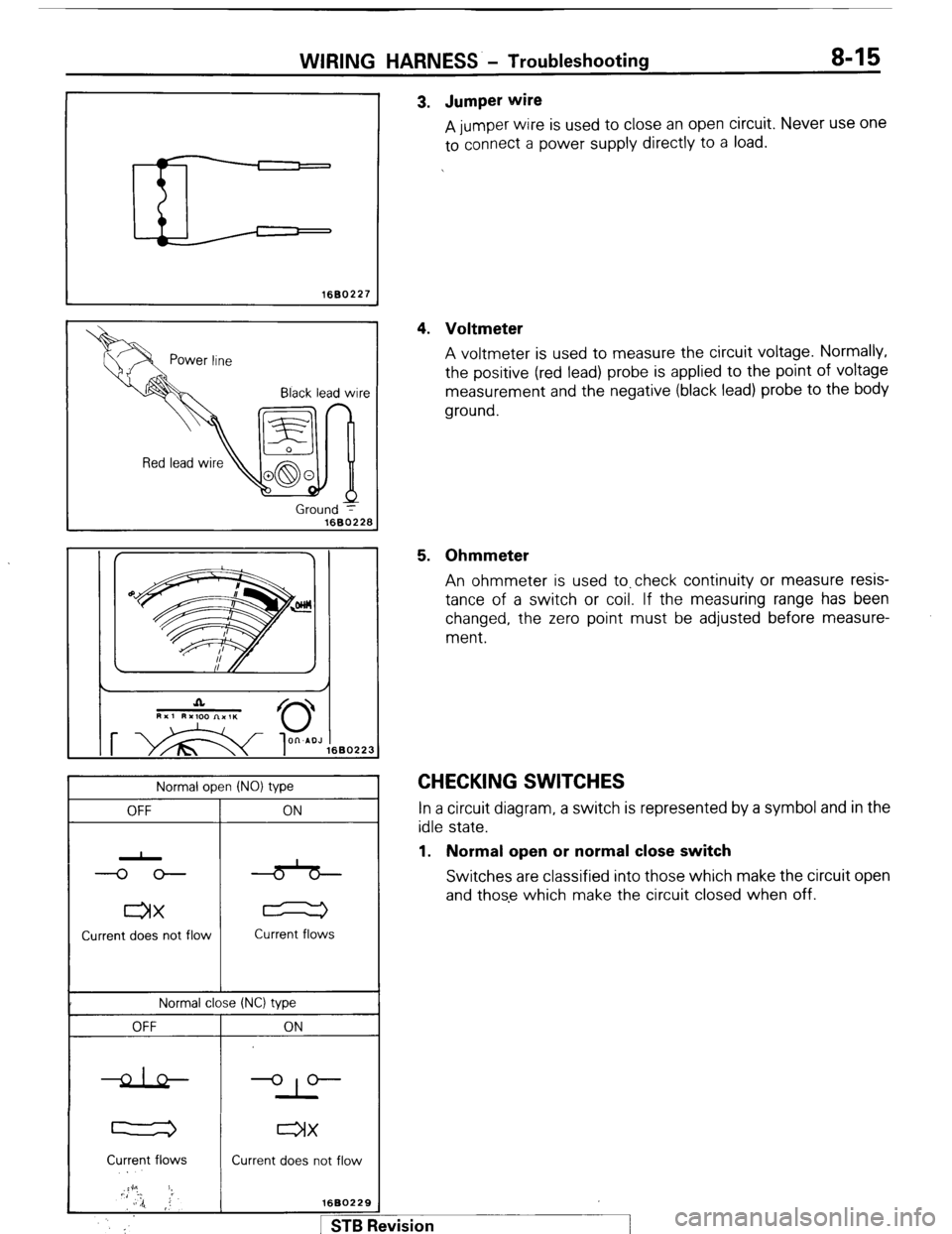

pm I 3. Jumper wire

A jumper wire is used to close an open circuit. Never use one

to connect a power supply directly to a load.

4. Voltmeter

A voltmeter is used to measure the circuit voltage. Normally,

the positive (red lead) probe is applied to the point of voltage

measurement and the negative (black lead) probe to the body

ground.

5. Ohmmeter

An ohmmeter is used to.check continuity or measure resis-

tance of a switch or coil. If the measuring range has been

changed, the zero point must be adjusted before measure-

ment.

CHECKING SWITCHES In a circuit diagram, a switch is represented by a symbol and in the

idle state.

1. Normal open or normal close switch

Switches are classified into those which make the circuit open

and those which make the circuit closed when off.

#vision

I

Page 40 of 284

8-20 WIRING HARNESS - How to Read Wiring Diagrams

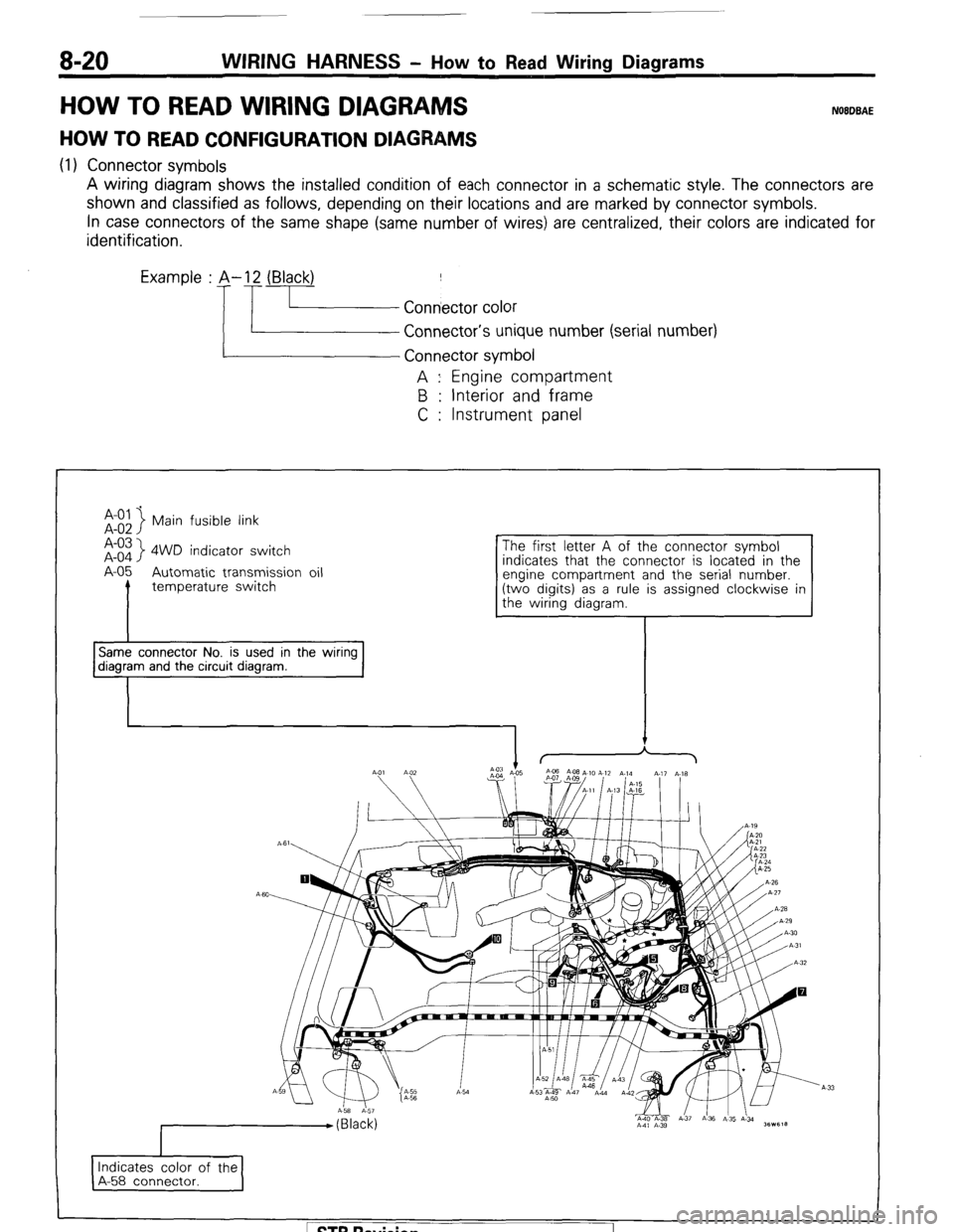

HOW TO READ WIRING DIAGRAM NOEDBAE

HOW TO READ CONFIGURATION DIAGRAMS

(1) Connector symbols

A wiring diagram shows the installed condition of each connector in a schematic style. The connectors are

shown and classified as follows, depending on their locations and are marked by connector symbols.

In case connectors of the same shape (same number of wires) are centralized, their colors are indicated for

identification.

Examp’e : p.!- f.~~~~ ~;~~o,

Connector’s unique number (serial number)

A : Engine compartment

B : Interior and frame

C : Instrument panel

Main fusible link

A-03

A-o4

> 4WD indicator switch

A-05 Automatic transmission oil

I temperature switch indicates that the connector is located in the

Same connector No. is used in the wiring diagram and the circuit diagram.

I Indicates color of the

A-58 connector. I

1 ST6 Revision

Page 41 of 284

WIRING HARNESS - HOW to Read Wiring Diagrams 8-21

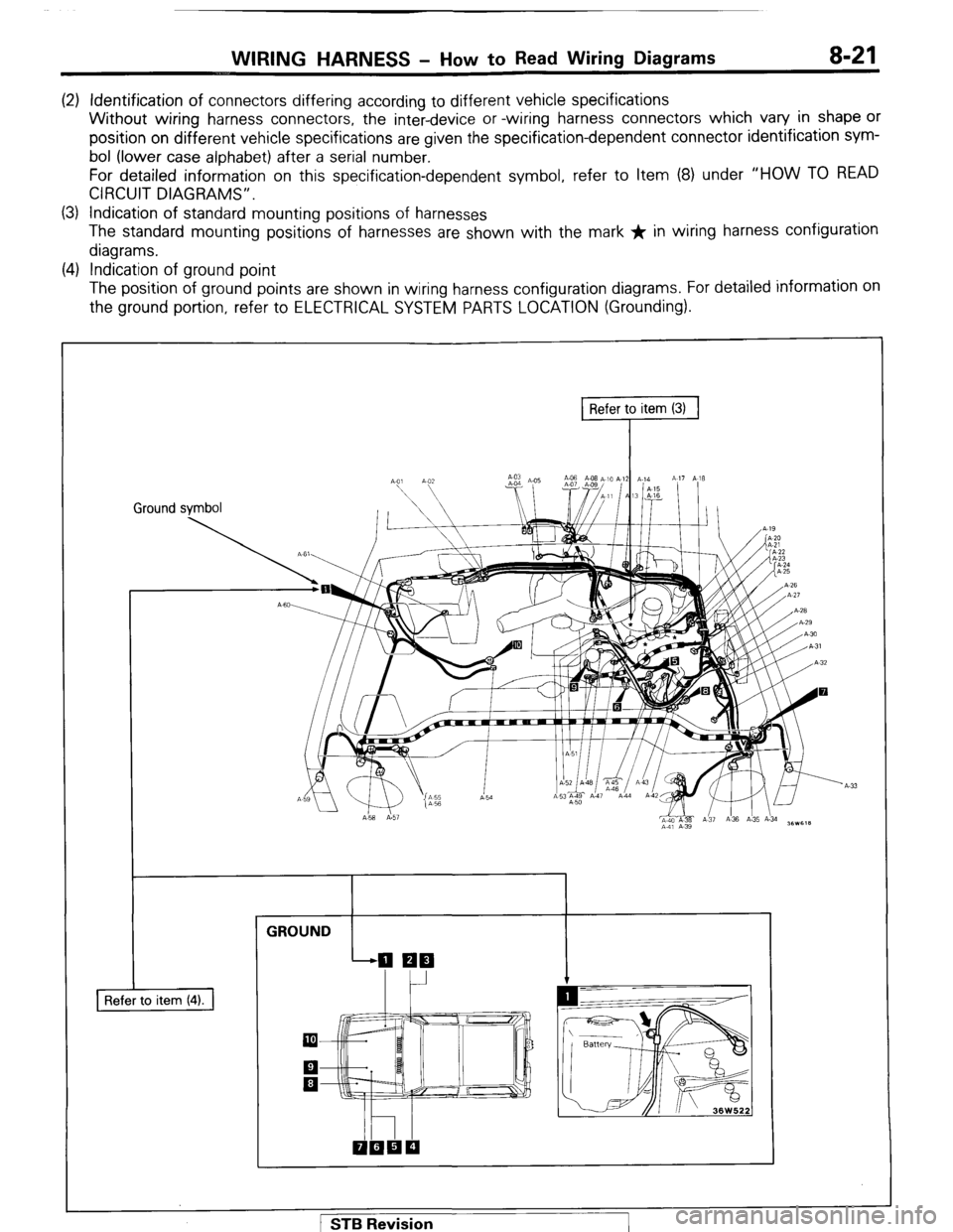

(2) Identification of connectors differing according to different vehicle specifications

Without wiring harness connectors, the inter-device or -wiring harness connectors which vary in shape or

position on different vehicle specifications are

given the specification-dependent connector identification svm-

bol (lower case alphabet) after a serial number.

For detailed information on this specification-dependent symbol, refer to Item (8) under “HOW

TO READ

CIRCUIT DIAGRAMS”.

(3) Indication of standard mounting positions of harnesses

The standard mounting positions of harnesses are shown with the mark * in wiring harness configuration

diagrams.

(4) Indication of ground point

The position of ground points are shown in wiring harness configuration diagrams. For detailed information on

the ground portion, refer to ELECTRICAL SYSTEM PARTS LOCATION (Grounding).

Refer to item (3)

7

Ground symbol / STB Revision

Page 42 of 284

8-22 WIRING HARNESS - How to Read Wiring Diagrams

HOW TO READ CIRCUIT DIAGRAMS

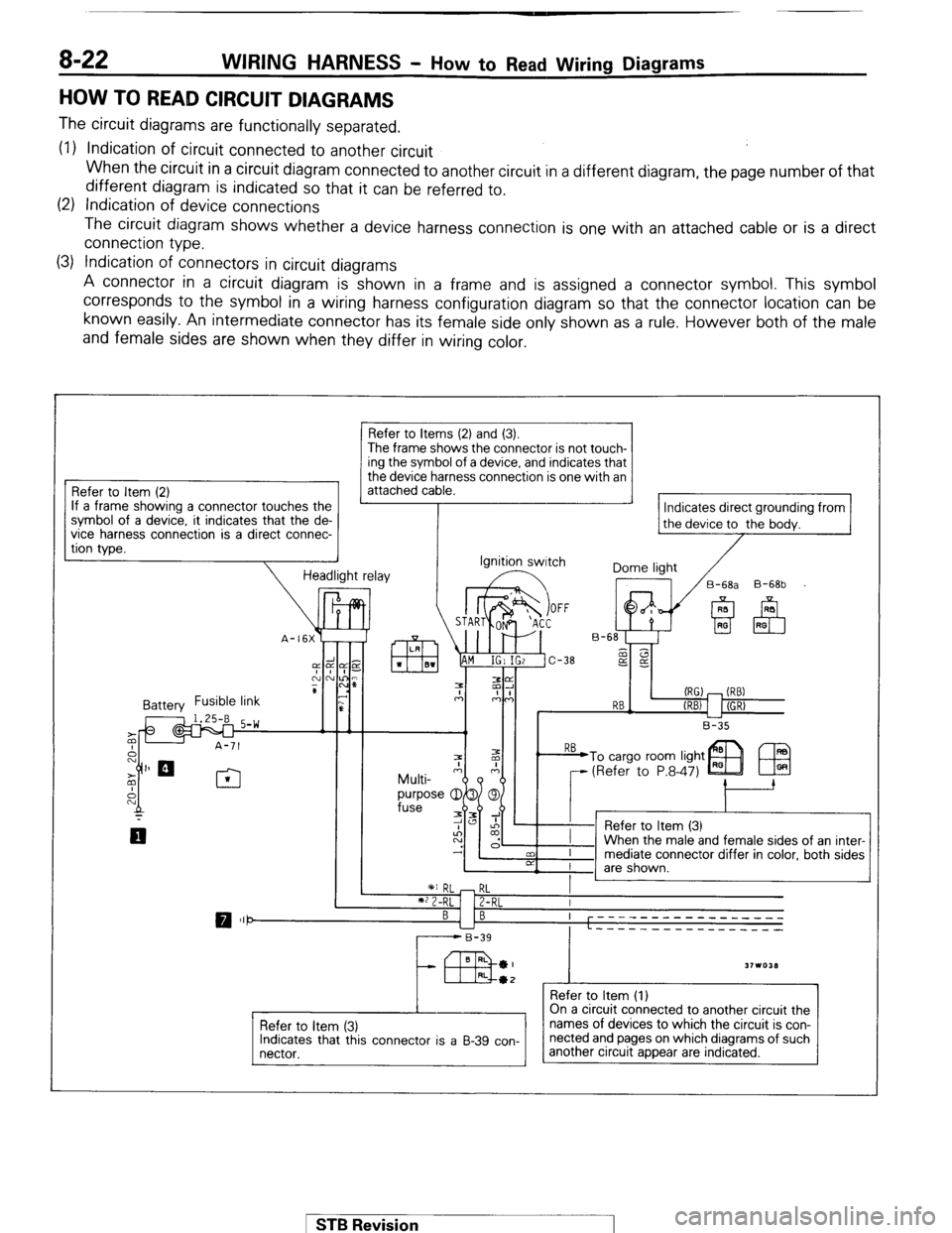

The circuit diagrams are functionally separated.

(1) Indication of circuit connected to another circuit

When the circuit in a circuit diagram connected to another circuit in a different diagram, the page number of that

different diagram is indicated so that it can be referred to.

(2) Indication of device connections

The circuit diagram shows whether a device harness connection is one with an attached cable or is a direct

connection type.

(3) Indication of connectors in circuit diagrams

A connector in a circuit diagram is shown in a frame and is assigned a connector symbol. This symbol

corresponds to the symbol in a wiring harness configuration diagram so that the connector location can be

known easily. An intermediate connector has its female side only shown as a rule. However both of the male

and female sides are shown when they differ in wiring color.

Refer to Item (2)

If a frame showing a connector touches the

?. it indicates that the de-

a direct connec- symbol of a device

vice

harness connectlon IS

tion type.

Refer to Items (2) and (3).

The frame shows the connector is not touch- ing the symbol of a device, and indicates that

the device harness connection is one with an

attached cable.

Indicates direct grounding from

the device to the bodv.

Ignition switch

Dome light

/

17 /B-6& B-68b

(RG) - (RB)

RB-

(REV 1 I (GR)

L-2

B-35

1 *I RL - RL

I

**2-RL 1 Z-RL I

BI B ----- ---- --------

L ----_ __---___----

r------B-39

43 BRL *I

31103LI RL*2 _

Refer to Item (1)

Refer to item (3)

Indicates that this connector is a B-39 con-

nectar. On a circuit connected to another circuit the

names of devices to which the circuit is con-

nected and pages on which diagrams of such

another circuit appear are indicated.

1 STB Revision 1

Page 43 of 284

WIRING HARNESS - HOW BO Read Wiring Diagrams 8-23

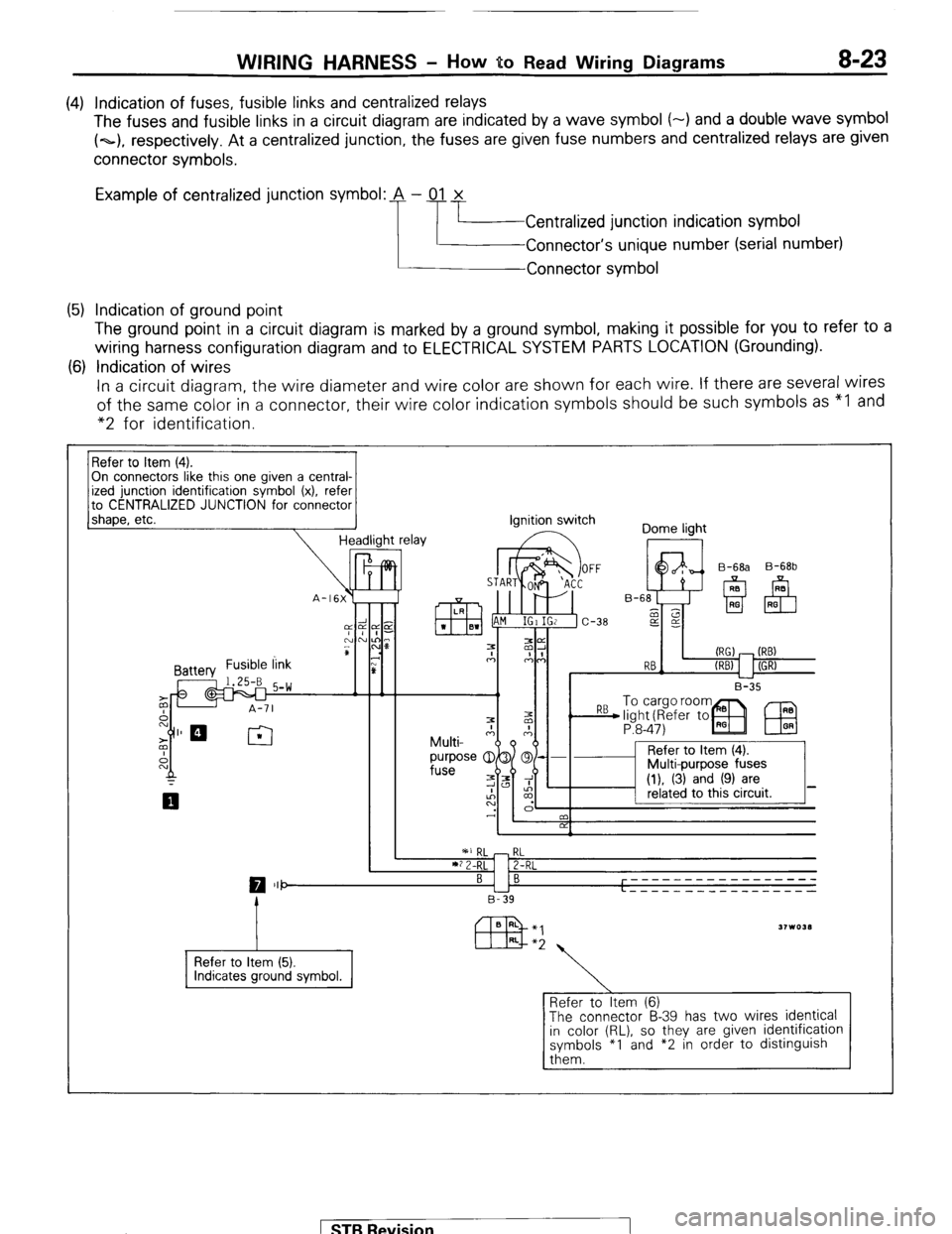

(4) Indication of fuses, fusible links and centralized relays

The fuses and fusible links in a circuit diagram are indicated by a wave symbol (-) and a double wave symbol

(~1, respectively. At a centralized junction, the fuses are given fuse numbers and centralized relays are given

connector symbols.

Example of centralized junction symbol: A - 01 x

Centralized junction indication symbol

Connector’s unique number (serial number)

Connector symbol

(5) Indication of ground point

The ground point in a circuit diagram is marked by a ground symbol, making it possible for you to refer to a

wiring harness configuration diagram and to ELECTRICAL SYSTEM PARTS LOCATION (Grounding).

(6) Indication of wires

In a circuit diagram, the wire diameter and wire color are shown for each wire. If there are several wires

of the same color in a connector, their wire color indication symbols should be such symbols as “I and

“2 for identification.

On connectors like this one given a central-

to CENTRALIZED JUNCTION for connector

1 shaoe. etc.

-I Headlight relay ignition switch

Dome light

I II I B-35 B-68b

P:8-47)

IEU

I ’ 2 I

RL

2-RL

0 III- BI B -----____________

L - - - - - _ _ _ _ _ __ _ _ _ _ _

B-39

Refer to Item (5).

Refer to Item (6)

The connector B-39 has two wires identical

in color (RL), so they are given identification

symbols *I and *2 in order to distinguish

them. 1 ST6 Revision

Page 44 of 284

8-24 WIRING HARNESS - How to Read Wiring Diagrams

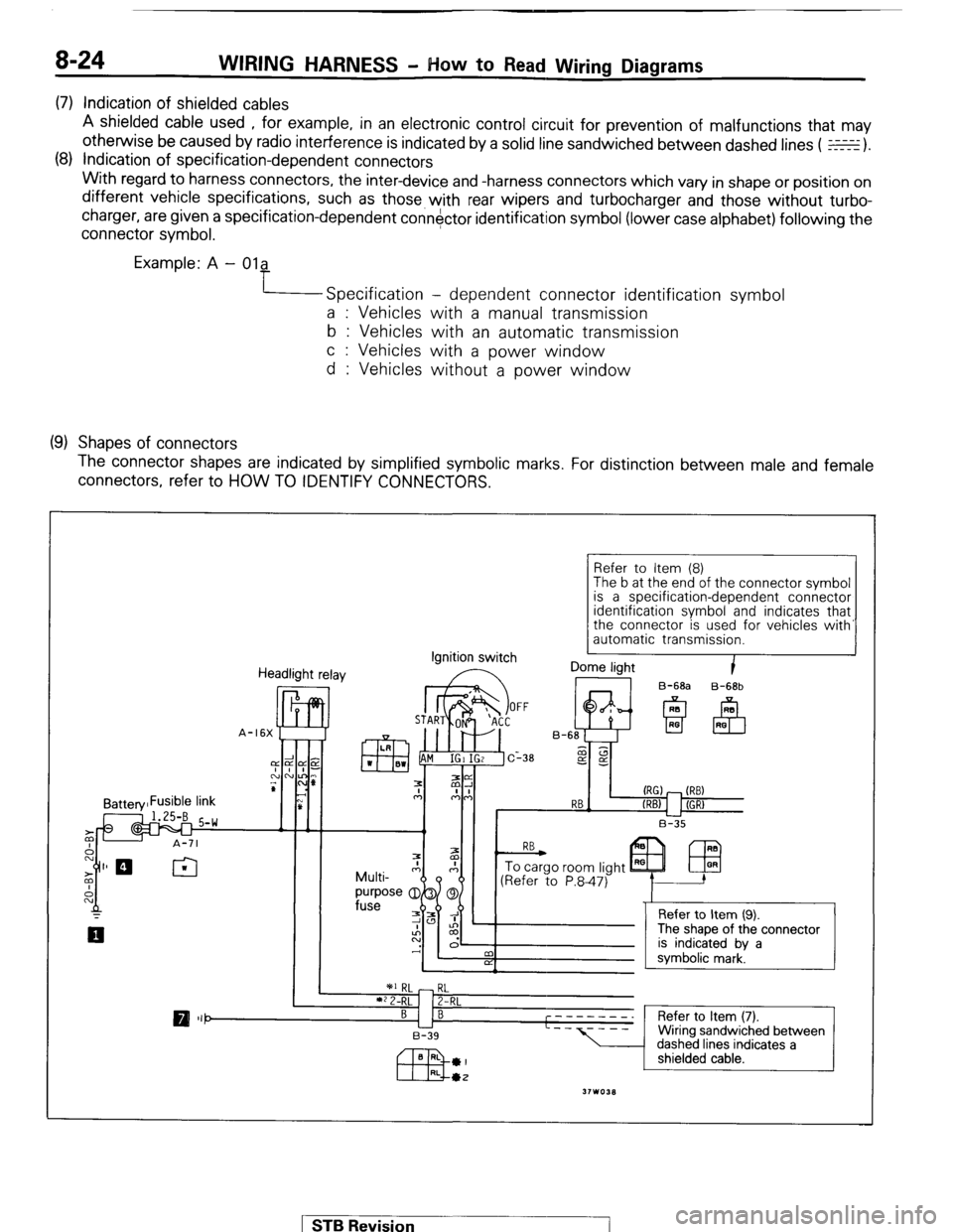

(7) Indication of shielded cables

A shielded cable used , for example, in an electronic control circuit for prevention of malfunctions that may

otherwise be caused by radio interference is indicated by a solid line sandwiched between dashed lines ( E).

(8) Indication of specification-dependent connectors

With regard to harness connectors, the inter-device and -harness connectors which vary in shape or position on

different vehicle specifications, such as those with rear wipers and turbocharger and those without turbo-

charger, are given a specification-dependent connector identification symbol (lower case alphabet) following the

connector symbol.

Example: A - Ola

Specification - dependent connector identification symbol

a : Vehicles with a manual transmission

b : Vehicles with an automatic transmission

c : Vehicles with a power window

d : Vehicles without a power window

(9) Shapes of connectors

The connector shapes are indicated by simplified symbolic marks. For distinction between male and female

connectors, refer to HOW TO IDENTIFY CONNECTORS.

Refer to Item (8)

The b at the end of the connector symbol

is a specification-dependent connector

identification

symbol and indicates that

the connector is used for vehicles with’

automatic transmission.

Headlight relay Ignition

switch I Dome light

B-68a B-68b STB Revision

Page 45 of 284

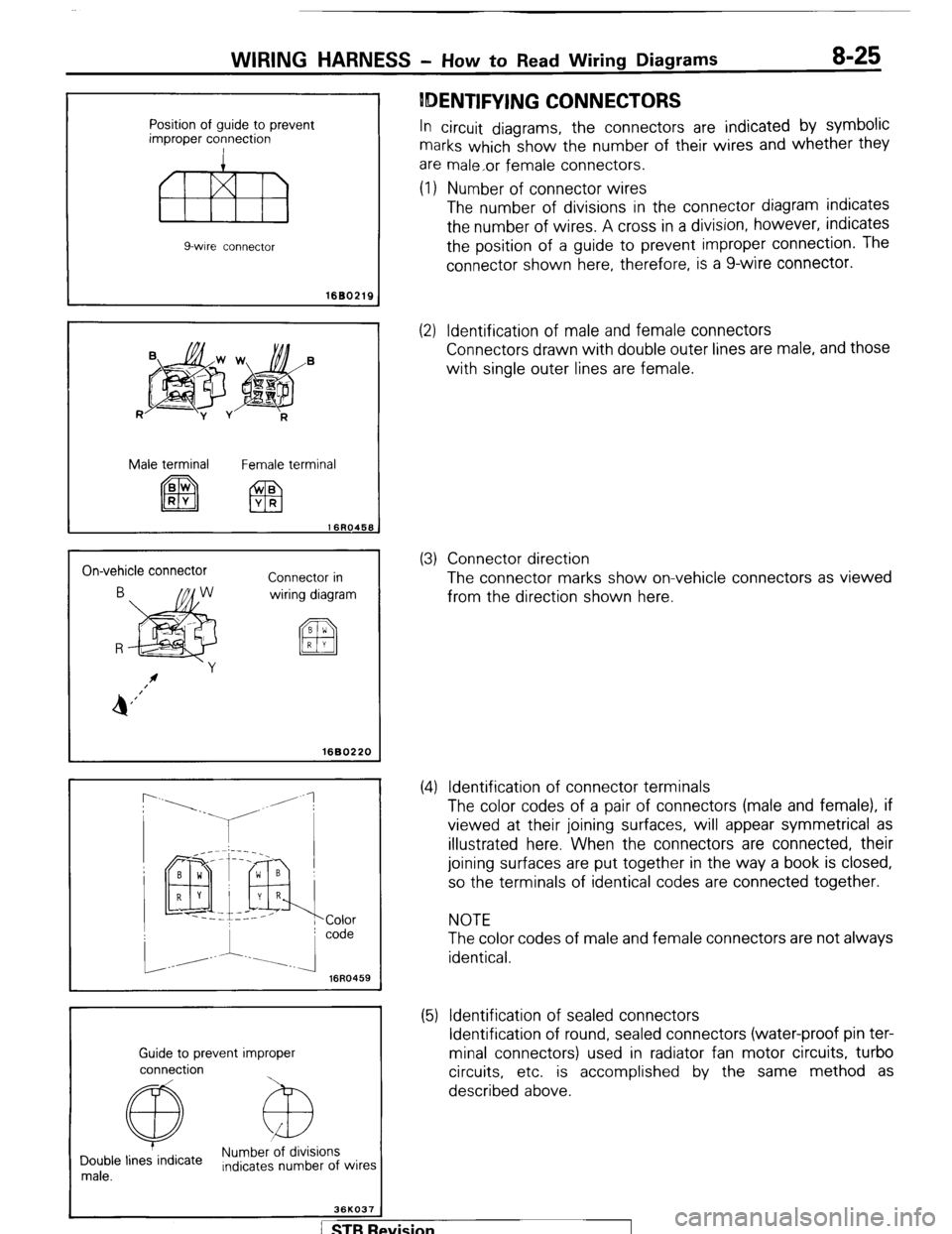

Position of guide to prevent

improper connection

fl!liB

9-wire connector

WIRING HARNESS - How to Read Wiring Diagrams 8-25

IDENTIFYING CONNECTORS

In circuit diagrams, the connectors are indicated by symbolic

marks which show the number of their wires and whether they

are male,or female connectors.

(1) Number of connector wires

The number of divisions in the connector diagram indicates

the number of wires. A cross in a division, however, indicates

the position of a guide to prevent improper connection. The

connector shown here, therefore, is a g-wire connector.

1680219

R

jpg$&’

-y v

R

Male terminal

Female terminal

On-vehicle connector

Connector in

wiring diagram

I 1680220

r

16R0459

Guide to prevent improper

connection

@ Numb&ions

Double lines indicate

male. Indicates number of wires

36KO37

(2) Identification of male and female connectors

Connectors drawn with double outer lines are male, and those

with single outer lines are female.

(3) Connector direction

The connector marks show on-vehicle connectors as viewed

from the direction shown here.

(4) Identification of connector terminals

The color codes of a pair of connectors (male and female), if

viewed at their joining surfaces, will appear symmetrical as

illustrated here. When the connectors are connected, their

joining surfaces are put together in the way a book is closed,

so the terminals of identical codes are connected together.

NOTE

The color codes of male and female connectors are not always

identical.

(5) Identification of sealed connectors

Identification of round, sealed connectors (water-proof pin ter-

minal connectors) used in radiator fan motor circuits, turbo

circuits, etc. is accomplished by the same method as

described above.

/ STB Revision

Page 46 of 284

8-26 WIRING HARNESS - HOW to Read Wiring Diagrams

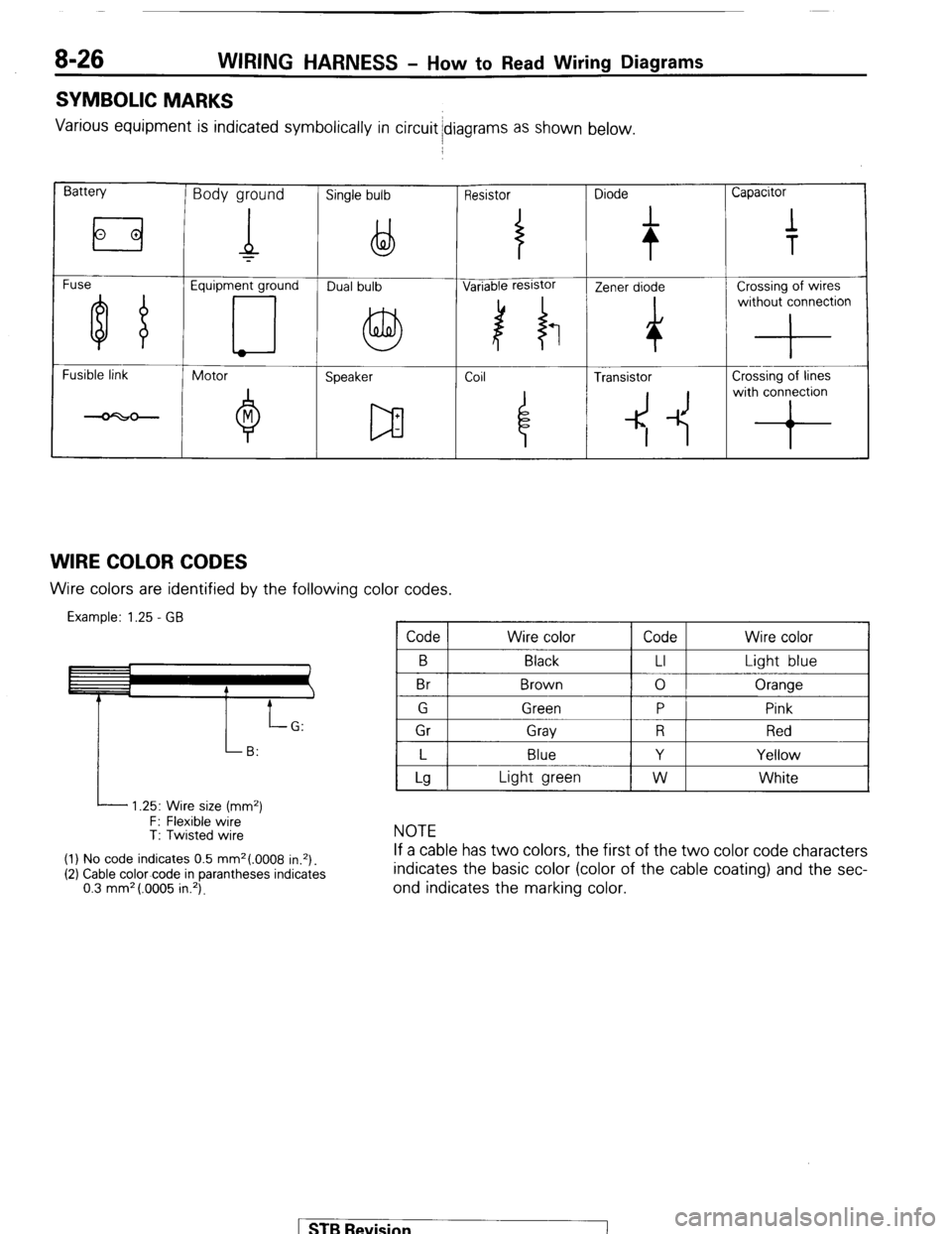

SYMBOLIC MARKS

Various equipment is indicated symbolically in circuit idiagrams as shown below.

Battery Body ground Single bulb Resistor Diode Capacitor

Fuse Equipment ground

Fusible link

Motor

Speaker Coil ~

4 Transistor Crossing of lines

4 -1~ with conron

WIRE COLOR CODES Wire colors are identified by the following color codes.

Example: 1.25 - GB Code Wire color Code Wire color

B

Br Black

Brown LI

0 Light blue

Oranqe

I P

i 1 Gr 1 Grav 1 R 1 Red I

I L I Blue

I Y I Yellow I

L 1.25: Wire size (mm2)

F: Flexible wire

T: Twisted wire

(1) No code indicates 0.5 mm2(.0008 in.*).

(2) Cable color-code in parantheses indicates

0.3 mm* (.0005 in.‘).

Lg Light green W White

NOTE

If a cable has two colors, the first of the two color code characters

indicates the basic color (color of the cable coating) and the sec-

ond indicates the marking color.

STB Revision