light MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1060 of 2103

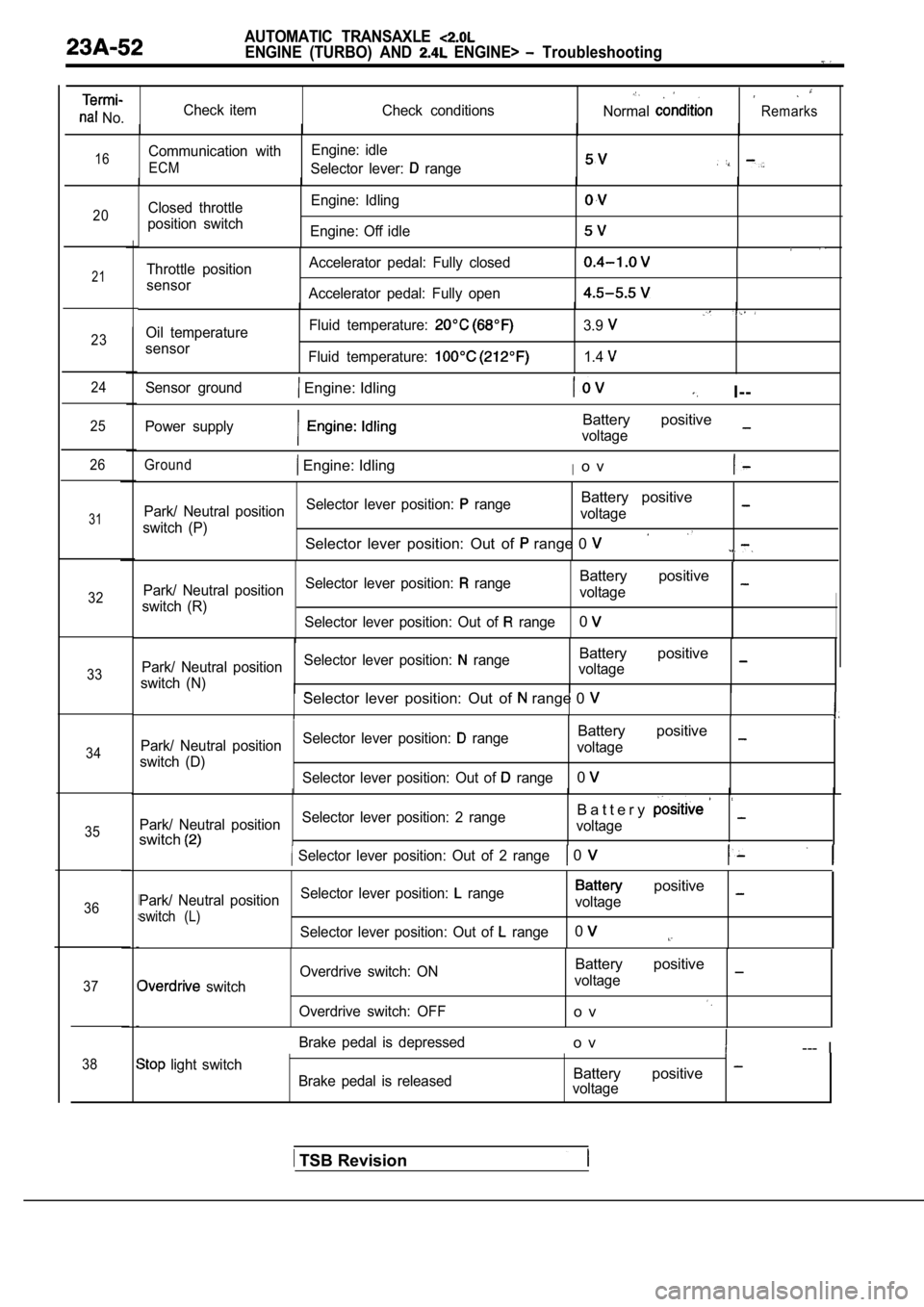

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

No.Check item

Check conditionsNormalRemarks

16Communication withEngine: idle

ECMSelector lever: range

20Closed throttle

position switch Engine: Idling

Engine: Off idle

21

23

24

25

26

31

32

33

34

35

36

37

38

Throttle position

sensor Accelerator pedal: Fully closed

Accelerator pedal: Fully open

Oil temperature

sensor Fluid temperature:

Fluid temperature:

3.9

1.4

Sensor ground Engine: IdlingI--

Power supplyBattery positive

voltage

Ground Engine: IdlingIo v

Park/ Neutral position

Selector lever position: rangeBattery positive

switch (P) voltage

Selector lever position: Out of range 0

Park/ Neutral position

Selector lever position: rangeBattery positive

switch (R) voltage

Selector lever position: Out of

range0

Park/ Neutral position Selector lever position: rangeBattery positive

switch (N) voltageSelector lever position: Out of range 0

Park/ Neutral position

Selector lever position: rangeBattery positive

switch (D) voltage

Selector lever position: Out of

range0

Park/ Neutral position Selector lever position: 2 rangeB a t t e r y

switchvoltage

Selector lever position: Out of 2 range 0

Park/ Neutral position

Selector lever position: range positive

switch (L)voltage

Selector lever position: Out of

range0

switch Overdrive switch: ON

Overdrive switch: OFF

Battery positive

voltage

o v

Brake pedal is depressedo v--- I

light switch Brake pedal is releasedBattery positive voltage

TSB Revision

Page 1065 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND On-vehicle

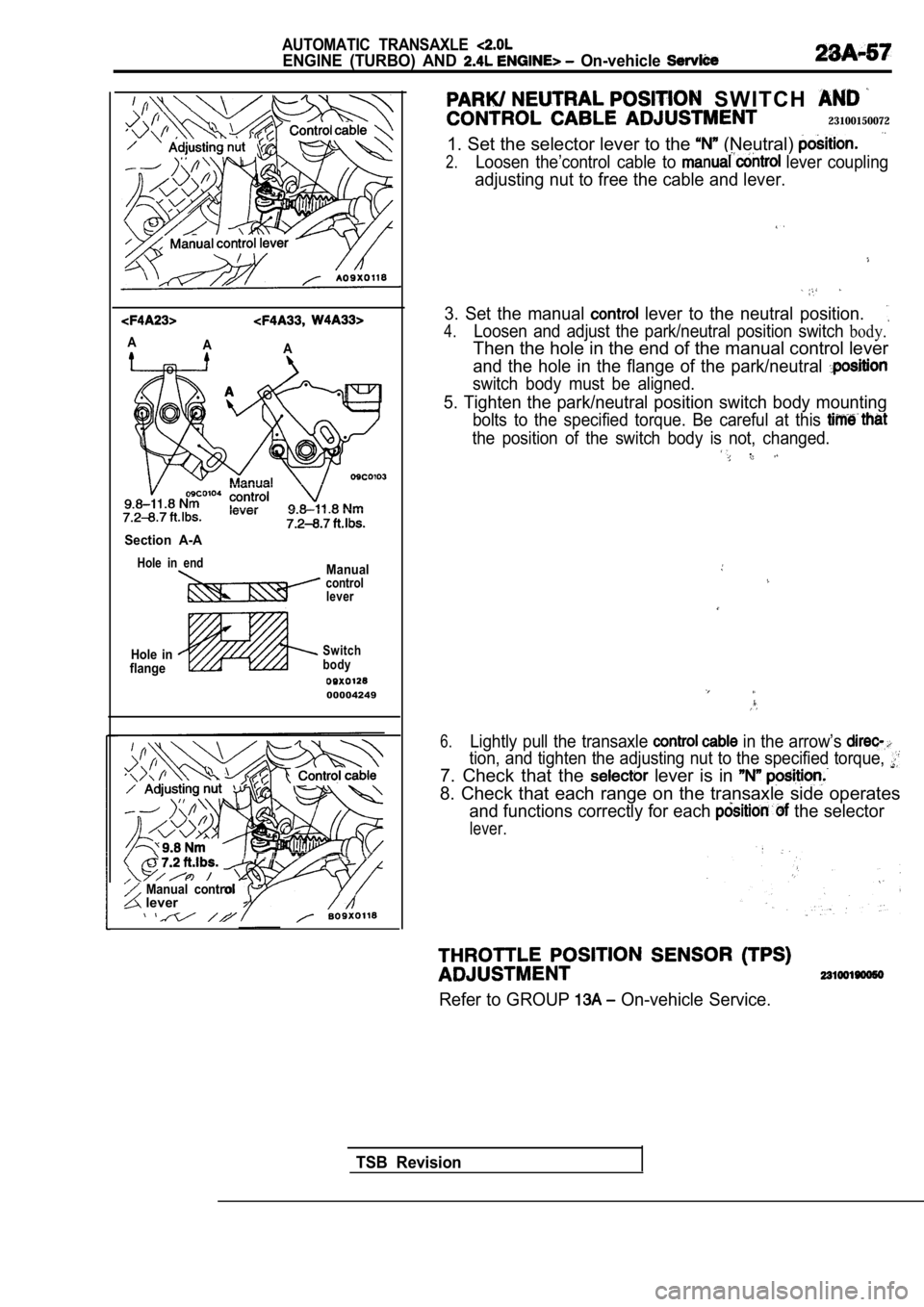

AA

A

Section A-A

Hole in endManualcontrol

lever

Hole in

flangeSwitch

body

00004249

Manual control lever

S W I T C H

23100150072

1. Set the selector lever to the (Neutral)

2.Loosen the’control cable to lever coupling

adjusting nut to free the cable and lever.

3. Set the manual lever to the neutral position.

4.Loosen and adjust the park/neutral position switch body.

Then the hole in the end of the manual control leve r

and the hole in the flange of the park/neutral

switch body must be aligned.

5. Tighten the park/neutral position switch body mo unting

bolts to the specified torque. Be careful at this

the position of the switch body is not, changed. ,

6.Lightly pull the transaxle in the arrow’s

tion, and tighten the adjusting nut to the specified torque,

7. Check that the lever is in

8. Check that each range on the transaxle side oper ates

and functions correctly for each the selector

lever.

Refer to GROUP On-vehicle Service.

TSB Revision

Page 1101 of 2103

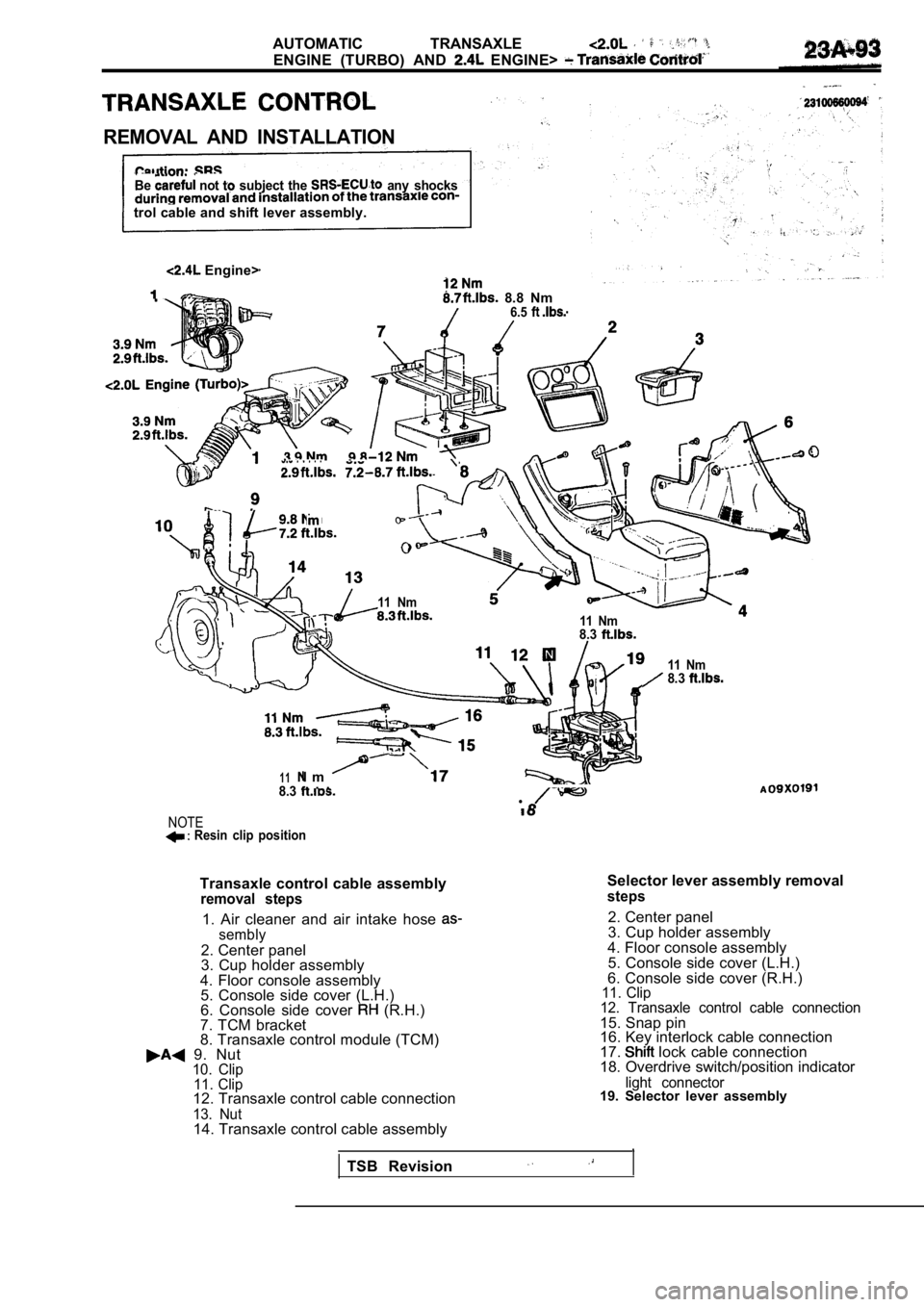

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE>

REMOVAL AND INSTALLATION

Be not subject the any shocks

trol cable and shift lever assembly.

Engine>

8.8 Nm6.5

11 Nm

11 Nm8.3

118.3l

N m . .

NOTE Resin clip position11 Nm

8.3

Transaxle control cable assemblyremoval steps

1. Air cleaner and air intake hose sembly

2. Center panel

3. Cup holder assembly

4. Floor console assembly 5. Console side cover (L.H.)

6. Console side cover

(R.H.)

7. TCM bracket

8. Transaxle control module (TCM)

9. Nut10. Clip 11. Clip

12. Transaxle control cable connection

13. Nut14. Transaxle control cable assembly Selector lever assembly removal

steps

2. Center panel

3. Cup holder assembly

4. Floor console assembly 5. Console side cover (L.H.)

6. Console side cover (R.H.)

11. Clip

12. Transaxle control cable connection

15. Snap pin

16. Key interlock cable connection

17.

lock cable connection

18. Overdrive switch/position indicator

light connector19. Selector lever assembly

TSB Revision

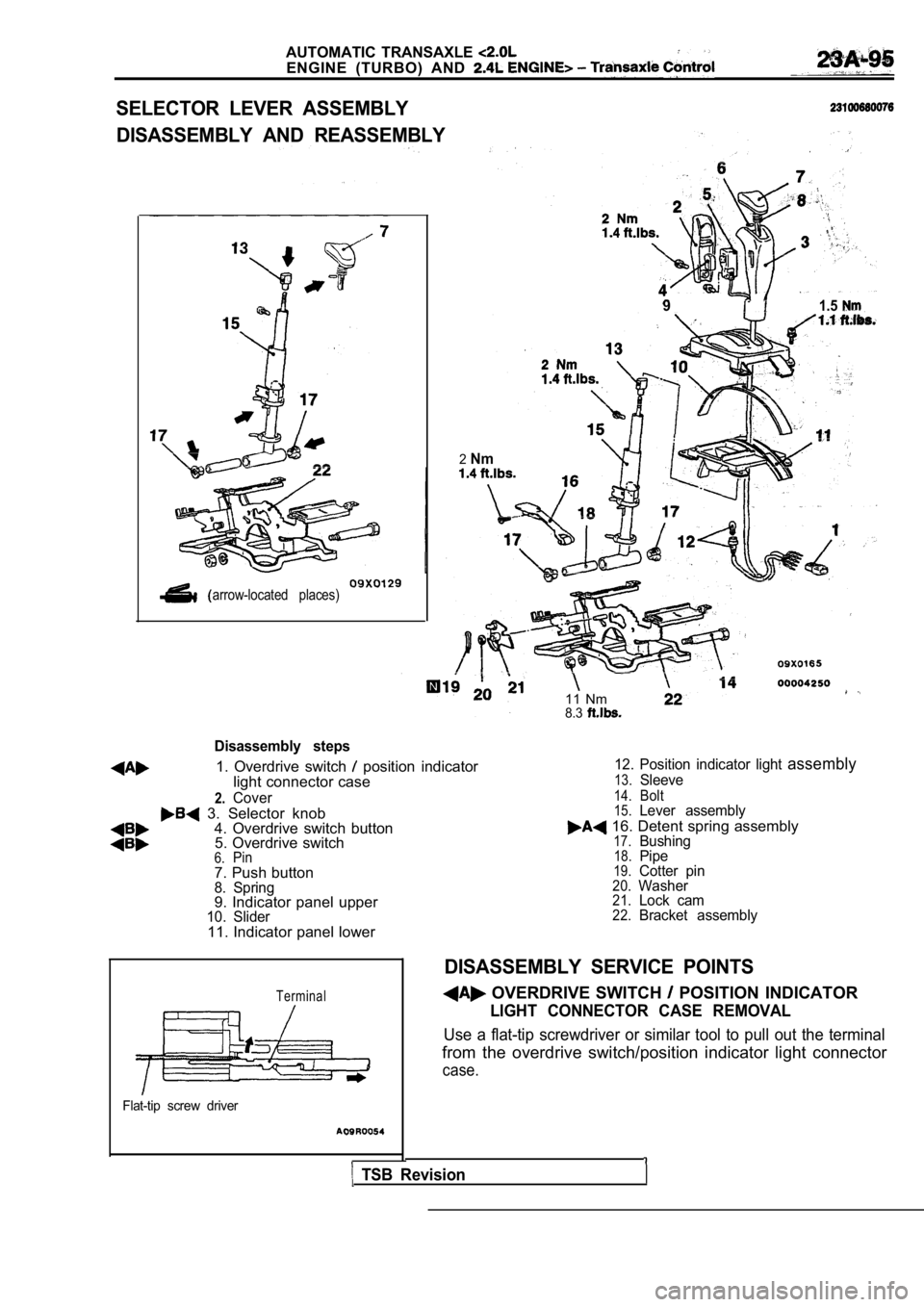

Page 1103 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND

SELECTOR LEVER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

arrow-located places)

Disassembly steps

11 Nm8.3

1. Overdrive switch position indicator12. Position indicator light assembly

light connector case

2.Cover

3. Selector knob4. Overdrive switch button5. Overdrive switch6.Pin

13.Sleeve

14.Bolt15.Lever assembly

16. Detent spring assembly17.Bushing18.Pipe19.Cotter pin20.Washer21.Lock cam22.Bracket assembly

91.5

2Nm

7. Push button8. Spring9. Indicator panel upper10. Slider11. Indicator panel lower

Terminal

Flat-tip screw driver

TSB Revision

DISASSEMBLY SERVICE POINTS

OVERDRIVE SWITCH POSITION INDICATOR

LIGHT CONNECTOR CASE REMOVAL

Use a flat-tip screwdriver or similar tool to pull out the terminal

from the overdrive switch/position indicator light connector

case.

Page 1107 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Lock

LOCK

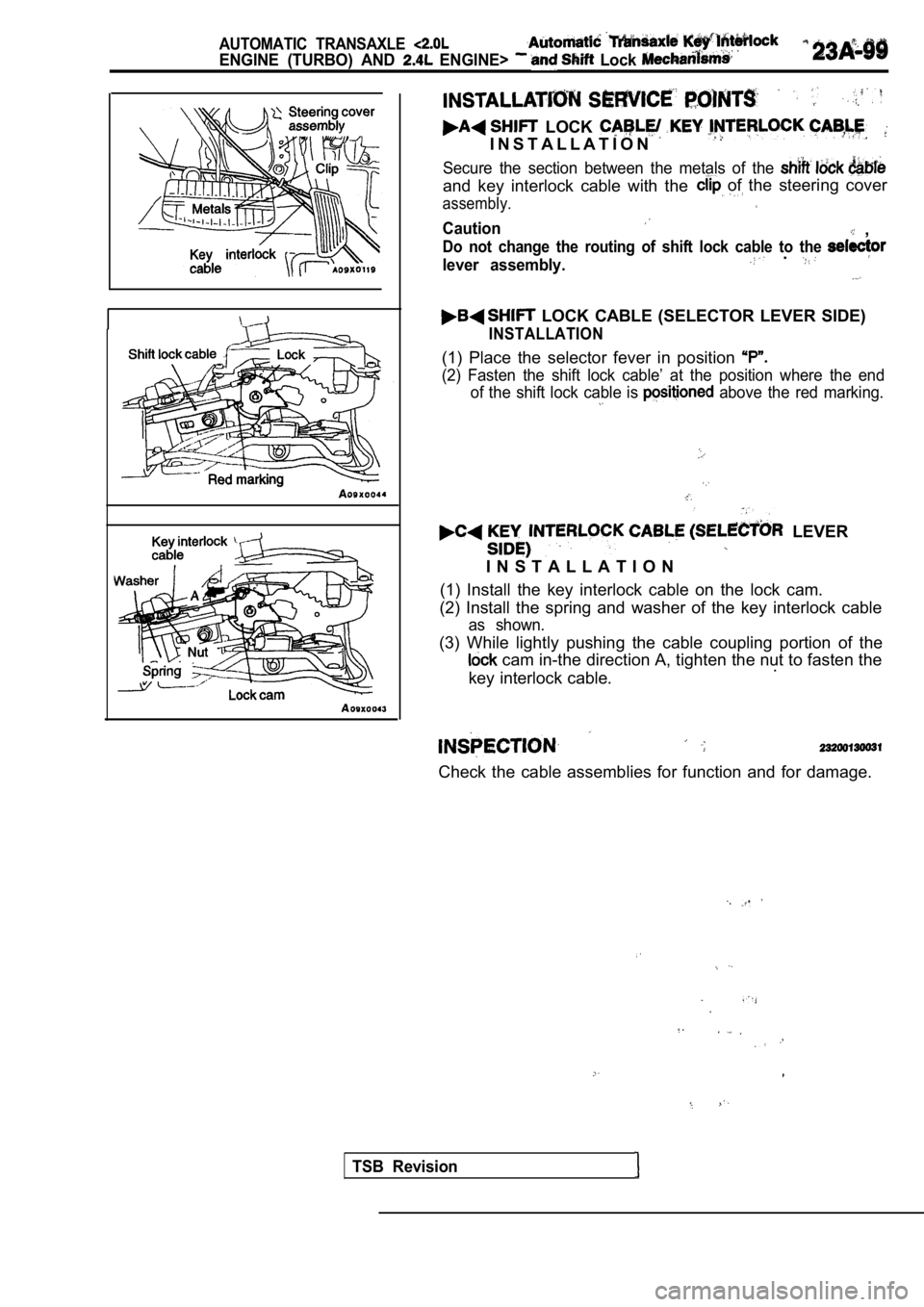

I N S T A L L A T I O N

Secure the section between the metals of the

and key interlock cable with the of the steering cover

assembly.

Caution ,

Do not change the routing of shift lock cable to the

lever assembly. .

LOCK CABLE (SELECTOR LEVER SIDE)

INSTALLATION

(1) Place the selector fever in position

(2) Fasten the shift lock cable’ at the position where the end

of the shift lock cable is

above the red marking.

LEVER

I N S T A L L A T I O N

(1) Install the key interlock cable on the lock cam .

(2) Install the spring and washer of the key interl ock cable

as shown.

(3) While lightly pushing the cable coupling portio n of the

cam in-the direction A, tighten the nut to fasten the

key interlock cable. .

Check the cable assemblies for function and for dam

age.

TSB Revision

Page 1117 of 2103

AUTOMATIC TRANSAXLE

ENGINE AND Transaxle

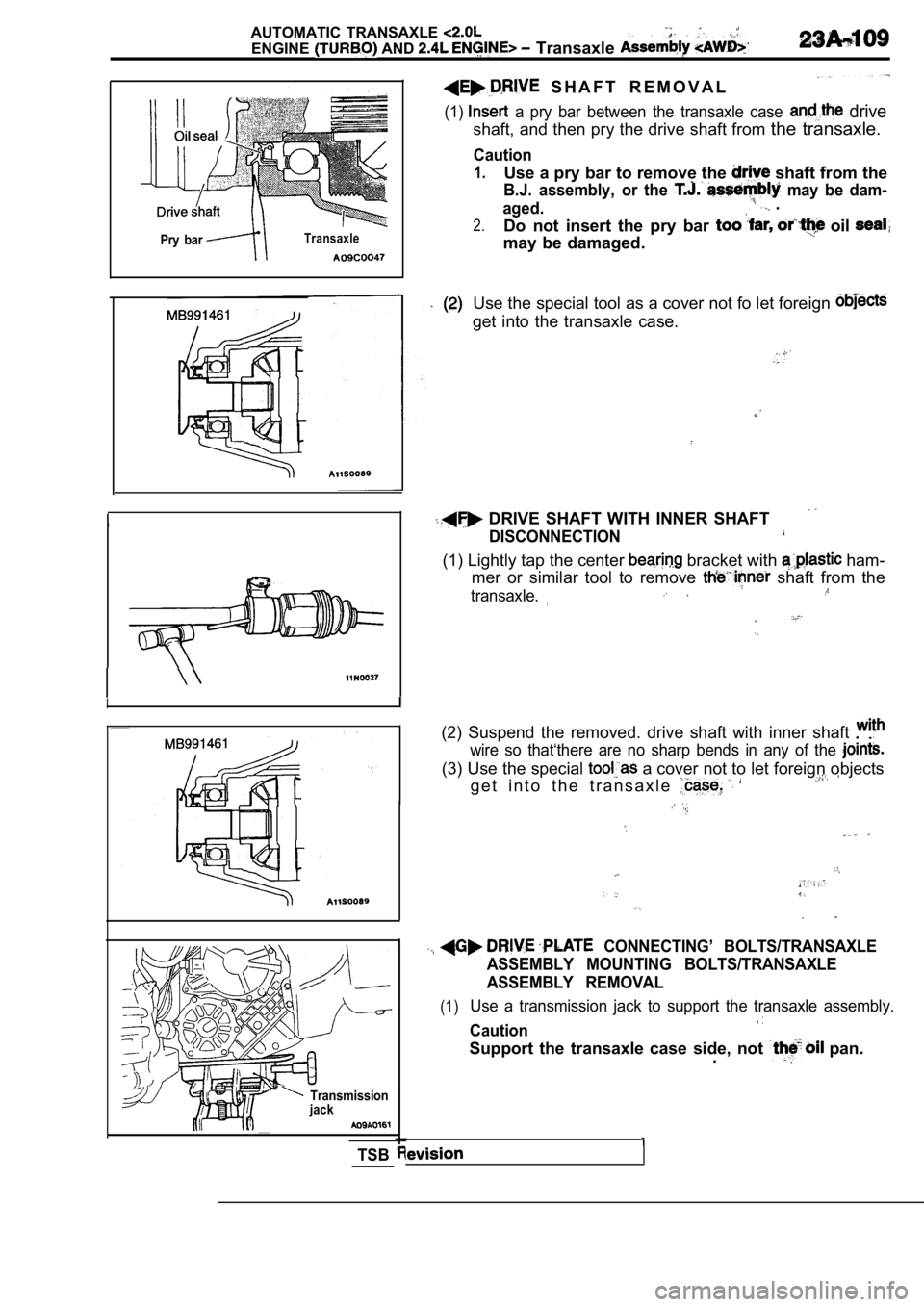

Pry barTransaxle

S H A F T R E M O V A L

(1) a pry bar between the transaxle case drive

shaft, and then pry the drive shaft from the transaxle.

Caution

1.Use a pry bar to remove the shaft from the

B.J. assembly, or the may be dam-

aged. .

2.Do not insert the pry bar oil

may be damaged.

I

Use the special tool as a cover not fo let foreign

get into the transaxle case.

DRIVE SHAFT WITH INNER SHAFT

DISCONNECTION

(1) Lightly tap the center bracket with ham-

mer or similar tool to remove

shaft from the

transaxle.

(2) Suspend the removed. drive shaft with inner sha ft

wire so that‘there are no sharp bends in any of the

(3) Use the special a cover not to let foreign objects

g e t i n t o t h e t r a n s a x l e

Transmission jack

TSB

CONNECTING’ BOLTS/TRANSAXLE

ASSEMBLY MOUNTING BOLTS/TRANSAXLE

ASSEMBLY REMOVAL

(1)Use a transmission jack to support the transaxle as sembly.

Caution

Support the transaxle case side, not pan.

.

Page 1148 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshootihg

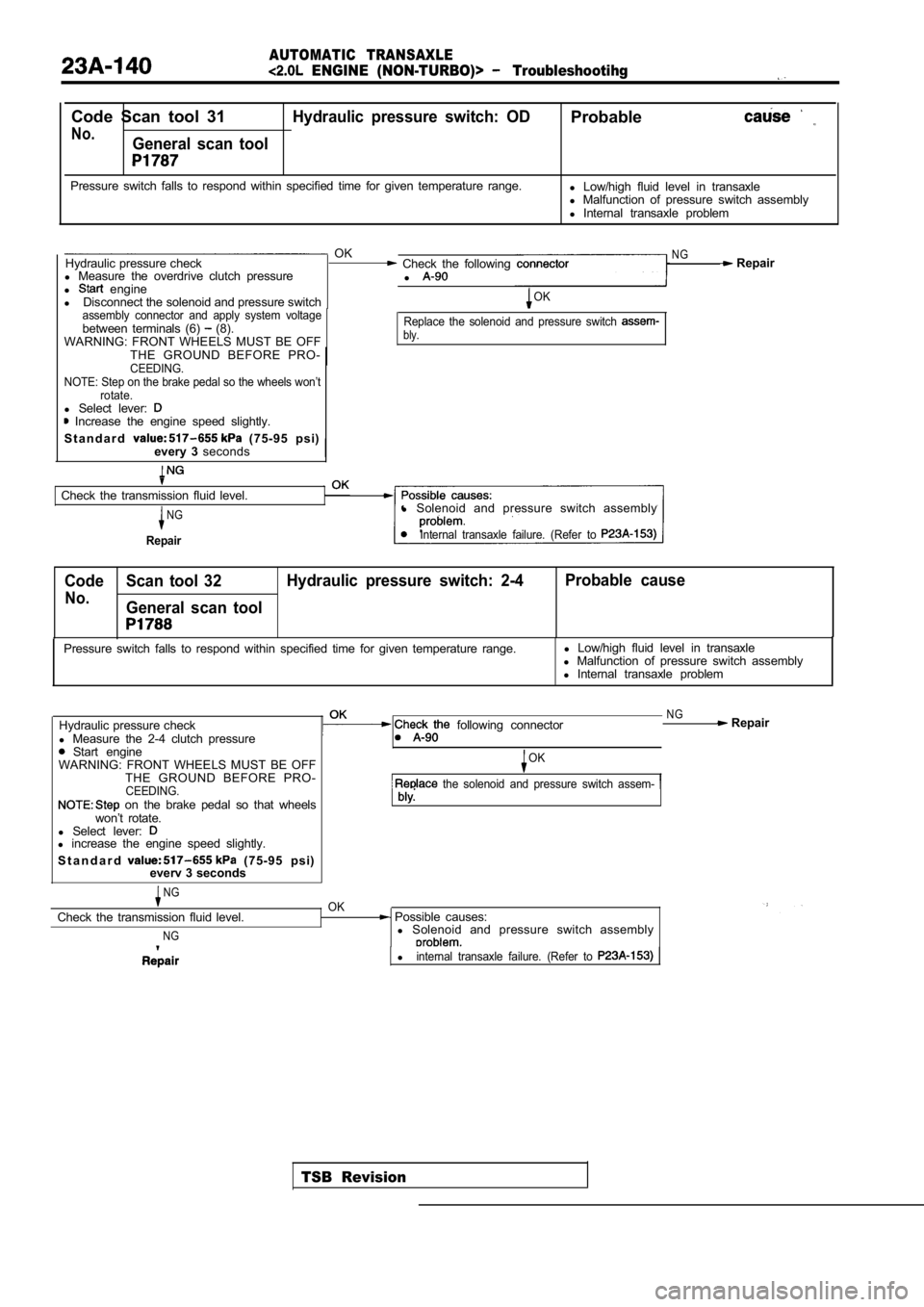

Code Scan tool 31Hydraulic pressure switch: ODProbable

No.General scan tool

Pressure switch falls to respond within specified time for given temperature range.

l Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

OKNGHydraulic pressure check Check the following Repair

l Measure the overdrive clutch pressure

l

l engine

l Disconnect the solenoid and pressure switchOK

assembly connector and apply system voltage

between terminals (6) (8).

WARNING: FRONT WHEELS MUST BE OFFReplace the solenoid and pressure switch bly.

THE GROUND BEFORE PRO-CEEDING.

NOTE: Step on the brake pedal so the wheels won’t rotate.

l Select lever: Increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

every 3 seconds

Check the transmission fluid level.

NG

Repair

l Solenoid and pressure switch assembly

Internal transaxle failure. (Refer to

Code Scan tool 32 Hydraulic pressure switch: 2-4 Probable cause

No.General scan tool

TSB Revision

Pressure switch falls to respond within specified t

ime for given temperature range.l

Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

Hydraulic pressure check

l Measure the 2-4 clutch pressure

Start engine

following connector

WARNING: FRONT WHEELS MUST BE OFF THE GROUND BEFORE PRO-

CEEDING. on the brake pedal so that wheels

won’t rotate.

l Select lever:

l increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

everv 3 seconds

NGOK

NG Repair

OK

the solenoid and pressure switch assem-

Check the transmission fluid level.

NG

Possible causes:

l Solenoid and pressure switch assembly

linternal transaxle failure. (Refer to

Page 1172 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> On-vehicle Service

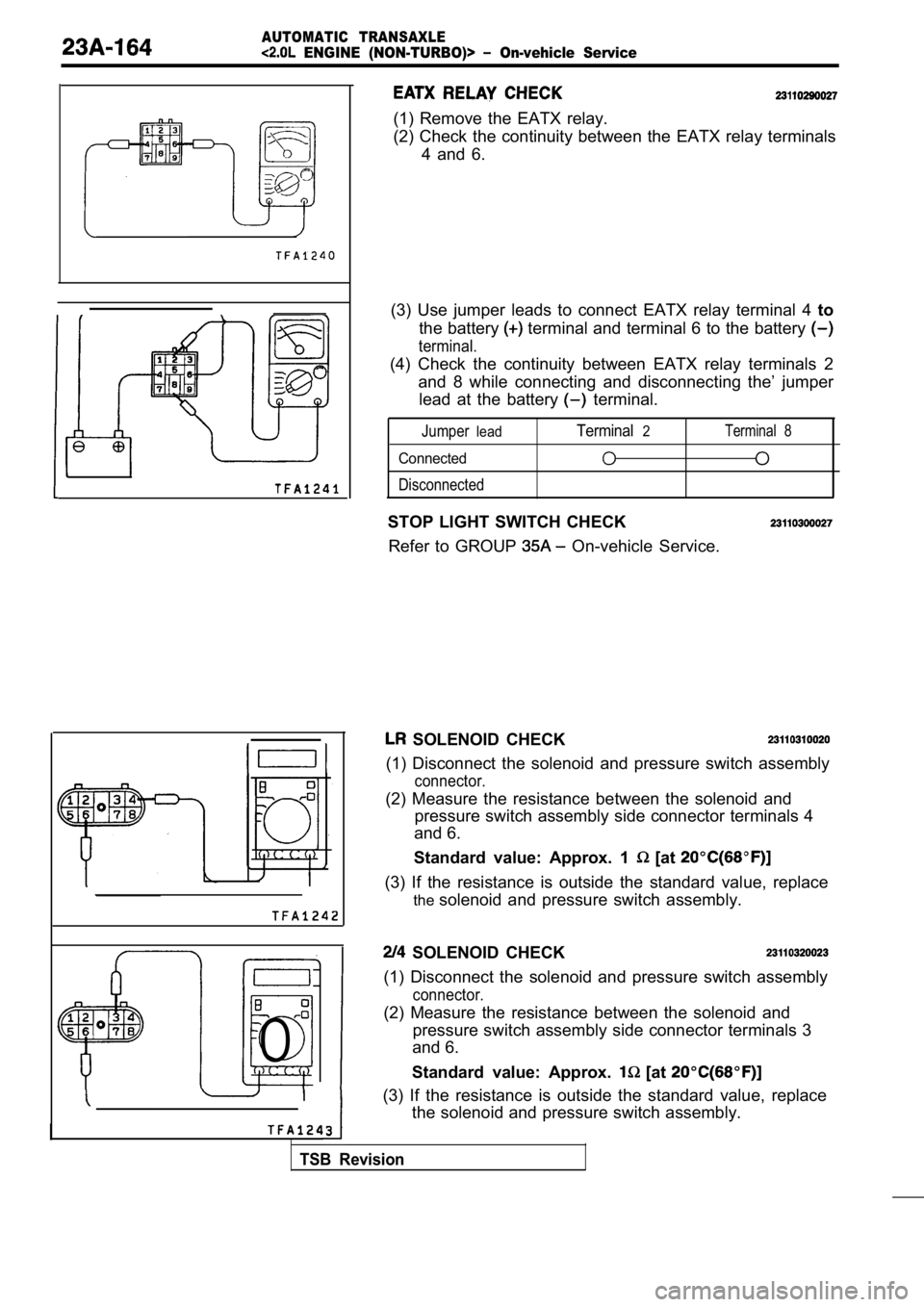

0

I

(1) Remove the EATX relay.

(2) Check the continuity between the EATX relay terminals

4 and 6.

(3) Use jumper leads to connect EATX relay terminal 4 to

the battery

terminal and terminal 6 to the battery

terminal.

(4) Check the continuity between EATX relay termina ls 2

and 8 while connecting and disconnecting the’ jumpe r

lead at the battery

terminal.

Jumperlead

Connected

Disconnected

Terminal2Terminal 8

STOP LIGHT SWITCH CHECK

Refer to GROUP

On-vehicle Service.

SOLENOID CHECK

(1) Disconnect the solenoid and pressure switch ass embly

connector.

(2) Measure the resistance between the solenoid and

pressure switch assembly side connector terminals 4

and 6.

Standard value: Approx. 1

[at

(3) If the resistance is outside the standard value , replace

the solenoid and pressure switch assembly.

SOLENOID CHECK

(1) Disconnect the solenoid and pressure switch ass embly

connector.

(2) Measure the resistance between the solenoid and

pressure switch assembly side connector terminals 3

and 6.

Standard value: Approx.

[at

(3) If the resistance is outside the standard value , replace

the solenoid and pressure switch assembly.

TSB Revision

Page 1174 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> On-vehicle Service

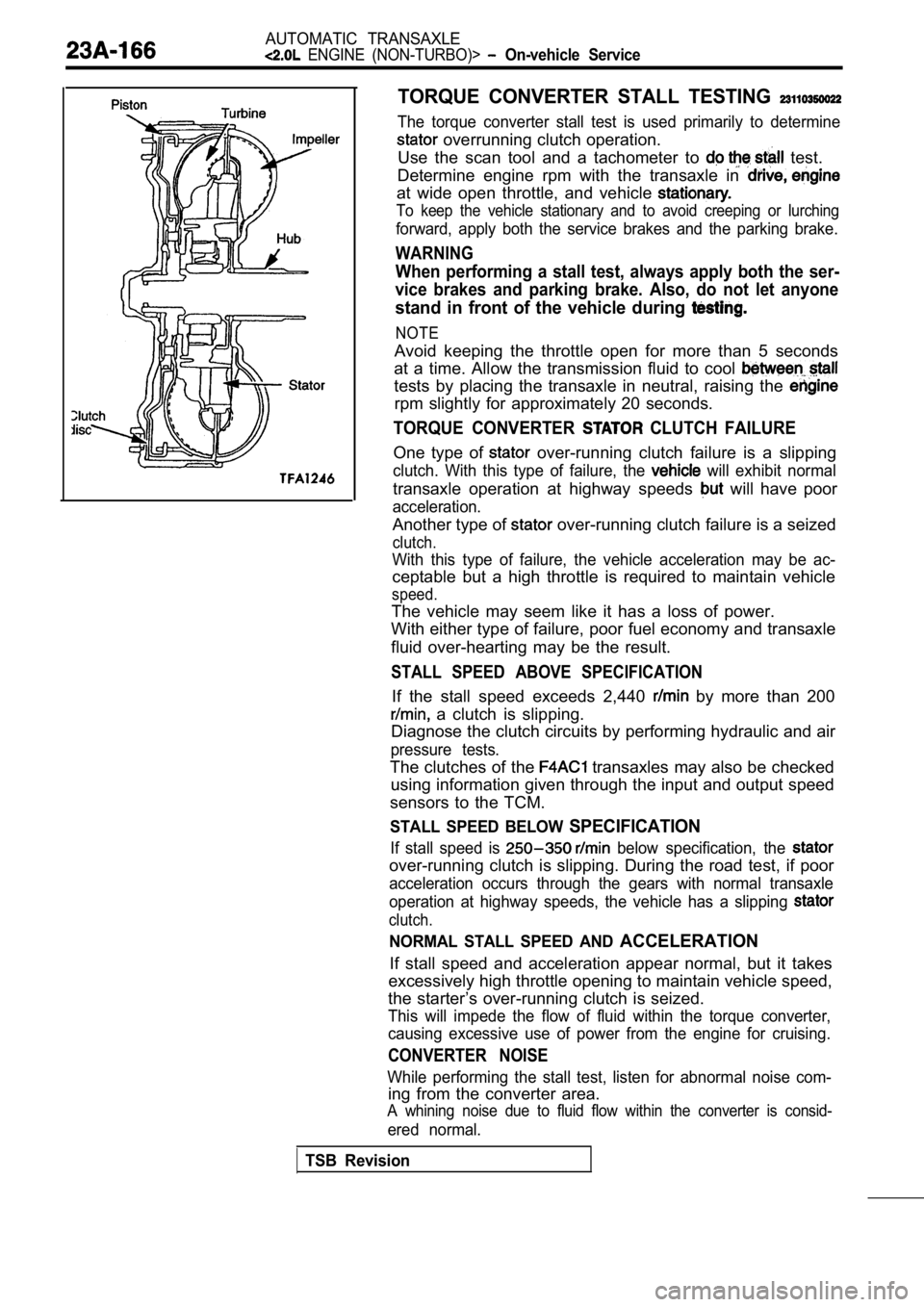

TORQUE CONVERTER STALL TESTING

The torque converter stall test is used primarily to determine

overrunning clutch operation.

Use the scan tool and a tachometer to

test.

Determine engine rpm with the transaxle in

at wide open throttle, and vehicle

To keep the vehicle stationary and to avoid creepin g or lurching

forward, apply both the service brakes and the parking brake.

WARNING

When performing a stall test, always apply both the ser-

vice brakes and parking brake. Also, do not let any one

stand in front of the vehicle during

NOTE

Avoid keeping the throttle open for more than 5 seconds

at a time. Allow the transmission fluid to cool

tests by placing the transaxle in neutral, raising the

rpm slightly for approximately 20 seconds.

TORQUE CONVERTER CLUTCH FAILURE

One type of over-running clutch failure is a slipping

clutch. With this type of failure, the will exhibit normal

transaxle operation at highway speeds will have poor

acceleration.

Another type of over-running clutch failure is a seized

clutch.

With this type of failure, the vehicle acceleration may be ac-

ceptable but a high throttle is required to maintai n vehicle

speed.

The vehicle may seem like it has a loss of power.

With either type of failure, poor fuel economy and transaxle

fluid over-hearting may be the result.

STALL SPEED ABOVE SPECIFICATION

If the stall speed exceeds 2,440 by more than 200

a clutch is slipping.

Diagnose the clutch circuits by performing hydrauli c and air

pressure tests.

The clutches of the transaxles may also be checked

using information given through the input and outpu t speed

sensors to the TCM.

STALL SPEED BELOW SPECIFICATION

If stall speed is below specification, the

over-running clutch is slipping. During the road te st, if poor

acceleration occurs through the gears with normal t ransaxle

operation at highway speeds, the vehicle has a slip ping

clutch.

NORMAL STALL SPEED AND ACCELERATION

If stall speed and acceleration appear normal, but it takes

excessively high throttle opening to maintain vehic le speed,

the starter’s over-running clutch is seized.

This will impede the flow of fluid within the torqu e converter,

causing excessive use of power from the engine for cruising.

CONVERTER NOISE

While performing the stall test, listen for abnormal noise com-

ing from the converter area.

A whining noise due to fluid flow within the conver ter is consid-

ered normal.

TSB Revision

Page 1193 of 2103

AUTOMATIC1 ENGINE (NON-TURBO)> Control

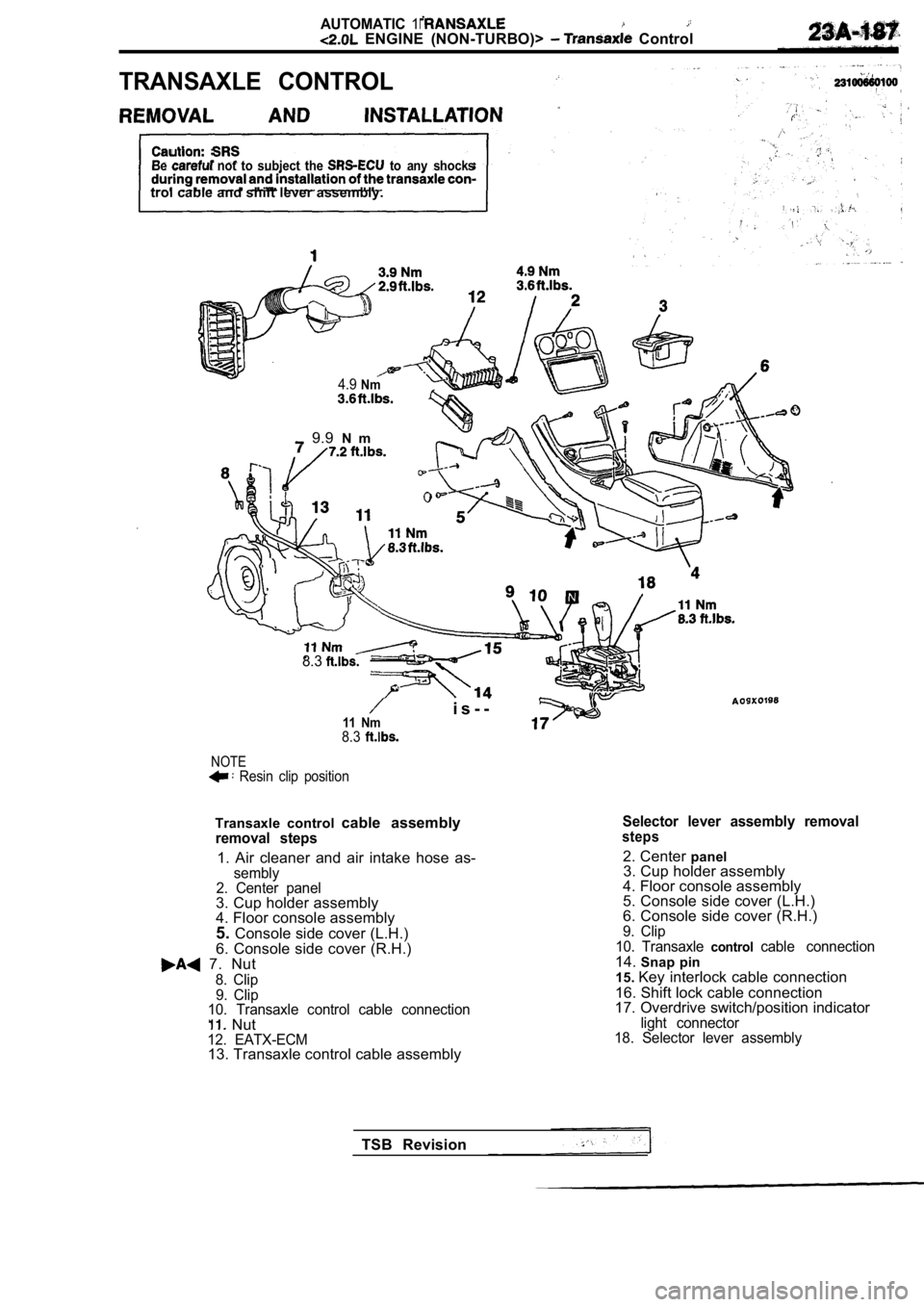

TRANSAXLE CONTROL

Be not to subject the to any shocks

trol cable and shift lever assembly.

4.9Nm

9.9 N m

8.3

i s - -11 Nm8.3

NOTE Resin clip position

Transaxle control cable assemblyremoval steps

1. Air cleaner and air intake hose as-sembly

2. Center panel

3. Cup holder assembly

4. Floor console assembly

5. Console side cover (L.H.)

6. Console side cover (R.H.)

7. Nut

8. Clip 9. Clip

10. Transaxle control cable connection

Nut12. EATX-ECM13. Transaxle control cable assembly

Selector lever assembly removalsteps

2. Center panel

3. Cup holder assembly

4. Floor console assembly

5. Console side cover (L.H.)

6. Console side cover (R.H.)

9. Clip

10. Transaxle controlcable connection14. Snap pin

15. Key interlock cable connection

16. Shift lock cable connection

17. Overdrive switch/position indicator

light connector

18. Selector lever assembly

TSB Revision