engine overheat MITSUBISHI MONTERO 1987 1.G Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 97 of 284

CHARGING SYSTEM - Service Adjustment Procedures 8-77

SERVICE ADJUSTMENT PROCEDUREswmAB

lEL15I

INSPECTION OF THE CHARGING SYSTEM

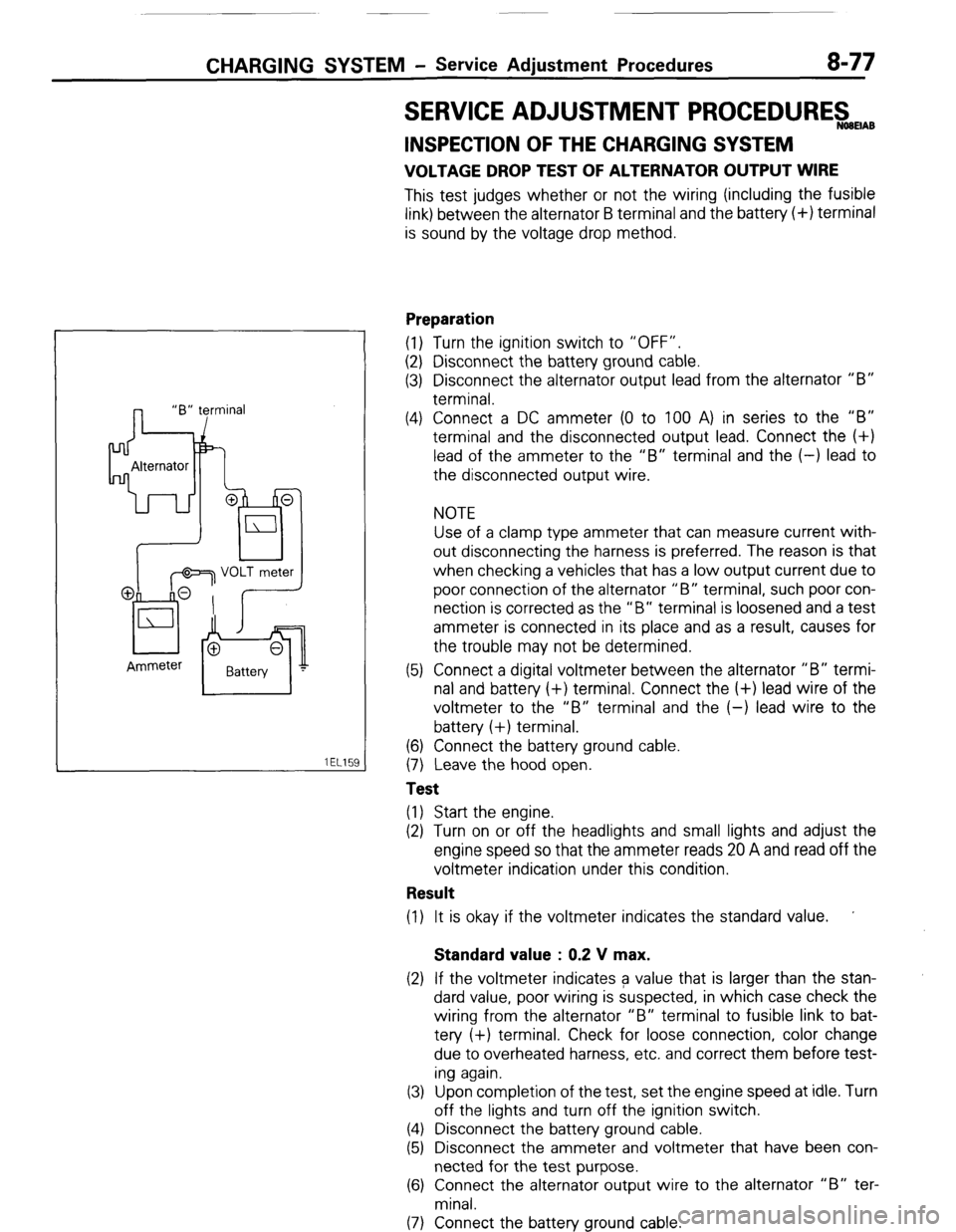

VOLTAGE DROP TEST OF ALTERNATOR OUTPUT WIRE

This test judges whether or not the wiring (including the fusible

link) between the alternator B terminal and the battery (+) terminal

is sound by the voltage drop method.

Preparation

(1) Turn the ignition switch to “OFF”.

(2) Disconnect the battery ground cable.

(3) Disconnect the alternator output lead from the alternator “B”

terminal.

(4) Connect a DC ammeter (0 to 100 A) in series to the “B”

terminal and the disconnected output lead. Connect the (+)

lead of the ammeter to the “B” terminal and the (-) lead to

the disconnected output wire.

NOTE

Use of a clamp type ammeter that can measure current with-

out disconnecting the harness is preferred. The reason is that

when checking a vehicles that has a low output current due to

poor connection of the alternator “B” terminal, such poor con-

nection is corrected as the “B” terminal is loosened and a test

ammeter is connected in its place and as a result, causes for

the trouble may not be determined.

(5) Connect a digital voltmeter between the alternator “B” termi-

nal and battery (+) terminal. Connect the (+) lead wire of the

voltmeter to the “B” terminal and the (-) lead wire to the

battery (+) terminal.

(6) Connect the battery ground cable.

(7) Leave the hood open.

Test

(1) Start the engine.

(2) Turn on or off the headlights and small lights and adjust the

engine speed so that the ammeter reads 20 A and read off the

voltmeter indication under this condition.

Result

(1) It is okay if the voltmeter indicates the standard value. ’

Standard value : 0.2 V max.

(2) If the voltmeter indicates a value that is larger than the stan-

dard value, poor wiring is suspected, in which case check the

wiring from the alternator “B” terminal to fusible link to bat-

tery (+) terminal. Check for loose connection, color change

due to overheated harness, etc. and correct them before test-

ing again.

(3) Upon completion of the test, set the engine speed at idle. Turn

off the lights and turn off the ignition switch.

(4) Disconnect the battery ground cable.

(5) Disconnect the ammeter and voltmeter that have been con-

nected for the test purpose.

(6) Connect the alternator output wire to the alternator “B” ter-

minal.

(7) Connect the battery ground cable.

( STB Revision

Page 129 of 284

IGNITLON SYSTEM -Troubleshooting 8-109

TROUBLESHOOTING

NOBGH--

Symptom Probable cause

Remedy

Reference

paw

Engine will not start or

Incorrect ignition timing

8-111

hard to start (cranks Adjust ignition timing

OKI Ignition coil faulty

Inspect ignition coil 8-116

Ignition faulty

Inspect igniter

8-120

Distributor faulty

Inspect distributor 8-120

High tension cord faulty

Inspect high tension 8-116

cord

Spark plugs faulty Replace plugs 8-115

Ignition wiring disconnected or broken

Inspect wiring -

Rough idle or stalls

Spark plugs faulty

Replace plugs 8-115

Ignition wiring faulty

Inspect wiring -

Incorrect ignition timing

Adjust ignition timing

8-111

Ignition coil faulty

Inspect ignition coil 8-116

Ignition faulty

Inspect igniter 8-120

High tension cord faulty

Inspect high tension 8-116

cord

Engine hesitates/poor

acceleration Spark plugs faulty Replace plugs 8-115

Ignition wiring faulty

Inspect wiring -

Incorrect ignition timing

Adjust timing 8-111

Poor gasoline mileage

Spark plugs faulty Replace plugs 8-115

Incorrect ignition timing Adjust ignition timing 8-111

Engine overheats Incorrect ignition timing

Adjust ignition timing

8-111 1 STB Revision

Page 256 of 284

24-20 AIR-CONDITION!NG-General Information

I

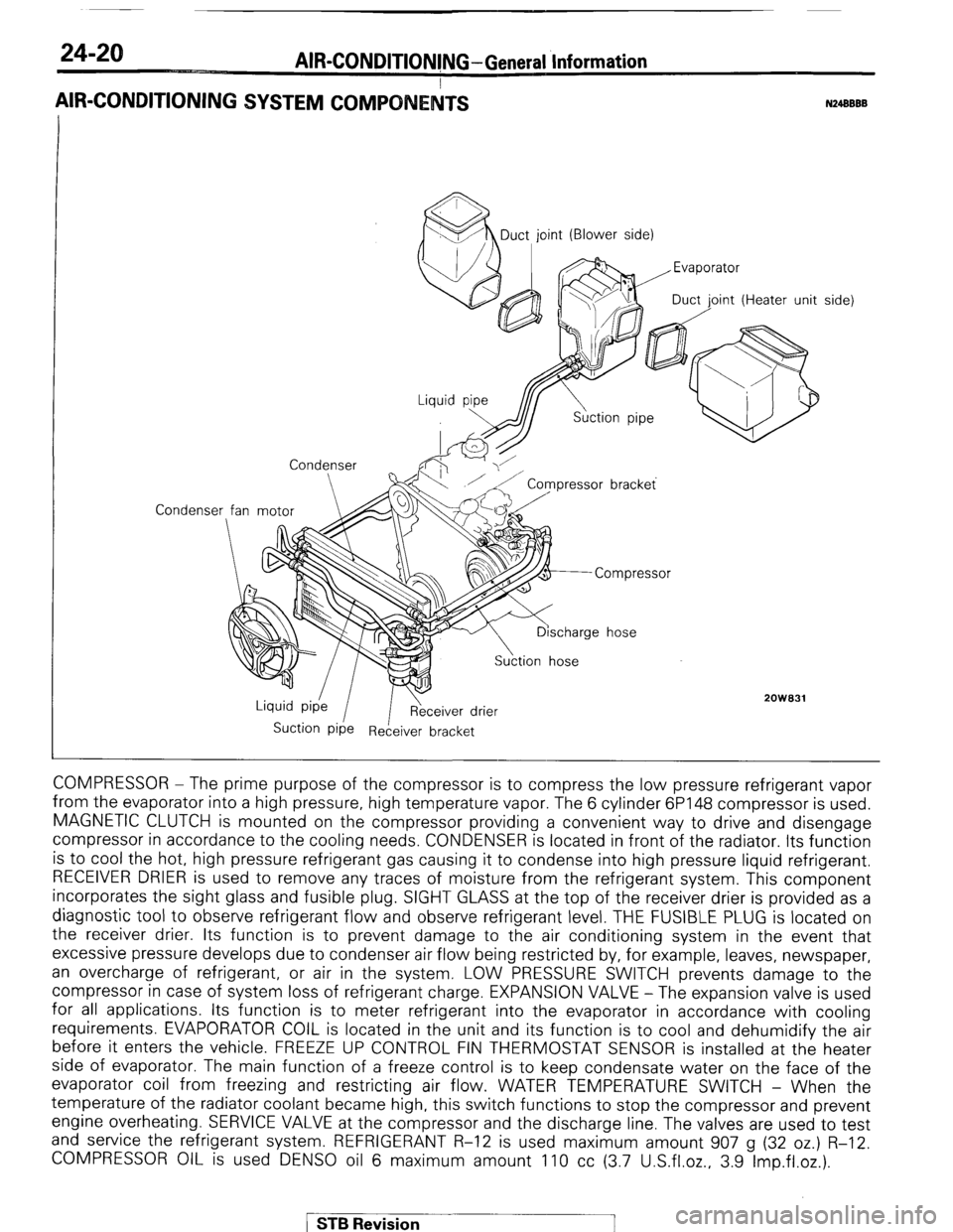

AIR-CONDITIONING SYSTEM COMPO

N24BBBB

Condenser MDuct, joint (Blower side)

oint (Heater unit

Condenser

2OWB31

Suction Pipe Receiver bracket side)

COMPRESSOR - The prime purpose of the compressor is to compress the low pressure refrigerant vapor

from the evaporator into a high pressure, high temperature vapor. The 6 cylinder 6P148 compressor is used.

MAGNETIC CLUTCH is mounted on the compressor providing a convenient way to drive and disengage

compressor in accordance to the cooling needs. CONDENSER is located in front of the radiator. Its function

is to cool the hot, high pressure refrigerant gas causing it to condense into high pressure liquid refrigerant.

RECEIVER DRIER is used to remove any traces of moisture from the refrigerant system. This component

incorporates the sight glass and fusible plug. SIGHT GLASS at the top of the receiver drier is provided as a

diagnostic tool to observe refrigerant flow and observe refrigerant level. THE FUSIBLE PLUG is located on

the receiver drier. Its function is to prevent damage to the air conditioning system in the event that

excessive pressure develops due to condenser air flow being restricted by, for example, leaves, newspaper,

an overcharge of refrigerant, or air in the system. LOW PRESSURE SWITCH prevents damage to the

compressor in case of system loss of refrigerant charge. EXPANSION VALVE - The expansion valve is used

for all applications. Its function is to meter refrigerant into the evaporator in accordance with cooling

requirements. EVAPORATOR COIL is located in the unit and its function is to cool and dehumidify the air

before it enters the vehicle. FREEZE UP CONTROL FIN THERMOSTAT SENSOR is installed at the heater

side of evaporator. The main function of a freeze control is to keep condensate water on the face of the

evaporator coil from freezing and restricting air flow. WATER TEMPERATURE SWITCH - When the

temperature of the radiator coolant became high, this switch functions to stop the compressor and prevent

engine overheating. SERVICE VALVE at the compressor and the discharge line. The valves are used to test

and service the refrigerant system. REFRIGERANT R-12 is used maximum amount 907 g (32 oz.) R-12.

COMPRESSOR OIL is used DENS0 oil 6 maximum amount 110 cc (3.7 U.S.fl.oz., 3.9 Imp.fl.oz.).

/ STB Revision

Page 267 of 284

AIR-CONDITIONING-Service Adiustment Procedures 24-31

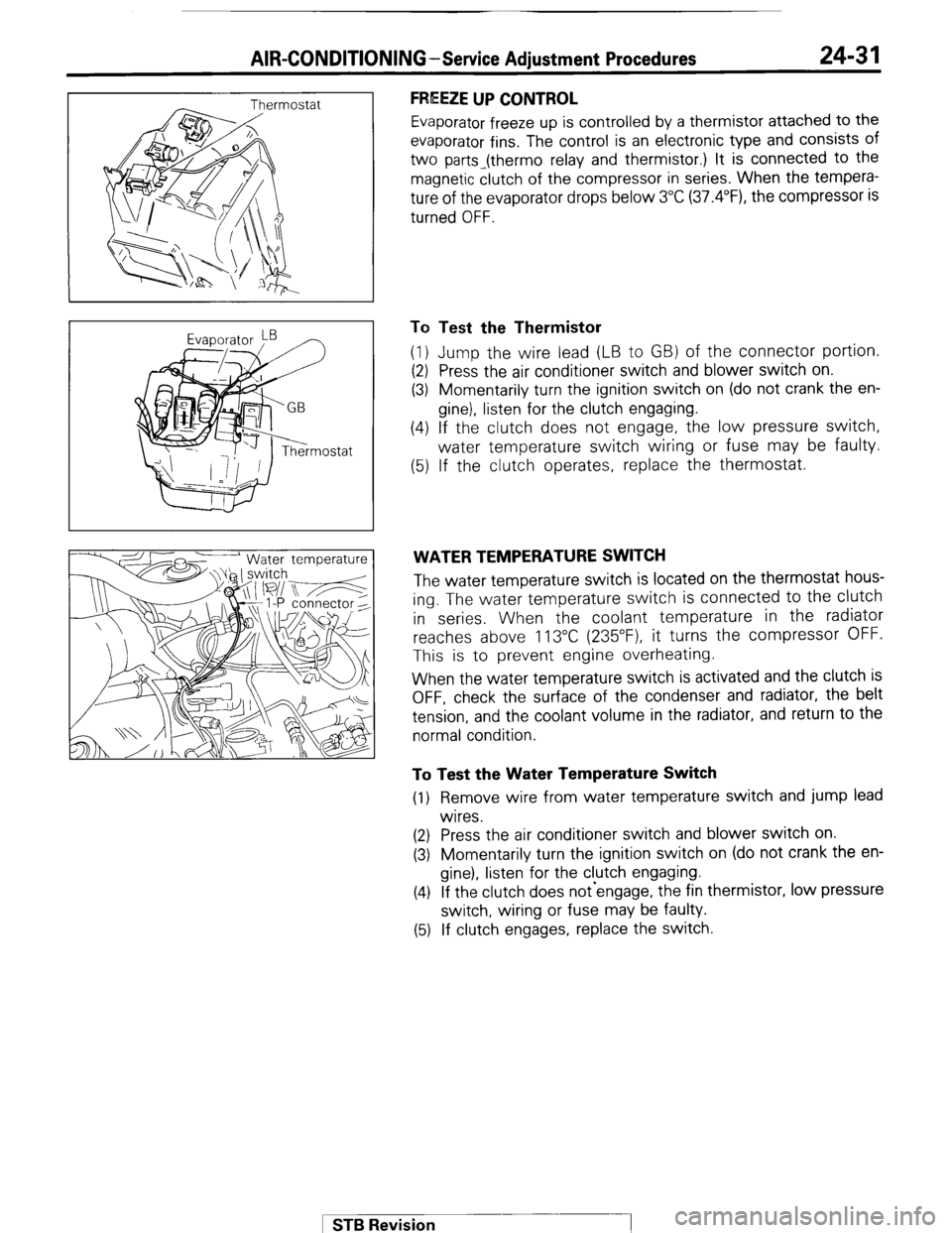

FREEZE UP CONTROL

Evaporator freeze up is controlled by a thermistor attached to the

evaporator fins. The control is an electronic type and consists of

two parts_(thermo relay and thermistor.) It is connected to the

magnetic clutch of the compressor in series. When the tempera-

ture of the evaporator drops below 3°C (37.4”F), the compressor is

turned OFF.

To Test the Thermistor

(1) Jump the wire lead (LB to GB) of the connector portion.

(2) Press the air conditioner switch and blower switch on.

(3) Momentarily turn the ignition switch on (do not crank the en-

gine), listen for the clutch engaging.

(4) If the clutch does not engage, the low pressure switch,

water temperature switch wiring or fuse may be faulty.

(5) If the clutch operates, replace the thermostat.

WATER TEMPERATURE SWITCH

The water temperature switch is located on the thermostat hous-

ing. The water temperature switch is connected to the clutch

in series. When the coolant temperature in the radiator

reaches above 113°C (235”F), it turns the compressor OFF.

This is to prevent engine overheating.

When the water temperature switch is activated and the clutch is

OFF, check the surface of the condenser and radiator, the belt

tension, and the coolant volume in the radiator, and return to the

normal condition.

To Test the Water Temperature Switch

(1) Remove wire from water temperature switch and jump lead

wires.

(2) Press the air conditioner switch and blower switch on.

(3) Momentarily turn the ignition switch on (do not crank the en-

gine), listen for the clutch engaging.

(4) If the clutch does not-engage, the fin thermistor, low pressure

switch, wiring or fuse may be faulty.

(5) If clutch engages, replace the switch.

1 STB Revision