oil type MITSUBISHI SHOGUN 2003 Owner's Manual (in English)

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2003, Model line: SHOGUN, Model: MITSUBISHI SHOGUN 2003Pages: 392, PDF Size: 14.34 MB

Page 100 of 392

NOTE

(1) In certain cases immediately after the engine hasbeen started or when the brake pedal is

depressed repeatedly, a noise generated by

operation of brake devices may be heard com-

ing from the engine compartment. This type of

noise is normal and is no need for concern in

fact, it indicates that the corresponding devices

are operating normally. (This applies to vehicles

fitted with anti-lock brake system)

(2) On vehicles equipped with anti-lock brake sys-

tem, the brake system uses brake fluid pres-

surized by the pump.

Please refer to the “Brake system ”on page 5-44.Oil pressure warning lamp - red

ED25A-Ah

This lamp illuminates when the ignition switch is

turned “ON ”, and goes off after the engine has

started. If it illuminates while the engine is run-

ning, the oil pressure is too low.

If the warning lamp illuminates while the engine is

running, turn the engine off and contact your near-

est authorized MITSUBISHI dealer for inspection.

CAUTION

(1)If this lamp illuminates when the engine oil level is not low, contact your nearest autho-

rized MITSUBISHI dealer for inspection.

(2)This warning lamp does not indicate the amount of oil in the crankcase. This must

be determined by checking the oil level on

the dipstick, while the engine is switched

off.

(3)If you continue driving with low engine oil level or with this warning lamp illumi-

nated, engine seizure may occur.

NOTE

The oil pressure warning lamp should not be treated

as an indication of the engine ’s oil level. The oil level

must be checked using the dipstick.

Instruments and controls

4-8Div:

Out put date:

Page 297 of 392

Chrome parts

EK06A-Aa

In order to prevent spots and corrosion of

chrome parts, wash with water, dry thor-

oughly, and apply a special protective coat-

ing. This should be done more frequently

in winter.Aluminium wheels*

EK35A-Af

A protective coating is provided over the

aluminium type wheels.

Clean aluminium wheels with a cleaner

designed for use on aluminium and apply

an appropriate protection agent.

NOTE

(1) When cleaning aluminium type wheels,

do not use abrasive cleaners. Wheels

exposed to sea water or road chemi-

cals should be cleaned as soon as

possible.

(2) Brushes may damage the aluminium

wheel surface. Always use a sponge,

chamois leather, etc.

(3) Do not apply hot water directly from the

steam cleaner or similar to the wheel

surface.

Window glass

EK10A-E

Window glass can normally be cleaned

using only a sponge and water.

Glass cleaner can be used to remove oil,

grease, dead insects, etc. After washing the

glass, wipe dry with a clean, dry, soft cloth.

Never use the same cloth to wipe the win-

dow glass as would be used to wipe the

paintwork; wax from the painted surfaces

could adhere to the glass and reduce its

transparency and visibility.

NOTE

To clean the inside of the backdoor win-

dow, always use a soft cloth and wipe the

window glass along the demister heater

element so as not to cause damage.Wiper blades

EK11A-Aa

Use a soft cloth and glass cleaner to

remove grease, dead insects, etc., from the

wiper blades. Replace the wiper blades

when they no longer wipe properly (Refer

to page 9-19).

Cleaning the sunroof*

EK30A-Ab

Clean the inside of the sunroof with a soft

cloth. Hard deposits should be wiped away

with a cloth dipped in warm, neutral deter-

gent solution. Wipe away the solution with

a sponge dipped in fresh water.

NOTE

The surface treatment on the inside of the

glass may be removed if a hard cloth or

organic solvent (benzine, thinner, etc.) is

used.

Vehicle care

7-7

Div:

Out put date:

Page 308 of 392

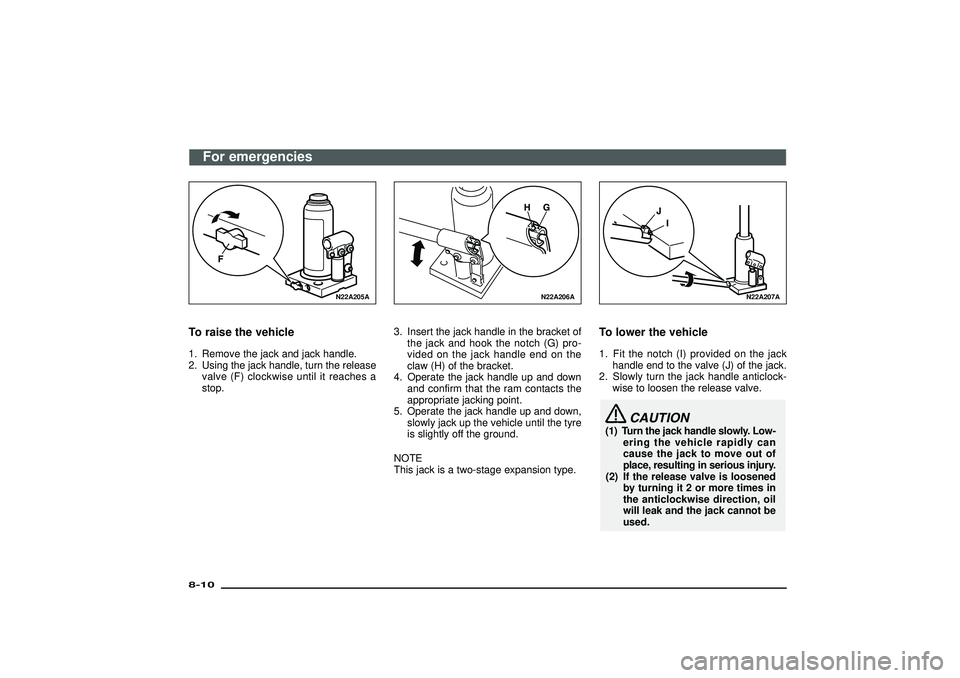

N22A205A

To raise the vehicle1. Remove the jack and jack handle.

2. Using the jack handle, turn the release

valve (F) clockwise until it reaches a

stop.

N22A206A

3. Insert the jack handle in the bracket of

the jack and hook the notch (G) pro-

vided on the jack handle end on the

claw (H) of the bracket.

4. Operate the jack handle up and down

and confirm that the ram contacts the

appropriate jacking point.

5. Operate the jack handle up and down,

slowly jack up the vehicle until the tyre

is slightly off the ground.

NOTE

This jack is a two-stage expansion type.

N22A207A

To lower the vehicle1. Fit the notch (I) provided on the jack

handle end to the valve (J) of the jack.

2. Slowly turn the jack handle anticlock-

wise to loosen the release valve.

CAUTION

(1) Turn the jack handle slowly. Low-

ering the vehicle rapidly can

cause the jack to move out of

place, resulting in serious injury.

(2) If the release valve is loosened

by turning it 2 or more times in

the anticlockwise direction, oil

will leak and the jack cannot be

used.

For emergencies

8-10Div:

Out put date:

Page 314 of 392

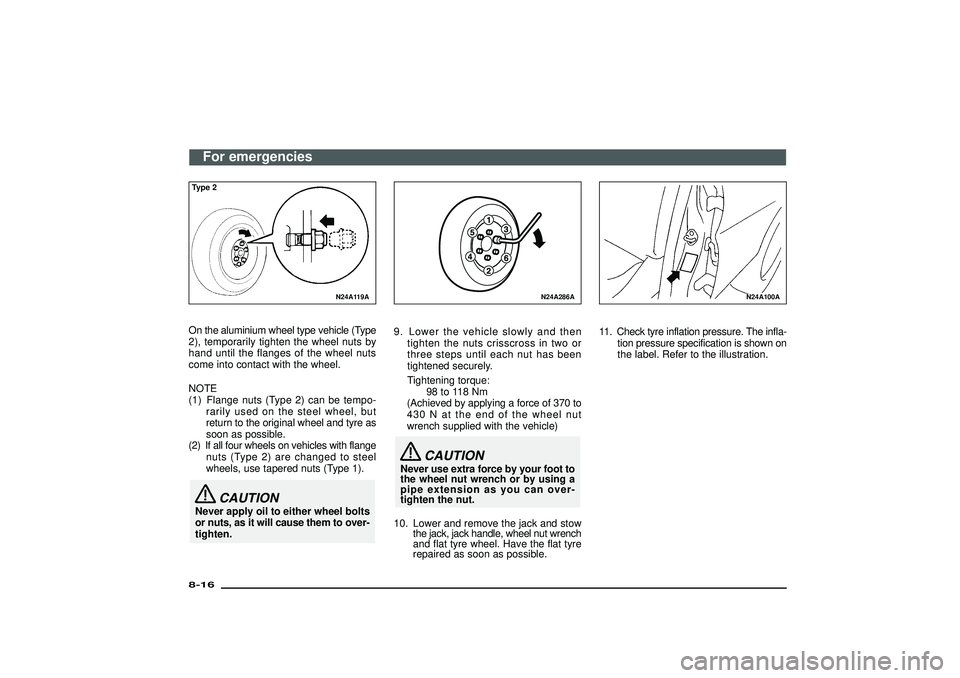

N24A119A

Type 2On the aluminium wheel type vehicle (Type

2), temporarily tighten the wheel nuts by

hand until the flanges of the wheel nuts

come into contact with the wheel.

NOTE

(1) Flange nuts (Type 2) can be tempo-

rarily used on the steel wheel, but

return to the original wheel and tyre as

soon as possible.

(2) If all four wheels on vehicles with flange

nuts (Type 2) are changed to steel

wheels, use tapered nuts (Type 1).

CAUTION

Never apply oil to either wheel bolts

or nuts, as it will cause them to over-

tighten.

N24A286A

9. Lower the vehicle slowly and then

tighten the nuts crisscross in two or

three steps until each nut has been

tightened securely.

Tightening torque:

98 to 118 Nm

(Achieved by applying a force of 370 to

430 N at the end of the wheel nut

wrench supplied with the vehicle)

CAUTION

Never use extra force by your foot to

the wheel nut wrench or by using a

pipe extension as you can over-

tighten the nut.

10. Lower and remove the jack and stow

the jack, jack handle, wheel nut wrench

and flat tyre wheel. Have the flat tyre

repaired as soon as possible.

N24A100A

11. Check tyre inflation pressure. The infla-

tion pressure specification is shown on

the label. Refer to the illustration.

For emergencies

8-16Div:

Out put date:

Page 332 of 392

N29C001A

6. Insert a new fuse of the same capac-

ity by using the fuse puller and insert the

fuse at the same place in the fuse box.

CAUTION

(1) If the newly inserted fuse blows

again after a short time, have the

electric system checked by an

authorized MITSUBISHI dealer to

find the cause and rectify it.

(2) Never use a fuse with a capac-

ity larger than that specified or

any substitute, such as wire, foil,

etc.; doing so will cause the cir-

cuit wiring to heat up and could

cause a fire.

Replacement of lamp bulbs

EN10A-Ab

Before replacing a bulb, ensure the lamp

is off. Do not touch the glass part of the

new bulb with your bare fingers; the skin oil

left on the glass will evaporate when the

bulb gets hot and the vapor will con-

dense on the reflector and dim the sur-

face.

N10B307A

Bulb capacity

EN10BOIb

A bulb should only be replaced with a new

bulb of the same rating and type. The des-

ignation can be found on the base of the

bulb.

Outside

1- Headlamps, upper/lower beam

..................................60/55W (H4)

2- Front fog lamps*

........................... 51W(HB4)·9006

3- Front turn-signal lamps . 21W (W21W)

4- Position lamps................ 5W(W5W)

5- Side turn-signal lamps ... 5W (WY5W)

6- Side step lamps*........... 5W(WY5W)

For emergencies

8-34Div:

Out put date:

Page 375 of 392

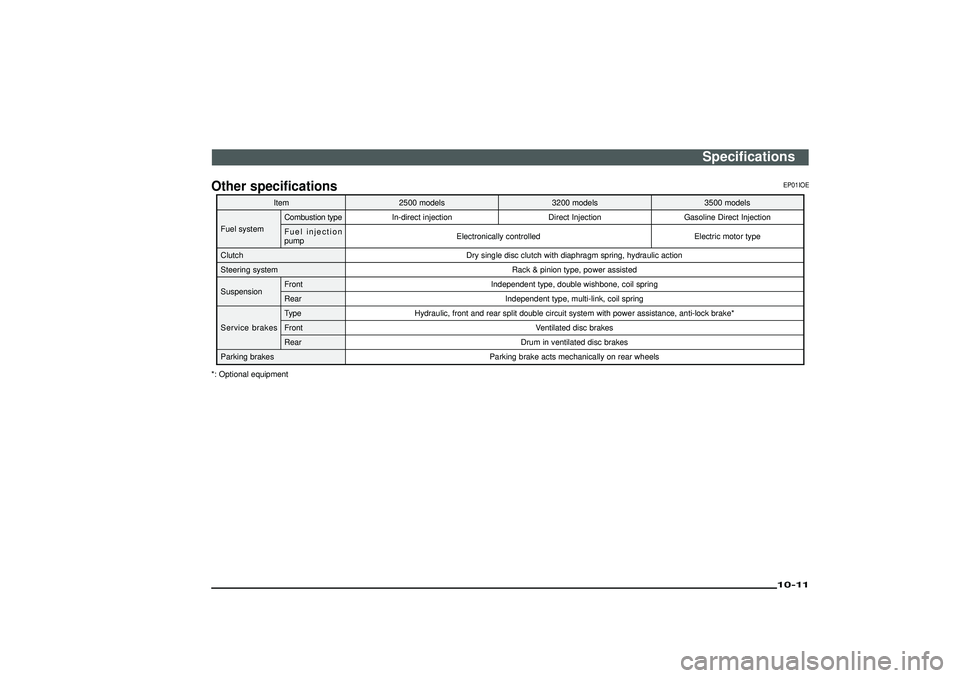

Other specifications

EP01IOE

Item 2500 models 3200 models 3500 models

Fuel systemCombustion typeIn-direct injection Direct Injection Gasoline Direct Injection

Fuel injection

pumpElectronically controlled Electric motor type

Clutch Dry single disc clutch with diaphragm spring, hydraulic action

Steering system Rack & pinion type, power assisted

SuspensionFront Independent type, double wishbone, coil spring

Rear Independent type, multi-link, coil spring

Service brakesType Hydraulic, front and rear split double circuit system with power assistance, anti-lock brake*

Front Ventilated disc brakes

Rear Drum in ventilated disc brakes

Parking brakes Parking brake acts mechanically on rear wheels

*: Optional equipment

Specifications

10-11

Div:

Out put date: