key MITSUBISHI SPYDER 1990 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 529 of 2103

E N G I N E

AND ENGINE>

ON-BOARD DIAGNOSTICS

The engine control module monitors the input/out-

put signals (some signals at all times and the othe rs

under specified conditions) of the engine control

module.

Whenamalfunction has continued for a specified

time or longer since the irregular signal is initia lly

monitored, the engine control module judges that

a malfunction has occurred.

After the ECM first detects a malfunction, a diagno s-

tic trouble code is recorded when the engine is

restarted and the same malfunction is re-detected.

However, for items marked with a

a diagnostic

trouble code is recorded on the first detection of

the malfunction.

There are 45 diagnostic items, and the diagnostic results can be read out with a scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ignition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector

is disconnected.

In addition, the diagnostic trouble code can also

be erased by turning the ignition switch to ON and

sending the diagnostic trouble code erase signal

from the scan tool to the engine control module.

Caution

If the sensor connector ‘is disconnected wlth

the’ ignition switch turned on, the diagnostic

trouble code is

In send

the diagnostic trouble code erase to the

engine control module in order to erase the

diagnostic memory.

The 45 diagnostic items are as follows,

and if plural items are activated, they are all ind i-

cated sequentially from the smallest code number.

Caution

The diagnostic trouble code of ignition

adjustment signal is output whenever

for ignition timing adjustment Is grounded.

Therefore, it is not a malfunction that the code

is output when adjusting

The ECM records the diagnostic, trouble code and

the engine operating conditions at the time the

malfunction was detected.’ These are called

“freeze frame” data.

This data indicates the engine operafing condition

from when nothing at all is detected to the initial

detection of malfunction.

This data can be read by using the scan tool, and

can then be used in simulation tests trouble-

shooting. Data items are as follows.,,

Data Unit

Engine coolant temperature.

Engine speed

Vehicle speed

Long-term fuel compensation

(Long-term fuel trim)

Short-term fuel compensation

(Short-term fuel trim)

km/h

Fuel control condition O p e n l o o p

l Closed loop

l Open loop-drive condition

l O p e n

set

l Closed

(rear) failed

Calculation load value

Diagnostic trouble code during data recording

TSB Revision

Page 647 of 2103

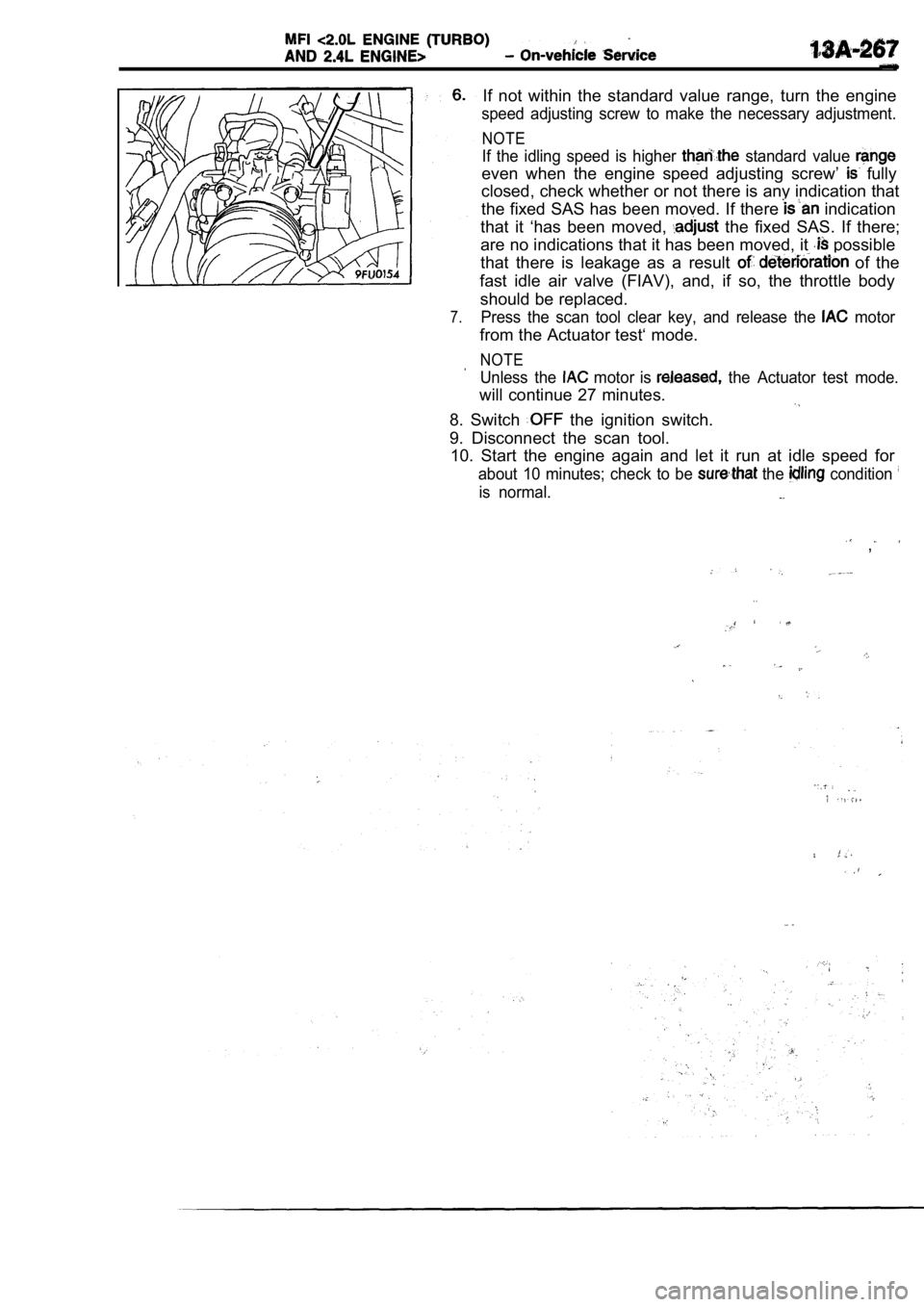

If not within the standard value range, turn the engine

speed adjusting screw to make the necessary adjustm ent.

NOTE

If the idling speed is higher standard value

even when the engine speed adjusting screw’ fully

closed, check whether or not there is any indicatio n that

the fixed SAS has been moved. If there

indication

that it ‘has been moved,

the fixed SAS. If there;

are no indications that it has been moved, it

possible

that there is leakage as a result

of the

fast idle air valve (FIAV), and, if so, the throttl e body

should be replaced.

7.Press the scan tool clear key, and release the motor

from the Actuator test‘ mode.

NOTE

Unless the motor is the Actuator test mode.

will continue 27 minutes.

8. Switch the ignition switch.

9. Disconnect the scan tool. 10. Start the engine again and let it run at idle s peed for

about 10 minutes; check to be the condition

is normal.

,

. .

Page 749 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control

TROUBLESHOOTING ENGINE (NON-TURBO)>

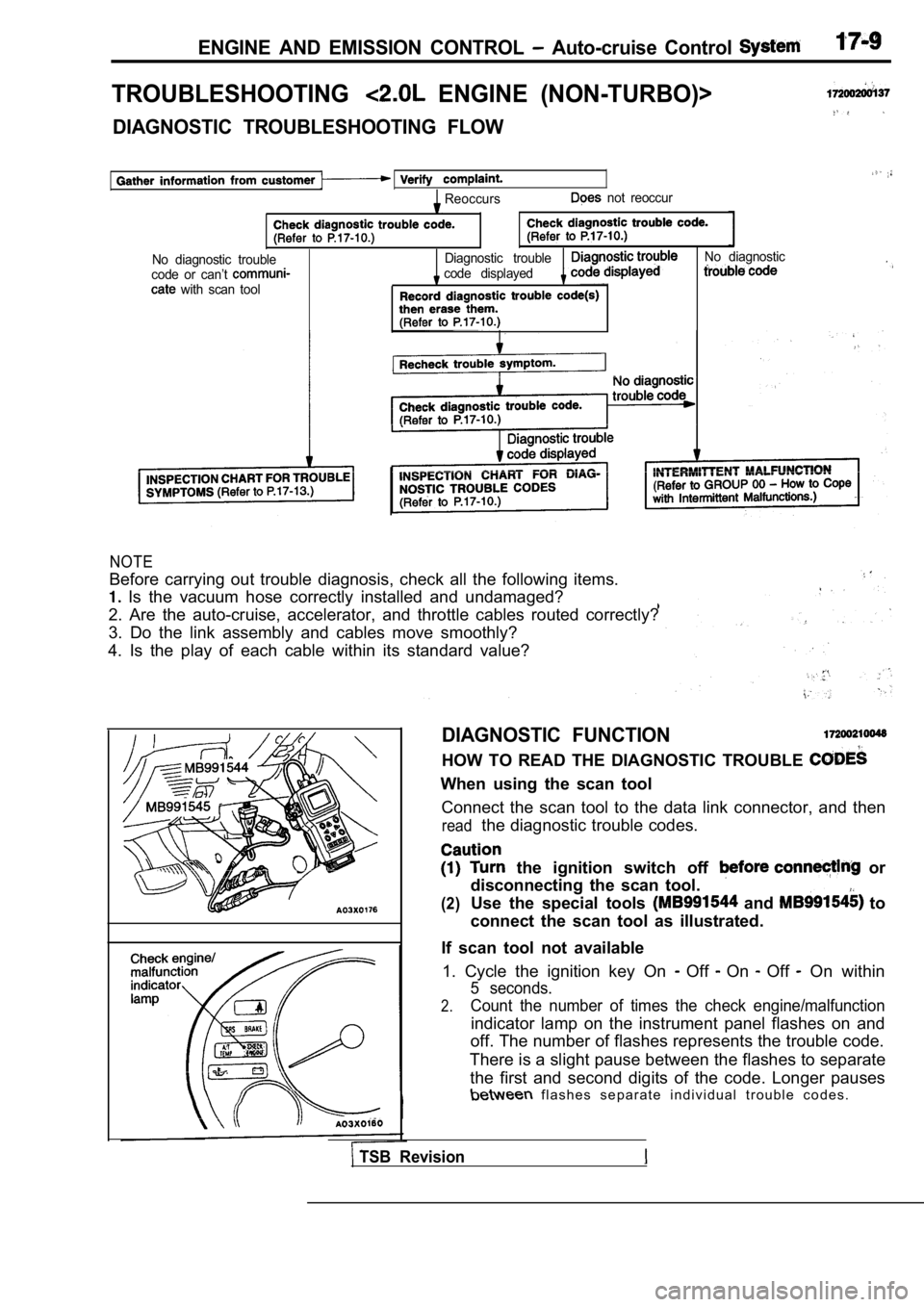

DIAGNOSTIC TROUBLESHOOTING FLOW

Reoccurs not reoccur

No diagnostic troubleDiagnostic troubleNo diagnostic

code or can’t code displayed

with scan tool

NOTE

Before carrying out trouble diagnosis, check all th e following items.

Is the vacuum hose correctly installed and undamag ed?

2. Are the auto-cruise, accelerator, and throttle c ables routed correctly?

3. Do the link assembly and cables move smoothly?

4. Is the play of each cable within its standard va lue?

DIAGNOSTIC FUNCTION

HOW TO READ THE DIAGNOSTIC TROUBLE

When using the scan tool

Connect the scan tool to the data link connector, a nd then

readthe diagnostic trouble codes.

the ignition switch off or

disconnecting the scan tool.

(2)Use the special tools and to

connect the scan tool as illustrated.

If scan tool not available 1. Cycle the ignition key On

Off On Off On within

5 seconds.

2.Count the number of times the check engine/malfunct ion

indicator lamp on the instrument panel flashes on and

off. The number of flashes represents the trouble c ode.

There is a slight pause between the flashes to sepa rate

the first and second digits of the code. Longer pau ses

f l a s h e s s e p a r a t e i n d i v i d u a l t r o u b l e c o d e s .

TSB Revision

Page 775 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise Control System

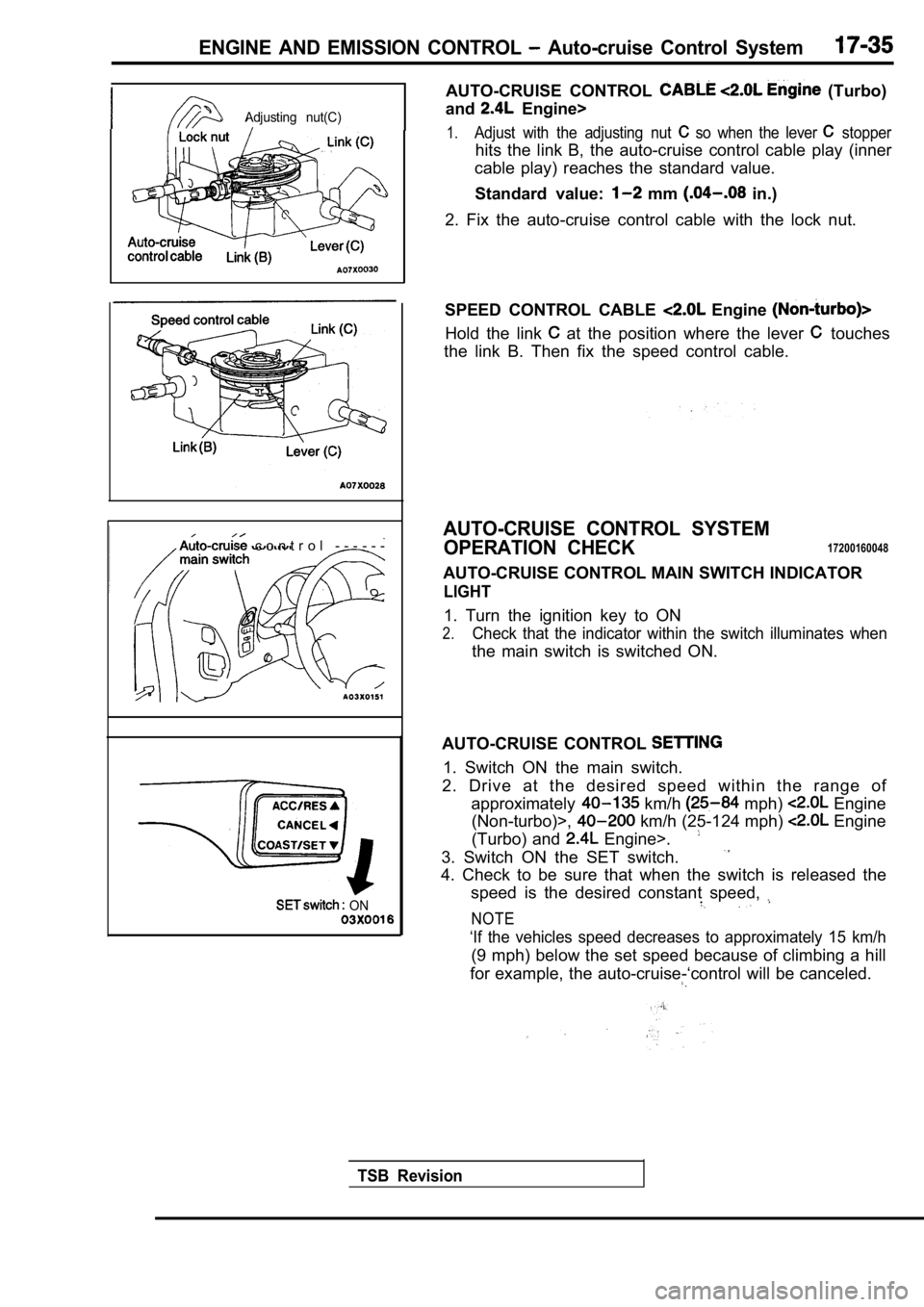

Adjusting nut(C)

c o n t r o l - - - - - -

ON

AUTO-CRUISE CONTROL (Turbo)

and

Engine>

1.Adjust with the adjusting nut so when the lever stopper

hits the link B, the auto-cruise control cable play (inner

cable play) reaches the standard value.

Standard value:

mm in.)

2. Fix the auto-cruise control cable with the lock nut.

SPEED CONTROL CABLE

Engine

Hold the link at the position where the lever touches

the link B. Then fix the speed control cable.

AUTO-CRUISE CONTROL SYSTEM

OPERATION CHECK

17200160048

AUTO-CRUISE CONTROL MAIN SWITCH INDICATOR

LIGHT

1. Turn the ignition key to ON

2.Check that the indicator within the switch illumina tes when

the main switch is switched ON.

AUTO-CRUISE CONTROL

1. Switch ON the main switch.

2. Drive at the desired speed within the range of approximately

km/h mph) Engine

(Non-turbo)>,

km/h (25-124 mph) Engine

(Turbo) and

Engine>.

3. Switch ON the SET switch.

4. Check to be sure that when the switch is release d the

speed is the desired constant speed,

.

NOTE

‘If the vehicles speed decreases to approximately 1 5 km/h

(9 mph) below the set speed because of climbing a h ill

for example, the auto-cruise-‘control will be cance led.

TSB Revision

Page 926 of 2103

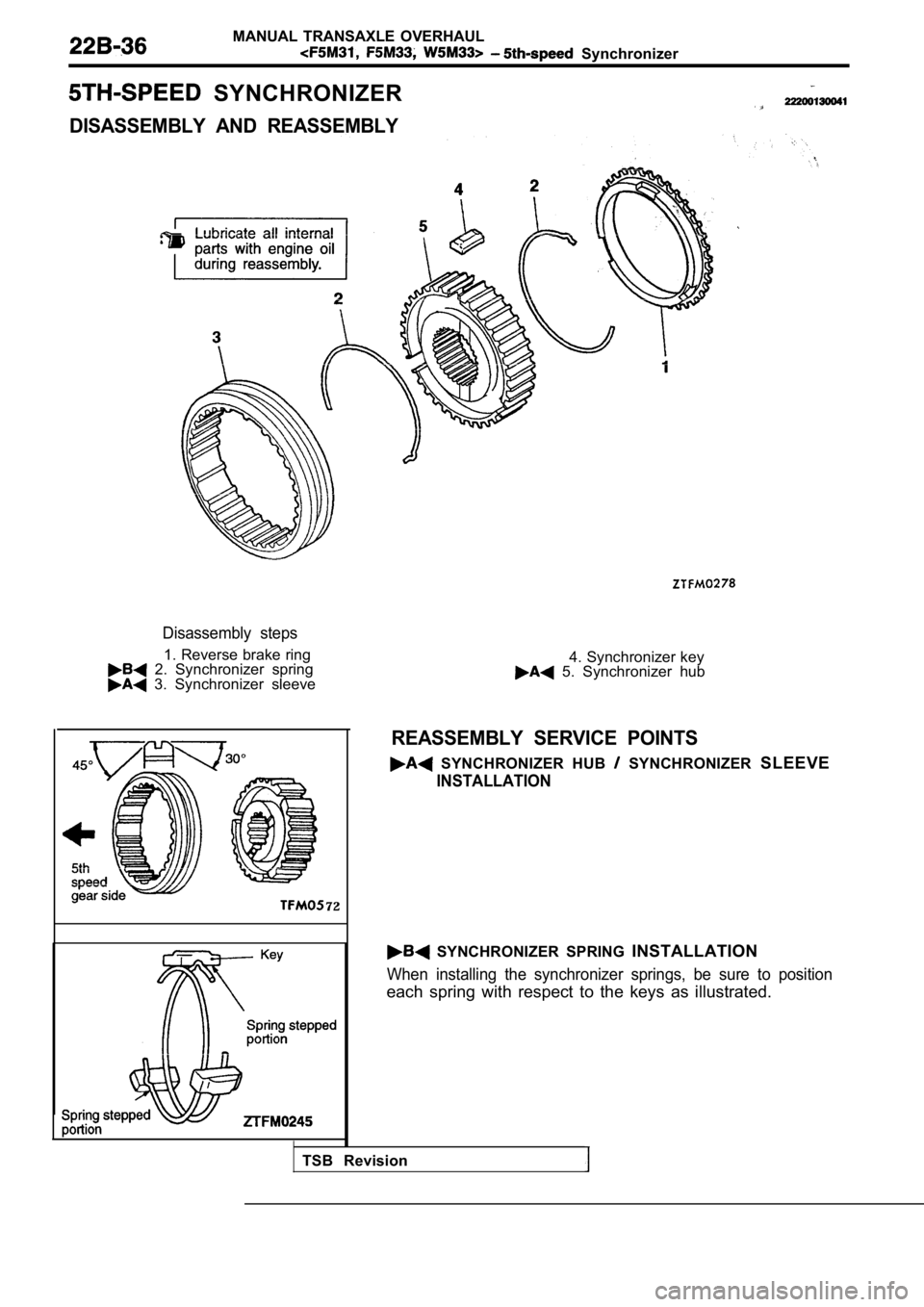

MANUAL TRANSAXLE OVERHAUL

Synchronizer

SYNCHRONIZER

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Reverse brake ring 2. Synchronizer spring 3. Synchronizer sleeve

72

4. Synchronizer key 5. Synchronizer hub

REASSEMBLY SERVICE POINTS

SYNCHRONIZER HUB SYNCHRONIZER SLEEVE

INSTALLATION

SYNCHRONIZER SPRING INSTALLATION

When installing the synchronizer springs, be sure t o position

each spring with respect to the keys as illustrated.

TSB Revision

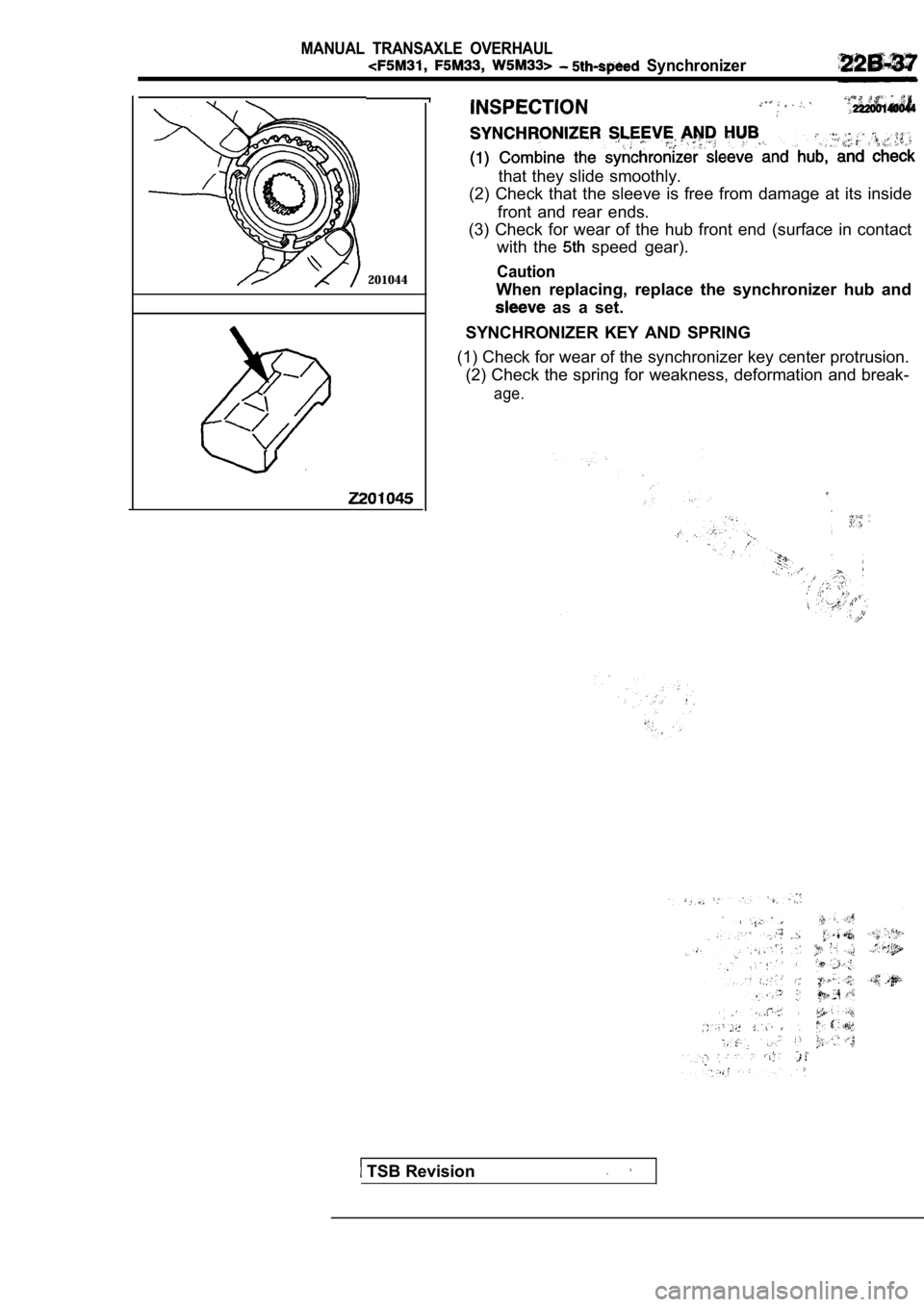

Page 927 of 2103

MANUAL TRANSAXLE OVERHAUL

Synchronizer

201044

that they slide smoothly.

(2) Check that the sleeve is free from damage at it s inside

front and rear ends.

(3) Check for wear of the hub front end (surface in contact

with the

speed gear).

Caution

When replacing, replace the synchronizer hub and

as a set.

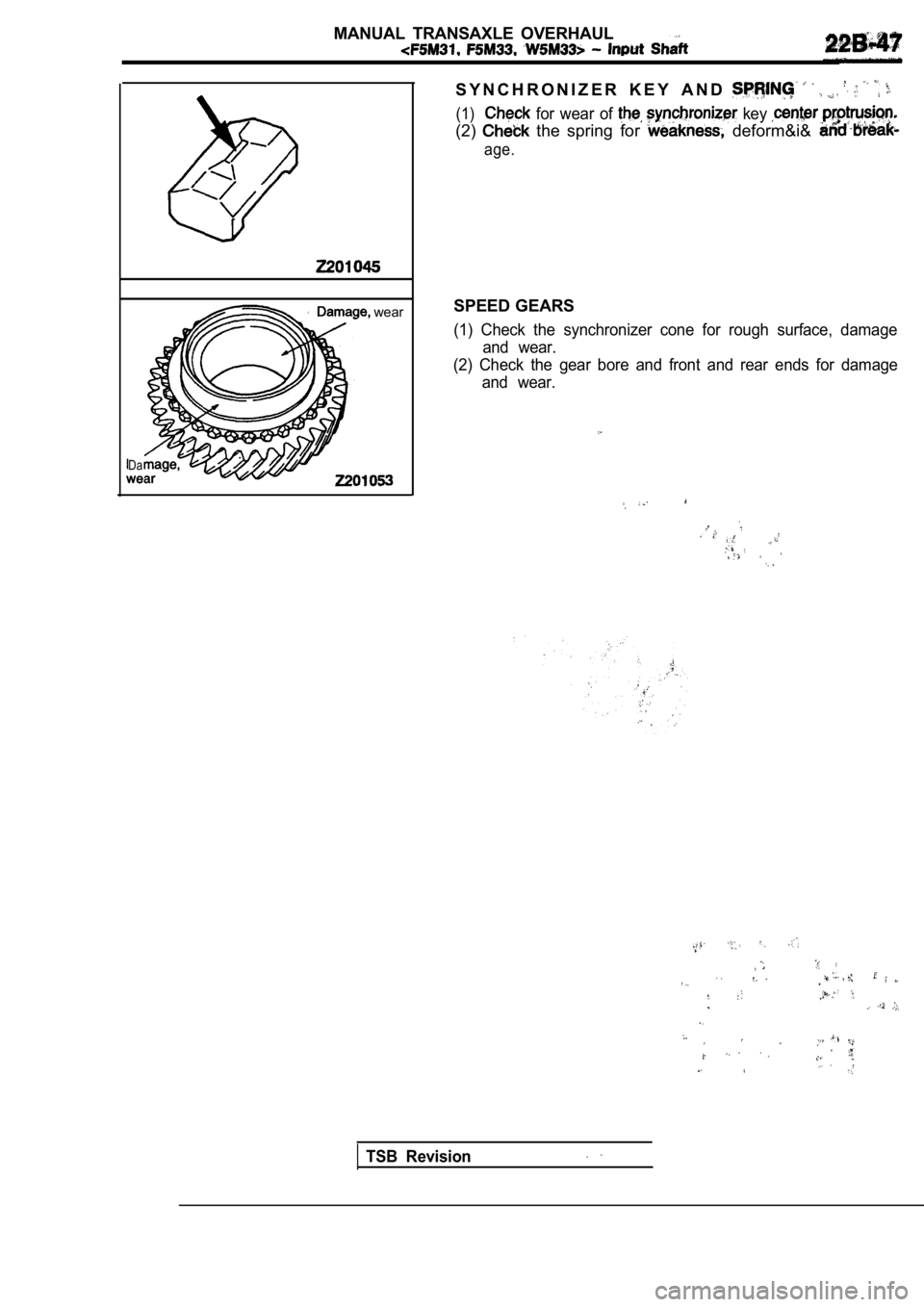

SYNCHRONIZER KEY AND SPRING

(1) Check for wear of the synchronizer key center p rotrusion.

(2) Check the spring for weakness, deformation and break-

age.

TSB Revision

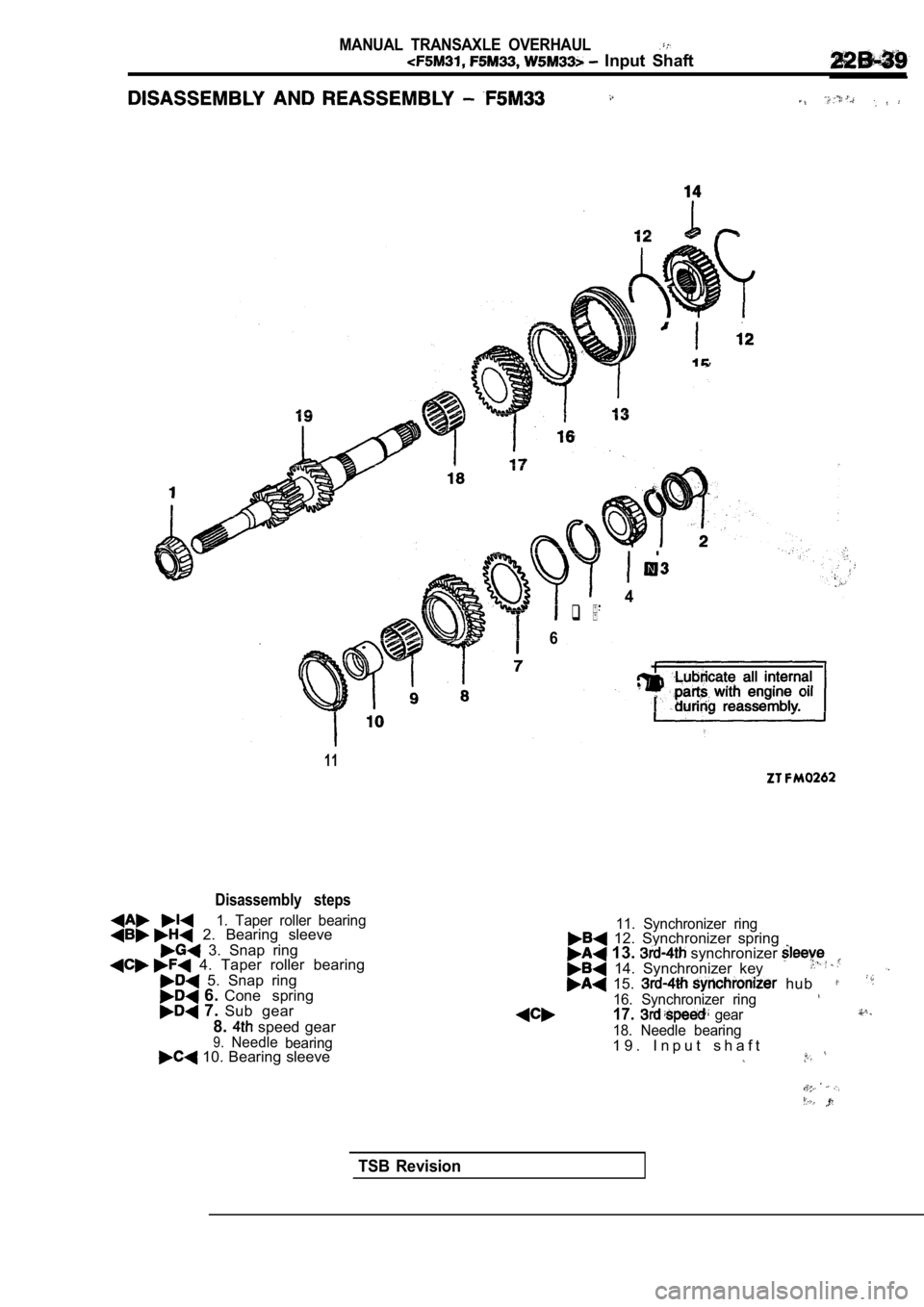

Page 929 of 2103

MANUAL TRANSAXLE OVERHAUL

Input Shaft

4

q 5

6

11

Disassembly steps

1. Taper roller bearing 2. Bearing sleeve

3. Snap ring 4. Taper roller bearing

5. Snap ring 6. Cone spring 7. Sub gear

8.

speed gear9.Needle bearing 10. Bearing sleeve

11. Synchronizer ring 12. Synchronizer spring 13. synchronizer 14. Synchronizer key 15. hub

16. Synchronizer ring17. gear

18. Needle bearing1 9 . I n p u t s h a f t

TSB Revision

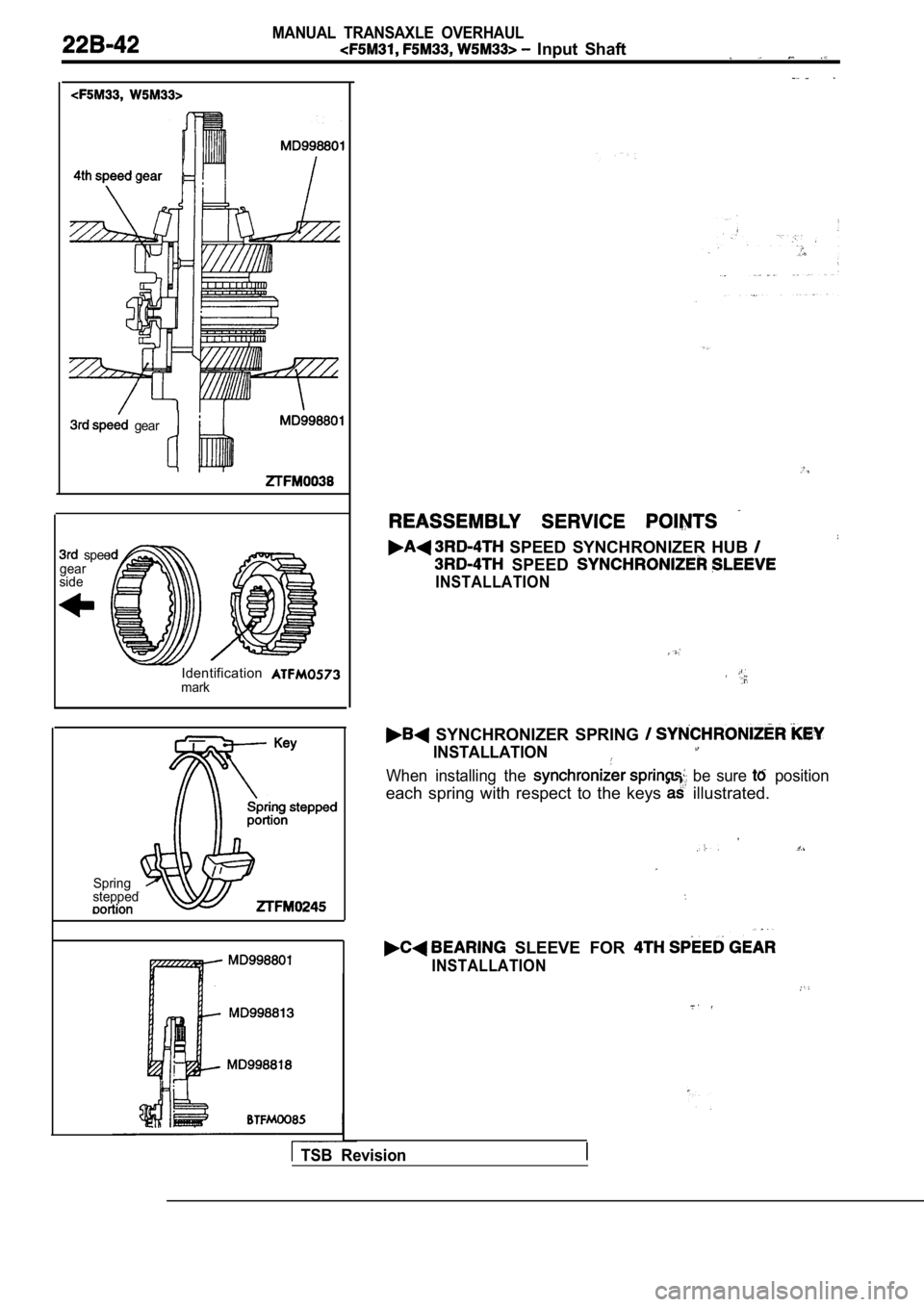

Page 932 of 2103

MANUAL TRANSAXLE OVERHAUL

Input Shaft

gear

spee

gear

side

Identificationmark

Spring

stepped

SPEED SYNCHRONIZER HUB

SPEED

INSTALLATION

SYNCHRONIZER SPRING

INSTALLATION

When installing the be sure position

each spring with respect to the keys illustrated.

SLEEVE FOR

INSTALLATION

TSB Revision

Page 937 of 2103

MANUAL TRANSAXLE OVERHAUL

wear

Da

S Y N C H R O N I Z E R K E Y A N D

(1) for wear of key

(2) the spring for deform&i&

age.

SPEED GEARS

(1) Check the synchronizer cone for rough surface, damage

and wear.

(2) Check the gear bore and front and rear ends for damage

and wear.

TSB Revision

Page 938 of 2103

MANUAL TRANSAXLE OVERHAUL

Intermediate Gear ,

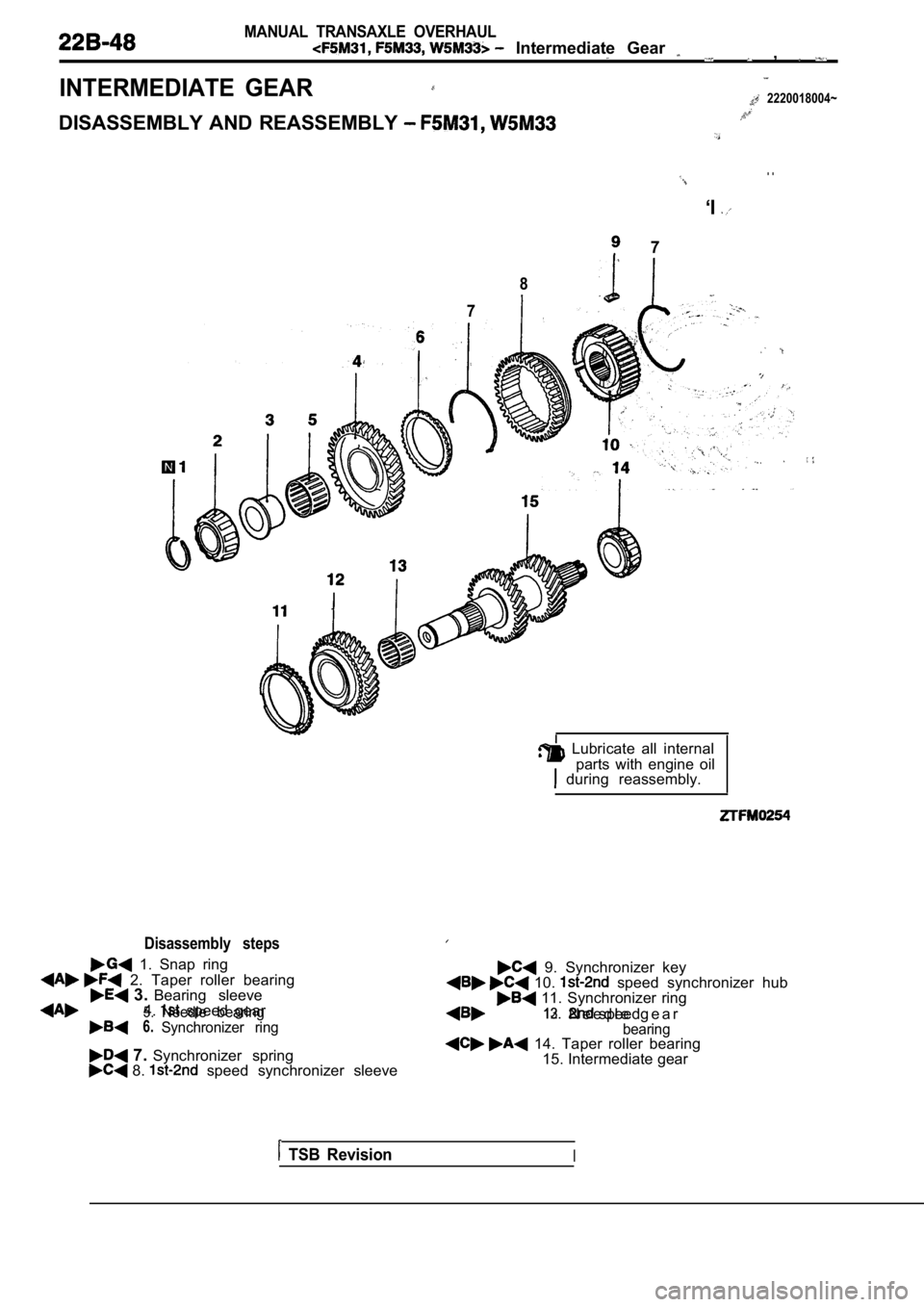

INTERMEDIATE GEAR 2220018004~

DISASSEMBLY AND REASSEMBLY

. .

‘I

7

8

7

Lubricate all internalparts with engine oil

during reassembly.

Disassembly steps

1. Snap ring

2. Taper roller bearing 9. Synchronizer key

3. Bearing sleeve 10. speed synchronizer hub

4.

speed gear 11. Synchronizer ring

12.

5. speed13.N e e d l e g e a r6.Needle bearing

Synchronizer ring bearing

7. Synchronizer spring 14. Taper roller bearing

8. speed synchronizer sleeve 15. Intermediate gear

TSB RevisionI