MITSUBISHI MONTERO 2000 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 251 of 1839

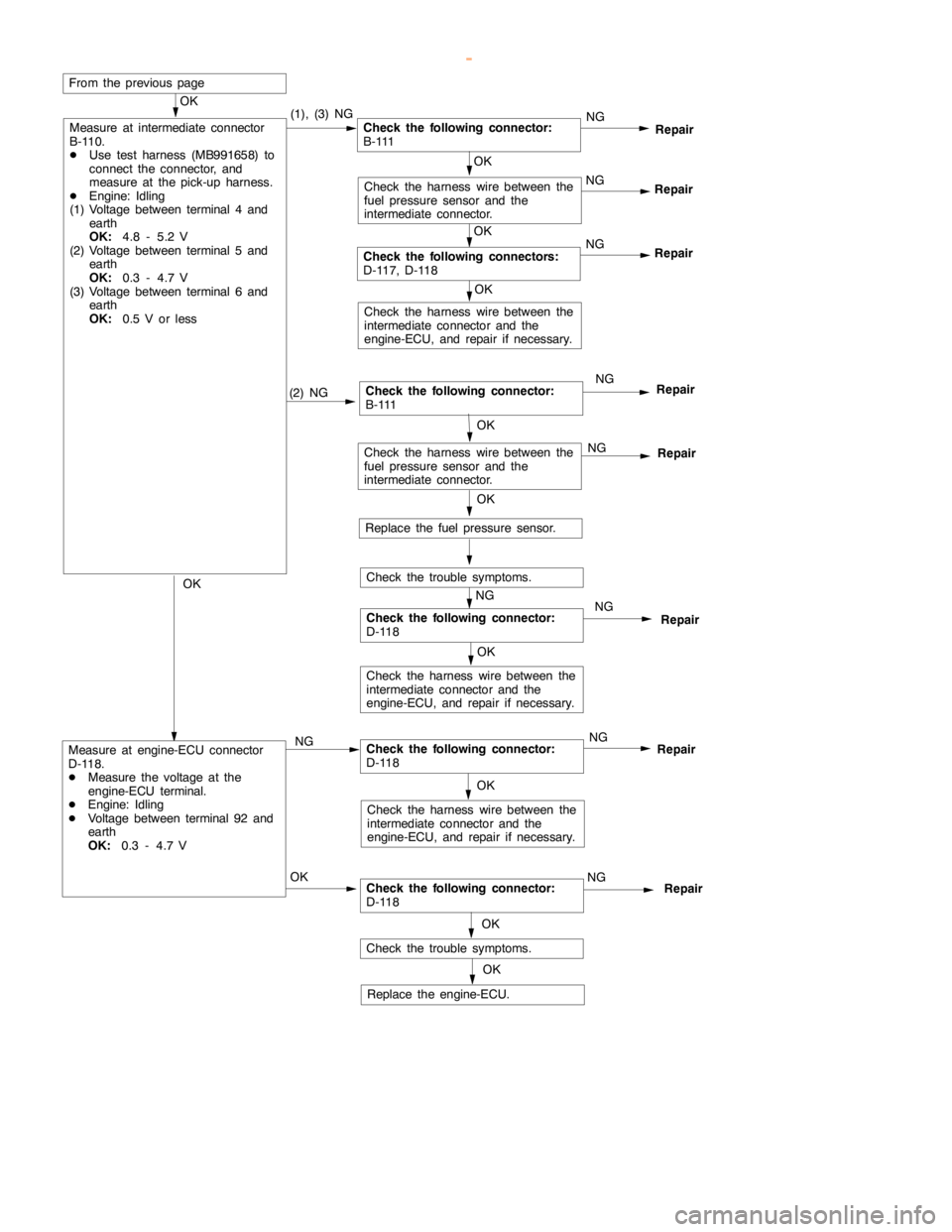

GDI -Troubleshooting

NG

(2) NGCheck the following connector:

B - 111NG

Repair

OK

Measure at intermediate connector

B-110.

DUse test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

DEngine: Idling

(1) Voltage between terminal 4 and

earth

OK:

4.8 - 5.2 V

(2) Voltage between terminal 5 and

earth

OK:

0.3 - 4.7 V

(3) Voltage between terminal 6 and

earth

OK:

0.5 V or less(1), (3) NGCheck the following connector:

B - 111

OK

Check the following connectors:

D-117, D-118NG

Repair

OK

Check the harness wire between the

fuel pressure sensor and the

intermediate connector.NG

Repair

From the previouspage

OK

Check the harness wire between the

intermediate connector and the

engine-ECU, and repair if necessary.

OK

Check the harness wire between the

fuel pressure sensor and the

intermediate connector.NG

Repair

OK

Replace the fuel pressure sensor.

Check the trouble symptoms.

Check the following connector:

D-118NG

Repair

NG

Check the harness wire between the

intermediate connector and the

engine-ECU, and repair if necessary.

OK

Measure at engine-ECU connector

D-118.

DMeasure the voltage at the

engine-ECU terminal.

DEngine: Idling

DVoltage between terminal 92 and

earth

OK:

0.3 - 4.7 VNGCheck the following connector:

D-118NG

Repair

OK

Check the harness wire between the

intermediate connector and the

engine-ECU, and repair if necessary.

OKCheck the following connector:

D-118NG

Repair

OK

Check the trouble symptoms.

OK

Replace the engine-ECU.OKRepair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 252 of 1839

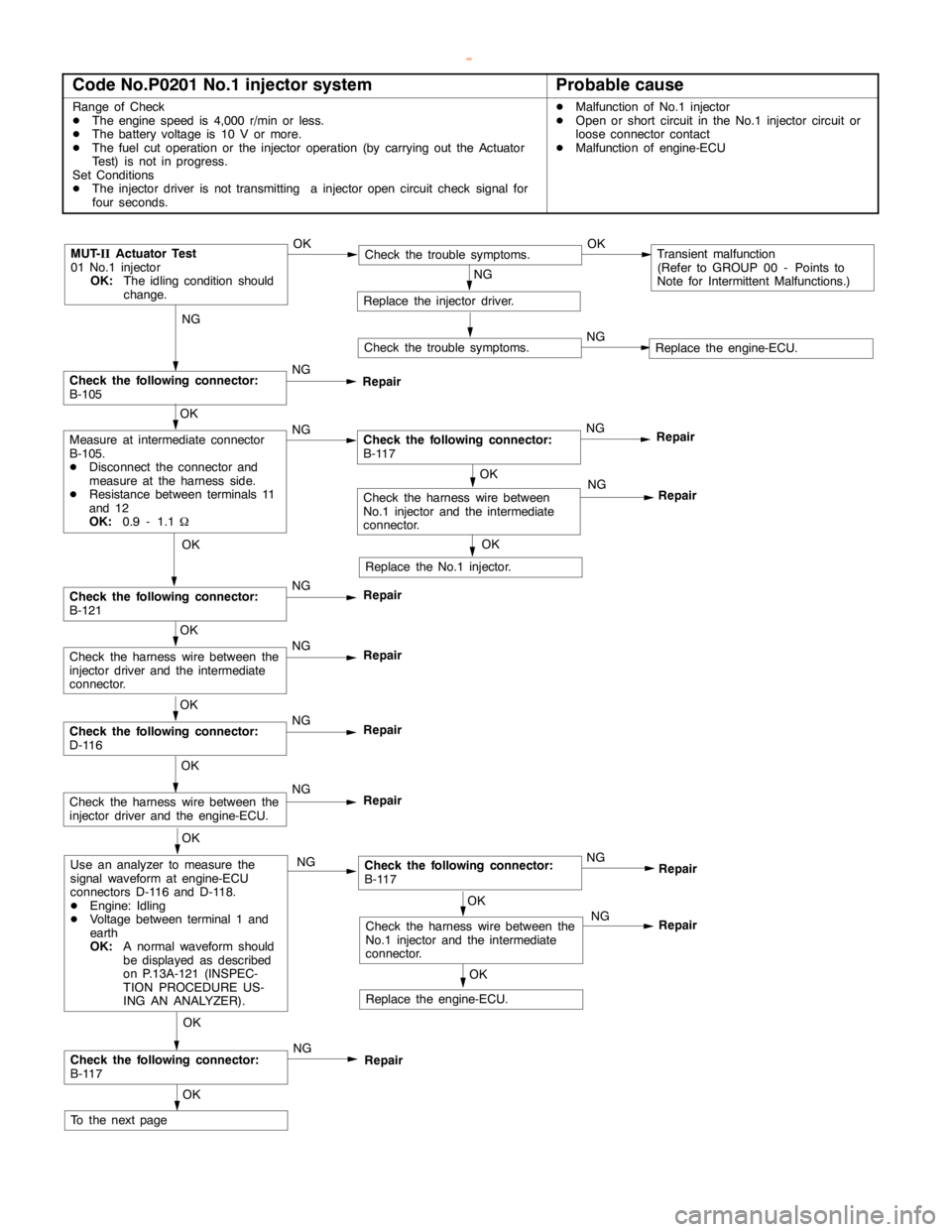

GDI -Troubleshooting

Code No.P0201 No.1 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.1 injector

DOpen or short circuit in the No.1 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

01 No.1 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 11

and 12

OK:

0.9 - 1.1WNGCheck the following connector:

B-117NG

Repair

OK

Replace the No.1 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 1 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-117

OK

Check the following connector:

B-117NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.1 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.1 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 253 of 1839

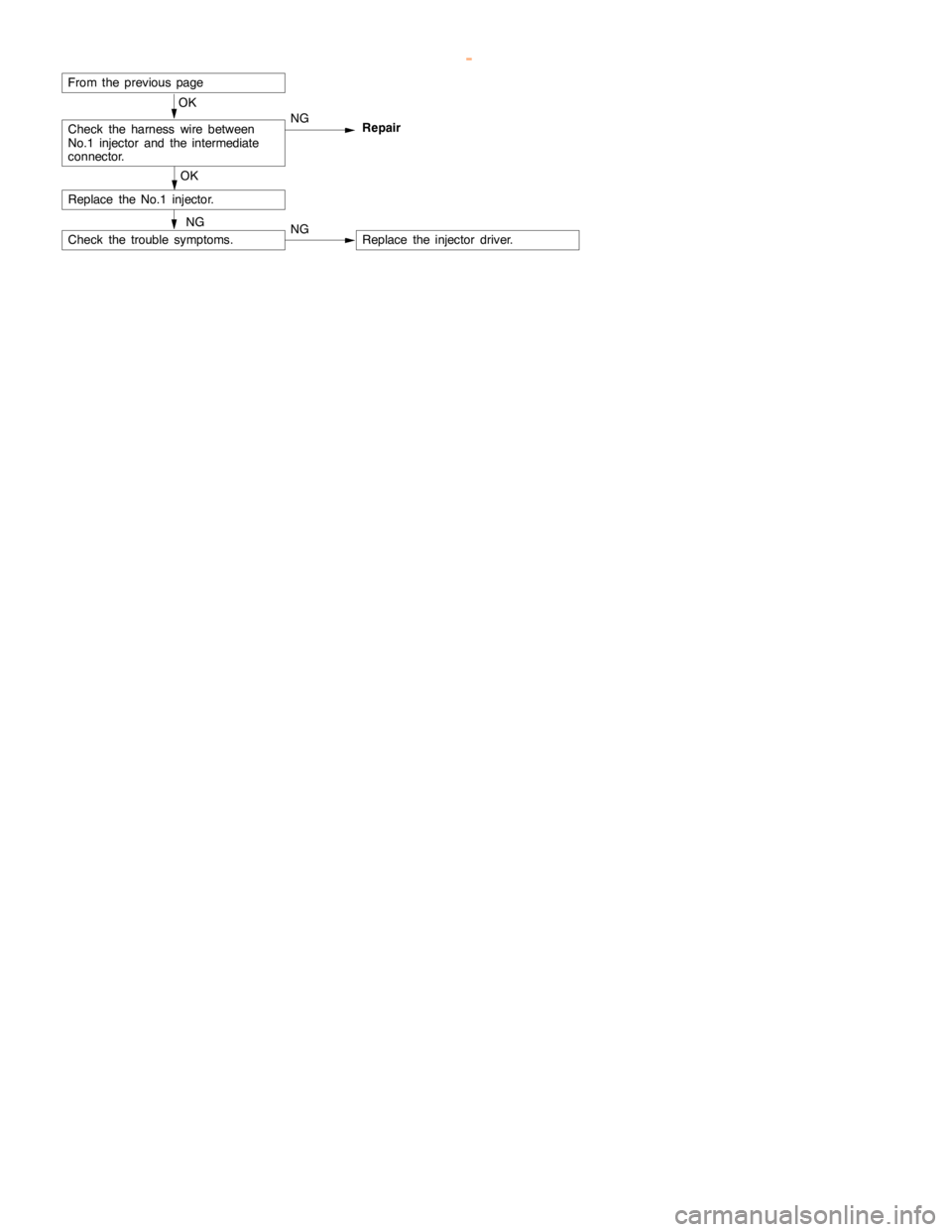

GDI -Troubleshooting

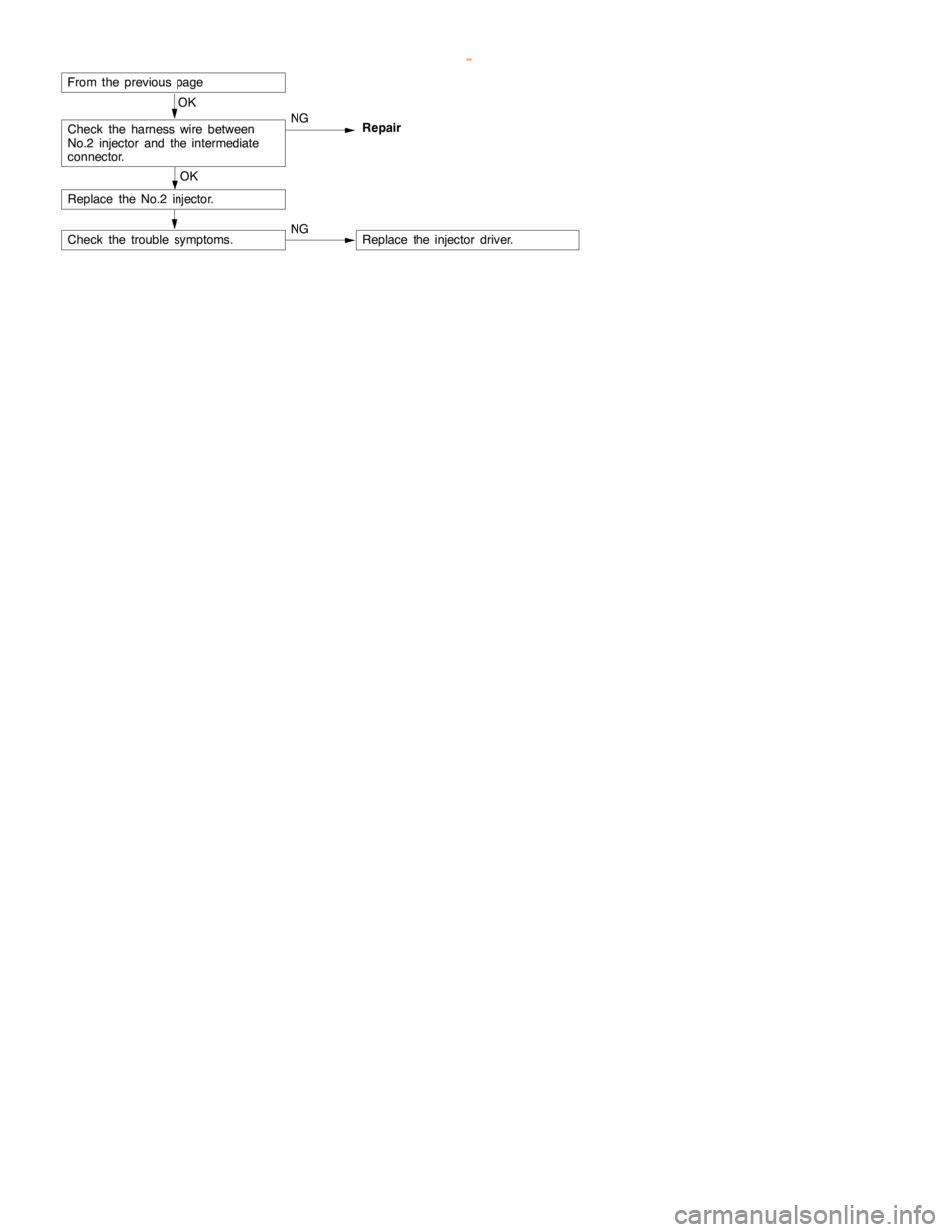

OK

Check the harness wire between

No.1 injector and the intermediate

connector.NG

Repair

From the previouspage

OK

Check the trouble symptoms.NGReplace the injector driver.

Replace the No.1 injector.

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 254 of 1839

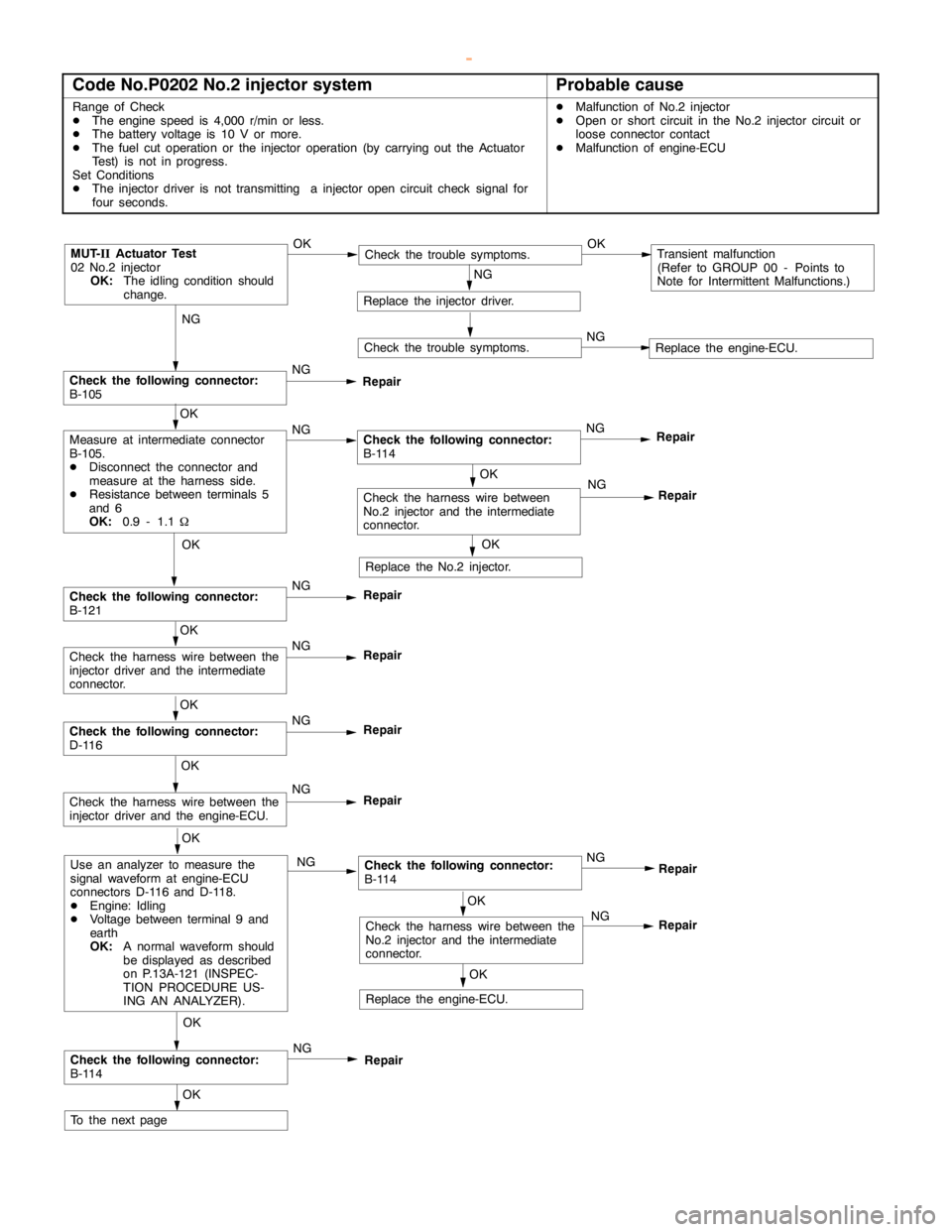

GDI -Troubleshooting

Code No.P0202 No.2 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.2 injector

DOpen or short circuit in the No.2 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

02 No.2 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 5

and 6

OK:

0.9 - 1.1WNGCheck the following connector:

B-114NG

Repair

OK

Replace the No.2 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 9 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-114

OK

Check the following connector:

B-114NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.2 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.2 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 255 of 1839

GDI -Troubleshooting

OK

Check the harness wire between

No.2 injector and the intermediate

connector.NG

Repair

From the previouspage

OK

Check the trouble symptoms.NGReplace the injector driver.

Replace the No.2 injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 256 of 1839

GDI -Troubleshooting

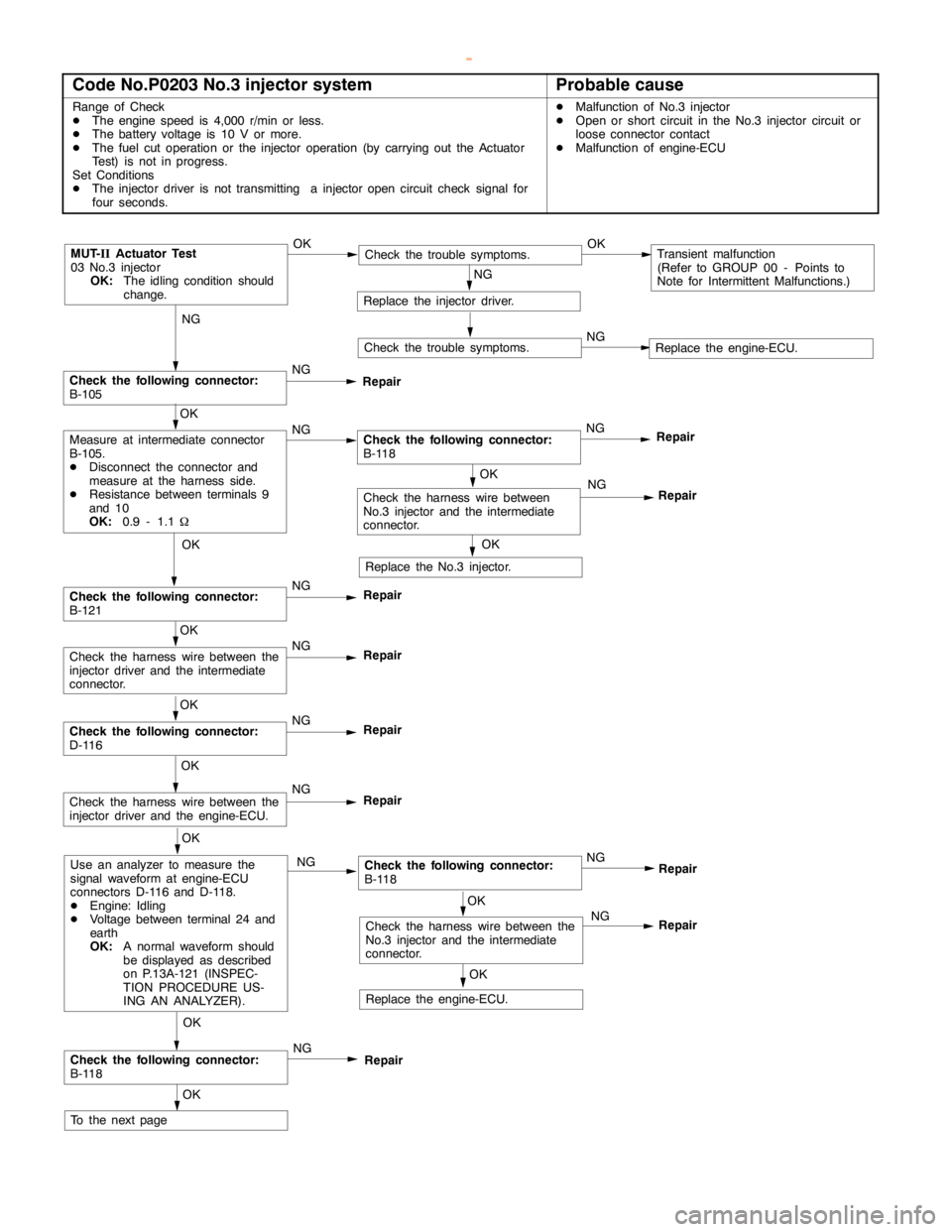

Code No.P0203 No.3 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.3 injector

DOpen or short circuit in the No.3 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

03 No.3 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 9

and 10

OK:

0.9 - 1.1WNGCheck the following connector:

B-118NG

Repair

OK

Replace the No.3 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 24 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-118

OK

Check the following connector:

B-118NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.3 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.3 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 257 of 1839

GDI -Troubleshooting

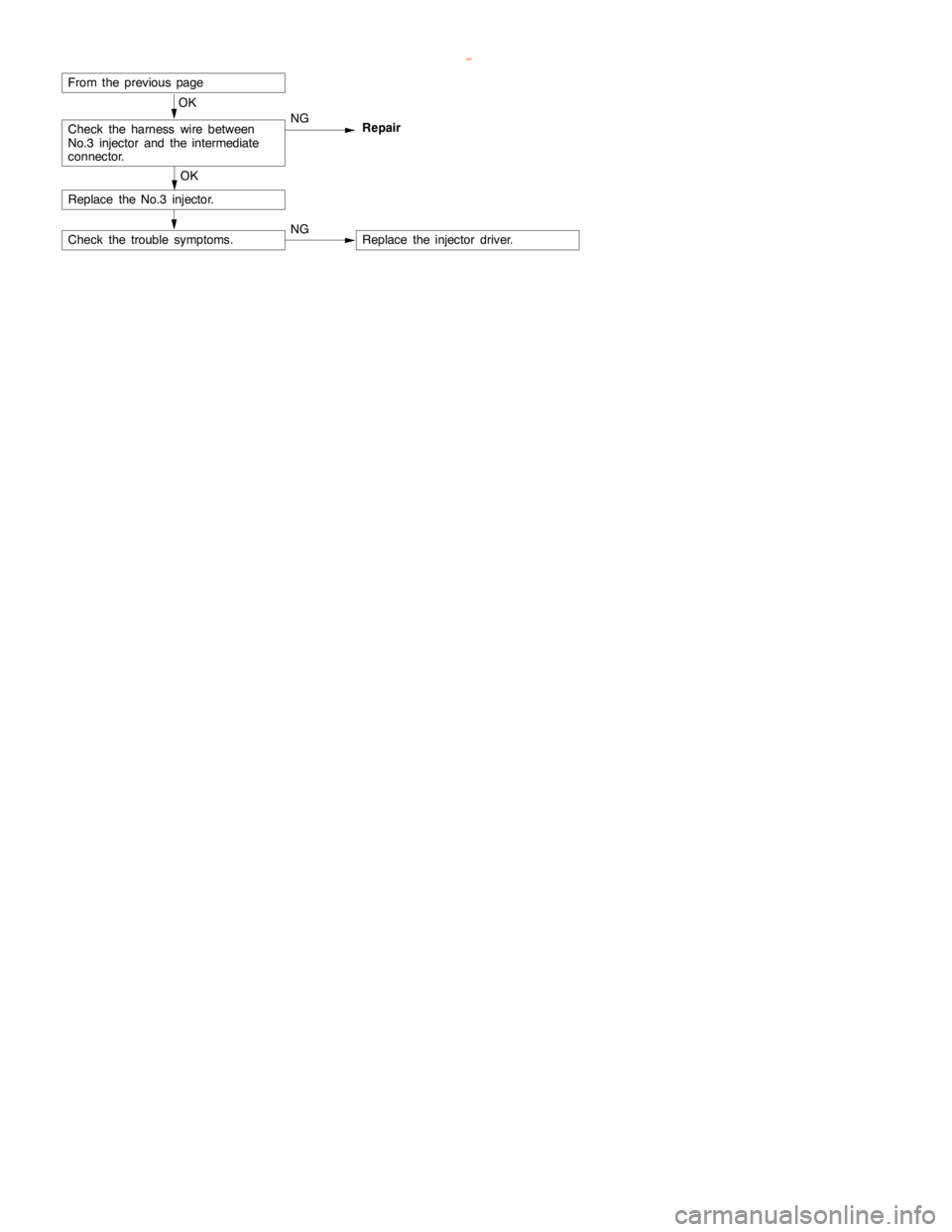

OK

Check the harness wire between

No.3 injector and the intermediate

connector.NG

Repair

From the previouspage

OK

Check the trouble symptoms.NGReplace the injector driver.

Replace the No.3 injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 258 of 1839

GDI -Troubleshooting

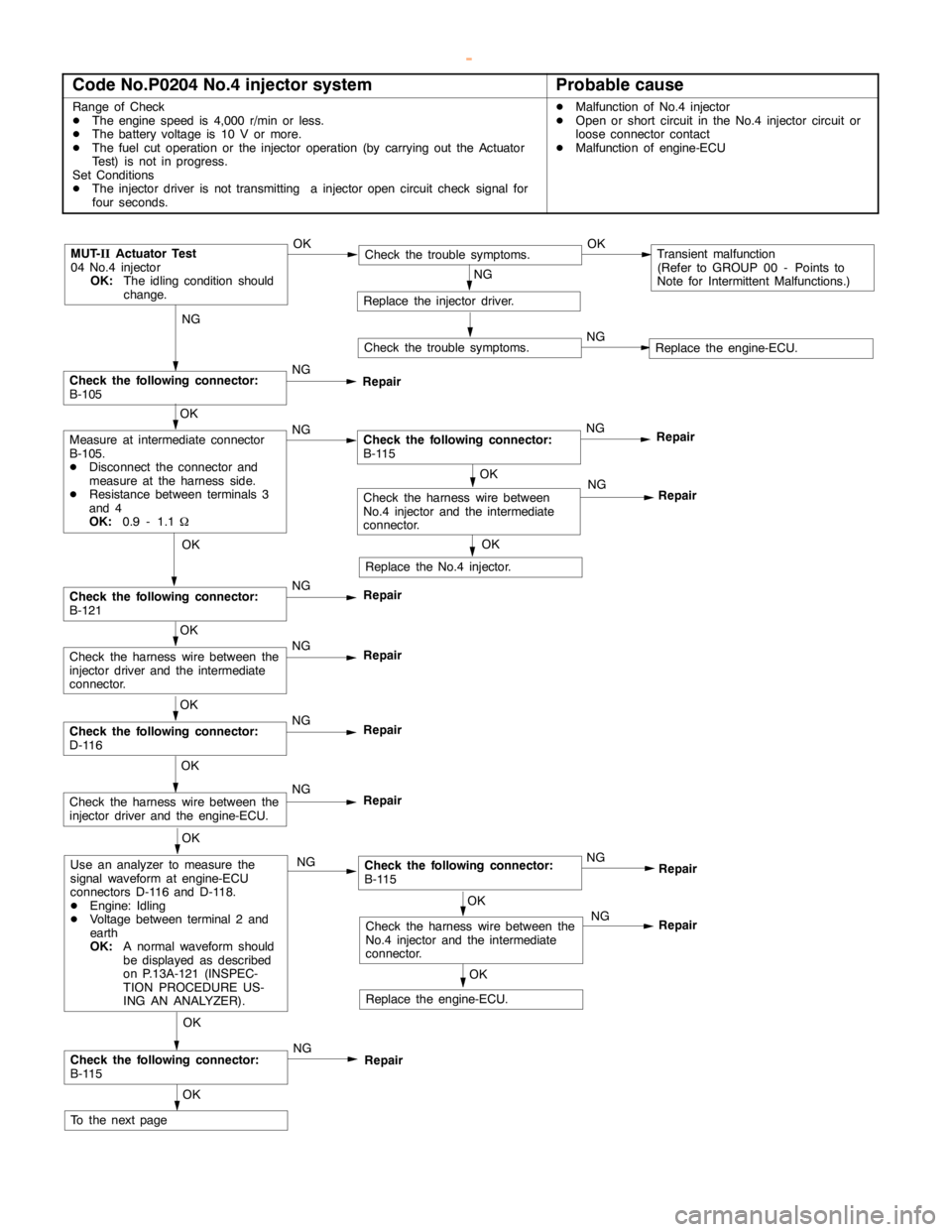

Code No.P0204 No.4 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.4 injector

DOpen or short circuit in the No.4 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

04 No.4 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 3

and 4

OK:

0.9 - 1.1WNGCheck the following connector:

B-115NG

Repair

OK

Replace the No.4 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 2 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-115

OK

Check the following connector:

B-115NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.4 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.4 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

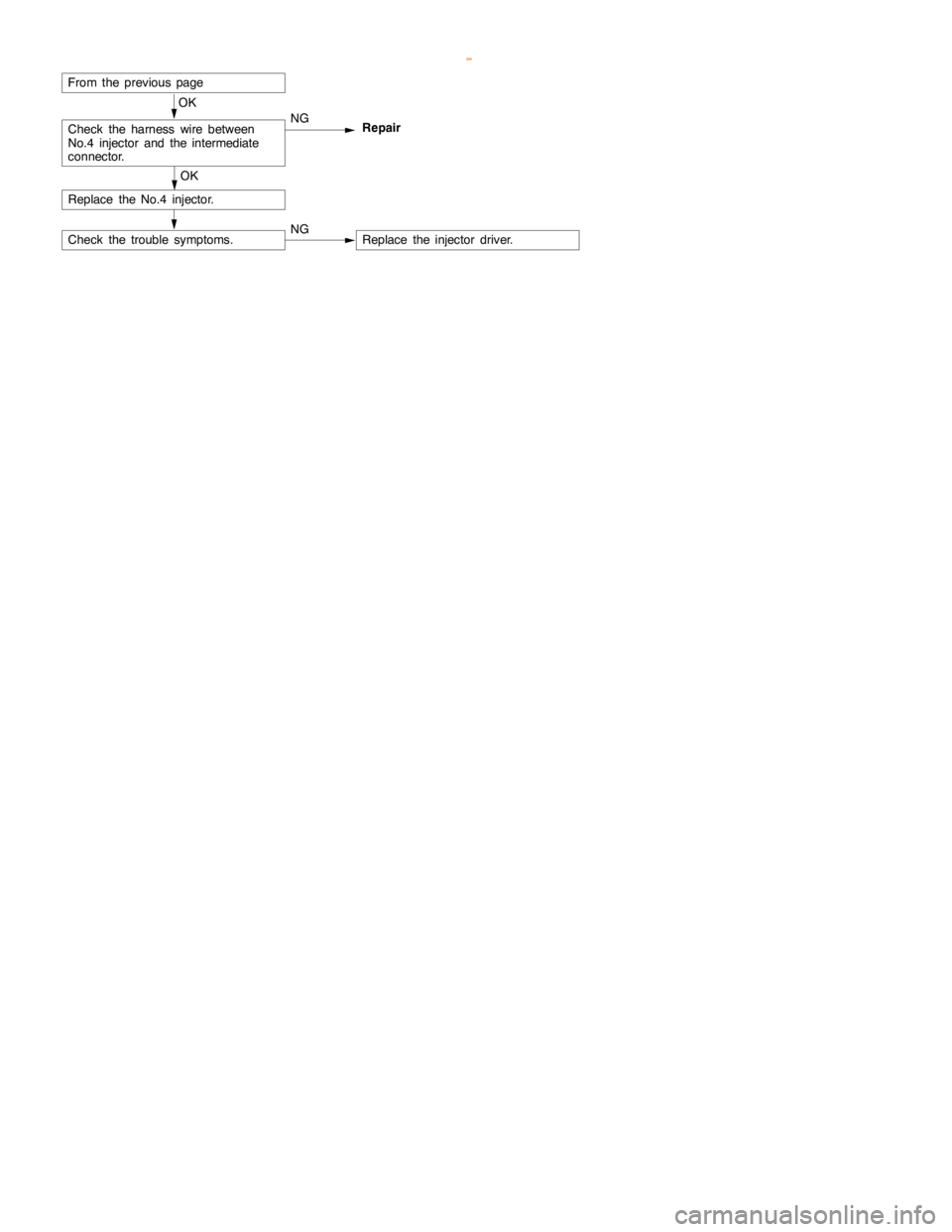

Page 259 of 1839

GDI -Troubleshooting

OK

Check the harness wire between

No.4 injector and the intermediate

connector.NG

Repair

From the previouspage

OK

Check the trouble symptoms.NGReplace the injector driver.

Replace the No.4 injector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 260 of 1839

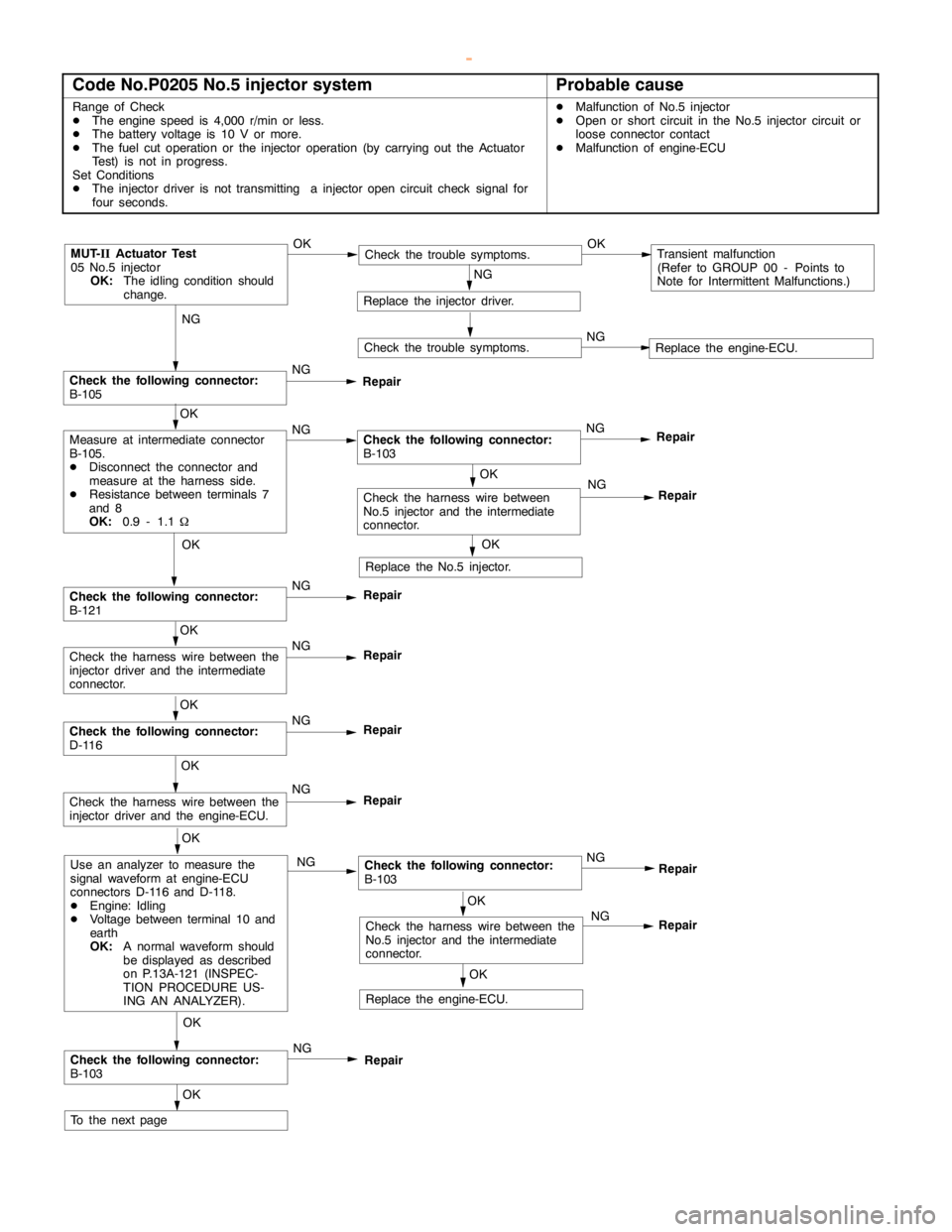

GDI -Troubleshooting

Code No.P0205 No.5 injector systemProbable cause

Range of Check

DThe enginespeed is 4,000 r/min or less.

DThe battery voltage is 10 V or more.

DThe fuel cut operation or the injector operation (by carrying out the Actuator

Test) is not in progress.

Set Conditions

DThe injector driver is not transmitting a injectoropencircuit check signal for

four seconds.DMalfunction of No.5 injector

DOpen or short circuit in the No.5 injector circuit or

loose connector contact

DMalfunction of engine-ECU

NG

Check the following connector:

B-105NG

Repair

OK

NG

Repair

MUT-

IIActuator Test

05 No.5 injector

OK:

The idling condition should

change.OKCheck the trouble symptoms.OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Replace the injector driver.

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at intermediate connector

B-105.

DDisconnect the connector and

measure at the harness side.

DResistance between terminals 7

and 8

OK:

0.9 - 1.1WNGCheck the following connector:

B-103NG

Repair

OK

Replace the No.5 injector.

OK

Check the following connector:

B-121NG

Repair

OK

Check the harness wire between the

injector driver and the intermediate

connector.NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

Check the harness wire between the

injector driver and the engine-ECU.NG

Repair

OK

Use an analyzer to measure the

signal waveform at engine-ECU

connectors D-116 and D-118.

DEngine: Idling

DVoltage between terminal 10 and

earth

OK:

A normal waveform should

be displayed as described

on P.13A-121 (INSPEC-

TION PROCEDURE US-

ING AN ANALYZER).NGCheck the following connector:

B-103

OK

Check the following connector:

B-103NG

Repair

OK

To the nextpageNG

OK

OK

Check the harness wire between the

No.5 injector and the intermediate

connector.NG

Replace the engine-ECU.

Repair

Repair

Check the harness wire between

No.5 injector and the intermediate

connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk