engine MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 1 of 284

Service Manual

MONTERO

1987 : Volume 2

FOREWORD

This Service Manual has been prepared with the

latest service information available at the time of

publication. It is subdivided into various group

categories and each section contains diagnosis,

disassembly, repair, and installation procedures

along with complete specifications and tightening

references. Use of this manual will aid in properly

performing any servicing necessary to maintain or

restore the high levels of performance and reliability

designed into these outstanding vehicles.

WE SUPPORT

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

MITSUBISHI MOTOR SALES OF AMERICA. Inc.

Mitsubishi Motors corporation reserves the right to make changes in

design or to make additions to or improvements in its products without

imposing any obligations upon itself to install them on its products

previously manufactured.

I

GROUP/SECTION INDEX ‘kme-.

INTRODUCTION ..............................

Electrical ...........................................

Electrical System Parts

Location .........................................

Relays, Control Units, Sensors,

Fuses, Groundings

Inspection of Harness

Connector ......................................

Wiring Harness .............................

Charging System ..........................

Starting System ............................

Ignition System .............................

Meters and Gauges ......................

Lighting System .............................

Wiper and Washer System ..........

Horn ...............................................

Accessory ......................................

Audio System ................................

Back Door Window Defogger ......

Automatic Free-wheeling Hub

Indicator System ..........................

Heaters and Air-conditioning .........

Heaters ..........................................

Air-conditioning ............................

**, For Engine Chassis & Body refer to

0 1986 Mitsubishi Motors Corporation Printed in Japan

Page 2 of 284

2 INTRODUCTION - How To Use This Manual

HOW TO USE THIS MANUAL NOOBAAK

CONTENTS

The preceding page contains the GROUP INDEX

which lists the group title and group number.

PAGE NUMBERS

All page numbers consist of two sets of digits

separated by a dash. The digits preceding the dash

identify the number of the group. The digits follow-

ing the dash represent the consecutive page

number within the group. The page numbers can

be found on the top left or right of each page.

TEXT

Unless otherwise specified, each service procedure

covers all models. Procedures covering specific

models are identified by the model codes, or similar

designation (engine type, transmission type, etc.).

A description of these designations is covered in

this unit under “VEHICLE IDENTIFICATION”.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attentions to be paid in performing vehicle ser-

vice are described in detail in SERVICE POINTS.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly

must be kept functionally or in strength. It is a value

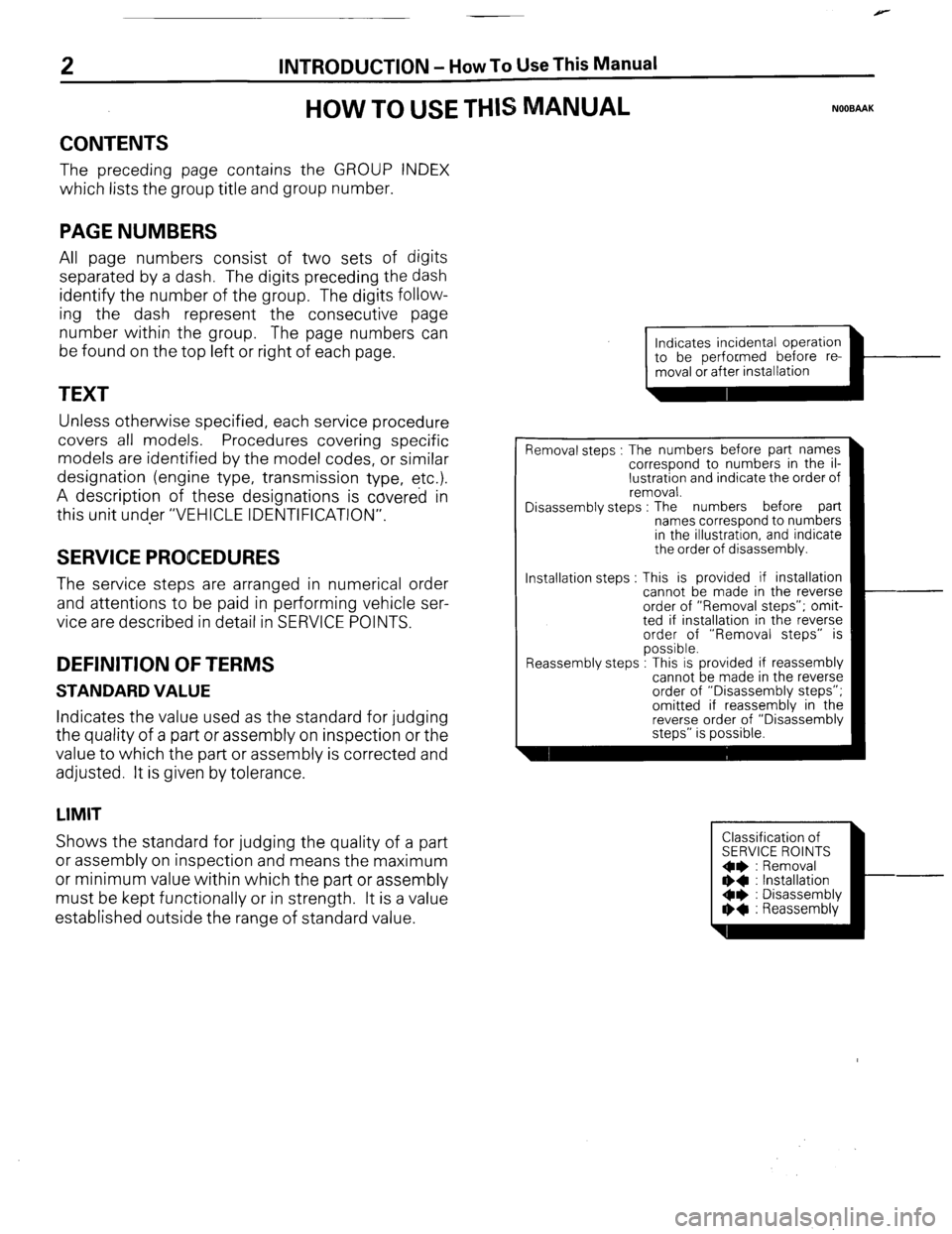

established outside the range of standard value. Installation steps

Indicates incidental operation

piiiKL=l-

Removal steps : The numbers before part names

correspond to numbers in the il-

lustration and indicate the order of

removal.

Disassembly steps : The numbers before part

names correspond to numbers

in the illustration, and indicate

the order of disassembly.

This is provided if installation

cannot be made in the reverse

order of “Removal steps”; omit-

ted if installation in the reverse

order of “Removal steps” is

possible.

.

Reassembly steps : I his IS provided It reassembly

cannot be made in the reverse

order of “Disassembly steps”;

omitted if reassembly in the

reverse order of “Disassembly

steps” is possible.

Classification of

SERVICE ROINTS

Oe : Removal

** : Installation

Oe : Disassembly

I)+ : Reassembly

Page 4 of 284

INTRODUCTION - Vehicle Identification

VEHlCLE IDENTIFICATION

“&LE IDENTIFICATION NUMBER LOCATIOyo(lcAmm

The vehicle identification number (V.I.N.) is located on a plate

attached to the left top side of the instrument panel.

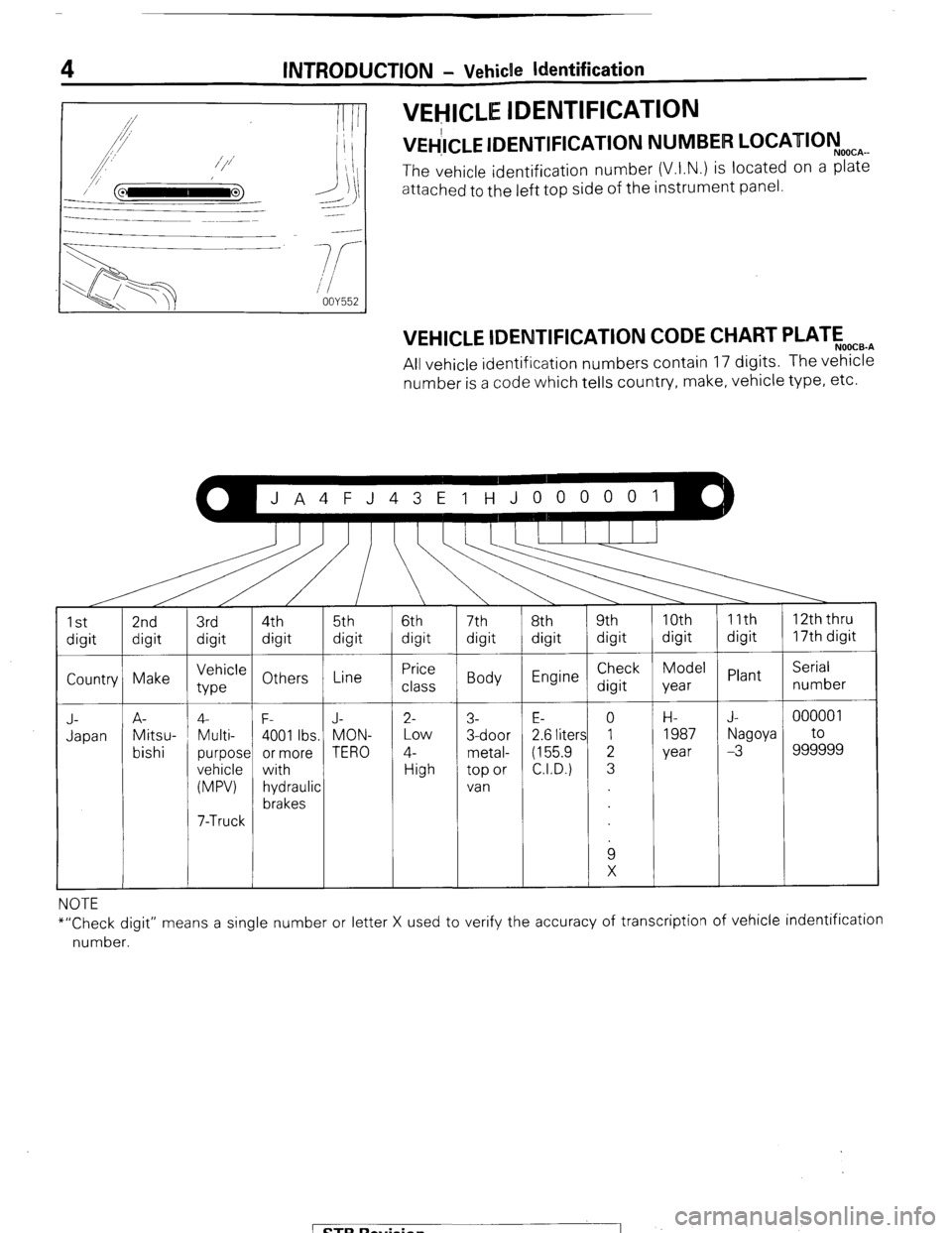

VEHICLE lDENTlFlCATlON CODE CHART PLATEo,,.,

All vehicle identification numbers contain 17 digits. The vehicle

number is a code which tells country, make, vehicle type, etc.

Country Make

!

J- A-

Japan Mitsu-

bishi Vehicle

type Line 4-

F- J-

Multi-

4001 Ibs. MON-

purpose or more TERO

vehicle

with

(MPW hydraulic

brakes

7-Truck

6th

digit

Price

class

2- Low

4- High 7th

8th 9th 10th

digit digit digit digit

Body Engine Check Model

digit year

3- E- 0 H-

3-door

2.6 liters 1 1987

metal- (155.9 2 year

top or C.I.D.) 3

van

9

X Plant

1 ZZ-Zer 1

NOTE

*“Check digit” means a single number or letter X used to verify the accuracy of transcription of vehicle indentification

number.

1 STB Revision

1 I : “’

Page 5 of 284

INTRODUCTION - Vehicle Identification

VEHICLE IDENTIFICATION NUMBER LIST

FEDERAL

VIN (except sequence number) Brand Engine displacement

JA4FJ43EoHJ

JA4FJ43EoHJ MITSUBISHI 2.555 liters

JA7FJ23EoHJ MONTERO (155.9 C.I.D.)

JA7FJ23EoHJ

5

NOOCC-

Model code

L042GVNJLF

L042GVRJLF

L042GTNSLF

L042GTRSLF

CALIFORNIA (Can also be sold in Federal states.)

VIN (except sequence number)

JA4FJ43EoHJ

JA4FJ43EoHJ

JA7FJ23EoHJ

JB7FJ23EoHJ Brand

MITSUBISHI

MONTERO Engine displacement

2.555 liters

(155.9 C.I.D.) Model code

L042GVNJLH

L042GVRJLH

L042GTNSLH

1 L042GTNSLH

OOK520

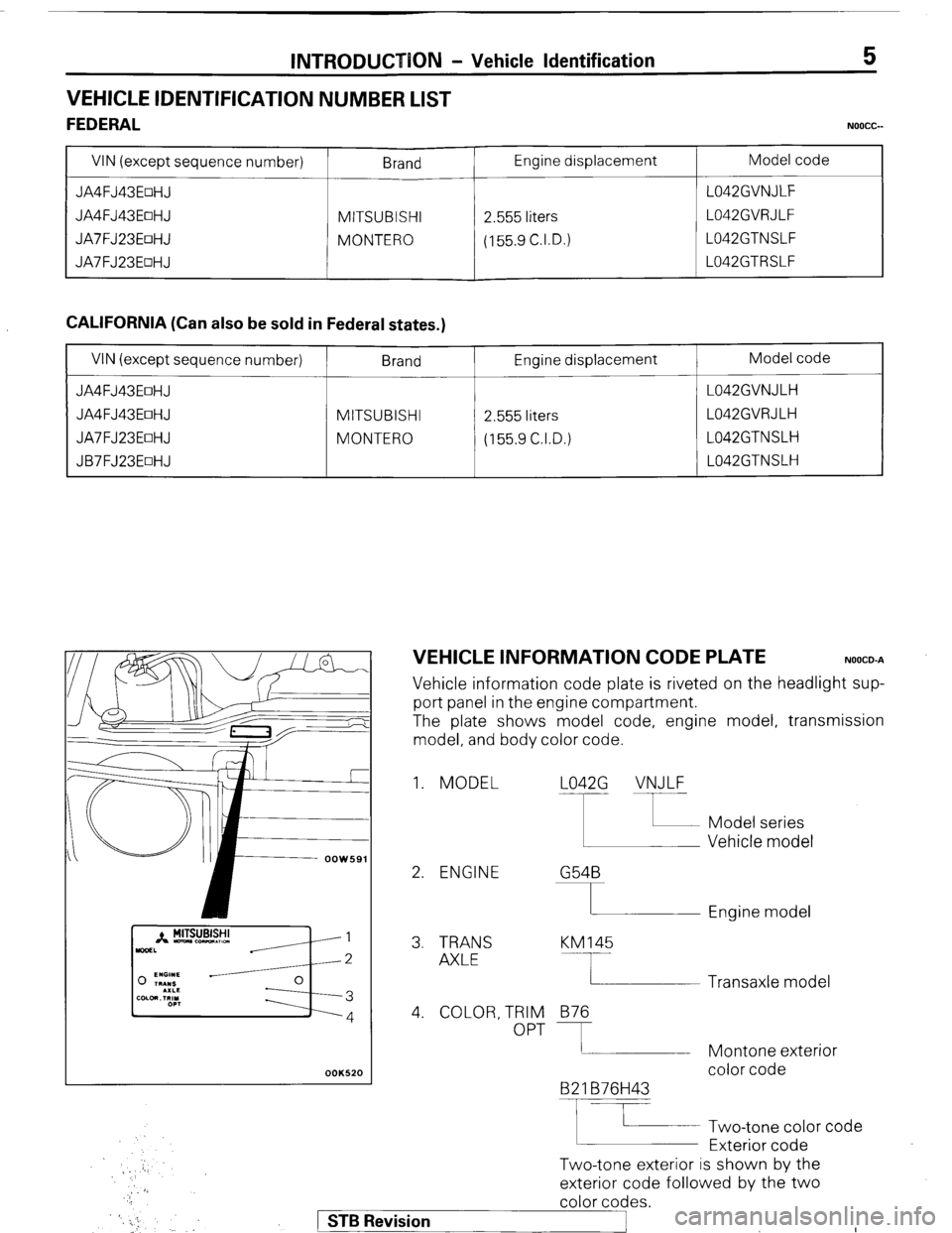

VEHICLE INFORMATION CODE PLATE NOOCO-A

Vehicle information code plate is riveted on the headlight sup-

port panel in the engine compartment.

The plate shows model code, engine model, transmission

model, and body color code.

1. MODEL L042G VNJLF

2. ENGINE G54B

I Engine model

3. TRANS

AXLE KM145

4. COLOR, TRIM

OPT 876

B2 1 B76H43

F

Two-tone exterior is shown by the Two-tone color code

Exterior code Transaxle model

Montone exterior

color code

exterior code followed by the two

color codes.

) STB Revision

._ :

Page 6 of 284

6 INTRODUCTION - Vehicle Identification

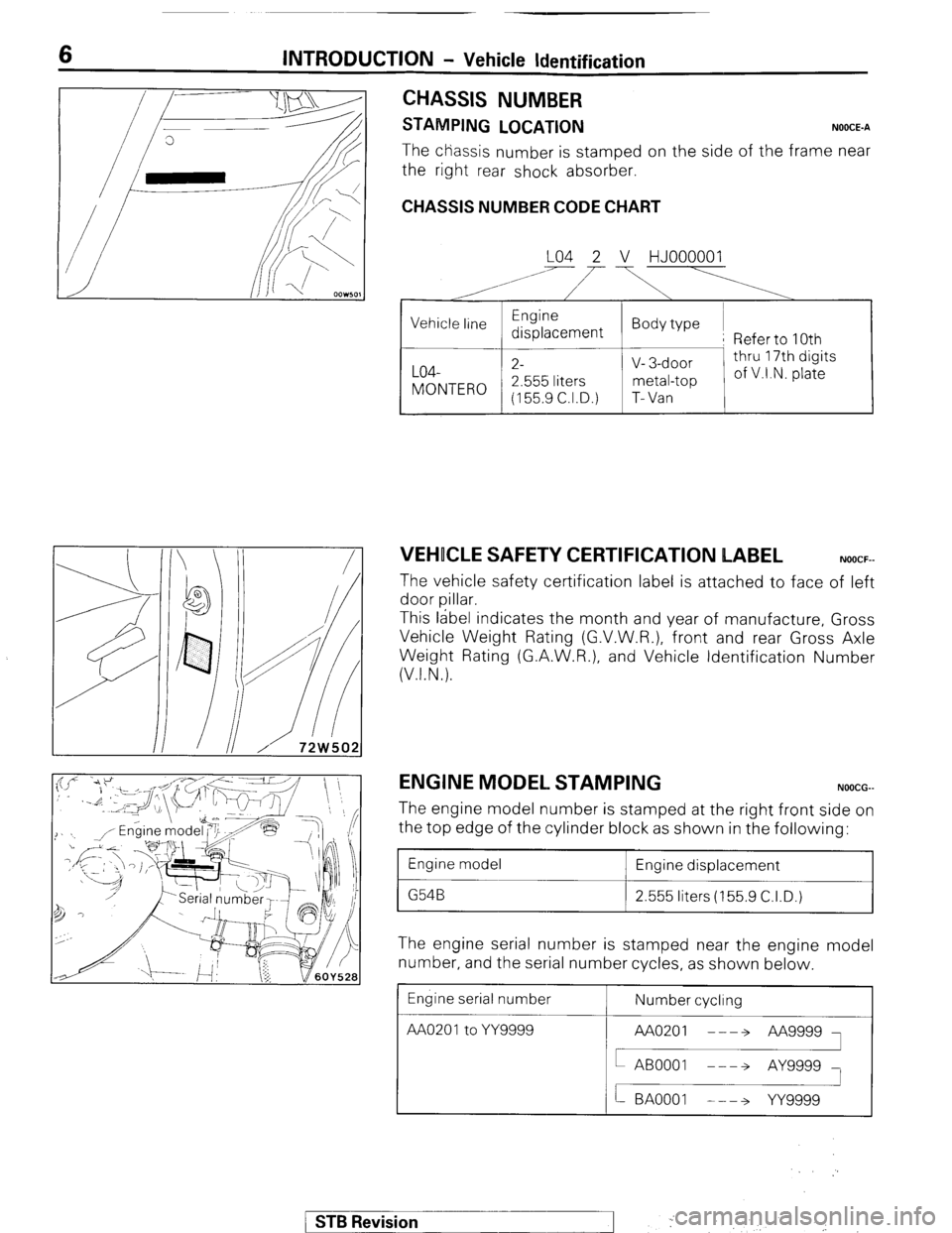

CHASSIS NUMBER

STAMPING LOCATION NOOCE-A

The chassis number is stamped on the side of the frame near

the right rear shock absorber.

CHASSIS NUMBER CODE CHART

LO4 2 V HJOOOOOl

A’ i’

,

VEHICLE SAFETY CERTIFICATION LABEL NOOCF-

The vehicle safety certification label is attached to face of left

door pillar.

This label indicates the month and year of manufacture, Gross

Vehicle Weight Rating (G.V.W.R.), front and rear Gross Axle

Weight Rating (G.A.W.R.), and Vehicle Identification Number

(V.I.N.).

ENGINE MODEL STAMPING NOOCG-

The engine model number is stamped at the right front side on

the top edge of the cylinder block as shown in the following:

1 Engine model

1 Engine displacement

1 2.555 liters (155.9 C.I.D.)

The engine serial number is stamped near the engine model

number, and the serial number cycles, as shown below

Engine serial number

AA020’toYY= Number cycling

/ STB Revision

--I f ,. ..-.

j ‘. .,

Page 9 of 284

INTRODUCTION - Precautions Before Service 9

nm (in.)

so0059

PARTS

When replacing parts, use MITSUBISHI genuine parts.

VEHICLE WVASHING

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least 300 mm (1 1.8 in.) from

any plastic parts and all opening parts (doors, luggage

compartment, etc.).

SERVICING THE ELECTRICAL SYSTEM

When servicing the electrical system, disconnect the negative

cable terminal from the battery.

Caution

Before connecting or disconnecting the negative cable, be

sure to turn off the ignition switch and the lighting switch.

(If this is not done, there is the possibility of semiconductor

parts being damaged.)

WIRING HARNESSES

1. Secure the wiring harnesses by using clamps so that there

is no slack. However, for any harness which passes to the

engine or other vibrating parts of the vehicle, allow some

slack within a range that does not allow the engine

vibrations to cause the harness to come into contact with

any of the surrounding parts. Then secure the harness by

using a clamp.

In addition, if a mounting indication mark (yellow tape) is

on a harness, secure the indication mark in the specified

location.

2. If any section of a wiring harness contacts the edge of a

part, or a corner, wrap the section of the harness with tape

or something similar in order to protect it from damage.

F161711

* :, :, 1 STB Revision

Page 13 of 284

INTRODUCTION - Precautions Before Service 13

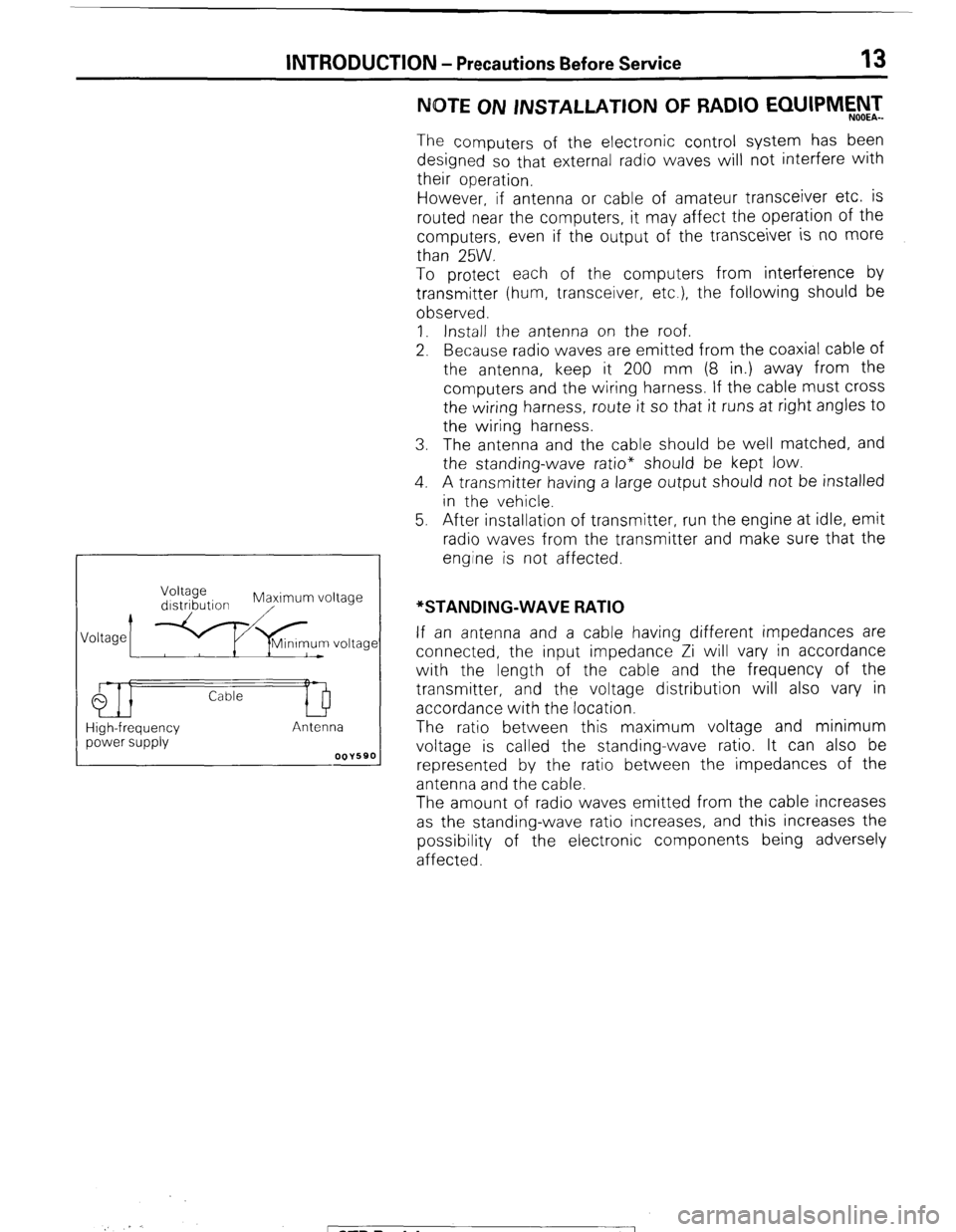

IKITE ON INSTALLATION OF RADIO EQUIPMW&

The computers of the electronic control system has been

designed so that external radio waves will not interfere with

their operation.

However, if antenna or cable of amateur transceiver etc. is

routed near the computers, it may affect the operation of the

computers, even if the output of the transceiver is no more

than 25W.

To protect each of the computers from interference by

transmitter (hum, transceiver, etc.), the following should be

observed.

1. Install the antenna on the roof.

2. Because radio waves are emitted from the coaxial cable of

the antenna, keep it 200 mm (8 in.) away from the

computers and the wiring harness. If the cable must cross

the wiring harness, route it so that it runs at right angles to

the wiring harness.

3. The antenna and the cable should be well matched, and

the standing-wave ratio* should be kept low.

4. A transmitter having a large output should not be installed

in the vehicle.

5. After installation of transmitter, run the engine at idle, emit

radio waves from the transmitter and make sure that the

engine is not affected.

High-frequency power supply If an antenna and a cable having different impedances are

connected, the input impedance Zi will vary in accordance

with the length of the cable and the frequency of the

transmitter, and the voltage distribution will also vary in

accordance with the location.

The ratio between this maximum voltage and minimum

voltage is called the standing-wave ratio. It can also be

represented by the ratio between the impedances of the

antenna and the cable.

The amount of radio waves emitted from the cable increases

as the standing-wave ratio increases, and this increases the

possibility of the electronic components being adversely

affected.

_. r.

; ST6 Revision

Page 18 of 284

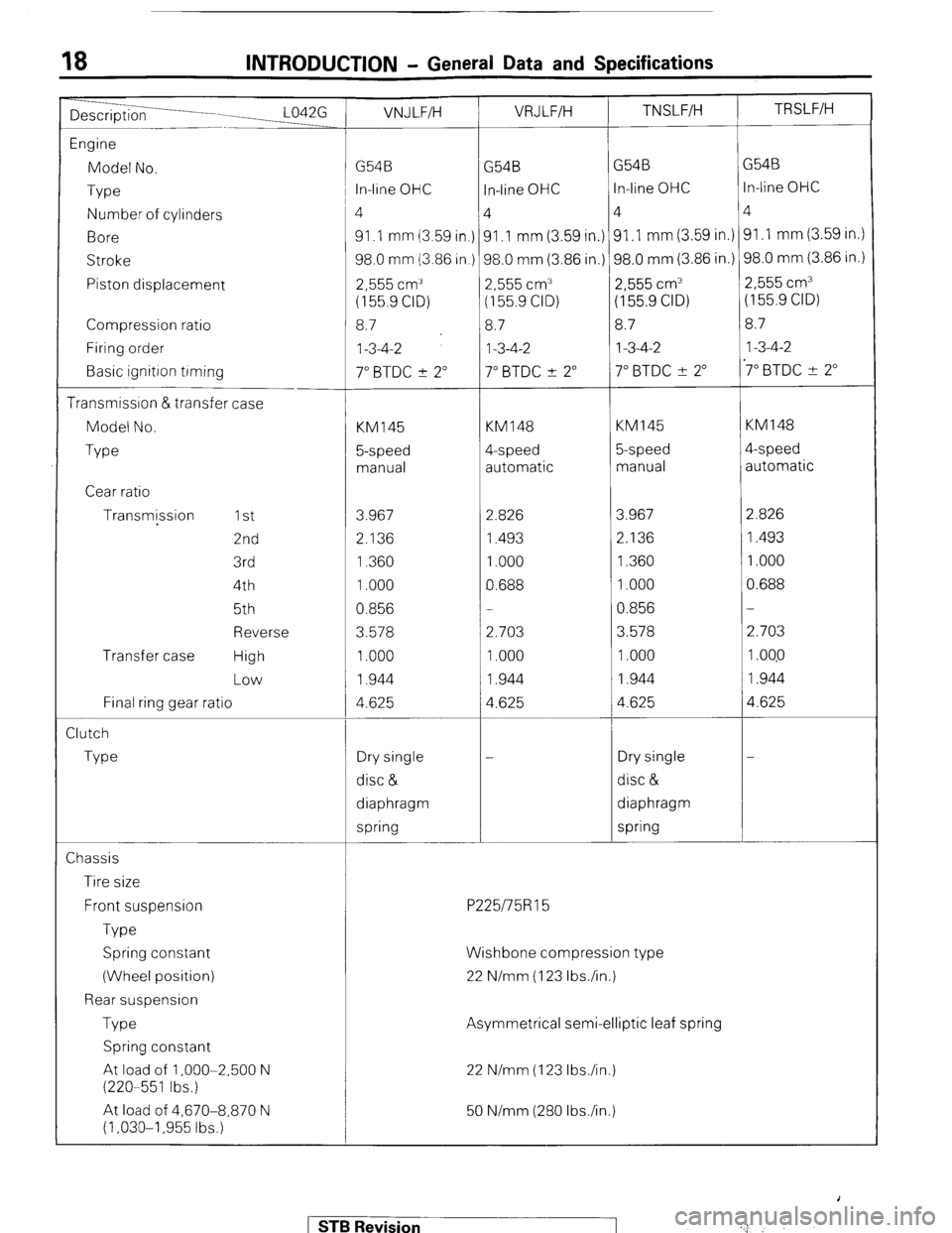

18 INTRODUCTION - General Data and Specifications

Description L042G VNJLFIH VRJ L.F/H TNSLFIH TRSLFIH

1

Engine

Model No. G54B

G54B G54B G54B

Type i In-line OHC

In-line OHC In-line OHC In-line OHC

Number of cylinders ‘4 4

4 4

Bore 91 .I mm (3.59 in.) 91 .I mm (3.59 in.) 91 ,I mm (3.59 in.) 91 .I mm (3.59 in.)

Stroke 98.0 mm (3.86 in.) 98.0 mm (3.86 in.) 98.0 mm (3.86 in.) 98.0 mm (3.86 in.)

Piston displacement

2,555 cm” 2,555 cm” 2,555 cm3

2,555 cm3

(155.9 CID) (155.9 CID) (155.9 CID) (155.9 CID)

Compression ratio 8.7

8.7 8.7

8.7

Firing order

I-3-4-2 I-3-4-2 1-3-4-2

1-3-4-2

Basic ignitron trming

7” BTDC ? 2” 7” BTDC ? 2” 7” BTDC 2 2” ‘7” BTDC ? 2”

Transmission &transfer case

Model No.

KM145 KM148 KM145 KM148

Type 5-speed 4-speed 5-speed 4-speed

manual automatic manual automatic

Cear ratio

Transmjssion 1 st

3.967 2.826 3.967

2.826

2nd

2.136 1.493 2.136

1.493

3rd 1.360

1 .ooo 1.360

1.000

4th

1.000 0.688 1 .ooo

0.688

5th

0.856 - 0.856

-

Reverse 3.578

2.703 3.578

2.703

Transfer case High 1.000

1.000 1.000

1 ,040

Low 1.944

1.944 1.944

1.944

Final ring ratio

gear 4.625 4.625 4.625

4.625

Zlutch

Type Dry single

- Dry single

-

disc & disc &

diaphragm diaphragm

spring spring

Chassis

Tire size

Front suspension

P225/75R15

Type

Spring constant

(Wheel position)

Rear suspension

Type

Spring constant

At load of 1 ,OOO-2,500 N

(220-551 Ibs.)

At load of 4,670-8,870 N

(1,030-I ,955 tbs.) Wishbone compression type

22 N/mm (123 Ibs./in.)

Asymmetrical semi-elliptic leaf spring

22 N/mm (123 Ibs./in.)

50 N/mm (280 Ibs./in.)

1 STB Revision ..,j ; : * :

Page 38 of 284

WIRING HARNESS - Troubleshooting

1660236

Power

supply

h

Fuse

ON

/----

/

/

Motor

1660239

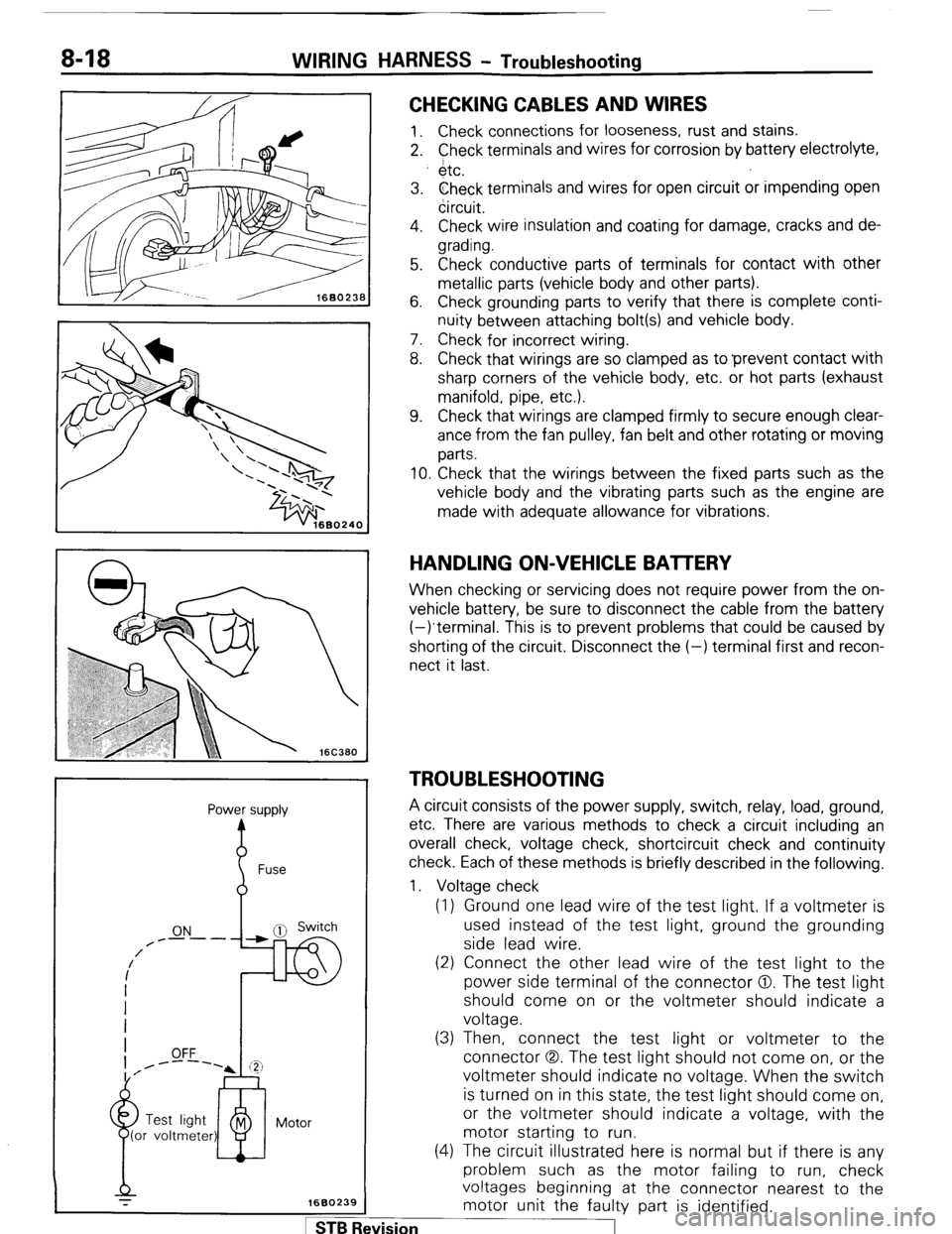

CHECKING CABLES AND WIRES

1. Check connections for looseness, rust and stains.

2. Check terminals and wires for corrosion by battery electrolyte,

$tc.

3. Check terminals and wires for open circuit or impending open

circuit.

4. Check wire insulation and coating for damage, cracks and de-

grading.

5. Check conductive parts of terminals for contact with other

metallic parts (vehicle body and other parts).

6. Check grounding parts to verify that there is complete conti-

nuity between attaching bolt(s) and vehicle body.

7. Check for incorrect wiring.

8. Check that wirings are so clamped as to ‘prevent contact with

sharp corners of the vehicle body, etc. or hot parts (exhaust

manifold, pipe, etc.).

9. Check that wirings are clamped firmly to secure enough clear-

ance from the fan pulley, fan belt and other rotating or moving

parts.

10. Check that the wirings between the fixed parts such as the

vehicle body and the vibrating parts such as the engine are

made with adequate allowance for vibrations.

HANDLING ON-VEHICLE BAlTERY

When checking or servicing does not require power from the on-

vehicle battery, be sure to disconnect the cable from the battery

(-)terminal. This is to prevent problems that could be caused by

shorting of the circuit. Disconnect the (-) terminal first and recon-

nect it last.

TROUBLESHOOTING

A circuit consists of the power supply, switch, relay, load, ground,

etc. There are various methods to check a circuit including an

overall check, voltage check, shortcircuit check and continuity

check. Each of these methods is briefly described in the following.

1. Voltage check

(1) Ground one lead wire of the test light. If a voltmeter is

used instead of the test light, ground the grounding

side lead wire.

(2) Connect the other lead wire of the test light to the

power side terminal of the connector 0. The test light

should come on or the voltmeter should indicate a

voltage.

(3) Then, connect the test light or voltmeter to the

connector (3,. The test light should not come on, or the

voltmeter should indicate no voltage. When the switch

is turned on in this state, the test light should come on,

or the voltmeter should indicate a voltage, with the

motor starting to run.

(4) The circuit illustrated here is normal but if there is any

problem such as the motor failing to run, check

voltages beginning at the connector nearest to the

motor unit the faulty part is identified. 1 ST6 Revision

Page 40 of 284

8-20 WIRING HARNESS - How to Read Wiring Diagrams

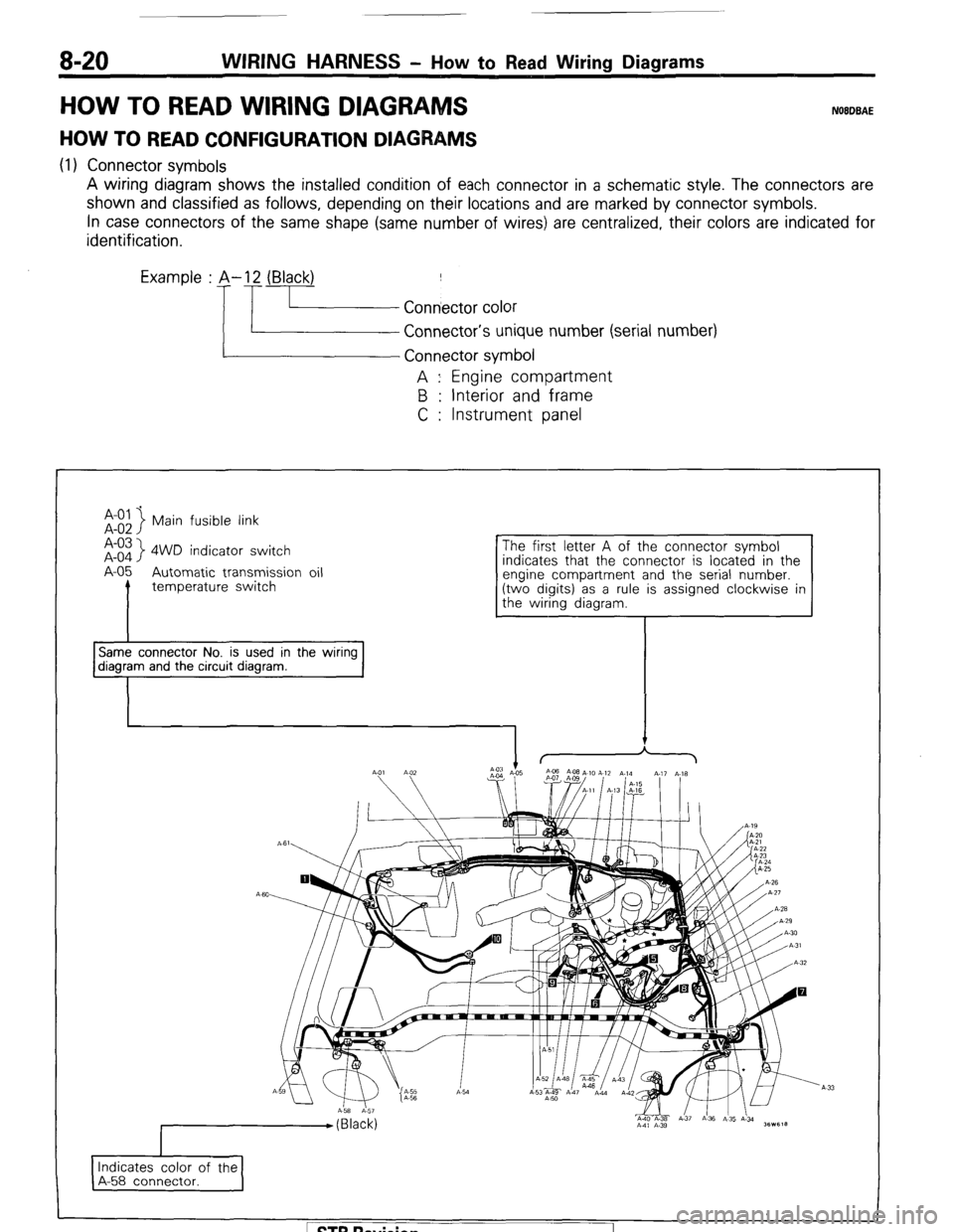

HOW TO READ WIRING DIAGRAM NOEDBAE

HOW TO READ CONFIGURATION DIAGRAMS

(1) Connector symbols

A wiring diagram shows the installed condition of each connector in a schematic style. The connectors are

shown and classified as follows, depending on their locations and are marked by connector symbols.

In case connectors of the same shape (same number of wires) are centralized, their colors are indicated for

identification.

Examp’e : p.!- f.~~~~ ~;~~o,

Connector’s unique number (serial number)

A : Engine compartment

B : Interior and frame

C : Instrument panel

Main fusible link

A-03

A-o4

> 4WD indicator switch

A-05 Automatic transmission oil

I temperature switch indicates that the connector is located in the

Same connector No. is used in the wiring diagram and the circuit diagram.

I Indicates color of the

A-58 connector. I

1 ST6 Revision