torque MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 126 of 2103

ENGINE OVERHAUL Timing

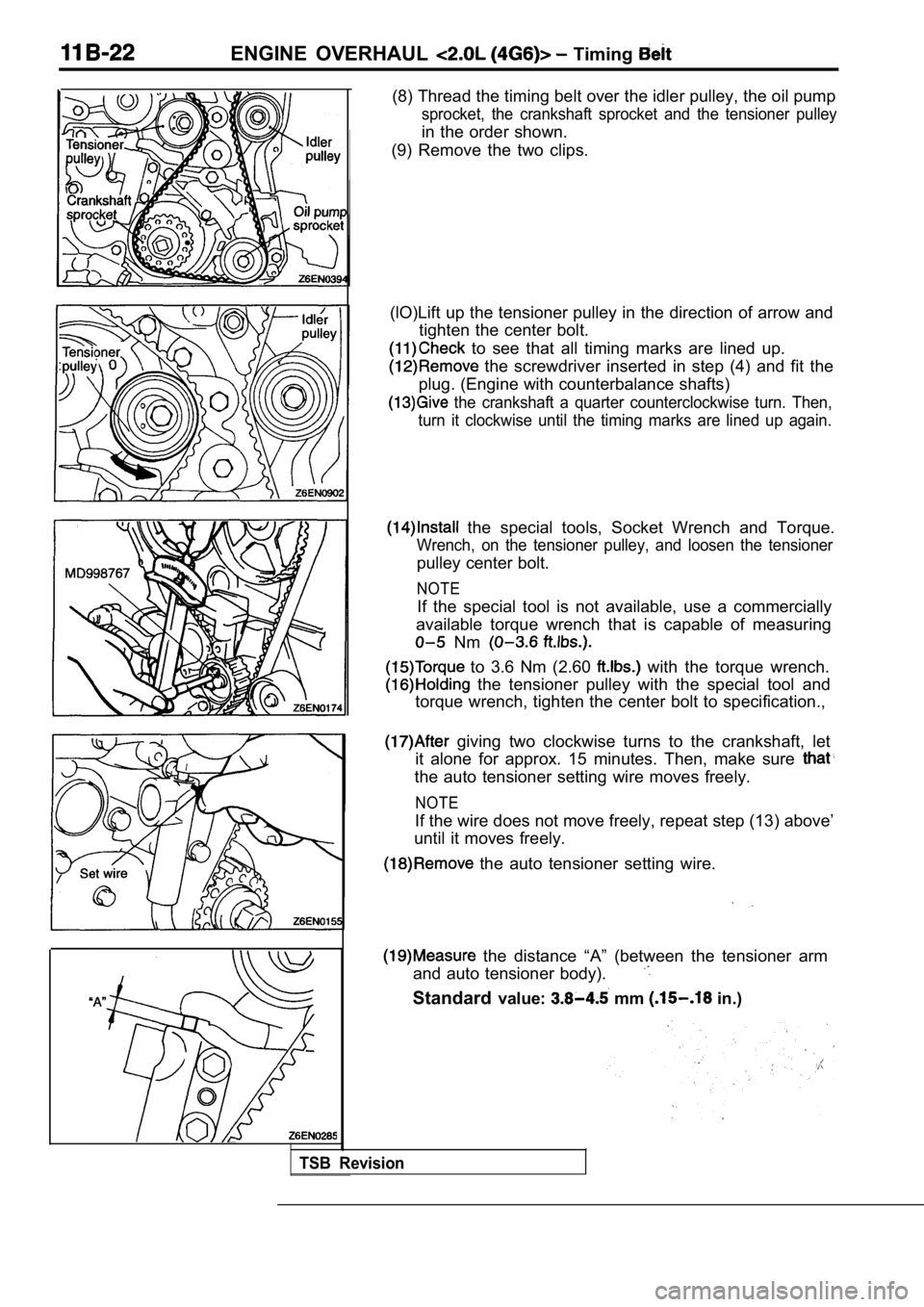

(8) Thread the timing belt over the idler pulley, the oil pump

sprocket, the crankshaft sprocket and the tensioner pulley

in the order shown.

(9) Remove the two clips.

(lO)Lift up the tensioner pulley in the direction o f arrow and

tighten the center bolt.

to see that all timing marks are lined up.

the screwdriver inserted in step (4) and fit the

plug. (Engine with counterbalance shafts)

the crankshaft a quarter counterclockwise turn. Th en,

turn it clockwise until the timing marks are lined up again.

the special tools, Socket Wrench and Torque.

Wrench, on the tensioner pulley, and loosen the ten sioner

pulley center bolt.

NOTE

If the special tool is not available, use a commercially

available torque wrench that is capable of measurin g

Nm

to 3.6 Nm (2.60 with the torque wrench.

the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specifica tion.,

giving two clockwise turns to the crankshaft, let

it alone for approx. 15 minutes. Then, make sure

the auto tensioner setting wire moves freely.

NOTE

If the wire does not move freely, repeat step (13) above’

until it moves freely.

the auto tensioner setting wire.

the distance “A” (between the tensioner arm

and auto tensioner body).

Standard value: mm in.)

TSB Revision

Page 142 of 2103

11 E N G I N E O V E R H A U L Cylinder Head

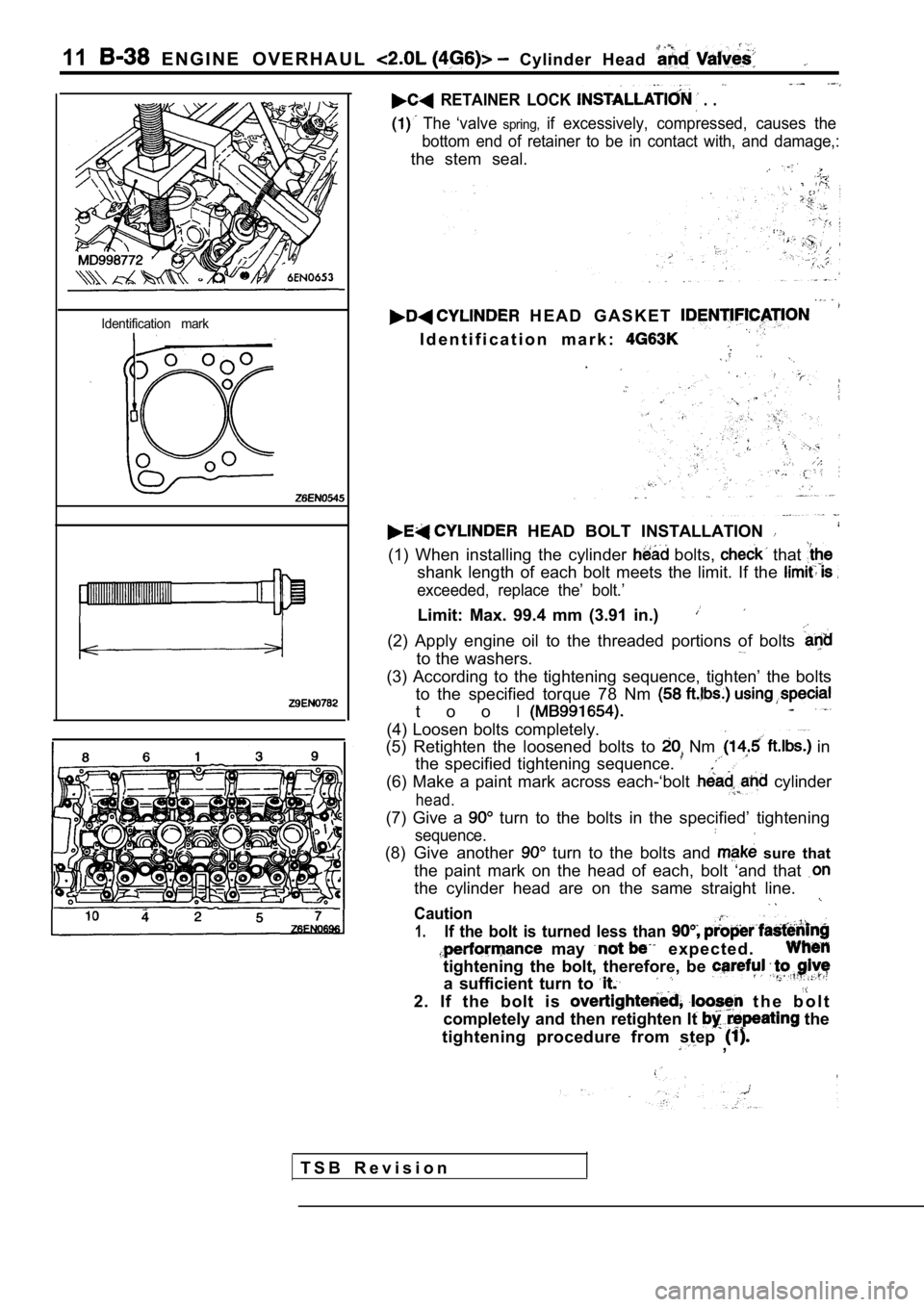

Identification mark

RETAINER LOCK . .

The ‘valve spring,if excessively, compressed, causes the

bottom end of retainer to be in contact with, and d amage,:

the stem seal.

H E A D G A S K E T

I d e n t i f i c a t i o n m a r k :

HEAD BOLT INSTALLATION

(1) When installing the cylinder bolts, that

shank length of each bolt meets the limit. If the

exceeded, replace the’ bolt.’

Limit: Max. 99.4 mm (3.91 in.)

(2) Apply engine oil to the threaded portions of bo lts

to the washers.

(3) According to the tightening sequence, tighten’ the bolts

to the specified torque 78 Nm

t o o l

(4) Loosen bolts completely.

(5) Retighten the loosened bolts to

Nm in

the specified tightening sequence.

(6) Make a paint mark across each-‘bolt cylinder

head.

(7) Give a turn to the bolts in the specified’ tightening

sequence.

(8) Give another turn to the bolts and sure that

the paint mark on the head of each, bolt ‘and that

the cylinder head are on the same straight line.

Caution

1.If the bolt is turned less than

may e x p e c t e d .

tightening the bolt, therefore, be

a sufficient turn to

2. If the bolt is t h e b o l t

completely and then retighten It

the

tightening procedure from step

,

T S B R e v i s i o n

Page 151 of 2103

Front Case,, ENGINE OVERHAUL Shaft and ‘Pan

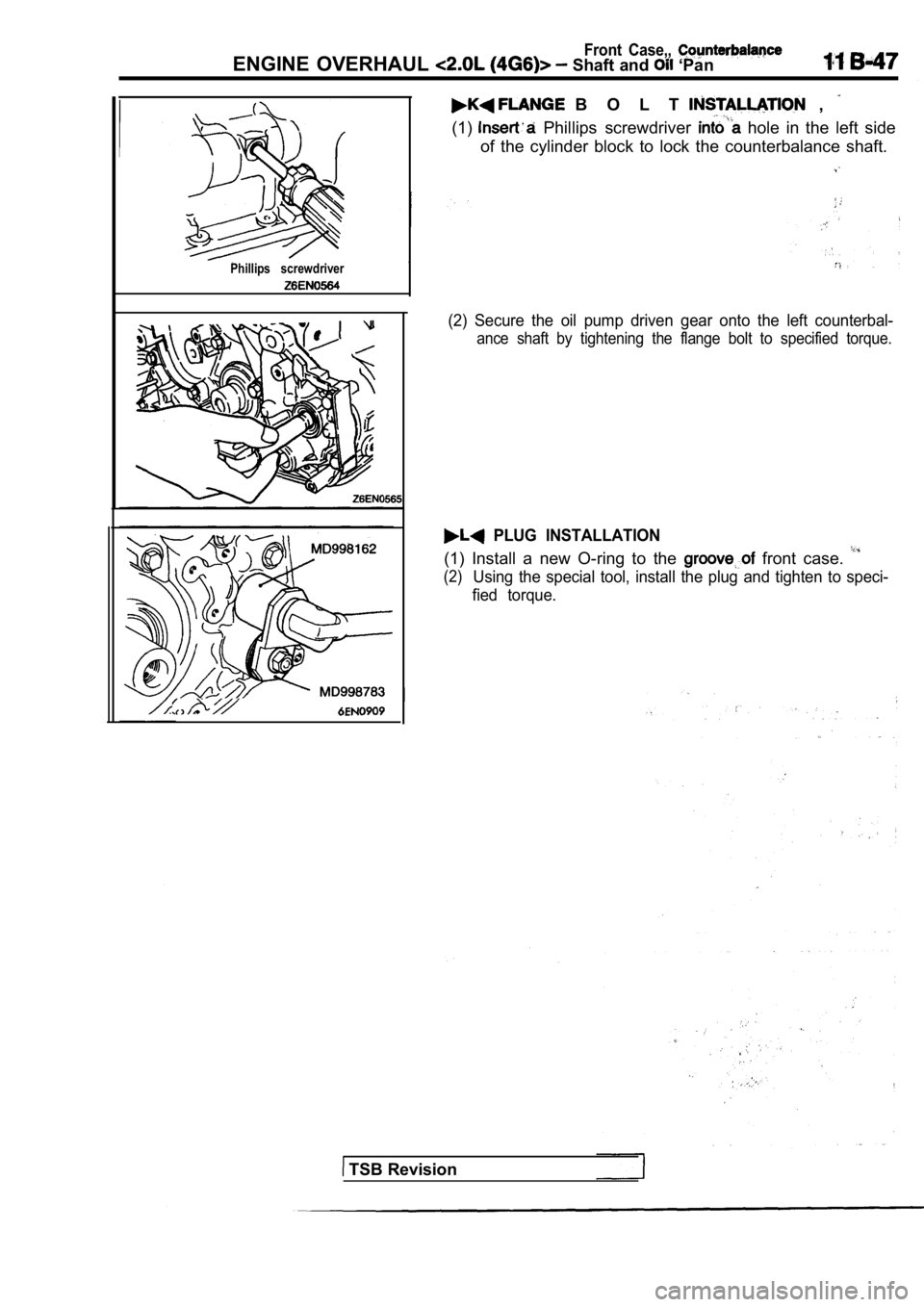

Phillips screwdriver

B O L T ,

(1) Phillips screwdriver hole in the left side

of the cylinder block to lock the counterbalance sh aft.

(2) Secure the oil pump driven gear onto the left c ounterbal-

ance shaft by tightening the flange bolt to specified torque.

PLUG INSTALLATION

(1) Install a new O-ring to the front case.

(2)Using the special tool, install the plug and tighten to speci-

fied torque.

TSB Revision

Page 153 of 2103

Front Case,

ENGINE OVERHAUL Shaft and

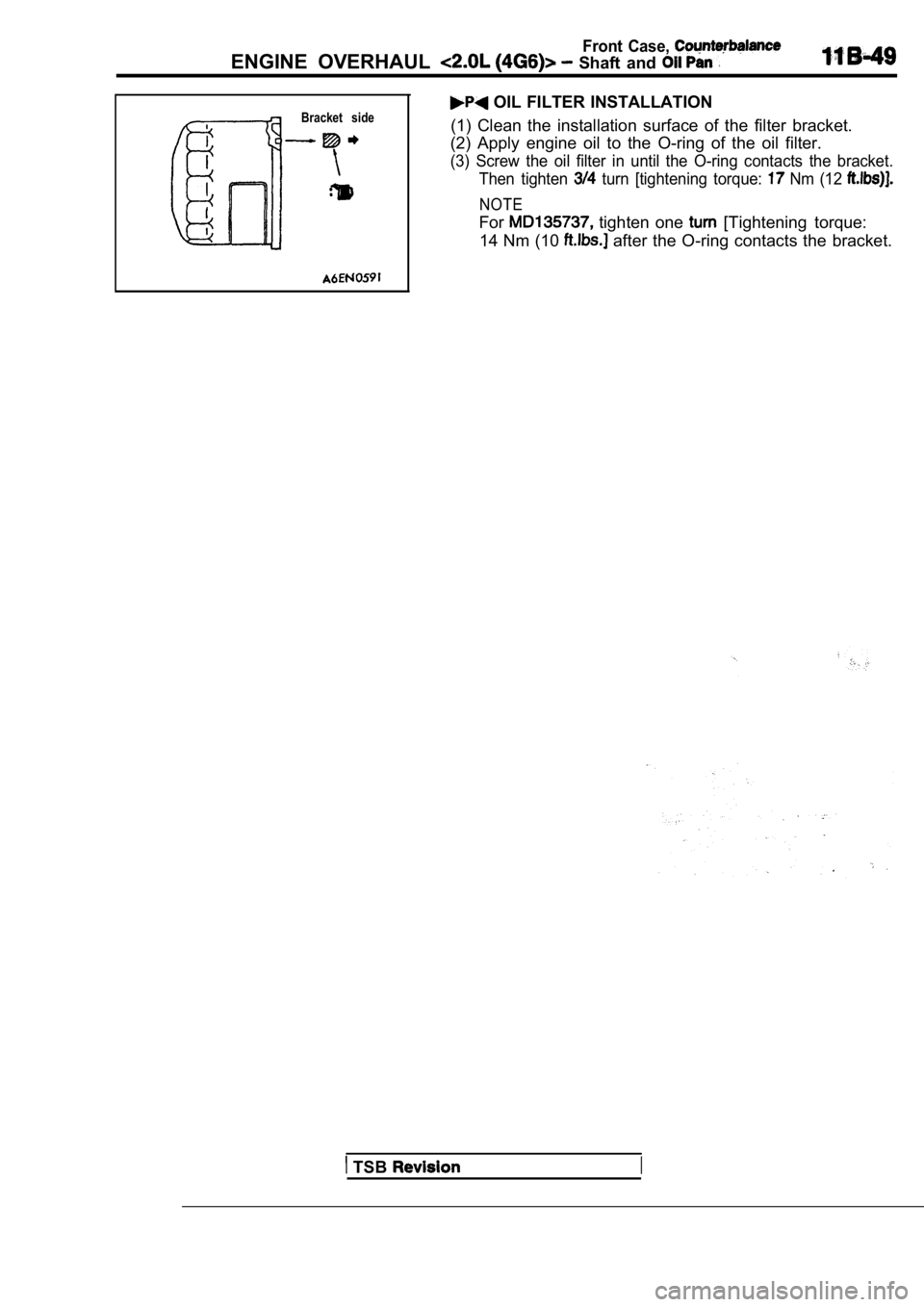

Bracket side OIL FILTER INSTALLATION

(1) Clean the installation surface of the filter br acket.

(2) Apply engine oil to the O-ring of the oil filte r.

(3) Screw the oil filter in until the O-ring contacts the bracket.

Then tighten

turn [tightening torque: Nm (12

NOTE

For tighten one [Tightening torque:

14 Nm (10

after the O-ring contacts the bracket.

TSB I

Page 160 of 2103

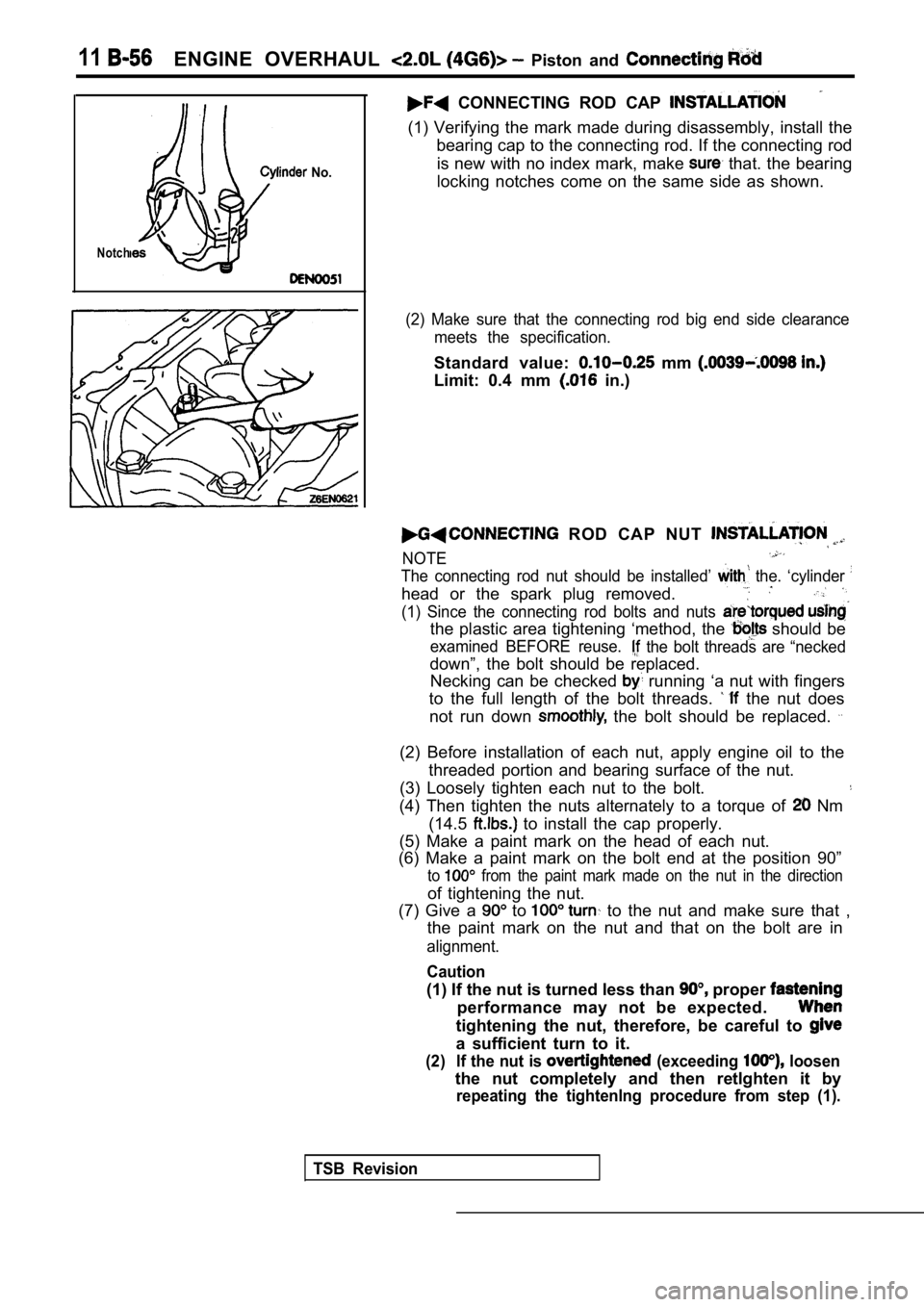

11ENGINE OVERHAUL Piston and

No.

Notch

CONNECTING ROD CAP

(1) Verifying the mark made during disassembly, install the

bearing cap to the connecting rod. If the connectin g rod

is new with no index mark, make

that. the bearing

locking notches come on the same side as shown.

(2) Make sure that the connecting rod big end side clearance

meets the specification.

Standard value: mm

Limit: 0.4 mm in.)

ROD CAP NUT

NOTE

The connecting rod nut should be installed’ the. ‘cylinder

head or the spark plug removed.

(1) Since the connecting rod bolts and nuts

the plastic area tightening ‘method, the should be

examined BEFORE reuse. the bolt threads are “necked

down”, the bolt should be replaced. Necking can be checked

running ‘a nut with fingers

to the full length of the bolt threads.

the nut does

not run down

the bolt should be replaced.

(2) Before installation of each nut, apply engine o il to the

threaded portion and bearing surface of the nut.

(3) Loosely tighten each nut to the bolt.

(4) Then tighten the nuts alternately to a torque o f Nm

(14.5

to install the cap properly.

(5) Make a paint mark on the head of each nut.

(6) Make a paint mark on the bolt end at the positi on 90”

to from the paint mark made on the nut in the direction

of tightening the nut.

(7) Give a

to to the nut and make sure that ,

the paint mark on the nut and that on the bolt are in

alignment.

Caution

(1) If the nut is turned less than proper

performance may not be expected.

tightening the nut, therefore, be careful to

a sufficient turn to it.

(2) If the nut is (exceeding loosen

the nut completely and then retlghten it by

repeating the tightenlng procedure from step (1).

TSB Revision

Page 162 of 2103

ENGINE OVERHAUL Piston Rod

1I

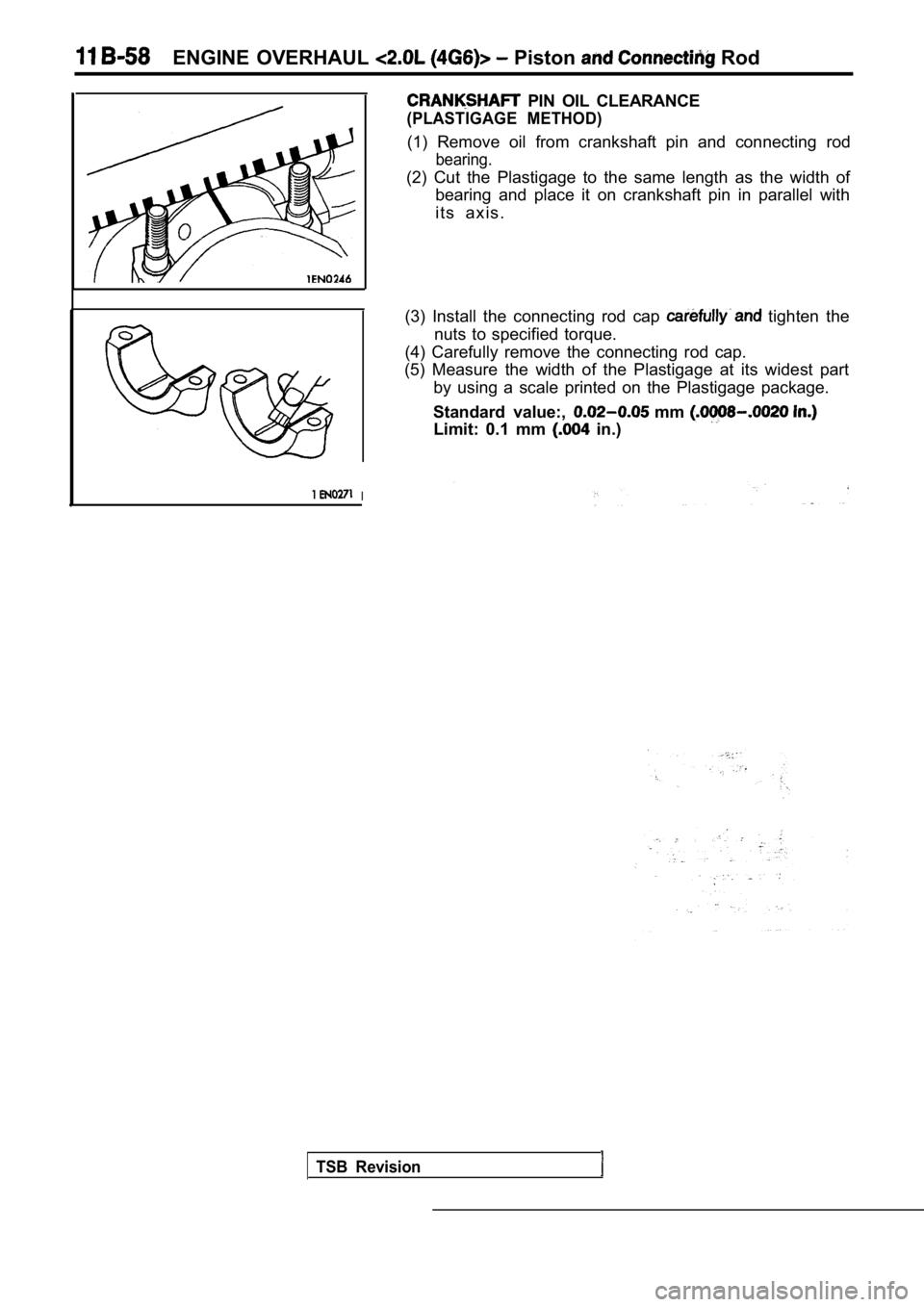

PIN OIL CLEARANCE

(PLASTIGAGE METHOD)

(1) Remove oil from crankshaft pin and connecting rod

bearing.

(2) Cut the Plastigage to the same length as the width of

bearing and place it on crankshaft pin in parallel with

i t s a x i s .

(3) Install the connecting rod cap

tighten the

nuts to specified torque.

(4) Carefully remove the connecting rod cap.

(5) Measure the width of the Plastigage at its wide st part

by using a scale printed on the Plastigage package.

Standard value:,

mm

Limit: 0.1 mm in.)

TSB Revision

Page 167 of 2103

ENGINE OVERHAUL and

A

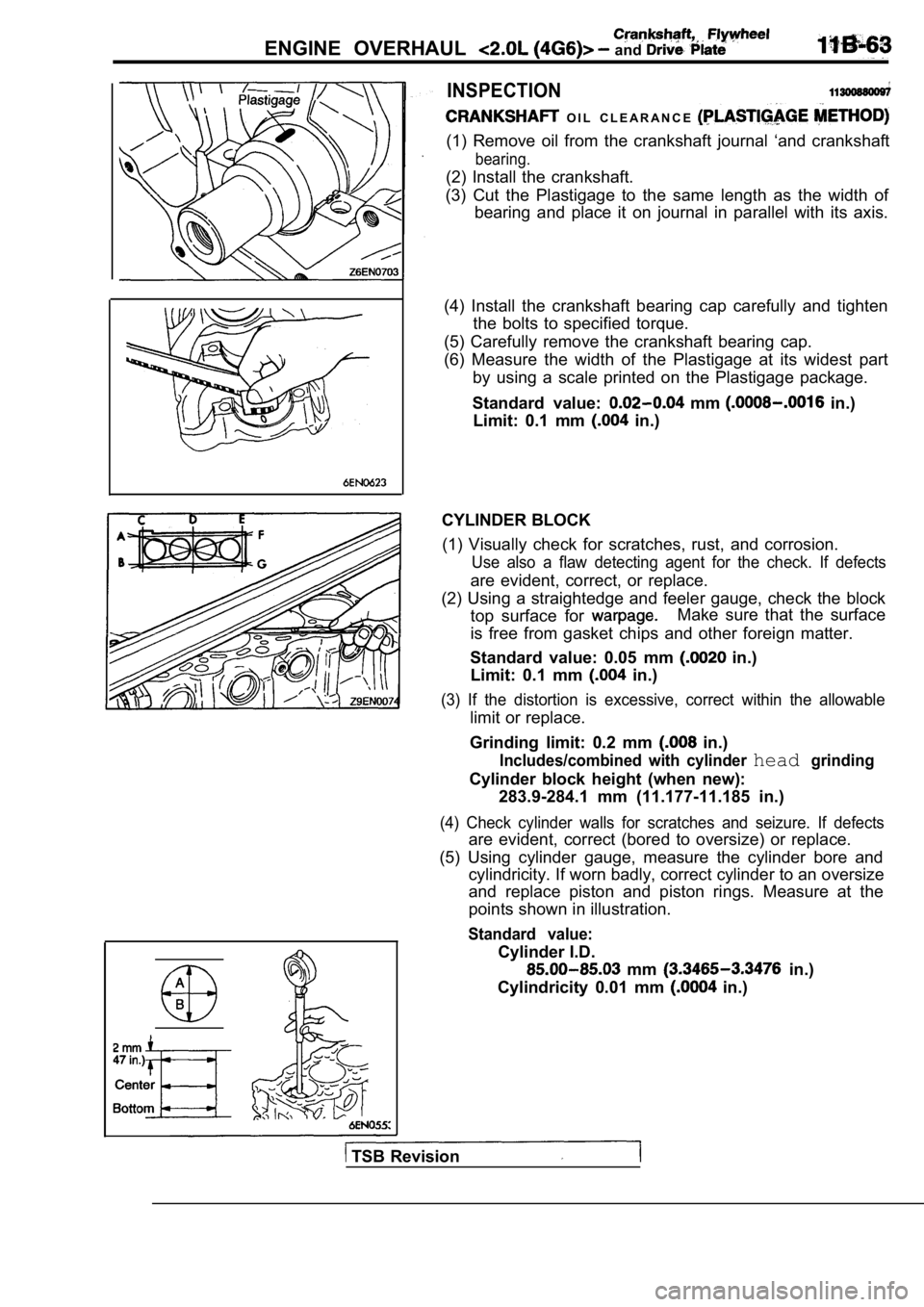

INSPECTION

O I L C L E A R A N C E

(1) Remove oil from the crankshaft journal ‘and crankshaft

bearing.

(2) Install the crankshaft.

(3) Cut the Plastigage to the same length as the wi dth of

bearing and place it on journal in parallel with it s axis.

(4) Install the crankshaft bearing cap carefully an d tighten

the bolts to specified torque.

(5) Carefully remove the crankshaft bearing cap.

(6) Measure the width of the Plastigage at its wide st part

by using a scale printed on the Plastigage package.

Standard value:

mm in.)

Limit: 0.1 mm

in.)

CYLINDER BLOCK (1) Visually check for scratches, rust, and corrosi on.

Use also a flaw detecting agent for the check. If d efects

are evident, correct, or replace.

(2) Using a straightedge and feeler gauge, check th e block

top surface for

Make sure that the surface

is free from gasket chips and other foreign matter.

Standard value: 0.05 mm

in.)

Limit: 0.1 mm

in.)

(3) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

in.)

Includes/combined with cylinder headgrinding

Cylinder block height (when new): 283.9-284.1 mm (11.177-11.185 in.)

(4) Check cylinder walls for scratches and seizure. If defects

are evident, correct (bored to oversize) or replace.

(5) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the

points shown in illustration.

Standard value:

Cylinder I.D.

mm in.)

Cylindricity 0.01 mm

in.)

TSB Revision

Page 178 of 2103

Crankshaft

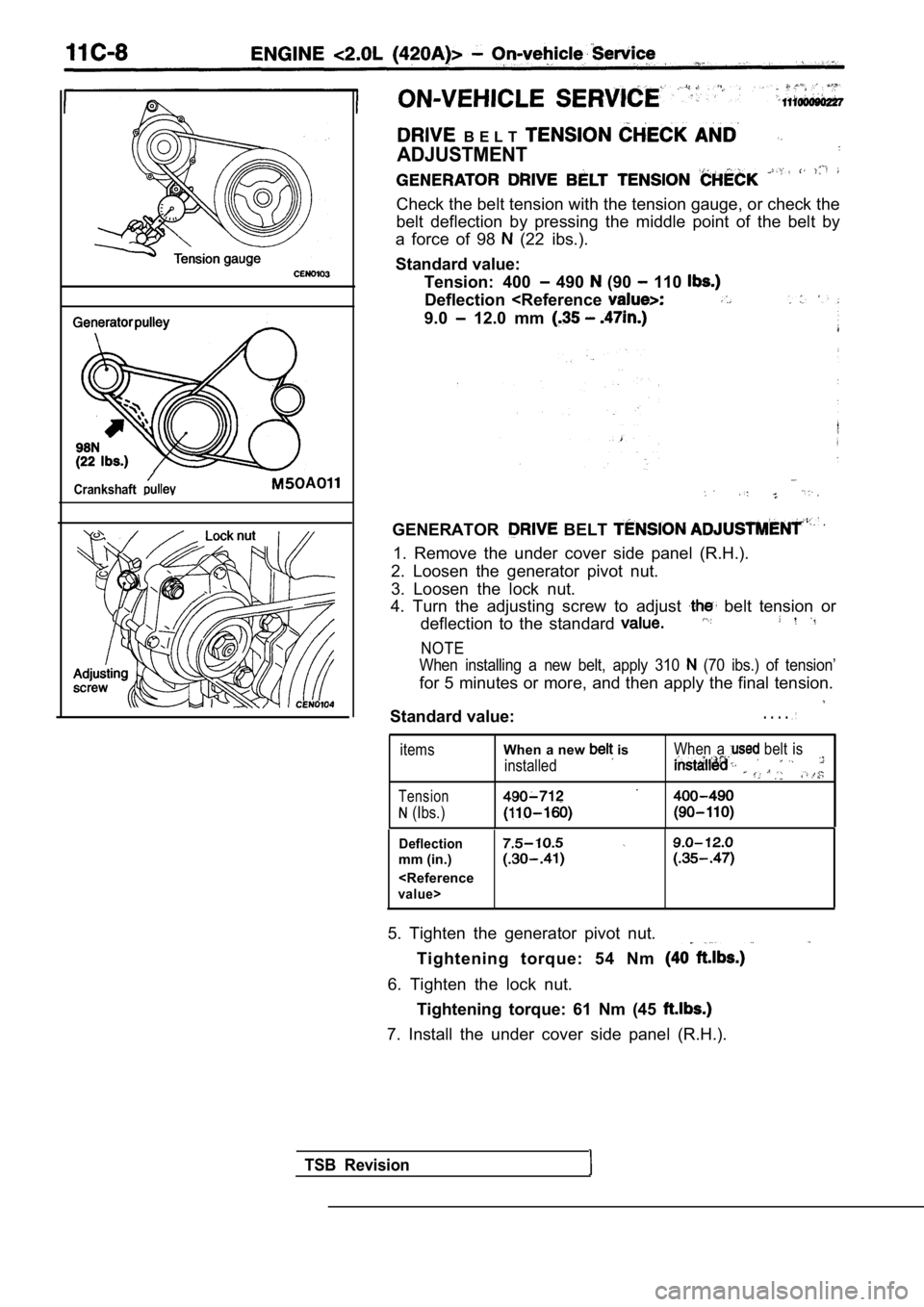

B E L T

ADJUSTMENT

Check the belt tension with the tension gauge, or check the

belt deflection by pressing the middle point of the belt by

a force of 98

(22 ibs.).

Standard value: Tension: 400

490 (90 110

Deflection

GENERATOR BELT

1. Remove the under cover side panel (R.H.).

2. Loosen the generator pivot nut.

3. Loosen the lock nut.

4. Turn the adjusting screw to adjust

belt tension or

deflection to the standard

NOTE

When installing a new belt, apply 310

(70 ibs.) of tension’

for 5 minutes or more, and then apply the final ten sion.

Standard value:. . . .

items

Tension

(Ibs.)

When a new is

installed

When a belt is

Deflection

mm (in.)

5. Tighten the generator pivot nut.

Tightening torque: 54 Nm

6. Tighten the lock nut.Tightening torque: 61 Nm (45

7. Install the under cover side panel (R.H.).

TSB Revision

Page 179 of 2103

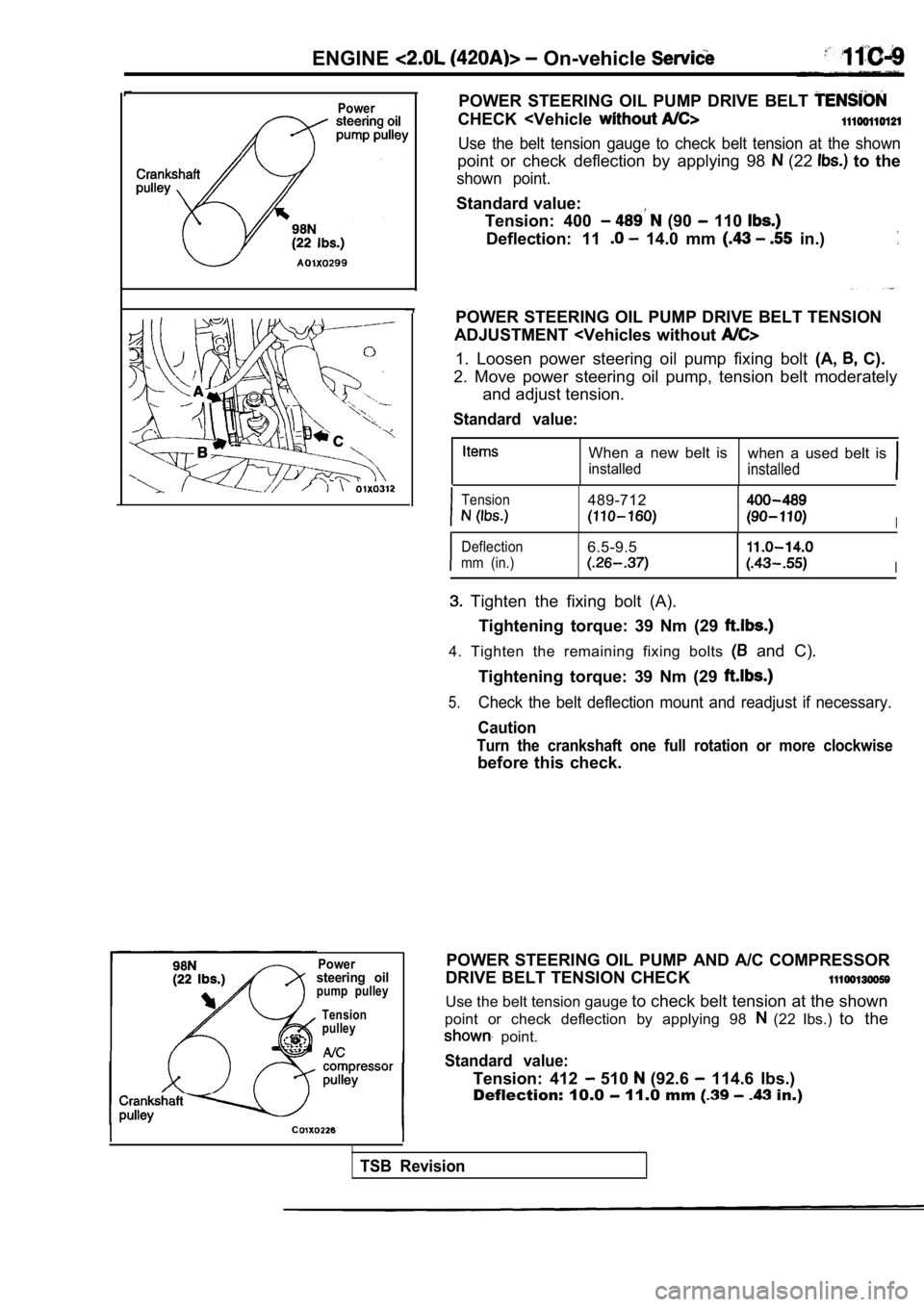

ENGINE On-vehicle

Power

Powersteering oilpump pulleyTension

pulley

POWER STEERING OIL PUMP DRIVE BELT

CHECK

point or check deflection by applying 98 (22 to the

shown point.

Standard value:

Tension: 400

(90 110

Deflection: 11 14.0 mm in.)

POWER STEERING OIL PUMP DRIVE BELT TENSION

ADJUSTMENT

2. Move power steering oil pump, tension belt moder ately

and adjust tension.

Standard value:

When a new belt is when a used belt is

installedinstalled

Tension489-712

I

Deflection6.5-9.5

mm (in.)I

Tighten the fixing bolt (A).

Tightening torque: 39 Nm (29

4. Tighten the remaining fixing bolts and C).

Tightening torque: 39 Nm (29

5.Check the belt deflection mount and readjust if nec essary.

Caution

Turn the crankshaft one full rotation or more clock wise

before this check.

POWER STEERING OIL PUMP AND A/C COMPRESSOR

DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

point or check deflection by applying 98

(22 Ibs.) to the

point.

Standard value:

Tension: 412 510 (92.6 114.6 Ibs.)

Deflection: 10.0

11.0 mm in.)

TSB Revision

Page 193 of 2103

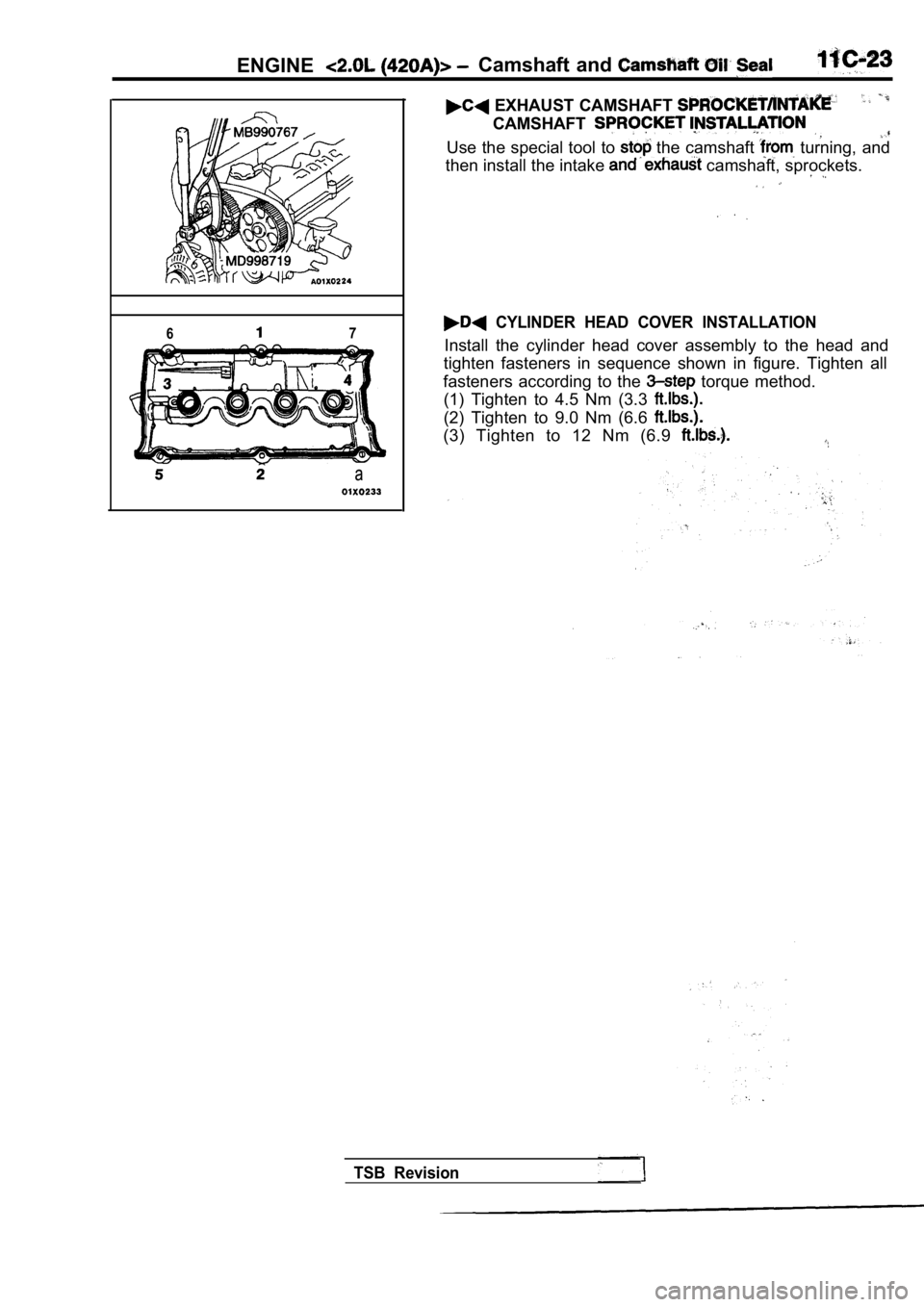

ENGINECamshaft and

67

a

EXHAUST CAMSHAFT

CAMSHAFT

Use the special tool to the camshaft turning, and

then install the intake

camshaft, sprockets.

CYLINDER HEAD COVER INSTALLATION

Install the cylinder head cover assembly to the hea d and

tighten fasteners in sequence shown in figure. Tigh ten all

fasteners according to the

torque method.

(1) Tighten to 4.5 Nm (3.3

(2) Tighten to 9.0 Nm (6.6

(3) Tighten to 12 Nm (6.9

TSB Revision