MITSUBISHI MONTERO 2000 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1221 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-13

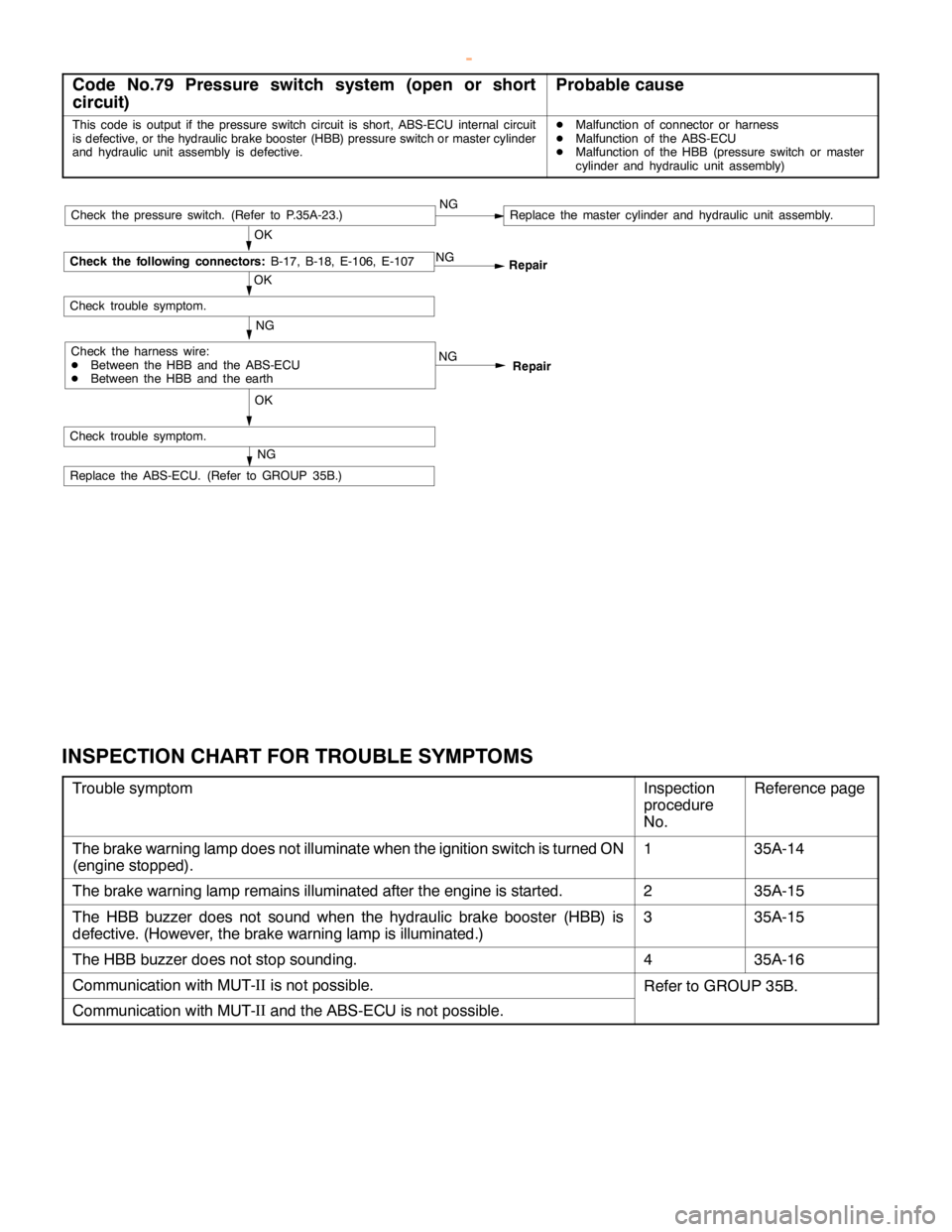

Code No.79 Pressure switch system (open or short

circuit)Probable cause

This code is output if the pressure switch circuit is short, ABS-ECU internal circuit

is defective, or the hydraulic brake booster (HBB) pressure switch or master cylinder

and hydraulic unit assembly is defective.DMalfunction of connector or harness

DMalfunction of the ABS-ECU

DMalfunction of the HBB (pressure switch or master

cylinder and hydraulic unit assembly)

NG

Repair

NG

OKRepair NG

OK

Check trouble symptom.

Check the following connectors:

B-17, B-18, E-106, E-107

Check the harness wire:

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check trouble symptom.

Replace the ABS-ECU. (Refer to GROUP 35B.)

NG

OKCheck the pressure switch. (Refer to P.35A-23.)Replace the master cylinder and hydraulic unit assembly.

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure

No.Reference page

The brake warning lamp does not illuminate when the ignition switch is turned ON

(engine stopped).135A-14

The brake warning lamp remains illuminated after the engine is started.235A-15

The HBB buzzer does not sound when the hydraulic brake booster (HBB) is

defective. (However, the brake warning lamp is illuminated.)335A-15

The HBB buzzer does not stop sounding.435A-16

Communication with MUT-II

is not possible.Refer to GROUP 35B.

Communication with MUT-II

and the ABS-ECU is not possible.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1222 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-14

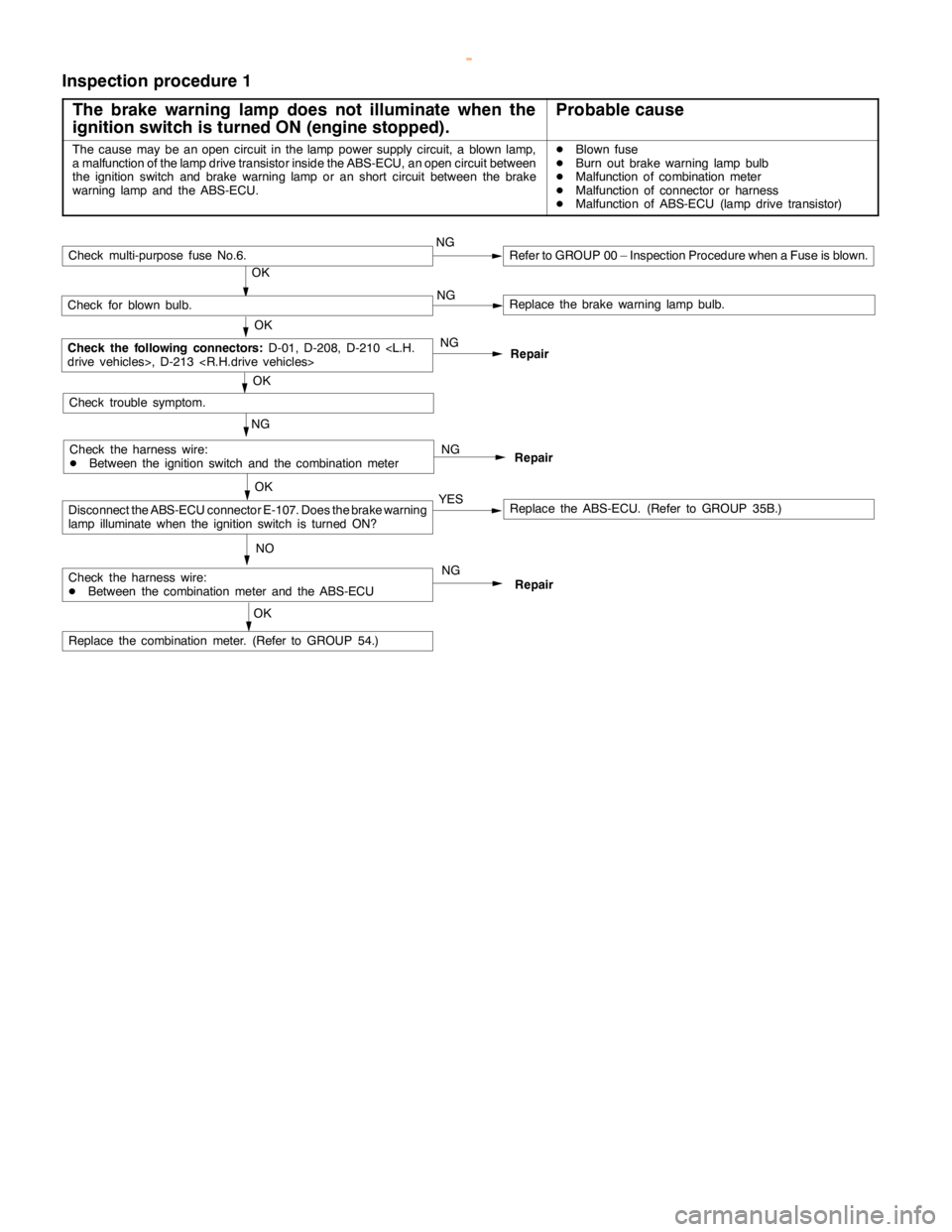

Inspection procedure 1

The brake warning lamp does not illuminate when the

ignition switch is turned ON (engine stopped).

Probable cause

The cause may be anopencircuit in thelamppower supply circuit, a blown lamp,

a malfunction of the lampdrive transistor inside the ABS-ECU, anopencircuit between

the ignition switch and brake warninglamp or anshort circuit between the brake

warning lamp and theABS-ECU.DBlown fuse

DBurn out brake warninglamp bulb

DMalfunction of combination meter

DMalfunction of connector or harness

DMalfunction of ABS-ECU (lamp drive transistor)

Repair NG NG

NO

Replace the ABS-ECU. (Refer to GROUP 35B.)

Repair

Repair

NG

OK

Check for blown bulb.Replace the brake warninglamp bulb.

OK

Check the following connectors:

D-01, D-208, D-210

NG

Replace the combination meter. (Refer to GROUP 54.)

OK

Check trouble symptom.

OK

YES

Check multi-purpose fuse No.6.NGRefer to GROUP 00 – Inspection Procedure when a Fuse is blown.

Check the harness wire:

DBetween the ignition switch and the combination meter

Check the harness wire:

DBetween the combination meter and the ABS-ECU

Disconnect the ABS-ECU connector E-107. Does the brake warning

lamp illuminatewhen the ignition switch is turned ON?

NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1223 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-15

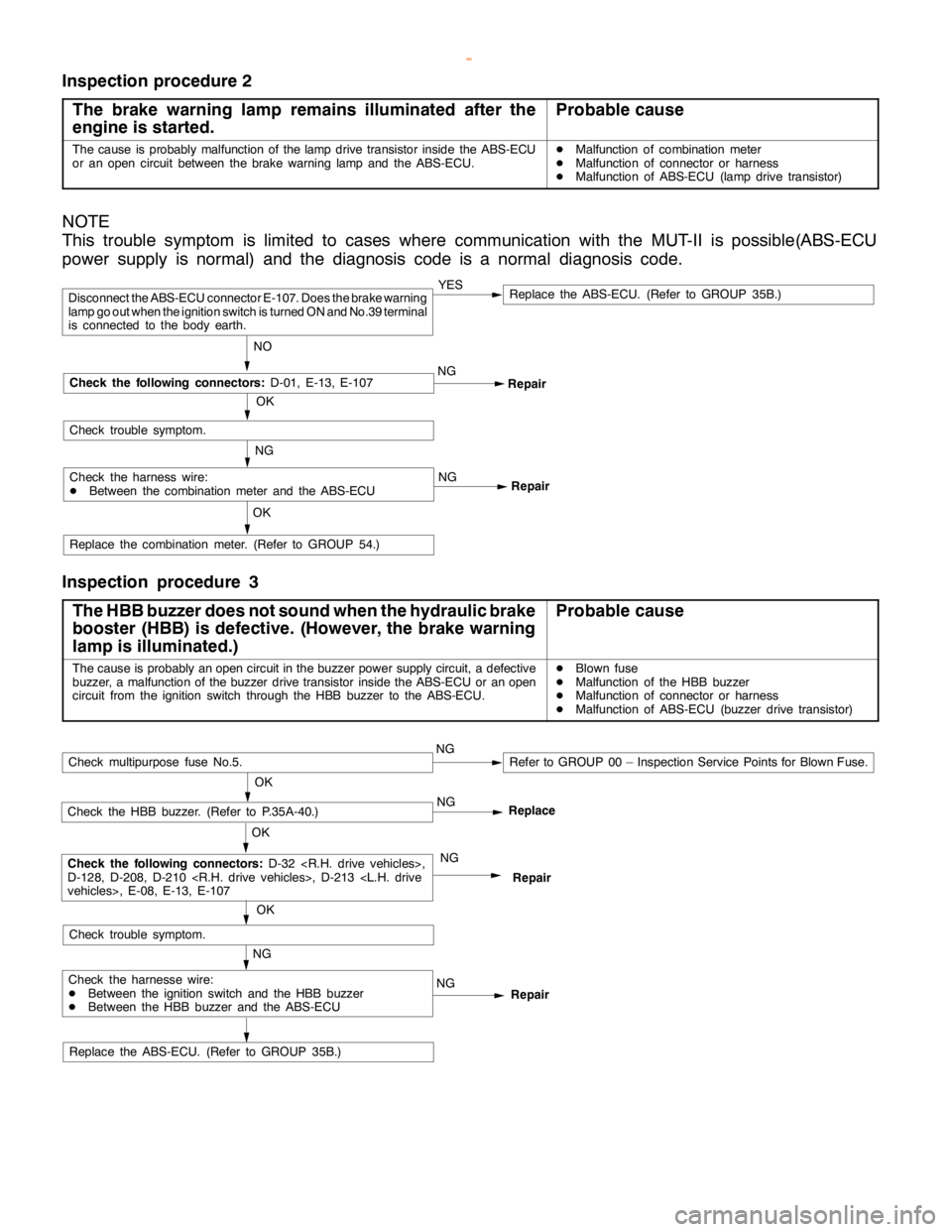

Inspection procedure 2

The brake warning lamp remains illuminated after the

engine is started.

Probable cause

The cause is probably malfunction of thelampdrive transistor inside the ABS-ECU

or an opencircuit between the brake warninglamp and theABS-ECU.DMalfunction of combination meter

DMalfunction of connector or harness

DMalfunction of ABS-ECU (lamp drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

Repair NG

Repair

Replace the combination meter. (Refer to GROUP 54.)

OK

YESReplace the ABS-ECU. (Refer to GROUP 35B.)

NO

Disconnect the ABS-ECU connector E-107. Does the brake warning

lamp go outwhen the ignition switch is turned ON and No.39 terminal

is connected to the body earth.

OK

Check the following connectors:

D-01, E-13, E-107

Check trouble symptom.

Check the harness wire:

DBetween the combination meter and the ABS-ECUNG

NG

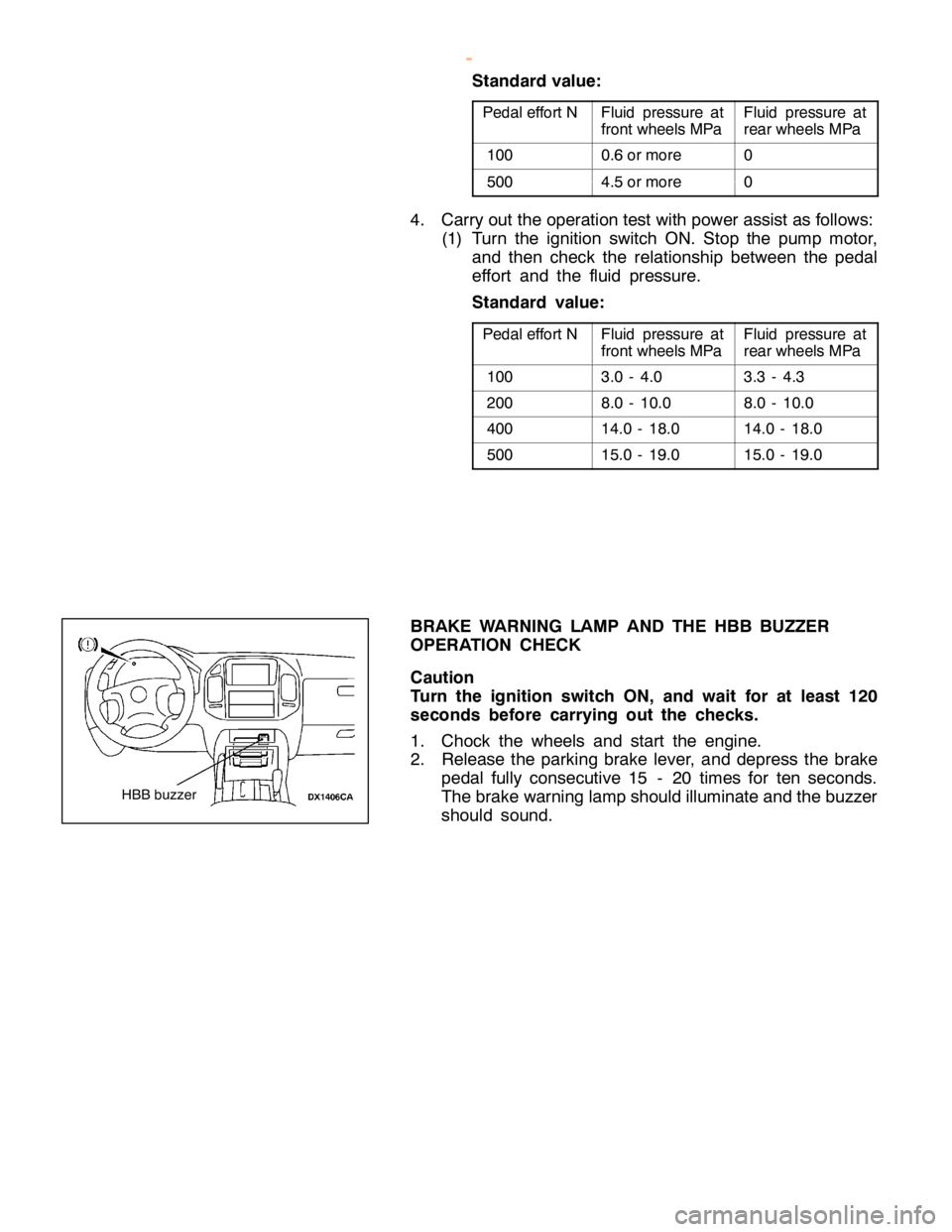

Inspection procedure 3

The HBB buzzer does not sound when the hydraulic brake

booster (HBB) is defective. (However, thebrake warning

lamp is illuminated.)

Probable cause

The cause is probably anopencircuit in the buzzer power supply circuit, a defective

buzzer, a malfunction of the buzzer drive transistor inside the ABS-ECU or anopen

circuit from the ignition switch through the HBB buzzer to the ABS-ECU.DBlown fuse

DMalfunction of the HBB buzzer

DMalfunction of connector or harness

DMalfunction of ABS-ECU (buzzer drive transistor)

Replace the ABS-ECU. (Refer to GROUP 35B.)

Repair NG

Repair

NG

OK

Check the HBB buzzer. (Refer to P.35A-40.)

OK

Check the following connectors:

D-32

D-128, D-208, D-210

NG

OK

Check trouble symptom.

Check multipurpose fuse No.5.NGRefer to GROUP 00 – Inspection Service Points for Blown Fuse.

Check the harnesse wire:

DBetween the ignition switch and the HBB buzzer

DBetween the HBB buzzer and the ABS-ECUNGReplace

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1224 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-16

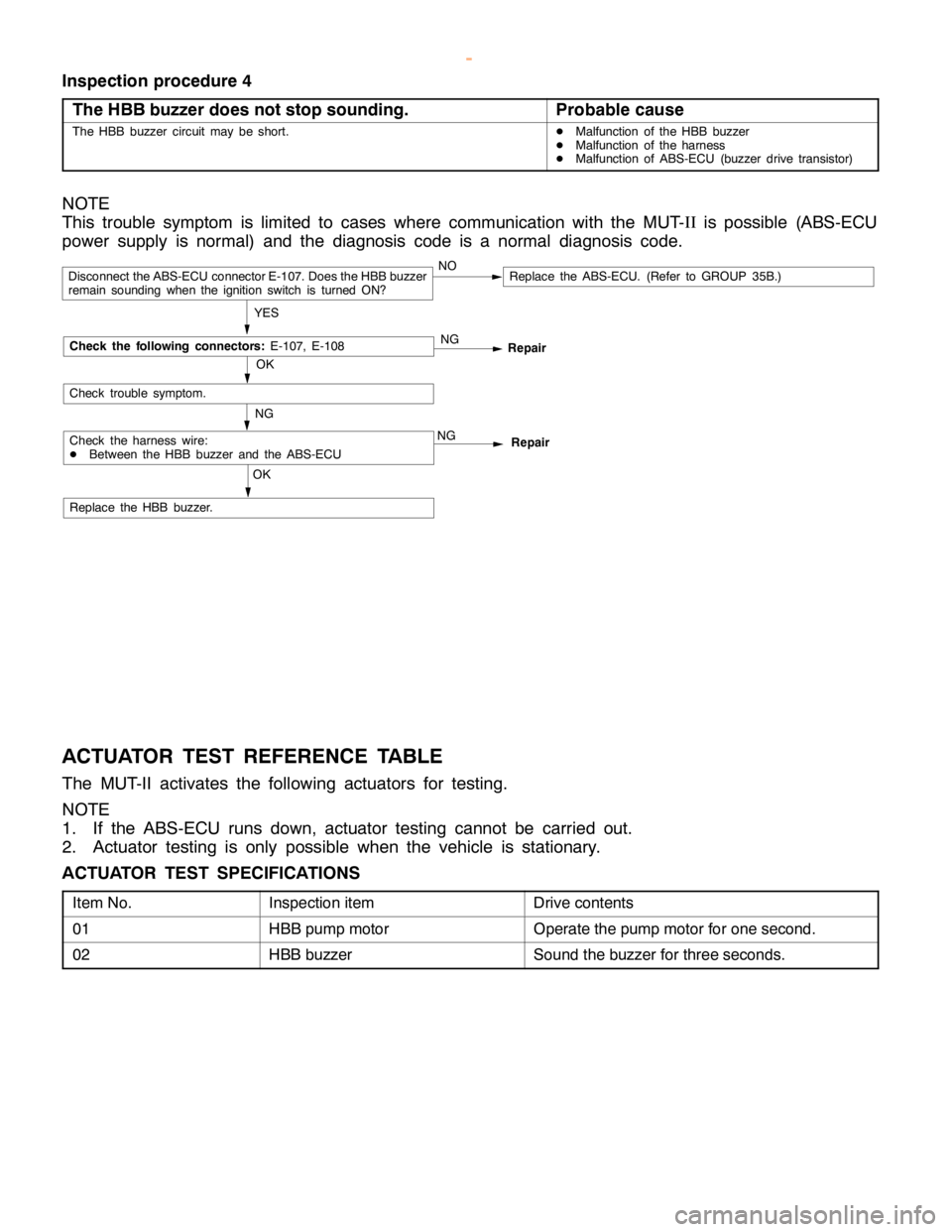

Inspection procedure 4

The HBB buzzer does not stop sounding.

Probable cause

The HBB buzzer circuit may be short.DMalfunction of the HBB buzzer

DMalfunction of the harness

DMalfunction of ABS-ECU (buzzer drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II

is possible (ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

OK

Repair NG

Repair

Replace the HBB buzzer.

OK

NG

YES

Replace the ABS-ECU. (Refer to GROUP 35B.)NODisconnect the ABS-ECU connector E-107. Does the HBB buzzer

remain sounding when the ignition switch is turned ON?

Check trouble symptom.

Check the harness wire:

DBetween the HBB buzzer and the ABS-ECUNG

Check the following connectors:

E-107, E-108

ACTUATOR TEST REFERENCE TABLE

The MUT-II activates the following actuators for testing.

NOTE

1. If the ABS-ECU runs down, actuator testing cannot be carried out.

2. Actuator testing is only possible when the vehicle is stationary.

ACTUATOR TEST SPECIFICATIONS

Item No.Inspection itemDrive contents

01HBB pump motorOperate the pump motor for one second.

02HBB buzzerSound the buzzer for three seconds.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

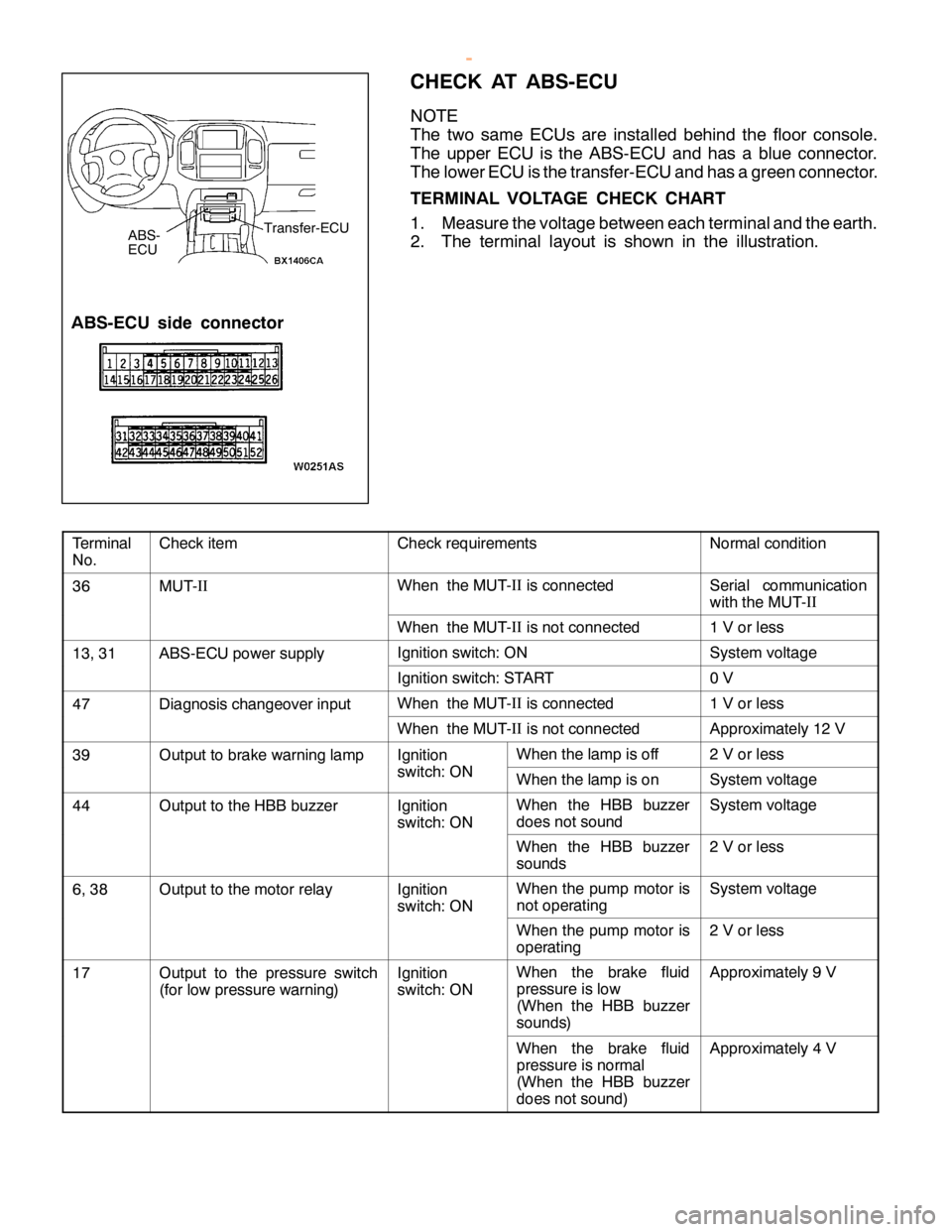

Page 1225 of 1839

C

heck it e m C

heck re quir e m ents N

orm alco ndit io n 3

6 M

UT-I

I S

eria l co m munic a tio n

w it h th e MUT-I

I 1

V or le ss 1

3,3 1 A

BS-E C U pow er su pply I

g nit io n sw it c h : O N S

yste m vo lt a ge I

g nit io n sw it c h : S TA R T 0

V 4

7 D

ia gnosis ch angeove r in put W

hen th e MUT-I

I

is co nnecte d 1

V or le ss W

hen th e MUT-I

I

is not co nnecte d A

ppro xim ate ly 12 V 3

9 O

utp ut to bra ke warn in g la m p I

g nit io n W

hen th e la m p is off 2

V or le ss s

w it c h :O N W

hen th e la m p is on S

yste m vo lt a ge 4

4 O

utp ut to th e HBB buzze r I

g nit io n

s w it c h :O N W

hen th e HBB buzze r

d oes notso und S

yste m vo lt a ge W

hen th e HBB buzze r

s o unds 2

V or le ss 6

, 38 O

utp ut to th e moto r re la y I

g nit io n

s w it c h :O N W

hen th e pum p moto r is

n otopera tin g S

yste m vo lt a ge W

hen th e pum p moto r is

o pera tin g 2

V or le ss 1

7 O

utp ut to th e pre ssu re sw it c h

( fo r lo w pre ssu re warn in g) I

g nit io n

s w it c h :O N W

hen th e bra ke flu id

p re ssu re is lo w

( W hen th e HBB buzze r

s o unds) A

ppro xim ate ly 9 V W

hen th e bra ke flu id

p re ssu re is norm al

( W hen th e HBB buzze r

d oes notso und) A

ppro xim ate ly 4 V

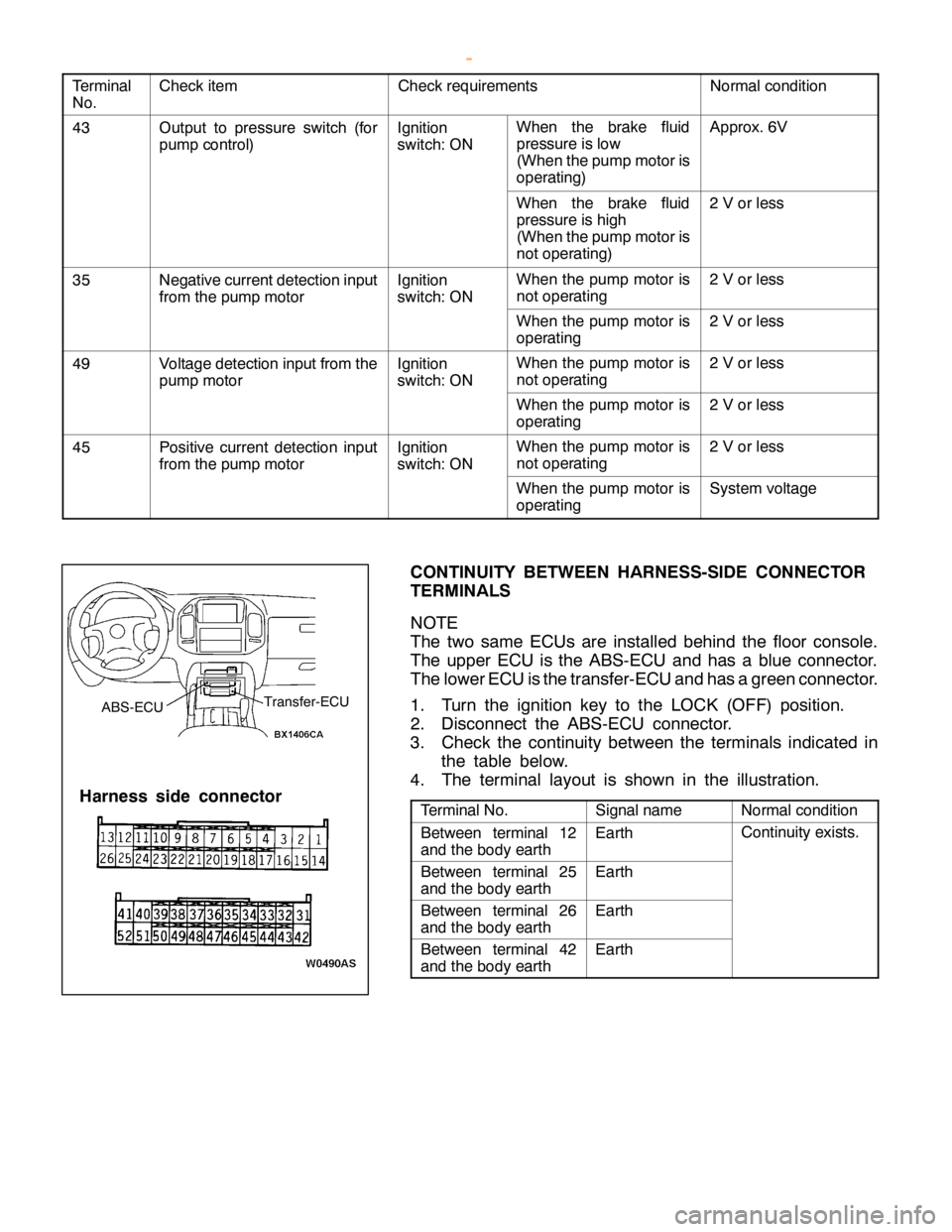

Page 1226 of 1839

4

3 O

utp ut to pre ssu re sw it c h (fo r

p um p co ntr o l) I

g nit io n

s w it c h :O N W

hen th e bra ke flu id

p re ssu re is lo w

( W hen th e pum pm oto r is

o pera tin g) A

ppro x. 6 V W

hen th e bra ke flu id

p re ssu re is hig h

( W hen th e pum pm oto r is

n ot opera tin g) 2

V or le ss 3

5 N

egativ e cu rre ntd ete ctio n in put

f r o m th e pum p moto r I

g nit io n

s w it c h :O N W

hen th e pum p moto r is

n otopera tin g 2

V or le ss W

hen th e pum p moto r is

o pera tin g 2

V or le ss 4

9 V

olt a ge dete ctio n in putfr o m th e

p um p moto r I

g nit io n

s w it c h :O N W

hen th e pum p moto r is

n otopera tin g 2

V or le ss W

hen th e pum p moto r is

o pera tin g 2

V or le ss 4

5 P

osit iv e cu rre nt dete ctio n in put

f r o m th e pum p moto r I

g nit io n

s w it c h :O N W

hen th e pum p moto r is

n otopera tin g 2

V or le ss W

hen th e pum p moto r is

o pera tin g S

yste m vo lt a ge S

ig naln am e N

orm alco ndit io n B

etw een te rm in al 12

a nd th e body earth E

arth C

ontin uit y exis ts . B

etw een te rm in al 25

a nd th e body earth E

arth B

etw een te rm in al 26

a nd th e body earth E

arth B

etw een te rm in al 42

a nd th e body earth E

arth

Page 1227 of 1839

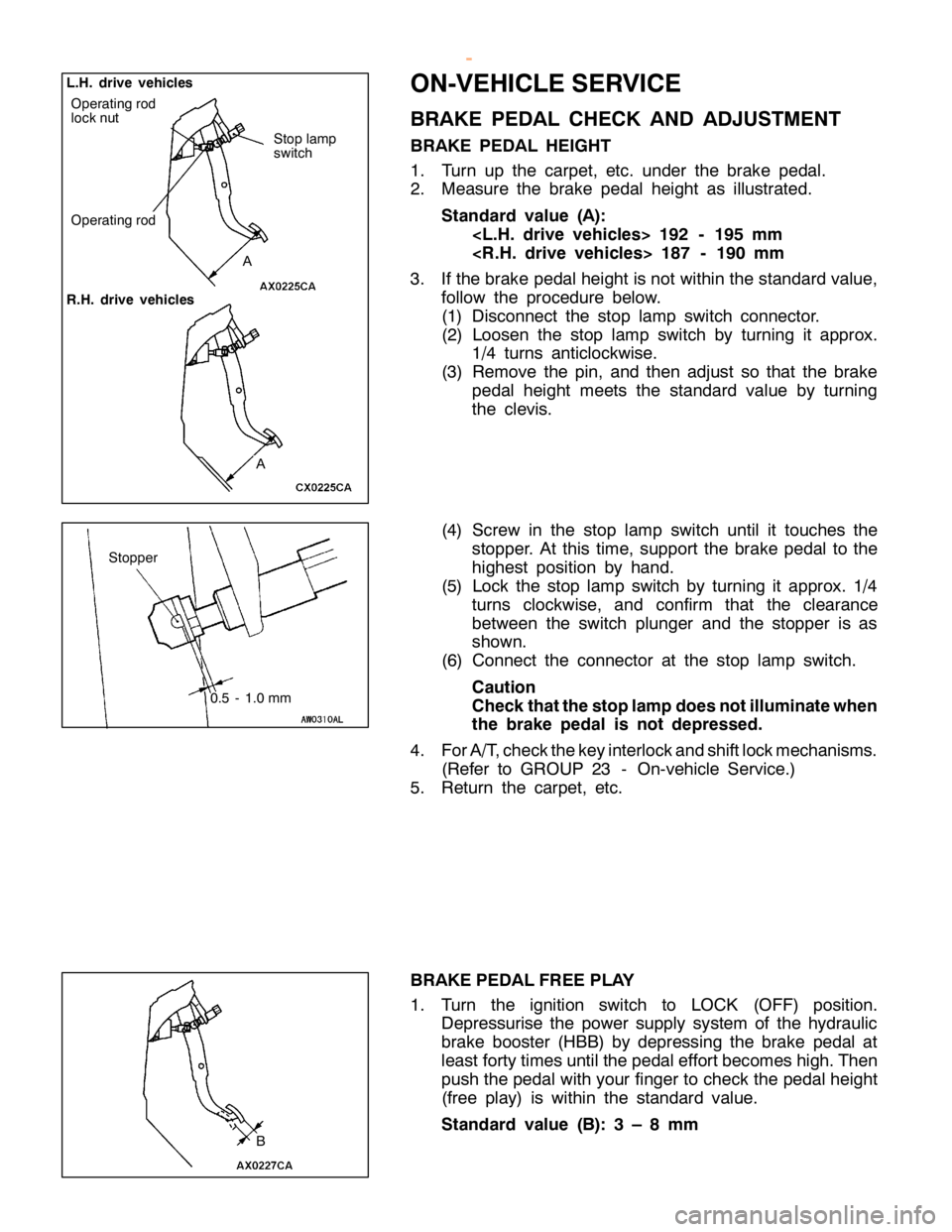

O

N-V EH IC LE SER VIC E

B RAKE PED AL CHEC K AND ADJU STM EN T

B RAKE PED AL HEIG HT

1 . Turn up th e ca rp et, etc . under th e bra ke pedal.

2 . Measu re th e bra ke pedal heig ht as illu str a te d.

S ta n dard valu e (A ):

< L .H . driv e veh ic le s> 192 -195 mm

< R .H . driv e veh ic le s> 187 -190 mm

3 . If th e bra ke pedalh eig ht is not w it h in th e sta ndard va lu e,

f o llo w th e pro ce dure belo w .

( 1 ) Dis co nnect th e sto p la m p sw it c h co nnecto r.

( 2 ) Loose n th e sto p la m p sw it c h by tu rn in g it appro x.

1 /4 tu rn s antic lo ckw is e .

( 3 ) Rem ove th e pin , and th en adju st so th at th e bra ke

p edal heig ht m eets th e sta ndard va lu e by tu rn in g

t h e cle vis .

( 4 ) Scre w in th e sto p la m p sw it c h until it to uch es th e

s to pper. A tth is tim e, su pport th e bra ke pedal to th e

h ig hest posit io n by hand.

( 5 ) Lock th e sto p la m p sw it c h by tu rn in g it appro x. 1/4

t u rn s clo ckw is e , and co nfir m th at th e cle ara nce

b etw een th e sw it c h plu nger and th e sto pper is as

s h ow n.

( 6 ) Connect th e co nnecto r at th e sto p la m p sw it c h .

C au tio n

C heck th atth e sto p la m pdoes notillu m in ate w hen

t h e bra ke ped al is not dep re ssed .

4 . ForA /T ,c h eck th e ke y in te rlo ck and sh if t lo ck m ech anis m s.

( R efe r to GRO UP 23 -On-v e hic le Serv ic e .)

5 . Retu rn th e ca rp et, etc .

B RAKE PED AL FR EE PLA Y

1 . Turn th e ig nit io n sw it c h to LO CK (O FF) posit io n.

D epre ssu ris e th e pow er su pply syste m of th e hyd ra ulic

b ra ke booste r (H BB) by depre ssin g th e bra ke pedal at

l e ast fo rty tim es until th e pedale ff o rt b eco m es hig h.T hen

p ush th e pedalw it h yo ur fin ger to ch eck th e pedalh eig ht

( fr e e pla y) is wit h in th e sta ndard va lu e.

S ta n dard valu e (B ): 3 –8mm A

L

.H .driv e veh ic le s

R .H .driv e veh ic le s O

pera tin g ro d S

to p la m p

s w it c h S

to pper

0.5 -1.0 mm B

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1228 of 1839

Page 1229 of 1839

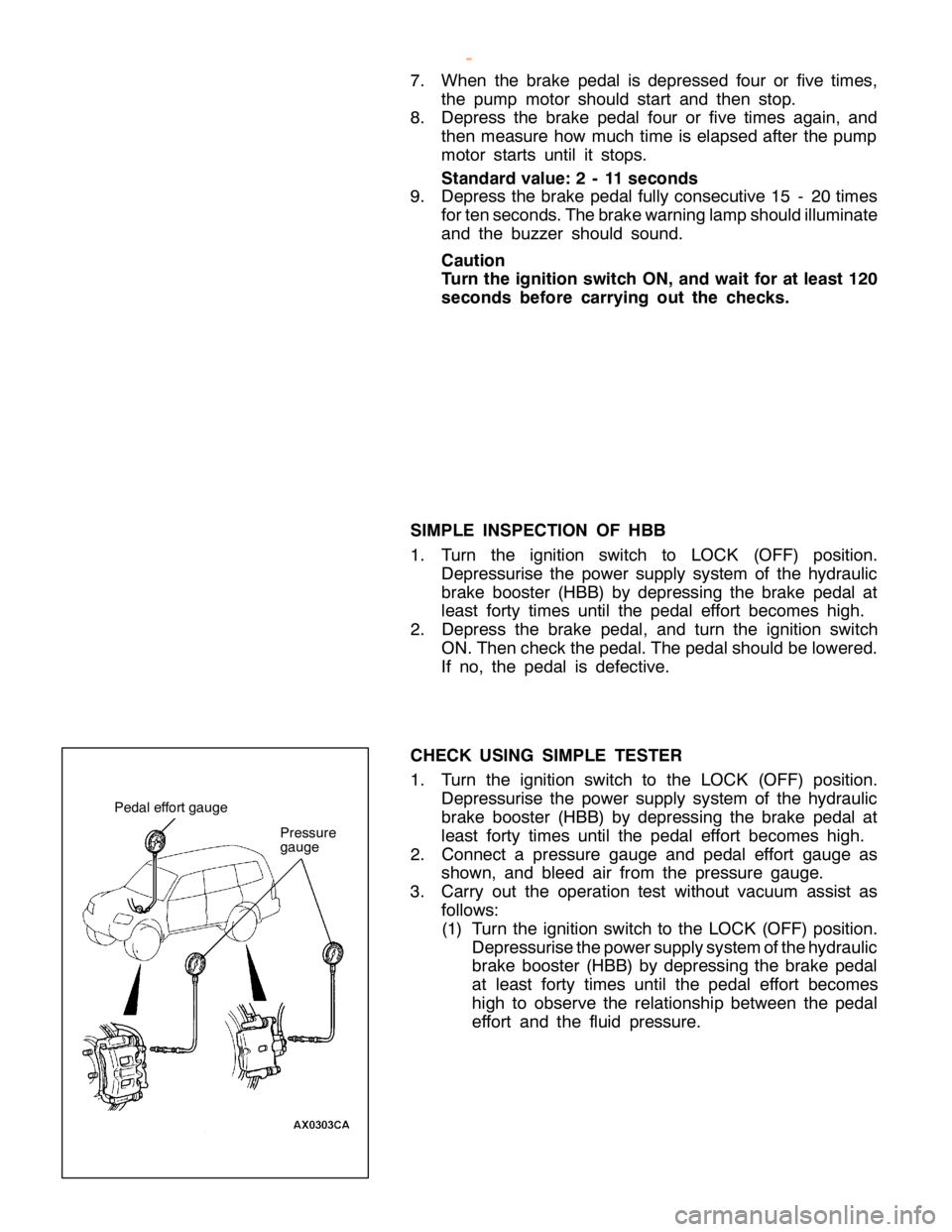

P

re ssu re

g auge

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1230 of 1839

F

lu id pre ssu re at

f r o nt w heels M Pa F

lu id pre ssu re at

r e ar w heels M Pa 1

00 0

.6 or m ore 0

5

00 4

.5 or m ore 0

F

lu id pre ssu re at

f r o nt w heels M Pa F

lu id pre ssu re at

r e ar w heels M Pa 1

00 3

.0 -4.0 3

.3 -4.3 2

00 8

.0 -10.0 8

.0 -10.0 4

00 1

4.0 -18.0 1

4.0 -18.0 5

00 1

5.0 -19.0 1

5.0 -19.0