MOTOR MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1213 of 1839

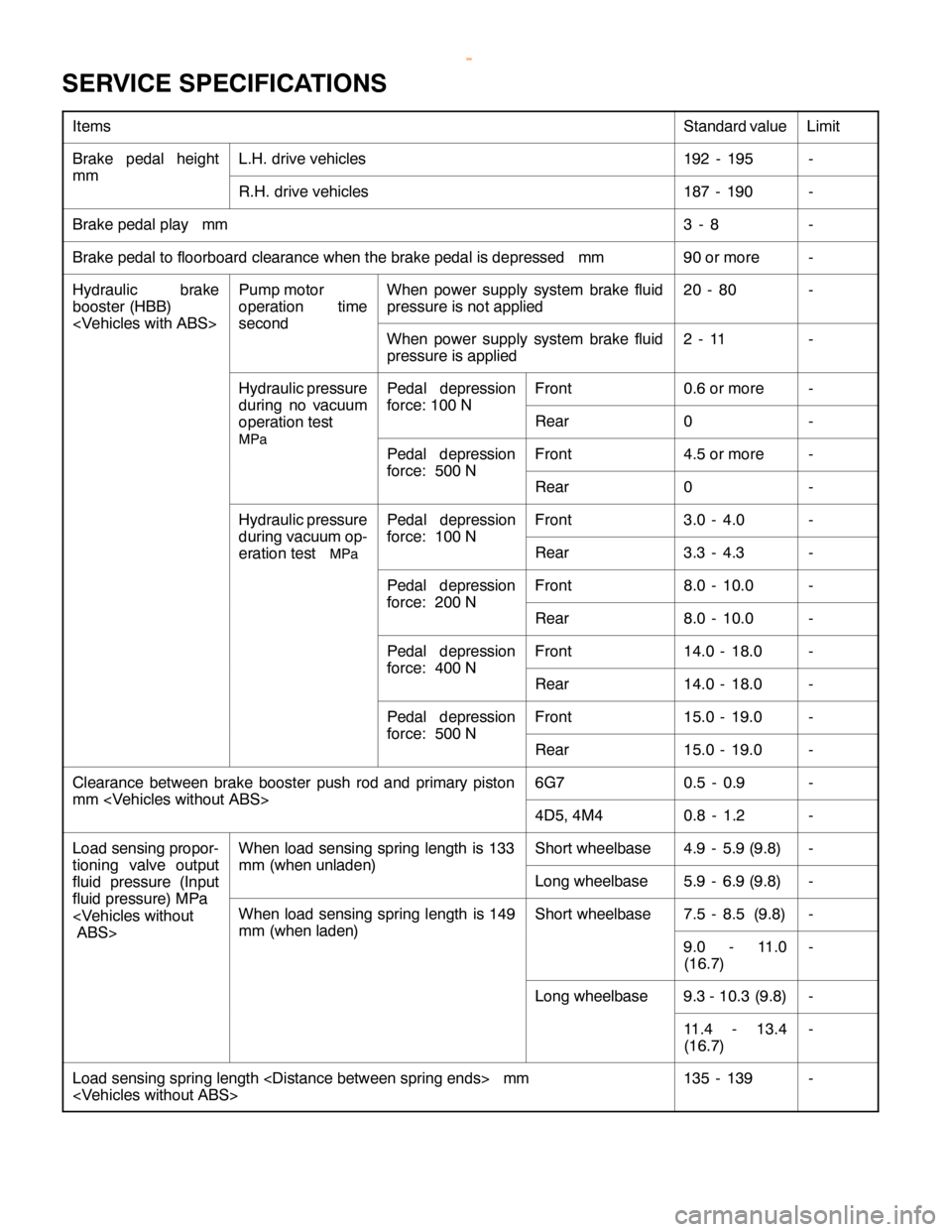

BASIC BRAKE SYSTEM -Service Specifications35A-5

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal heightL.H. drive vehicles192 - 195-

mm

R.H. drive vehicles187 - 190-

Brake pedal play mm3-8-

Brake pedal to floorboard clearance when the brake pedal is depressed mm90 or more-

Hydraulic brake

booster (HBB)Pump motor

operation timeWhen power supply system brake fluid

pressure is not applied20 - 80-

When power supply system brake fluid

pressure is applied2-11-

Hydraulic pressurePedal depressionFront0.6 or more-

during no vacuum

operation testforce: 100 N

Rear0-

MPa

Pedal depressionFront4.5 or more-

force: 500 N

Rear0-

Hydraulic pressurePedal depressionFront3.0 - 4.0-

during vacuum op-

eration test

MPa

force: 100 N

Rear3.3 - 4.3-

Pedal depressionFront8.0 - 10.0-

force: 200 N

Rear8.0 - 10.0-

Pedal depressionFront14.0 - 18.0-

force: 400 N

Rear14.0 - 18.0-

Pedal depressionFront15.0 - 19.0-

force: 500 N

Rear15.0 - 19.0-

Clearance between brake booster push rod and primary piston6G70.5 - 0.9-

mm

4D5, 4M40.8 - 1.2-

Load sensing propor-When load sensing spring length is 133Short wheelbase4.9 - 5.9 (9.8)-

tioning valve output

fluid pressure (Inputmm (when unladen)

Long wheelbase5.9 - 6.9 (9.8)-

fluid pressure) MPa

9.0 - 11.0

(16.7)-

Long wheelbase9.3 - 10.3 (9.8)-

11.4 - 13.4

(16.7)-

Load sensing spring length

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1217 of 1839

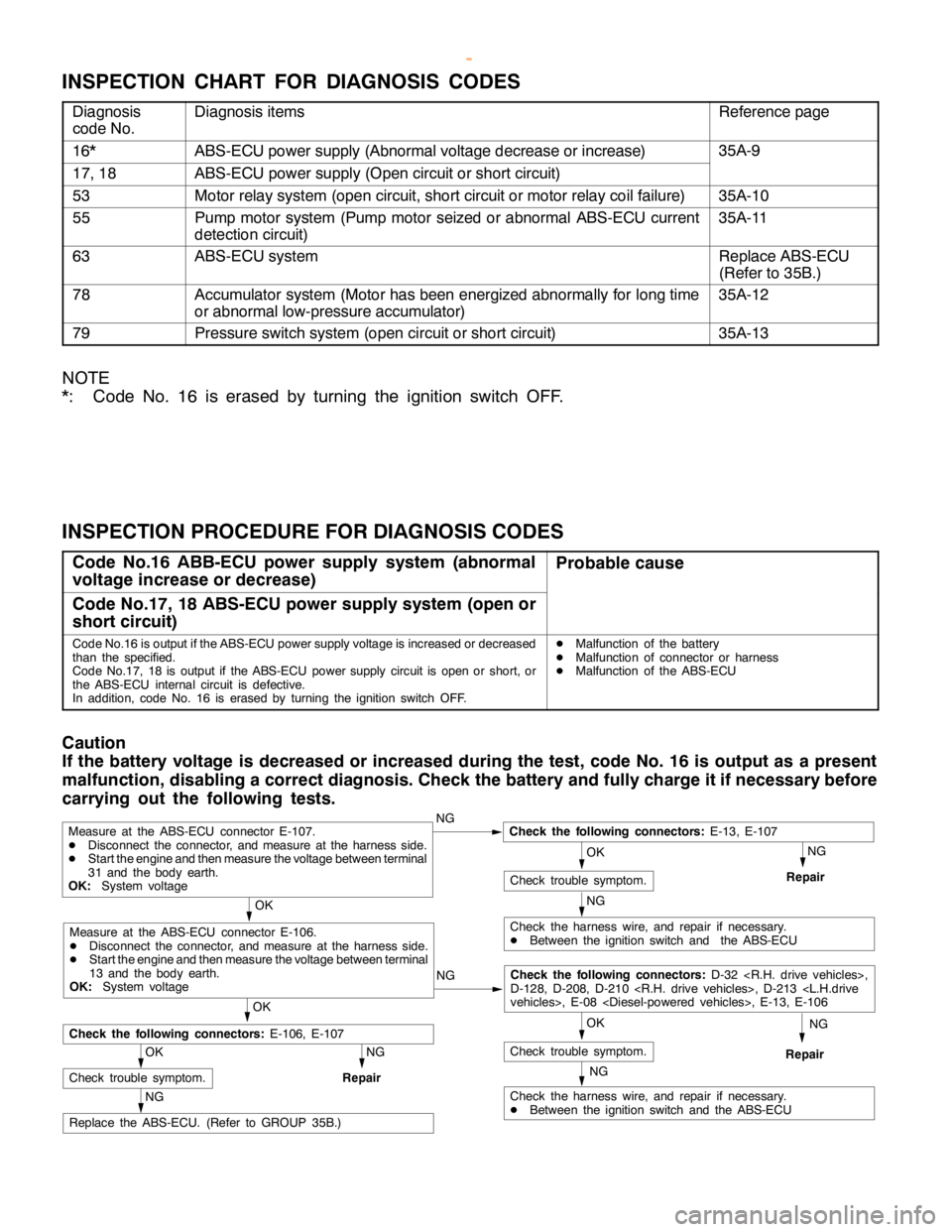

BASIC BRAKE SYSTEM -Troubleshooting35A-9

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

16*ABS-ECU power supply (Abnormal voltage decrease or increase)35A-9

17, 18ABS-ECU power supply (Open circuit or short circuit)

53Motor relay system (open circuit, short circuit or motor relay coil failure)35A-10

55Pump motor system (Pump motor seized or abnormal ABS-ECU current

detection circuit)35A-11

63ABS-ECU systemReplace ABS-ECU

(Refer to 35B.)

78Accumulator system (Motor has been energized abnormally for long time

or abnormal low-pressure accumulator)35A-12

79Pressure switch system (open circuit or short circuit)35A-13

NOTE

*: Code No. 16 is erased by turning the ignition switch OFF.

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.16 ABB-ECU power supply system (abnormal

voltage increase or decrease)Probable cause

Code No.17, 18 ABS-ECU power supply system (open or

short circuit)

Code No.16 is output if the ABS-ECU power supply voltage is increased or decreased

than the specified.

Code No.17, 18 is output if the ABS-ECU power supply circuit isopen orshort, or

the ABS-ECU internal circuit is defective.

In addition, code No. 16 is erased by turning the ignition switch OFF.DMalfunction of the battery

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

Caution

If the battery voltage is decreased or increased during the test, code No. 16 is output as a present

malfunction, disabling a correct diagnosis. Check the battery and fully charge it if necessary before

carrying out the following tests.

NG

NG

OK

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

OK

Check trouble symptom.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-107.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

31 and the body earth.

OK:System voltageNGCheck the following connectors:E-13, E-107

Repair

OK

Check the following connectors:E-106, E-107

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-106.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

13 and the body earth.

OK:System voltageNG

Check the following connectors:D-32

D-128, D-208, D-210

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1218 of 1839

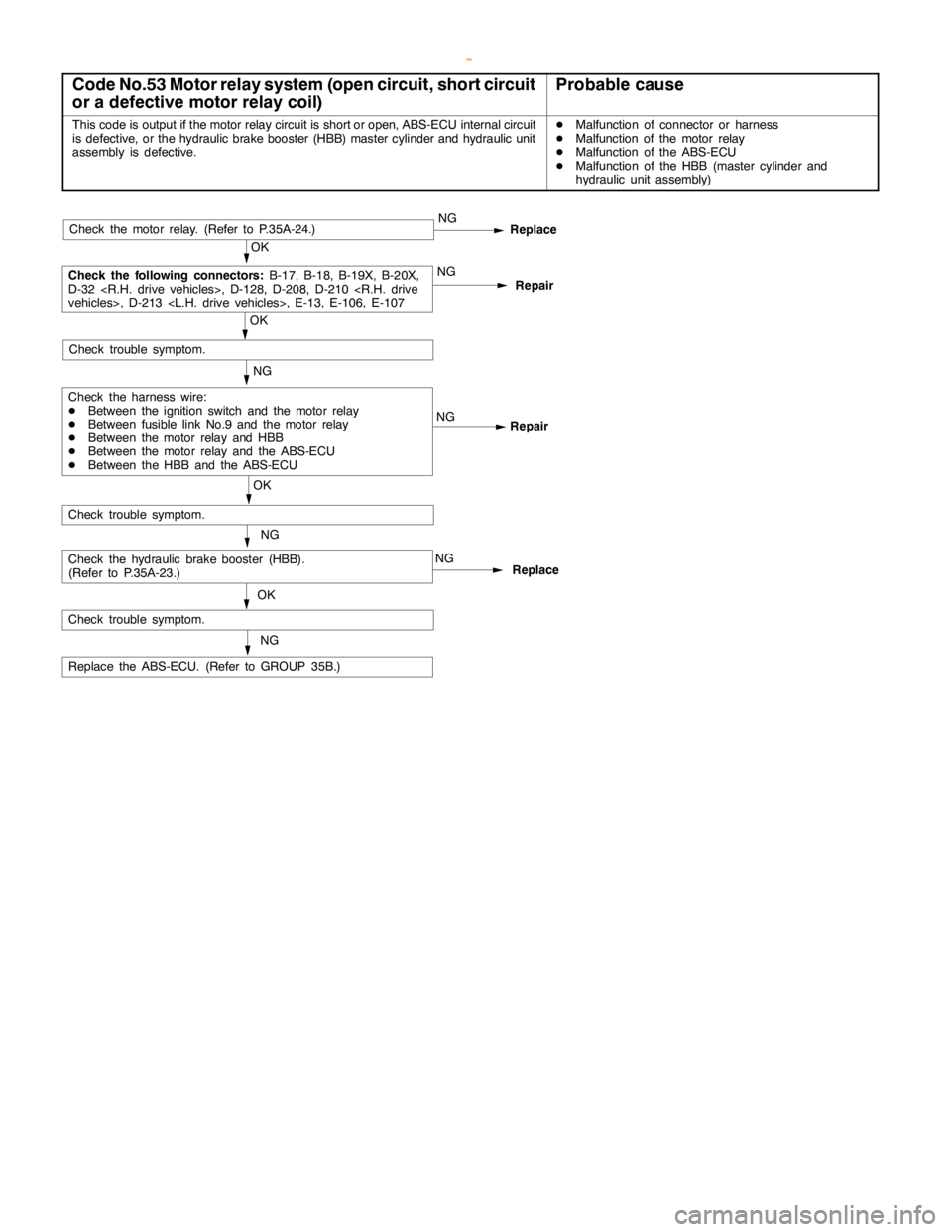

BASIC BRAKE SYSTEM -Troubleshooting35A-10

Code No.53 Motor relay system (open circuit, short circuit

or a defective motor relay coil)Probable cause

This code is output if the motor relay circuit is short or open, ABS-ECU internal circuit

is defective, or the hydraulic brake booster (HBB) master cylinder and hydraulic unit

assembly is defective.DMalfunction of connector or harness

DMalfunction of the motor relay

DMalfunction of the ABS-ECU

DMalfunction of the HBB (master cylinder and

hydraulic unit assembly)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

D-32

Check the harness wire:

DBetween the ignition switch and the motor relay

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the motor relay and the ABS-ECU

DBetween the HBB and the ABS-ECU

Check trouble symptom.

NG

NG

Replace

OK

Check the motor relay. (Refer to P.35A-24.)

Check the hydraulic brake booster (HBB).

(Refer to P.35A-23.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

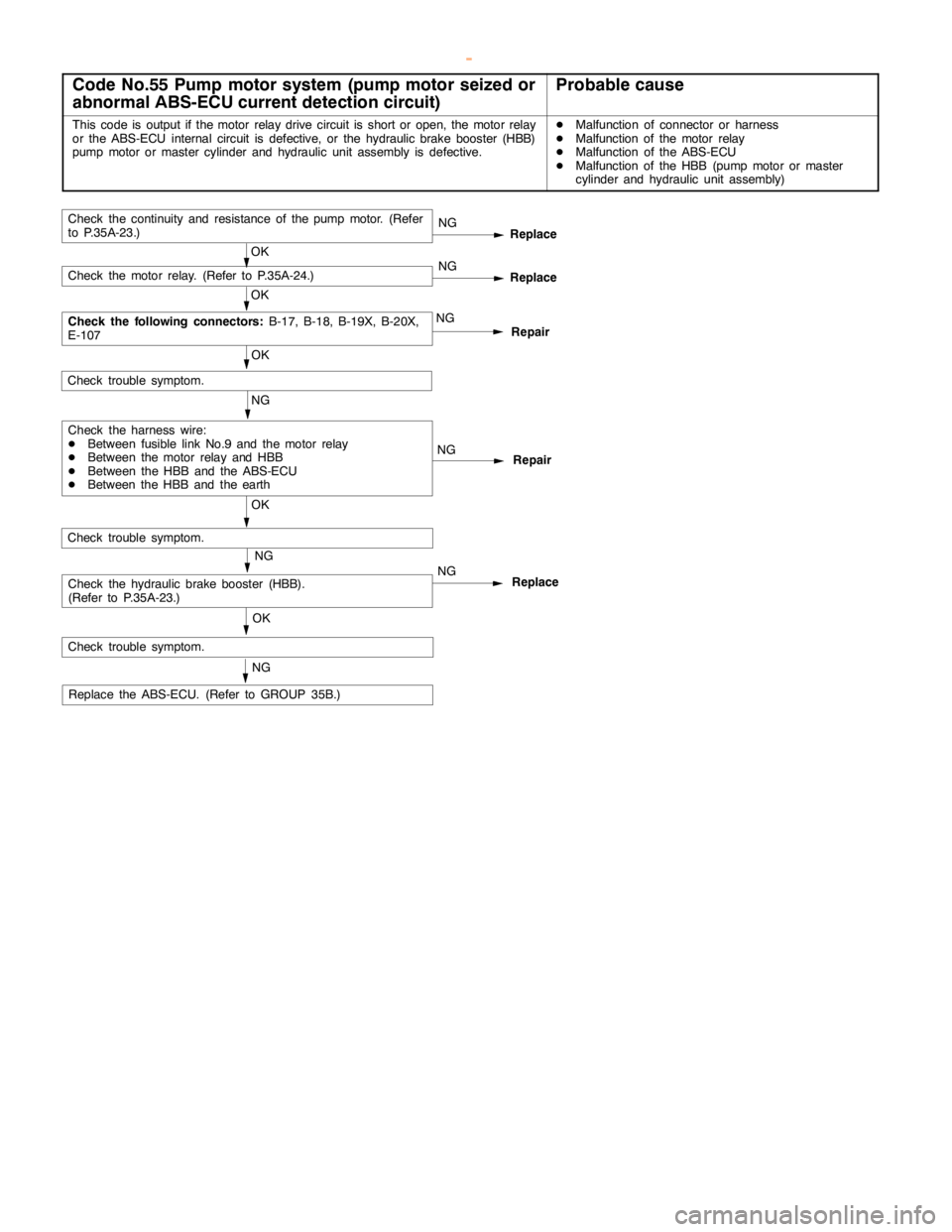

Page 1219 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-11

Code No.55 Pump motor system (pump motor seized or

abnormal ABS-ECU current detection circuit)Probable cause

This code is output if the motor relay drive circuit is short or open, the motor relay

or the ABS-ECU internal circuit is defective, or the hydraulic brake booster (HBB)

pump motor ormaster cylinder and hydraulic unit assembly is defective.DMalfunction of connector or harness

DMalfunction of the motor relay

DMalfunction of the ABS-ECU

DMalfunction of the HBB (pump motor or master

cylinder and hydraulic unit assembly)

NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

E-107

Check the harness wire:

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check the motor relay. (Refer to P.35A-24.)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

Check trouble symptom.

NG

OKCheck the hydraulic brake booster (HBB).

(Refer to P.35A-23.)Replace NG

Replace

OKCheck the continuity and resistance of thepump motor.(Refer

to P.35A-23.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1220 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-12

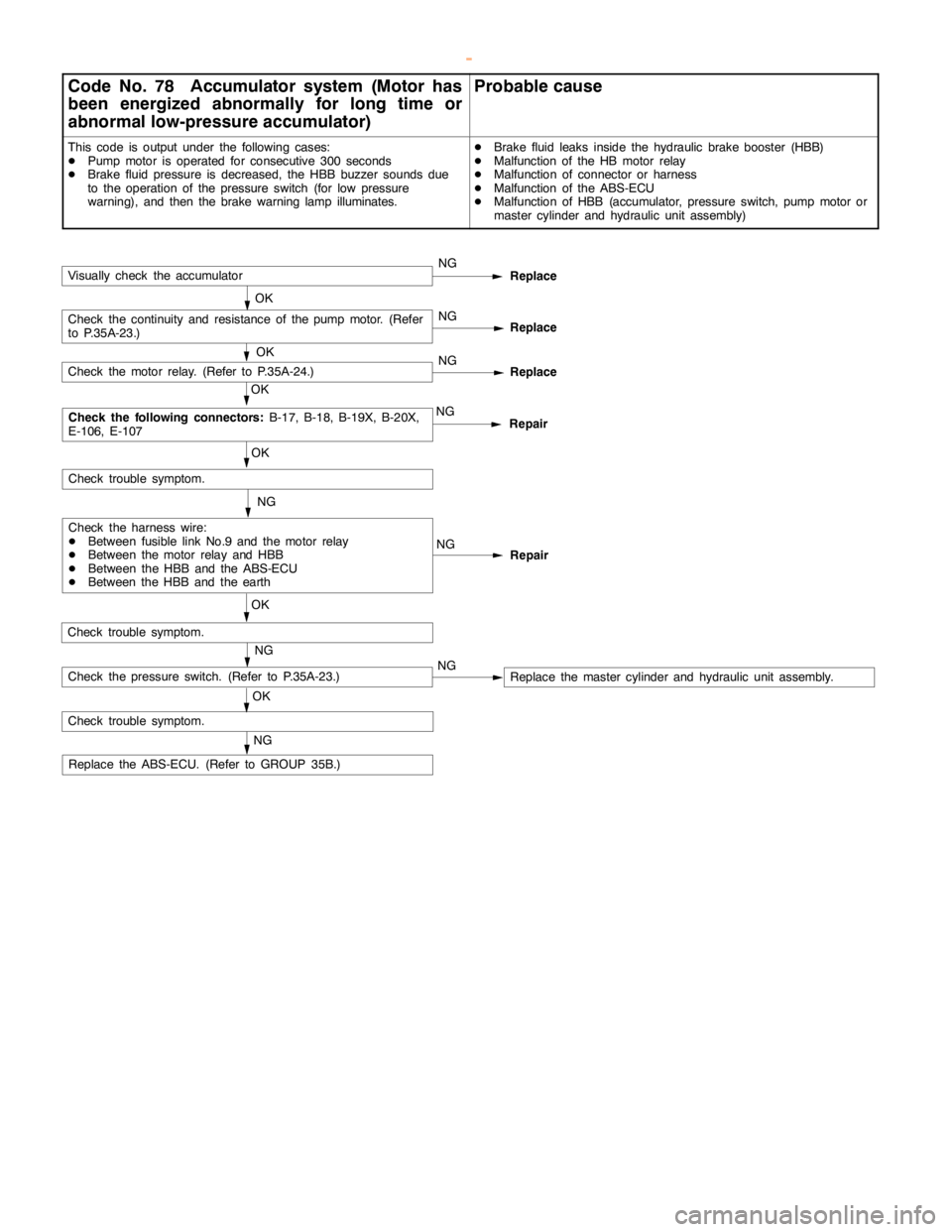

Code No. 78 Accumulator system (Motor has

been energized abnormally for long time or

abnormal low-pressure accumulator)Probable cause

This code is output under the following cases:

DPump motor is operated for consecutive 300 seconds

DBrake fluid pressure is decreased, the HBB buzzer sounds due

to the operation of the pressure switch (for low pressure

warning), and then the brake warninglamp illuminates.DBrake fluid leaks inside the hydraulic brake booster (HBB)

DMalfunction of the HB motor relay

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

DMalfunction of HBB (accumulator, pressure switch,pump motor or

master cylinder and hydraulic unit assembly)

NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

E-106, E-107

Check the harness wire:

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check the motor relay. (Refer to P.35A-24.)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

Check trouble symptom.

NG

OKCheck the pressure switch. (Refer to P.35A-23.)NG

Replace

OKCheck the continuity and resistance of thepump motor.(Refer

to P.35A-23.)NG

Replace

OKVisually check the accumulator

Replace the master cylinder and hydraulic unit assembly.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1224 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-16

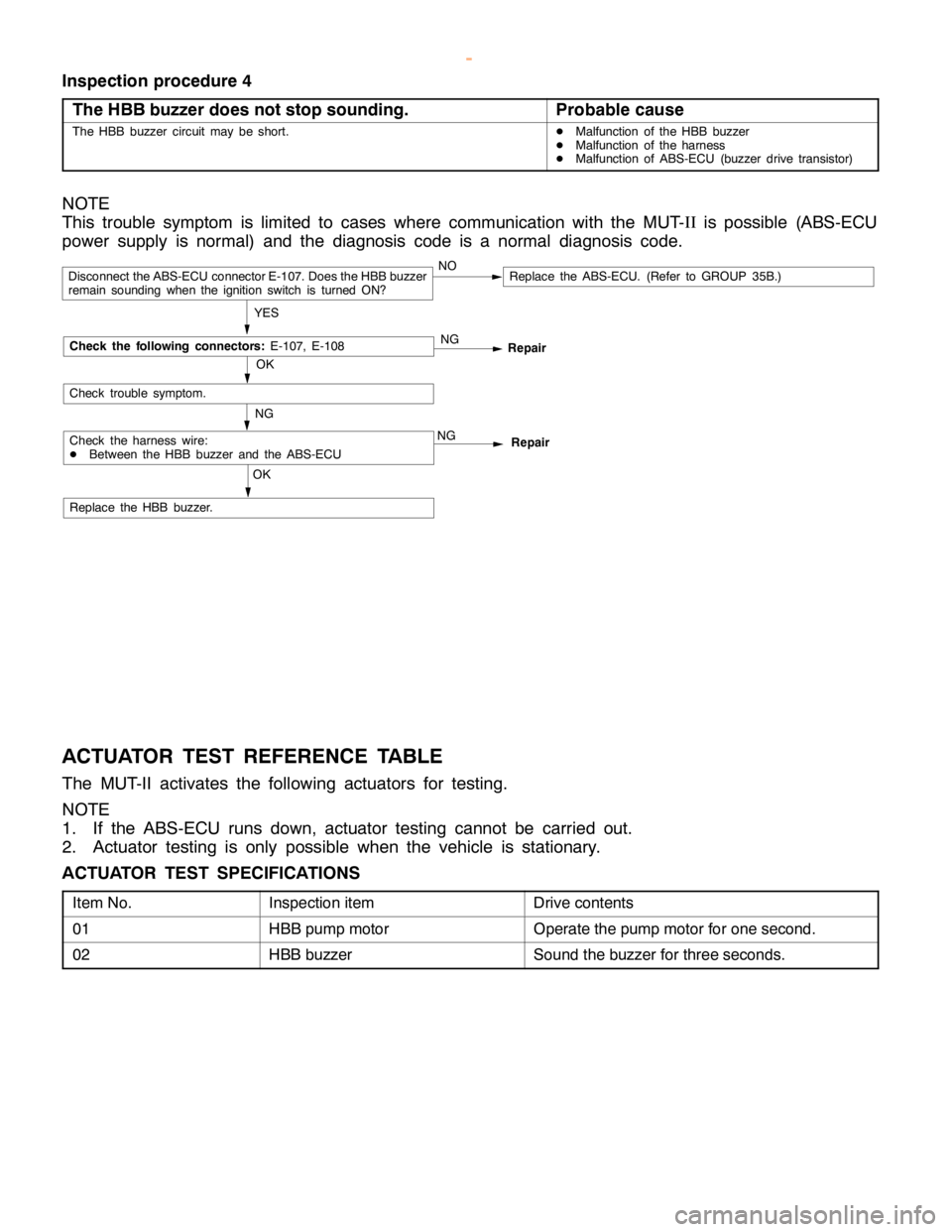

Inspection procedure 4

The HBB buzzer does not stop sounding.

Probable cause

The HBB buzzer circuit may be short.DMalfunction of the HBB buzzer

DMalfunction of the harness

DMalfunction of ABS-ECU (buzzer drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II

is possible (ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

OK

Repair NG

Repair

Replace the HBB buzzer.

OK

NG

YES

Replace the ABS-ECU. (Refer to GROUP 35B.)NODisconnect the ABS-ECU connector E-107. Does the HBB buzzer

remain sounding when the ignition switch is turned ON?

Check trouble symptom.

Check the harness wire:

DBetween the HBB buzzer and the ABS-ECUNG

Check the following connectors:

E-107, E-108

ACTUATOR TEST REFERENCE TABLE

The MUT-II activates the following actuators for testing.

NOTE

1. If the ABS-ECU runs down, actuator testing cannot be carried out.

2. Actuator testing is only possible when the vehicle is stationary.

ACTUATOR TEST SPECIFICATIONS

Item No.Inspection itemDrive contents

01HBB pump motorOperate the pump motor for one second.

02HBB buzzerSound the buzzer for three seconds.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1235 of 1839

BASIC BRAKE SYSTEM -On-vehicle ServiceBASIC BRAKE SYSTEM -On-vehicle Service35A-27

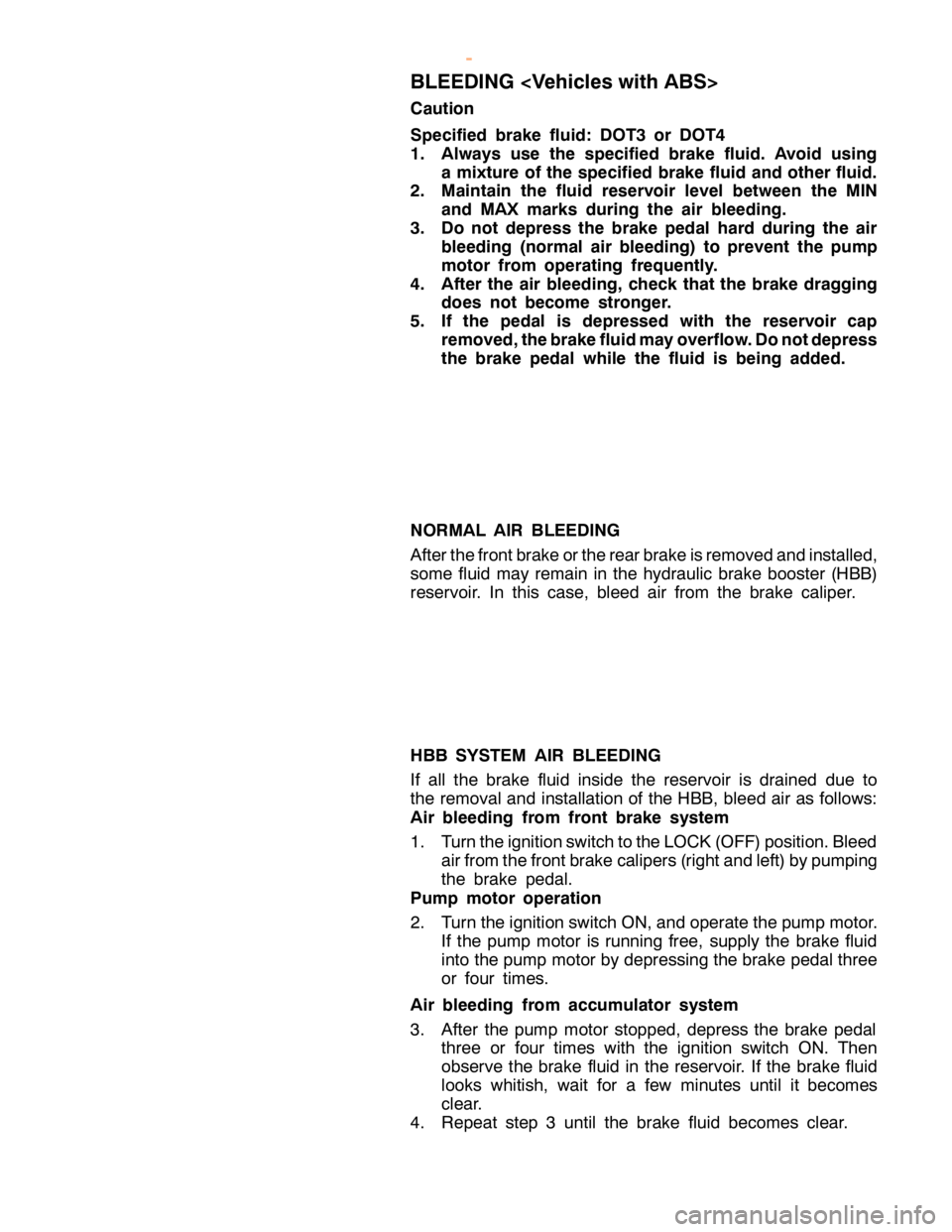

BLEEDING

Caution

Specified brake fluid: DOT3 or DOT4

1. Always use the specified brake fluid. Avoid using

a mixture of the specified brake fluid and other fluid.

2. Maintain the fluid reservoir level between the MIN

and MAX marks during the air bleeding.

3. Do not depress the brake pedal hard during the air

bleeding (normal air bleeding) to prevent the pump

motor from operating frequently.

4. After the air bleeding, check that the brake dragging

does not become stronger.

5. If the pedal is depressed with the reservoir cap

removed, the brake fluid may overflow. Do not depress

the brake pedal while the fluid is being added.

NORMAL AIR BLEEDING

After the front brake or the rear brake is removed and installed,

some fluid may remain in the hydraulic brake booster (HBB)

reservoir. In this case, bleed air from the brake caliper.

HBB SYSTEM AIR BLEEDING

If all the brake fluid inside the reservoir is drained due to

the removal and installation of the HBB, bleed air as follows:

Air bleeding from front brake system

1. Turn the ignition switch to the LOCK (OFF) position. Bleed

air from the front brake calipers (right and left) by pumping

the brake pedal.

Pump motor operation

2. Turn the ignition switch ON, and operate the pump motor.

If the pump motor is running free, supply the brake fluid

into the pump motor by depressing the brake pedal three

or four times.

Air bleeding from accumulator system

3. After the pump motor stopped, depress the brake pedal

three or four times with the ignition switch ON. Then

observe the brake fluid in the reservoir. If the brake fluid

looks whitish, wait for a few minutes until it becomes

clear.

4. Repeat step 3 until the brake fluid becomes clear.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1264 of 1839

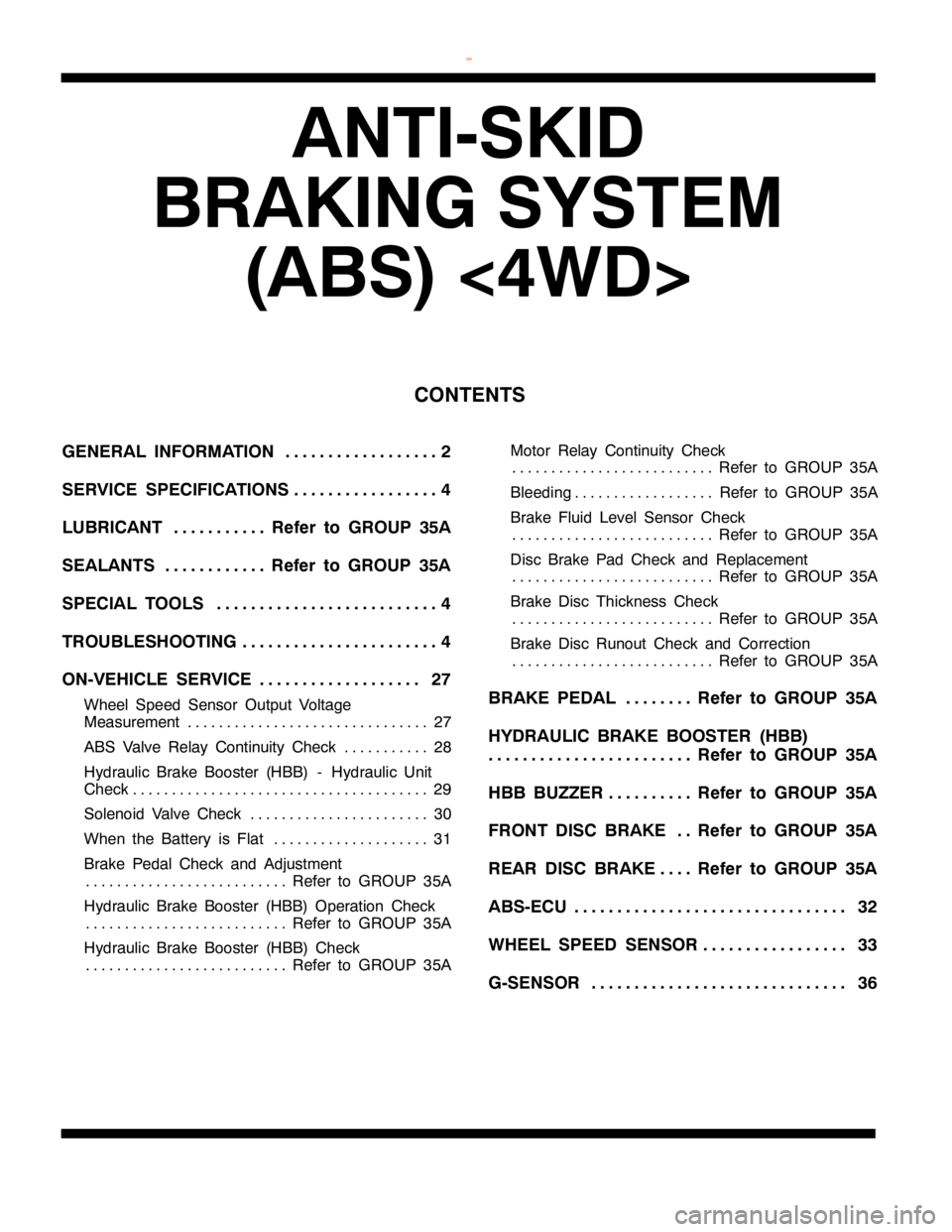

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANT Refer to GROUP 35A...........

SEALANTS Refer to GROUP 35A............

SPECIAL TOOLS 4..........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 27...................

Wheel Speed Sensor Output Voltage

Measurement 27...............................

ABS Valve Relay Continuity Check 28...........

Hydraulic Brake Booster (HBB) - Hydraulic Unit

Check 29......................................

Solenoid Valve Check 30.......................

When the Battery is Flat 31....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Operation Check

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Check

Refer to GROUP 35A ..........................Motor Relay Continuity Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and Replacement

Refer to GROUP 35A ..........................

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Runout Check and Correction

Refer to GROUP 35A ..........................BRAKE PEDAL Refer to GROUP 35A........

HYDRAULIC BRAKE BOOSTER (HBB)

Refer to GROUP 35A ........................

HBB BUZZER Refer to GROUP 35A..........

FRONT DISC BRAKE Refer to GROUP 35A..

REAR DISC BRAKE Refer to GROUP 35A....

ABS-ECU 32................................

WHEEL SPEED SENSOR 33.................

G-SENSOR 36..............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1353 of 1839

42-1

BODY

CONTENTS

HOOD3 ....................................

FENDER5 ..................................

FUEL FILLER DOOR6 .....................

WINDOW GLASS8 .........................

ADHESIVES 8.............................

SPECIAL TOOL 8.........................

WINDOW REPAIR 8.......................

WINDSHIELD 10..........................

QUARTER WINDOW GLASS 14...........

BACK DOOR GLASS 16..................

DOORS18 .................................

SERVICE SPECIFICATIONS 18............

SEALANT 18.............................

SPECIAL TOOLS 18......................

TROUBLESHOOTING 19..................ON-VEHICLE SERVICE 19................

Door Fit Adjustment 19.................

Door Window Glass Adjustment 19......

Defective Power Window Adjustment and

Replacement

20 .........................

Power Window Safety Mechanism Check 20..

Door Outside Handle Play Check 21.....

Power Window Operation Current

Check 21..............................

Circuit Breaker (Incorporated in the Power

Window Motor) Check 21...............

Door Inside Handle Play Check and

Adjustment 21..........................

DOOR ASSEMBLY 22.....................

DOOR TRIM AND WATERPROOF

FILM 24..................................

DOOR GLASS AND REGULATOR 30......

DOOR HANDLE AND LATCH 33..........

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING WEATHERSTRIP 36.....

BACK DOOR39 ...........................

SERVICE SPECIFICATION 39.............

SEALANT 39.............................

SPECIAL TOOL 39.......................

TROUBLESHOOTING 39..................

CONTINUED ON NEXT PAGE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1402 of 1839

BODY -SunroofBODY -Sunroof42-50

"

BA

SUNROOF MOTOR ASSEMBLY INSTALLATION

1. Install the roof lid glass assembly and the sunroof motor

assembly with the sunroof motor assembly in the

fully-closed position.

2. Connect the sunroof motor assembly harness connector

and the sunroof switch harness connector to the vehicle

wiring harness connector.

3. Operate the sunroof and check that it operates correctly.

1. Install the roof lid glass assembly and the sunroof motor

assembly with the sunroof motor assembly in the

fully-closed position.

2. Connect the sunroof motor assembly harness connector

and the sunroof switch harness connector to the vehicle

wiring harness connector.

3. Operate the sunroof switch to slide the roof lid glass

to the fully-open position, and then tilt it up in steps of

30 mm to the fully-open position and then keep pressing

the switch for 3 seconds or more.

4. Operate the sunroof switch (CLOSE) using the one-touch

function to slide the roof lid glass to the fully-closed

position.

5. Operate the sunroof switch (OPEN) using the one-touch

function to slide the roof lid glass to the fully-open position.

6. Operate the sunroof switch (CLOSE) using the one-touch

function to slide the roof lid glass to the fully-closed

position.

7. Press the tilt - up switch to operate the sunroof and check

that learning is complete.

NOTE

(1) During initialisation (learning mode), use only the

CLOSE/DOWN switch to move the roof lid glass from

the fully-closed position to the fully tilted open position.

During initialisation, the TILT UP switch will not work

when pressed. Furthermore, the sunroof-ECU will stop

running in learning mode as soon as the roof lid glass

is tilted up.

(2) When the clamping prevention mechanism is

cancelled, the operation is the same as when the

roof lid glass operates 30 mm at a time.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk