engine MITSUBISHI MONTERO 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 190 of 1839

2

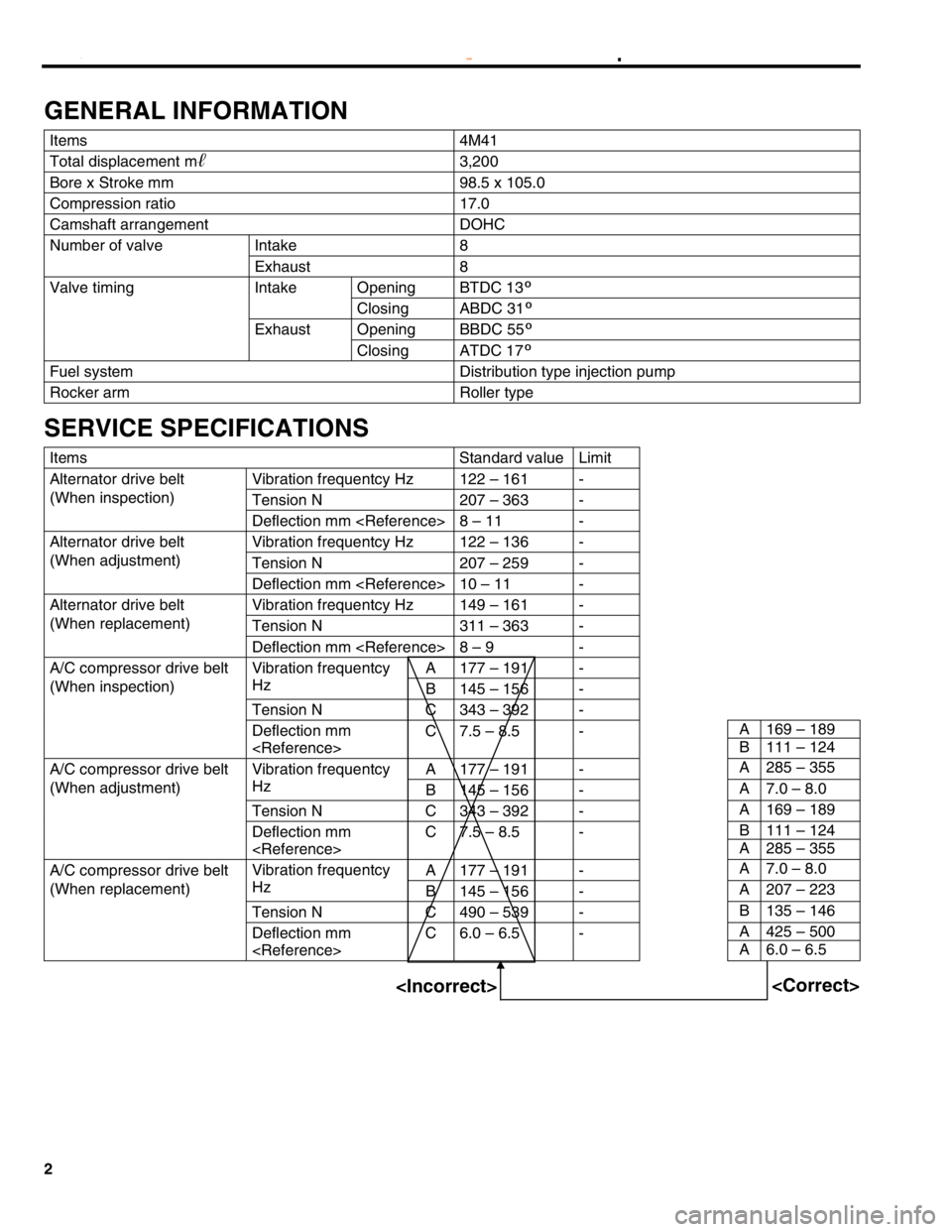

GENERAL INFORMATION

Items 4M41

Total displacement mℓ

3,200

Bore x Stroke mm 98.5 x 105.0

Compression ratio 17.0

Camshaft arrangement DOHC

Intake 8Number of valve

Exhaust 8

Opening BTDC 13ºIntake

Closing ABDC 31º

Opening BBDC 55º

Valve timing

Exhaust

Closing ATDC 17º

Fuel system Distribution type injection pump

Rocker arm Roller type

SERVICE SPECIFICATIONS

Items Standard value Limit

Vibration frequentcy Hz 122 – 161 -

Tension N 207 – 363 -

Alternator drive belt

(When inspection)

Deflection mm

Vibration frequentcy Hz 122 – 136 -

Tension N 207 – 259 -

Alternator drive belt

(When adjustment)

Deflection mm

Vibration frequentcy Hz 149 – 161 -

Tension N 311 – 363 -

Alternator drive belt

(When replacement)

Deflection mm

A 177 – 191 -Vibration frequentcy

Hz

B 145 – 156 -

Tension N C 343 – 392 -

A 169 – 189

A/C compressor drive belt

(When inspection)

Deflection mm

B 111 – 124

A 177 – 191 -A 285 – 355Vibration frequentcy

Hz

B 145 – 156 -A 7.0 – 8.0

Tension N C 343 – 392 -A 169 – 189

B 111 – 124

A/C compressor drive belt

(When adjustment)

Deflection mm

A 285 – 355

A 177 – 191 -A 7.0 – 8.0Vibration frequentcy

Hz

B 145 – 156 -A 207 – 223

Tension N C 490 – 539 -B 135 – 146

A 425 – 500

A/C compressor drive belt

(When replacement)

Deflection mm

A 6.0 – 6.5

11C-2ENGINE <4M4> - General Information/Service Specifications

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 201 of 1839

ENGINE LUBRICATION

Click on the applicable bookmark to selected the required model year.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 202 of 1839

12-1

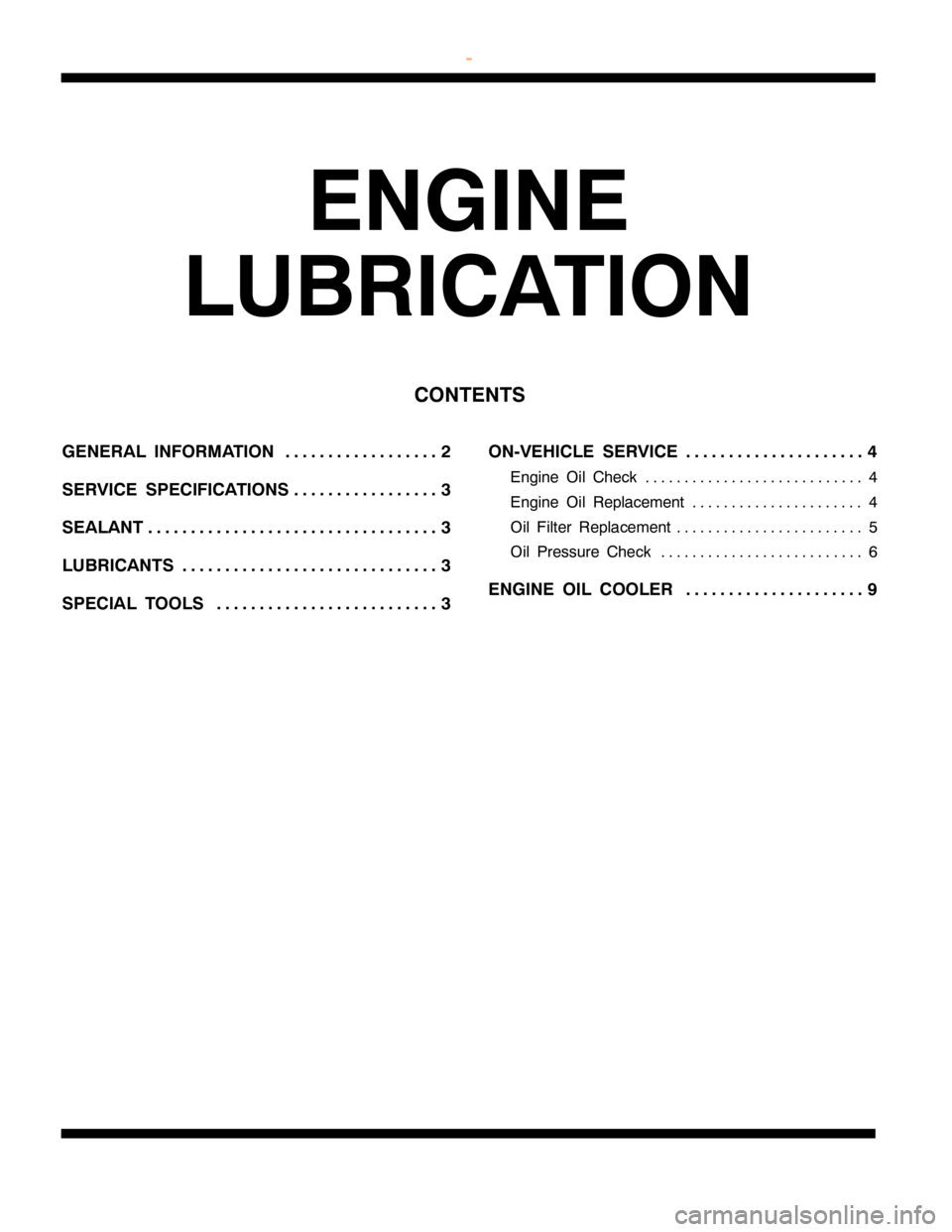

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

LUBRICANTS 3..............................

SPECIAL TOOLS 3..........................ON-VEHICLE SERVICE 4.....................

Engine Oil Check 4............................

Engine Oil Replacement 4......................

Oil Filter Replacement 5........................

Oil Pressure Check 6..........................

ENGINE OIL COOLER 9.....................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 203 of 1839

ENGINE LUBRICATION -General Information12-2

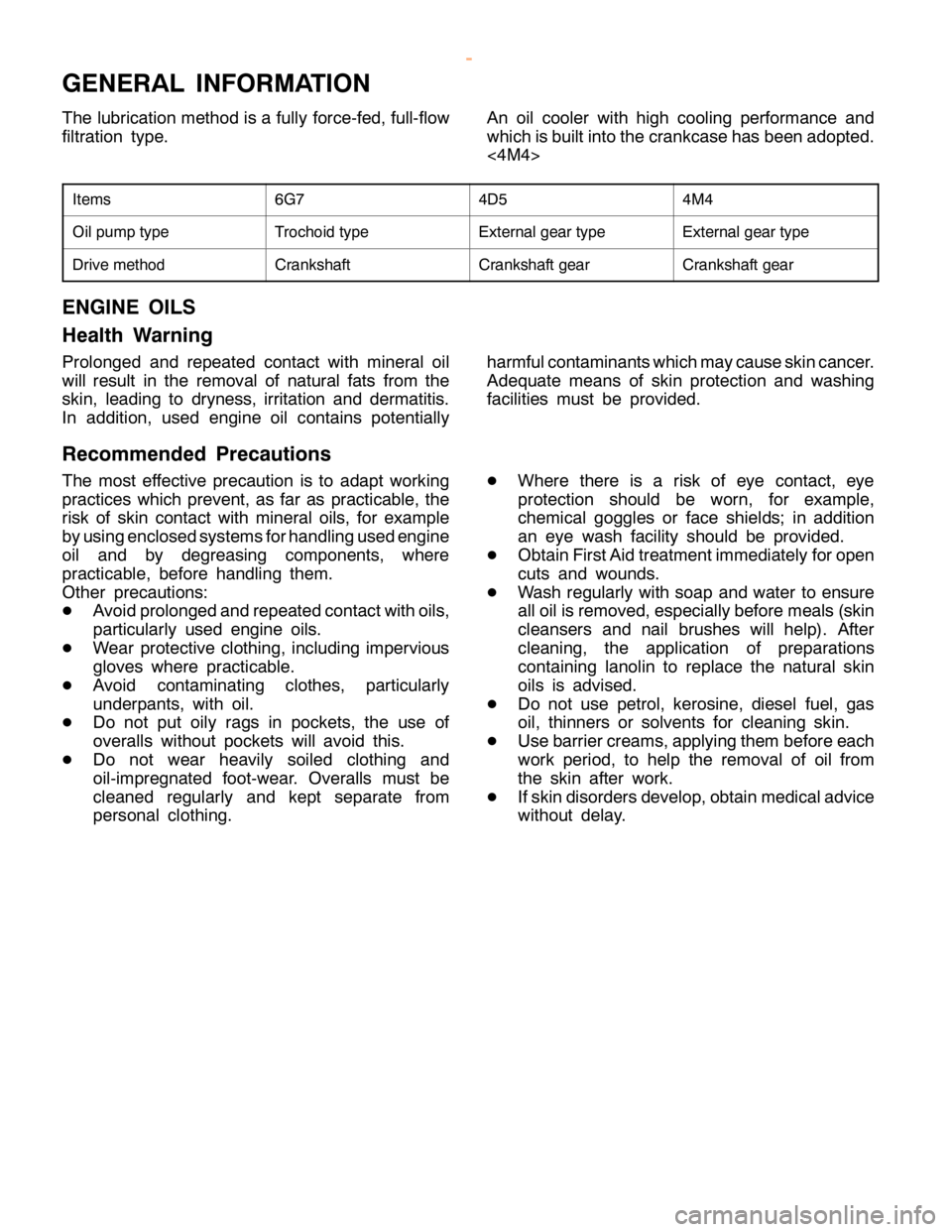

GENERAL INFORMATION

The lubrication method is a fully force-fed, full-flow

filtration type.An oil cooler with high cooling performance and

which is built into the crankcase has been adopted.

<4M4>

Items6G74D54M4

Oil pump typeTrochoid typeExternal gear typeExternal gear type

Drive methodCrankshaftCrankshaft gearCrankshaft gear

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentiallyharmful contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example

by using enclosed systems for handling used engine

oil and by degreasing components, where

practicable, before handling them.

Other precautions:

DAvoid prolonged and repeated contact with oils,

particularly used engine oils.

DWear protective clothing, including impervious

gloves where practicable.

DAvoid contaminating clothes, particularly

underpants, with oil.

DDo not put oily rags in pockets, the use of

overalls without pockets will avoid this.

DDo not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.DWhere there is a risk of eye contact, eye

protection should be worn, for example,

chemical goggles or face shields; in addition

an eye wash facility should be provided.

DObtain First Aid treatment immediately for open

cuts and wounds.

DWash regularly with soap and water to ensure

all oil is removed, especially before meals (skin

cleansers and nail brushes will help). After

cleaning, the application of preparations

containing lanolin to replace the natural skin

oils is advised.

DDo not use petrol, kerosine, diesel fuel, gas

oil, thinners or solvents for cleaning skin.

DUse barrier creams, applying them before each

work period, to help the removal of oil from

the skin after work.

DIf skin disorders develop, obtain medical advice

without delay.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 214 of 1839

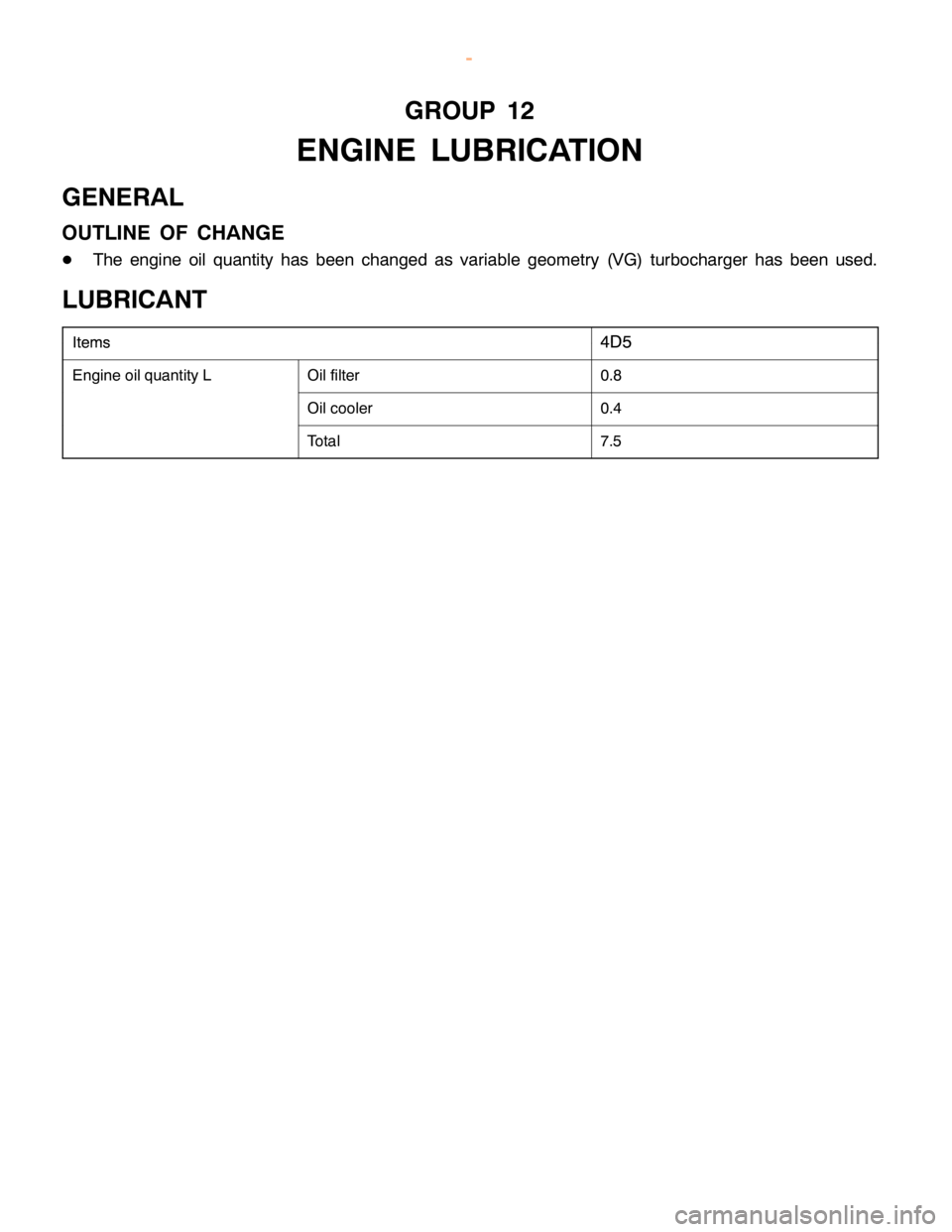

Engine Lubrication -General/Lubricant12-1

GROUP 12

ENGINE LUBRICATION

GENERAL

OUTLINE OF CHANGE

DThe engine oil quantity has been changed as variable geometry (VG) turbocharger has been used.

LUBRICANT

Items4D5Items4D5

Engine oil quantity LOil filter0.8

Oil cooler0.4

Total7.5

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 216 of 1839

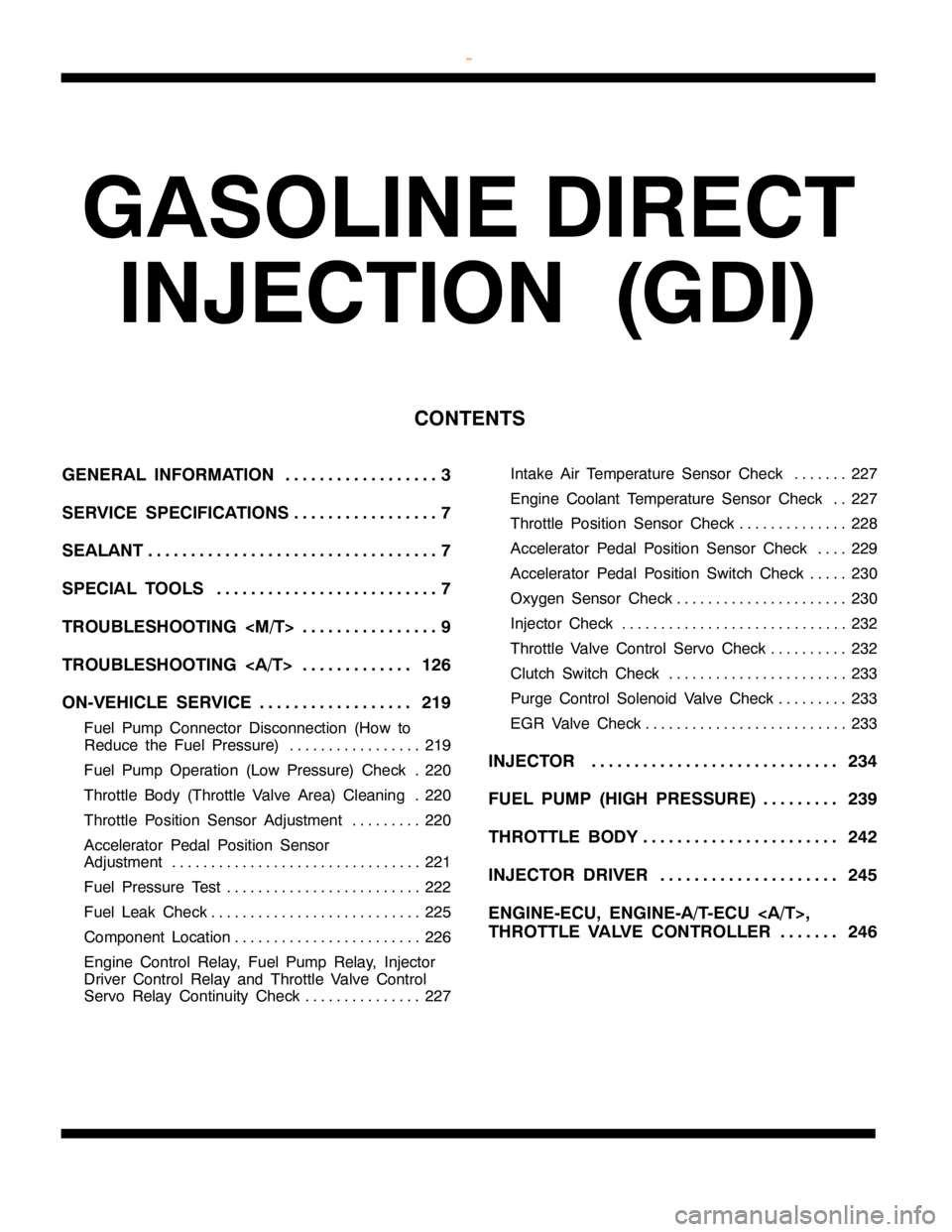

13A-2

GASOLINE DIRECT

INJECTION (GDI)

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 7.................

SEALANT 7..................................

SPECIAL TOOLS 7..........................

TROUBLESHOOTING

TROUBLESHOOTING 126.............

ON-VEHICLE SERVICE 219..................

Fuel Pump Connector Disconnection (How to

Reduce the Fuel Pressure) 219.................

Fuel Pump Operation (Low Pressure) Check 220.

Throttle Body (Throttle Valve Area) Cleaning 220.

Throttle Position Sensor Adjustment 220.........

Accelerator Pedal Position Sensor

Adjustment 221................................

Fuel Pressure Test 222.........................

Fuel Leak Check 225...........................

Component Location 226........................

Engine Control Relay, Fuel Pump Relay, Injector

Driver Control Relay and Throttle Valve Control

Servo Relay Continuity Check 227...............Intake Air Temperature Sensor Check 227.......

Engine Coolant Temperature Sensor Check 227..

Throttle Position Sensor Check 228..............

Accelerator Pedal Position Sensor Check 229....

Accelerator Pedal Position Switch Check 230.....

Oxygen Sensor Check 230......................

Injector Check 232.............................

Throttle Valve Control Servo Check 232..........

Clutch Switch Check 233.......................

Purge Control Solenoid Valve Check 233.........

EGR Valve Check 233..........................

INJECTOR 234.............................

FUEL PUMP (HIGH PRESSURE) 239.........

THROTTLE BODY 242.......................

INJECTOR DRIVER 245.....................

ENGINE-ECU, ENGINE-A/T-ECU ,

THROTTLE VALVE CONTROLLER 246.......

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 217 of 1839

GDI -General Information13A-3

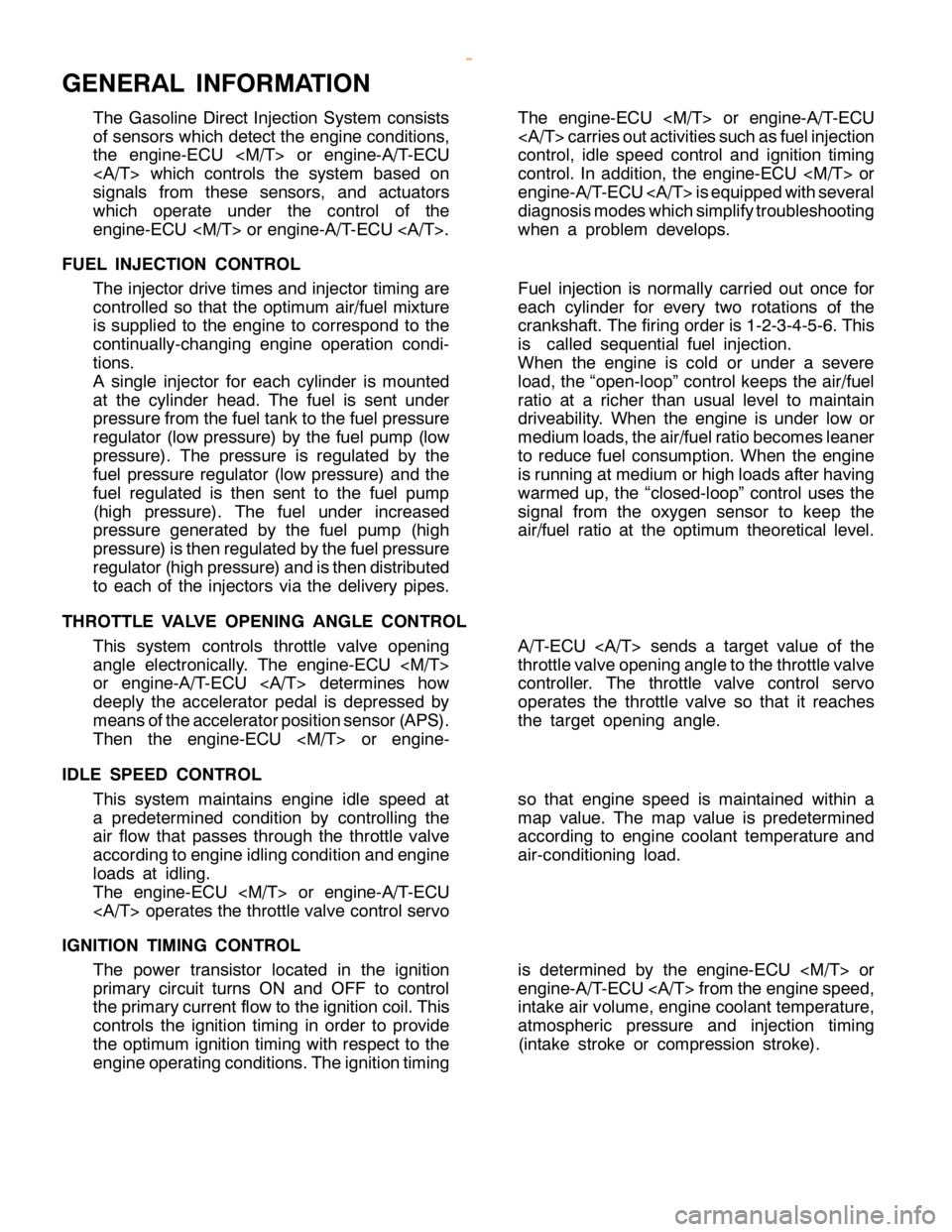

GENERAL INFORMATION

The Gasoline Direct Injection System consists

of sensors which detect the engine conditions,

the engine-ECU

which controls the system based on

signals from these sensors, and actuators

which operate under the control of the

engine-ECU

carries out activities such as fuel injection

control, idle speed control and ignition timing

control. In addition, the engine-ECU

engine-A/T-ECU is equipped with several

diagnosis modes which simplify troubleshooting

when a problem develops.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector for each cylinder is mounted

at the cylinder head. The fuel is sent under

pressure from the fuel tank to the fuel pressure

regulator (low pressure) by the fuel pump (low

pressure). The pressure is regulated by the

fuel pressure regulator (low pressure) and the

fuel regulated is then sent to the fuel pump

(high pressure). The fuel under increased

pressure generated by the fuel pump (high

pressure) is then regulated by the fuel pressure

regulator (high pressure) and is then distributed

to each of the injectors via the delivery pipes.Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is 1-2-3-4-5-6. This

is called sequential fuel injection.

When the engine is cold or under a severe

load, the “open-loop” control keeps the air/fuel

ratio at a richer than usual level to maintain

driveability. When the engine is under low or

medium loads, the air/fuel ratio becomes leaner

to reduce fuel consumption. When the engine

is running at medium or high loads after having

warmed up, the “closed-loop” control uses the

signal from the oxygen sensor to keep the

air/fuel ratio at the optimum theoretical level.

THROTTLE VALVE OPENING ANGLE CONTROL

This system controls throttle valve opening

angle electronically. The engine-ECU

or engine-A/T-ECU determines how

deeply the accelerator pedal is depressed by

means of the accelerator position sensor (APS).

Then the engine-ECU

throttle valve opening angle to the throttle valve

controller. The throttle valve control servo

operates the throttle valve so that it reaches

the target opening angle.

IDLE SPEED CONTROL

This system maintains engine idle speed at

a predetermined condition by controlling the

air flow that passes through the throttle valve

according to engine idling condition and engine

loads at idling.

The engine-ECU

operates the throttle valve control servoso that engine speed is maintained within a

map value. The map value is predetermined

according to engine coolant temperature and

air-conditioning load.

IGNITION TIMING CONTROL

The power transistor located in the ignition

primary circuit turns ON and OFF to control

the primary current flow to the ignition coil. This

controls the ignition timing in order to provide

the optimum ignition timing with respect to the

engine operating conditions. The ignition timingis determined by the engine-ECU

engine-A/T-ECU from the engine speed,

intake air volume, engine coolant temperature,

atmospheric pressure and injection timing

(intake stroke or compression stroke).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 218 of 1839

GDI -General Information13A-4

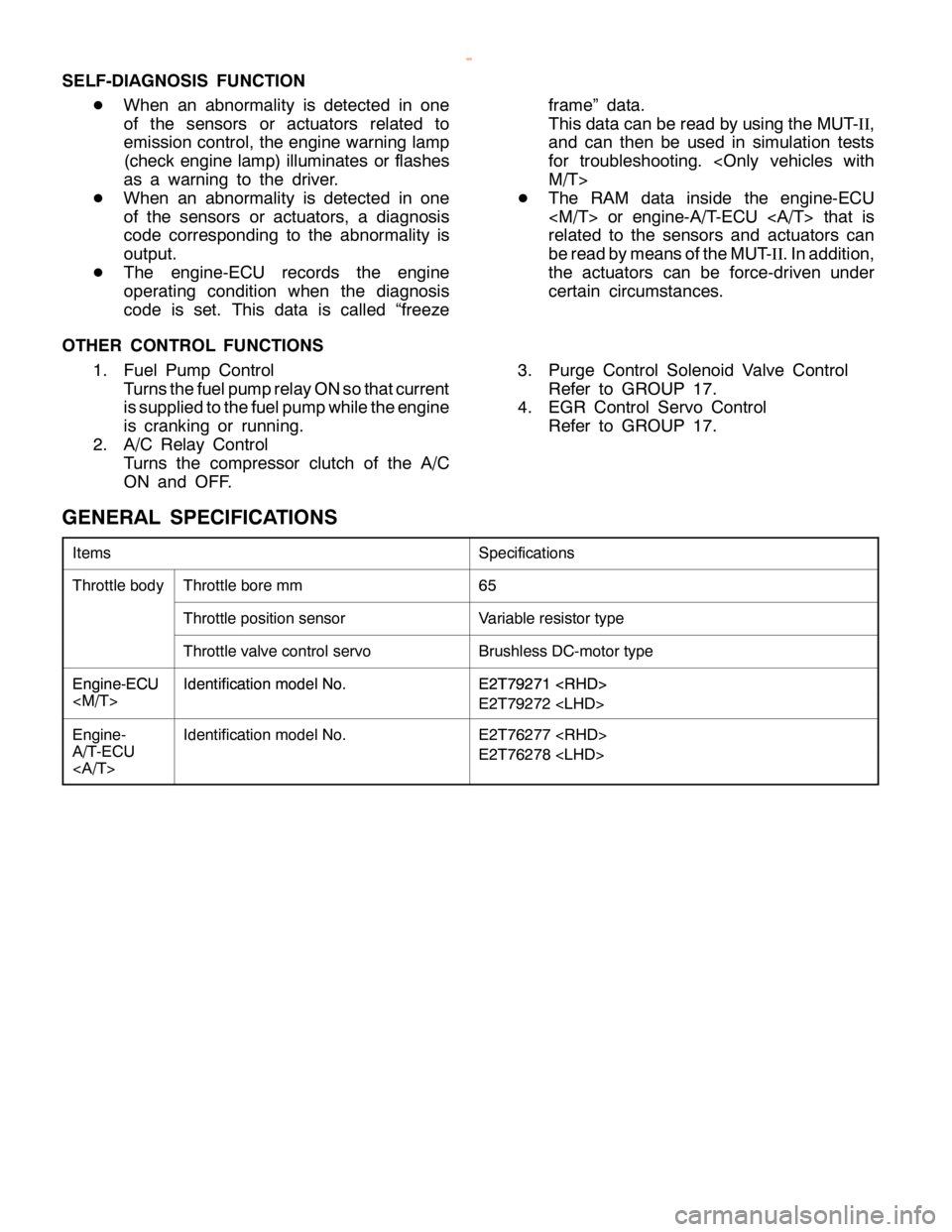

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in one

of the sensors or actuators related to

emission control, the engine warning lamp

(check engine lamp) illuminates or flashes

as a warning to the driver.

DWhen an abnormality is detected in one

of the sensors or actuators, a diagnosis

code corresponding to the abnormality is

output.

DThe engine-ECU records the engine

operating condition when the diagnosis

code is set. This data is called “freezeframe” data.

This data can be read by using the MUT-II,

and can then be used in simulation tests

for troubleshooting.

DThe RAM data inside the engine-ECU

related to the sensors and actuators can

be read by means of the MUT-II. In addition,

the actuators can be force-driven under

certain circumstances.

OTHER CONTROL FUNCTIONS

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Relay Control

Turns the compressor clutch of the A/C

ON and OFF.3. Purge Control Solenoid Valve Control

Refer to GROUP 17.

4. EGR Control Servo Control

Refer to GROUP 17.

GENERAL SPECIFICATIONS

ItemsSpecifications

Throttle bodyThrottle bore mm65

Throttle position sensorVariable resistor type

Throttle valve control servoBrushless DC-motor type

Engine-ECUIdentification model No.E2T79271

E2T79272

Engine-Identification model No.E2T76277

A/T-ECU

E2T76278

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 219 of 1839

GDI -General Information13A-5

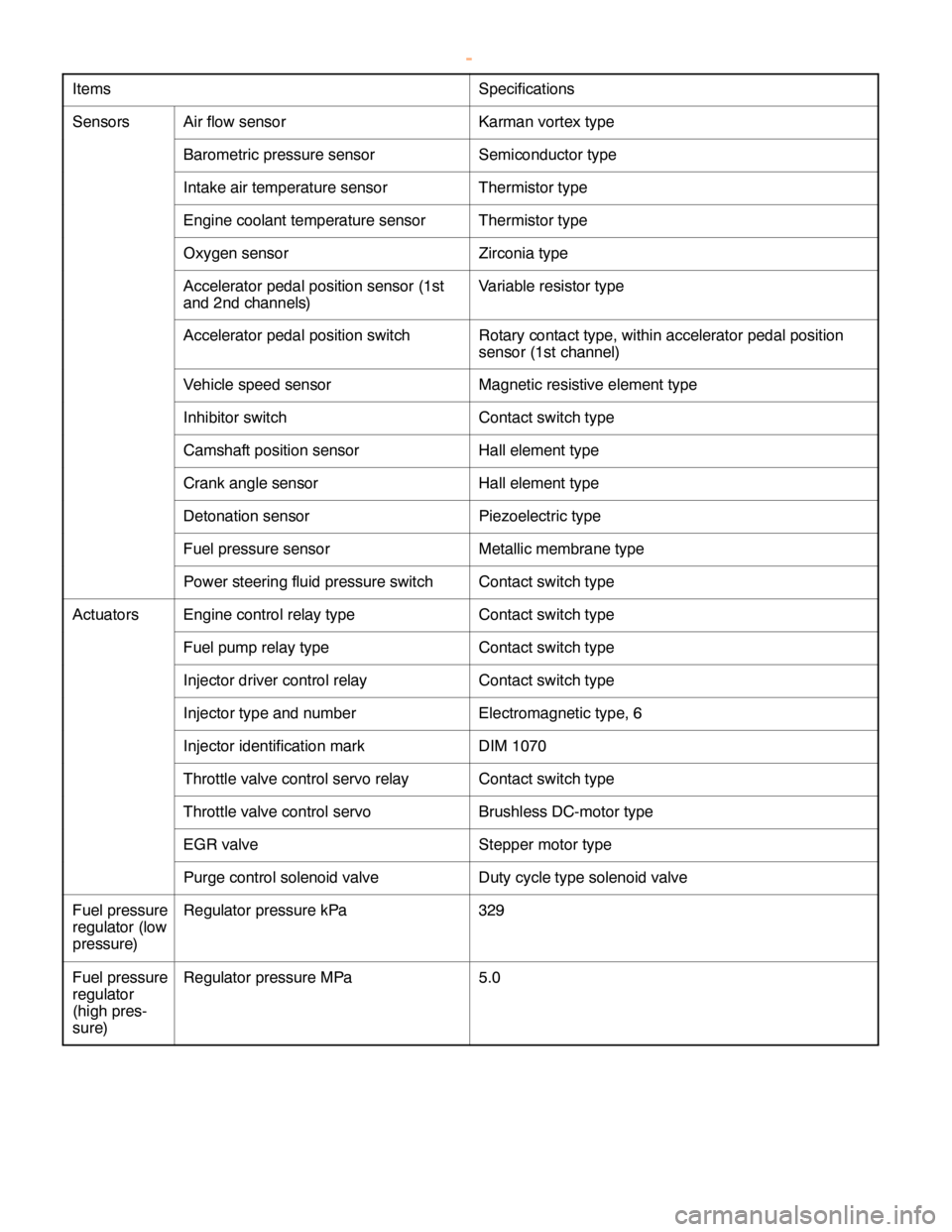

Items Specifications

SensorsAir flow sensorKarman vortex type

Barometric pressure sensorSemiconductor type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Accelerator pedal position sensor (1st

and 2nd channels)Variable resistor type

Accelerator pedal position switchRotary contact type, within accelerator pedal position

sensor (1st channel)

Vehicle speed sensorMagnetic resistive element type

Inhibitor switchContact switch type

Camshaft position sensorHall element type

Crank angle sensorHall element type

Detonation sensorPiezoelectric type

Fuel pressure sensorMetallic membrane type

Power steering fluid pressure switchContact switch type

ActuatorsEngine control relay typeContact switch type

Fuel pump relay typeContact switch type

Injector driver control relayContact switch type

Injector type and numberElectromagnetic type, 6

Injector identification markDIM 1070

Throttle valve control servo relayContact switch type

Throttle valve control servoBrushless DC-motor type

EGR valveStepper motor type

Purge control solenoid valveDuty cycle type solenoid valve

Fuel pressure

regulator (low

pressure)Regulator pressure kPa329

Fuel pressure

regulator

(high pres-

sure)Regulator pressure MPa5.0

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 224 of 1839

GDI -Troubleshooting

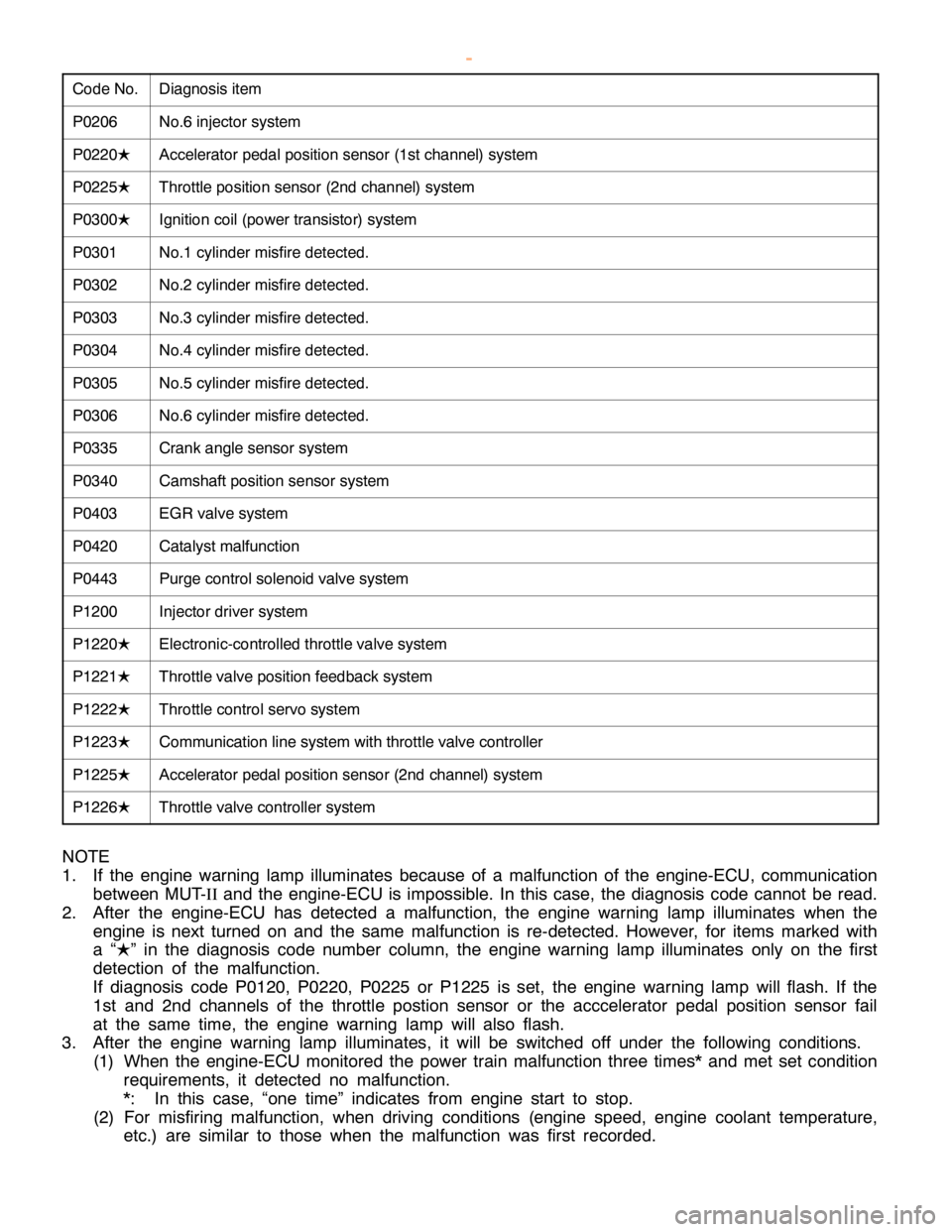

Code No. Diagnosis item

P0206No.6 injector system

P0220LAccelerator pedal position sensor (1st channel) system

P0225LThrottle position sensor (2nd channel) system

P0300LIgnition coil (power transistor) system

P0301No.1 cylinder misfire detected.

P0302No.2 cylinder misfire detected.

P0303No.3 cylinder misfire detected.

P0304No.4 cylinder misfire detected.

P0305No.5 cylinder misfire detected.

P0306No.6 cylinder misfire detected.

P0335Crank angle sensor system

P0340Camshaft position sensor system

P0403EGR valve system

P0420Catalyst malfunction

P0443Purge control solenoid valve system

P1200Injector driver system

P1220LElectronic-controlled throttle valve system

P1221LThrottle valve position feedback system

P1222LThrottle control servo system

P1223LCommunication line system with throttle valve controller

P1225LAccelerator pedal position sensor (2nd channel) system

P1226LThrottle valve controller system

NOTE

1. If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication

between MUT-

IIand the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

2. After the engine-ECU has detected a malfunction, the engine warning lamp illuminates when the

engine is next turned on and the same malfunction is re-detected. However, for items marked with

a“

L” in the diagnosis code number column, the engine warning lamp illuminates only on the first

detection of the malfunction.

If diagnosis code P0120, P0220, P0225 or P1225 is set, the engine warning lamp will flash. If the

1st and 2nd channels of the throttle postion sensor or the acccelerator pedal position sensor fail

at the same time, the engine warning lamp will also flash.

3. After the engine warning lamp illuminates, it will be switched off under the following conditions.

(1) When the engine-ECU monitored the power train malfunction three times* and met set condition

requirements, it detected no malfunction.

*: In this case, “one time” indicates from engine start to stop.

(2) For misfiring malfunction, when driving conditions (engine speed, engine coolant temperature,

etc.) are similar to those when the malfunction was first recorded.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk