ESP MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 260 of 1839

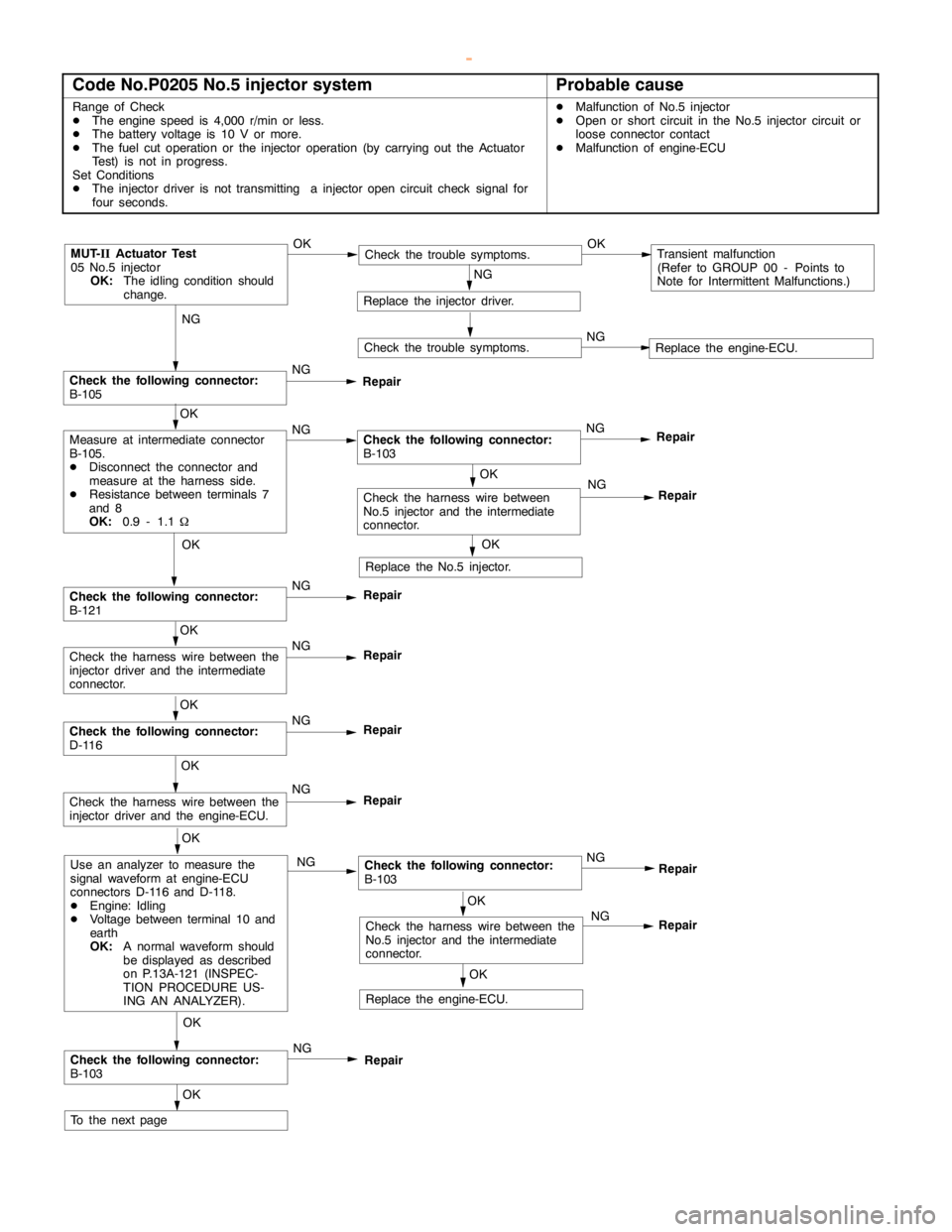

GDI -Troubleshooting

Code No.P0205 No.5 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.5 injector

DOpen or short circuit in the No.5 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

05 No.5 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 7

and 8

OK:

0.9 - 1.1WNGCheck the following connector:

B-103NG

Repair

OK

Replace the No.5 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 10 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-103

OK

Check the following connector:

B-103NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.5 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.5 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 262 of 1839

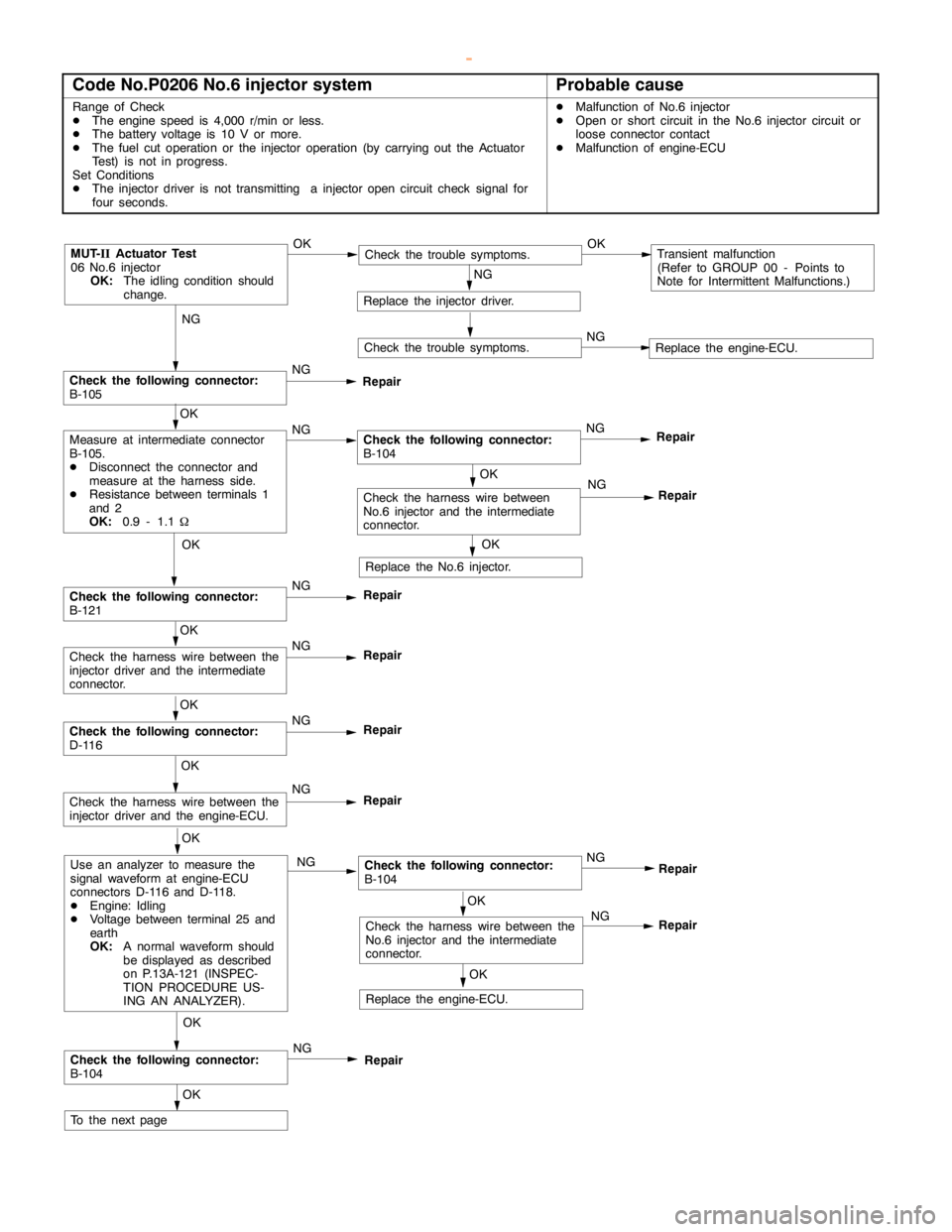

GDI -Troubleshooting

Code No.P0206 No.6 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.6 injector

DOpen or short circuit in the No.6 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

06 No.6 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 1

and 2

OK:

0.9 - 1.1WNGCheck the following connector:

B-104NG

Repair

OK

Replace the No.6 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 25 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-104

OK

Check the following connector:

B-104NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.6 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.6 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 268 of 1839

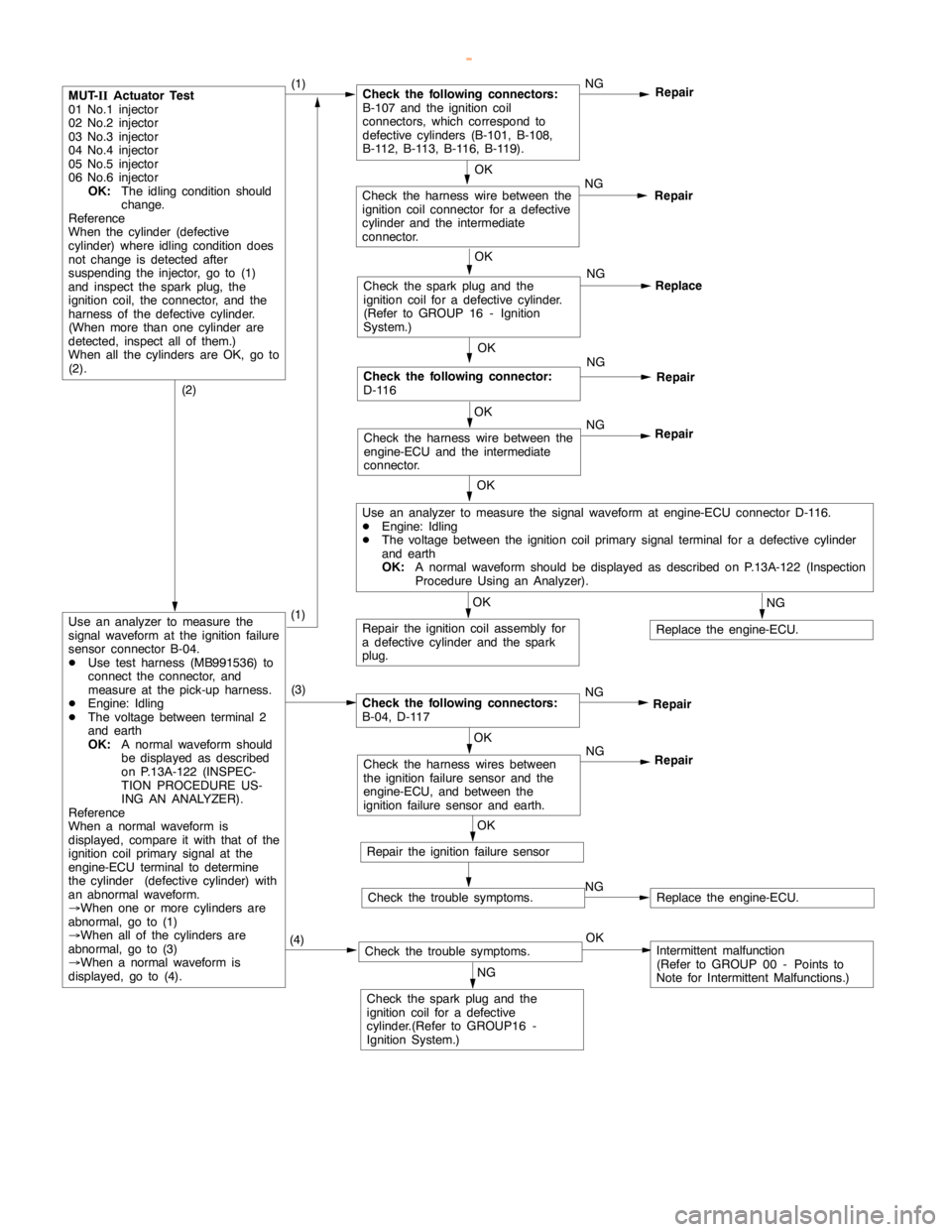

GDI -Troubleshooting

OK

Check the harness wire between the

engine-ECU and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

ignition coil connector for a defective

cylinder and the intermediate

connector.NG

Repair

MUT-

IIActuator Test

01 No.1 injector

02 No.2 injector

03 No.3 injector

04 No.4 injector

05 No.5 injector

06 No.6 injector

OK:

The idling condition should

change.

Reference

When the cylinder (defective

cylinder) whereidling conditiondoes

not change is detected after

suspending the injector, go to (1)

and inspect the spark plug, the

ignition coil, the connector, and the

harness of the defective cylinder.

(When more than one cylinder are

detected, inspect all of them.)

When all the cylinders are OK, go to

(2).(1)Check the following connectors:

B-107 and the ignition coil

connectors, which correspond to

defective cylinders (B-101, B-108,

B-112, B-113, B-116, B-119).NG

Repair

OK

Check the sparkplug and the

ignition coil for a defective cylinder.

(Refer to GROUP 16 - Ignition

System.)NG

Replace

OK

Use an analyzer to measure the signal waveform at engine-ECU connector D-116.

DEngine: Idling

DThe voltage between the ignition coil primary signal terminal for a defective cylinder

and earth

OK:

A normal waveform should be displayed as described on P.13A-122 (Inspection

Procedure Using an Analyzer).

OK

Repair the ignition coil assembly for

a defective cylinder and the spark

plug.

NG

Replace the engine-ECU.

(2)

Use an analyzer to measure the

signal waveform at the ignition failure

sensor connector B-04.

DUse test harness (MB991536) to

connect the connector, and

measure at the pick-up harness.

DEngine: Idling

DThe voltage between terminal 2

and earth

OK:

A normal waveform should

be displayed as described

on P.13A-122 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).

Reference

When a normal waveform is

displayed, compare it with that of the

ignition coil primary signal at the

engine-ECU terminal to determine

the cylinder (defective cylinder) with

an abnormal waveform.

®When one or more cylinders are

abnormal, go to (1)

®When all of the cylinders are

abnormal, go to (3)

®When a normal waveform is

displayed, go to (4).(3)

Check the following connectors:

B-04, D-117NG

Repair

OK

Check the harness wires between

the ignition failure sensor and the

engine-ECU, and between the

ignition failure sensor and earth.NG

Repair

OK

Repair the ignition failure sensor

Check the trouble symptoms.NGReplace the engine-ECU.

(4)Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Check the sparkplug and the

ignition coil for a defective

cylinder.(Refer to GROUP16 -

Ignition System.)

(1)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

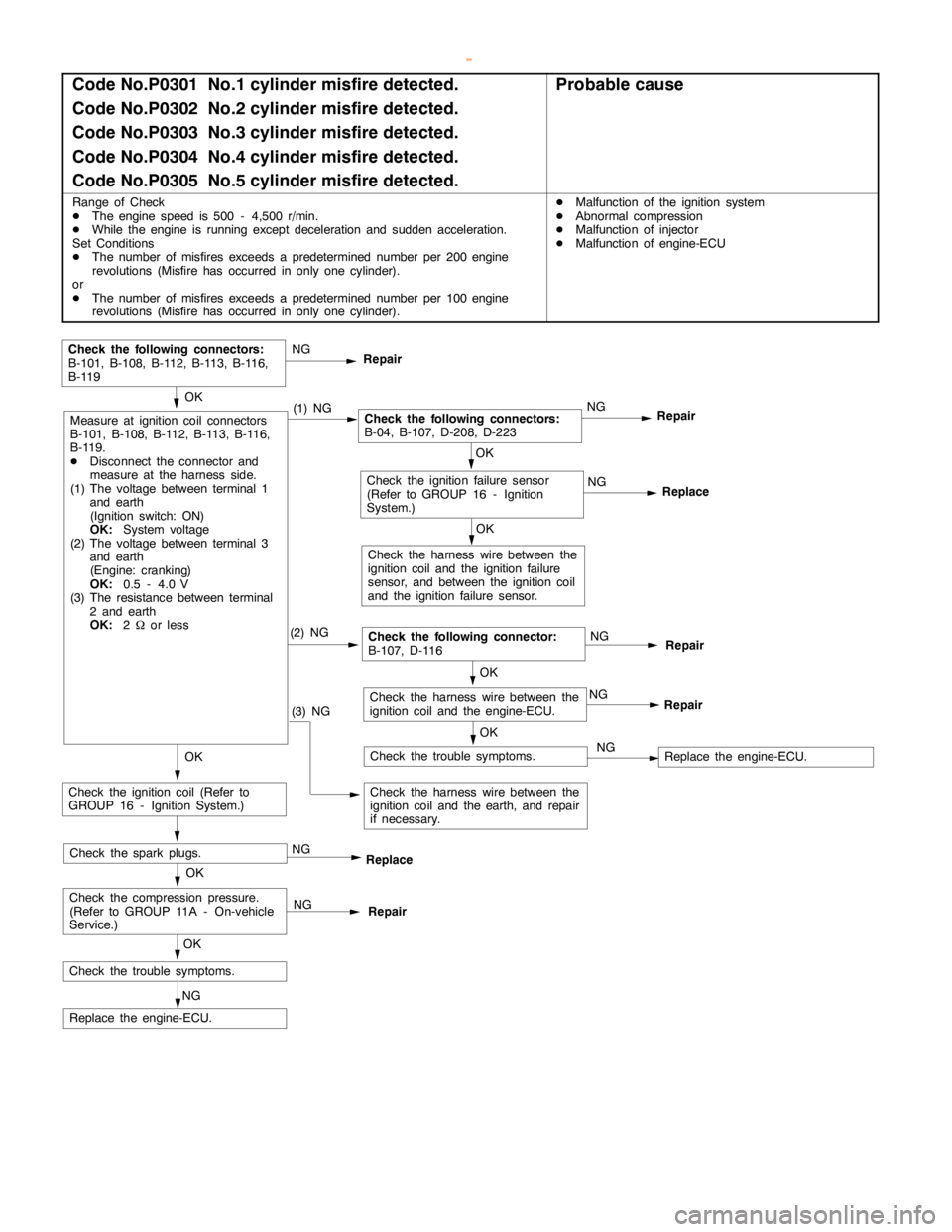

Page 269 of 1839

GDI -Troubleshooting

Code No.P0301 No.1 cylinder misfire detected.

Code No.P0302 No.2 cylinder misfire detected.

Code No.P0303 No.3 cylinder misfire detected.

Code No.P0304 No.4 cylinder misfire detected.

Code No.P0305 No.5 cylinder misfire detected.Probable cause

Range of Check

DThe enginespeed is 500 - 4,500 r/min.

DWhile the engine is runningexcept deceleration and sudden acceleration.

Set Conditions

DThe number of misfires exceeds a predetermined number per 200engine

revolutions (Misfire has occurred in only one cylinder).

or

DThe number of misfires exceeds a predetermined number per 100engine

revolutions (Misfire has occurred in only one cylinder).DMalfunction of the ignition system

DAbnormal compression

DMalfunction of injector

DMalfunction of engine-ECU

NG

Check the harness wire between the

ignition coil and the engine-ECU.

NG

Replace

NG

Repair

(2) NG

OK

Check the ignition failure sensor

(Refer to GROUP 16 - Ignition

System.)

OK

Check the harness wire between the

ignition coil and the earth, and repair

if necessary. (3) NG

OK

Measure at ignition coil connectors

B-101, B-108, B-112, B-113, B-116,

B-119.

DDisconnect the connector and

measure at the harness side.

(1) The voltage between terminal 1

and earth

(Ignition switch: ON)

OK:

System voltage

(2) The voltage between terminal 3

and earth

(Engine: cranking)

OK:

0.5 - 4.0 V

(3) The resistance between terminal

2 and earth

OK:

2Wor less(1) NGCheck the following connectors:

B-04, B-107, D-208, D-223NG

Repair

Check the ignition coil (Refer to

GROUP 16 - Ignition System.)

Check the compression pressure.

(Refer to GROUP 11A - On-vehicle

Service.)Repair

Replace the engine-ECU.

OK

Check the harness wire between the

ignition coil and the ignition failure

sensor, and between the ignition coil

and the ignition failure sensor.

NG

Repair

OK

NGNG

Repair

OKReplace

NG

Check the spark plugs.

Check the trouble symptoms.

OK

Check the trouble symptoms.NGReplace the engine-ECU.

Check the following connectors:

B-101, B-108, B-112, B-113, B-116,

B-119

Check the following connector:

B-107, D-116

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 275 of 1839

GDI -Troubleshooting

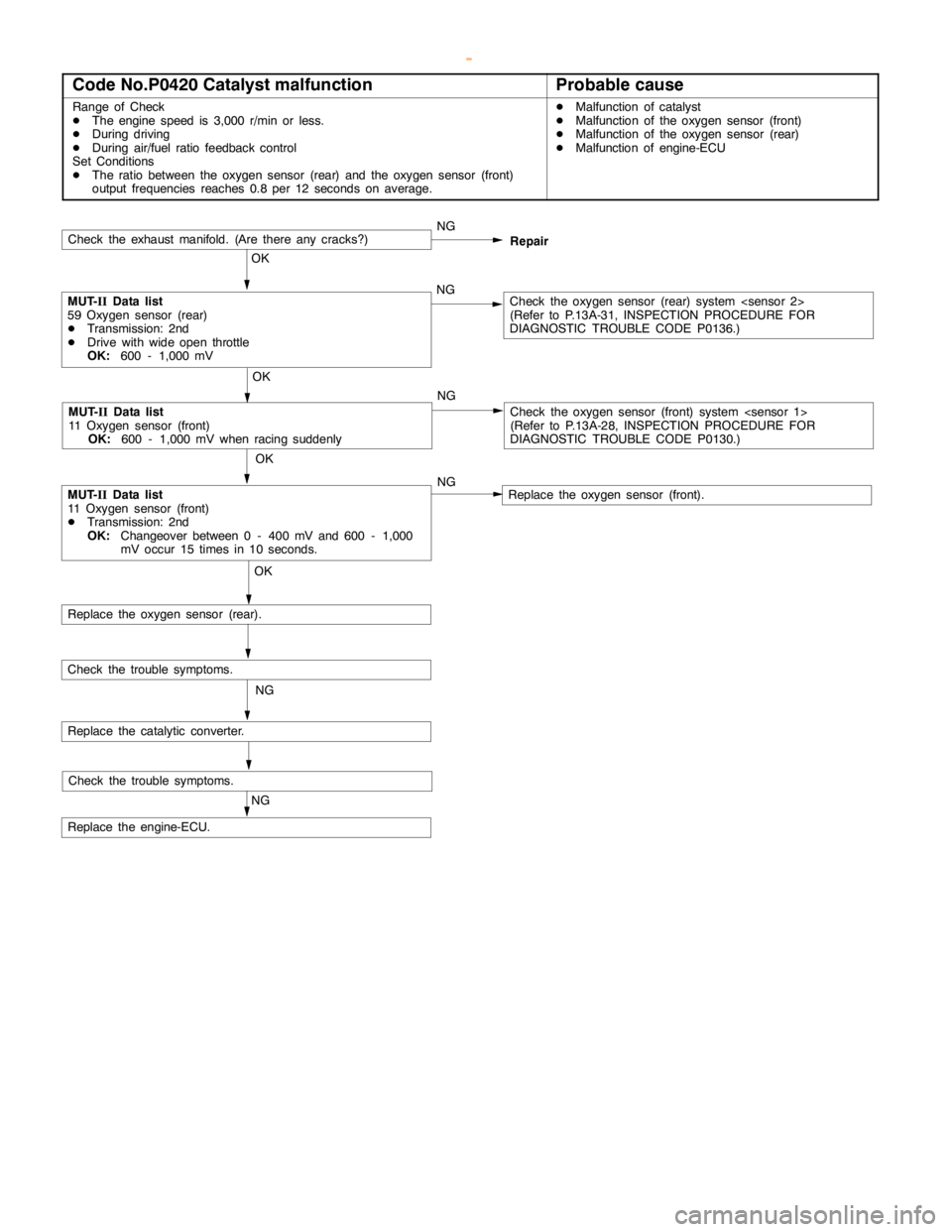

Code No.P0420 Catalyst malfunctionProbable cause

Range of Check

DThe enginespeed is 3,000 r/min or less.

DDuring driving

DDuring air/fuel ratio feedback control

Set Conditions

DThe ratio between the oxygen sensor (rear) and the oxygen sensor (front)

output frequencies reaches 0.8 per 12 seconds on average.DMalfunction of catalyst

DMalfunction of the oxygen sensor (front)

DMalfunction of the oxygen sensor (rear)

DMalfunction of engine-ECU

Check the trouble symptoms.

Check the exhaust manifold. (Are there anycracks?)NG

OK

MUT-

IIData list

59 Oxygen sensor (rear)

DTransmission: 2nd

DDrive with wideopen throttle

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system

(Refer to P.13A-31, INSPECTIONPROCEDURE FOR

DIAGNOSTIC TROUBLE CODE P0136.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

DTransmission: 2nd

OK:

Changeover between 0 - 400 mV and 600 - 1,000

mV occur 15 times in 10 seconds.

OK

Replace the oxygen sensor (rear).

NG

Replace the catalytic converter.

Check the trouble symptoms.

NG

Replace the engine-ECU.

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when racing suddenly

OK

NGRepair

Check the oxygen sensor (front) system

(Refer to P.13A-28, INSPECTIONPROCEDURE FOR

DIAGNOSTIC TROUBLE CODE P0130.)

Replace the oxygen sensor (front). NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 295 of 1839

GDI -Troubleshooting

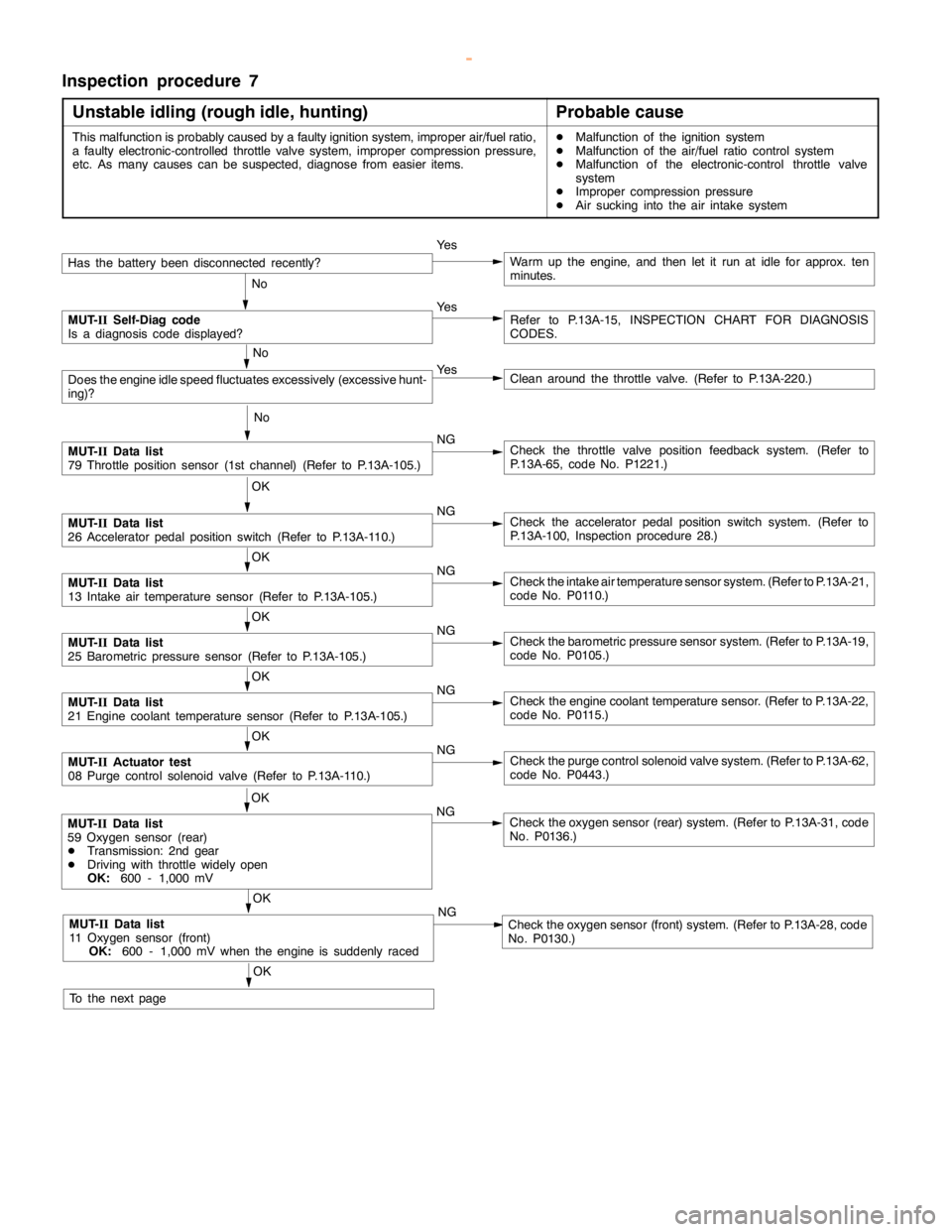

Inspection procedure 7

Unstable idling (rough idle, hunting)

Probable cause

This malfunction is probably caused by a faulty ignition system, improper air/fuel ratio,

a faulty electronic-controlled throttle valve system, improper compression pressure,

etc. As many causes can be suspected, diagnose from easier items.DMalfunction of the ignition system

DMalfunction of the air/fuel ratio control system

DMalfunction of the electronic-control throttle valve

system

DImproper compression pressure

DAir sucking into the air intake system

Has the batterybeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

Does theengine idlespeed fluctuates excessively (excessivehunt-

ing)?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-110.)NGCheck the acceleratorpedal positionswitch system. (Refer to

P.13A-100, Inspection procedure 28.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor system. (Refer to P.13A-21,

code No. P0110.)

OK

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor system. (Refer to P.13A-19,

code No. P0105.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIActuator test

08 Purge control solenoid valve (Refer to P.13A-110.)NGCheck the purge control solenoid valve system. (Refer to P.13A-62,

code No. P0443.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyracedNGCheck the oxygen sensor (front) system. (Refer to P.13A-28, code

No. P0130.)

OK

MUT-

IIData list

59 Oxygen sensor (rear)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

OK

To the nextpage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 310 of 1839

GDI -Troubleshooting

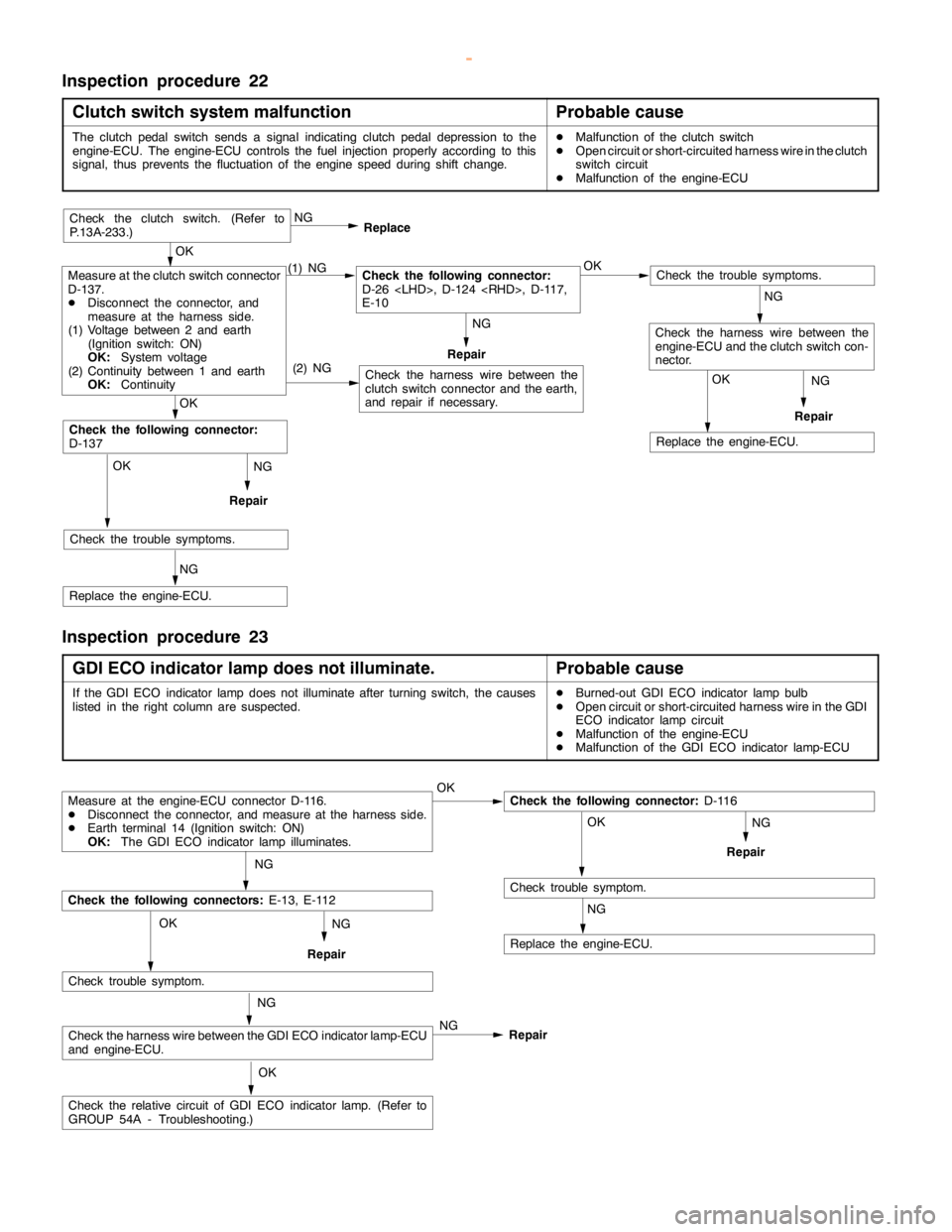

Inspection procedure 22

Clutch switch system malfunction

Probable cause

The clutchpedalswitch sends a signal indicating clutchpedal depression to the

engine-ECU. The engine-ECU controls the fuel injection properly according to this

signal, thus prevents the fluctuation of theenginespeed during shift change.DMalfunction of the clutch switch

DOpen circuit or short-circuited harness wire in the clutch

switch circuit

DMalfunction of the engine-ECU

NG

Repair

NG

Repair

OK

Replace the engine-ECU.

(2) NG

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

OK

Check the following connector:

D-137

Check the harness wire between the

clutch switch connector and the earth,

and repair if necessary.

Check the trouble symptoms.

Check the harness wire between the

engine-ECU and the clutch switch con-

nector.

Measure at the clutch switch connector

D-137.

DDisconnect the connector, and

measure at the harness side.

(1) Voltage between 2 and earth

(Ignition switch: ON)

OK:

System voltage

(2) Continuity between 1 and earth

OK:

Continuity(1) NGCheck the following connector:

D-26

E-10OK NG

Replace

Repair

OK

Check the clutch switch. (Refer to

P.13A-233.)

NG

NG

Inspection procedure 23

GDI ECO indicator lamp does not illuminate.

Probable cause

If the GDI ECO indicator lampdoes notilluminate after turningswitch, the causes

listed in the right column are suspected.DBurned-out GDI ECO indicator lamp bulb

DOpen circuit or short-circuited harness wire in the GDI

ECO indicator lampcircuit

DMalfunction of the engine-ECU

DMalfunction of the GDI ECO indicator lamp-ECU

NG

Repair

Measure at the engine-ECU connector D-116.

DDisconnect the connector, and measure at the harness side.

DEarth terminal 14 (Ignition switch: ON)

OK:

The GDI ECO indicator lamp illuminates.OKCheck the following connector:

D-116

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Check the following connectors:

E-13, E-112

Check trouble symptom.

Check the harness wire between the GDI ECO indicator lamp-ECU

and engine-ECU.

Check the relative circuit of GDI ECO indicatorlamp.(Refer to

GROUP 54A - Troubleshooting.)NG OK

OK NG

NG

Repair

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 316 of 1839

GDI -Troubleshooting

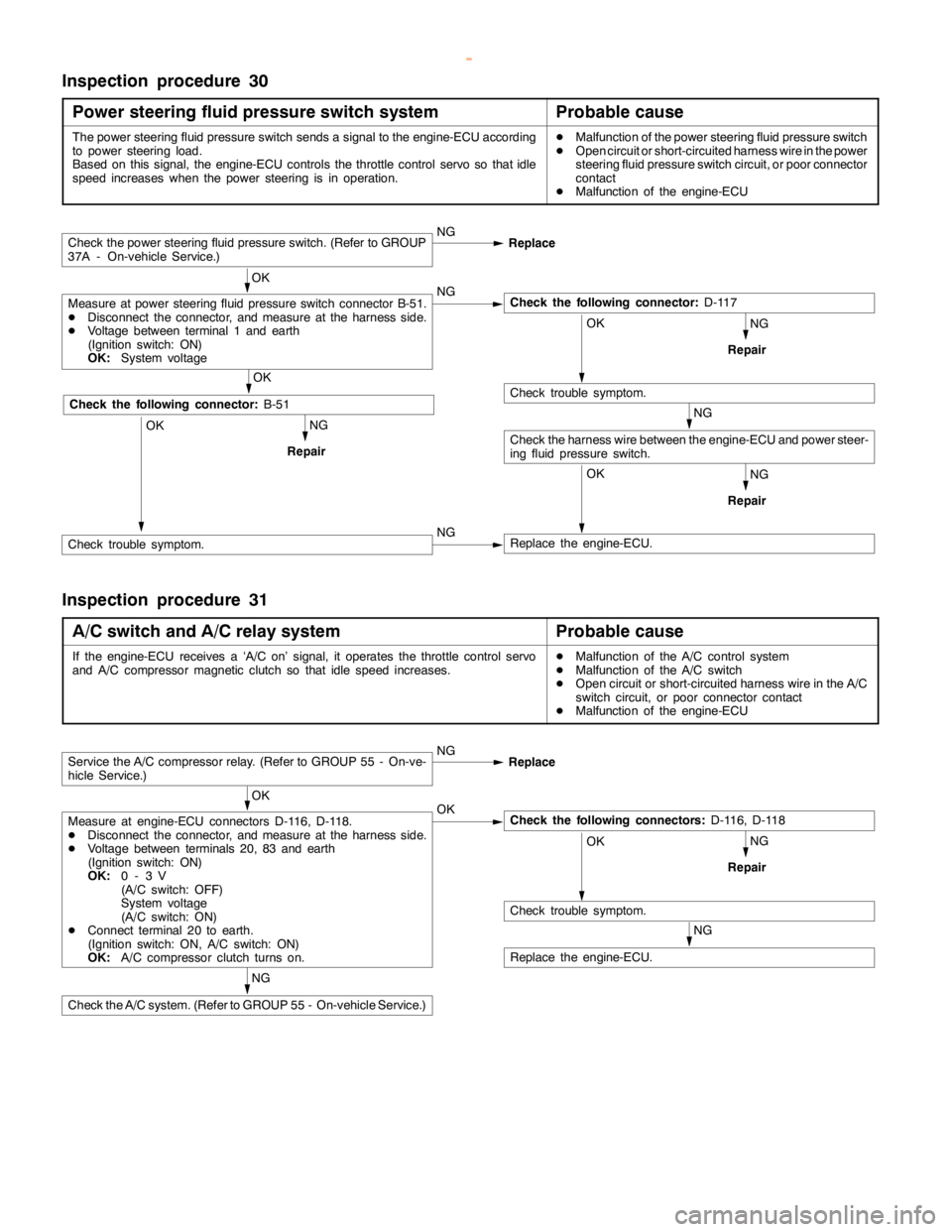

Inspection procedure 30

Power steering fluid pressure switch system

Probable cause

The power steering fluid pressure switch sends a signal to the engine-ECU according

to power steering load.

Based on this signal, the engine-ECU controls the throttle control servo so thatidle

speed increases when the power steering is in operation.DMalfunction of the power steering fluid pressure switch

DOpen circuit or short-circuited harness wire in the power

steering fluid pressure switch circuit, or poor connector

contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Replace the engine-ECU.

NG

Repair

Check the power steering fluid pressure switch. (Refer to GROUP

37A - On-vehicle Service.)NG

Replace

OK

Measure at power steering fluid pressure switch connector B-51.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 1 and earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

D-117

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and power steer-

ing fluid pressure switch.NG

RepairOK

OK

Check the following connector:

B-51

Check trouble symptom.NG

Inspection procedure 31

A/C switch and A/C relay system

Probable cause

If the engine-ECU receives a ‘A/C on’ signal, it operates the throttle control servo

and A/C compressor magnetic clutch so thatidlespeed increases.DMalfunction of the A/C control system

DMalfunction of the A/C switch

DOpen circuit or short-circuited harness wire in the A/C

switch circuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Check trouble symptom.

NG

Replace the engine-ECU.

Service the A/C compressor relay. (Refer to GROUP 55 - On-ve-

hicle Service.)NG

Replace

OK

Measure at engine-ECU connectors D-116, D-118.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminals 20, 83 and earth

(Ignition switch: ON)

OK:

0-3V

(A/C switch: OFF)

System voltage

(A/C switch: ON)

DConnect terminal 20 to earth.

(Ignition switch: ON, A/C switch: ON)

OK:

A/C compressor clutch turns on.OKCheck the following connectors:

D-116, D-118

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 320 of 1839

GDI -Troubleshooting

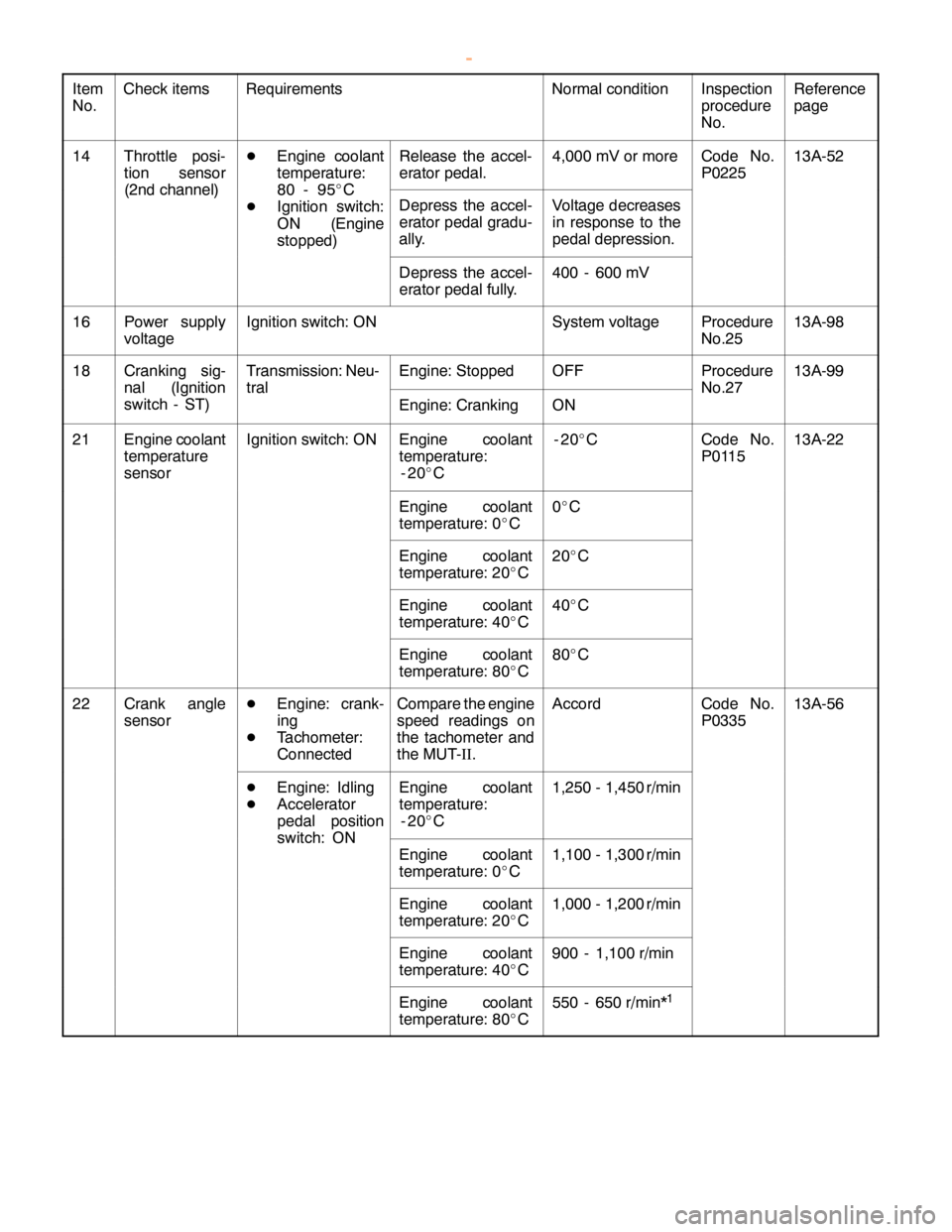

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

14Throttle posi-

tion sensorDEngine coolant

temperature:Release the accel-

erator pedal.4,000 mV or moreCode No.

P022513A-52

(2nd channel)80 - 95_C

DIgnition switch:

ON (Engine

stopped)

Depress the accel-

erator pedal gradu-

ally.Voltage decreases

in response to the

pedal depression.

Depress the accel-

erator pedal fully.400 - 600 mV

16Power supply

voltageIgnition switch: ONSystem voltageProcedure

No.2513A-98

18Cranking sig-Transmission: Neu-Engine: StoppedOFFProcedure13A-99

nal (Ignition

switch - ST)tral

Engine: CrankingON

No.27

21Engine coolant

temperature

sensorIgnition switch: ONEngine coolant

temperature:

-20_C-20_CCode No.

P011513A-22

Engine coolant

temperature: 0_C0_C

Engine coolant

temperature: 20_C20_C

Engine coolant

temperature: 40_C40_C

Engine coolant

temperature: 80_C80_C

22Crank angle

sensorDEngine: crank-

ing

DTachometer:

ConnectedCompare the engine

speed readings on

the tachometer and

the MUT-II.AccordCode No.

P033513A-56

DEngine: Idling

DAccelerator

pedal positionEngine coolant

temperature:

-20_C1,250 - 1,450 r/min

switch: ON

Engine coolant

temperature: 0_C1,100 - 1,300 r/min

Engine coolant

temperature: 20_C1,000 - 1,200 r/min

Engine coolant

temperature: 40_C900 - 1,100 r/min

Engine coolant

temperature: 80_C550 - 650 r/min*1

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 321 of 1839

GDI -Troubleshooting

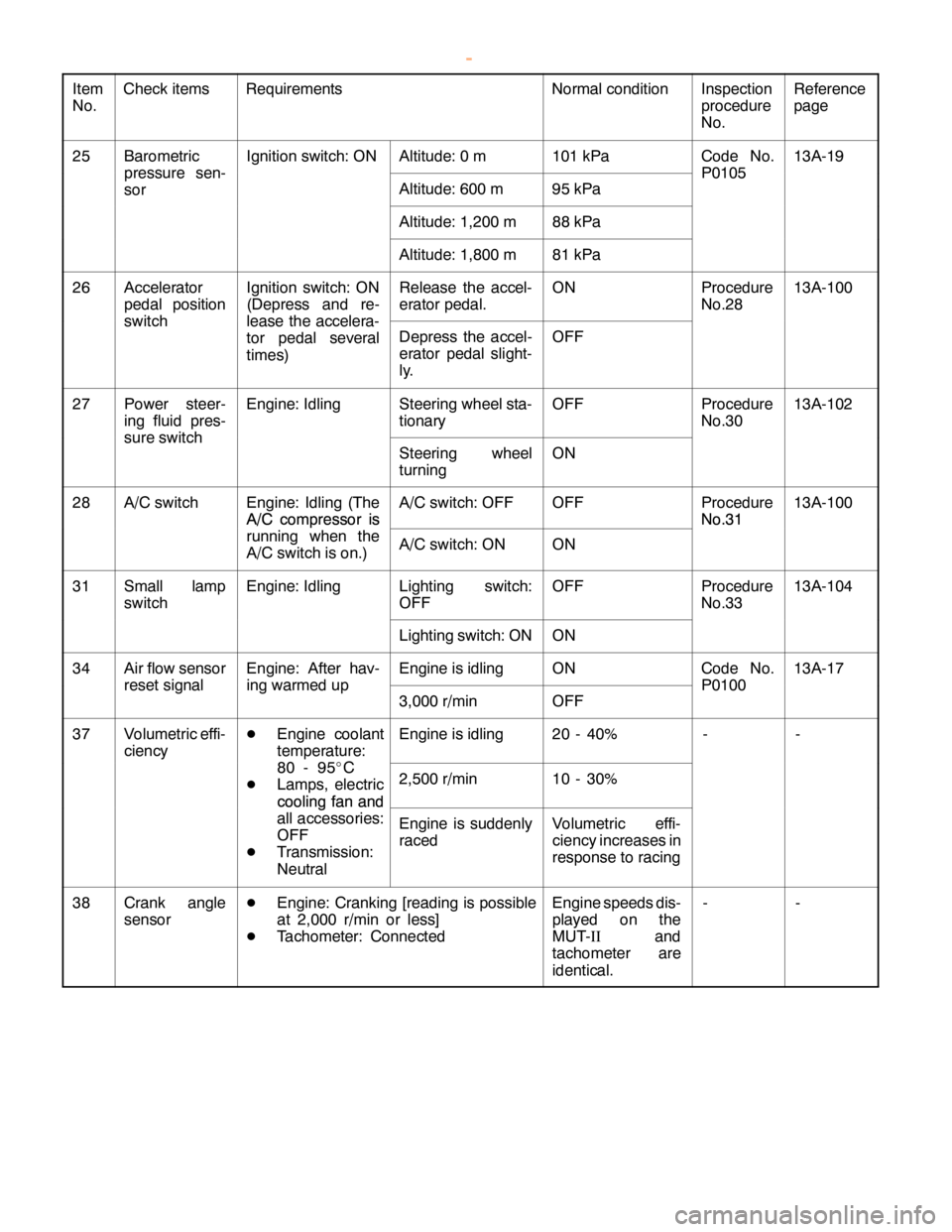

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

25BarometricIgnition switch: ONAltitude: 0 m101 kPaCode No.13A-19

pressure sen-

sor

Altitude: 600 m95 kPa

P0105

Altitude: 1,200 m88 kPa

Altitude: 1,800 m81 kPa

26Accelerator

pedal positionIgnition switch: ON

(Depress and re-Release the accel-

erator pedal.ONProcedure

No.2813A-100

switchlease the accelera-

tor pedal several

times)

Depress the accel-

erator pedal slight-

ly.OFF

27Power steer-

ing fluid pres-Engine: IdlingSteering wheel sta-

tionaryOFFProcedure

No.3013A-102

sure switch

Steering wheel

turningON

28A/C switchEngine: Idling (The

A/C compressor isA/C switch: OFFOFFProcedure

No.3113A-100

A/C compressor is

running when the

A/C switch is on.)

A/C switch: ONON

No.31

31Small lamp

switchEngine: IdlingLighting switch:

OFFOFFProcedure

No.3313A-104

Lighting switch: ONON

34Air flow sensorEngine: After hav-Engine is idlingONCode No.13A-17

reset signaling warmed up

3,000 r/minOFF

P0100

37Volumetric effi-

ciencyDEngine coolant

temperature:Engine is idling20 - 40%--

80 - 95_C

DLamps, electric

cooling fan and2,500 r/min10 - 30%

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

Engine is suddenly

racedVolumetric effi-

ciency increases in

response to racing

38Crank angle

sensorDEngine: Cranking [reading is possible

at 2,000 r/min or less]

DTachometer: ConnectedEngine speeds dis-

played on the

MUT-IIand

tachometer are

identical.--

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk