MITSUBISHI SHOGUN 2008 Owner's Manual (in English)

Manufacturer: MITSUBISHI, Model Year: 2008, Model line: SHOGUN, Model: MITSUBISHI SHOGUN 2008Pages: 538, PDF Size: 25.09 MB

Page 421 of 538

For emergencies

6-17

6

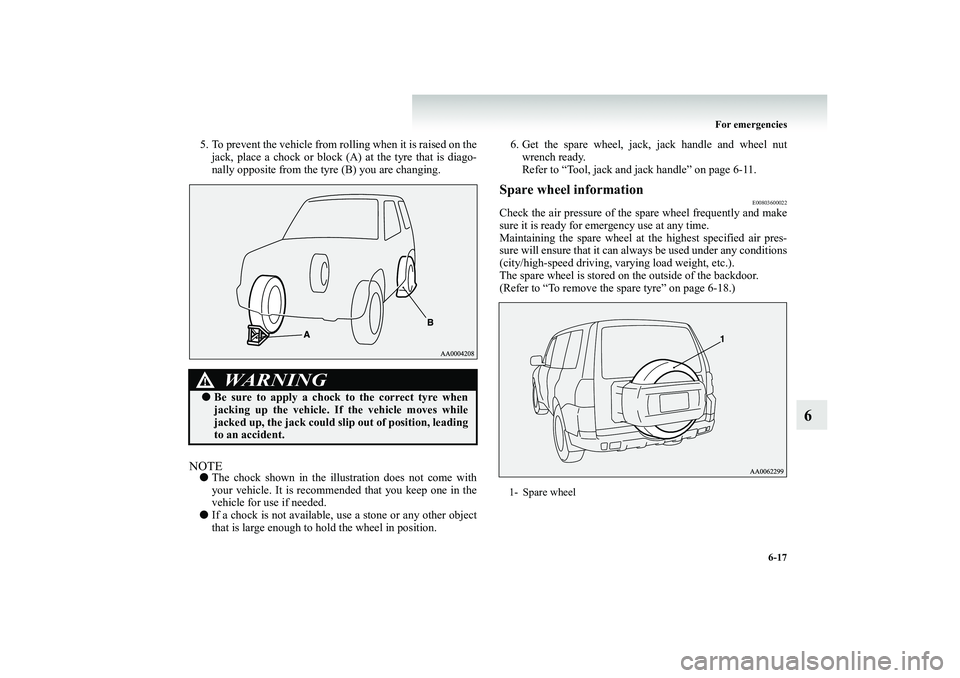

5. To prevent the vehicle from rol

ling when it is raised on the

jack, place a chock or block (A)

at the tyre that is diago-

nally opposite from the tyre (B) you are changing.

NOTE●

The chock shown in the illustration does not come with your vehicle. It is recommended that you keep one in thevehicle for use if needed.

●

If a chock is not available,

use a stone or any other object

that is large enough to hold the wheel in position.

6. Get the spare wheel, jack,

jack handle and wheel nut

wrench ready. Refer to “Tool, jack and jack handle” on page 6-11.

Spare wheel information

E00803600022

Check the air pressure of the

spare wheel frequently and make

sure it is ready for emergency use at any time. Maintaining the spare wheel at

the highest specified air pres-

sure will ensure that it can al

ways be used under any conditions

(city/high-speed driving, varying load weight, etc.). The spare wheel is stored on

the outside of the backdoor.

(Refer to “To remove the spare tyre” on page 6-18.)

WARNING

!●

Be sure to apply a chock to the correct tyre when jacking up the vehicle. If

the vehicle moves while

jacked up, the jack could sl

ip out of position, leading

to an accident.

1- Spare wheel

BK-BK2008E1ENUK.en-uk-Section9.fm Page

17 Wednesday, January 9, 2008 4:46 PM

Page 422 of 538

6-18 For emergencies

6

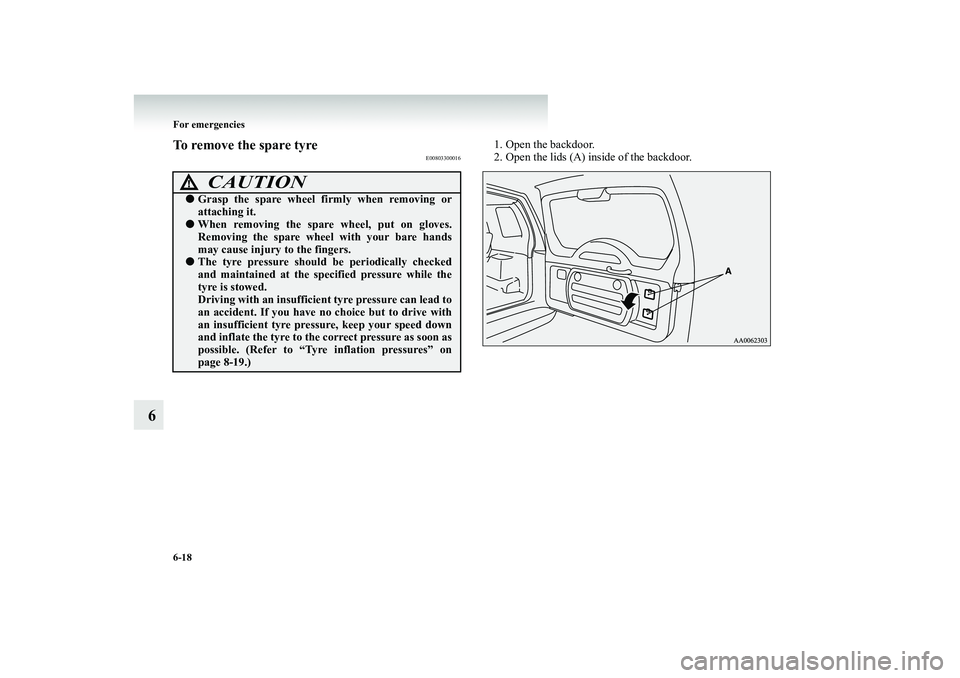

To remove the spare tyre

E00803300016

1. Open the backdoor. 2. Open the lids (A) inside of the backdoor.

CAUTION

!●

Grasp the spare wheel firmly when removing or attaching it.

●

When removing the spare wheel, put on gloves. Removing the spare wheel with your bare hands may cause injury to the fingers.

●

The tyre pressure should

be periodically checked

and maintained at the speci

fied pressure while the

tyre is stowed.Driving with an insufficient tyre pressure can lead to an accident. If you have no choice but to drive with an insufficient tyre pres

sure, keep your speed down

and inflate the tyre to the

correct pressure as soon as

possible. (Refer to “Tyre

inflation pressures” on

page 8-19.)

BK-BK2008E1ENUK.en-uk-Section9.fm Page

18 Wednesday, January 9, 2008 4:46 PM

Page 423 of 538

For emergencies

6-19

6

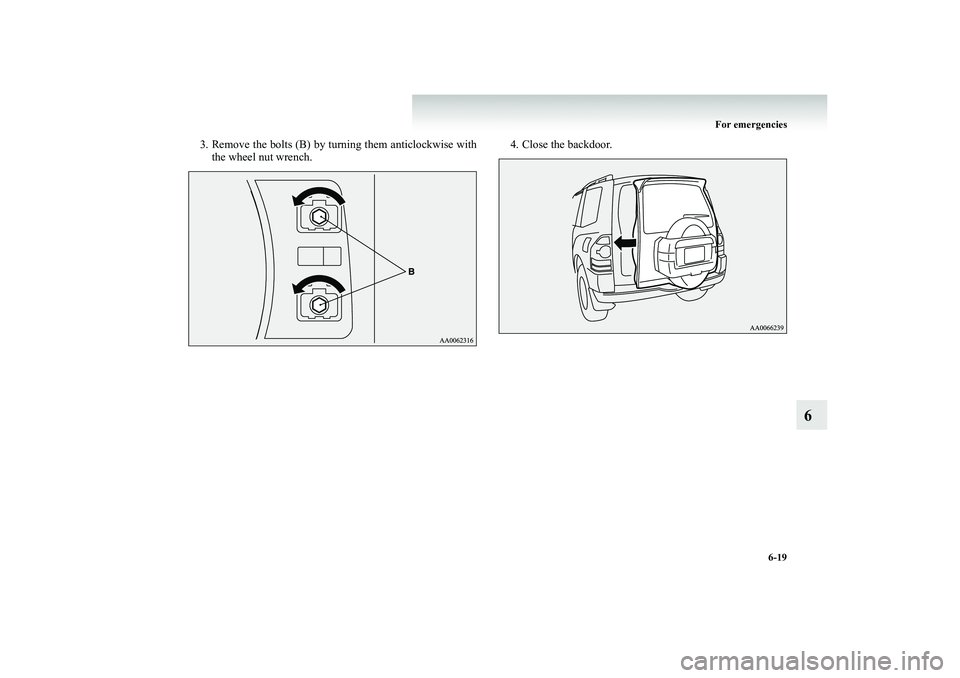

3. Remove the bolts (B) by turning them anticlockwise with

the wheel nut wrench.

4. Close the backdoor.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

19 Wednesday, January 9, 2008 4:46 PM

Page 424 of 538

6-20 For emergencies

6

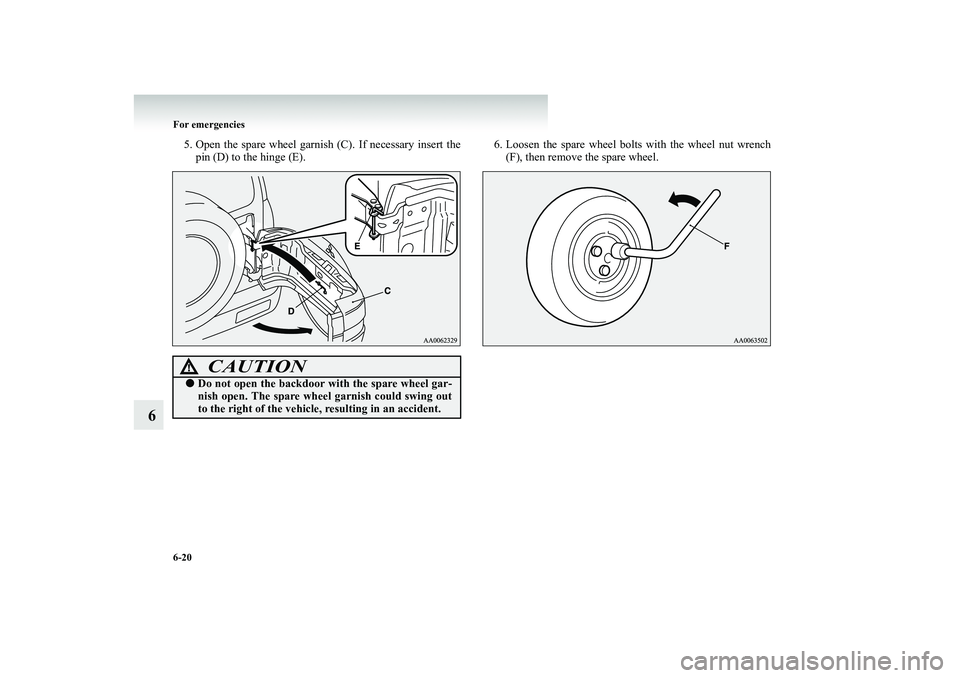

5. Open the spare wheel garnish

(C). If necessary insert the

pin (D) to the hinge (E).

6. Loosen the spare wheel bolts

with the wheel nut wrench

(F), then remove the spare wheel.

CAUTION

!●

Do not open the backdoor

with the spare wheel gar-

nish open. The spare wheel

garnish could swing out

to the right of the vehicle,

resulting in an accident.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

20 Wednesday, January 9, 2008 4:46 PM

Page 425 of 538

For emergencies

6-21

6

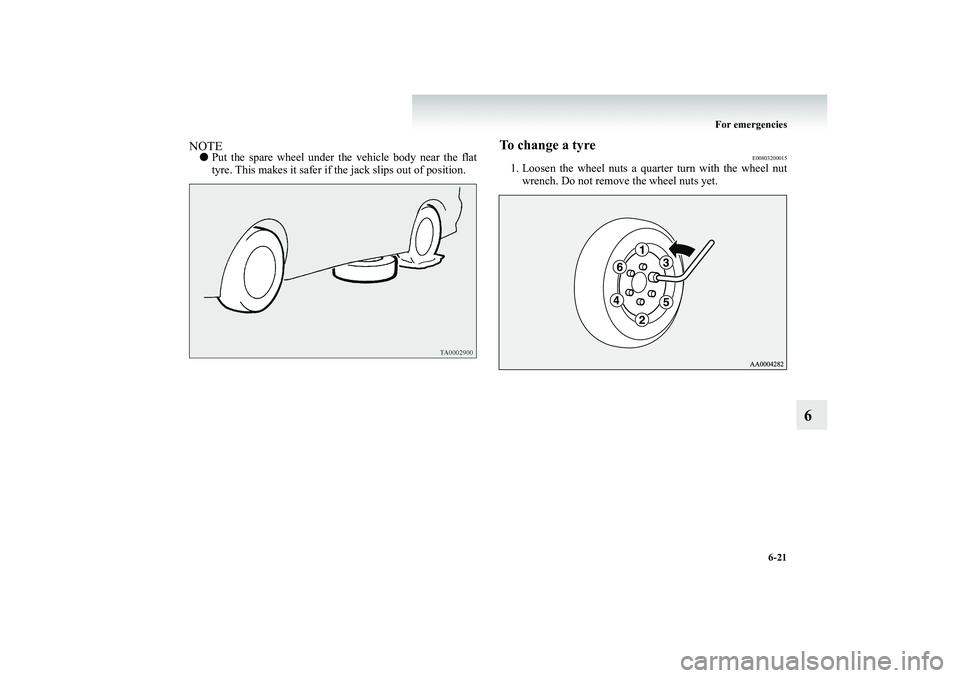

NOTE●

Put the spare wheel under th

e vehicle body near the flat

tyre. This makes it safer if the jack slips out of position.

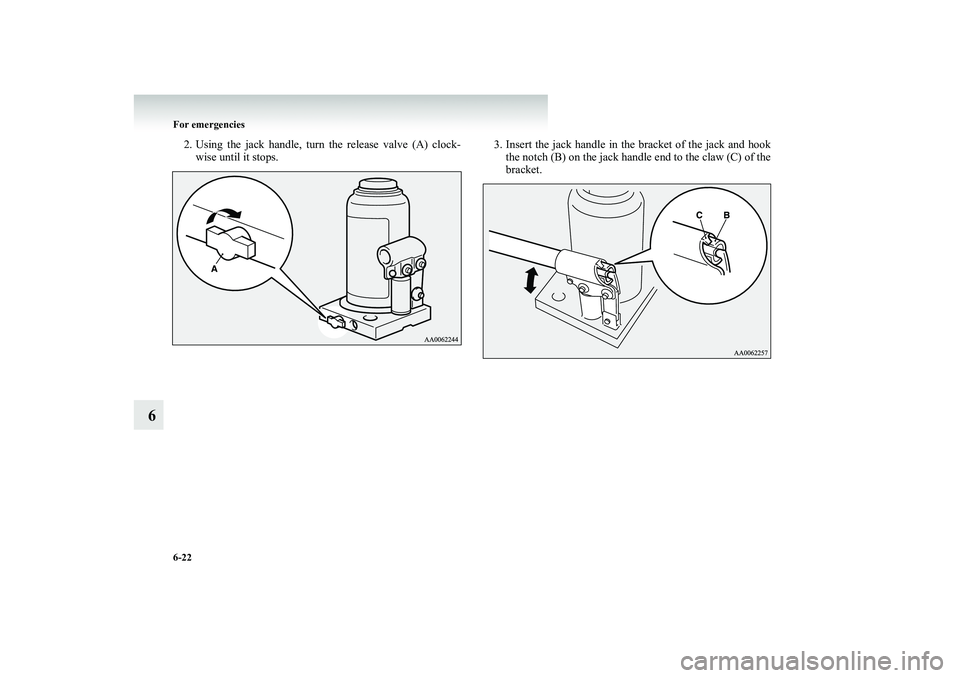

To change a tyre

E00803200015

1. Loosen the wheel nuts a quar

ter turn with the wheel nut

wrench. Do not remove the wheel nuts yet.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

21 Wednesday, January 9, 2008 4:46 PM

Page 426 of 538

6-22 For emergencies

6

2. Using the jack handle, turn

the release valve (A) clock-

wise until it stops.

3. Insert the jack handle in the bracket of the jack and hook

the notch (B) on the jack handle

end to the claw (C) of the

bracket.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

22 Wednesday, January 9, 2008 4:46 PM

Page 427 of 538

For emergencies

6-23

6

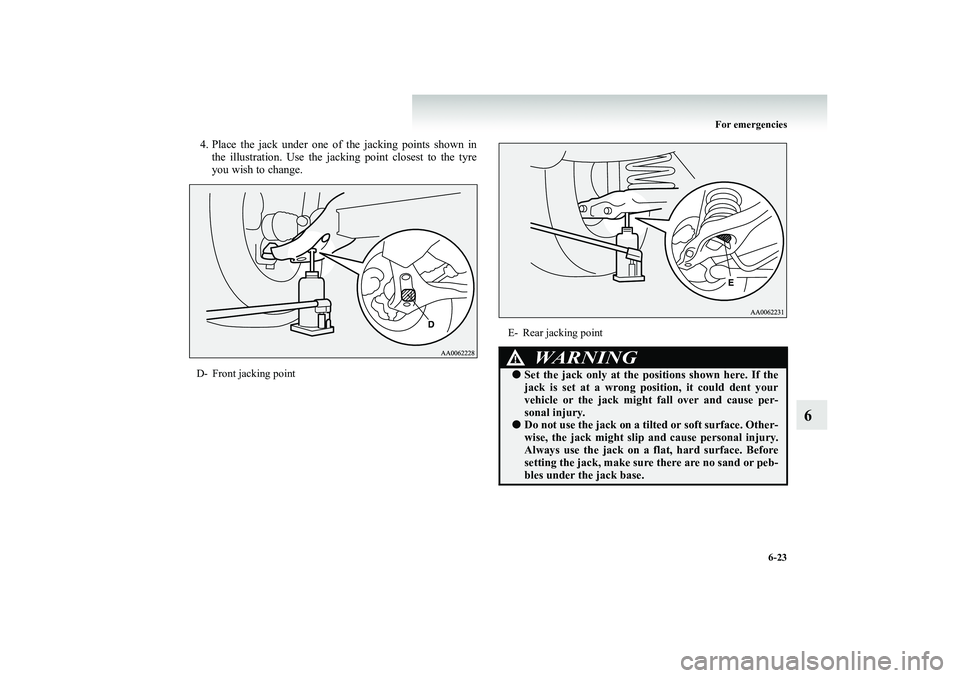

4. Place the jack under one of

the jacking points shown in

the illustration. Use the jack

ing point closest to the tyre

you wish to change.

D- Front jacking point

E- Rear jacking point

WARNING

!●

Set the jack only at the po

sitions shown here. If the

jack is set at a wrong position, it could dent yourvehicle or the jack might

fall over and cause per-

sonal injury.

●

Do not use the jack on a tilt

ed or soft surface. Other-

wise, the jack might slip

and cause personal injury.

Always use the jack on a

flat, hard surface. Before

setting the jack, make sure there are no sand or peb-bles under the jack base.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

23 Wednesday, January 9, 2008 4:46 PM

Page 428 of 538

6-24 For emergencies

6

5. Move the jack handle up a

nd down to raise the ram until

just before the jack contacts

the jacking point of the vehi-

cle. Ensure that the jack will

properly contact the vehicle

jacking point.

NOTE●

This jack is a 3 stage expansion type.

6. Raise the vehicle until the tyre is slightly off the ground.

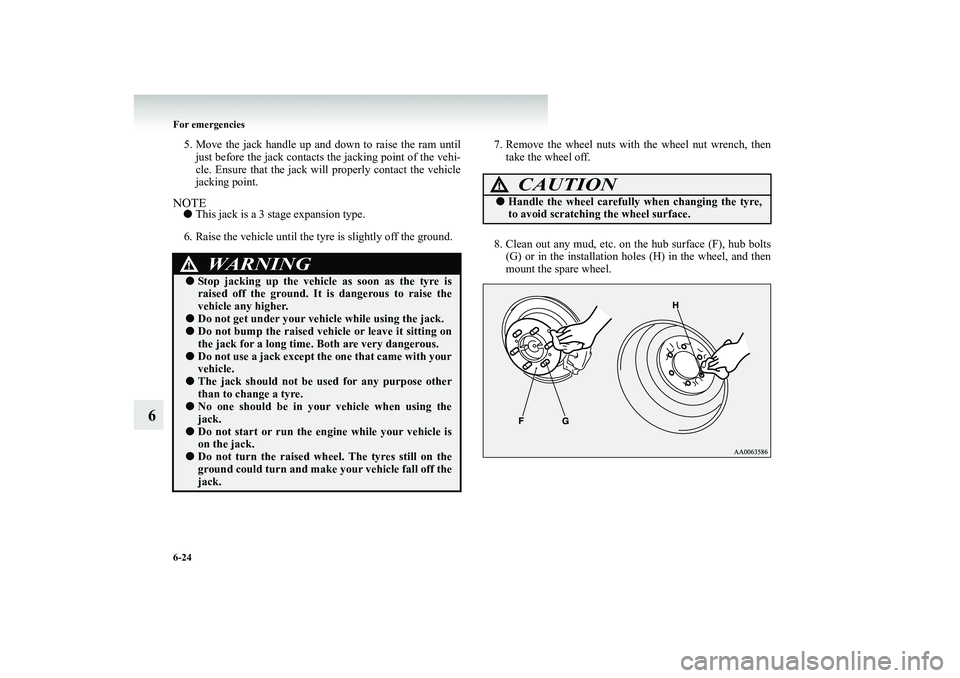

7. Remove the wheel nuts with the wheel nut wrench, then

take the wheel off.

8. Clean out any mud, etc. on

the hub surface

(F), hub bolts

(G) or in the installation holes (H) in the wheel, and thenmount the spare wheel.

WARNING

!●

Stop jacking up the vehicle as soon as the tyre is raised off the ground. It

is dangerous to raise the

vehicle any higher.

●

Do not get under your vehicle while using the jack.

●

Do not bump the raised vehicle or leave it sitting on the jack for a long time.

Both are very dangerous.

●

Do not use a jack except th

e one that came with your

vehicle.

●

The jack should not be us

ed for any purpose other

than to change a tyre.

●

No one should be in your vehicle when using the jack.

●

Do not start or run the en

gine while your vehicle is

on the jack.

●

Do not turn the raised wheel. The tyres still on the ground could turn and make your vehicle fall off thejack.

CAUTION

!●

Handle the wheel carefully

when changing the tyre,

to avoid scratching the wheel surface.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

24 Wednesday, January 9, 2008 4:46 PM

Page 429 of 538

For emergencies

6-25

6

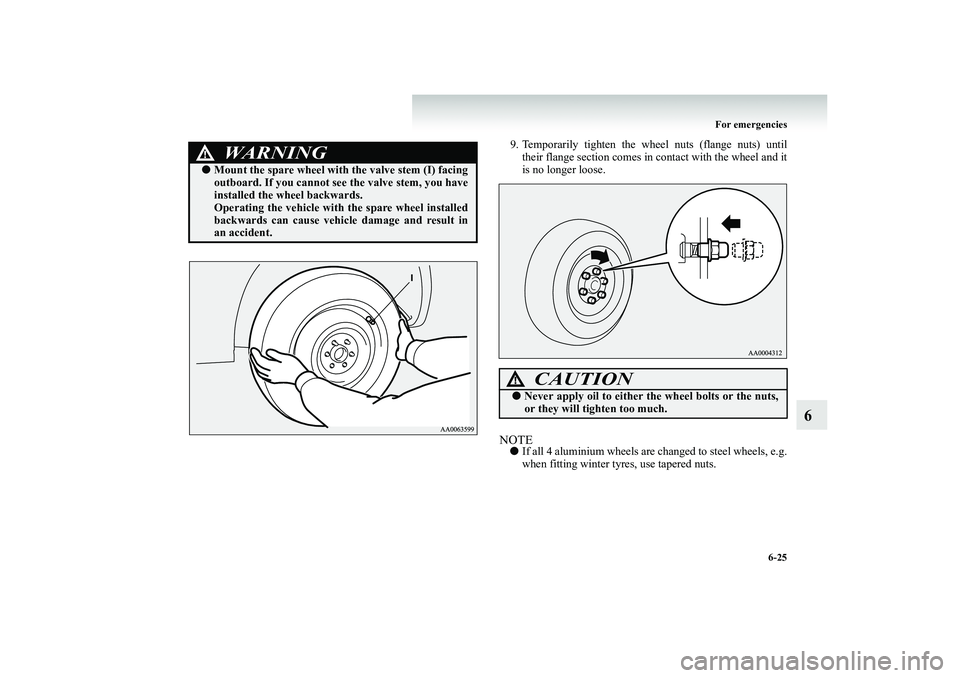

9. Temporarily tighten the wheel nuts (flange nuts) until

their flange section

comes in contact with the wheel and it

is no longer loose.

NOTE●

If all 4 aluminium wheels are

changed to steel wheels, e.g.

when fitting winter tyres, use tapered nuts.

WARNING

!●

Mount the spare wheel with the valve stem (I) facing outboard. If you cannot s

ee the valve stem, you have

installed the wheel backwards. Operating the vehicle with

the spare wheel installed

backwards can cause vehicle damage and result inan accident.

CAUTION

!●

Never apply oil to either the wheel bolts or the nuts, or they will tighten too much.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

25 Wednesday, January 9, 2008 4:46 PM

Page 430 of 538

6-26 For emergencies

6

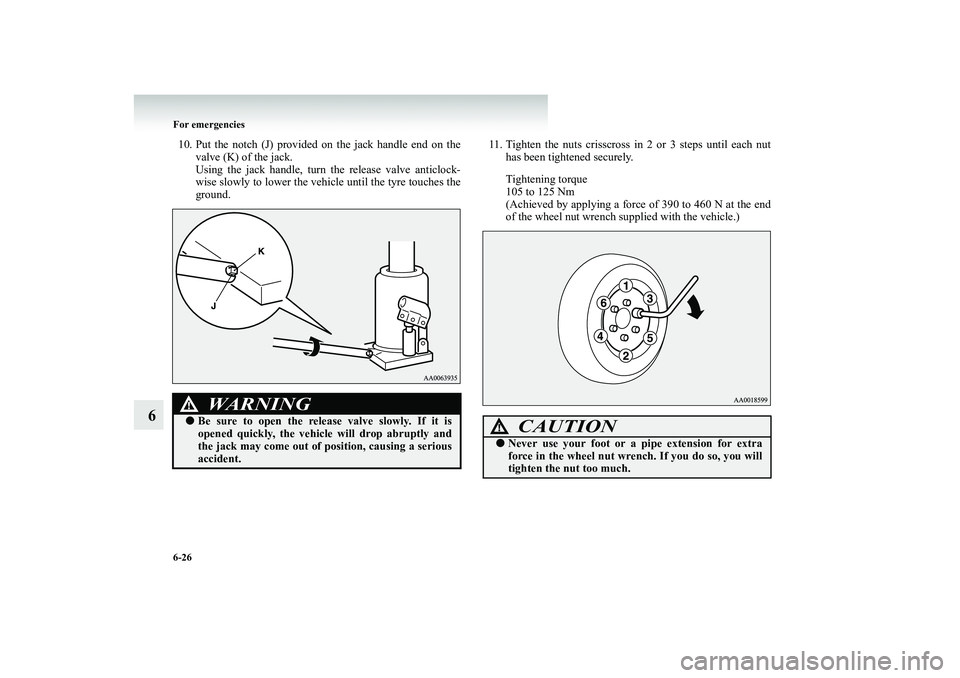

10. Put the notch (J) provided on the jack handle end on the

valve (K) of the jack. Using the jack handle, turn the release valve anticlock- wise slowly to lower the vehicle until the tyre touches theground.

11. Tighten the nuts crisscross

in 2 or 3 steps until each nut

has been tightened securely. Tightening torque 105 to 125 Nm (Achieved by applying a force of 390 to 460 N at the endof the wheel nut wrench s

upplied with the vehicle.)

WARNING

!●

Be sure to open the release valve slowly. If it is opened quickly, the vehicl

e will drop abruptly and

the jack may come out of

position, causing a serious

accident.

CAUTION

!●

Never use your foot or a pipe extension for extra force in the wheel nut wren

ch. If you do so, you will

tighten the nut too much.

BK-BK2008E1ENUK.en-uk-Section9.fm Page

26 Wednesday, January 9, 2008 4:46 PM