engine coolant MITSUBISHI MONTERO 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 415 of 1839

Page 419 of 1839

Page 474 of 1839

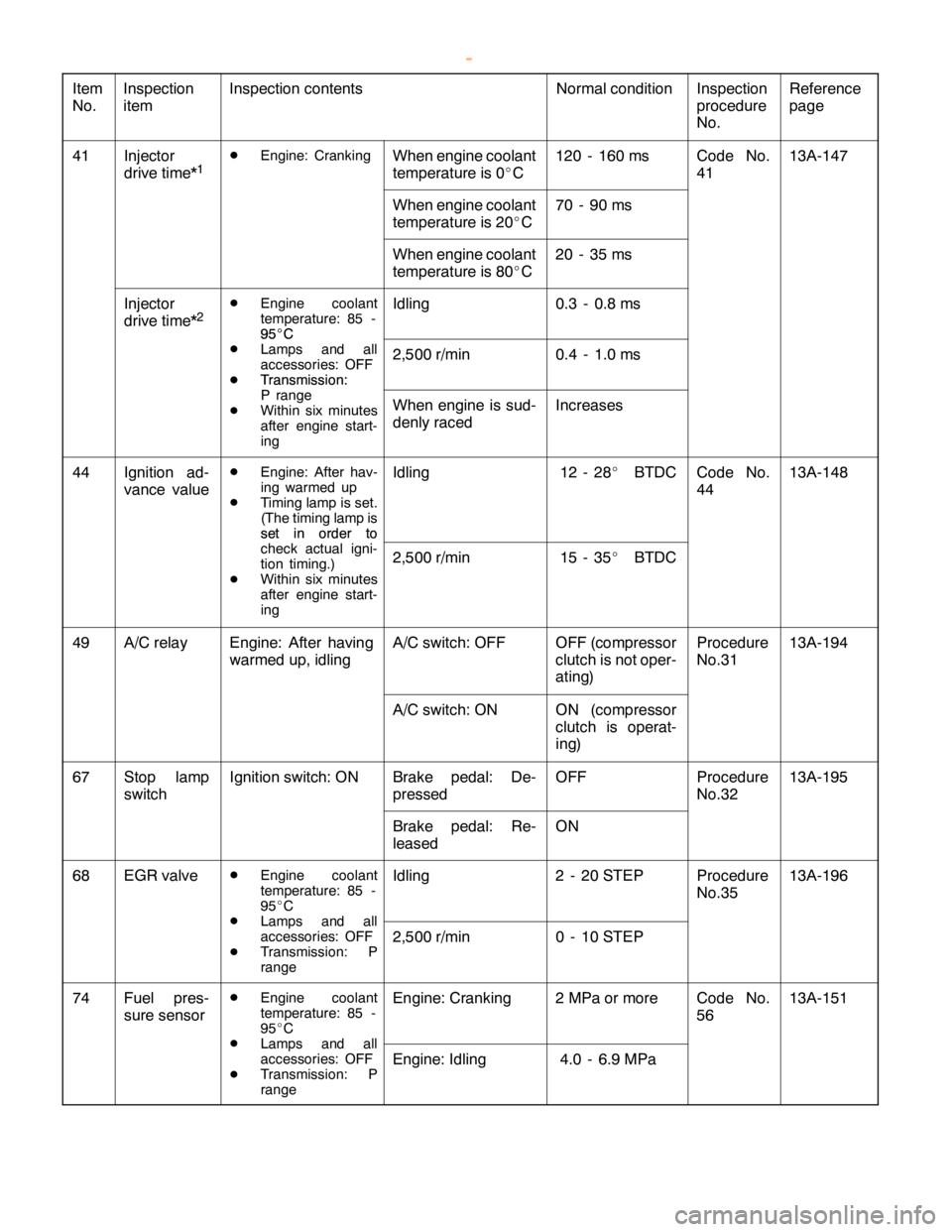

GDI -Troubleshooting13A-5

DATA LIST REFERENCE TABLE

The data list has been changed as the engine-ECU and the engine-A/T-ECU have been changed. The

other items are the same as for M/T.

Item

No.Inspection

itemInspection contentsNormal conditionInspec-

tion pro-

cedure

No.Refer-

ence

page

22Crank angle

sensorDEngine: Cranking

DTachometer:

ConnectedCompare the engine

speed readings on

the tachometer and

the MUT-II.AccordCode

No.

P033513A-56*

DEngine: Idling

DIdle position

switch: ONWhen engine

coolant temperature

is - 20_C1,300 - 1,500

r/min

When engine

coolant temperature

is 0_C1,300 - 1,500

r/min

When engine

coolant temperature

is 20_C1,250 - 1,450

r/min

When engine

coolant temperature

is 40_C1,100 - 1,300

r/min

When engine

coolant temperature

is 80_C (more than

four minutes later

after engine has

started)600 - 800 r/min

A1LOxygen

sensorEngine: After having

warmed up. (Air/fuel

mixture is made

leaner when deceler-When at 4,000

r/min, engine is

decelerated200 mV or lessCode

No.

P013013A-28*

leanerwhendeceler

ating, and is made

richer when racing.)Rev the engine.600 - 1000 mV

Engine: After having

warmed up (The

oxygen sensor signal

is used to check the

air/fuel mixture ratio,

and control condition

isalsocheckbythe

Engine is idling

(more than 4

minutes later after

engine has started)Voltage should

alternate between

400 mV or less

and 600 - 1,200

mV (more than 4

minutes after the

enginehasisalso checkbythe

engine-ECU

or engine-A/T-ECU

.)

2,500 r/min

enginehas

started).

24LVehicle

speed sen-

sorDrive at 40 km/hApproximately 40

km/hCode

No.

P050013A-63*

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 492 of 1839

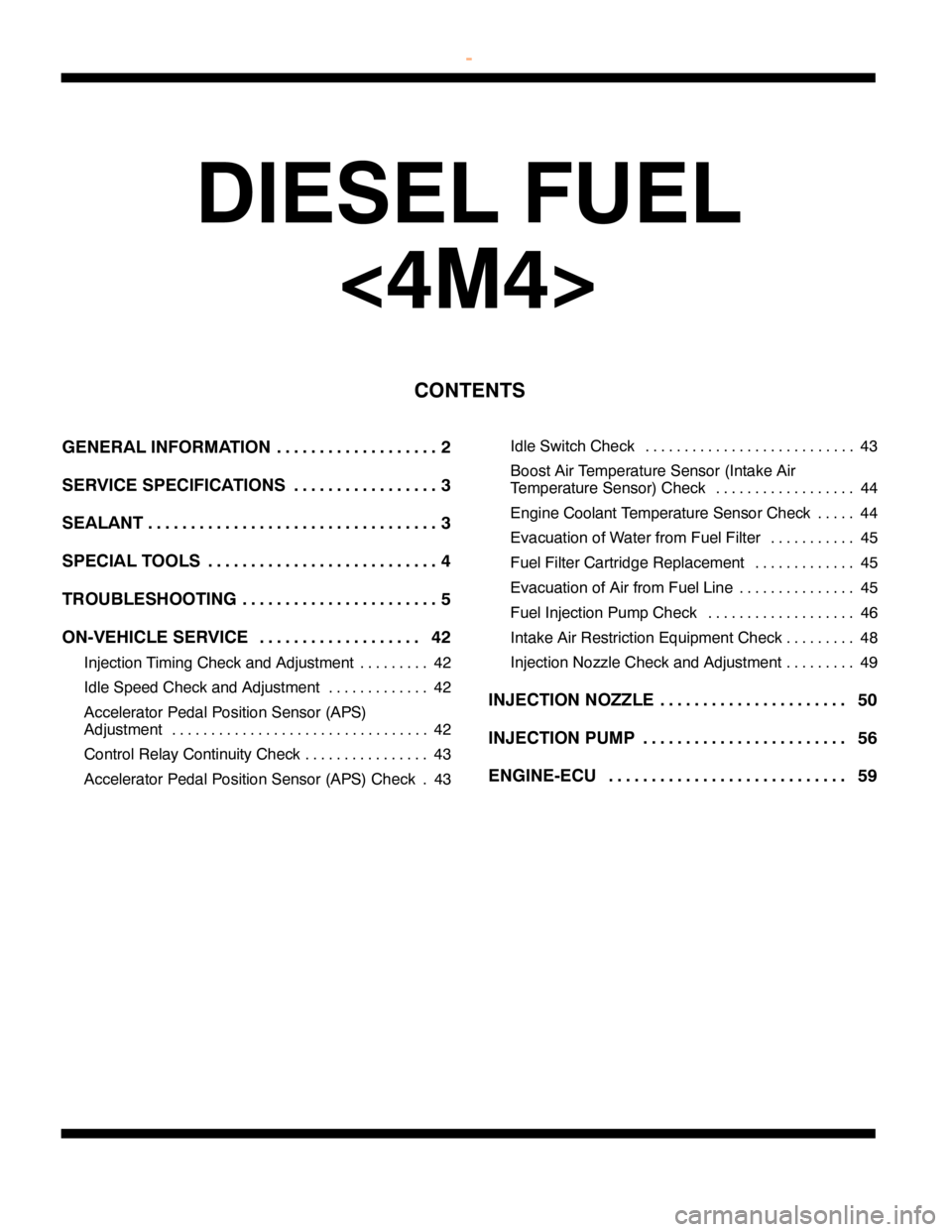

13C-1

DIESEL FUEL

<4M4>

CONTENTS

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING 5.......................

ON-VEHICLE SERVICE 42...................

Injection Timing Check and Adjustment 42.........

Idle Speed Check and Adjustment 42.............

Accelerator Pedal Position Sensor (APS)

Adjustment 42.................................

Control Relay Continuity Check 43................

Accelerator Pedal Position Sensor (APS) Check 43.Idle Switch Check 43...........................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 44..................

Engine Coolant Temperature Sensor Check 44.....

Evacuation of Water from Fuel Filter 45...........

Fuel Filter Cartridge Replacement 45.............

Evacuation of Air from Fuel Line 45...............

Fuel Injection Pump Check 46...................

Intake Air Restriction Equipment Check 48.........

Injection Nozzle Check and Adjustment 49.........

INJECTION NOZZLE 50......................

INJECTION PUMP 56........................

ENGINE-ECU 59............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 493 of 1839

DIESEL FUEL <4M4> -General Information13C-2

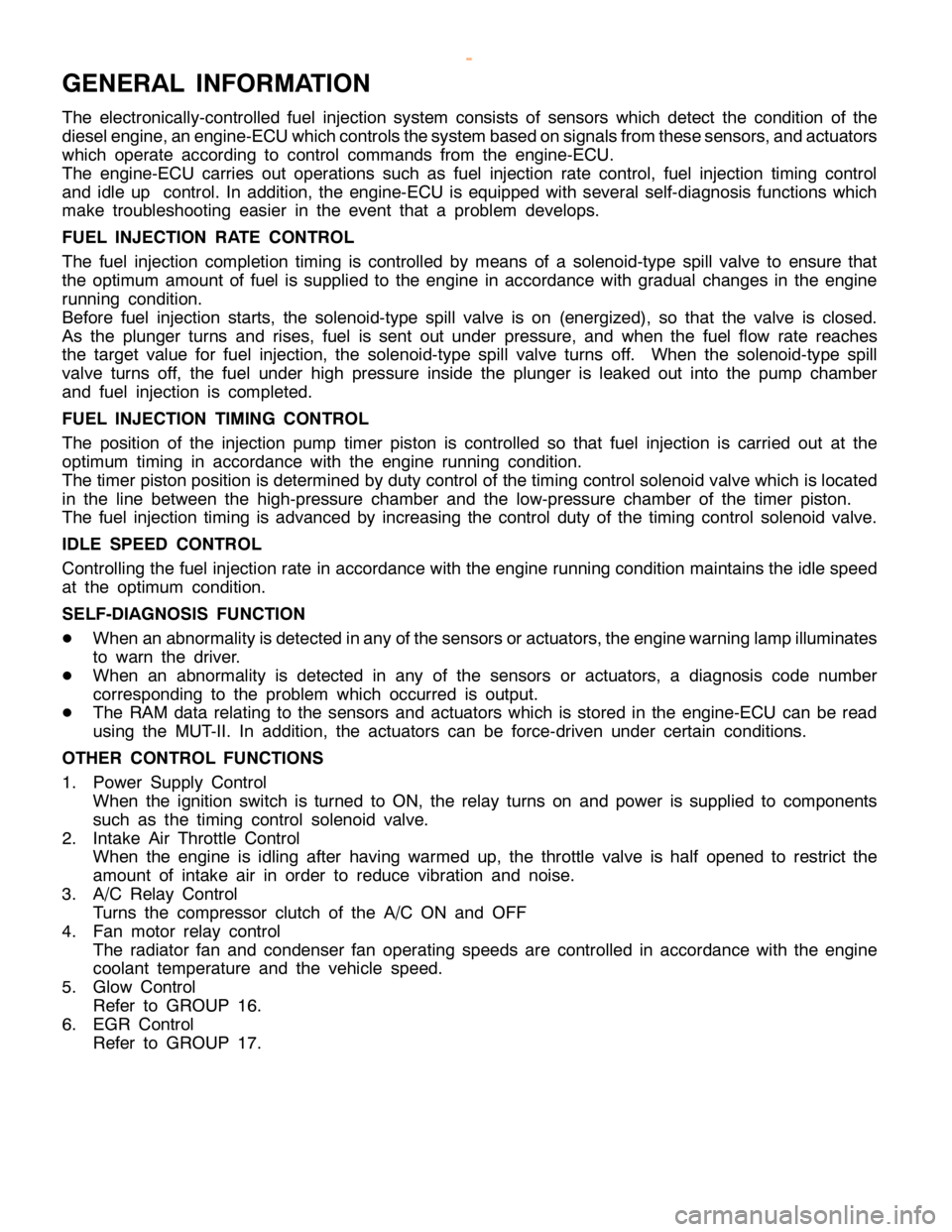

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine is idling after having warmed up, the throttle valve is half opened to restrict the

amount of intake air in order to reduce vibration and noise.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Fan motor relay control

The radiator fan and condenser fan operating speeds are controlled in accordance with the engine

coolant temperature and the vehicle speed.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 494 of 1839

DIESEL FUEL <4M4> -Service Specifications/Sealant13C-3

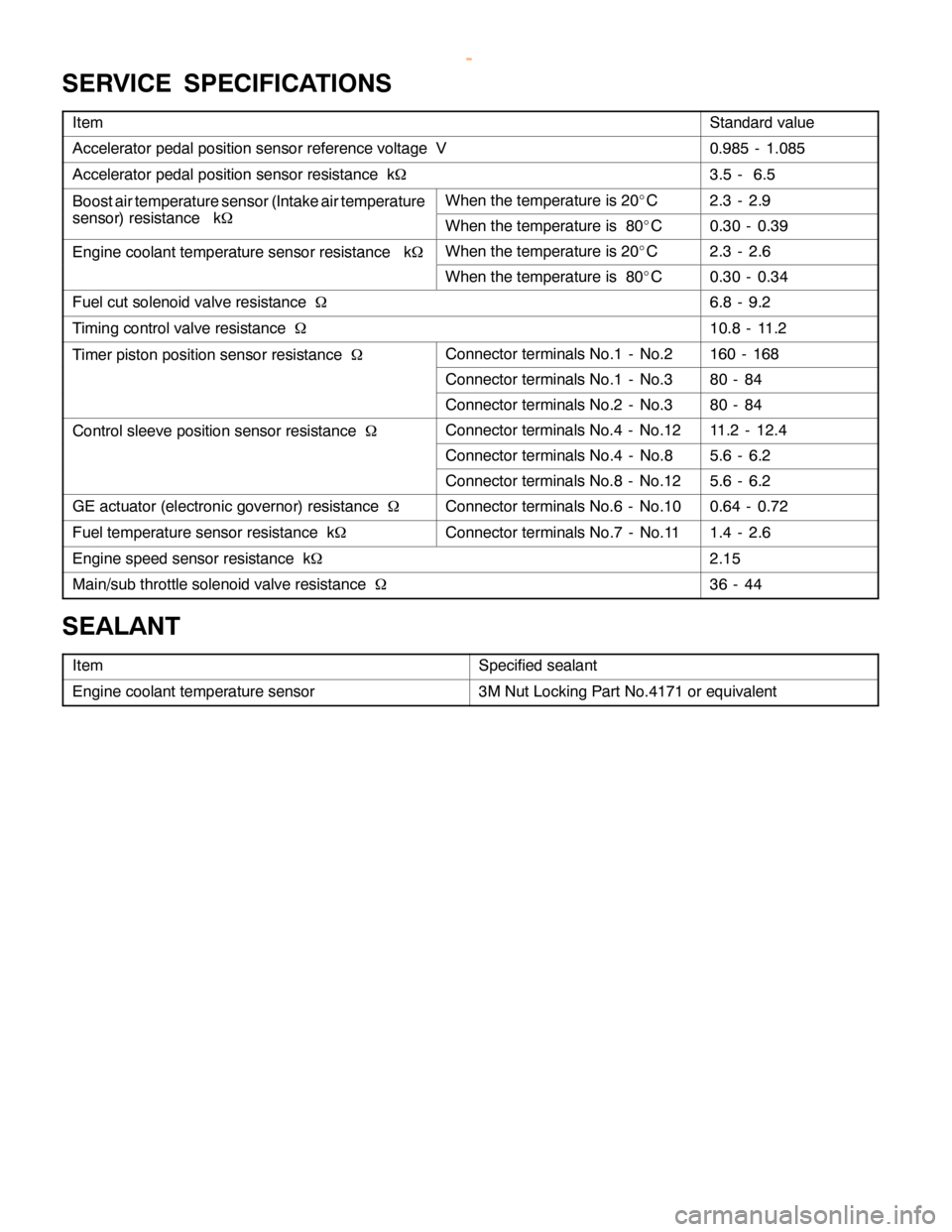

SERVICE SPECIFICATIONS

ItemStandard value

Accelerator pedal position sensor reference voltage V0.985 - 1.085

Accelerator pedal position sensor resistance kW3.5 - 6.5

Boost air temperature sensor (Intake air temperatureWhen the temperature is 20_C2.3 - 2.9

sensor) resistance kWWhen the temperature is 80_C0.30 - 0.39

Engine coolant temperature sensor resistance kWWhen the temperature is 20_C2.3 - 2.6

When the temperature is 80_C0.30 - 0.34

Fuel cut solenoid valve resistanceW6.8 - 9.2

Timing control valve resistanceW10.8 - 11.2

Timer piston position sensor resistanceWConnector terminals No.1 - No.2160 - 168

Connector terminals No.1 - No.380 - 84

Connector terminals No.2 - No.380 - 84

Control sleeve position sensor resistanceWConnector terminals No.4 - No.1211.2 - 12.4

Connector terminals No.4 - No.85.6 - 6.2

Connector terminals No.8 - No.125.6 - 6.2

GE actuator (electronic governor) resistanceWConnector terminals No.6 - No.100.64 - 0.72

Fuel temperature sensor resistance kWConnector terminals No.7 - No.111.4 - 2.6

Engine speed sensor resistance kW2.15

Main/sub throttle solenoid valve resistanceW36 - 44

SEALANT

ItemSpecified sealant

Engine coolant temperature sensor3M Nut Locking Part No.4171 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 497 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-6

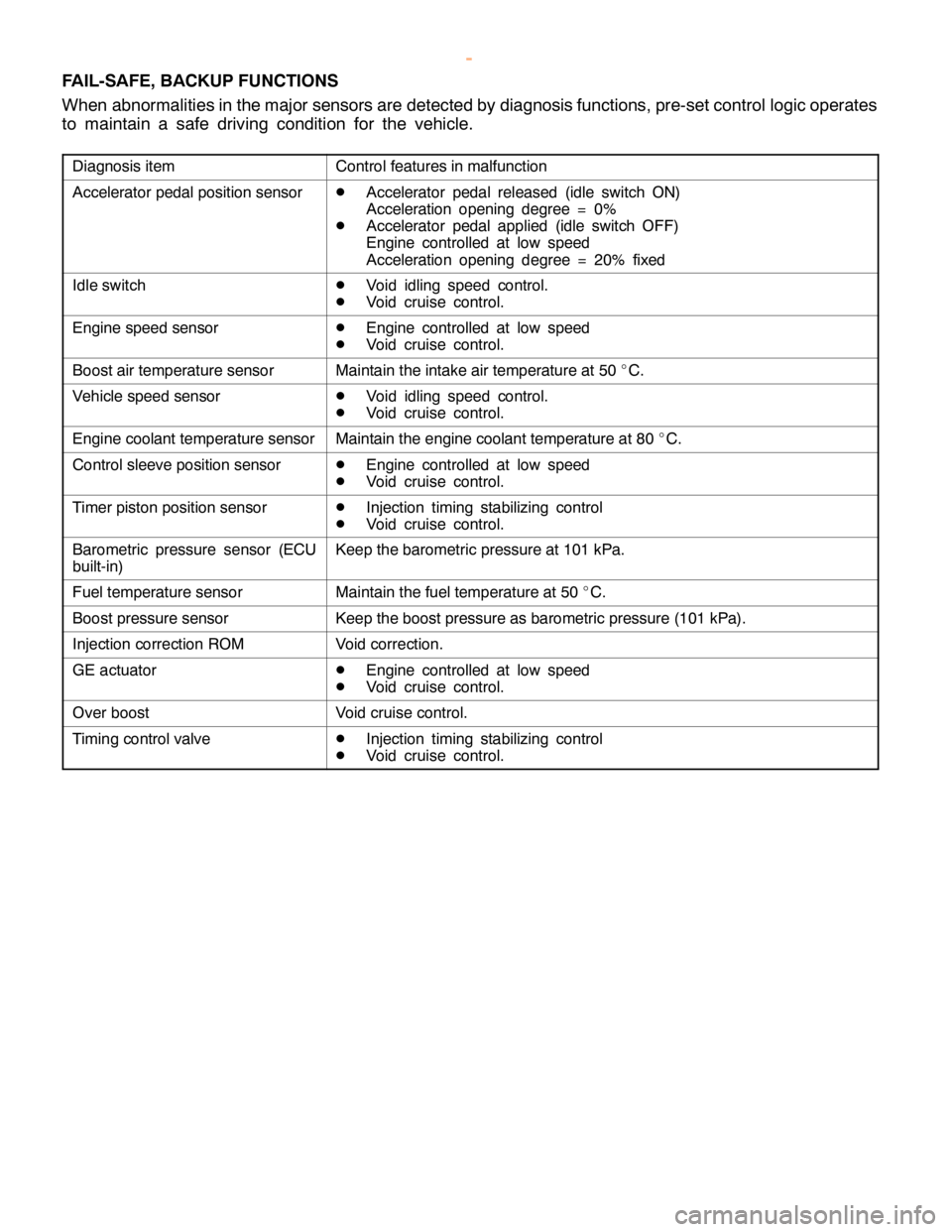

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis itemControl features in malfunction

Accelerator pedal position sensorD

Accelerator pedal released (idle switch ON)

Acceleration opening degree = 0%

D

Accelerator pedal applied (idle switchOFF)

Engine controlled at low speed

Acceleration opening degree = 20% fixed

Idle switchD

Void idling speed control.

D

Void cruise control.

Engine speed sensorD

Engine controlled at low speed

D

Void cruise control.

Boost air temperature sensorMaintain the intake air temperature at 50_

C.

Vehicle speed sensorD

Void idling speed control.

D

Void cruise control.

Engine coolant temperature sensorMaintain the engine coolant temperature at 80_

C.

Control sleeve position sensorD

Engine controlled at low speed

D

Void cruise control.

Timer piston position sensorD

Injection timing stabilizing control

D

Void cruise control.

Barometric pressure sensor (ECU

built-in)Keep the barometric pressure at 101 kPa.

Fuel temperature sensorMaintain the fuel temperature at 50_

C.

Boost pressure sensorKeep the boost pressure as barometric pressure (101 kPa).

Injection correction ROMVoid correction.

GE actuatorD

Engine controlled at low speed

D

Void cruise control.

Over boostVoid cruise control.

Timing control valveD

Injection timing stabilizing control

D

Void cruise control.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 498 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-7

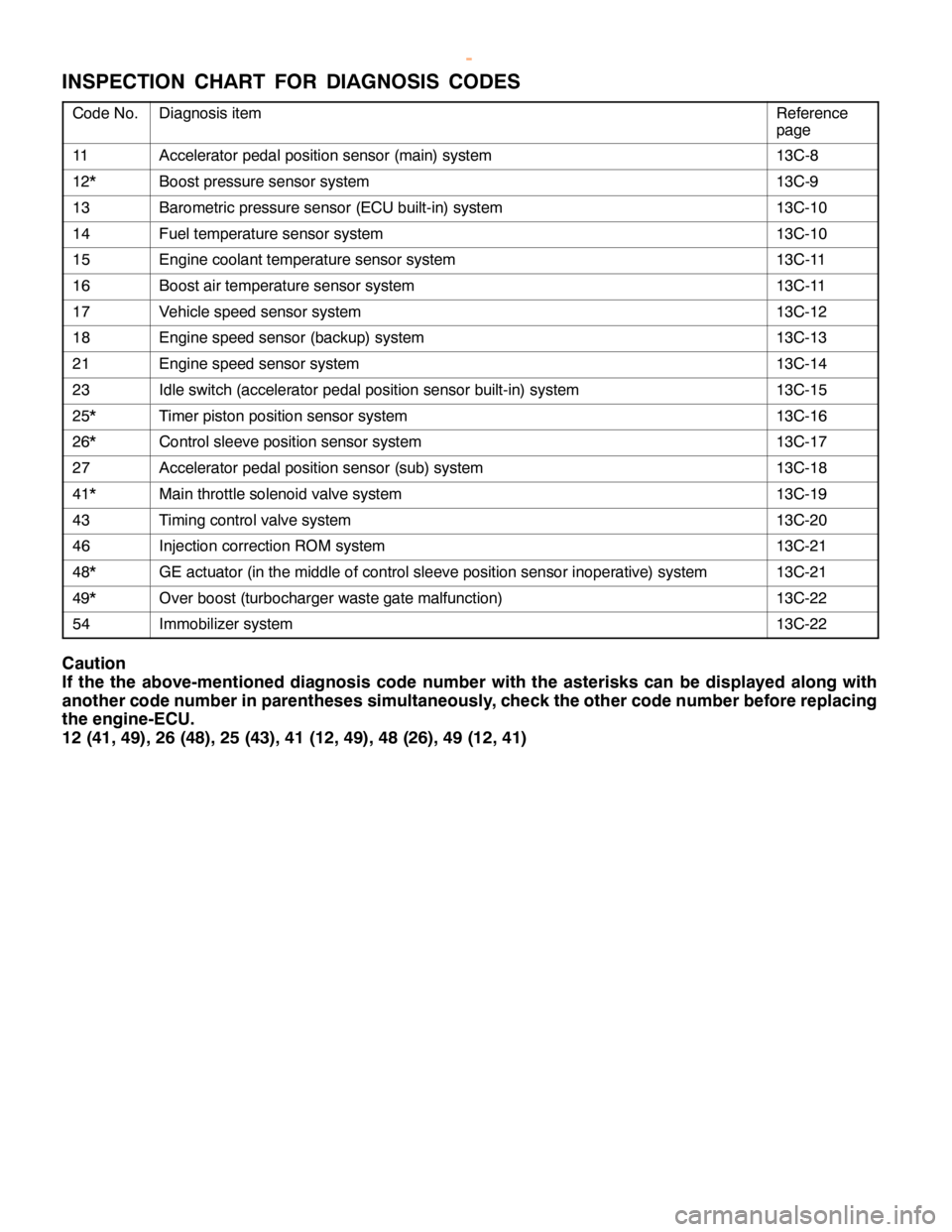

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference

page

11Accelerator pedal position sensor (main) system13C-8

12*Boost pressure sensor system13C-9

13Barometric pressure sensor (ECU built-in) system13C-10

14Fuel temperature sensor system13C-10

15Engine coolant temperature sensor system13C-11

16Boost air temperature sensor system13C-11

17Vehicle speed sensor system13C-12

18Engine speed sensor (backup) system13C-13

21Engine speed sensor system13C-14

23Idle switch (accelerator pedal position sensor built-in) system13C-15

25*Timer piston position sensor system13C-16

26*Control sleeve position sensor system13C-17

27Accelerator pedal position sensor (sub) system13C-18

41*Main throttle solenoid valve system13C-19

43Timing control valve system13C-20

46Injection correction ROM system13C-21

48*GE actuator (in the middle of control sleeve position sensor inoperative) system13C-21

49*Over boost (turbocharger waste gate malfunction)13C-22

54Immobilizer system13C-22

Caution

If the the above-mentioned diagnosis code number with the asterisks can be displayed along with

another code number in parentheses simultaneously, check the other code number before replacing

the engine-ECU.

12 (41, 49), 26 (48), 25 (43), 41 (12, 49), 48 (26), 49 (12, 41)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 502 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-11

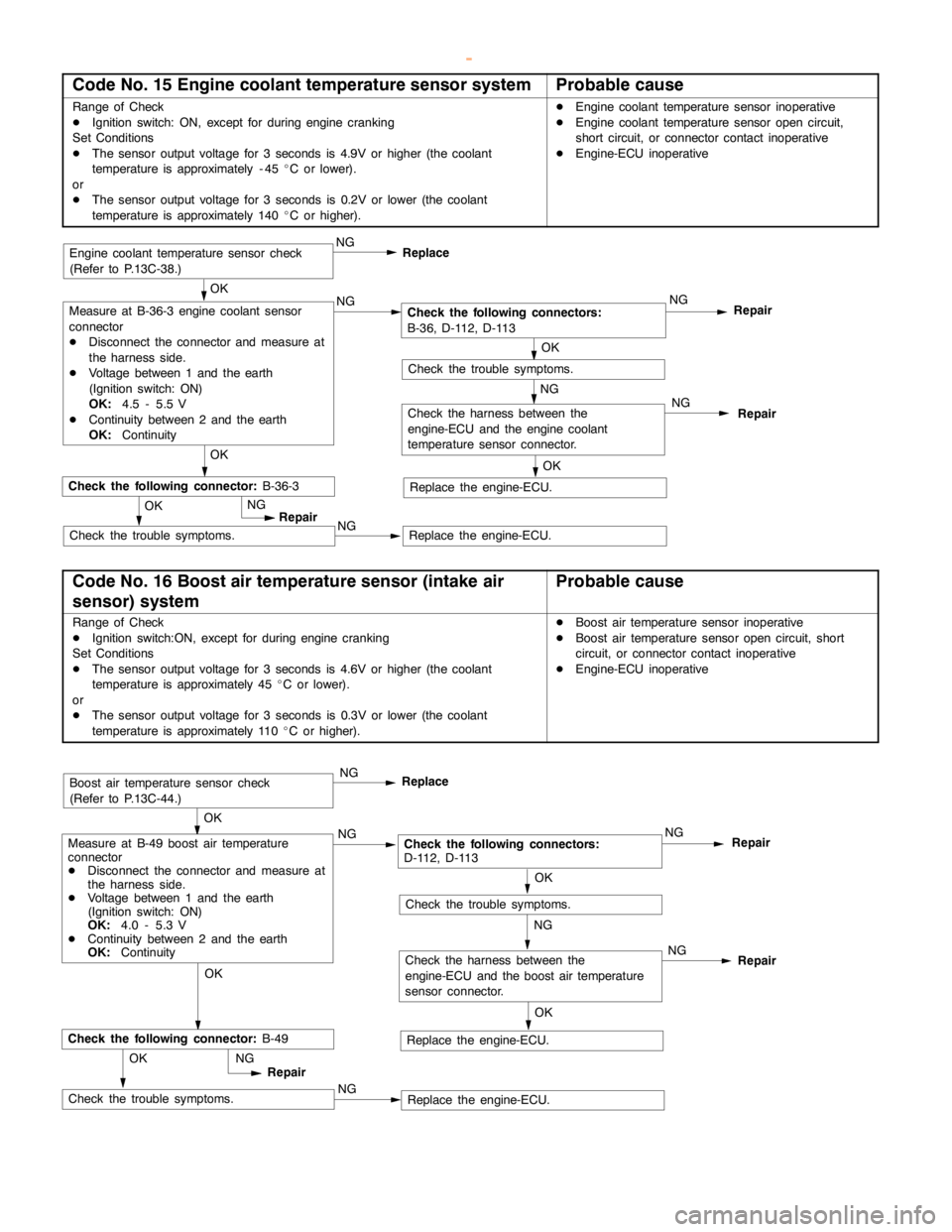

Code No. 15 Engine coolant temperature sensor systemProbable cause

Range of Check

DIgnition switch: ON, except for duringenginecranking

Set Conditions

DThe sensor output voltage for 3 seconds is 4.9V or higher (the coolant

temperature is approximately - 45_C or lower).

or

DThe sensor output voltage for 3 seconds is 0.2V or lower (the coolant

temperature is approximately 140_C or higher).DEngine coolant temperature sensor inoperative

DEngine coolant temperature sensoropencircuit,

short circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

NGNG

Repair

OK

OKRepair

NGEngine coolant temperature sensor check

(Refer to P.13C-38.)

Replace the engine-ECU.NG

Replace the engine-ECU.OK NG

OK

Repair

Check the following connector:

B-36-3

NGCheck the trouble symptoms.NG

Measure at B-36-3 engine coolantsensor

connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:

4.5 - 5.5 V

DContinuity between 2 and the earth

OK:

ContinuityCheck the following connectors:

B-36, D-112, D-113

Check the harness between the

engine-ECU and the engine coolant

temperature sensor connector.

Check the trouble symptoms. Replace

Code No. 16 Boost air temperature sensor (intake air

sensor) systemProbable cause

Range of Check

DIgnition switch:ON, except for duringenginecranking

Set Conditions

DThe sensor output voltage for 3 seconds is 4.6V or higher (the coolant

temperature is approximately 45_C or lower).

or

DThe sensor output voltage for 3 seconds is 0.3V or lower (the coolant

temperature is approximately 110_C or higher).DBoost air temperature sensor inoperative

DBoost air temperature sensoropencircuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

Measure at B-49 boost air temperature

connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:

4.0 - 5.3 V

DContinuity between 2 and the earth

OK:

ContinuityNGCheck the following connectors:

D-112, D-113NG

Repair

OK

OKRepair

NGBoost air temperature sensor check

(Refer to P.13C-44.)

Check the trouble symptoms.

Replace the engine-ECU.NG

Replace the engine-ECU.OK NG

OK

Repair

Check the following connector:

B-49Replace

NGCheck the trouble symptoms.NG

Check the harness between the

engine-ECU and the boost air temperature

sensor connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 511 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-20

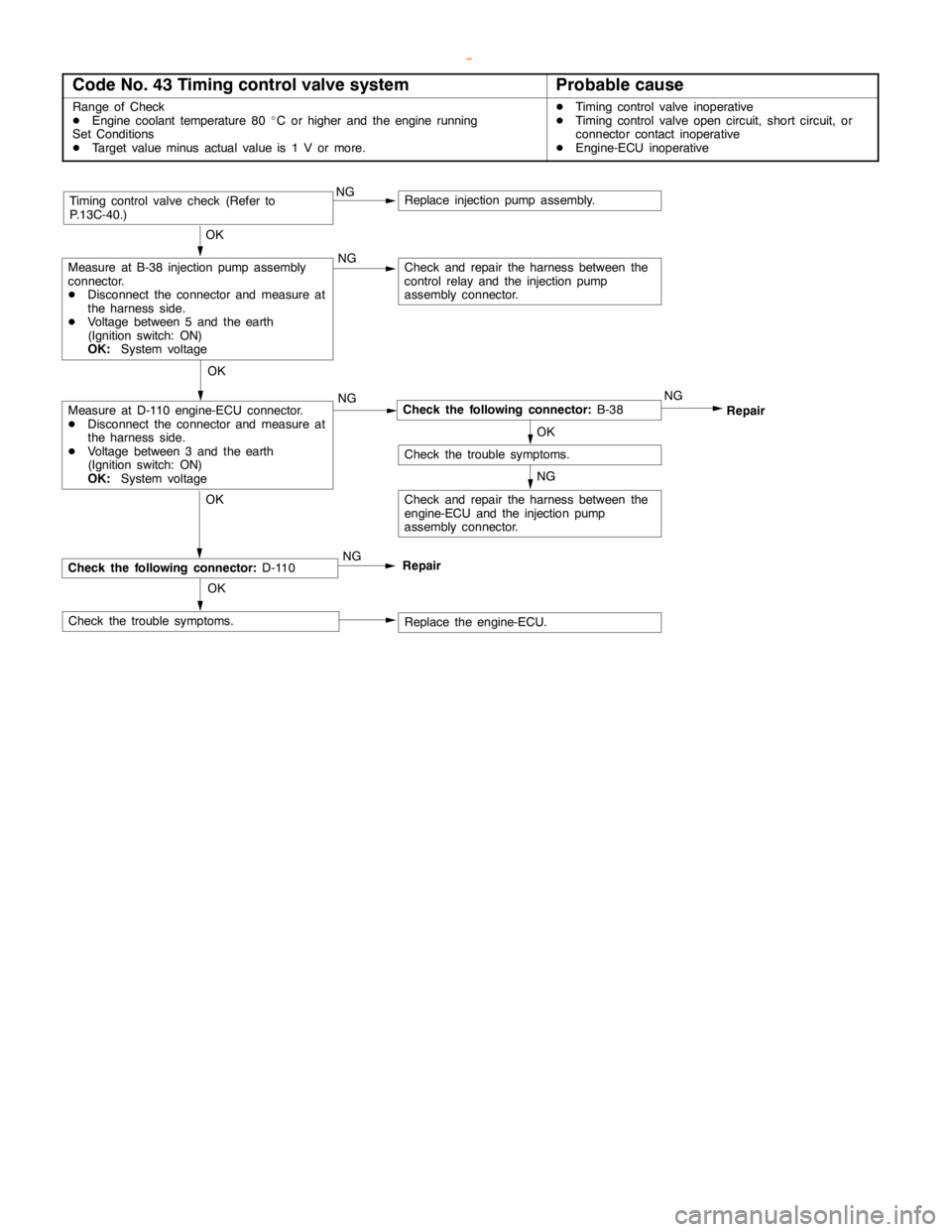

Code No. 43 Timing control valve systemProbable cause

Range of Check

DEngine coolant temperature 80_C or higher and the engine running

Set Conditions

DTarget value minus actual value is 1 V or more.DTiming controlvalve inoperative

DTiming controlvalveopencircuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

OK

OK

Check and repair the harness between the

control relay and the injectionpump

assembly connector.

Timing controlvalve check (Refer to

P.13C-40.)

Replace the engine-ECU. OK

RepairCheck the following connector:

D-110

Check the trouble symptoms.NG NG NG

Check the following connector:

B-38NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:

System voltageOK

Measure at B-38 injectionpumpassembly

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 5 and the earth

(Ignition switch: ON)

OK:

System voltage

Replace injection pumpassembly.

Check and repair the harness between the

engine-ECU and the injection pump

assembly connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk