MOTOR MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 493 of 1839

DIESEL FUEL <4M4> -General Information13C-2

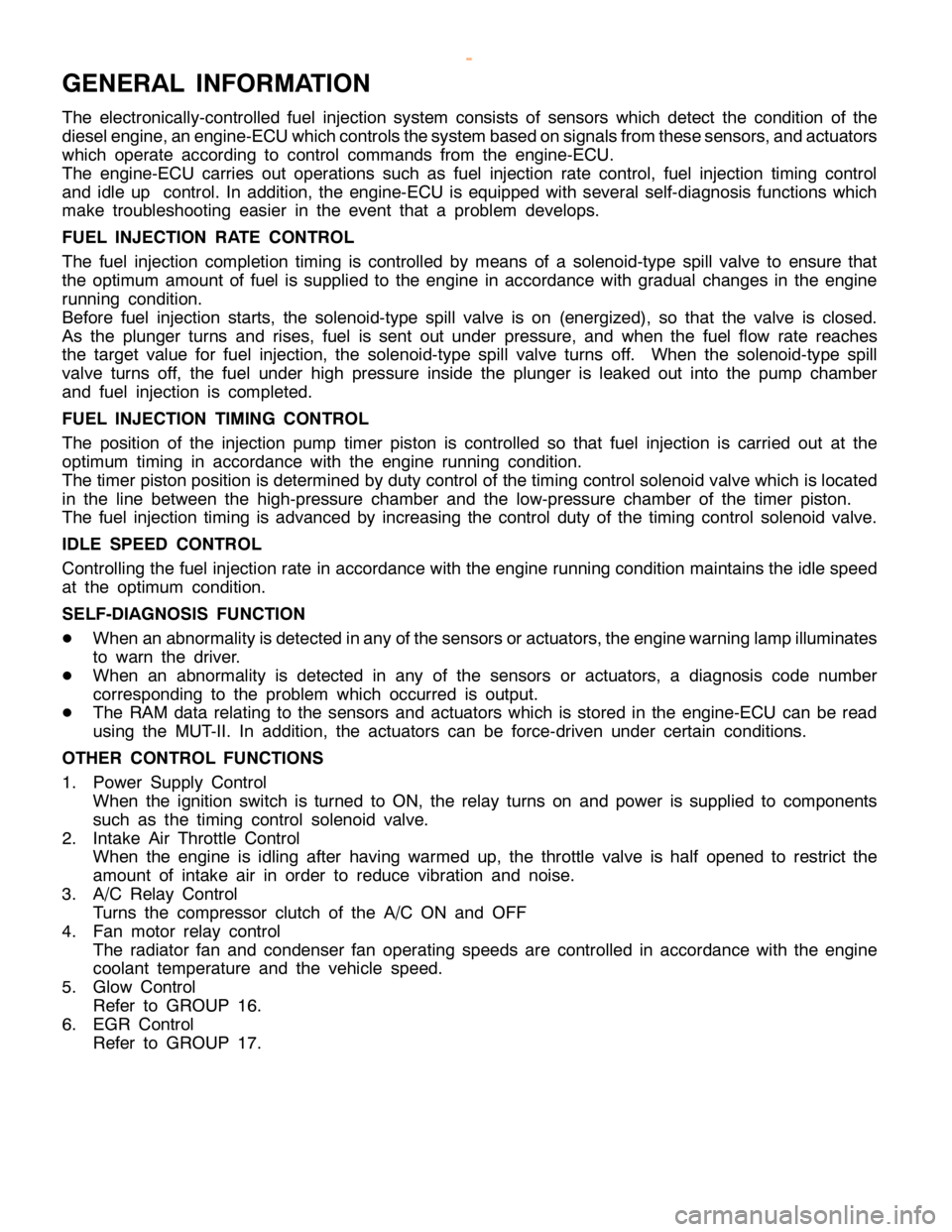

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine is idling after having warmed up, the throttle valve is half opened to restrict the

amount of intake air in order to reduce vibration and noise.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Fan motor relay control

The radiator fan and condenser fan operating speeds are controlled in accordance with the engine

coolant temperature and the vehicle speed.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 558 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-3

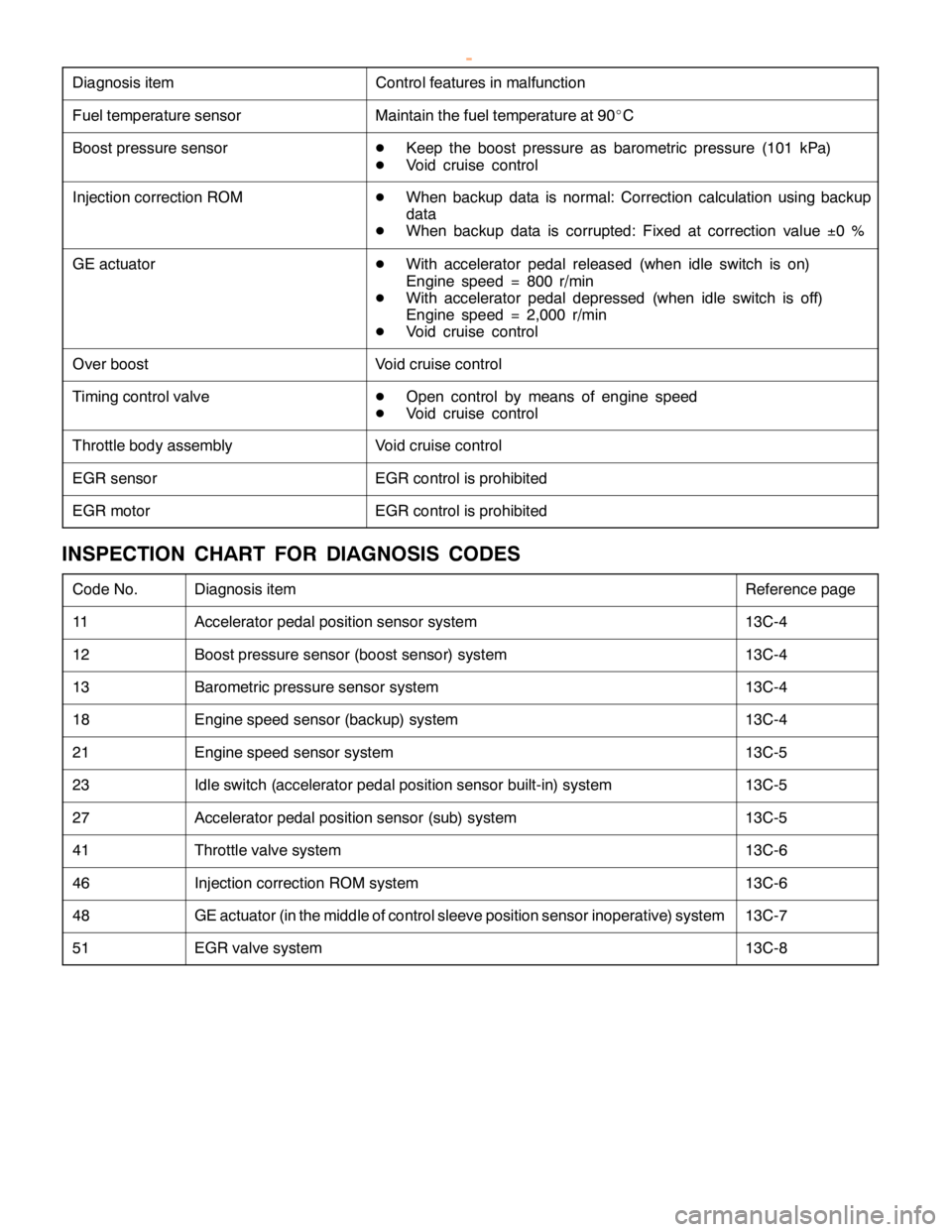

Diagnosis item Control features in malfunction

Fuel temperature sensorMaintain the fuel temperature at 90_C

Boost pressure sensorDKeep the boost pressure as barometric pressure (101 kPa)

DVoid cruise control

Injection correction ROMDWhen backup data is normal: Correction calculation using backup

data

DWhen backup data is corrupted: Fixed at correction value±0%

GE actuatorDWith accelerator pedal released (when idle switch is on)

Engine speed = 800 r/min

DWith accelerator pedal depressed (when idle switch is off)

Engine speed = 2,000 r/min

DVoid cruise control

Over boostVoid cruise control

Timing control valveDOpen control by means of engine speed

DVoid cruise control

Throttle body assemblyVoid cruise control

EGR sensorEGR control is prohibited

EGR motorEGR control is prohibited

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

11Accelerator pedal position sensor system13C-4

12Boost pressure sensor (boost sensor) system13C-4

13Barometric pressure sensor system13C-4

18Engine speed sensor (backup) system13C-4

21Engine speed sensor system13C-5

23Idle switch (accelerator pedal position sensor built-in) system13C-5

27Accelerator pedal position sensor (sub) system13C-5

41Throttle valve system13C-6

46Injection correction ROM system13C-6

48GE actuator (in the middle of control sleeve position sensor inoperative) system13C-7

51EGR valve system13C-8

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 566 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-11

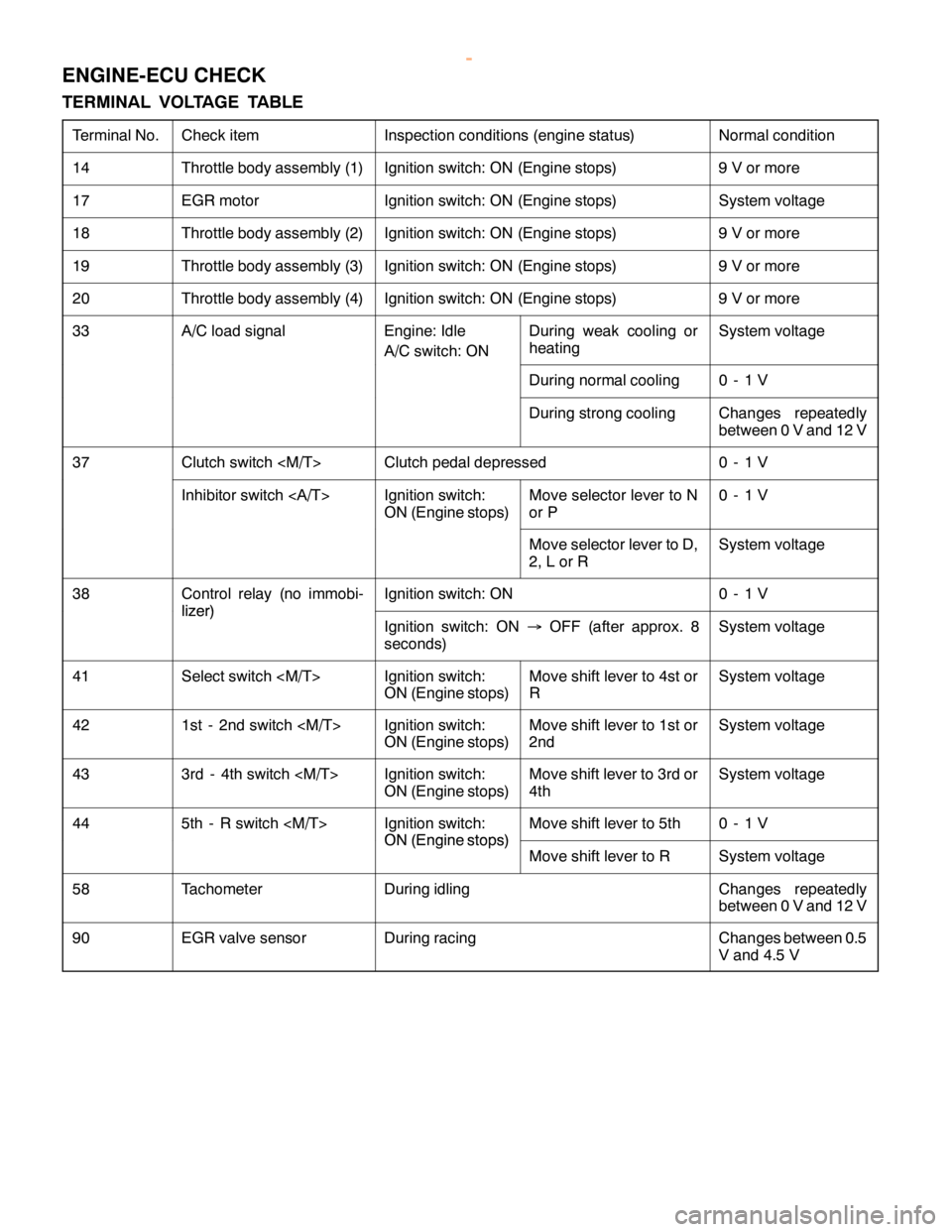

ENGINE-ECU CHECK

TERMINAL VOLTAGE TABLE

Terminal No.Check itemInspection conditions (engine status)Normal condition

14Throttle body assembly (1)Ignition switch: ON (Engine stops)9 V or more

17EGR motorIgnition switch: ON (Engine stops)System voltage

18Throttle body assembly (2)Ignition switch: ON (Engine stops)9 V or more

19Throttle body assembly (3)Ignition switch: ON (Engine stops)9 V or more

20Throttle body assembly (4)Ignition switch: ON (Engine stops)9 V or more

33A/C load signalEngine: Idle

A/C switch: ONDuring weak cooling or

heatingSystem voltage

During normal cooling0-1V

During strong coolingChanges repeatedly

between 0 V and 12 V

37Clutch switch

Inhibitor switch Ignition switch:

ON (Engine stops)Move selector lever to N

or P0-1V

Move selector lever to D,

2, L or RSystem voltage

38Control relay (no immobi-

lizer)

Ignition switch: ON0-1V

lizer)

Ignition switch: ON→OFF (after approx. 8

seconds)System voltage

41Select switch

ON (Engine stops)Move shift lever to 4st or

RSystem voltage

421st - 2nd switch

ON (Engine stops)Move shift lever to 1st or

2ndSystem voltage

433rd - 4th switch

ON (Engine stops)Move shift lever to 3rd or

4thSystem voltage

445th - R switch

ON(Enginestops)

Move shift lever to 5th0-1V

ON(Engine stops)

Move shift lever to RSystem voltage

58TachometerDuring idlingChanges repeatedly

between 0 V and 12 V

90EGR valve sensorDuring racingChanges between 0.5

V and 4.5 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 612 of 1839

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

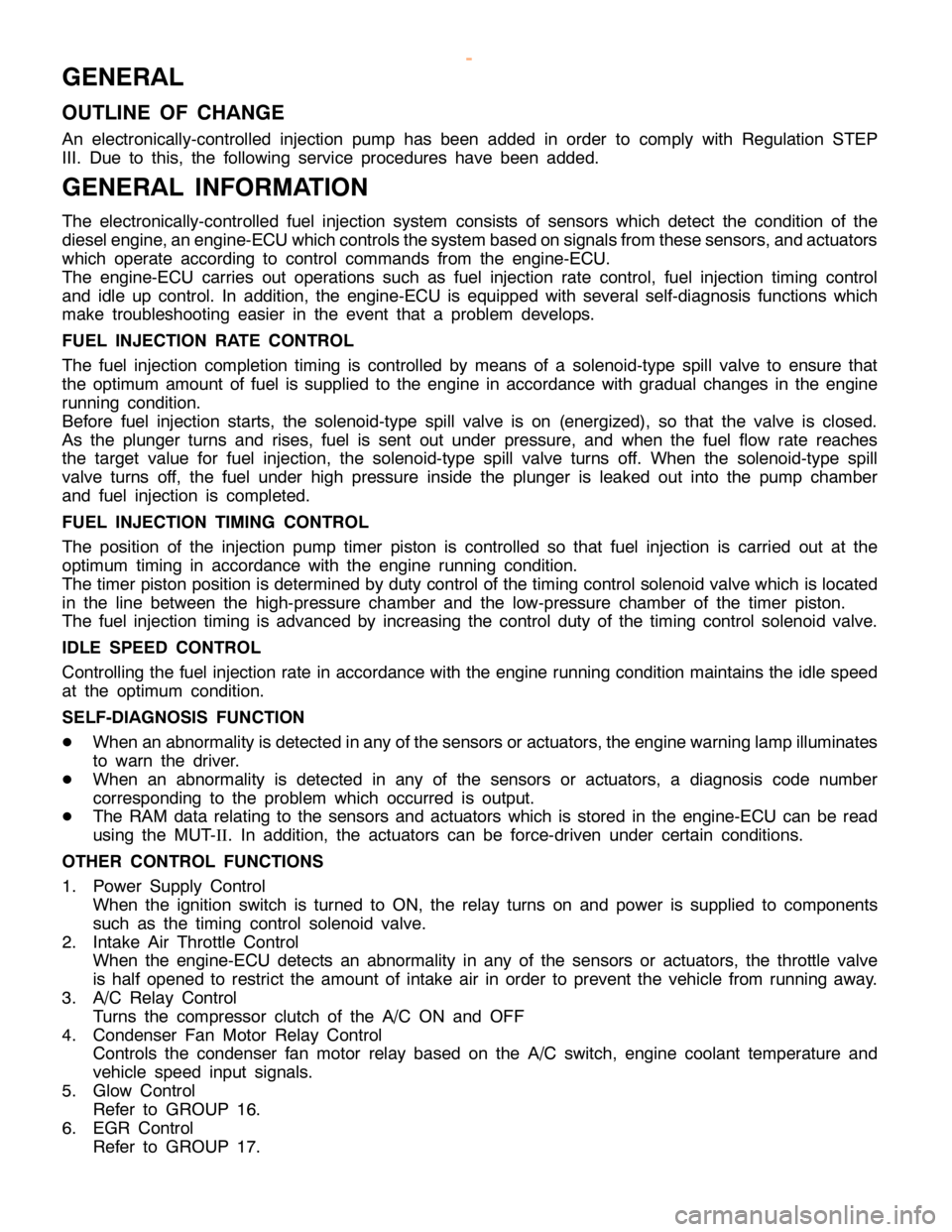

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 646 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-36

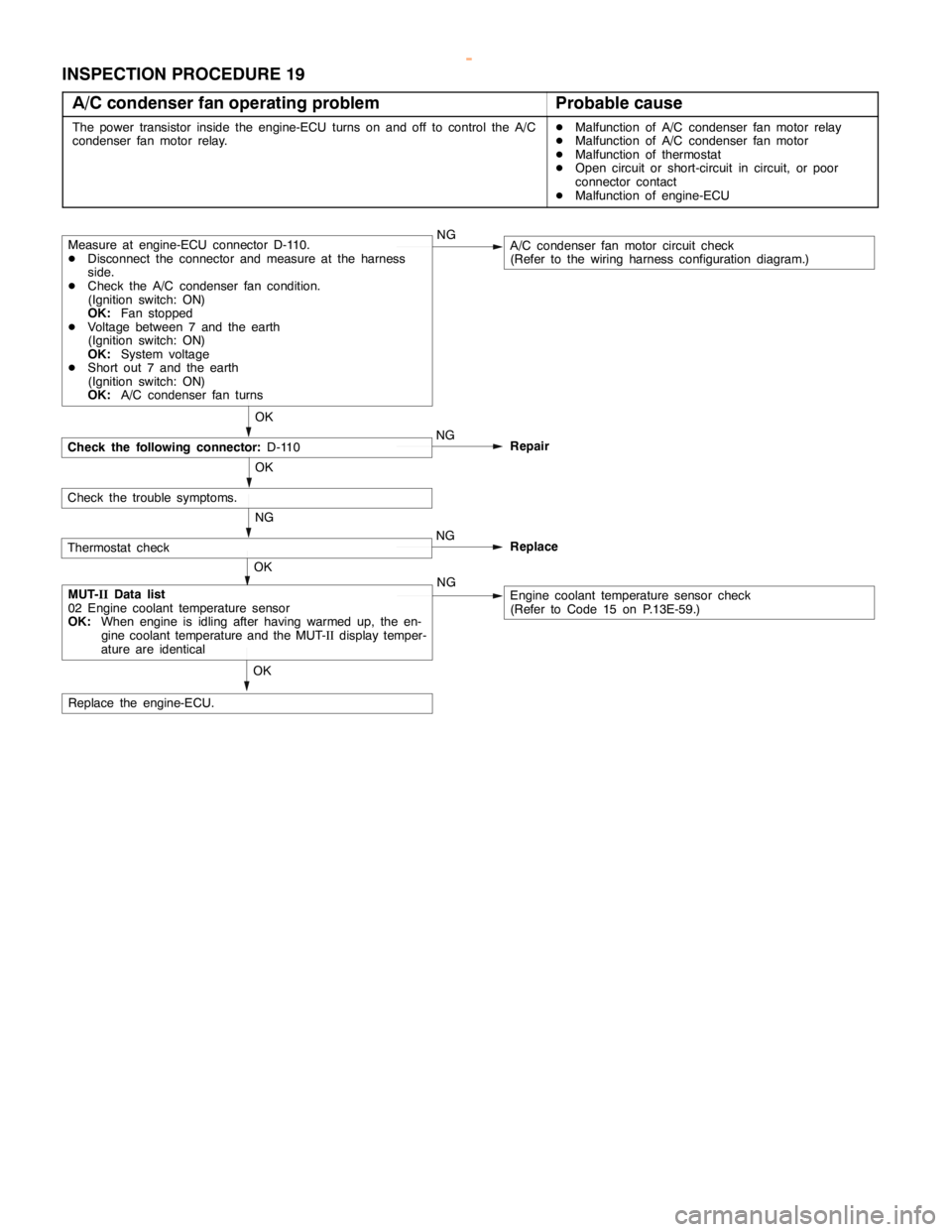

INSPECTION PROCEDURE 19

A/C condenser fan operating problem

Probable cause

The power transistor inside the engine-ECU turns on and off to control the A/C

condenser fan motor relay.DMalfunction of A/C condenser fan motor relay

DMalfunction of A/C condenser fan motor

DMalfunction of thermostat

DOpen circuit or short-circuit in circuit, or poor

connector contact

DMalfunction of engine-ECU

Check the following connector:D-110

OK

Measure at engine-ECU connector D-110.

DDisconnect the connector and measure at the harness

side.

DCheck the A/C condenser fan condition.

(Ignition switch: ON)

OK:Fan stopped

DVoltage between 7 and the earth

(Ignition switch: ON)

OK:System voltage

DShort out 7 and the earth

(Ignition switch: ON)

OK:A/C condenser fan turnsNGA/C condenser fan motor circuit check

(Refer to the wiring harness configuration diagram.)

OK

MUT-IIData list

02 Engine coolant temperature sensor

OK:When engine is idling after having warmed up, the en-

gine coolant temperature and the MUT-IIdisplay temper-

ature are identicalNGEngine coolant temperature sensor check

(Refer to Code 15 on P.13E-59.)

Check the trouble symptoms.OK

Replace the engine-ECU.NG

Repair

Thermostat checkNG

NGReplace

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 749 of 1839

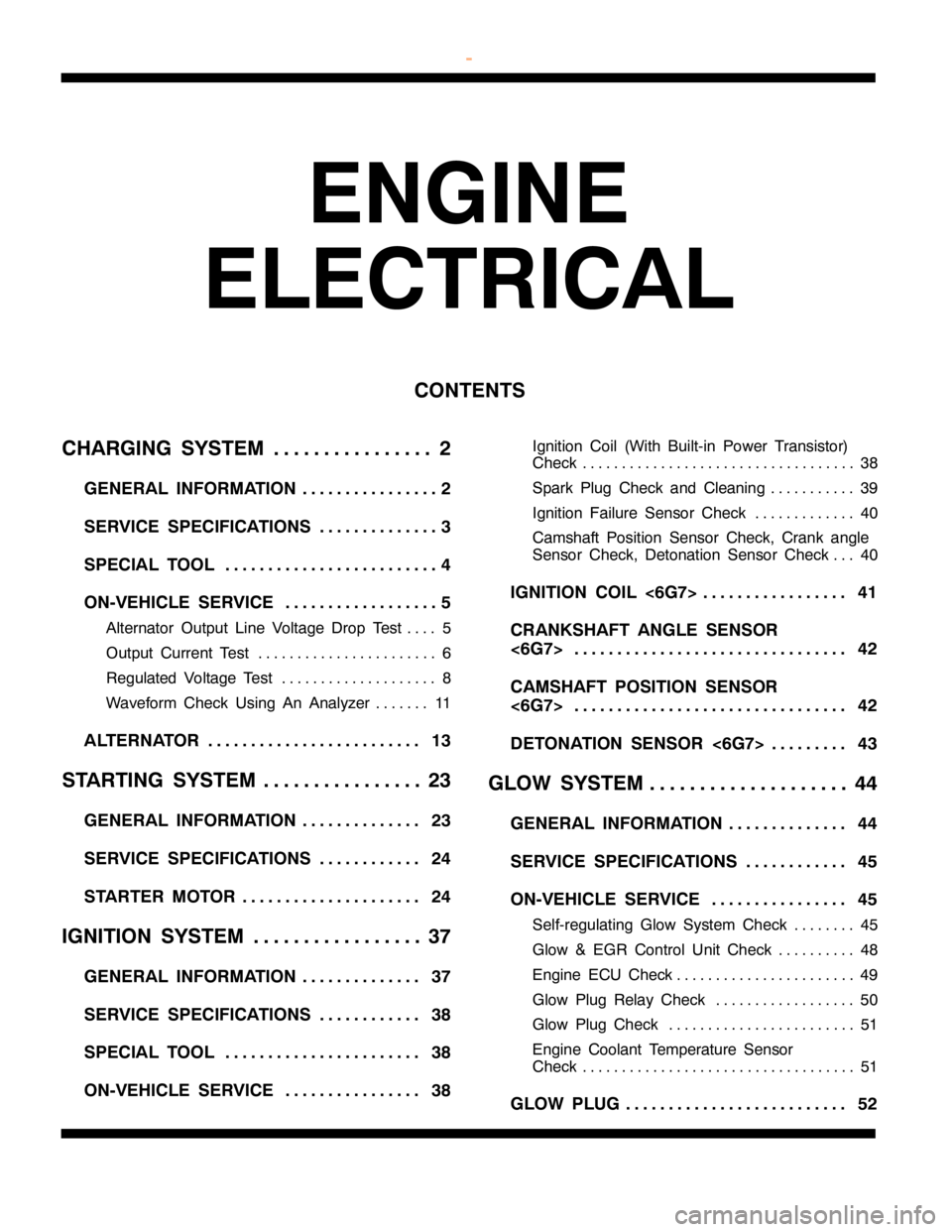

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 4.........................

ON-VEHICLE SERVICE 5..................

Alternator Output Line Voltage Drop Test 5....

Output Current Test 6.......................

Regulated Voltage Test 8....................

Waveform Check Using An Analyzer 11.......

ALTERNATOR 13.........................

STARTING SYSTEM 23................

GENERAL INFORMATION 23..............

SERVICE SPECIFICATIONS 24............

STARTER MOTOR 24.....................

IGNITION SYSTEM 37.................

GENERAL INFORMATION 37..............

SERVICE SPECIFICATIONS 38............

SPECIAL TOOL 38.......................

ON-VEHICLE SERVICE 38................

Ignition Coil (With Built-in Power Transistor)

Check 38...................................

Spark Plug Check and Cleaning 39...........

Ignition Failure Sensor Check 40.............

Camshaft Position Sensor Check, Crank angle

Sensor Check, Detonation Sensor Check 40...

IGNITION COIL <6G7> 41.................

CRANKSHAFT ANGLE SENSOR

<6G7> 42................................

CAMSHAFT POSITION SENSOR

<6G7> 42................................

DETONATION SENSOR <6G7> 43.........

GLOW SYSTEM 44....................

GENERAL INFORMATION 44..............

SERVICE SPECIFICATIONS 45............

ON-VEHICLE SERVICE 45................

Self-regulating Glow System Check 45........

Glow & EGR Control Unit Check 48..........

Engine ECU Check 49.......................

Glow Plug Relay Check 50..................

Glow Plug Check 51........................

Engine Coolant Temperature Sensor

Check 51...................................

GLOW PLUG 52..........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 804 of 1839

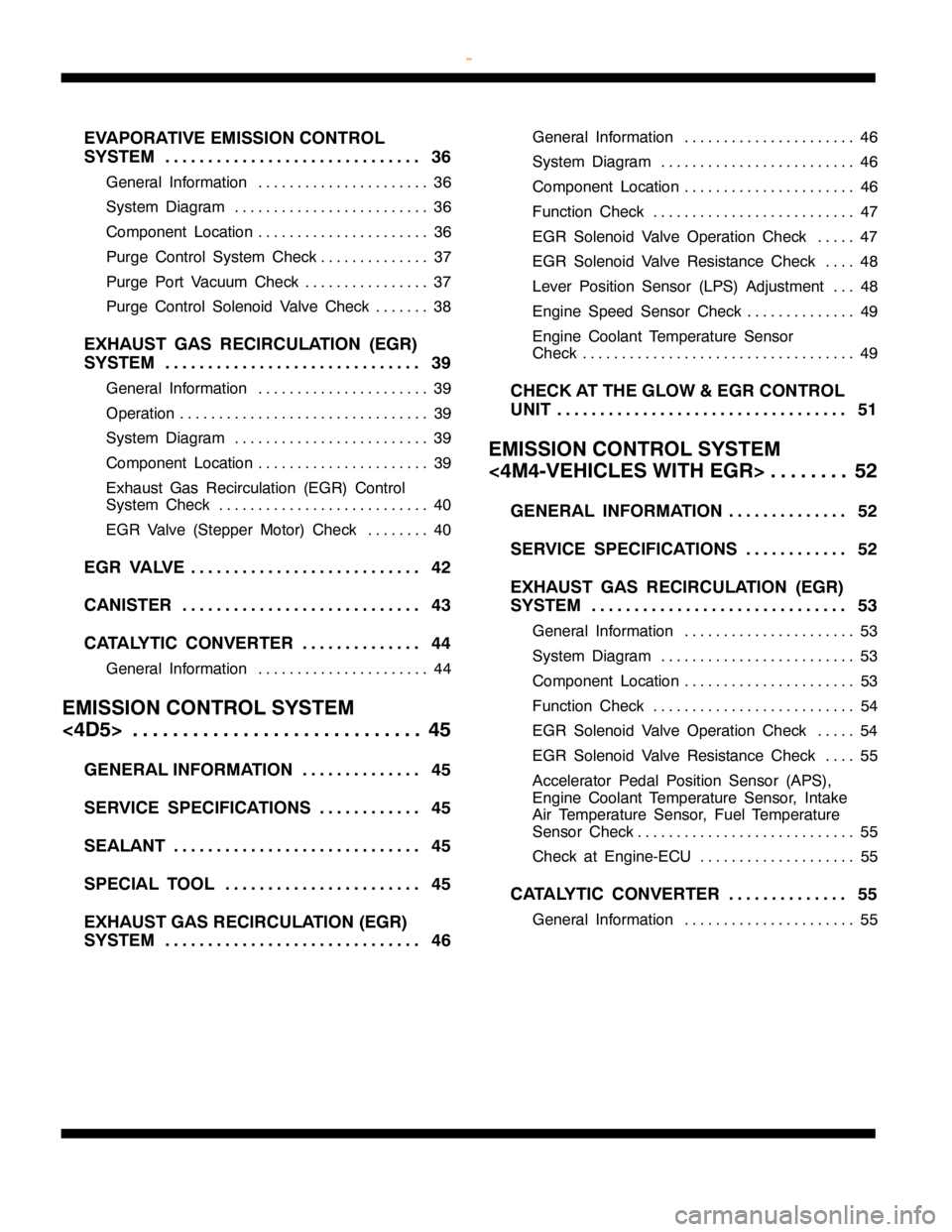

17-2

EVAPORATIVE EMISSION CONTROL

SYSTEM 36..............................

General Information 36......................

System Diagram 36.........................

Component Location 36......................

Purge Control System Check 37..............

Purge Port Vacuum Check 37................

Purge Control Solenoid Valve Check 38.......

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 39..............................

General Information 39......................

Operation 39................................

System Diagram 39.........................

Component Location 39......................

Exhaust Gas Recirculation (EGR) Control

System Check 40...........................

EGR Valve (Stepper Motor) Check 40........

EGR VALVE 42...........................

CANISTER 43............................

CATALYTIC CONVERTER 44..............

General Information 44......................

EMISSION CONTROL SYSTEM

<4D5> 45.............................

GENERAL INFORMATION 45..............

SERVICE SPECIFICATIONS 45............

SEALANT 45.............................

SPECIAL TOOL 45.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 46..............................

General Information 46......................

System Diagram 46.........................

Component Location 46......................

Function Check 47..........................

EGR Solenoid Valve Operation Check 47.....

EGR Solenoid Valve Resistance Check 48....

Lever Position Sensor (LPS) Adjustment 48...

Engine Speed Sensor Check 49..............

Engine Coolant Temperature Sensor

Check 49...................................

CHECK AT THE GLOW & EGR CONTROL

UNIT 51..................................

EMISSION CONTROL SYSTEM

<4M4-VEHICLES WITH EGR> 52........

GENERAL INFORMATION 52..............

SERVICE SPECIFICATIONS 52............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 53..............................

General Information 53......................

System Diagram 53.........................

Component Location 53......................

Function Check 54..........................

EGR Solenoid Valve Operation Check 54.....

EGR Solenoid Valve Resistance Check 55....

Accelerator Pedal Position Sensor (APS),

Engine Coolant Temperature Sensor, Intake

Air Temperature Sensor, Fuel Temperature

Sensor Check 55............................

Check at Engine-ECU 55....................

CATALYTIC CONVERTER 55..............

General Information 55......................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 833 of 1839

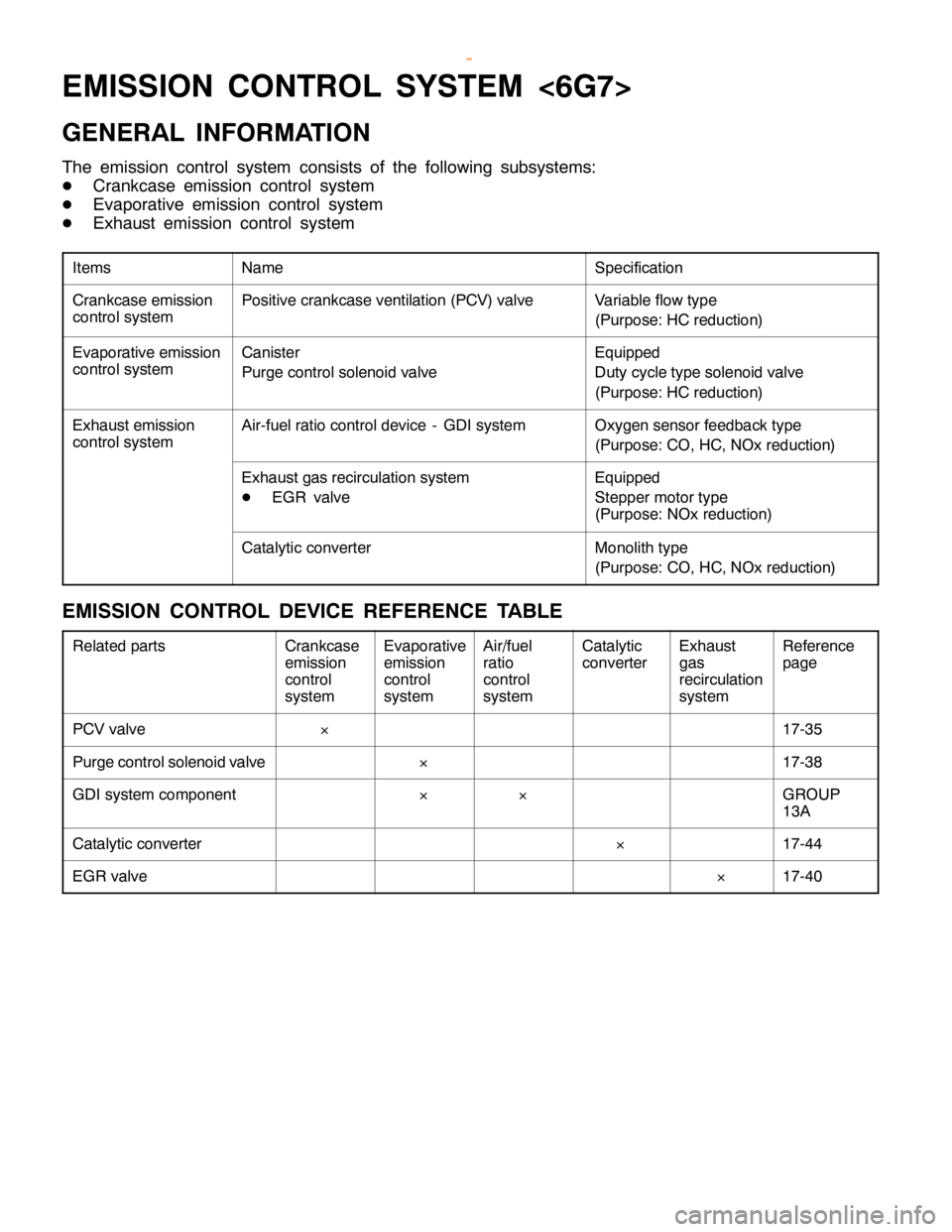

ENGINE AND EMISSION CONTROL -Emission Control System <6G7>17-31

EMISSION CONTROL SYSTEM <6G7>

GENERAL INFORMATION

The emission control system consists of the following subsystems:

DCrankcase emission control system

DEvaporative emission control system

DExhaust emission control system

ItemsNameSpecification

Crankcase emission

control systemPositive crankcase ventilation (PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission

control systemCanister

Purge control solenoid valveEquipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission

control systemAir-fuel ratio control device - GDI systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

DEGR valveEquipped

Stepper motor type

(Purpose: NOx reduction)

Catalytic converterMonolith type

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE REFERENCE TABLE

Related partsCrankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel

ratio

control

systemCatalytic

converterExhaust

gas

recirculation

systemReference

page

PCV valve´17-35

Purge control solenoid valve´17-38

GDI system component´´GROUP

13A

Catalytic converter´17-44

EGR valve´17-40

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 988 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

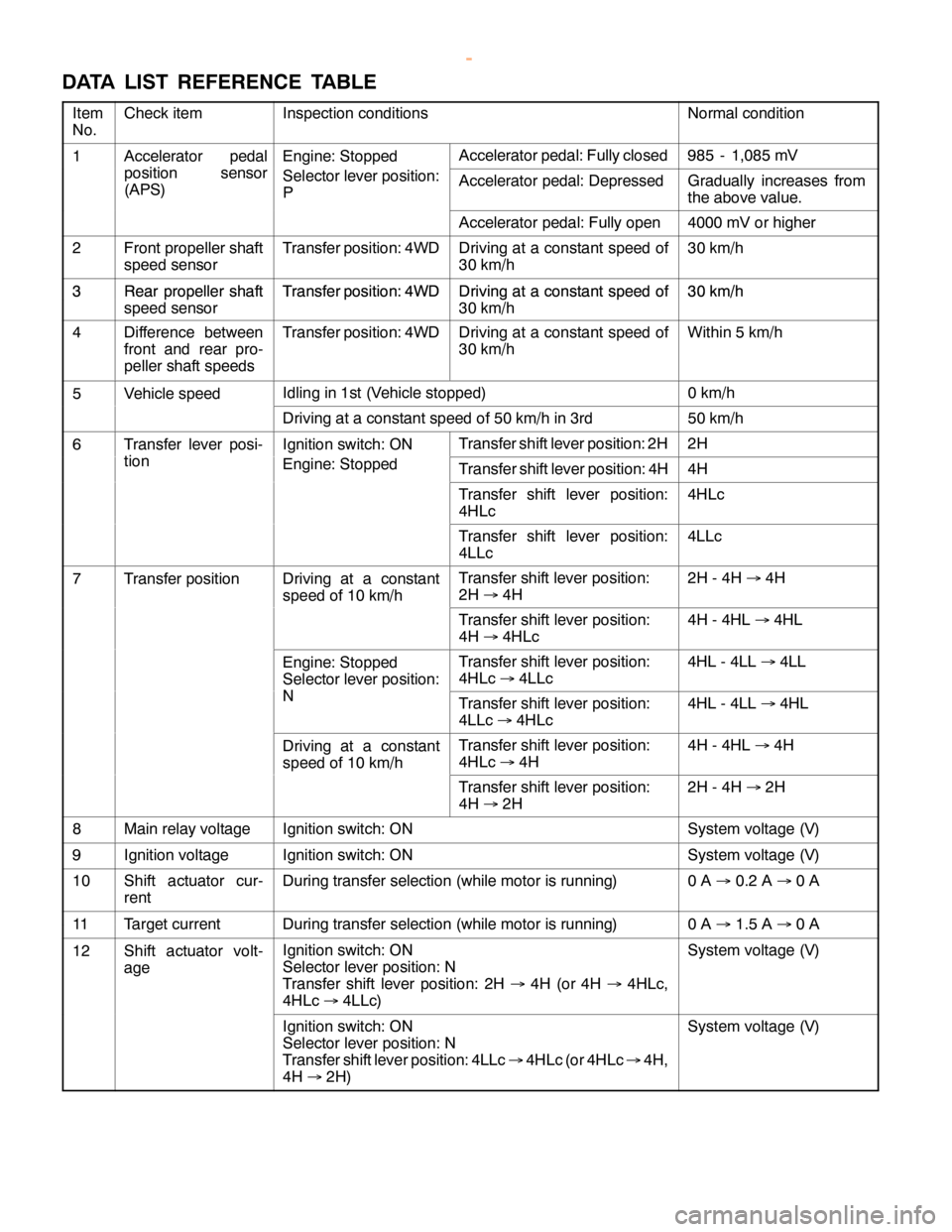

DATA LIST REFERENCE TABLE

Item

No.Check itemInspection conditionsNormal condition

1Accelerator pedalEngine: StoppedAccelerator pedal: Fully closed985 - 1,085 mV

position sensor

(APS)Selector lever position:

PAccelerator pedal: DepressedGradually increases from

the above value.

Accelerator pedal: Fully open4000 mV or higher

2Front propeller shaft

speed sensorTransfer position: 4WDDriving at a constant speed of

30 km/h30 km/h

3Rear propeller shaftTransfer position: 4WDDriving at a constant speed of30 km/h3Rear propeller shaft

speed sensorTransfer position: 4WDDriving at a constant speed of

30 km/h30 km/h

4Difference between

front and rear pro-

peller shaft speedsTransfer position: 4WDDriving at a constant speed of

30 km/hWithin 5 km/h

5Vehicle speedIdling in 1st (Vehicle stopped)0 km/h

Driving at a constant speed of 50 km/h in 3rd50 km/h

6Transfer lever posi-Ignition switch: ONTransfer shift lever position: 2H2H

tionEngine: StoppedTransfer shift lever position: 4H4H

Transfer shift lever position:

4HLc4HLc

Transfer shift lever position:

4LLc4LLc

7Transfer positionDriving at a constant

speed of 10 km/hTransfer shift lever position:

2H®4H2H - 4H®4H

Transfer shift lever position:

4H®4HLc4H - 4HL®4HL

Engine: Stopped

Selector lever position:Transfer shift lever position:

4HLc®4LLc4HL - 4LL®4LL

NTransfer shift lever position:

4LLc®4HLc4HL - 4LL®4HL

Driving at a constant

speed of 10 km/hTransfer shift lever position:

4HLc®4H4H - 4HL®4H

Transfer shift lever position:

4H®2H2H - 4H®2H

8Main relay voltageIgnition switch: ONSystem voltage (V)

9Ignition voltageIgnition switch: ONSystem voltage (V)

10Shift actuator cur-

rentDuring transfer selection (while motor is running)0A®0.2 A®0A

11Target currentDuring transfer selection (while motor is running)0A®1.5 A®0A

12Shift actuator volt-

ageIgnition switch: ON

Selector lever position: N

Transfer shift lever position: 2H®4H (or 4H®4HLc,

4HLc®4LLc)System voltage (V)

Ignition switch: ON

Selector lever position: N

Transfer shift lever position: 4LLc®4HLc (or 4HLc®4H,

4H®2H)System voltage (V)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1210 of 1839

35A-2

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 6..............................

SPECIAL TOOLS 6..........................

TROUBLESHOOTING

ON-VEHICLE SERVICE 19...................

Brake Pedal Check and Adjustment 19..........

Hydraulic Brake Booster (HBB) Operation Check

HBB Check

HBB Motor Relay Continuity Check

Brake Booster Operating Test

Check Valve Operation Check

Load Sensing Spring Length Check and

Adjustment

Load Sensing Proportioning Valve Function

Test

Bleeding

Brake Fluid Level Sensor Check 30.............

Brake Booster Vacuum Switch Check

Disc Brake Pad Check and Replacement 31.....

Disc Brake Rotor Check 32.....................

Brake Disc Thickness Check 32.................

Brake Disc Run-out Check and Correction 33....

BRAKE PEDAL 34..........................

HYDRAULIC BRAKE BOOSTER (HBB)

HBB BUZZER

MASTER CYLINDER AND BRAKE

BOOSTER

Master Cylinder 43.............................

FRONT DISC BRAKE 44....................

REAR DISC BRAKE 49......................

LOAD SENSING PROPORTIONING

VALVE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk