engine coolant MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 523 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-32

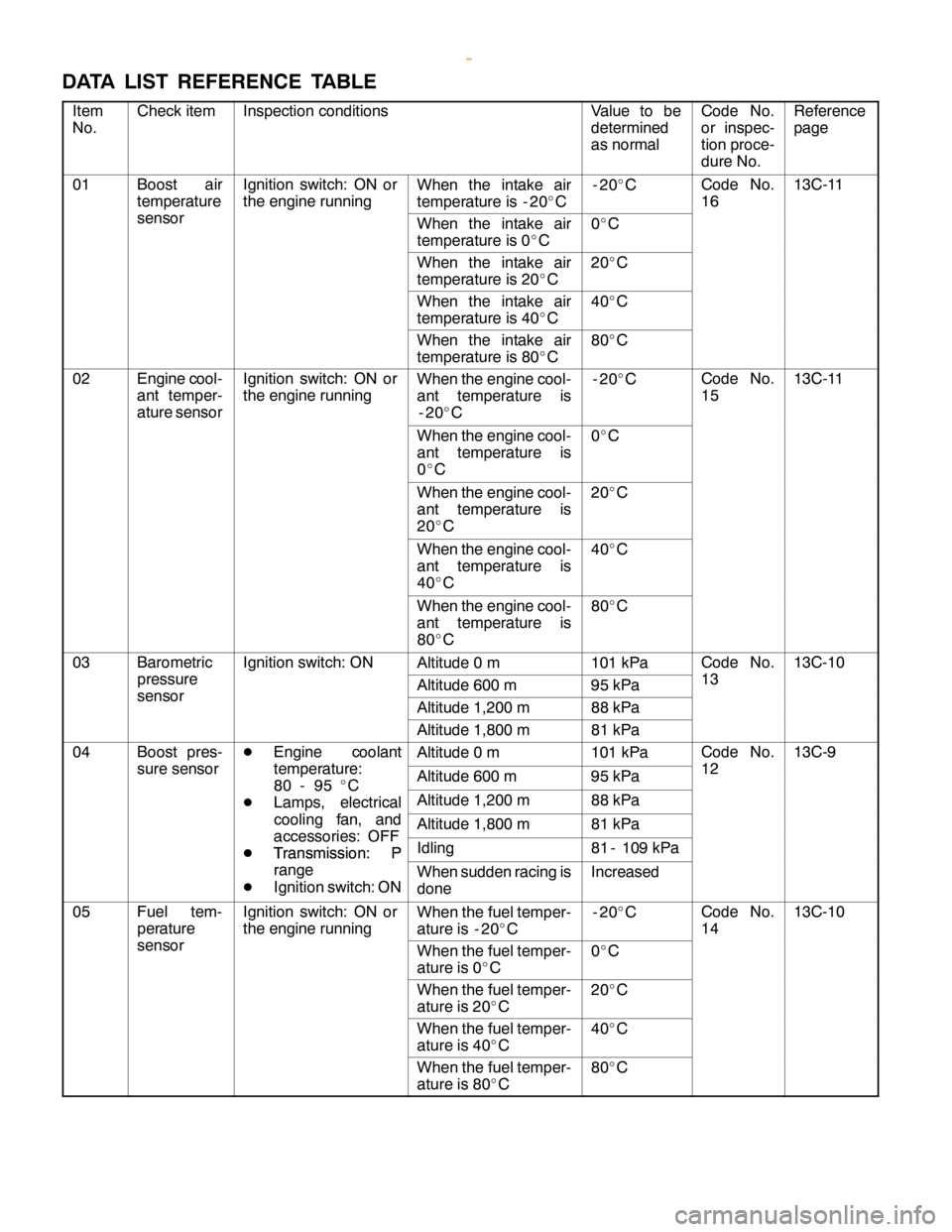

DATA LIST REFERENCE TABLE

Item

No.Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

01Boost air

temperatureIgnition switch: ON or

the engine runningWhen the intake air

temperature is - 20_C-20_CCode No.

1613C-11

sensorWhen the intake air

temperature is 0_C0_C

When the intake air

temperature is 20_C20_C

When the intake air

temperature is 40_C40_C

When the intake air

temperature is 80_C80_C

02Engine cool-

ant temper-

ature sensorIgnition switch: ON or

the engine runningWhen the engine cool-

ant temperature is

-20_C-20_CCode No.

1513C-11

When the engine cool-

ant temperature is

0_C0_C

When the engine cool-

ant temperature is

20_C20_C

When the engine cool-

ant temperature is

40_C40_C

When the engine cool-

ant temperature is

80_C80_C

03BarometricIgnition switch: ONAltitude 0 m101 kPaCode No.13C-10

pressureAltitude 600 m95 kPa13

sensorAltitude 1,200 m88 kPa

Altitude 1,800 m81 kPa

04Boost pres-DEngine coolantAltitude 0 m101 kPaCode No.13C-9

sure sensortemperature:Altitude 600 m95 kPa12

80 - 95_C

DLamps, electricalAltitude 1,200 m88 kPa

cooling fan, andAltitude 1,800 m81 kPaaccessories: OFF

DTransmission: PIdling81 - 109 kPaDTransmission: P

range

DIgnition switch: ON

When sudden racing is

doneIncreased

05Fuel tem-

peratureIgnition switch: ON or

the engine runningWhen the fuel temper-

ature is - 20_C-20_CCode No.

1413C-10

sensorWhen the fuel temper-

ature is 0_C0_C

When the fuel temper-

ature is 20_C20_C

When the fuel temper-

ature is 40_C40_C

When the fuel temper-

ature is 80_C80_C

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 526 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-35

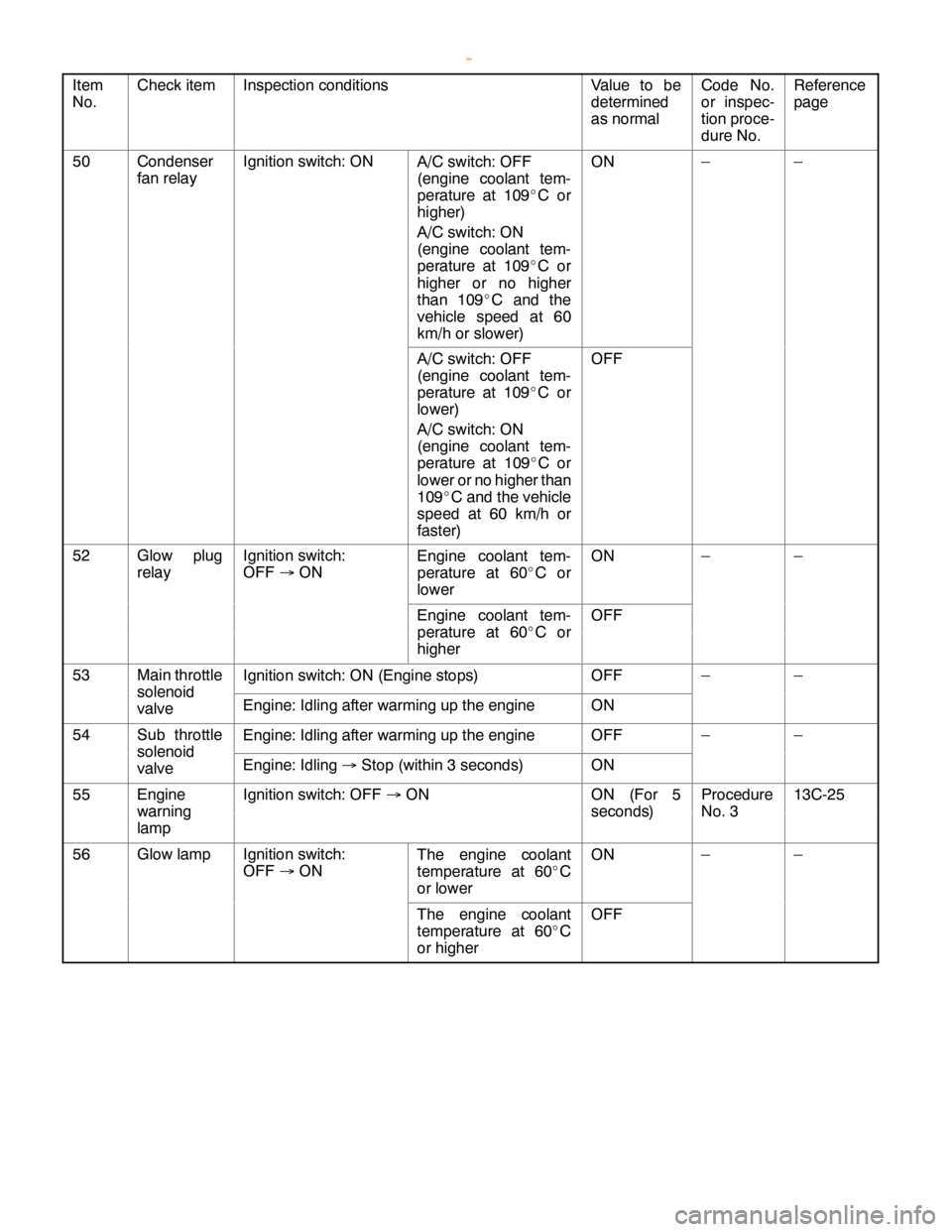

Item

No.Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

50Condenser

fan relayIgnition switch: ONA/C switch: OFF

(engine coolant tem-

perature at 109_Cor

higher)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

higher or no higher

than 109_C and the

vehicle speed at 60

km/h or slower)ON––

A/C switch: OFF

(engine coolant tem-

perature at 109_Cor

lower)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

lower or no higher than

109_C and the vehicle

speed at 60 km/h or

faster)OFF

52Glow plug

relayIgnition switch:

OFF®ONEngine coolant tem-

perature at 60_Cor

lowerON––

Engine coolant tem-OFF

perature at 60_Cor

higher

53Main throttleIgnition switch: ON (Engine stops)OFF––

solenoid

valveEngine: Idling after warming up the engineON

54Sub throttleEngine: Idling after warming up the engineOFF––

solenoid

valveEngine: Idling®Stop (within 3 seconds)ON

55EngineIgnition switch: OFF®ONON (For 5Procedure13C-25

warning

lampseconds)No. 3

56Glow lampIgnition switch:

OFF®ONThe engine coolant

temperature at 60_C

or lowerON––

The engine coolant

temperature at 60_C

or higherOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 527 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-36

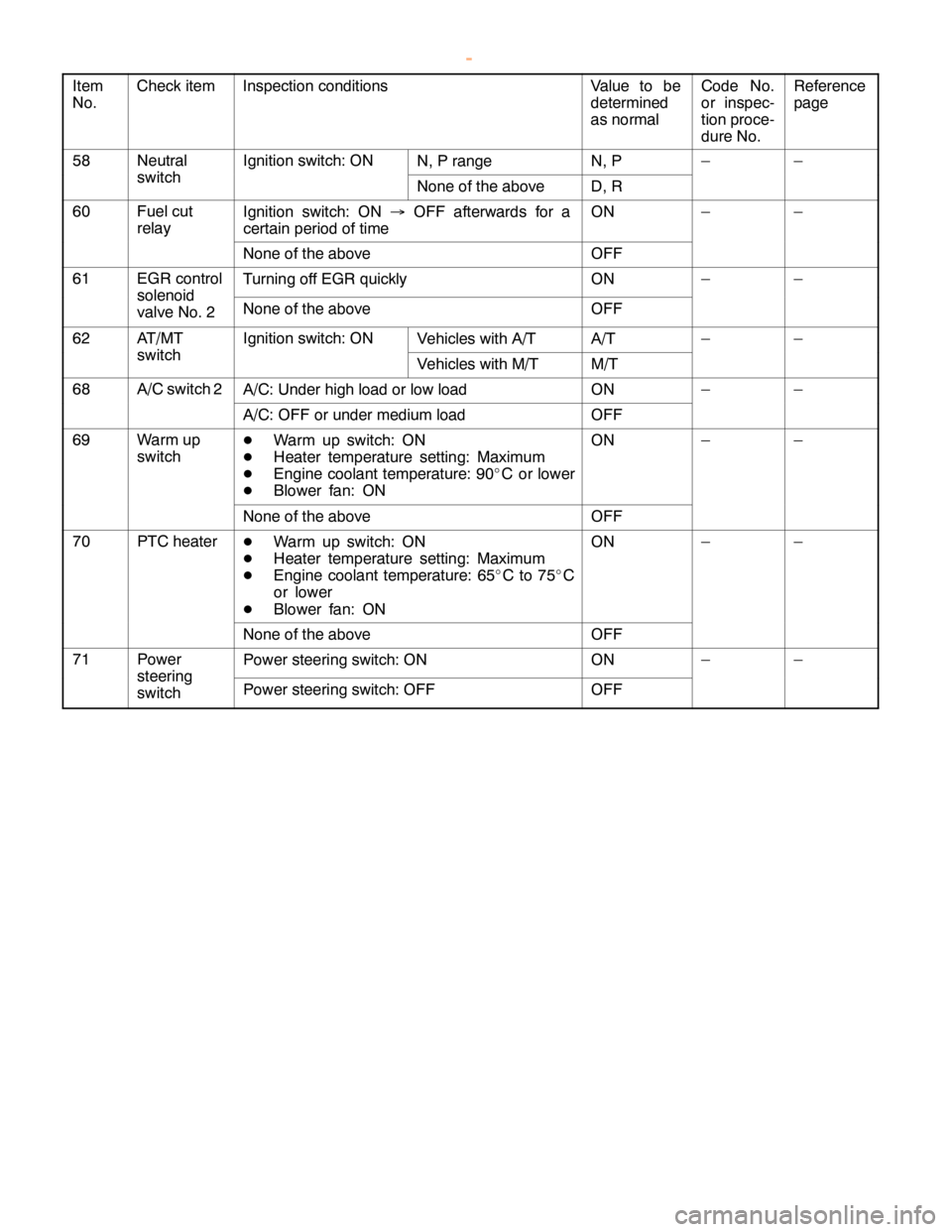

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

58NeutralIgnition switch: ONN, P rangeN, P––

switchNone of the aboveD, R

60Fuel cut

relayIgnition switch: ON®OFF afterwards for a

certain period of timeON––

None of the aboveOFF

61EGR controlTurning off EGR quicklyON––

solenoid

valve No. 2None of the aboveOFF

62AT/MTIgnition switch: ONVehicles with A/TA/T––

switchVehicles with M/TM/T

68A/C switch 2A/C: Under high load or low loadON––

A/C: OFF or under medium loadOFF

69Warm up

switchDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 90_C or lower

DBlower fan: ONON––

None of the aboveOFF

70PTC heaterDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 65_Cto75_C

or lower

DBlower fan: ONON––

None of the aboveOFF

71PowerPower steering switch: ONON––

steering

switchPower steering switch: OFFOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 531 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-40

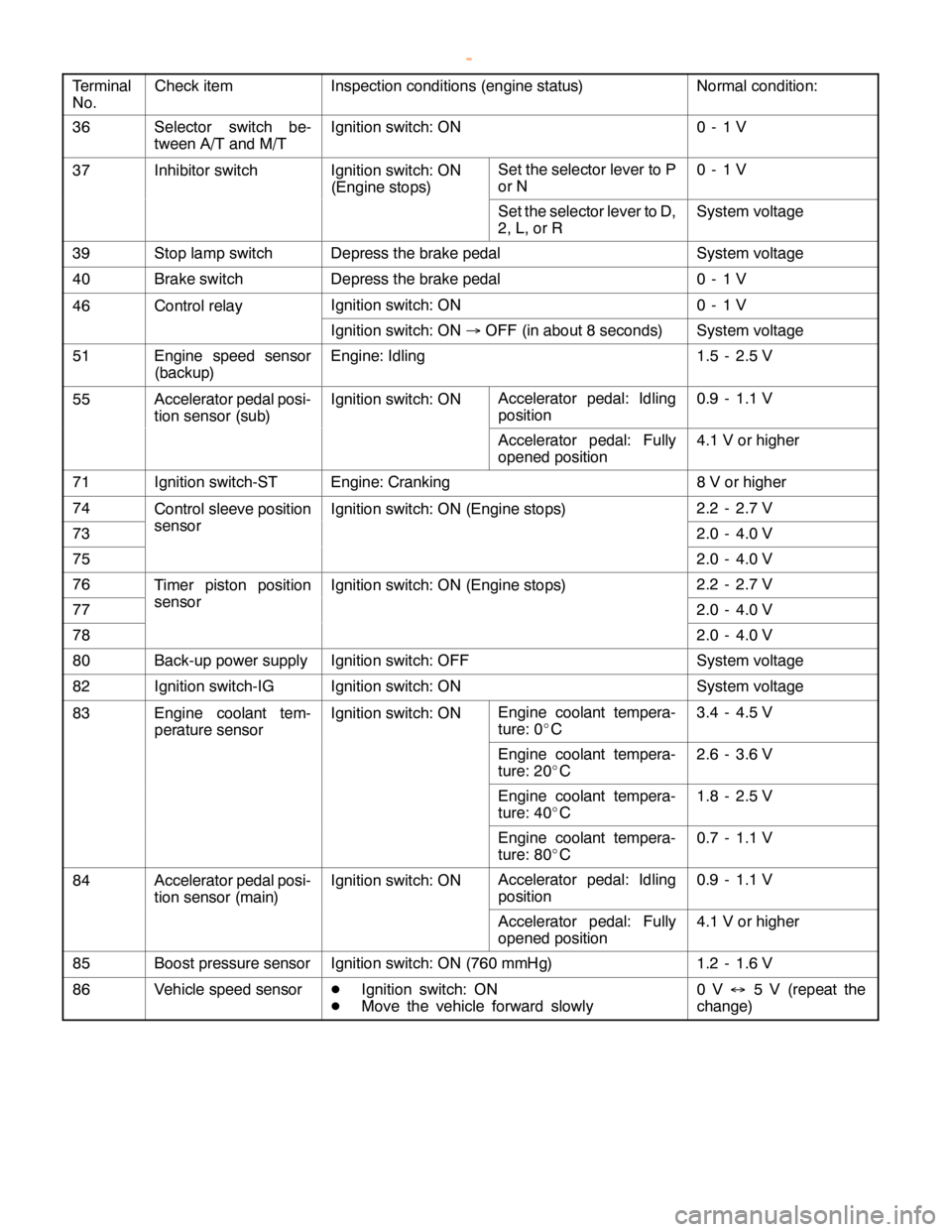

Terminal

No.Normal condition: Inspection conditions (engine status) Check item

36Selector switch be-

tween A/T and M/TIgnition switch: ON0-1V

37Inhibitor switchIgnition switch: ON

(Engine stops)Set the selector lever to P

or N0-1V

Set the selector lever to D,

2, L, or RSystem voltage

39Stop lamp switchDepress the brake pedalSystem voltage

40Brake switchDepress the brake pedal0-1V

46Control relayIgnition switch: ON0-1V

Ignition switch: ON®OFF (in about 8 seconds)System voltage

51Engine speed sensor

(backup)Engine: Idling1.5 - 2.5 V

55Accelerator pedal posi-

tion sensor (sub)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position4.1 V or higher

71Ignition switch-STEngine: Cranking8 V or higher

74Control sleeve positionIgnition switch: ON (Engine stops)2.2 - 2.7 V

73sensor2.0 - 4.0 V

752.0 - 4.0 V

76Timer piston positionIgnition switch: ON (Engine stops)2.2 - 2.7 V

77sensor2.0 - 4.0 V

782.0 - 4.0 V

80Back-up power supplyIgnition switch: OFFSystem voltage

82Ignition switch-IGIgnition switch: ONSystem voltage

83Engine coolant tem-

perature sensorIgnition switch: ONEngine coolant tempera-

ture: 0_C3.4 - 4.5 V

Engine coolant tempera-

ture: 20_C2.6 - 3.6 V

Engine coolant tempera-

ture: 40_C1.8 - 2.5 V

Engine coolant tempera-

ture: 80_C0.7 - 1.1 V

84Accelerator pedal posi-

tion sensor (main)Ignition switch: ONAccelerator pedal: Idling

position0.9 - 1.1 V

Accelerator pedal: Fully

opened position4.1 V or higher

85Boost pressure sensorIgnition switch: ON (760 mmHg)1.2 - 1.6 V

86Vehicle speed sensorDIgnition switch: ON

DMove the vehicle forward slowly0V«5 V (repeat the

change)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 557 of 1839

DIESEL FUEL <4M4> -General/Service Specifications/Troubleshooting13C-2

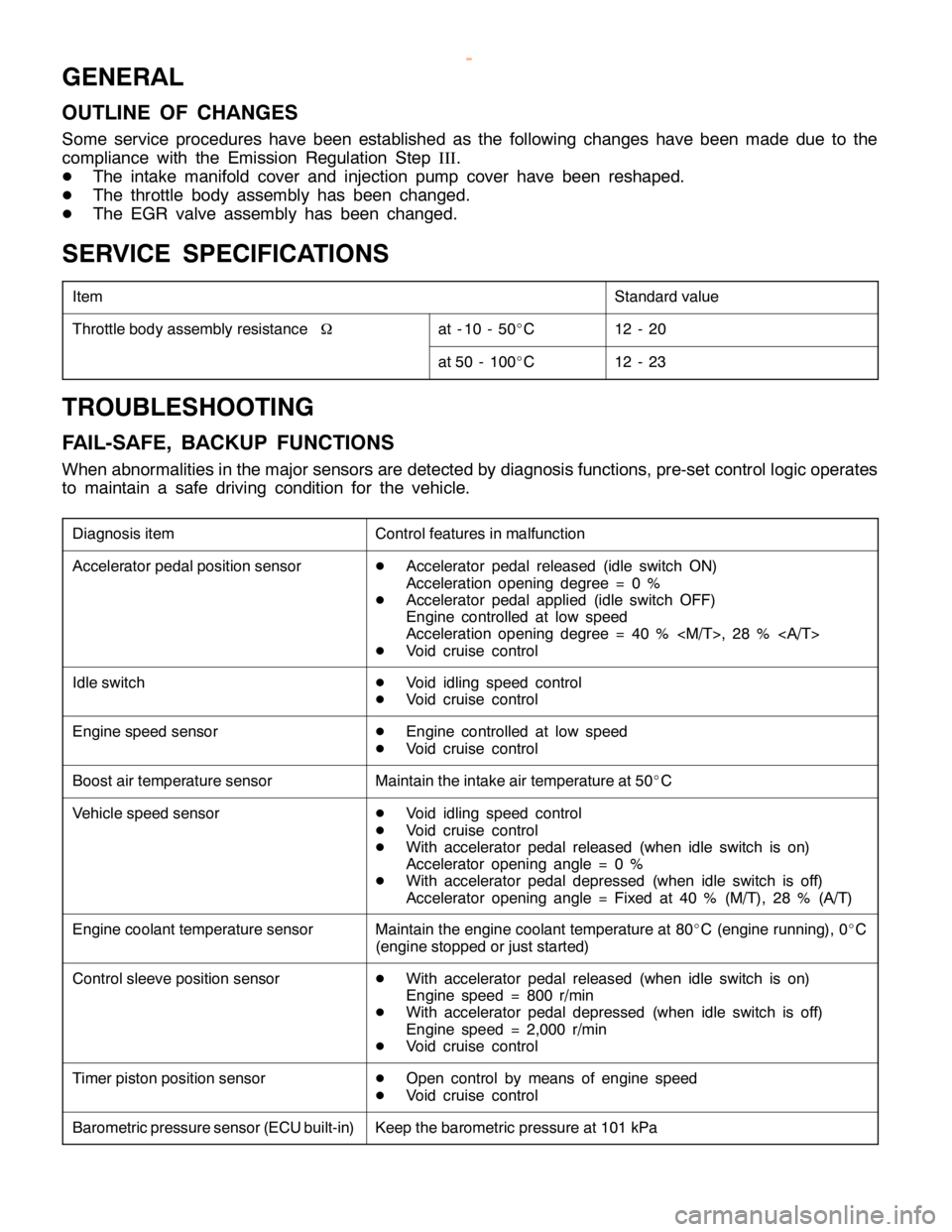

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation StepIII.

DThe intake manifold cover and injection pump cover have been reshaped.

DThe throttle body assembly has been changed.

DThe EGR valve assembly has been changed.

SERVICE SPECIFICATIONS

ItemStandard value

Throttle body assembly resistanceΩat - 10 - 50_C12 - 20

at 50 - 100_C12 - 23

TROUBLESHOOTING

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis itemControl features in malfunction

Accelerator pedal position sensorDAccelerator pedal released (idle switch ON)

Acceleration opening degree = 0 %

DAccelerator pedal applied (idle switch OFF)

Engine controlled at low speed

Acceleration opening degree = 40 %

DVoid cruise control

Idle switchDVoid idling speed control

DVoid cruise control

Engine speed sensorDEngine controlled at low speed

DVoid cruise control

Boost air temperature sensorMaintain the intake air temperature at 50_C

Vehicle speed sensorDVoid idling speed control

DVoid cruise control

DWith accelerator pedal released (when idle switch is on)

Accelerator opening angle = 0 %

DWith accelerator pedal depressed (when idle switch is off)

Accelerator opening angle = Fixed at 40 % (M/T), 28 % (A/T)

Engine coolant temperature sensorMaintain the engine coolant temperature at 80_C (engine running), 0_C

(engine stopped or just started)

Control sleeve position sensorDWith accelerator pedal released (when idle switch is on)

Engine speed = 800 r/min

DWith accelerator pedal depressed (when idle switch is off)

Engine speed = 2,000 r/min

DVoid cruise control

Timer piston position sensorDOpen control by means of engine speed

DVoid cruise control

Barometric pressure sensor (ECU built-in)Keep the barometric pressure at 101 kPa

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 611 of 1839

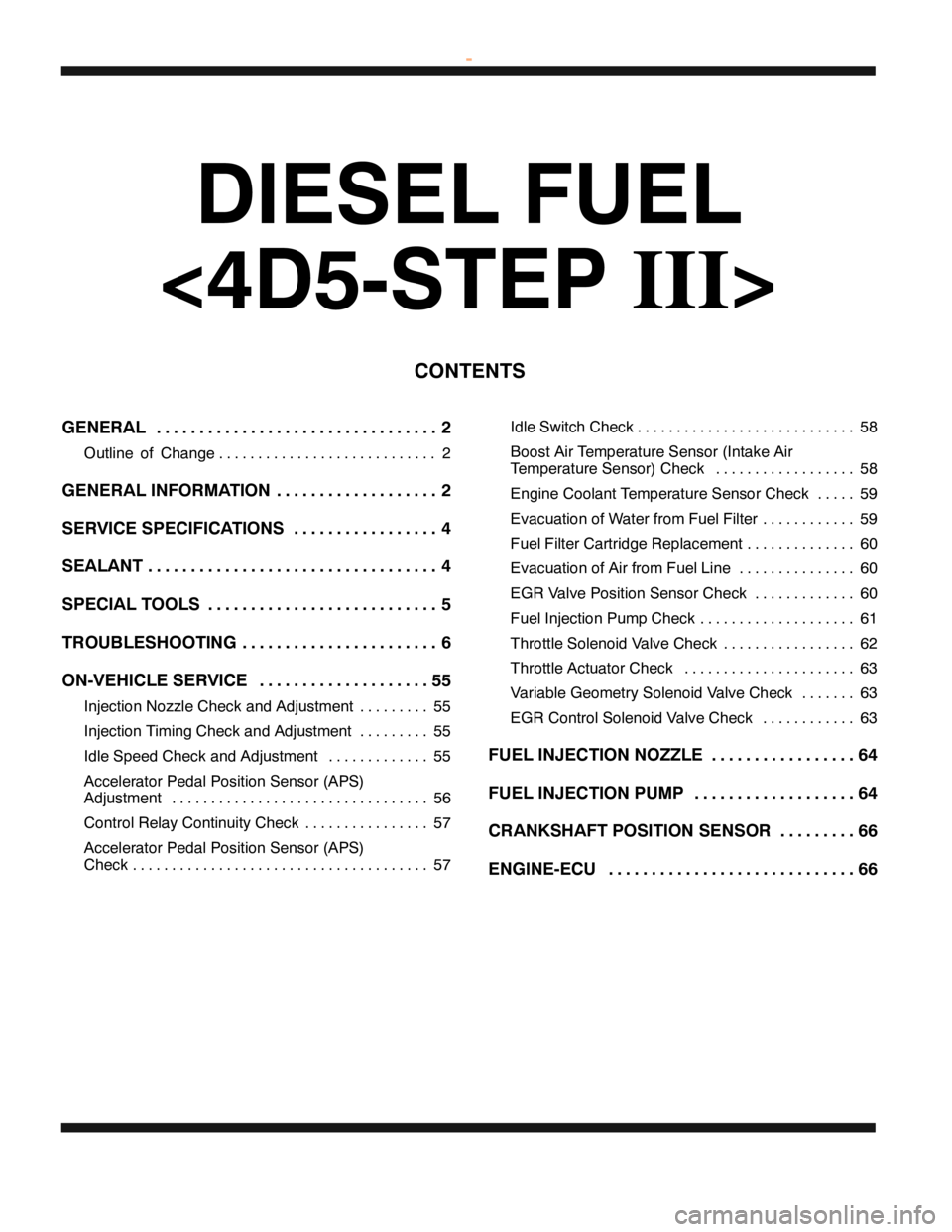

13E-1

DIESEL FUEL

<4D5-STEPIII

>

CONTENTS

GENERAL 2.................................

Outline of Change 2............................

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 4.................

SEALANT 4..................................

SPECIAL TOOLS 5...........................

TROUBLESHOOTING 6.......................

ON-VEHICLE SERVICE 55....................

Injection Nozzle Check and Adjustment 55.........

Injection Timing Check and Adjustment 55.........

Idle Speed Check and Adjustment 55.............

Accelerator Pedal Position Sensor (APS)

Adjustment 56.................................

Control Relay Continuity Check 57................

Accelerator Pedal Position Sensor (APS)

Check 57......................................Idle Switch Check 58............................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 58..................

Engine Coolant Temperature Sensor Check 59.....

Evacuation of Water from Fuel Filter 59............

Fuel Filter Cartridge Replacement 60..............

Evacuation of Air from Fuel Line 60...............

EGR Valve Position Sensor Check 60.............

Fuel Injection Pump Check 61....................

Throttle Solenoid Valve Check 62.................

Throttle Actuator Check 63......................

Variable Geometry Solenoid Valve Check 63.......

EGR Control Solenoid Valve Check 63............

FUEL INJECTION NOZZLE 64.................

FUEL INJECTION PUMP 64...................

CRANKSHAFT POSITION SENSOR 66.........

ENGINE-ECU 66.............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 612 of 1839

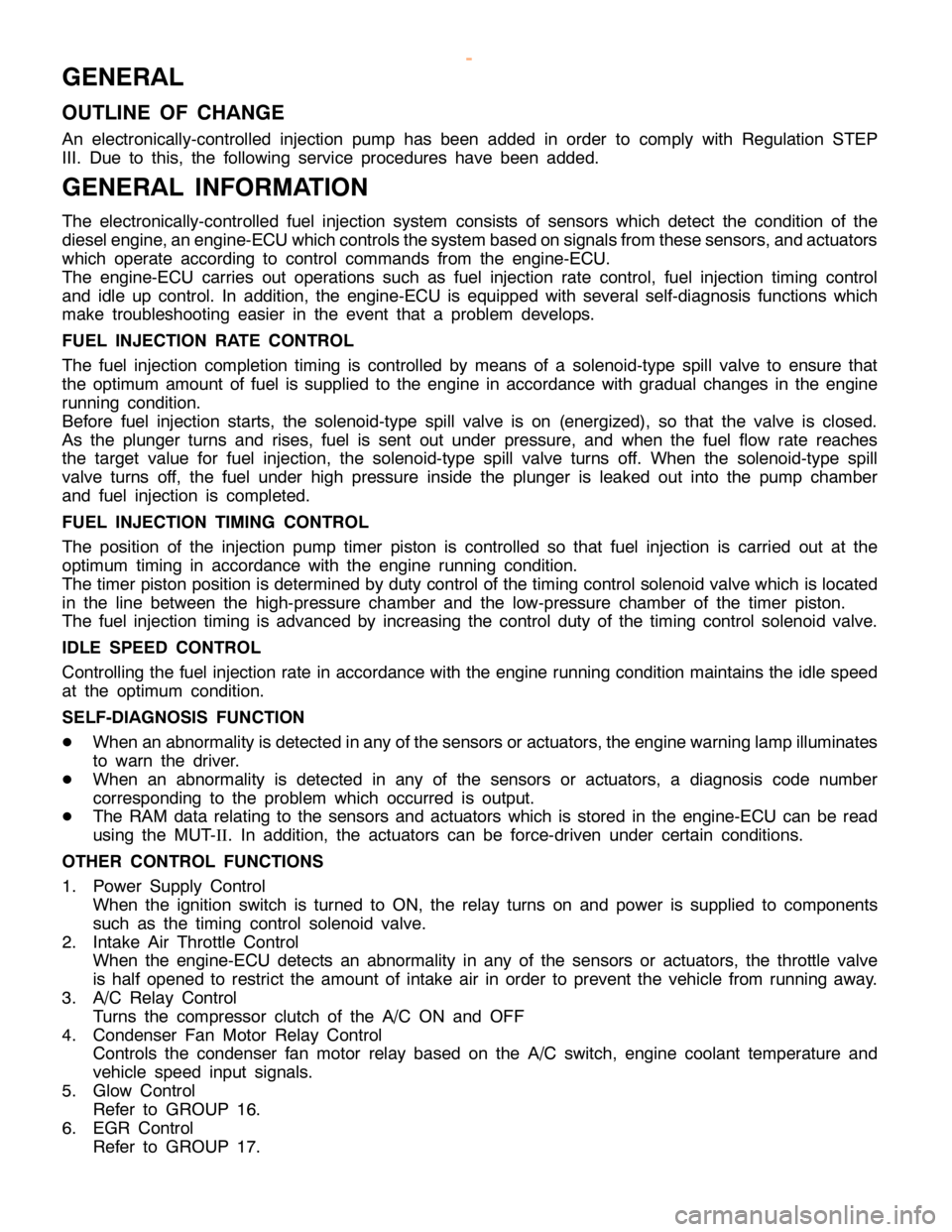

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

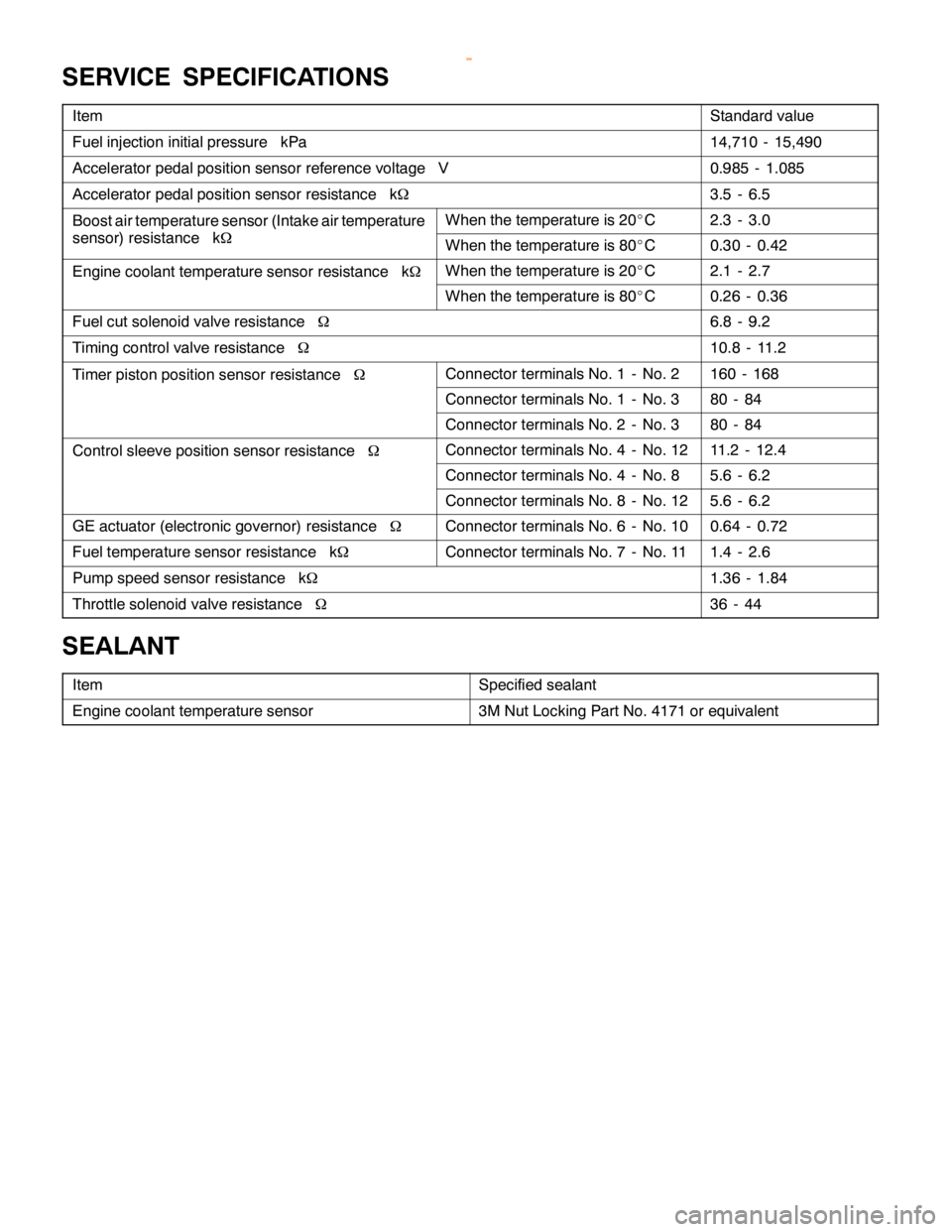

Page 614 of 1839

DIESEL FUEL <4D5-stepIII>-Service Specifications/Sealant13E-4

SERVICE SPECIFICATIONS

ItemStandard value

Fuel injection initial pressure kPa14,710 - 15,490

Accelerator pedal position sensor reference voltage V0.985 - 1.085

Accelerator pedal position sensor resistance kΩ3.5 - 6.5

Boost air temperature sensor (Intake air temperature

)itkΩ

When the temperature is 20_C2.3 - 3.0p(p

sensor) resistance kΩWhen the temperature is 80_C0.30 - 0.42

Engine coolant temperature sensor resistance kΩWhen the temperature is 20_C2.1 - 2.7gp

When the temperature is 80_C0.26 - 0.36

Fuel cut solenoid valve resistanceΩ6.8 - 9.2

Timing control valve resistanceΩ10.8 - 11.2

Timer piston position sensor resistanceΩConnector terminals No. 1 - No. 2160 - 168pp

Connector terminals No. 1 - No. 380 - 84

Connector terminals No. 2 - No. 380 - 84

Control sleeve position sensor resistanceΩConnector terminals No. 4 - No. 1211.2 - 12.4p

Connector terminals No. 4 - No. 85.6 - 6.2

Connector terminals No. 8 - No. 125.6 - 6.2

GE actuator (electronic governor) resistanceΩConnector terminals No. 6 - No. 100.64 - 0.72

Fuel temperature sensor resistance kΩConnector terminals No. 7 - No. 111.4 - 2.6

Pump speed sensor resistance kΩ1.36 - 1.84

Throttle solenoid valve resistanceΩ36 - 44

SEALANT

ItemSpecified sealant

Engine coolant temperature sensor3M Nut Locking Part No. 4171 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 617 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-7

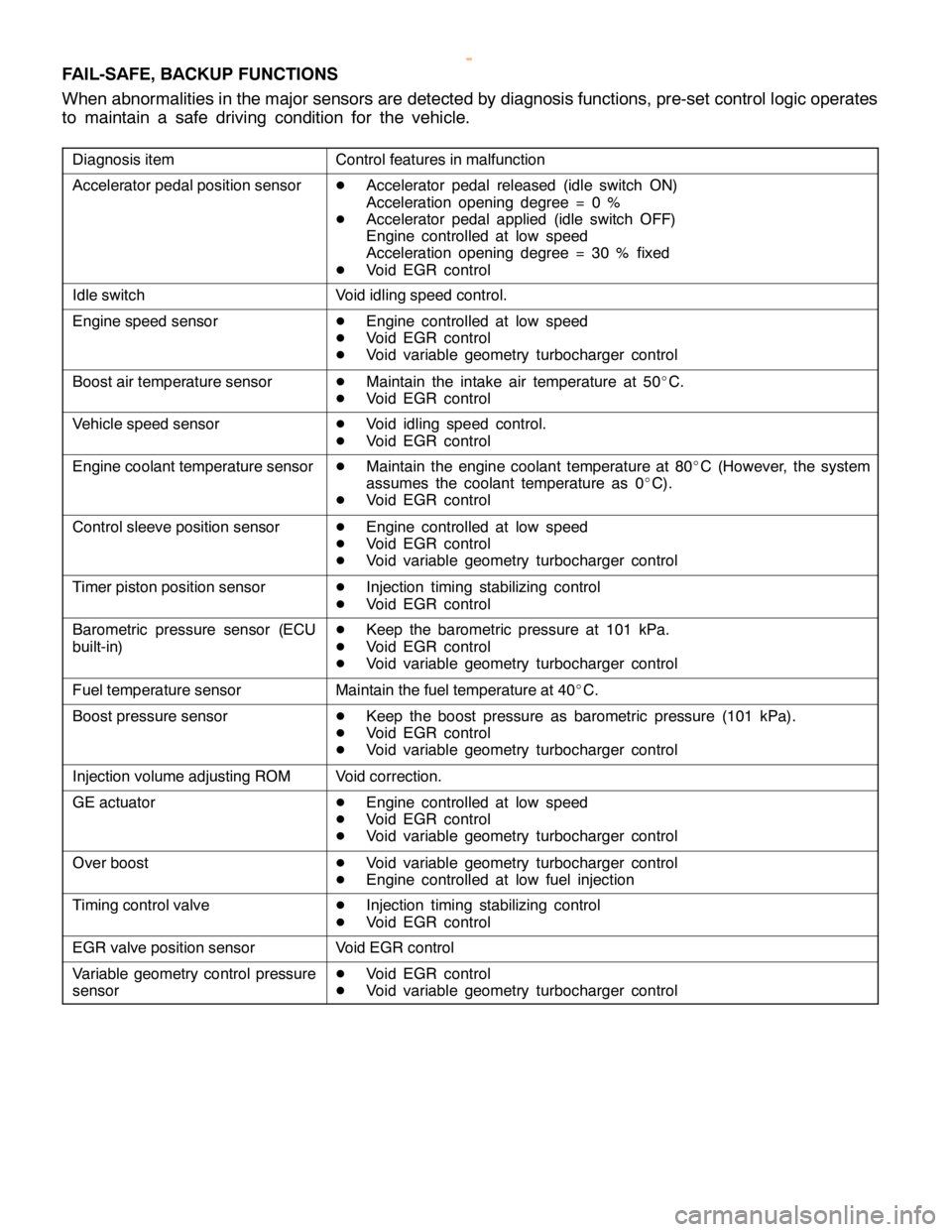

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis itemControl features in malfunction

Accelerator pedal position sensorDAccelerator pedal released (idle switch ON)

Acceleration opening degree = 0 %

DAccelerator pedal applied (idle switch OFF)

Engine controlled at low speed

Acceleration opening degree = 30 % fixed

DVoid EGR control

Idle switchVoid idling speed control.

Engine speed sensorDEngine controlled at low speed

DVoid EGR control

DVoid variable geometry turbocharger control

Boost air temperature sensorDMaintain the intake air temperature at 50_C.

DVoid EGR control

Vehicle speed sensorDVoid idling speed control.

DVoid EGR control

Engine coolant temperature sensorDMaintain the engine coolant temperature at 80_C (However, the system

assumes the coolant temperature as 0_C).

DVoid EGR control

Control sleeve position sensorDEngine controlled at low speed

DVoid EGR control

DVoid variable geometry turbocharger control

Timer piston position sensorDInjection timing stabilizing control

DVoid EGR control

Barometric pressure sensor (ECU

built-in)DKeep the barometric pressure at 101 kPa.

DVoid EGR control

DVoid variable geometry turbocharger control

Fuel temperature sensorMaintain the fuel temperature at 40_C.

Boost pressure sensorDKeep the boost pressure as barometric pressure (101 kPa).

DVoid EGR control

DVoid variable geometry turbocharger control

Injection volume adjusting ROMVoid correction.

GE actuatorDEngine controlled at low speed

DVoid EGR control

DVoid variable geometry turbocharger control

Over boostDVoid variable geometry turbocharger control

DEngine controlled at low fuel injection

Timing control valveDInjection timing stabilizing control

DVoid EGR control

EGR valve position sensorVoid EGR control

Variable geometry control pressure

sensorDVoid EGR control

DVoid variable geometry turbocharger control

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 618 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-8

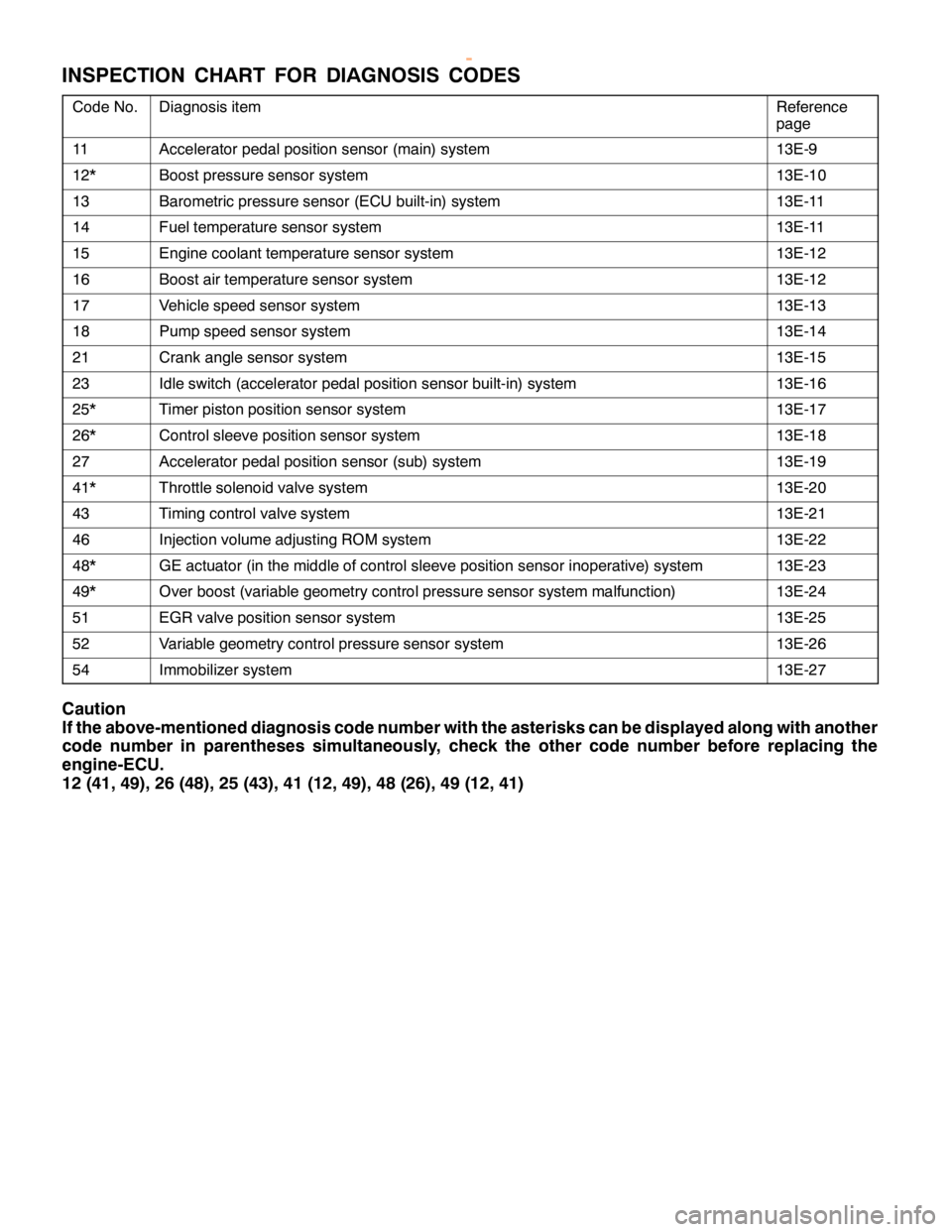

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference

page

11Accelerator pedal position sensor (main) system13E-9

12*Boost pressure sensor system13E-10

13Barometric pressure sensor (ECU built-in) system13E-11

14Fuel temperature sensor system13E-11

15Engine coolant temperature sensor system13E-12

16Boost air temperature sensor system13E-12

17Vehicle speed sensor system13E-13

18Pump speed sensor system13E-14

21Crank angle sensor system13E-15

23Idle switch (accelerator pedal position sensor built-in) system13E-16

25*Timer piston position sensor system13E-17

26*Control sleeve position sensor system13E-18

27Accelerator pedal position sensor (sub) system13E-19

41*Throttle solenoid valve system13E-20

43Timing control valve system13E-21

46Injection volume adjusting ROM system13E-22

48*GE actuator (in the middle of control sleeve position sensor inoperative) system13E-23

49*Over boost (variable geometry control pressure sensor system malfunction)13E-24

51EGR valve position sensor system13E-25

52Variable geometry control pressure sensor system13E-26

54Immobilizer system13E-27

Caution

If the above-mentioned diagnosis code number with the asterisks can be displayed along with another

code number in parentheses simultaneously, check the other code number before replacing the

engine-ECU.

12 (41, 49), 26 (48), 25 (43), 41 (12, 49), 48 (26), 49 (12, 41)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk