timing belt MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 56 of 1839

11A-2

ENGINE <6G7>

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

SEALANT 4..................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 6.....................

Drive Belt Tension Check and Adjustment 6......

Auto-tensioner Check 6.........................

Ignition Timing Check 6........................

Idle Speed Check 7............................

Idle Mixture Check 8...........................Compression Pressure Check 9.................

Intake Manifold Vacuum Check 10...............

Lash Adjuster Check 10........................

OIL PAN AND OIL SCREEN 13..............

TIMING BELT 15............................

CRANKSHAFT OIL SEAL 23.................

CAMSHAFT OIL SEAL 25...................

CYLINDER HEAD GASKET 27...............

ENGINE ASSEMBLY 30.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 57 of 1839

ENGINE <6G7> -General Information/Service Specifications11A-3

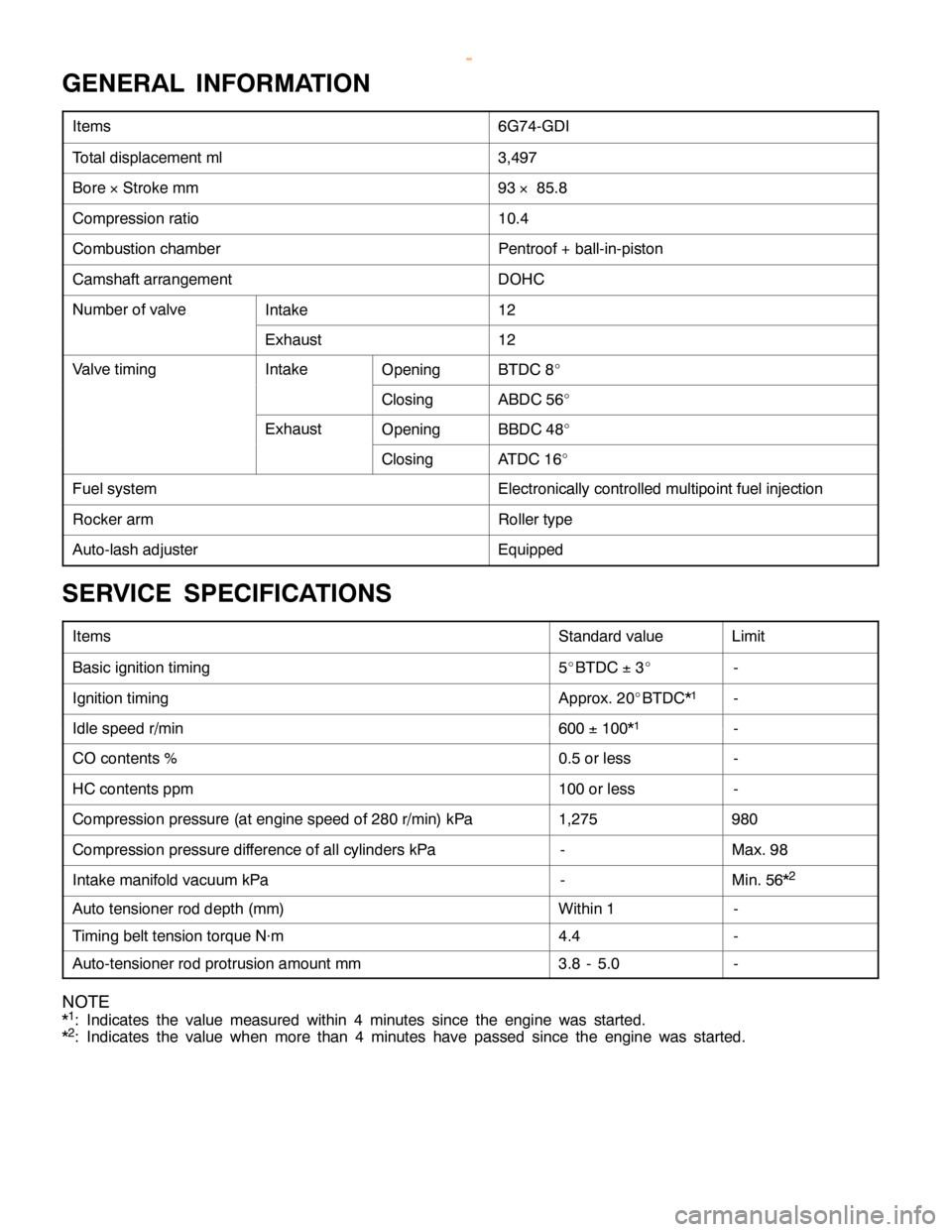

GENERAL INFORMATION

Items6G74-GDI

Total displacement ml3,497

Bore´Stroke mm93´85.8

Compression ratio10.4

Combustion chamberPentroof + ball-in-piston

Camshaft arrangementDOHC

Number of valveIntake12

Exhaust12

Valve timingIntakeOpeningBTDC 8_

ClosingABDC 56_

ExhaustOpeningBBDC 48_

ClosingATDC 16_

Fuel systemElectronically controlled multipoint fuel injection

Rocker armRoller type

Auto-lash adjusterEquipped

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Basic ignition timing5_BTDC±3_-

Ignition timingApprox. 20_BTDC*1-

Idle speed r/min600±100*1-

CO contents %0.5 or less-

HC contents ppm100 or less-

Compression pressure (at engine speed of 280 r/min) kPa1,275980

Compression pressure difference of all cylinders kPa-Max. 98

Intake manifold vacuum kPa-Min. 56*2

Auto tensioner rod depth (mm)Within 1-

Timing belt tension torque N×m4.4-

Auto-tensioner rod protrusion amount mm3.8 - 5.0-

NOTE

*1: Indicates the value measured within 4 minutes since the engine was started.

*2: Indicates the value when more than 4 minutes have passed since the engine was started.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 88 of 1839

11B-1

ENGINE <4D5>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANTS 3................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 5.....................

Drive Belt Tension Check and Adjustment 5......

Auto-tensioner check 7.........................

Valve Clearance Check and Adjustment 8........

Injection Timing Check and Adjustment 9........

Idle Speed Check and Adjustment 12............

Idle-up Mechanism Check and

Adjustment-For A/C 12.........................Compression Pressure Check 13................

Timing Belt Tension Adjustment 14..............

Timing Belt B Tension Adjustment 15............

OIL PAN AND OIL SCREEN 17..............

TIMING BELT AND TIMING BELT B 19......

CRANKSHAFT OIL SEAL 25.................

CAMSHAFT AND CAMSHAFT OIL SEAL 27..

CYLINDER HEAD GASKET 30...............

ENGINE ASSEMBLY 34.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 90 of 1839

ENGINE <4D5> -Service Specifications/Sealants11B-3

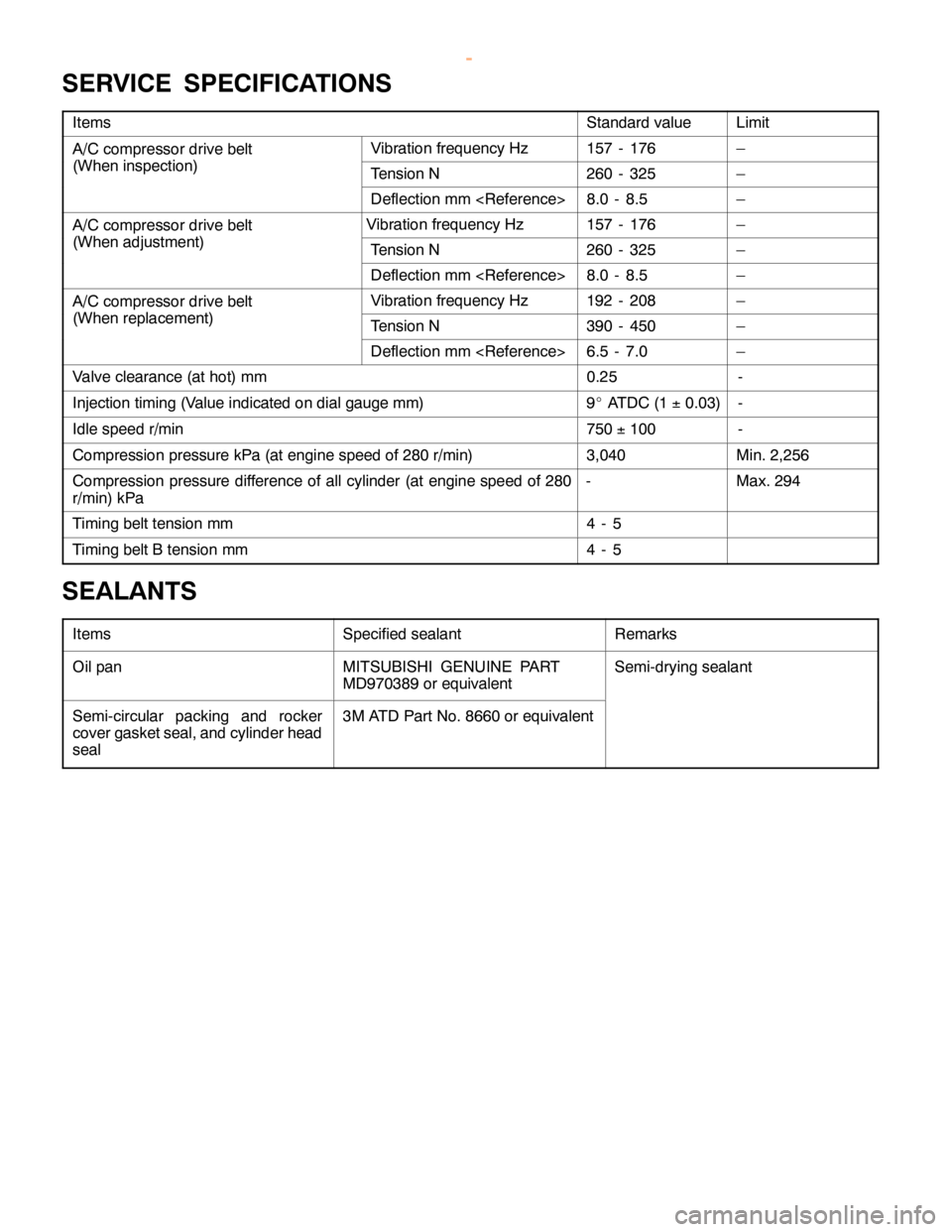

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

A/C compressor drive beltVibration frequency Hz157 - 176–

(When inspection)Tension N260 - 325–

Deflection mm

A/C compressor drive beltVibration frequency Hz157 - 176–

(When adjustment)Tension N260 - 325–

Deflection mm

A/C compressor drive beltVibration frequency Hz192 - 208–

(When replacement)Tension N390 - 450–

Deflection mm

Valve clearance (at hot) mm0.25-

Injection timing (Value indicated on dial gauge mm)9_ATDC (1±0.03)-

Idle speed r/min750±100-

Compression pressure kPa (at engine speed of 280 r/min)3,040Min. 2,256

Compression pressure difference of all cylinder (at engine speed of 280

r/min) kPa-Max. 294

Timing belt tension mm4-5

Timing belt B tension mm4-5

SEALANTS

ItemsSpecified sealantRemarks

Oil panMITSUBISHI GENUINE PART

MD970389 or equivalentSemi-drying sealant

Semi-circular packing and rocker

cover gasket seal, and cylinder head

seal3M ATD Part No. 8660 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 124 of 1839

11B-1

ENGINE <4D5>

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANT 2..................................

SPECIAL TOOLS 3...........................ON-VEHICLE SERVICE 4.....................

Injection Timing Check and Adjustment 4.........

Idle Speed Check 4............................

OIL PAN AND OIL SCREEN 5................

TIMING BELT AND TIMING BELT B 7........

CYLINDER HEAD GASKET 13................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 125 of 1839

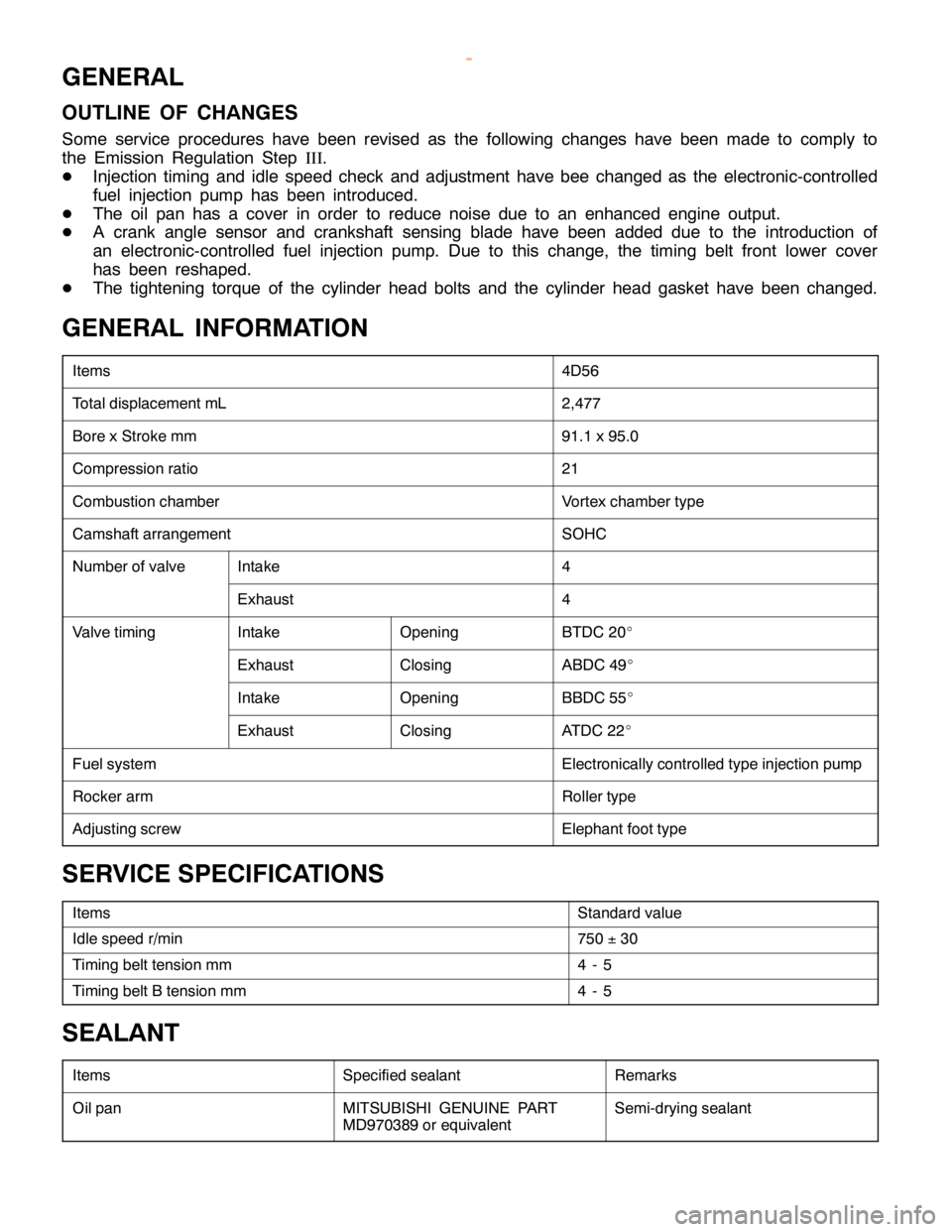

ENGINE <4D5> -General/General Information/Service Specifications/Sealant11B-2

GENERAL

OUTLINE OF CHANGES

Some service procedures have been revised as the following changes have been made to comply to

the Emission Regulation StepIII.

DInjection timing and idle speed check and adjustment have bee changed as the electronic-controlled

fuel injection pump has been introduced.

DThe oil pan has a cover in order to reduce noise due to an enhanced engine output.

DA crank angle sensor and crankshaft sensing blade have been added due to the introduction of

an electronic-controlled fuel injection pump. Due to this change, the timing belt front lower cover

has been reshaped.

DThe tightening torque of the cylinder head bolts and the cylinder head gasket have been changed.

GENERAL INFORMATION

Items4D56

Total displacement mL2,477

Bore x Stroke mm91.1 x 95.0

Compression ratio21

Combustion chamberVortex chamber type

Camshaft arrangementSOHC

Number of valveIntake4

Exhaust4

Valve timingIntakeOpeningBTDC 20_

ExhaustClosingABDC 49_

IntakeOpeningBBDC 55_

ExhaustClosingATDC 22_

Fuel systemElectronically controlled type injection pump

Rocker armRoller type

Adjusting screwElephant foot type

SERVICE SPECIFICATIONS

ItemsStandard value

Idle speed r/min750±30

Timing belt tension mm4-5

Timing belt B tension mm4-5

SEALANT

ItemsSpecified sealantRemarks

Oil panMITSUBISHI GENUINE PART

MD970389 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 142 of 1839

11C-1

ENGINE <4M4>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANTS AND ADHESIVES 3..............

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 5.....................

Drive Belt Tension Check and Adjustment 5......

Valve Clearance Check and Adjustment 8........

Injection Timing Check and Adjustment 9........

Idle Speed Check 12...........................Compression Pressure Check 12................

OIL PAN 14.................................

VACUUM PUMP 16..........................

TIMING CHAIN 17...........................

CRANKSHAFT OIL SEAL 21.................

CAMSHAFT 23..............................

CYLINDER HEAD GASKET 27...............

ENGINE ASSEMBLY 33.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 143 of 1839

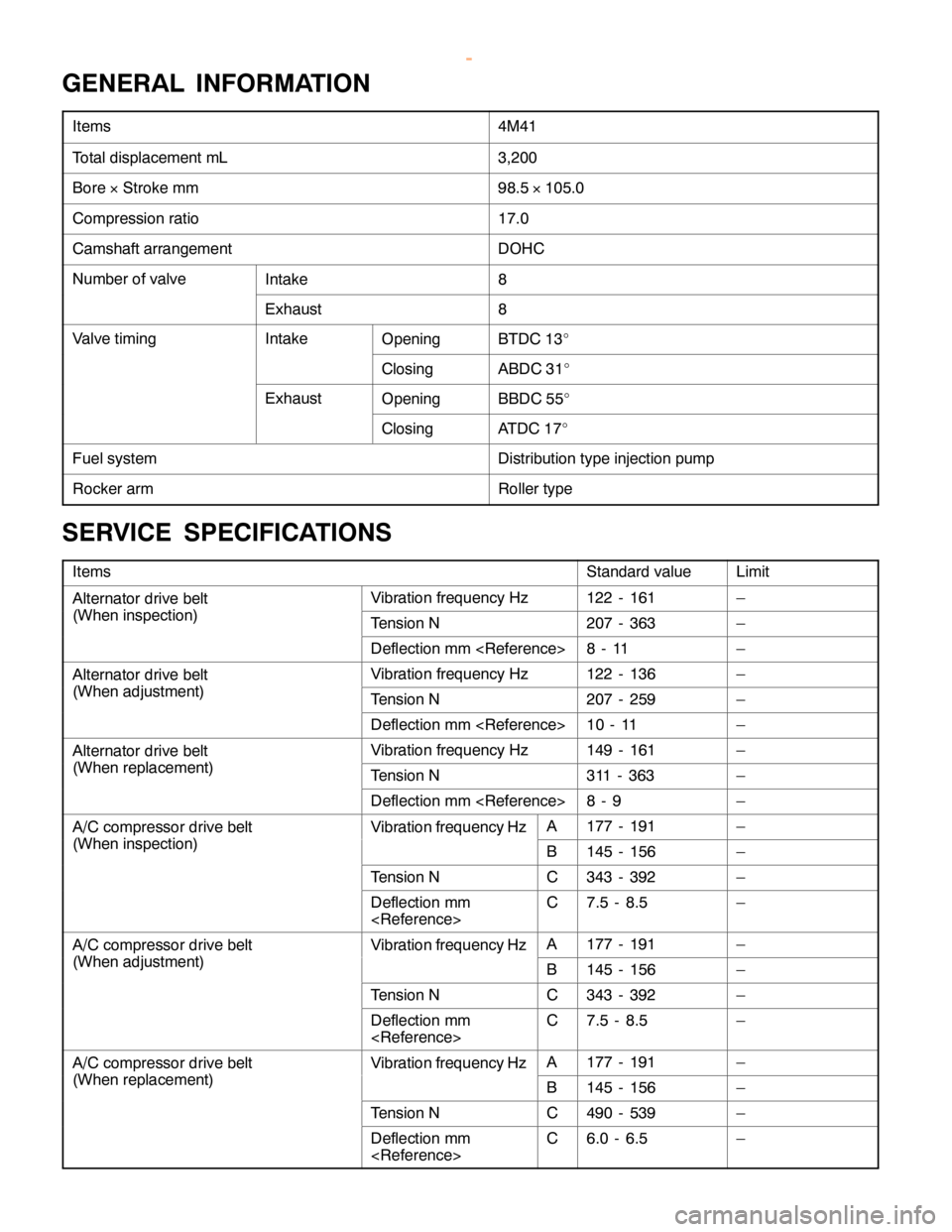

ENGINE <4M4> -General Information/Service Specifications11C-2

GENERAL INFORMATION

Items4M41

Total displacement mL3,200

Bore´Stroke mm98.5´105.0

Compression ratio17.0

Camshaft arrangementDOHC

Number of valveIntake8

Exhaust8

Valve timingIntakeOpeningBTDC 13_

ClosingABDC 31_

ExhaustOpeningBBDC 55_

ClosingATDC 17_

Fuel systemDistribution type injection pump

Rocker armRoller type

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Alternator drive beltVibration frequency Hz122 - 161–

(When inspection)Tension N207 - 363–

Deflection mm

Alternator drive beltVibration frequency Hz122 - 136–

(When adjustment)Tension N207 - 259–

Deflection mm

Alternator drive beltVibration frequency Hz149 - 161–

(When replacement)Tension N311 - 363–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When inspection)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When adjustment)B145 - 156–

Tension NC343 - 392–

Deflection mm

A/C compressor drive beltVibration frequency HzA177 - 191–

(When replacement)B145 - 156–

Tension NC490 - 539–

Deflection mm

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

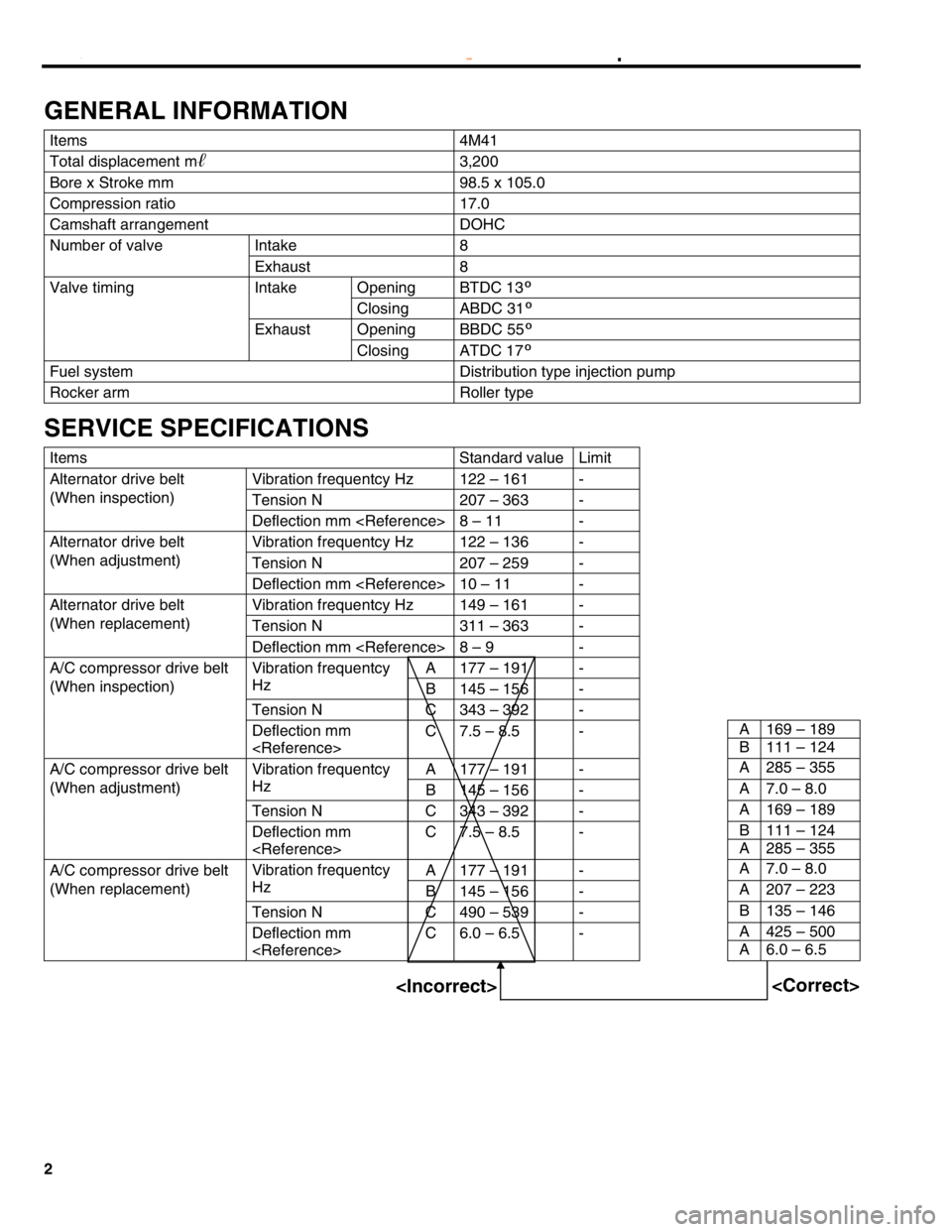

Page 190 of 1839

2

GENERAL INFORMATION

Items 4M41

Total displacement mℓ

3,200

Bore x Stroke mm 98.5 x 105.0

Compression ratio 17.0

Camshaft arrangement DOHC

Intake 8Number of valve

Exhaust 8

Opening BTDC 13ºIntake

Closing ABDC 31º

Opening BBDC 55º

Valve timing

Exhaust

Closing ATDC 17º

Fuel system Distribution type injection pump

Rocker arm Roller type

SERVICE SPECIFICATIONS

Items Standard value Limit

Vibration frequentcy Hz 122 – 161 -

Tension N 207 – 363 -

Alternator drive belt

(When inspection)

Deflection mm

Vibration frequentcy Hz 122 – 136 -

Tension N 207 – 259 -

Alternator drive belt

(When adjustment)

Deflection mm

Vibration frequentcy Hz 149 – 161 -

Tension N 311 – 363 -

Alternator drive belt

(When replacement)

Deflection mm

A 177 – 191 -Vibration frequentcy

Hz

B 145 – 156 -

Tension N C 343 – 392 -

A 169 – 189

A/C compressor drive belt

(When inspection)

Deflection mm

B 111 – 124

A 177 – 191 -A 285 – 355Vibration frequentcy

Hz

B 145 – 156 -A 7.0 – 8.0

Tension N C 343 – 392 -A 169 – 189

B 111 – 124

A/C compressor drive belt

(When adjustment)

Deflection mm

A 285 – 355

A 177 – 191 -A 7.0 – 8.0Vibration frequentcy

Hz

B 145 – 156 -A 207 – 223

Tension N C 490 – 539 -B 135 – 146

A 425 – 500

A/C compressor drive belt

(When replacement)

Deflection mm

A 6.0 – 6.5

11C-2ENGINE <4M4> - General Information/Service Specifications

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 291 of 1839

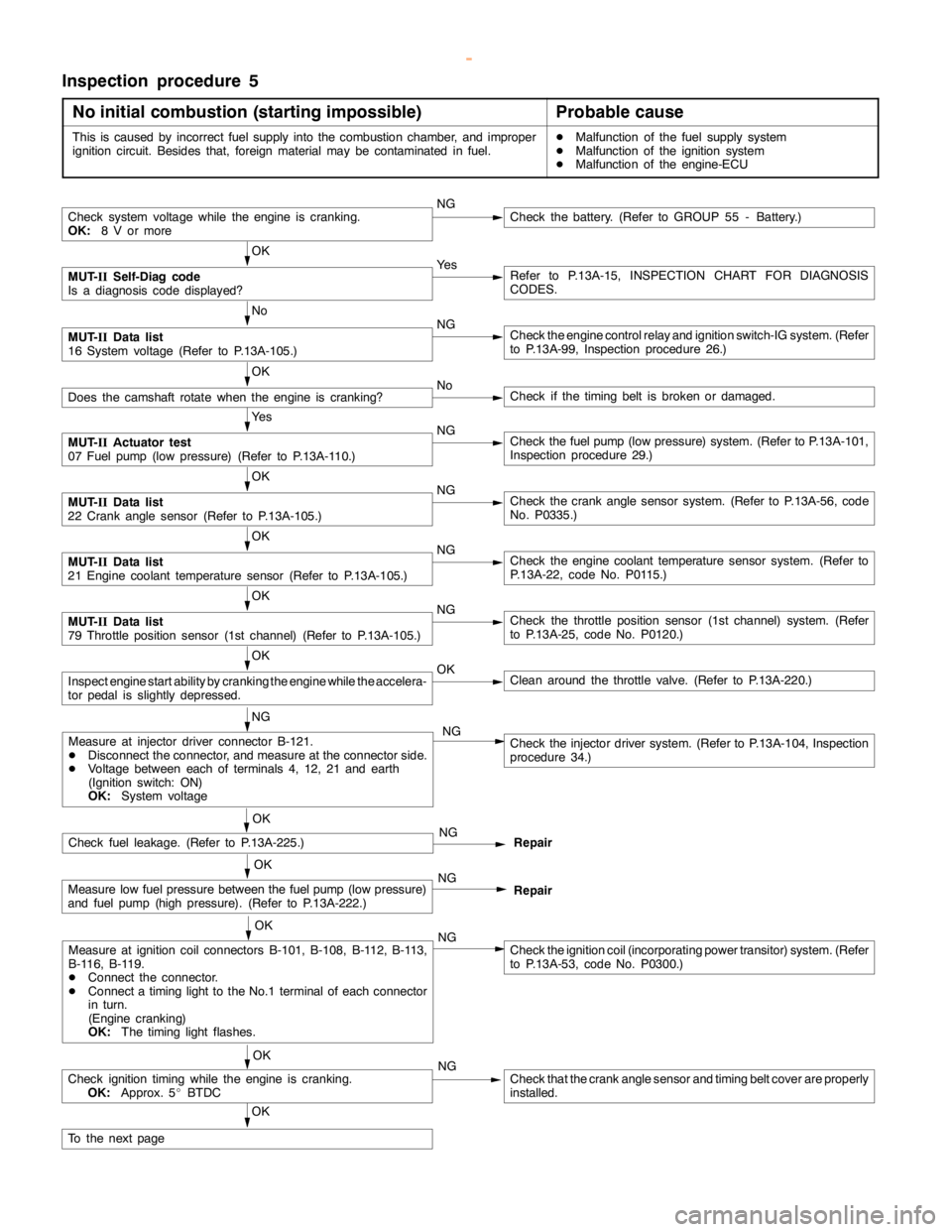

GDI -Troubleshooting

Inspection procedure 5

No initial combustion (starting impossible)

Probable cause

This is caused by incorrect fuel supply into the combustion chamber, and improper

ignition circuit. Besides that, foreign material may be contaminated in fuel.DMalfunction of the fuel supply system

DMalfunction of the ignition system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

16 System voltage (Refer to P.13A-105.)NGCheck theengine controlrelay and ignition switch-IG system. (Refer

to P.13A-99, Inspection procedure 26.)

OK

Does the camshaft rotate when theengine is cranking?NoCheck if thetiming belt isbroken ordamaged.

Ye s

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)NGCheck the crankanglesensor system. (Refer to P.13A-56, code

No. P0335.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor system. (Refer to

P.13A-22, code No. P0115.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle position sensor (1st channel) system. (Refer

to P.13A-25, code No. P0120.)

OK

Inspectenginestart ability by cranking theengine while theaccelera-

tor pedal isslightly depressed.OKClean around the throttle valve. (Refer to P.13A-220.)

NG

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Measure low fuel pressure between the fuelpump(low pressure)

and fuel pump (highpressure). (Refer to P.13A-222.)NG

Repair

OK

Measure at ignition coil connectors B-101, B-108, B-112, B-113,

B-116, B-119.

DConnect the connector.

DConnect atiming light to theNo.1 terminal of each connector

in turn.

(Engine cranking)

OK:

The timing lightflashes.NGCheck the ignition coil (incorporating power transitor) system. (Refer

to P.13A-53, code No. P0300.)

OK

Check ignitiontiming while the engine iscranking.

OK:

Approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpage

Measure at injector driver connector B-121.

DDisconnect the connector, and measure at the connector side.

DVoltage between each of terminals 4, 12, 21 and earth

(Ignition switch: ON)

OK:

System voltageCheck the injector driver system. (Refer to P.13A-104, Inspection

procedure 34.) NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk