torque MITSUBISHI SPYDER 1990 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 67 of 2103

ENGINE On-vehicle

98 (22

Generator

pulley

pulley

v

pulley

ON-VEHICLE

DRIVE BELT TENSION CHECK’ AND

ADJUSTMENT

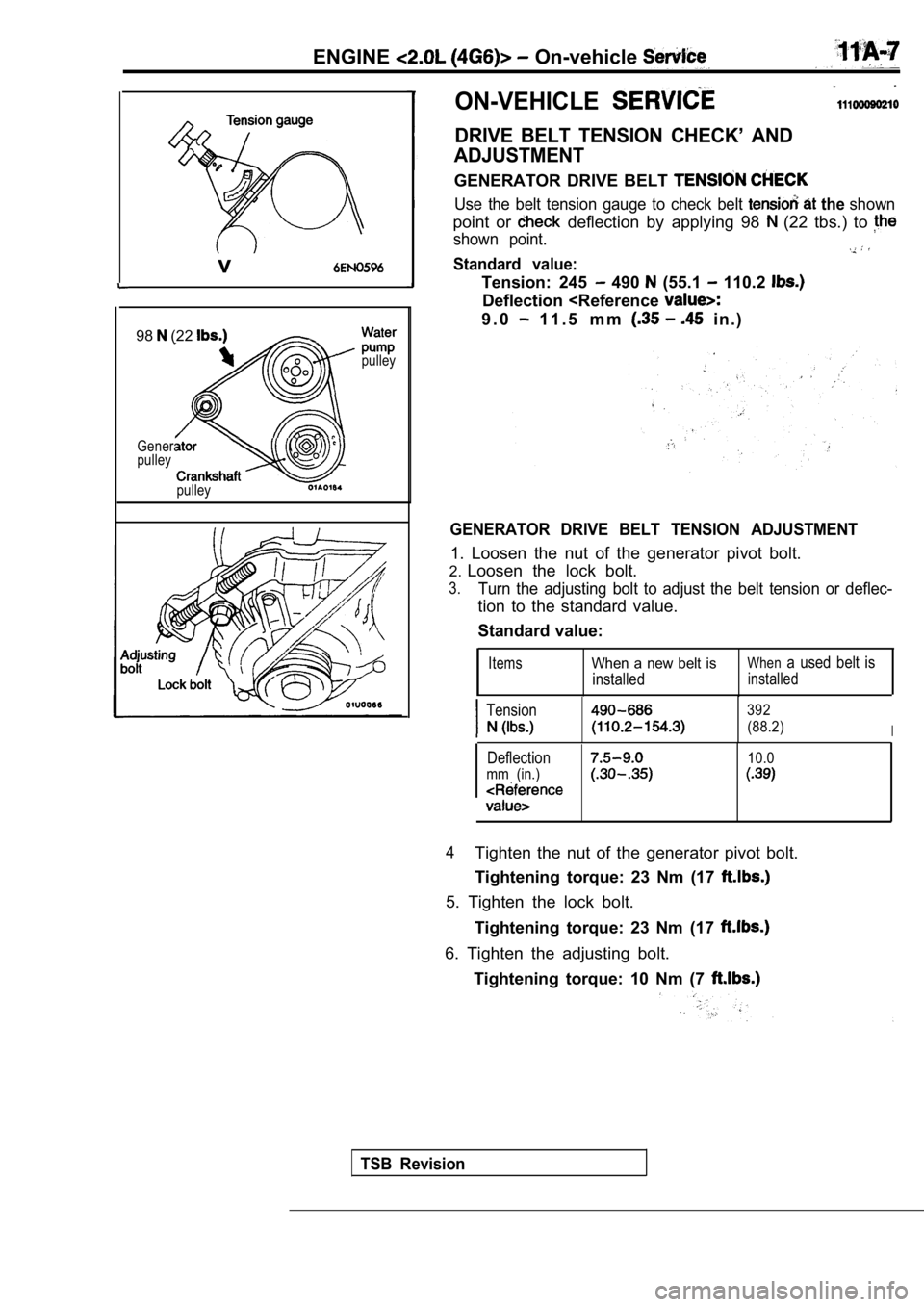

GENERATOR DRIVE BELT

Use the belt tension gauge to check belt the shown

point or deflection by applying 98 (22 tbs.) to

shown point.

Standard value:

Tension: 245 490 (55.1 110.2

Deflection

GENERATOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen the nut of the generator pivot bolt.

2. Loosen the lock bolt.

3.Turn the adjusting bolt to adjust the belt tension or deflec-

tion to the standard value.

Standard value:

ItemsWhen a new belt is

installed

Whena used belt is

installed

Tension392

(88.2)I

Deflection10.0

mm (in.)

4Tighten the nut of the generator pivot bolt.

Tightening torque: 23 Nm (17

5. Tighten the lock bolt.

Tightening torque: 23 Nm (17

6. Tighten the adjusting bolt.Tightening torque: 10 Nm (7

TSB Revision

Page 68 of 2103

ENGINE On-vehicle Service

pump pulley

Cranksh

pulley

pulley

a

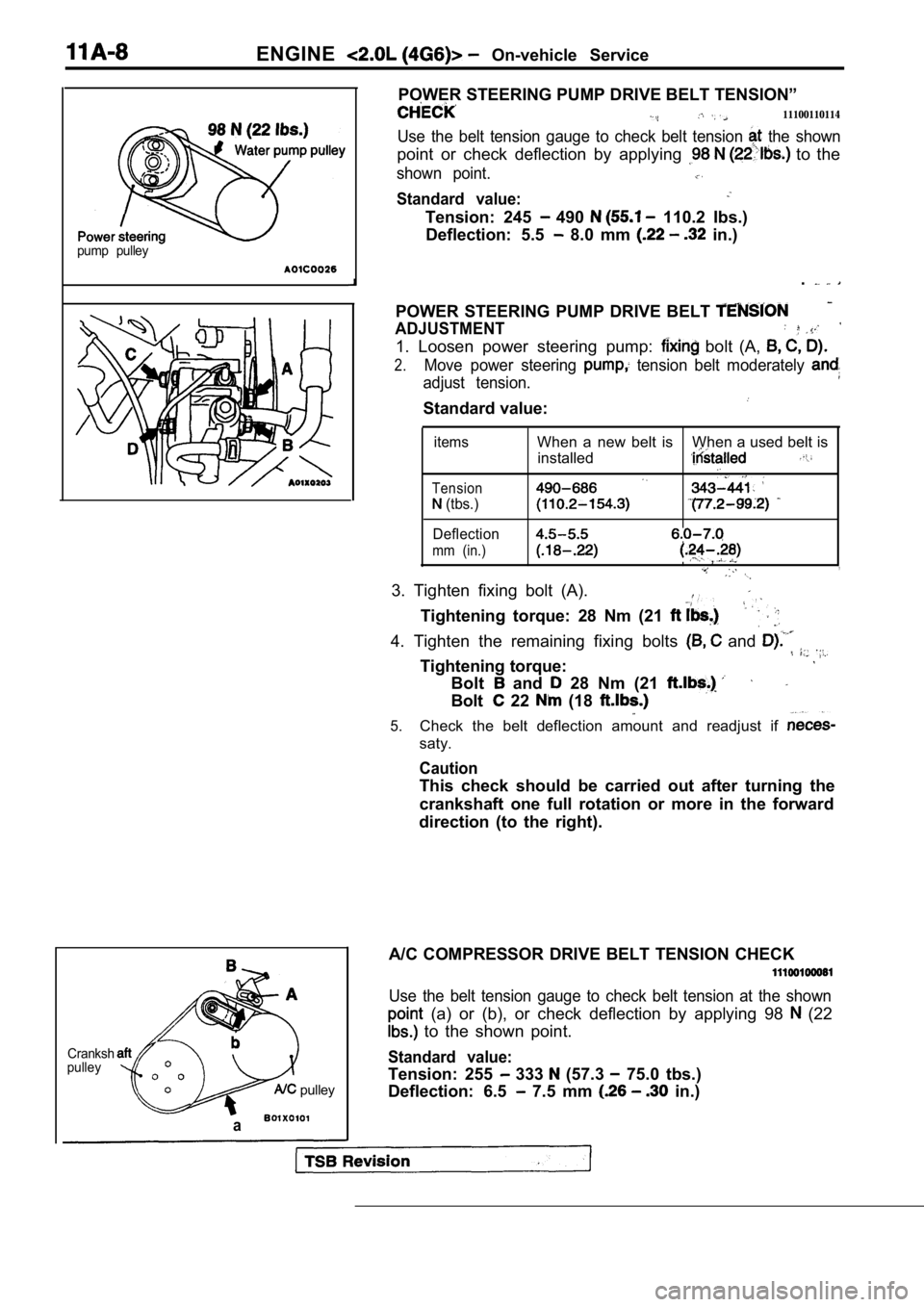

POWER STEERING PUMP DRIVE BELT TENSION”

11100110114

Use the belt tension gauge to check belt tension the shown

point or check deflection by applying to the

shown point.

Standard value:

Tension: 245 490 110.2 Ibs.)

Deflection: 5.5

8.0 mm in.)

.

POWER STEERING PUMP DRIVE BELT

ADJUSTMENT

1. Loosen power steering pump: bolt (A,

2.Move power steering tension belt moderately

adjust tension.

Standard value:

items

Tension

(tbs.)

Deflection

mm (in.)

When a new belt is When a used belt is installed

,,

3. Tighten fixing bolt (A).

Tightening torque: 28 Nm (21

4. Tighten the remaining fixing bolts and

Tightening torque:

Bolt and 28 Nm (21

Bolt 22 (18

5.Check the belt deflection amount and readjust if

saty.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

A/C COMPRESSOR DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

(a) or (b), or check deflection by applying 98 (22

to the shown point.

Standard value:

Tension: 255 333 (57.3 75.0 tbs.)

Deflection: 6.5

7.5 mm in.)

Page 69 of 2103

ENGINE On-vehicle

A/C COMPRESSOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt tension with adjusting bolt B.

Standard value:

Items

Tension

(Ibs.)

Deflection

When a new belt isWhen a used belt is

installedinstalled

382-411255-333

6.5-7.5

3. Tighten fixing nut A.

Tightening torque: 23-26 Nm

4.Check the belt deflection and readjust if neces-

sary.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

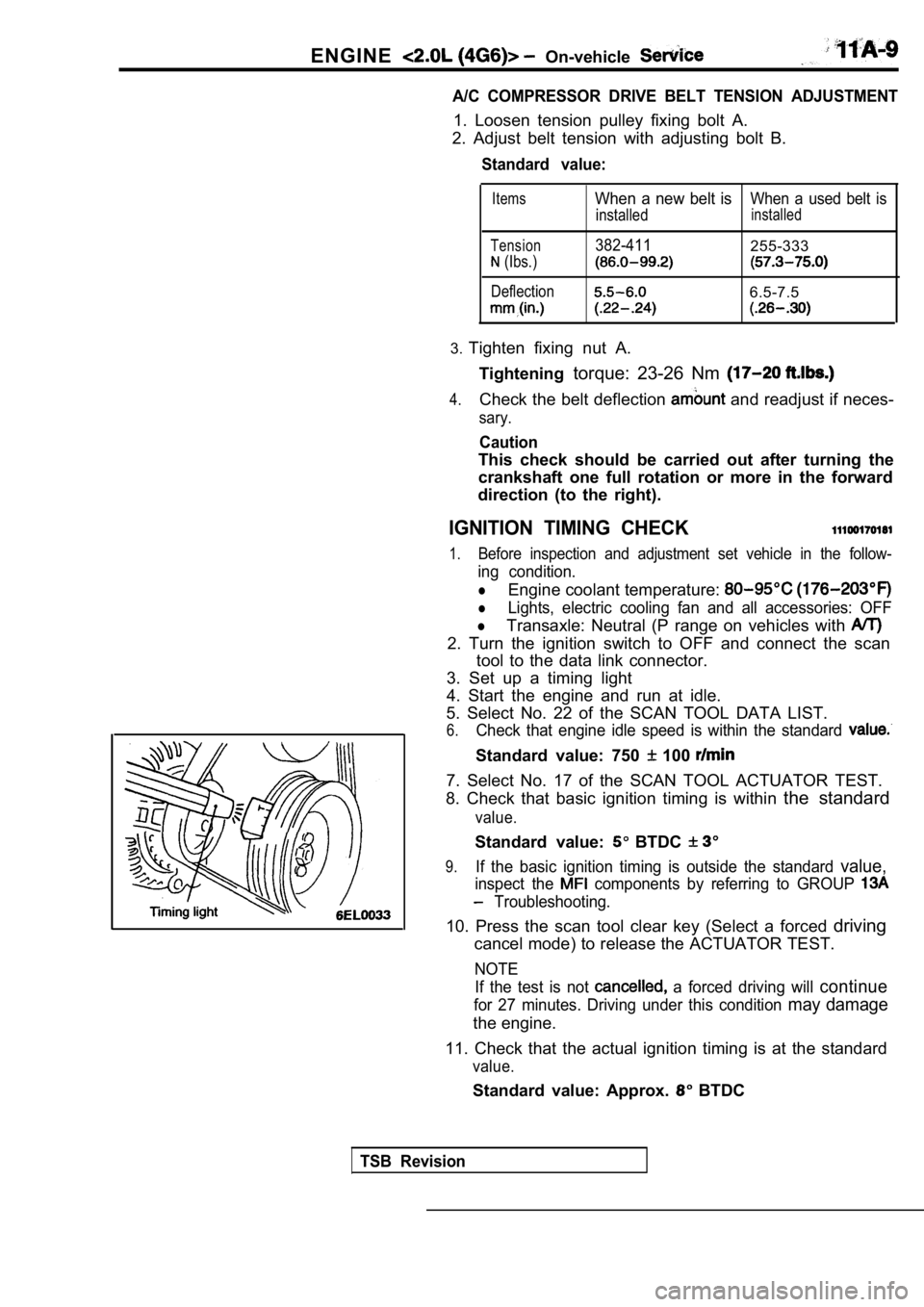

IGNITION TIMING CHECK

1.Before inspection and adjustment set vehicle in the follow-

ing condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Set up a timing light

4. Start the engine and run at idle.

5. Select No. 22 of the SCAN TOOL DATA LIST.

6.Check that engine idle speed is within the standard

Standard value: 750 100

7. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

8. Check that basic ignition timing is within the standard

value.

Standard value: BTDC

9.If the basic ignition timing is outside the standar d value,

inspect the components by referring to GROUP

Troubleshooting.

10. Press the scan tool clear key (Select a forced driving

cancel mode) to release the ACTUATOR TEST.

NOTE

If the test is not

a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

11. Check that the actual ignition timing is at the standard

value.

Standard value: Approx. BTDC

TSB Revision

Page 85 of 2103

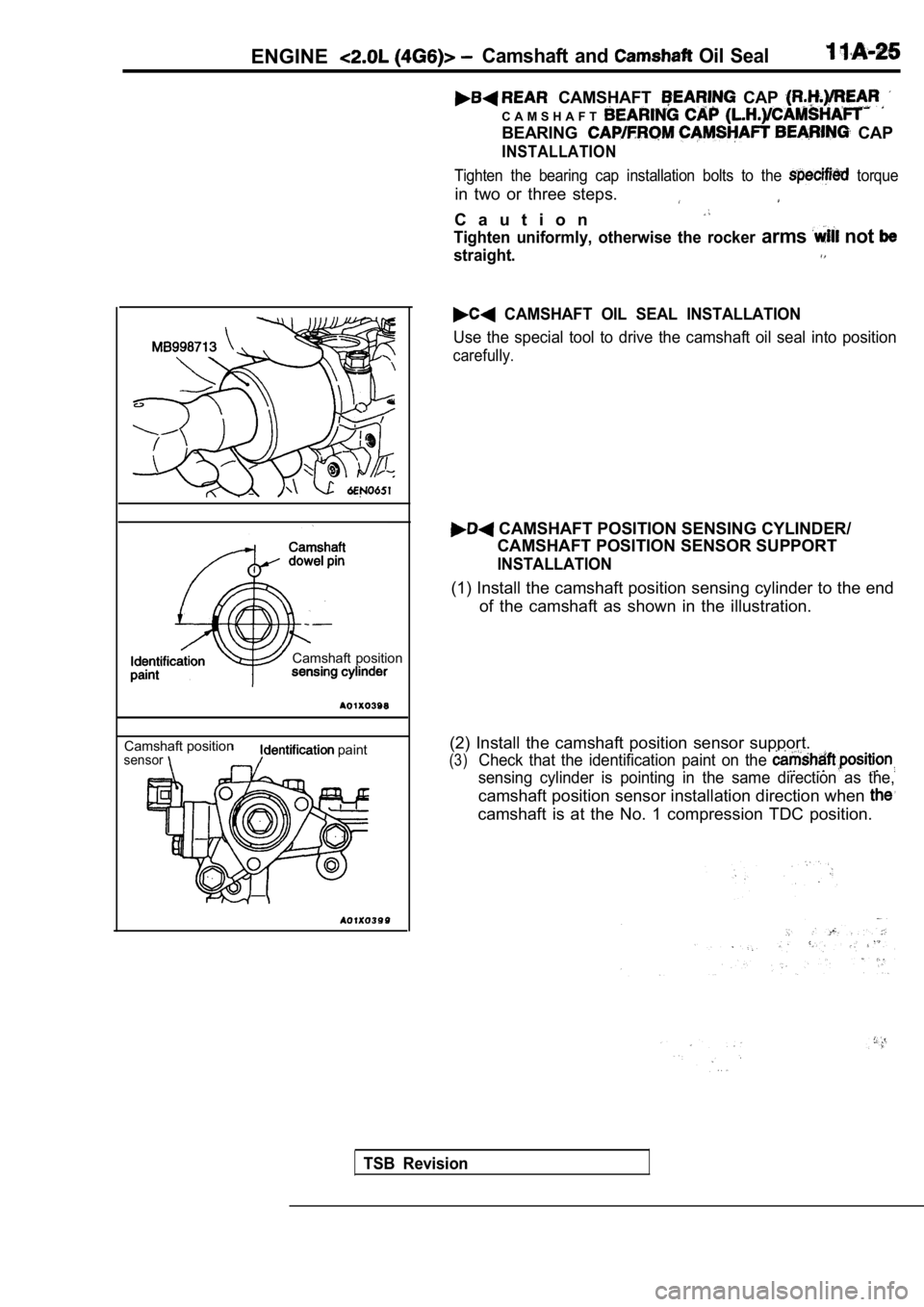

ENGINECamshaft and Oil Seal

CAMSHAFT CAP

C A M S H A F T

BEARING CAP

INSTALLATION

Tighten the bearing cap installation bolts to the torque

in two or three steps.

C a u t i o n

Tighten uniformly, otherwise the rocker arms not

straight.

Camshaft position

Camshaft positionsensor paint

CAMSHAFT OIL SEAL INSTALLATION

Use the special tool to drive the camshaft oil seal into position

carefully.

CAMSHAFT POSITION SENSING CYLINDER/

CAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

(1) Install the camshaft position sensing cylinder to the end

of the camshaft as shown in the illustration.

(2) Install the camshaft position sensor support.

(3)Check that the identification paint on the

sensing cylinder is pointing in the same direction as the,

camshaft position sensor installation direction when

camshaft is at the No. 1 compression TDC position.

TSB Revision

Page 90 of 2103

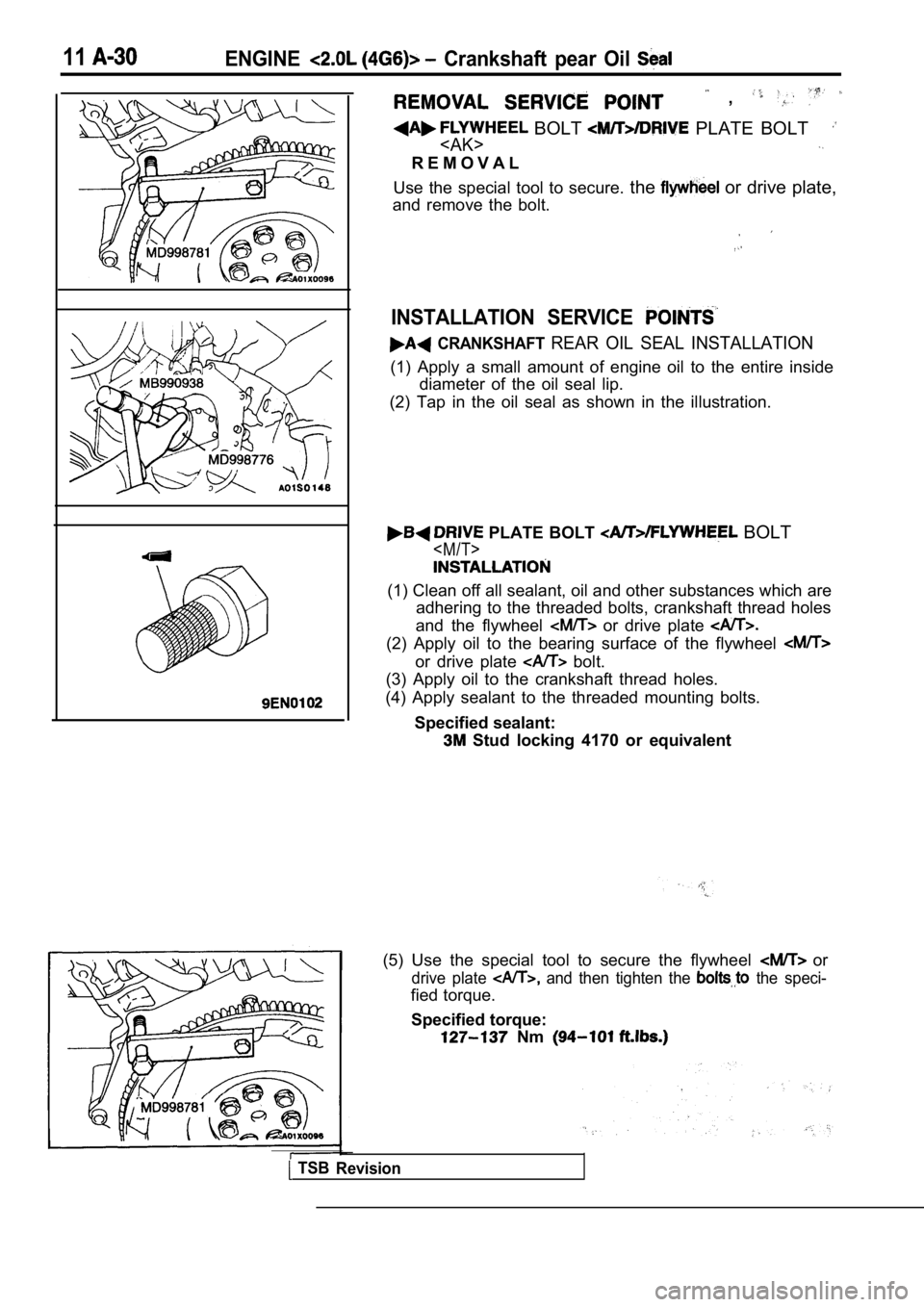

11ENGINE Crankshaft pear Oil

,

BOLT PLATE BOLT

R E M O V A L

Use the special tool to secure. the

or drive plate,

and remove the bolt.

INSTALLATION SERVICE

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

PLATE BOLT BOLT

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

TSB Revision

(5) Use the special tool to secure the flywheel or

drive plate and then tighten the the speci-

fied torque.

Specified torque:

Nm

Page 99 of 2103

E N G I N E

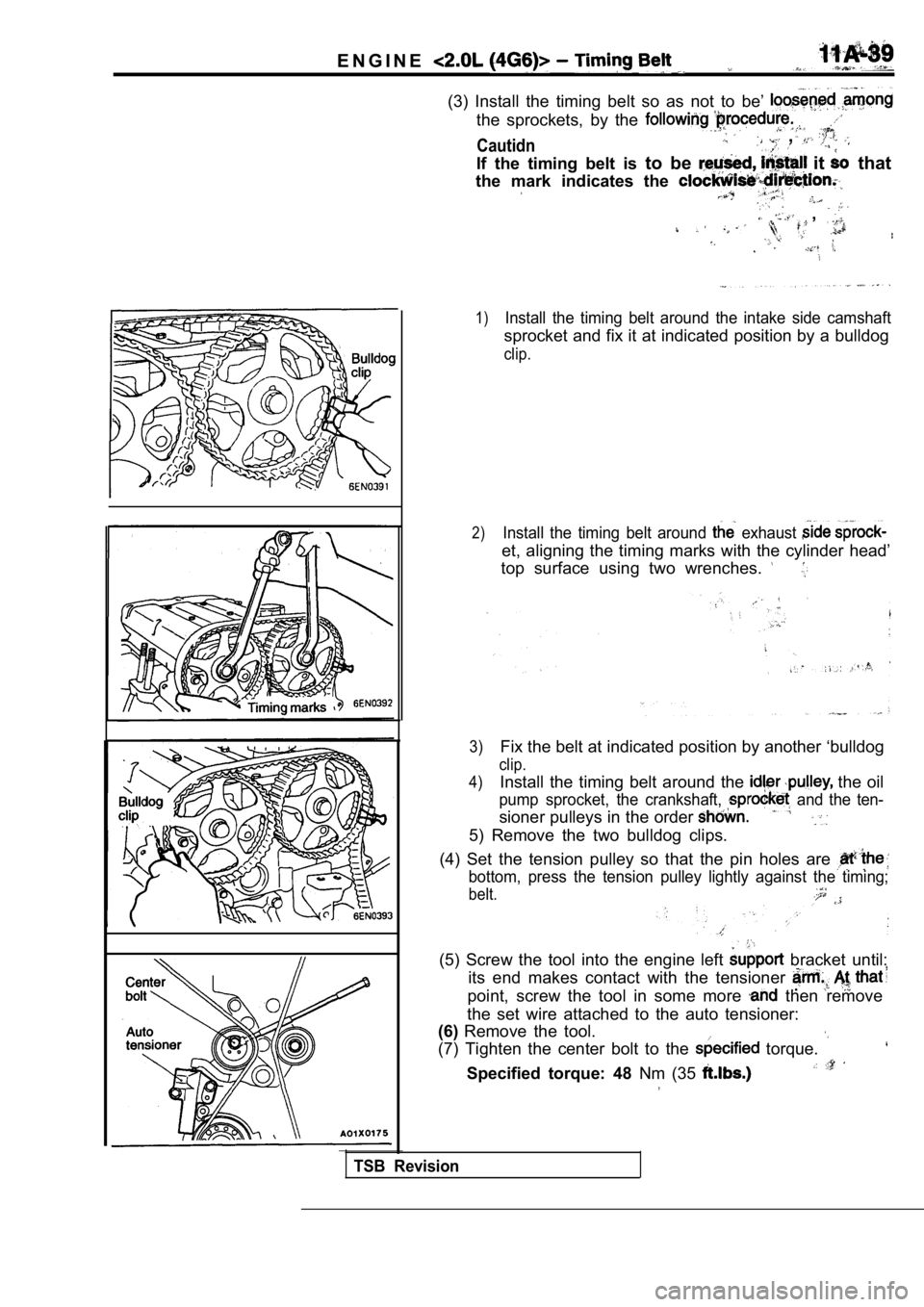

(3) Install the timing belt so as not to be’

the sprockets, by the

Cautidn ,

If the timing belt is to be it that

the mark indicates the

,

1)Install the timing belt around the intake side cams haft

sprocket and fix it at indicated position by a bulldog

clip.

2)Install the timing belt around exhaust

et, aligning the timing marks with the cylinder hea d’

top surface using two wrenches.

3)Fix the belt at indicated position by another ‘bull dog

clip.

4)

Install the timing belt around the the oil

pump sprocket, the crankshaft, and the ten-

sioner pulleys in the order

5) Remove the two bulldog clips.

(4) Set the tension pulley so that the pin holes ar e

bottom, press the tension pulley lightly against the timing;

belt.

(5) Screw the tool into the engine left bracket until:

its end makes contact with the tensioner

point, screw the tool in some more then remove

the set wire attached to the auto tensioner:

(6) Remove the tool.

(7) Tighten the center bolt to the

torque.

Specified torque: 48 Nm (35

TSB Revision

Page 100 of 2103

E N G I N E Belt

Auto tensioner

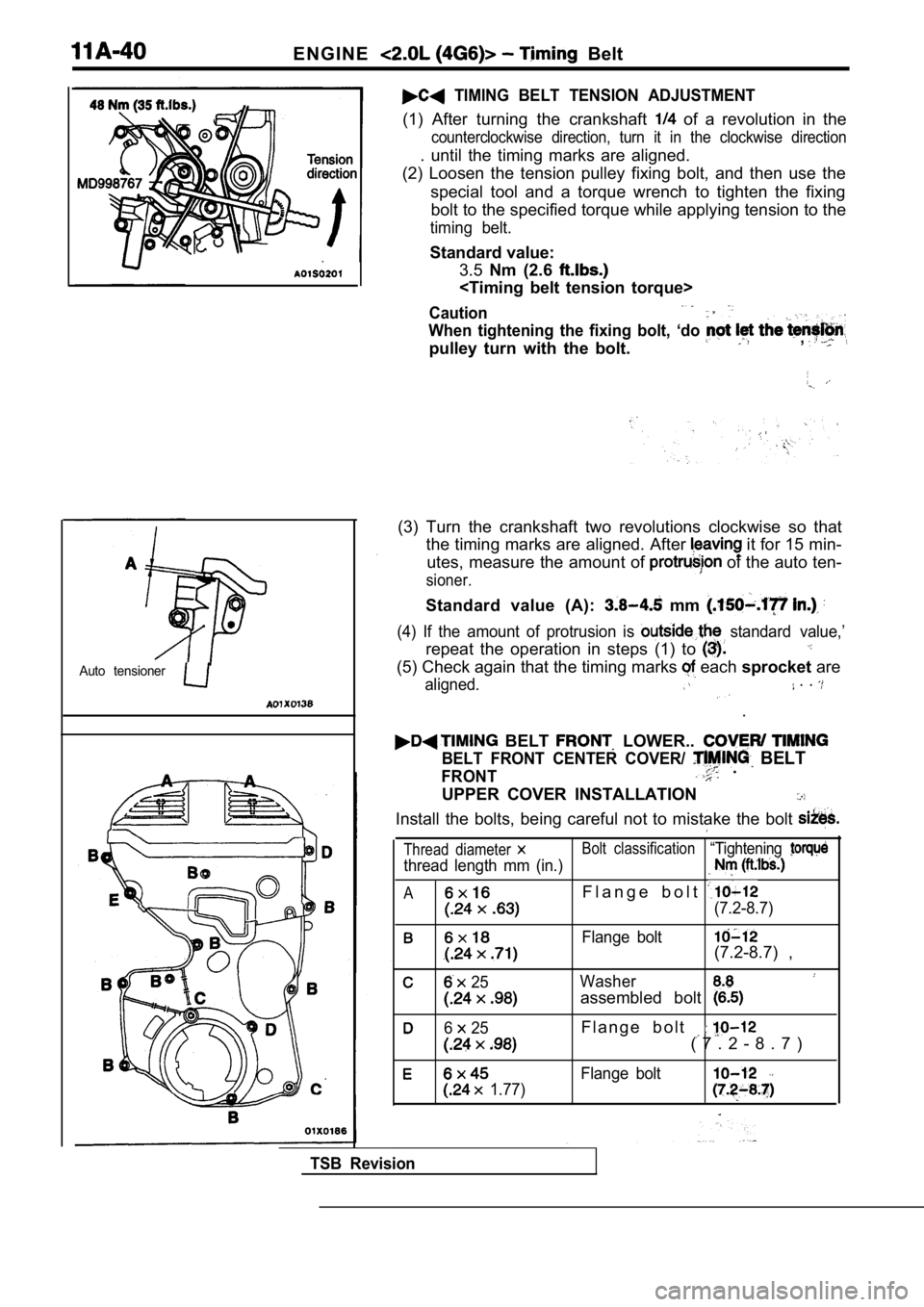

TIMING BELT TENSION ADJUSTMENT

(1) After turning the crankshaft of a revolution in the

counterclockwise direction, turn it in the clockwise direction

. until the timing marks are aligned.

(2) Loosen the tension pulley fixing bolt, and then use the

special tool and a torque wrench to tighten the fix ing

bolt to the specified torque while applying tension to the

timing belt.

Standard value:

3.5 Nm (2.6

Caution

When tightening the fixing bolt, ‘do

pulley turn with the bolt.,

(3) Turn the crankshaft two revolutions clockwise s o that

the timing marks are aligned. After

it for 15 min-

utes, measure the amount of

of the auto ten-

sioner.

Standard value (A): mm

(4) If the amount of protrusion is standard value,’

repeat the operation in steps (1) to

(5) Check again that the timing marks each sprocket are

aligned. . .

.

BELT LOWER..

BELT FRONT CENTER COVER/ BELT

FRONT .

UPPER COVER INSTALLATION

Install the bolts, being careful not to mistake the bolt

Thread diameter Bolt classification“Tightening

thread length mm (in.)

AF l a n g e b o l t

(7.2-8.7)

Flange bolt(7.2-8.7) ,

25Washer

assembled bolt

6 25F l a n g e b o l t

( 7 . 2 - 8 . 7 )

Flange bolt

1.77)

TSB Revision

Page 105 of 2103

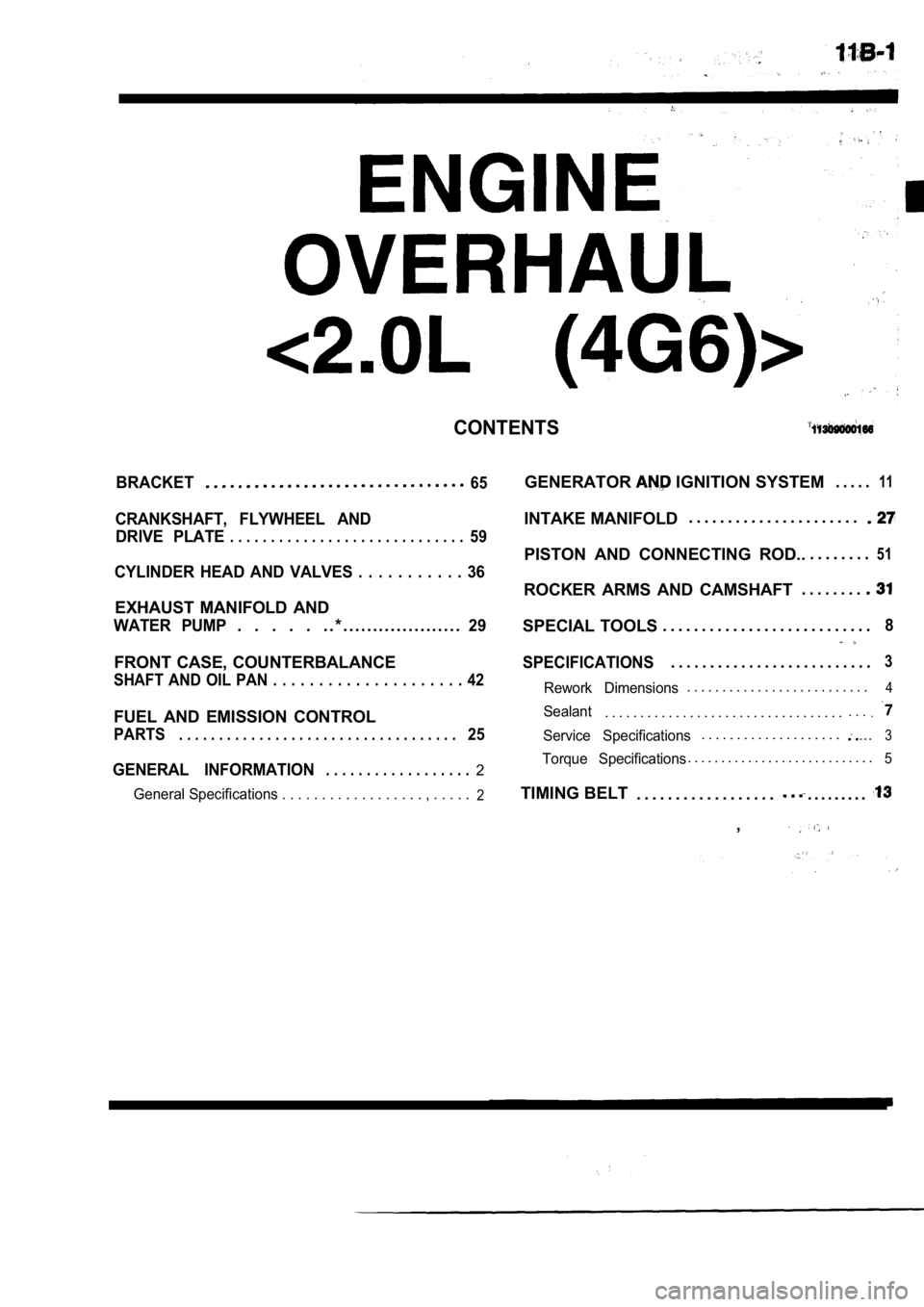

CONTENTS

BRACKET65

CRANKSHAFT, FLYWHEEL ANDDRIVE PLATE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

CYLINDER HEAD AND VALVES . . . . . . . . . . . 36

EXHAUST MANIFOLD AND

WATER PUMP. . . . . . . * . . . . . . . . . . . . . . . . . . . .29

FRONT CASE, COUNTERBALANCE

SHAFT AND OIL PAN . . . . . . . . . . . . . . . . . . . . . 42

FUEL AND EMISSION CONTROL

PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2

General Specifications . . . . . . . . . . . . . . . . . . , . . . . .2

GENERATOR IGNITION SYSTEM. . . . .11

INTAKE MANIFOLD. . . . . . . . . . . . . . . . . . . . . .

PISTON AND CONNECTING ROD..

. . . . . . . .51

ROCKER ARMS AND CAMSHAFT. . . . . . . .

SPECIAL TOOLS

. . . . . . . . . . . . . . . . . . . . . . . . . . .8

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . .3

Rework Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . .4

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ..

Service Specifications. . . . . . . . . . . . . . . . . . . ....3

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TIMING BELT

. . . . . . . . . . . . . . . . . .. . . . . . . . .

,

Page 109 of 2103

ENGINE OVERHAUL

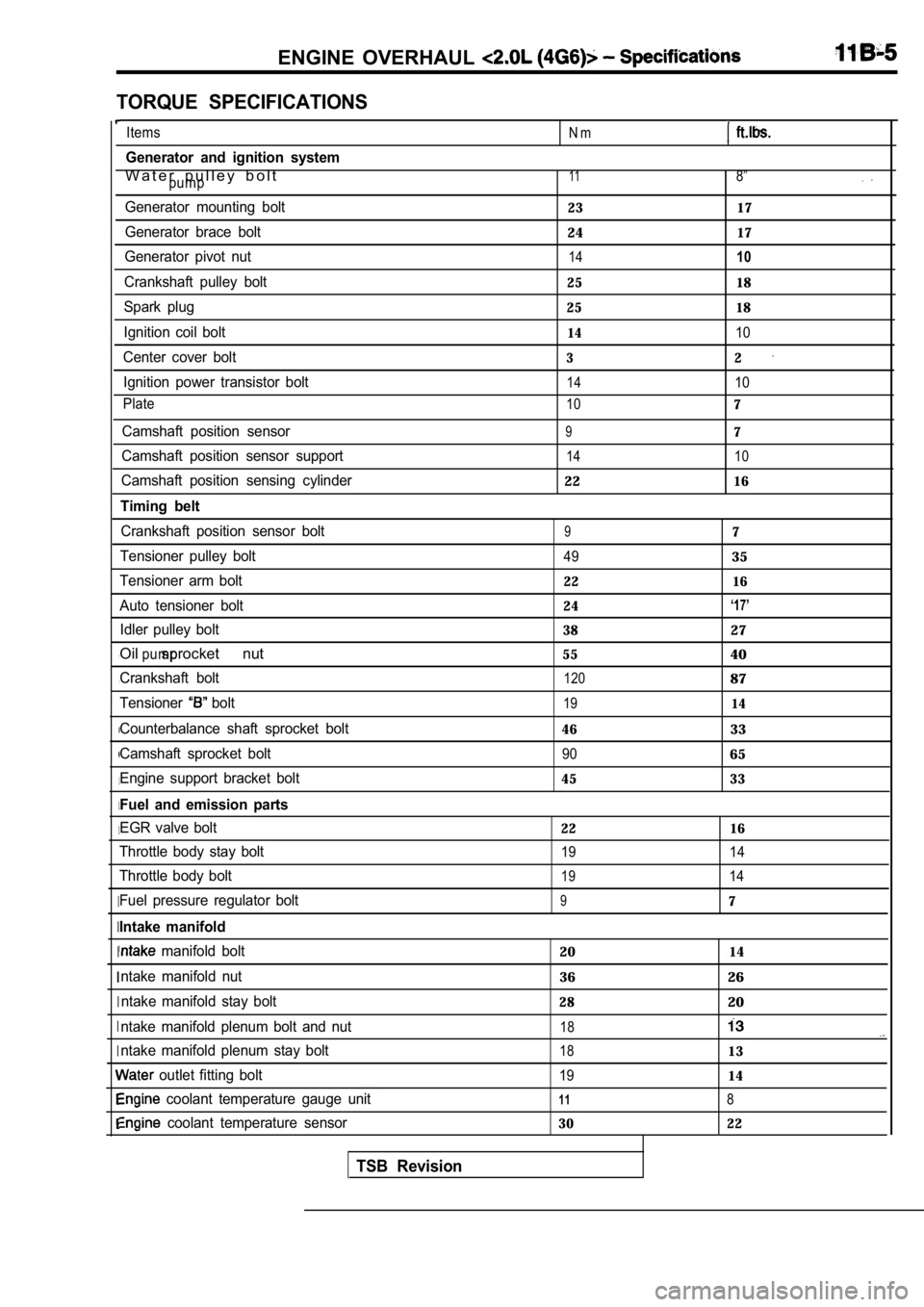

TORQUE SPECIFICATIONS

, ,

I

I I

I

I I

I

I

I I

Items

Generator and ignition system

W a t e r p u l l e y b o l tpump

Generator mounting bolt

Generator brace bolt

Generator pivot nut

Crankshaft pulley bolt

Spark plug

Ignition coil bolt

Center cover bolt Ignition power transistor bolt

Plate

Camshaft position sensor

Camshaft position sensor support

Camshaft position sensing cylinder

Timing belt

Crankshaft position sensor bolt

Tensioner pulley bolt

Tensioner arm bolt

Auto tensioner bolt Idler pulley bolt

Oil sprocket nutpump

Crankshaft bolt

Tensioner

bolt

Counterbalance shaft sprocket bolt

Camshaft sprocket bolt

Engine support bracket bolt

Fuel and emission parts

EGR valve bolt

Throttle body stay bolt

Throttle body bolt

Fuel pressure regulator bolt

Intake manifold

manifold bolt

ntake manifold nut ntake manifold stay bolt

ntake manifold plenum bolt and nut

ntake manifold plenum stay bolt

outlet fitting bolt

coolant temperature gauge unit

coolant temperature sensor

TSB Revision

N m

118”

23 17

2417

1410

25 18

25 18

1410

32

1410

107

97

14 10

2216

97

4935

22 16

24

‘17’

3827

5540

12087

1914

4633

9065

45 33

22 16

19 14

1914

97

2014

3626

2820

18

1813

1914

118

30 22

Page 123 of 2103

![MITSUBISHI SPYDER 1990 Service User Guide ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde MITSUBISHI SPYDER 1990 Service User Guide ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinde](/img/19/57345/w960_57345-122.png)

ENGINE OVERHAUL Belt

Phillips screwdriver

BOLT

O I L S P R O C K E T

(1) a Phillips screwdriver [shank diameter 8 mm

in.) shaft] through the plug hole on the the

cylinder block to block the left counterbalance sha ft.

(2)

the oil pump sprocket. .

(3) Apply a proper amount of engine oil-to the bearing

of the nuts.

(4) Tighten the nuts to the specified‘ torque.

AUTO TENSIONER INSTALLATION

(1) If the auto tensioner rod is in its fully exten ded position,

reset it as follows.

(2) Clamp the auto-tensioner in the vise

jaws.

(3) Push in the rod little by little with the vise the

hole A in the rod is aligned with the hole in the

(4) a wire mm in.) diameter] into the

(5) Unclamp the auto tensioner from the vise.

.

,

the auto tensioner to front case and tighten.

the specified torque.

Caution

Leave the wire installed the

,

. .

,

TSB Revision