light MITSUBISHI SPYDER 1990 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 772 of 2103

E N G I N E EMISSION CONTROL Auto-cruise Control

No.

14

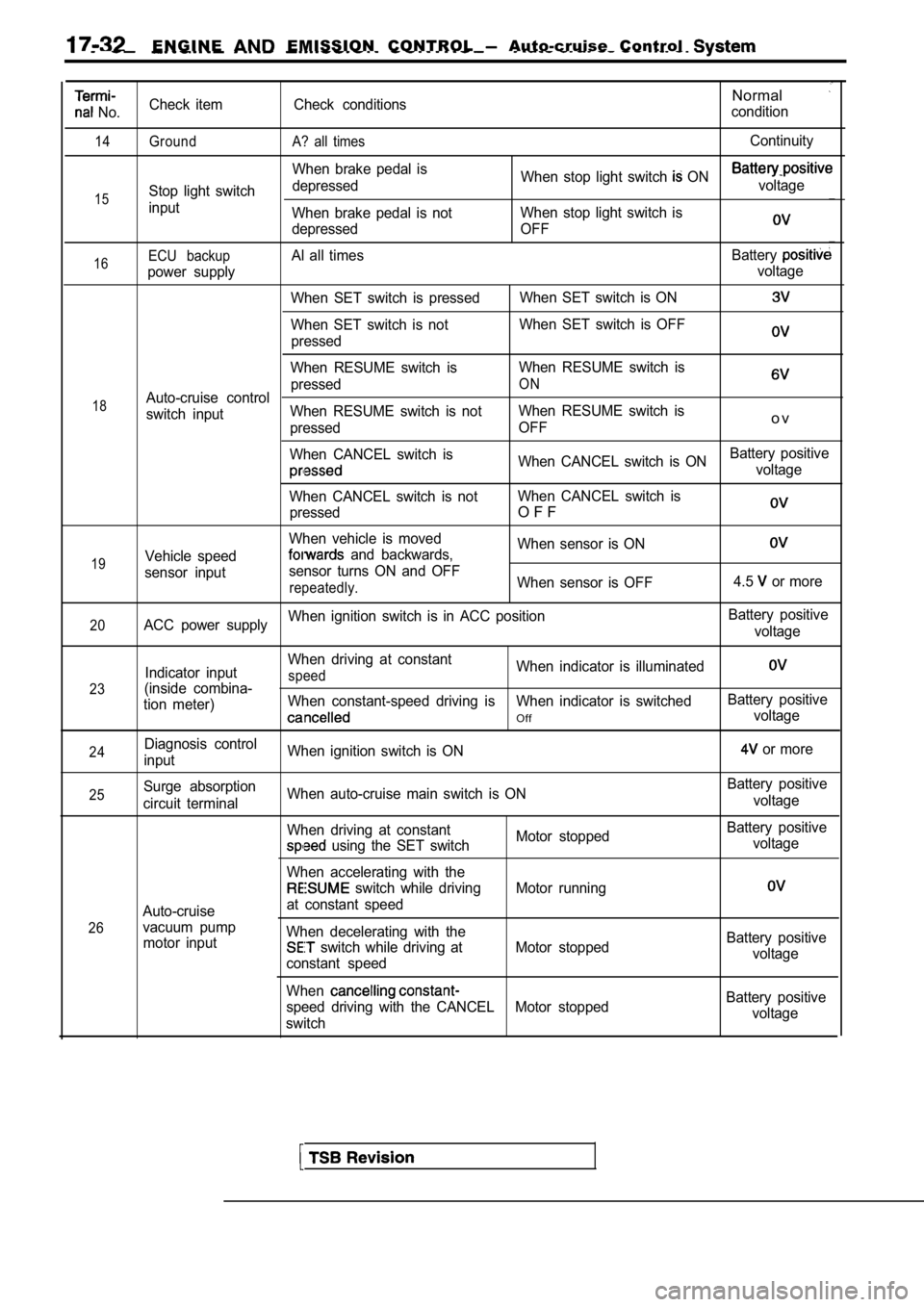

15

Check item

Ground

Stop light switch

inputCheck conditions

A? all times

When brake pedal is

depressed

When brake pedal is not

depressed

Normal

condition

Continuity

When stop light switch ON voltage

When stop light switch is

OFF

16

18

19ECU backupAl all times Battery

power supply voltage

When SET switch is pressed When SET switch is ON

When SET switch is notWhen SET switch is OFF

pressed

When RESUME switch is When RESUME switch is

pressed

ONAuto-cruise control

switch input When RESUME switch is not

When RESUME switch is

pressed OFF

o v

When CANCEL switch is

When CANCEL switch is ONBattery positivevoltage

When CANCEL switch is not When CANCEL switch is

pressed

O F F

When vehicle is moved When sensor is ON

Vehicle speed and backwards,

sensor input sensor turns ON and OFF

repeatedly.When sensor is OFF

4.5 or more

20ACC power supplyWhen ignition switch is in ACC position

Battery positive

voltage

23

24

Indicator input

(inside combina-

tion meter)

Diagnosis control

input When driving at constantspeedWhen indicator is illuminated

When constant-speed driving is When indicator is swi

tchedBattery positive

Offvoltage

When ignition switch is ON

or more

25

26Surge absorption

circuit terminal

Auto-cruise

vacuum pump motor input When auto-cruise main switch is ON

When driving at constant

Motor stopped

using the SET switch

When accelerating with the

switch while driving Motor running

at constant speed

When decelerating with the

switch while driving at Motor stopped

constant speed

When

speed driving with the CANCEL Motor stopped

switch Battery positive

voltage

Battery positive voltage

Battery positivevoltage

Battery positive voltage

Page 775 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control System

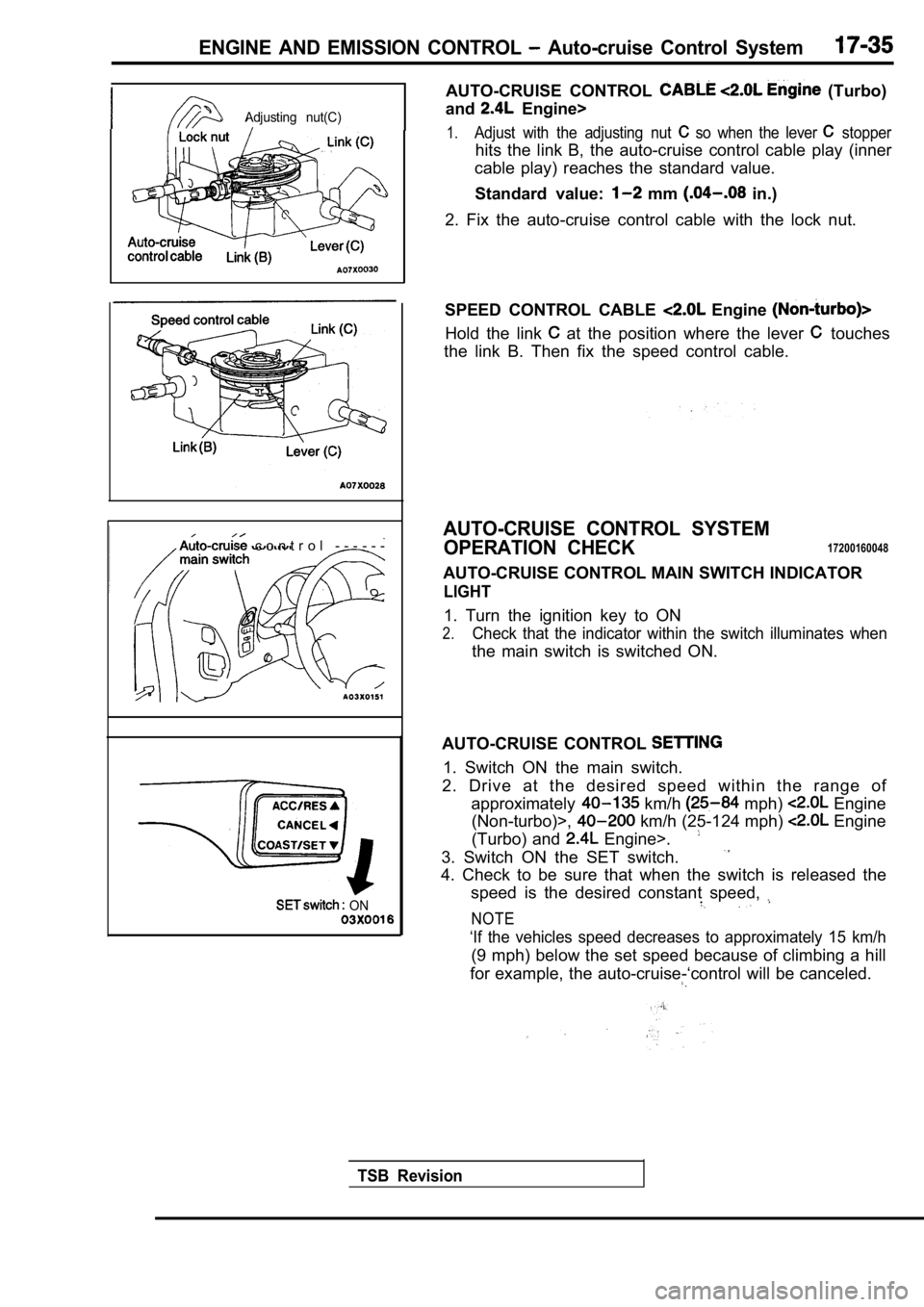

Adjusting nut(C)

c o n t r o l - - - - - -

ON

AUTO-CRUISE CONTROL (Turbo)

and

Engine>

1.Adjust with the adjusting nut so when the lever stopper

hits the link B, the auto-cruise control cable play (inner

cable play) reaches the standard value.

Standard value:

mm in.)

2. Fix the auto-cruise control cable with the lock nut.

SPEED CONTROL CABLE

Engine

Hold the link at the position where the lever touches

the link B. Then fix the speed control cable.

AUTO-CRUISE CONTROL SYSTEM

OPERATION CHECK

17200160048

AUTO-CRUISE CONTROL MAIN SWITCH INDICATOR

LIGHT

1. Turn the ignition key to ON

2.Check that the indicator within the switch illumina tes when

the main switch is switched ON.

AUTO-CRUISE CONTROL

1. Switch ON the main switch.

2. Drive at the desired speed within the range of approximately

km/h mph) Engine

(Non-turbo)>,

km/h (25-124 mph) Engine

(Turbo) and

Engine>.

3. Switch ON the SET switch.

4. Check to be sure that when the switch is release d the

speed is the desired constant speed,

.

NOTE

‘If the vehicles speed decreases to approximately 1 5 km/h

(9 mph) below the set speed because of climbing a h ill

for example, the auto-cruise-‘control will be cance led.

TSB Revision

Page 777 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control System

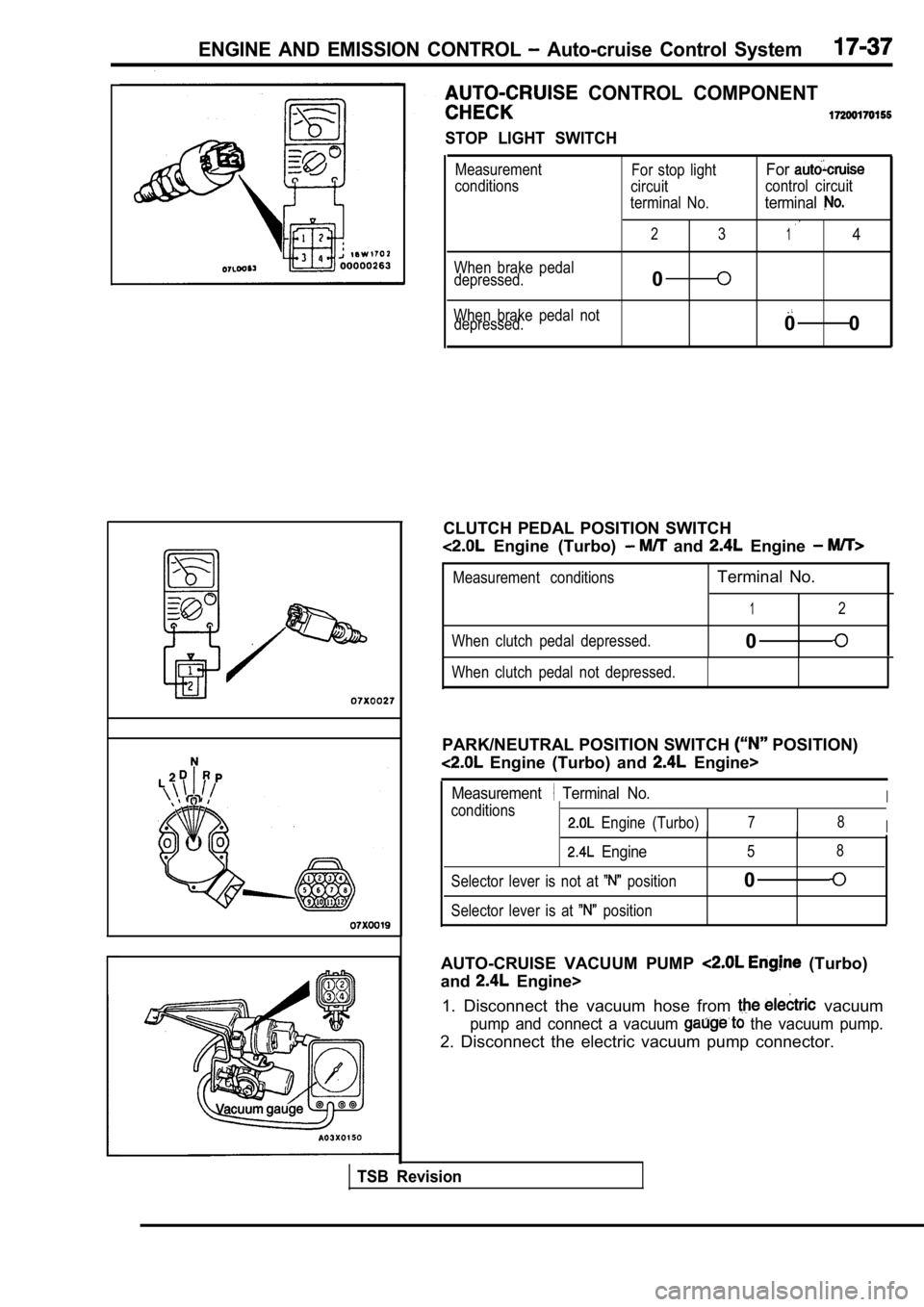

CONTROL COMPONENT

STOP LIGHT SWITCH

MeasurementFor stop lightFor

conditionscircuitcontrol circuit

terminal No.

terminal

2314

When brake pedal

depressed.0

When brake pedal notdepressed.0 0

CLUTCH PEDAL POSITION SWITCH

Engine (Turbo) and Engine

Measurement conditions

When clutch pedal depressed.Terminal No.

12

0

When clutch pedal not depressed.

PARK/NEUTRAL POSITION SWITCH POSITION)

Engine (Turbo) and Engine>

Measurement Terminal No.Iconditions Engine (Turbo)7 8I

Engine

Selector lever is not at position

Selector lever is at

position 5

8

0

AUTO-CRUISE VACUUM PUMP (Turbo)

and

Engine>

1. Disconnect the vacuum hose from

vacuum

pump and connect a vacuum the vacuum pump.

2. Disconnect the electric vacuum pump connector.

TSB Revision

Page 782 of 2103

17-42ENGINE AND EMISSION CONTROL Auto-cruise Control System

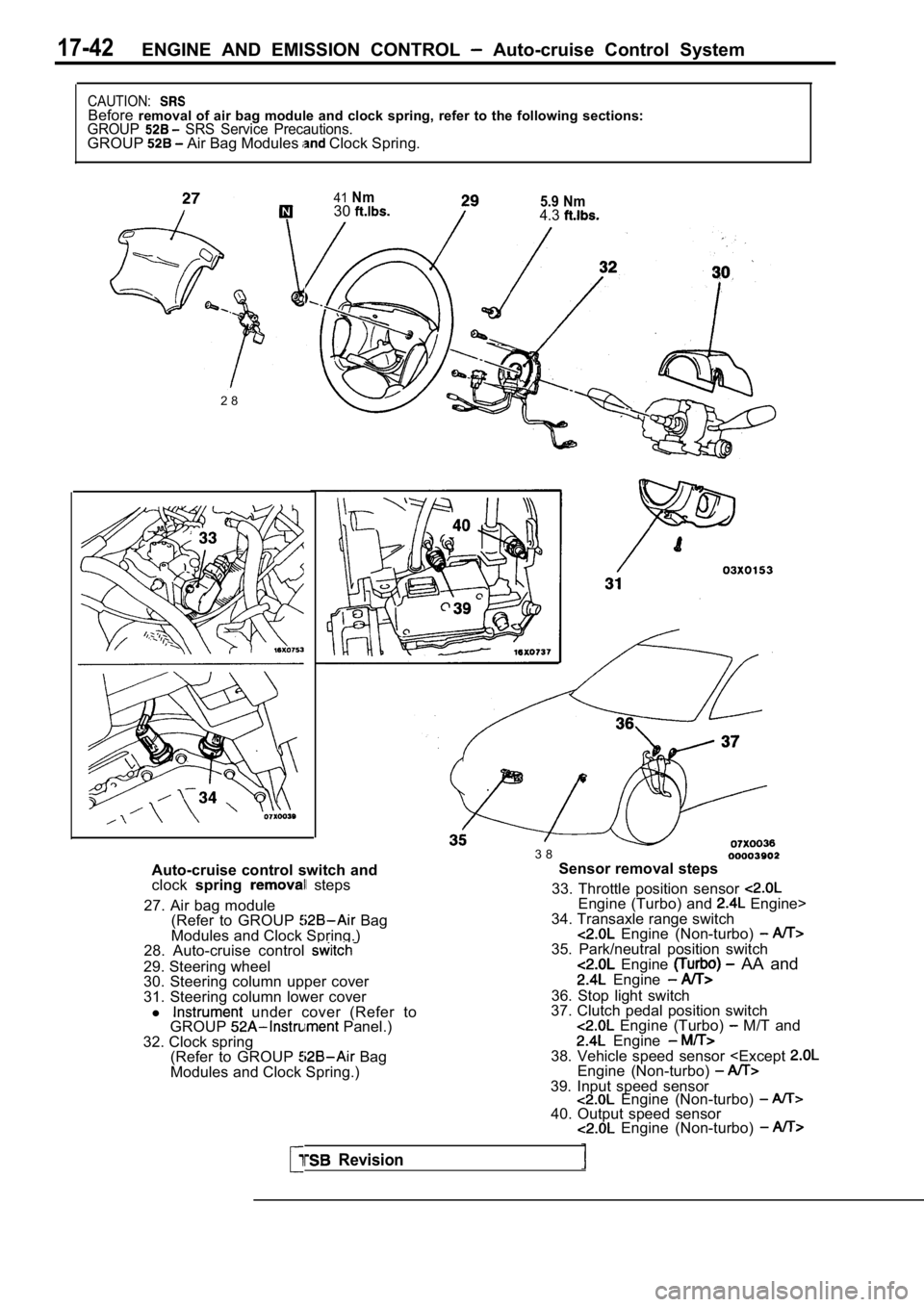

CAUTION:Beforeremoval of air bag module and clock spring, refer t o the following sections:GROUP SRS Service Precautions.GROUP Air Bag Modules Clock Spring.

5.9 Nm4.3

41Nm30

2 8

Auto-cruise control switch and

clock spring

steps

27. Air bag module (Refer to GROUP

Bag

Modules and Clock Spring.)

28. Auto-cruise control

29. Steering wheel

30. Steering column upper cover

31. Steering column lower cover

l

under cover (Refer to

GROUP Panel.)

32. Clock spring (Refer to GROUP

Bag

Modules and Clock Spring.) 3 8

Sensor removal steps

33. Throttle position sensor

Engine (Turbo) and Engine>

34. Transaxle range switch

Engine (Non-turbo) 35. Park/neutral position switch Engine AA and Engine

36. Stop light switch

37. Clutch pedal position switch

Engine (Turbo) M/T and Engine 38. Vehicle speed sensor

Page 800 of 2103

(Turbo) and Engine>

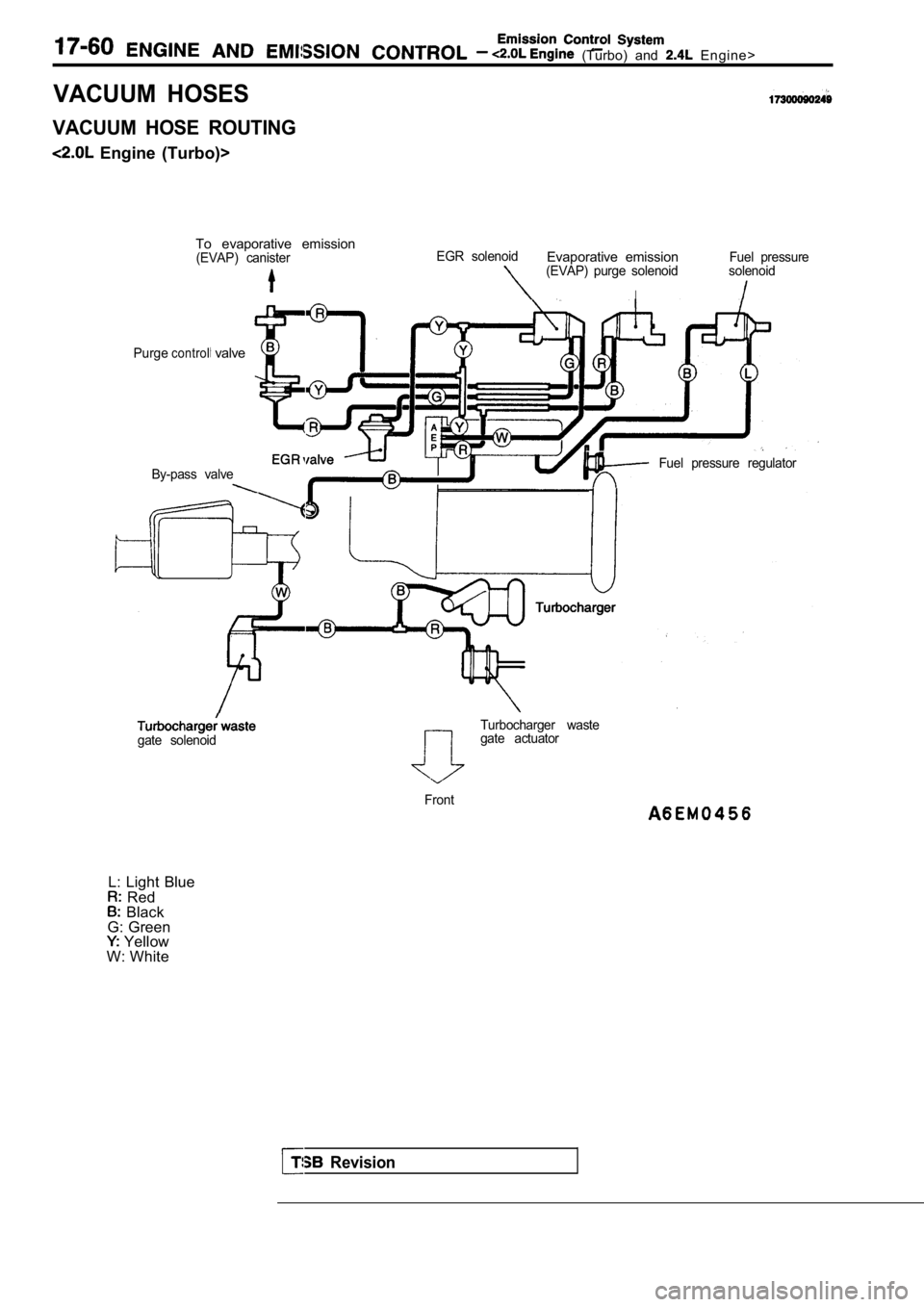

VACUUM HOSES

VACUUM HOSE ROUTING

Engine (Turbo)>To evaporative emission

(EVAP) canisterEGR solenoidEvaporative emissionFuel pressure(EVAP) purge solenoid solenoid

I

Purgecontrol valve

By-pass valveFuel pressure regulator

Revision

Turbocharger waste

gate solenoidgate actuator

Front

L: Light Blue Red Black

G: Green

Yellow

W: White

Page 802 of 2103

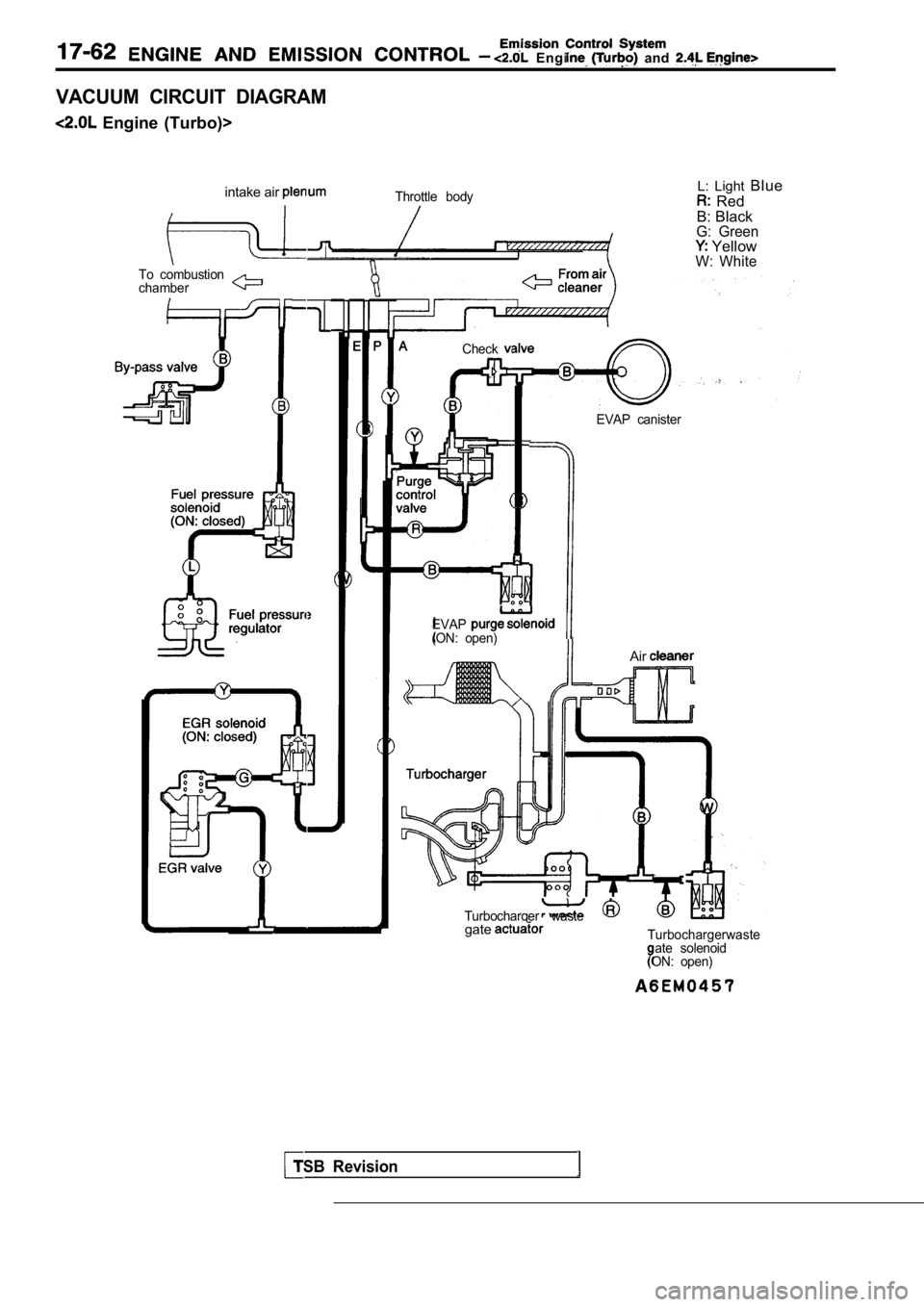

Engine and

VACUUM CIRCUIT DIAGRAM

Engine (Turbo)>intake air

Throttle bodyL: Light Blue

Red

B: Black

G: Green YellowW: WhiteTo combustion

chamber

Check

EVAP(ON: open)

EVAP canister

TSB Revision

Air

Turbocharger wastegateTurbochargerwasteate solenoid

ON: open)

Page 807 of 2103

(Turbo) and

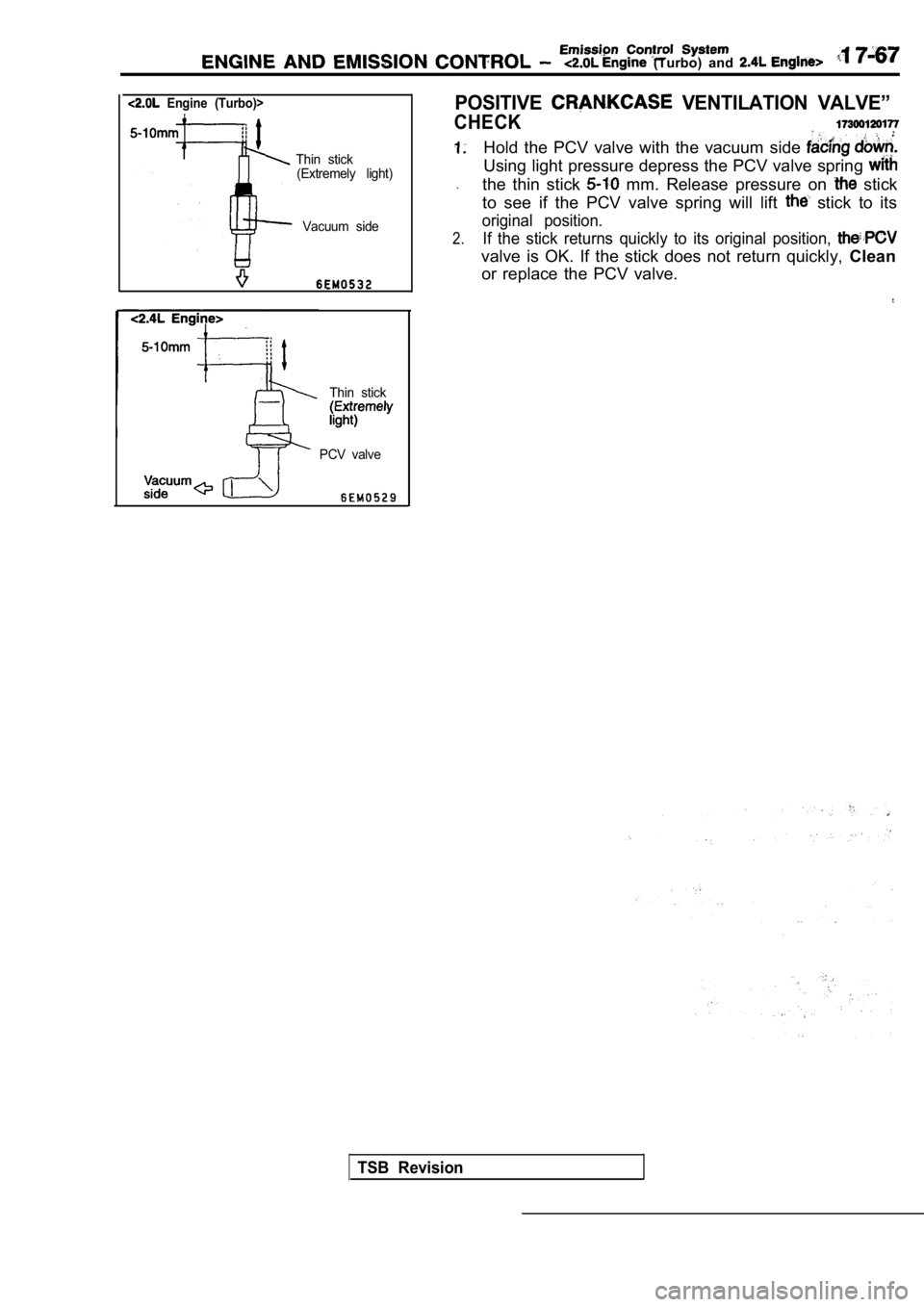

Engine (Turbo)>

Thin stick(Extremely light)

Vacuum side

Thin stick

PCV valve

POSITIVE VENTILATION VALVE”

CHECK

Hold the PCV valve with the vacuum side

Using light pressure depress the PCV valve spring

the thin stick mm. Release pressure on stick

to see if the PCV valve spring will lift

stick to its

original position.

2.If the stick returns quickly to its original positi on,

valve is OK. If the stick does not return quickly, Clean

or replace the PCV valve.

TSB Revision

Page 810 of 2103

17-70 CONTROL (Turbo) and Engine>

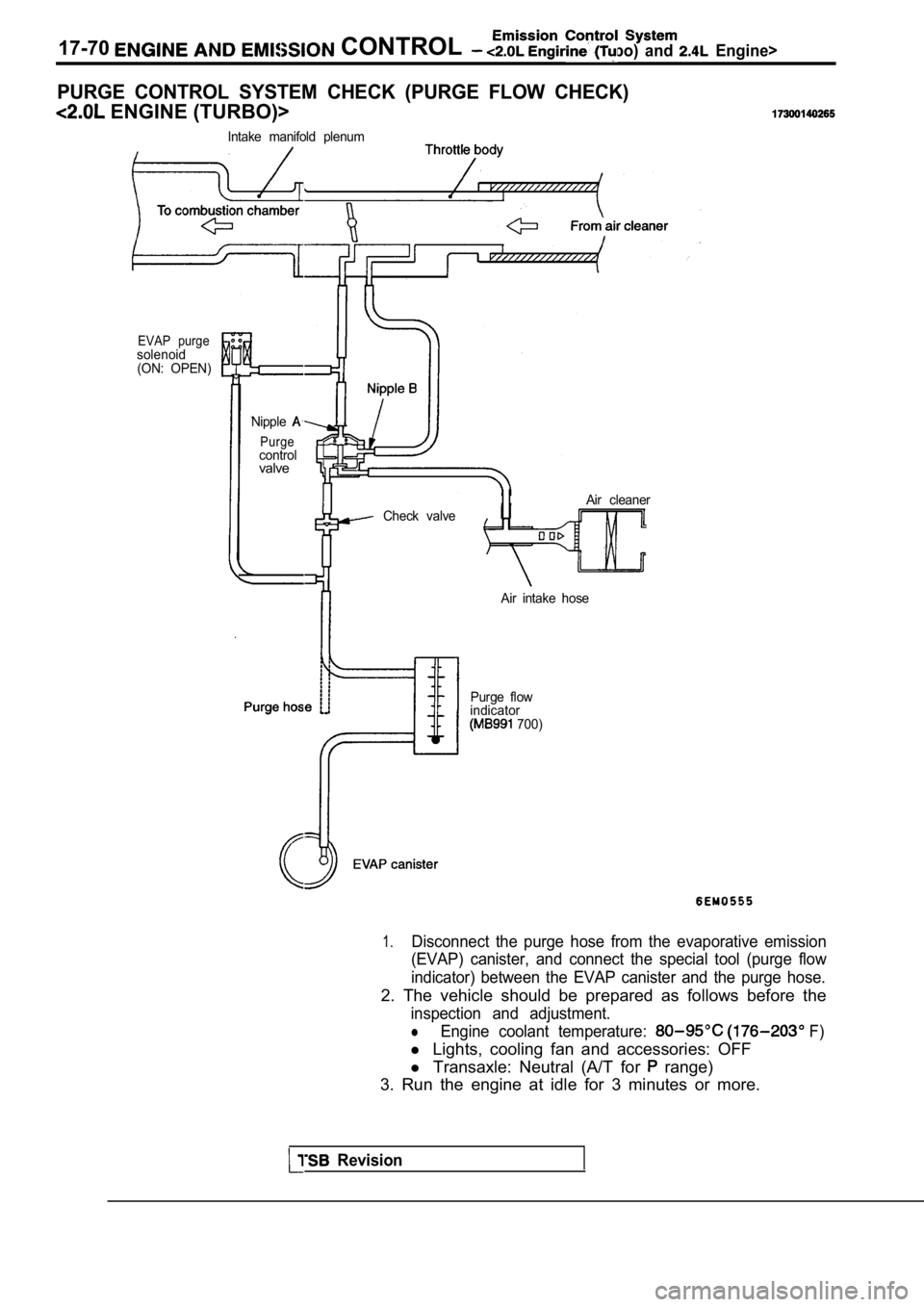

PURGE CONTROL SYSTEM CHECK (PURGE FLOW CHECK)

ENGINE (TURBO)>

Intake manifold plenum

EVAP purgesolenoid(ON: OPEN)

Nipple

Purgecontrolvalve

Check valve Air cleaner

Air intake hose

Purge flow

indicator

700)

1.Disconnect the purge hose from the evaporative emis sion

(EVAP) canister, and connect the special tool (purg e flow

indicator) between the EVAP canister and the purge hose.

2. The vehicle should be prepared as follows before the

inspection and adjustment.

lEngine coolant temperature: F)

l Lights, cooling fan and accessories: OFF

l Transaxle: Neutral (A/T for

range)

3. Run the engine at idle for 3 minutes or more.

Revision

Page 812 of 2103

(Turbo) and Engine>

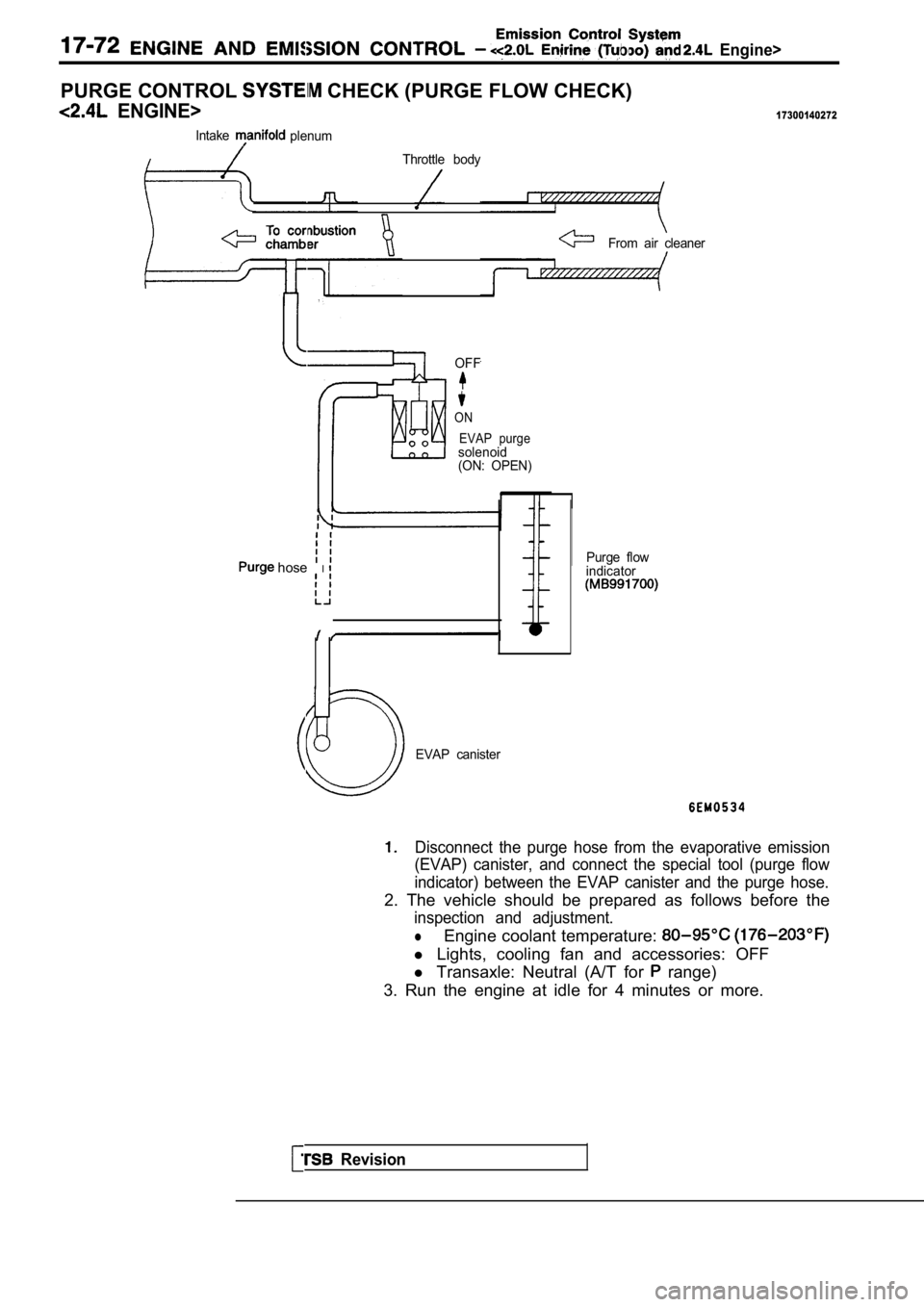

PURGE CONTROL CHECK (PURGE FLOW CHECK)

ENGINE>17300140272

IntakeplenumThrottle body

From air cleaner

OFF

ON EVAP purge

solenoid

(ON: OPEN)

hose IPurge flow

indicator

Revision

EVAP canister

Disconnect the purge hose from the evaporative emis sion

(EVAP) canister, and connect the special tool (purg e flow

indicator) between the EVAP canister and the purge hose.

2. The vehicle should be prepared as follows before the

inspection and adjustment.

lEngine coolant temperature:

l Lights, cooling fan and accessories: OFF

l Transaxle: Neutral (A/T for

range)

3. Run the engine at idle for 4 minutes or more.

Page 816 of 2103

AND C O N T R O L (Turbo) and Engine>

Valve

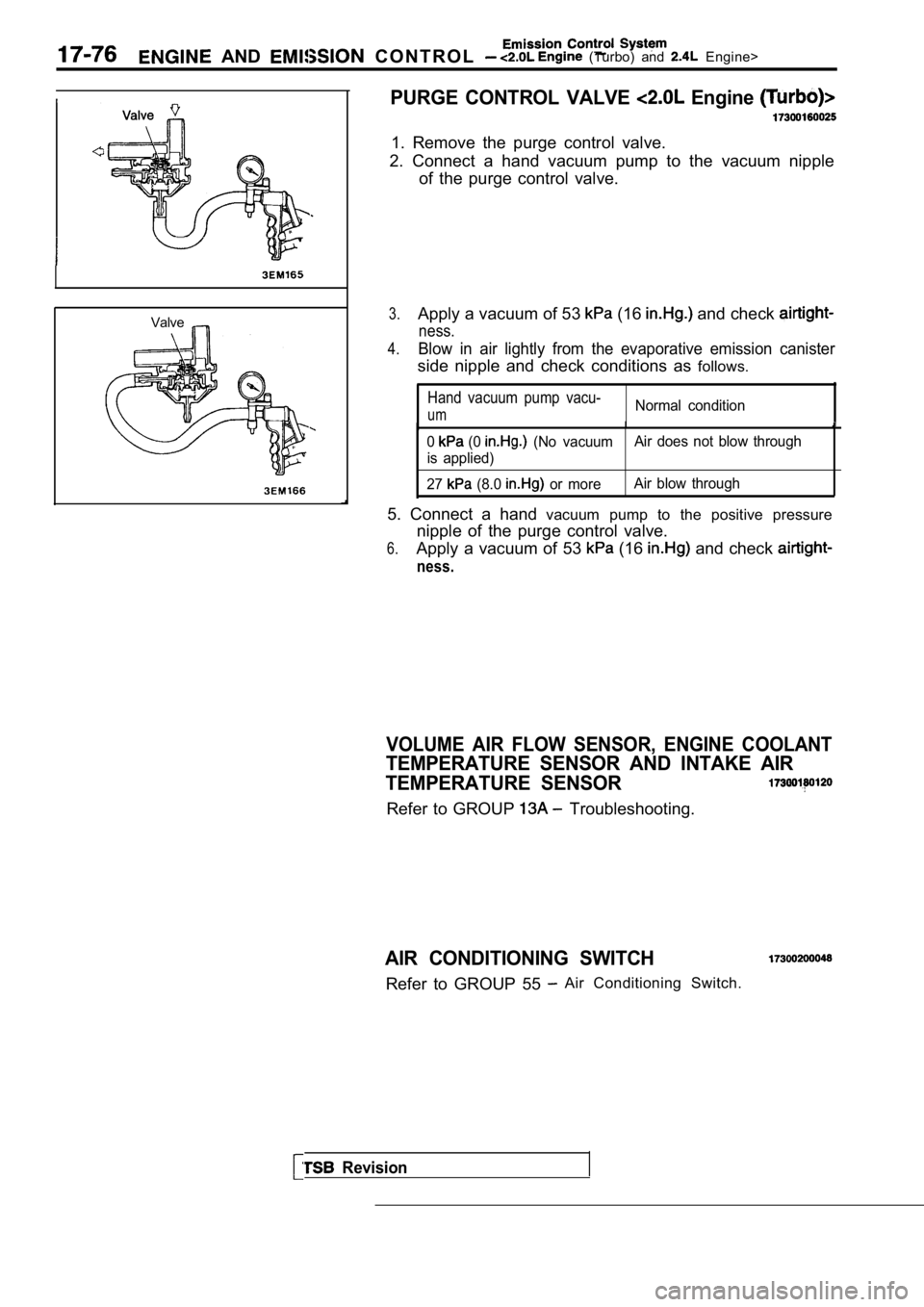

PURGE CONTROL VALVE Engine

1. Remove the purge control valve.

2. Connect a hand vacuum pump to the vacuum nipple of the purge control valve.

3.Apply a vacuum of 53 (16 and check

ness.

4.Blow in air lightly from the evaporative emission c anister

side nipple and check conditions as follows.

Hand vacuum pump vacu-

umNormal condition

0 (0 (No vacuumAir does not blow through

is applied)

27

(8.0 or more Air blow through

5. Connect a hand

vacuum pump to the positive pressure

nipple of the purge control valve.

6.Apply a vacuum of 53 (16 and check

ness.

Revision

VOLUME AIR FLOW SENSOR, ENGINE COOLANT

TEMPERATURE SENSOR AND INTAKE AIR

TEMPERATURE SENSOR

Refer to GROUP Troubleshooting.

AIR CONDITIONING SWITCH

Refer to GROUP 55 Air Conditioning Switch.